#titanium price per kg in india

Explore tagged Tumblr posts

Photo

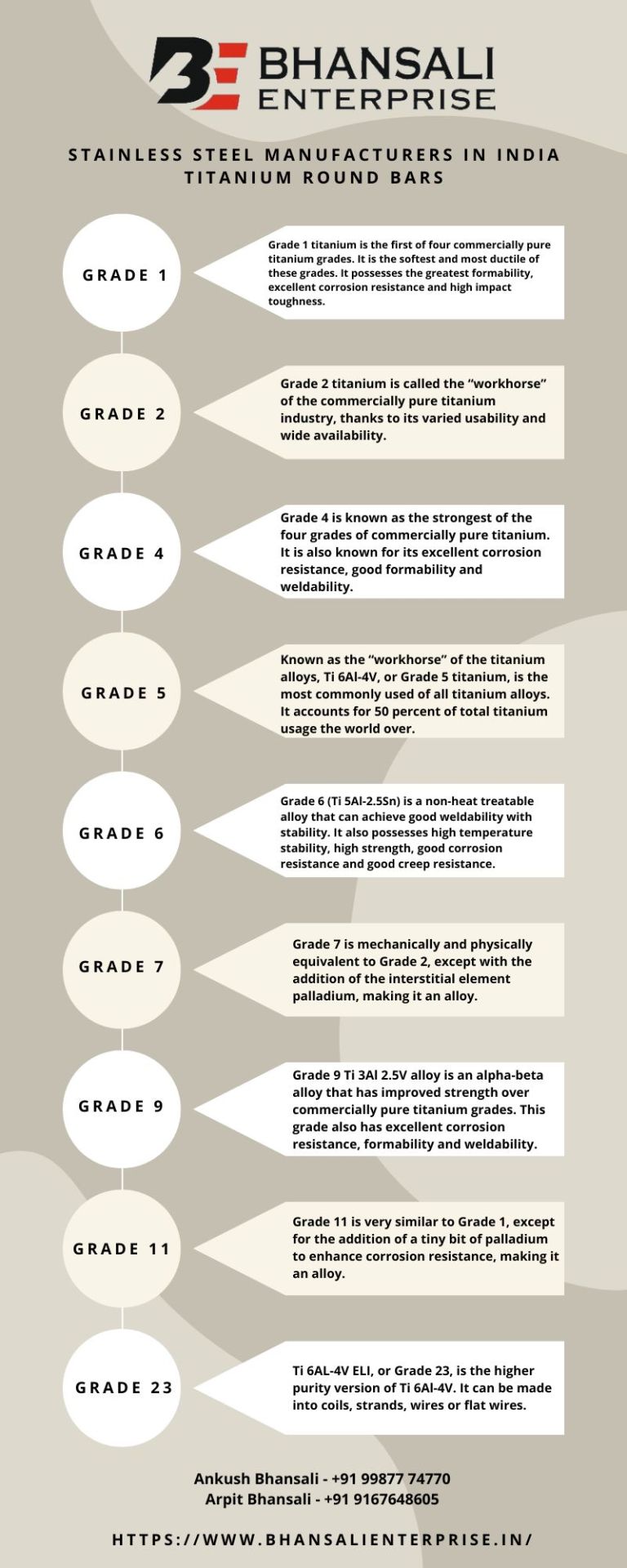

"Titanium Round Bar Grades."

Grade 1 titanium is the first of four commercially pure titanium grades. It is the softest and most ductile of these grades. It possesses the greatest formability, excellent corrosion resistance and high impact toughness. Grade 2 titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It shares many of the same qualities as Grade 1 titanium, but it is slightly stronger. Both are equally corrosion resistant. Grade 4 is known as the strongest of the four grades of commercially pure titanium. It is also known for its excellent corrosion resistance, good formability and weldability. Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 titanium, is the most commonly used of all titanium alloys. It accounts for 50 percent of total titanium usage the world over. Grade 6 (Ti 5Al-2.5Sn) is a non-heat treatable alloy that can achieve good weldability with stability. It also possesses high temperature stability, high strength, good corrosion resistance and good creep resistance. Creep refers to the phenomenon of plastic strain over long periods of time, which happens at high temperatures. Grade 7 is mechanically and physically equivalent to Grade 2, except with the addition of the interstitial element palladium, making it an alloy. Grade 7 possesses excellent weldability and fabricality, and is the most corrosion resistance of all titanium alloys. In fact, it is most resistant to corrosion in reducing acids. Grade 9 Ti 3Al 2.5V alloy is an alpha-beta alloy that has improved strength over commercially pure titanium grades. This grade also has excellent corrosion resistance, formability and weldability. Grade 11 is very similar to Grade 1, except for the addition of a tiny bit of palladium to enhance corrosion resistance, making it an alloy. Ti 6AL-4V ELI, or Grade 23, is the higher purity version of Ti 6Al-4V. It can be made into coils, strands, wires or flat wires.

#manufacturer of stainless steel in india#stainless steel round bar#Titanium grade 2#titanium grade 5#titanium pipes#titanium price in india per kg#polished stainless steel#stainless steel manufacturers in india#titanium price per kg in india#titanium rod#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor

0 notes

Text

SS 304 price per kg

Table of Contents

Stainless Steel 304 Price Per Kg

304 Pipe Price, Stainless Steel 304 Seamless Pipe Price, SS 304 Seamless Pipe Price Per Kg, Jindal Steel Pipe 304 Price Per Kg, SS 304 Pipe Price Per Meter, Stainless Steel 304 Seamless Pipe Price Per Kg in India.

Stainless Steel 304 Price Per Kg In Rupees

Stainless Steel 304 Stockist, SS 304 suppliers in Mumbai

Stainless Steel 304 Suppliers

Stainless Steel 304 Price Per Kg

We are leading Manufacturers, Supplier, Dealers, and Exporter of 304 Stainless Steel Pipes in India. Our 304 Stainless Steel Pipes are available in different sizes, shapes, and grades. SS 304 price per kg, We supply these Pipes in most of the major Indian cities in more than 20 States. We Sachiya Steel International offer different types of grades like Stainless Steel Pipes, Super Duplex Pipes, Duplex Pipes, Carbon Steel Pipes, Alloys Steel Pipes, Nickel Alloys Pipes, Titanium , Aluminium Pipes, etc.

Navigating the vast realm of the stainless steel market, one must recognize the prevailing ss 304 price per kg. As a grade of stainless steel that stands out for its versatility, durability, and affordability, ss 304 is highly sought-after in various industries, from construction to kitchenware. With a substantial market demand and its extensive application, the ss 304 price per kg is a subject of immense interest for manufacturers, suppliers, and consumers alike, given its influence on cost calculations and budget planning. The price per kg can vary significantly based on global market trends, demand and supply balance, and raw material costs.

More Details:- https://steeltube.co.in/ss-304-price-per-kg/

#stainlesssteel304#stainlesssteelrailingprice#304stainlesssteelprice#stainlesssteelrailingdesign#ss304vs202#ss202vsss304whichisbetter#steelrailingprice#304grillpriceperkg

0 notes

Text

SS 304 price per kg

We are leading Manufacturers, Supplier, Dealers, and Exporter of 304 Stainless Steel Pipes in India. Our 304 Stainless Steel Pipes are available in different sizes, shapes, and grades. SS 304 price per kg, We supply these Pipes in most of the major Indian cities in more than 20 States. We Sachiya Steel International offer different types of grades like Stainless Steel Pipes, Super Duplex Pipes, Duplex Pipes, Carbon Steel Pipes, Alloys Steel Pipes, Nickel Alloys Pipes, Titanium , Aluminium Pipes, etc.

0 notes

Text

What is per kg Price of Corten Steel in India ?

Corten steel price in india have steadily increased over the years due to high demand, rapid economic growth, and increasing environmental concerns. Construction materials, automotive components, and other industrial applications have all seen prices rise as a result. Corten steel price in india is a steel sheet manufactured from the coil of the bar. It is also known as a strip, strip stock. In the construction industry, it is commonly used for roofing and building materials. Depending on its corten steel cut to size and shape, this metal varies in Corten steel price per kg in india. In spite of this, it is relatively inexpensive and readily available.

Additionally, it is used in the construction of doors and similar structures. Using it in the construction of expensive wood structures is a good idea. It is a high-quality product that can be found almost anywhere. When purchasing this type of steel, you need to measure it carefully and cut it according to your measurements before purchasing.

As a result, you will get exactly what you want. Corten steel is made from hard materials such as steel and iron. Depending on their application, these metals can be found as bars or coils.

We will discuss the cost of Corten steel price per kg in india in this section. The different types of steel available in the market and the best price range for Corten steel will also be discussed. Steel per square foot: Corten steel is a relatively cheap metal. Below are some Corten steel price per kg in india. These metals range in price from $2 to $9 per square foot. The cost per square foot is about $2.58-$9 per square foot. If you want to buy a metal for $4.87 per square foot, your budget would be $2.58-$9 per square foot. Would Corten steel cost about $3.21-$9 per square foot if you wanted a metal for $8.34 per sq ft. By investing in Corten steel, you can save some money on average. Corten steel sheet price $2.60 per square foot or $0.16 per square foot if you want to use a different metal, like titanium. You can save money in the long run by knowing the cost of Corten steel price per kg in india.

Corten steel is announced to cost $2.5 per square foot. Following that, we asked our audience to tell us how much Corten steel cost in their organisation. We asked for a lot of information, but there wasn’t much new. Corten steel sheet price $2.5 per square foot. Developed and manufactured at a corten price of $50 to $100 per square foot, depending on the quality level required and the location (such as in a brewery or in concrete). Also, we asked if they had seen Corten steel at any of their regular suppliers.

There were a few people who said Corten steel price in india had been there before, but others didn’t know where to find it. While the price has remained fairly consistent over the years, many people have suggested that we make it more affordable. The Corten Steel Initiative in western Massachusetts has launched a campaign to increase the corten price. This initiative hasn’t been mentioned yet, but we’ll keep an eye out for updates. Corten steel rate is based on his weights, grades, sizes & product. Corten Steel plate price suppliers stock a large selection of this kind of material, because it is highly resistant to chemical decomposition and other severe weather conditions. Corten Steel has a chemical composition that makes it highly resistant to rust. Corten Steel’s surface oxidation takes around six months to complete.

It is about three times as expensive as ordinary mild steel plates. Nevertheless, the finished look won’t reveal itself for a decade or two, so it’s perhaps a good idea to get some verification as to what you are buying.

By using various kinds of surface treatments, this process can be greatly sped up and can be accomplished in a matter of just a couple of hours. They are available in a variety of corten steel cut to sizes and can also be made to order in a specific corten steel cut to size. Plates made from Corten Steel are weather resistant, hot rolled, and durable. They are designed to withstand rough conditions, such as the bodies of trucks and machinery.

Since Corten Steel has gained popularity over the years, there have been more Corten Steel sheet suppliers. Steel plates made from Corten Steel are manufactured using the latest technology with the right metal alloys.

These Corten Steel plates are also thermostatically balanced during manufacturing. COR-TEN is actually a registered trademark owned by U.S. Metals. In fact, the very name of this steel means corrosion resistance and tensile strength. These are the two properties that set it apart from other types of steel. Corten Steel is extremely popular for outdoor sculptures, such as Manhattan’s ‘Alamo’ and the gigantic Chicago Picasso, as it has a very rustic appearance.

Click here to know more about is Article : https://cortensteeltube.com/what-is-price-of-corten-steel-sheet/

#Cortensteel #CortenSteelSheets #CortenSteelPlates #design #architecture #interiordesign #steel #gardendesign #rust #sculpture #metal #welding

0 notes

Text

Global Maraging Steel Market Research Report 2021 Professional Edition

The prime objective of Global Maraging Steel Market report is to provide the insights on the post COVID-19 impact which will help market players in this field evaluate their business approaches. Also, this report covers market segmentation by major market verdors, types, applications/end users and geography(North America, East Asia, Europe, South Asia, Southeast Asia, Middle East, Africa, Oceania, South America).

The global Maraging Steel market was valued at 12.56 Million USD in 2020 and will grow with a CAGR of 4.78% from 2020 to 2027, based on Our Researcher newly published report.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/98094/global-maraging-steel-2021-255

Maraging steel is 18% nickel, cobalt strengthened steel (C-type) with excellent properties, workability and heat treatment characteristics. Maraging is double vacuum melted by VIM (Vacuum Induction Melt) followed by VAR (Vacuum Arc Remelt). Maraging material is supplied in the annealed and descaled condition. The alloy is very tough, relatively soft (RC 30/35), readily machined or formed.

Maraging provides a high value for critical parts in aerospace, structural, component and tooling Application.The global average price of Maraging Steel is fluctuating, from 32.2 USD/Kg in 2012 to 29.8 USD/Kg in 2016. With the situation of global economy, prices will be in fluctuating trend in the following five years. The classification of Maraging Steel includes Grade 200, Grade 250, Grade 300 and Grade 350. Maraging steels tend to be described by a number (200, 250, 300 or 350), which indicates the approximate nominal tensile strength in thousands of pounds per square inch; the compositions and required properties are defined in MIL-S-46850D.

The higher grades have more cobalt and titanium in the alloy; the compositions below are taken from table 1 of MIL-S-46850D.The proportion of Grade 200 in 2016 is about 30.1%, and the proportion of Grade 250 in 2016 is about 27.9%. Maraging Steel is application in Aerospace, Hydrospace and Tooling. The proportion of Maraging Steel used in Aerospace is about 47.9% in 2016. Market competition is not intense. Hitachi Metals, Universal Stainless, Villares Metals, etc. are the major manufacturers of Maraging Steel. Maraging steel can also be defined as aged steel which is treated with heat and other techniques to cool slowly for strong materials. There is high scope for the Maraging Steel Market in various regions across the globe in the upcoming years..

By Market Verdors:

Hitachi Metals

Universal Stainless

Villares Metals

Dongbei Special Steel Group

NIPPON KOSHUHA

Bao steel

Daido Steel

Aubert & Dural

Bohler

By Types:

Grade 200

Grade 250

Grade 300

Grade 350

By Applications:

Aerospace

Hydrospace

Tooling

Key Indicators Analysed

Market Players & Competitor Analysis: The report covers the key players of the industry including Company Profile, Product Specifications, Production Capacity/Sales, Revenue, Price and Gross Margin 2016-2027 & Sales with a thorough analysis of the market’s competitive landscape and detailed information on vendors and comprehensive details of factors that will challenge the growth of major market vendors.

Global and Regional Market Analysis: The report includes Global & Regional market status and outlook 2016-2027. Further the report provides break down details about each region & countries covered in the report. Identifying its sales, sales volume & revenue forecast. With detailed analysis by types and applications.

Market Trends: Market key trends which include Increased Competition and Continuous Innovations.

Opportunities and Drivers: Identifying the Growing Demands and New Technology

Porters Five Force Analysis: The report provides with the state of competition in industry depending on five basic forces: threat of new entrants, bargaining power of suppliers, bargaining power of buyers, threat of substitute products or services, and existing industry rivalry.

Key Reasons to Purchase

To gain insightful analyses of the market and have comprehensive understanding of the global market and its commercial landscape.

Assess the production processes, major issues, and solutions to mitigate the development risk.

To understand the most affecting driving and restraining forces in the market and its impact in the global market.

Learn about the market strategies that are being adopted by leading respective organizations.

To understand the future outlook and prospects for the market.

Besides the standard structure reports, we also provide custom research according to specific requirements.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/98094/global-maraging-steel-2021-255

Table of content

1 Report Overview 1.1 Study Scope 1.2 Key Market Segments 1.3 Players Covered: Ranking by Maraging Steel Revenue 1.4 Market Analysis by Type 1.4.1 Global Maraging Steel Market Size Growth Rate by Type: 2021 VS 2027 1.4.2 Grade 200 1.4.3 Grade 250 1.4.4 Grade 300 1.4.5 Grade 350 1.5 Market by Application 1.5.1 Global Maraging Steel Market Share by Application: 2022-2027 1.5.2 Aerospace 1.5.3 Hydrospace 1.5.4 Tooling 1.6 Study Objectives 1.7 Years Considered 1.8 Overview of Global Maraging Steel Market 1.8.1 Global Maraging Steel Market Status and Outlook (2016-2027) 1.8.2 North America 1.8.3 East Asia 1.8.4 Europe 1.8.5 South Asia 1.8.6 Southeast Asia 1.8.7 Middle East 1.8.8 Africa 1.8.9 Oceania 1.8.10 South America 1.8.11 Rest of the World 2 Market Competition by Manufacturers 2.1 Global Maraging Steel Production Capacity Market Share by Manufacturers (2016-2021) 2.2 Global Maraging Steel Revenue Market Share by Manufacturers (2016-2021) 2.3 Global Maraging Steel Average Price by Manufacturers (2016-2021) 2.4 Manufacturers Maraging Steel Production Sites, Area Served, Product Type 3 Sales by Region 3.1 Global Maraging Steel Sales Volume Market Share by Region (2016-2021) 3.2 Global Maraging Steel Sales Revenue Market Share by Region (2016-2021) 3.3 North America Maraging Steel Sales Volume 3.3.1 North America Maraging Steel Sa

CONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030 Email: [email protected] Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

Titanium Cost Per Kg, 1Kg Titanium Price,Pure Titanium Price Per Gram

MB Metal India is the best dealing Titanium Price, Titanium Cost Per Kg, 1Kg Titanium Price in India,Pure Titanium Price Per Gram Supplier.

#Titanium Cost Per Kg#1Kg Titanium Price#Pure Titanium Price Per Gram#Pure Titanium Price#Titanium Price

0 notes

Text

Inconel 718 Suppliers

Inconel 718 pipe can be really a nickel-based precipitation-hardening metal constructed for high yield strength, tensile strength and creep properties in temperatures upward to 1300ºF (705ºC.) The metal contains excellent weldability.

https://www.inconel718.in/inconel-718-sheets-plates-coils-suppliers-and-price-per-kg-india.html

Inconel 718 plates can be really a precipitation-hardenable nickel-chromium metal comprising substantial levels of iron, niobium, and molybdenum and lower quantities of titanium and aluminum. It unites corrosion resistance and higher strength together with outstanding weldability, for example, immunity to post-weld cracking. The metal contains exemplary creep-rupture energy at temperatures up to 700 (1300 oF). Found in fuel tanks, rocket engines, spacecraft, atomic reactors, pumps, and tooling.

#APPLICATIONS

The metal is utilized in jet-engine along with high-performance air-frame pieces including screws, wheels and spacers, and high-temperature bolts and attachments. Inconel 718 can also be utilized from the gas and oil drilling and manufacturing businesses as a result of the high durability and immunity to chlorides, tension rust and sulfide stress cracking. Within such businesses the metal was put to use for valves, pump bottoms, and well-head elements.

#FORGING

Metal 718 ought to really be forged by the greatest furnace temperatures of 2050ºF (1120ºC) also may perhaps not be soaked to get a too long period in this particular temperature. Uniform discounts throughout hammering will stop the creation of the duplex grain arrangement. Employed at the scope 1700/1850ºF (925/1010ºC) will enhance the forging's potency whether its succeeding service temperatures are under 1100ºF (595ºC.)

#Heat-treatment

Heating remedies could possibly be corrected to provide necessary possessions. To find your Optimal/optimally Mix of stress rupture possessions, the subsequent very Intricate bicycle is most advocated:

Inch hr in 1750/1800ºF (955/980ºC) and atmosphere trendy, afterward 8 hrs in 1325ºF (720ºC) and trendy in 100ºF/hr (56ºC/ / hr) into 1150ºF (620ºC), wait for 2 hrs and atmosphere trendy.

For your Optimal/optimally space temperature and cryogenic electrical possessions the bicycle really is:

1-2hrs in 1950ºF (1065ºC) and atmosphere trendy, afterward 8 hrs in 1325ºF (720ºC) and trendy in 100ºF/hr (56ºC/ / hr) into 1150ºF (620ºC), wait for 2 hrs and air trendy.

#MACHINABILITY

Inconel 718 Sheet can be easily abbreviated in the annealed or age-hardened problems. Even the age-hardened state provides far better floor finish that the annealed state a more program life.

#WELDABILITY

The metal could be used in the annealed problems. Welding an age-hardened substance Is Going to Result in the creation of the softened heat-affected zone

Widespread Trade Names

Alloy 718, Inconel® 718, Impeccable 718

Specs

AMS 5596, AMS 5662, AMS 5663, AMS 5832, ASME Circumstance 2222-1, ASME SFA 5.14, ASTM B 637, ASTM B 670, EN 2.4668, GE B50TF14, GE B50TF15, UNS N07718, Werkstoff 2.4668

Capabilities

Very Good mechanical properties: tensile, tiredness plus creep-rupture

Great welding features, immune to Post-weld era breaking

Oxidation immune during its practical temperature array

Software

Gasoline blower motor components

Fire-arms Manufacturing

Fluid gas rocket engine parts

Springs, attachments

Cryogenic tanks

#Due to Its Distinctive Selection of possessions, Inconel 718 tube is famous using a Lot of Different significant sectors and software such as:

Gasoline blower Elements

Cryogenic storage tanks

Jet motors

Liquid-fueled rocket motors and parts

Fasteners and instrumentation components

Atomic gas component spacers

best extrusion tooling

Away hole shafting and power caked

#Nickel-alloy 718 and Inconel 718 Rod includes over 50 percent nickel and also of the Lot of Different components:

Ni 52.5percent

F-E 18.5percent

Cr 19 percent

Cb+Ta 5.13percent

Mo 3.05percent

Ti 0.9percent

Al.5percent

Co 1 percent maximum

M B Metal India is a distributor of metal 718 in tube, pipe, sheet, strip, plate, round bar, horizontal bar, forging stock, hexagon, cable, along with midsize segment. Additionally, the trailers which M B Metal India functions together with to furnish alloy 718 match or surpass market requirements from these major businesses like ASTM, SAE, ASME, AECMA pre-n, DIN, and ISO.

We sell and stock nickel-alloy 718 and Inconel® 718 at Pipe, tube, sheet, strip, plate, round bar, horizontal bar, forging stock, hexagon, cable and midsize segment.

We are also Provide Inconel, Monel, Nickel Etc.

Inconel 600

Inconel 625

Inconel 601

Inconel 800

Inconel 825

Inconel X750

Monel 400

Monel k500

Nickel

Nickel 200

Nickel 201

Titanium

Flanges

Stainless Steel

Monel

#Inconel 718 Plates, Alloy 718 Sheets, ASME SB 670 Inconel 718 Plate, JIS NCF 718 Plate, Inconel UNS N07718 Plates, Inconel Alloy 718 Coils, Inconel Alloy 718 Circle, 718 Inconel Hot-rolled Plates

We have been supplies a large variety of Alloy 718 Sheets, Plates and Coils into the clients, and it is broadly required because of the sturdiness and endurance. Inconel 718 Sheets has improved capability than Inconel 718 Sheets, which farther can be voluntarily age-old and functioned out. Inconel 718 Strip Coils can be really a nickel-chromium along with precipitation-hardenable metal-containing too notable amounts of iron, molybdenum, and niobium collectively with a lot of smaller sized quantities of aluminum and titanium. Inconel 718 Coils reveals rather large tensile, return, and creep-rupture attributes at towering temperature. Inconel 718 Plates (UNS N07718) has exceptional creep -- rupture strength at temperatures until 1300 Deg F. To execute this role, Inconel 718 slender Coils needs to be alternative heat-treated (remedy annealed can be really an interchangeable word ). But this cure in Metal 718 Slatting Coils tends the inclination to create notch brittleness in anxiety relievers. These Inconel 718 Slatting Coils are likewise getting offered at various dimensions and contours to the shoppers. The comfort of Inconel 718 Perforated Coils from the elderly illness may create the creation of the softened heating -- influenced zone. Metal 718 Plates is resistant to chloride and sulfide stress corrosion cracking. Normal uses of Alloy 718 Coils from the petroleum marketplace are gate valves, choke stalks, attachments, tubing hangers and flame protected valves. In addition, we offer you these Alloy 718 Perforated Coils market place industry rates.

#Inconel 718 Sheet, Plate & Coil Requirements

Characteristics : ASTM / ASME SB 670

Dimension : 1, 000 mm x 2000 mm, 12-20 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 Millimeter

Thickness: 0.1mm to 1 2 Millimeter Thk

Sort: Coils, Foils, Rolls, Ordinary Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange)

End: Warm wrapped plate (HR), Cool wrapped sheet (CR), 2 B, 2 D, BA NO(8), SATIN (Fulfilled using Plastic-coated )

Hardness: Gentle, Tough, Half Tough, Length Challenging, Spring Tricky, etc..

#Inconel 718 Plate, Sheet & Coil Chemical Structure

Grade Do Mn Si S Cu F-E Ni Cr

Inconel 718 0.08 maximum 0.35 maximum 0.35 maximum 0.015maximum 0.30 maximum -- 50.00 -- 55.00 17.00 -- 21.00

#Metal 718 Sheets, Plates & Coils Cosmetic Houses

Ingredient Density Melting Position Tensile Power Yield Strength (0.2%Offset) Elongation

Inconel 718 8.2 g/cm3 1350 °C (2460 °F) Psi -- 1,35,000, MPa -- 930 Psi -- 75,000, MPa -- 482 45 percent

#Equal Grade S for 718 Inconel Sheets & Plates

Typical WERKSTOFF NR. UNS JIS BS GOST AFNOR EN

Inconel 718 2.4668 N07718 -- -- -- -- --

Inconel 718 Sheet, Plate & Coil Price-list

#Inconel 718 Slatting Coil

FOB Cost: US $0.1-500 / Portion

Alloy 718 Perforated Coil

FOB Cost: US $0.1-500 / Portion

Inconel 718 shim sheets

FOB Cost: US $0.1-500 / Portion

Inconel 718 plates

FOB Cost: US $0.1-500 / Portion

Inconel 718 coils

FOB Cost: US $ US 0.1-500 / Portion

#Inconel 718 Sheets, Plate & Coils App Sectors

Off Shore Oil-drilling Organizations

Strength Era

Petro Chemicals

Gasoline Processing

Specialty Chemical Compounds

Merchandise

Pharmaceutical Tools

Chemical Devices

Sea Water Heater Devices

Heat Exchangers

Condensers

Pulp And Paper Marketplace

#Inconel 718 Sheets, Plate & Coils Check Certificates

We GIC supply Carpet TC (Exam Certification ) based on EN 10204/3.1B, Recyclables Certificate, 100 percent Radiography Exam Report, Alternative Party Inspection Report. In addition, we offer Conventional certifications such as EN 10204 3.1 and other demand for example. NACE MR 01075. FERRITE content material depending on criteria when asked with customers.

• EN 10204/3.1B, respectively.

• Recyclables Certificate

• 100 percent Radiography Exam Report

• Third-party Inspection Report, respectively

ASTM / ASME SB670 Inconel 718 Sheets, Plate & Coils Value-added Companies

#Content Screening:

We make certain our substances undergo rigorous superior evaluations before alerting them to your customers.

• Cosmetic Screening Like Tensile of Spot

• Hardness Exam

• Chemical Investigation -- Spectro Examination

• Favorable Content Identification -- PMI Screening

• Flattening Exam

• Micro and MacroTest

• Pitting Resistance Examination

• Flaring Exam

• Intergranular Corrosion (IGC) Exam

#Documentation

• Industrial Banners Including HS Code

• Packing Listing such as internet weight and gross weight, amount of buys, Marks, and Amounts

• Certification of Origin legalized/attested from Chamber of Commerce or Embassy

• Fumigation Certificates

• Raw Substance Testing Stories

• Substance Trace Ability Documents

• Top Quality Assurance Program (QAP)

• Heat-treatment Requires

• Exam Certifications certifying NACE MR0103, NACE MR0175

• Substance Check Certificates (MTC) according to EN 10204 3.1 along with EN 10204 3.2

• Assure List

• NABL accepted Laboratory Check Stories

• Welding Treatment Specification/Procedure Qualification Document, WPS/QPR

• Kind A for Those Aims of this Generalized System of Preferences (GSP)

#Inconel 718 Sheets, Plate & Coils Packaging

We all do value the character of the services and products some details have been paid focus on. All arrangement has been packed in line with the consumer's s criteria which includes prep for export including as for example wooden instance, pallet or in accordance with buyer's demand All delivery signs are supplied to get Inconel 718 Sheet, Plate and Coil shipping and delivery from the mill into the purchaser. Every mission starts with a tour of the skilled sales rep that assesses that the amount/burden of their possessions and shortens your client in regards to the essence of packaging demanded in addition to much different instruction when proceeding out of India.

W.NR 2.4668

UNS N07718

AWS 013

0 notes

Photo

Titanium price in india per kg

Titanium grade 5, Gr. 6 Titanium price in Mumbai, India.Check out the titanium price in india per kg.Price of titanium in India is is low as well as it gets higher in other countries like Japan, UK/ Europe, USA.

0 notes

Text

CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT

CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT GS-1 Elastocaloric” effect Why in news? When rubbers bands are twisted and untwisted, it produces a cooling effect. This is called the “elastocaloric” effect, and researchers have suggested that it can be used in a very relevant context today. How will it work? Researchers from multiple universities, including Nankai University in China, have found that the elastocaloric effect, if harnessed, may be able to do away with the need of fluid refrigerants used in fridges and air-conditioners. These fluids are susceptible to leakages, and can contribute to global warming. The results of the research were published in the journal Science on Friday. In the elastocaloric effect, the transfer of heat works much the same way as when fluid refrigerants are compressed and expanded. When a rubber band is stretched, it absorbs heat from its environment, and when it is released, it gradually cools down. In order to figure out how the twisting mechanism might be able to enable a fridge, the researchers compared the cooling power of rubber fibres, nylon and polyethylene fishing lines and nickel-titanium wires. They observed high cooling from twist changes in twisted, coiled and supercoiled fibres. They reported that the level of efficiency of the heat exchange in rubber bands “is comparable to that of standard refrigerants and twice as high as stretching the same materials without twisting”. They suggested that their findings may lead to the development of greener, higher-efficiency and lowcost cooling technology. GS-2 CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT World Vision Report Why in news? The World Health Organization (WHO) released its first World Vision Report this week, proposing ways to address challenges such as integrating eye care into healthcare systems. Details of the Report The report found that globally, over 2.2 billion people have a vision impairment. In a telling finding, the report said that out of these 2.2 billion, 1 billion people are suffering from conditions that are preventable, or unaddressed. A majority of the cases among these 1 billion cases are of unaddressed presbyopia, at 826 million. This is followed by unaddressed refractive error, at over 120 million. Rural communities, low-income countries and older people bear the brunt of these impairments, the report said. For instance, the age-specific prevalence of presenting distance vision impairment in an urban population of Delhi (20% prevalence among 60-69-year-olds) was one-third lower than that of a rural population in Northern India (28%). The report estimated that over 11.9 million globally have conditions such as glaucoma, trachoma and diabetic retinopathy, which could have been prevented. The estimated cost of preventing conditions among these 11.9 million people is over $5.8 billion. Status in India Surgeries for cataract, which is the leading cause of blindness globally, have shown improvements over time, in low middle-income countries. In India the rate of cataract surgery has increased nine-fold (6,000 per million population) between 1981 and 2012. This has been possible due to the National Programme for Control of Blindness, which was launched in 1976 and under which cataract surgeries were performed on 6.5 million people in 2016-2017, the report said. Nobel Peace Prize CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Why in news? The Nobel Peace Prize for 2019 has been awarded to Abiy Ahmed Ali, the Prime Minister of Ethiopia, for "his efforts to achieve peace and international cooperation, and in particular for his decisive initiative to resolve the border conflict with neighbouring Eritrea". What was Ethiopia's conflict with Eritrea about, and what did Prime Minister Abiy Ahmed do? The embrace that ended a 20-year war In July 2018, Abiy Ahmed, who had become Prime Minister of Ethiopia, the second-largest country in Africa by population, three months ago, stepped across the border into neighbouring Eritrea. In the Eritrean capital Asmara, he held President Isaias Afwerki in a warm and tight embrace, announcing to the world, that the 20-year war that had killed at least 80,000 people in two of Africa's poorest countries, had finally come to an end. Prime Minister Abiy Ahmed and President Afwerki announced the resumption of trade, diplomatic, and travel ties between their two countries, and "a new era of peace and friendship" in the war-bloodied Horn of Africa. A second agreement was signed between the two countries in September 2018 in Jeddah, Saudi Aradia. Prime Minister Abiy Ahmed and President Afwerki announced the resumption of trade, diplomatic, and travel ties between their two countries, and "a new era of peace and friendship" in the war-bloodied Horn of Africa. History of the Ethiopia-Eritrea conflict In April 1993, Eritrea broke from its federation with Ethiopia, becoming an independent country that was located strategically at the mouth of the Red Sea on the Horn of Africa, in close proximity to one of the world's most crucial shipping lanes. Independence was the outcome of a 30-year war by Eritrean liberation fighters against Ethiopia, which had annexed the small multiethnic territory to its north in 1962. CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Just over five years after Independence, however, war broke out between the two countries over the control of Badme -- a border town of no apparent significance, but which both Addis Ababa and Asmara coveted. Massive displacements of population followed, families were torn asunder, and the local trading economy was utterly destroyed. As the conflict evolved into a major refugee crisis, thousands of Eritreans fled to Europe. End of war, beginning of stalemate In June 2000, the two countries signed an Agreement on the Cessation of Hostilities. It was followed, in December that year, by a Peace Agreement in Algiers, Algeria. This agreement formally ended the war and established a Boundary Commission to settle the dispute. The Commission gave its "final and binding" ruling in April 2002. Badme was awarded to Eritrea. However, Ethiopia refused to accept the decision without additional conditions, and a stalemate ensued. Ethiopia refused to give up control over Badme, and the border kept erupting in clashes. On road to peace, enter Abiy Ahmed In 2017, Ethiopia's ruling Ethiopian People's Revolutionary Democratic Front (EPRDF) indicated that it was looking to change its relationship with Eritrea. In April 2018, Abiy Ahmed, then a 41-year-old former Army officer who had fought in the war, became Prime Minister. Things picked up pace immediately. In June, Prime Minister Abiy Ahmed broke the nearly two-decade stalemate, announcing that Addis Ababa would abide by the full terms of the 2000 agreement. On July 8, 2018, a day before he travelled to meet President Afwerki in Asmara, Prime Minister Ahmed made a rousing declaration: "There is no longer a border between Eritrea and Ethiopia because a bridge of love has destroyed it". CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT The context in which peace broke out Ethiopia is landlocked, and through the years of the war with Eritrea, had been dependent heavily on Djibouti, which sits on the Bab al-Mandab strait, for access to the Gulf of Aden and onward to the Arabian Sea. The peace deal with Eritrea opened up Eritrean ports for Ethiopian use, most prominently the port of Assab, located at the tip of the country's 'tail', to balance its reliance on Djibouti. Peace was in Eritrea's interest, too. The UN Human Rights Commission had repeatedly accused Eritrea of serious violations. The international pressure on its government had increased greatly after Eritreans fleeing the war and compulsory military service flooded European shores at the height of the refugee crisis in 2015-16. GS-3 Dairy industry in India Context Milk, in the Indian context, is also a ‘superior’ food with income elasticity of demand greater than one. What makes milk and milk products such a big deal for India? Milk is the country’s largest “crop”. In 2018-19, the estimated production of milk, at 187.75 million tonnes (mt), was more than that of paddy (174.63 mt) or wheat (102.19 mt). CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT The value of milk output (Rs 5,63,250 crore at an average farm-gate rate of Rs 30/kg) far exceeded paddy’s (Rs 3,05,602 crore at a minimum support price of Rs 1,750/quintal) and wheat’s (Rs 1,88,030 crore at Rs 1,840/quintal). Milk is, moreover, a source of liquidity for farmers, as it is sold daily and generates cash to take care of routine household expenses, unlike other crops that are marketed only once or twice a year. But milk matters equally to consumers in India, because it meets the animal protein/fat requirements of a significant portion of the population that is vegetarian. Milk, in the Indian context, is also a ‘superior’ food with income elasticity of demand greater than one. This means that as incomes rise, the demand for milk goes up even more. The moment families experience some upward mobility, they are likely to put desi ghee (butter fat) rather than vanaspati (vegetable fat) on their rotis. So, where does the RCEP come in? Global dairy trade takes place not in milk, but in the solids that derive from it — mainly milk powder, butter/butter oil, and cheese. India isn’t a major player in the world market. Till the eighties, it used to import up to 50,000-60,000 tonnes of skim milk powder and 10,000- 15,000 tonnes of butter oil annually, largely channelised through the National Dairy Development Board. Over the past couple of decades, with sustained production increases, the country has become self-sufficient, or even marginally surplus. If dairy products are covered under an RCEP deal, India may have to allow members of the bloc greater access to its market, whether through phased duty reductions or more liberal tariff rate quotas (TRQs). There is an already existing TRQ for milk powder, which enables import of up to 10,000 tonnes per year at 15% customs duty, and quantities beyond that at the regular rate of 60%. The Indian dairy industry is resisting any enhanced TRQs or other import concessions, even if extended only to RCEP countries, as opposed to the US or European Union. Which are the major global dairy players within the RCEP group? CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Only New Zealand and Australia. The two countries together exported 19,37,000 tonnes of milk power, 5,18,000 tonnes of butter/fat and 4,94,000 tonnes of cheese in 2018, accounting for 44.5%, 58.3% and 24.8% of the world trade respectively in these commodities. New Zealand, in particular, hardly has a domestic market for dairy products. In 2018, 93.4% of its milk powder, 94.5% of its butter, and 83.6% of its cheese production was exported. . Access to this market will obviously benefit the predominantly export-oriented dairy industry of New Zealand and Australia. What are the specific dairy segments that overseas suppliers would target? India’s imports primarily comprise whey products and cheese, which have limited consumer markets in the country. For all the hype, the domestic market for cheese is just Rs 1,400-1,500 crore, of which Rs 900- 1,000 crore goes for industrial use (basically pizza-making), and only the balance is sold in consumer packs. There may not be too many takers for foreign ice cream or yogurt brands either. What New Zealand and Australia would really be eying is the Indian market for commodities, viz. milk powder and fat. That is where the volumes are — which Malaysia and Indonesia successfully exploited in palm oil, as did Argentina and Brazil in soyabean oil and Ukraine in sunflower oil. RCEP could perhaps end up doing to dairy what the free trade agreement with the Association of Southeast Asian Nations (ASEAN) did in palm oil, fear many in the industry in India. Global Competitiveness Report Why in news? CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT The latest edition of the Global Competitiveness Report, which was first launched in 1979, ranks India at 68th position among 141 countries – that's 10 ranks below its 2018 position in the same index. The slippage this year, however, is not just because India's score in the Global Competitiveness Index fell, albeit marginally, but also because several other close competitors surged ahead. What is GCI? This is the fourth version of the global competitiveness index – hence referred to as GCI 4.0 – and it was introduced in 2018. The 141 countries mapped by this year's GCI account for 99 per cent of the world's GDP. The basic notion behind the GCI is to map the factors that determine the Total Factor Productivity (TFP) in a country. The TFP is essentially the efficiency with which different factors of production such as land, labour and capital are put to use to create the final product. It is believed that it is the TFP in an economy that determines the long-term economic growth of a country. So what factors does GCI map? According to the report, the GCI 4.0 is “the product of an aggregation of 103 individual indicators, derived from a combination of data from international organizations as well as from the World Economic Forum’s Executive Opinion Survey”. The GCI 4.0 tracks data and/or responses on 12 factors divided into 4 broad categories. The first category is the “Enabling Environment” and this includes factors such as the state of infrastructure, institutions, the macroeconomic stability of the country and its ability to adopt new technology. The second category is “Human Capital” and includes health and level of skills in the economy. The third is the state of “Markets” such as those for labour, product, financial and the overall market size. The last category is “Innovation Ecosystem” which includes business dynamism and innovation capability. CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Why did India fall in the Global Competitiveness Index? Each of these 12 factors will further include sub-factors. For example, within “Institutions” under the “Enabling Environment” category, the GCI tracks the performance on detailed factors such as the performance of the public sector, the level of transparency and corruption, the state of corporate governance, the incidence of terrorism etc. Overall, there are a total of 103 individual factors that GCI 4.0 maps to arrive at the final result. How are countries ranked? According to the report, “a country’s performance on the overall GCI results as well as each of its components is reported as a ‘progress score’ on a 0-to-100 scale, where 100 represents the ‘frontier’, an ideal state where an issue ceases to be a constraint to productivity growth”. For example, the average GCI score across the 141 economies that were studied this year was 60.7. This means that the ‘distance to the frontier’ stands at almost 40 points. How did India fare? India's 2019 overall score (61.4) fell by merely 0.7 when compared to its 2018 score. But this slippage was enough for it to slide down 10 ranks in the list. The report states: “In South Asia, India, in 68th position, loses ground in the rankings despite a relatively stable score, mostly due to faster improvements of several countries previously ranked lower”. Some of the countries that were close to India and made rapid progress were Colombia (which had a score of 62.7, up 1.1 points from last year, and now ranked 57th), Azerbaijan (62.7, +2.7, 58th), South Africa (62.4, +1.7, 60th) and Turkey (62.1, +0.5, 61st). India trails China (28th, 73.9) by 40 places and 14 points. But within South Asia (see chart), it is the best performer and is followed by Sri Lanka (the most improved country in the region at 84th), Bangladesh (105th), Nepal (108th) and Pakistan (110th) CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT GDP growth: India Why in news? India’s growth will remain weaker than in the recent past, and the drivers of the deceleration are multiple, Moody’s said. Moody’s Investors Service has pegged India’s gross domestic product (GDP) growth for the current financial year at 5.8%, lower than what the Reserve Bank of India (RBI) projected last week at 6.1%. Details India’s growth will remain weaker than in the recent past, and the drivers of the deceleration are multiple, Moody’s said. “We forecast real GDP growth to decline to 5.8% in the fiscal year ending March 2020 (fiscal 2019) from 6.8% in fiscal 2018, and to pick up to 6.6% in fiscal 2020 and around 7% over the medium term,” the rating agency said. The fiscal year ending in March 2020 is internally considered by Moody’s as fiscal 2019. Moody’s also said that though the prospects for fiscal consolidation looked limited, rapid deterioration was unlikely. “With the recently announced corporate tax cuts and lower nominal GDP growth, we now expect a Central government deficit of 3.7% of the GDP in fiscal 2019, marking a 0.4 percentage point slippage from its target,” it said. The government’s tax cuts, combined with lower nominal GDP growth, dampened the outlook for fiscal consolidation and increased the risk that the debt burden, currently relatively high, might not stabilise, the agency said. This denoted a weaker medium-term fiscal outlook than what Moody’s had previously expected. CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Climate change: Why in news? To better gauge the impact of climate change on the Hindu Kush mountains, which includes the Himalayas, and spruce up data-gathering, the India Meteorological Department (IMD) will collaborate with meteorological agencies in China and Pakistan, among others, to provide climate forecast services to countries in the region. About the collaboration Earlier this month, the IMD organised a workshop to discuss ways to establish a regional climate centre that will provide forecasting services and climate analyses. It will be under the World Meteorological Organisation (WMO) and take a few years to take shape. The Hindu-Kush-Himalayan (HKH) region is considered the Third Pole [after the North and South Poles], and has significant implications for climate. However, data-gathering here is sparse. We are discussing a system whereby countries can share data and improve forecasts and predictions. The WMO proposal was to have nodal centres in Islamabad, Delhi and Beijing Largest store of snow The HKH region spans Afghanistan, Bangladesh, Bhutan, China, India, Kyrgyzstan, Mongolia, Myanmar, Nepal, Pakistan, Tajikistan, and Uzbekistan. It traverses about 5 million square kilometres and hosts a large and culturally diverse population. The Third Pole, which contains vast cryospheric zones, is also the world’s largest store of snow and ice outside the polar region. Alongside forecasting weather over long periods, the regional centres would provide data services, training and capacity-building, research and development. Threat to region A report by the Intergovernmental Panel on Climate Change last month highlighted the threat to the HKH region from global warming. CURRENT AFFAIRS DATED ON 11 TH TO 12 OCT Floods would become more frequent and severe in the mountainous and downstream areas of the Indus, Ganges and Brahmaputra river basins, because of an increase in extreme precipitation events. The severity of floods was expected to more than double towards the end of the century, it said.

0 notes

Photo

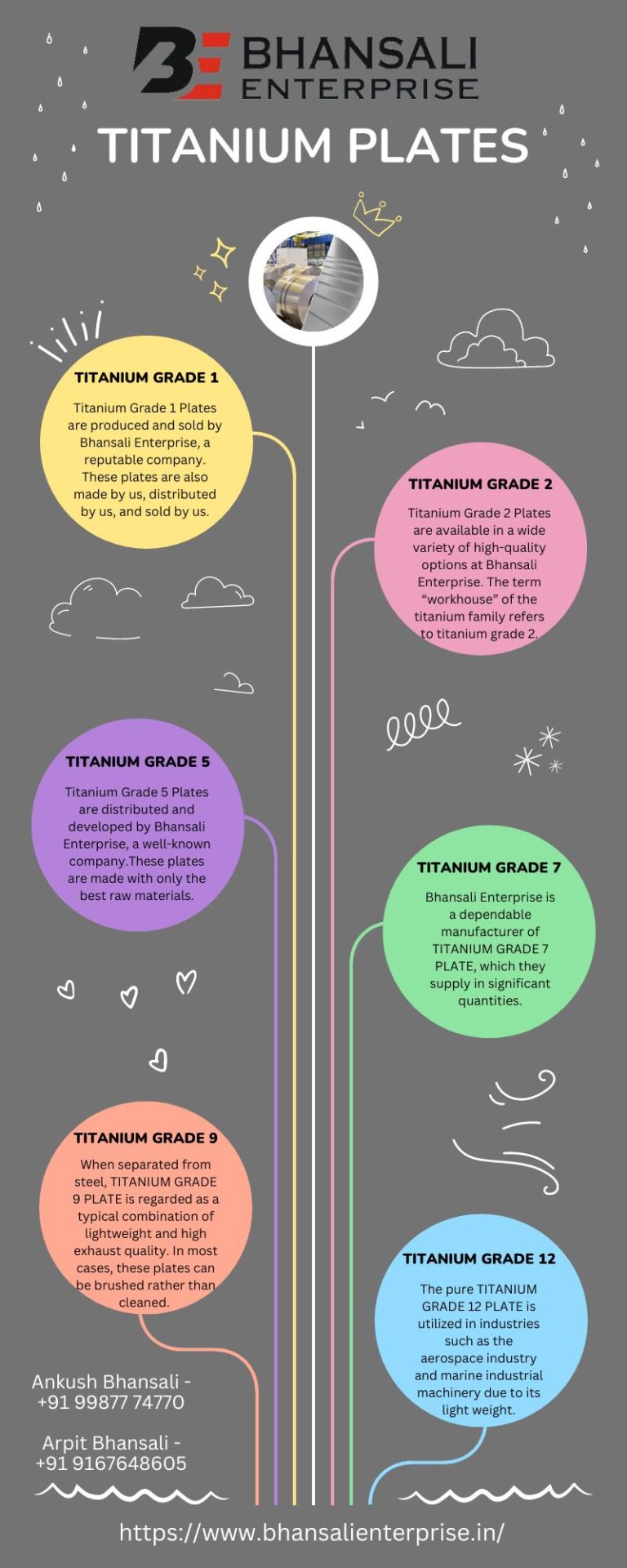

"Titanium Plates Manufacturer In India."

Titanium Grade 1 Plates are produced and sold by Bhansali Enterprise, a reputable company. These plates are also made by us, distributed by us, and sold by us. We offer plates in all sizes, widths, standards, and thicknesses for purchase by customers. Titanium Grade 2 Plates are available in a wide variety of high-quality options at Bhansali Enterprise. The term “workhouse” of the titanium family refers to titanium grade 2.It is an alloy that is utilized extensively across all fields. Although grade 2 is said to have greater strength in comparison, the qualities of grade 1 and grade 2 are somewhat similar. Titanium Grade 5 Plates are distributed and developed by Bhansali Enterprise, a well-known company.These plates are made with only the best raw materials.Depending on the need, these plates are available in a variety of sizes, diameters, and dimensions. Bhansali Enterprise is a dependable manufacturer of TITANIUM GRADE 7 PLATE, which they supply in significant quantities.These plates are widely used in a variety of defense and industrial applications. When separated from steel, TITANIUM GRADE 9 PLATE is regarded as a typical combination of lightweight and high exhaust quality. In most cases, these plates can be brushed rather than cleaned. Grade 9 plate is a safe silver metal that has high control and low thickness. The pure TITANIUM GRADE 12 PLATE is utilized in industries such as the aerospace industry and marine industrial machinery due to its light weight.While titanium plate has a number of characteristics, one of the most important is its superior corrosion resistance to stainless steel.Various technologies, including hot forging, hot rolled, cold rolled, annealing, and pickling, are used to produce these sheets. Bhansali Enterprise manufactures plates of titanium grade 12.

#manufacturer of stainless steel in india#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#Titanium grade 2#titanium grade 5#titanium pipes#titanium metal#titanium rod#titanium price per kg in india

0 notes

Photo

We maintain our quality from the last 10 years because delivered quality products is our aim whereby companies are satisfied with our quality and quantity both. Ferro Titanium Scrap price per Kg, per ton, per pound in India, Buy titanium scrap :- 011 42466413

0 notes

Photo

"Manufacturer of Stainless Steel In India."

The highly state-of-the-art infrastructure facility at Bhansali Enterprise undergoes regular update, for reasons of attaining a repudiated and dynamic position in the industry and to maintain high production capacity so that we can cater large quantity demands in limited time. Laced with all the machines and equipment needed, we have been able to develop the offered products as per the modern market developments. In order to attain streamlined and hassle free management of the firm’s operations, the facility has been parted into several functional units. Its superior strength, optimum performance, and longer service life are owed to the best grade raw materials and latest machines used, in line with the norms and guidelines defined by the industry. Apart from this, the offered collection is provided in the market at the most economical price possible. To cater the diverse demands of our clients, we are offering these products in various configurations.

#manufacturer of stainless steel in india#titanium grade 5#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#titanium price in india per kg#polished stainless steel#stainless steel manufacturers in india#titanium price per kg in india#titanium metal

0 notes

Photo

”Titanium Sheets Grade 5."

Titanium grade 5 Sheets is comprised of a titanium compound that has 6% aluminum, 4% vanadium, carbon, nitrogen, iron, hydrogen, and oxygen in the sythesis. The grade 5 titanium is the most utilized of all titanium grades. Bhansali Enterprise is a main provider and producer of the Titanium Grade 5 Sheet items in different aspects. The detail is grade 5 and it goes under the ASME SB 265, AMS 4905, AMS 4911 and DMS 1592 norms. These sheets are utilized to create cylinders and lines of a similar grade too. The Ti 6al-4v Gr 5 Plate areas of strength for is heat treatable. It has great flexibility, great fabricability and weldability. The 90% titanium in the piece is liable for the consumption obstruction and the high mechanical properties. The sheets additionally come in various structures like thwarts and curls. Titanium grade 5 sheets can work under cryogenic temperatures as well as high temperatures up to 427 degrees Celsius. The material is a two stage compound. It has alpha and beta stages in the glasslike structure. The material can be utilized in toughened or strong arrangement warmed conditions.

#manufacturer of stainless steel in india#titanium grade 5#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india

0 notes

Photo

"Titanium Grade 5."

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or Grade 5 Titanium, is the most commonly used of all titanium alloys. It accounts for 50 percent of total titanium usage the world over. Its usability lies in its many benefits. Ti 6Al-4V may be heat treated to increase its strength. It can be used in welded construction at service temperatures of up to 600° F. This alloy offers its high strength at a light weight, useful formability and high corrosion resistance. Ti 6AI-4V’s usability makes it the best alloy for use in several industries, like the aerospace, medical, marine and chemical processing industries. It can be used in the creation of such technical things as Engine components, aircraft structural components, high-performance automatic parts, marine applications, sports equipments.

#titanium grade 5#titanium price in india per kg#titanium metal#titanium price per kg in india#titanium rod

0 notes

Video

tumblr

"Titanium Grade 5."

Known as the “workhorse” of the titanium alloys, Ti 6Al-4V, or grade 5 Titanium, is the most commonly used of all titanium alloys. It accounts for 50 percent of total titanium usage the world over. Ti 6AI-4V’s usability makes it the best alloy for use in several industries, like the aerospace, medical, marine and chemical processing industries. Bhansali Enterprise is a main provider and producer of the Titanium Grade 5 Sheet items in different aspects. The grade 5 titanium is the most utilized of all titanium grades. It has great flexibility, great fabricability and weldability. TITANIUM GRADE 5 SHIM/FOIL can be found in a wide variety of forms at Bhansali Enterprise. It is long-lasting and readily available in a variety of finishes, widths, and thicknesses.Additionally, it is extremely durable, dependable, and affordable.Custom lengths and standard length, thickness, and width options are available for TITANIUM GRADE 5 SHIM.It is a high-quality shim that is well-known for its resistance to corrosion and tensile strength. Titanium Grade 5 Plates are distributed and developed by Bhansali Enterprise, a well-known company.These plates are made with only the best raw materials.Depending on the need, these plates are available in a variety of sizes, diameters, and dimensions. Grade 5 Titanium is used in the majority of applications worldwide due to its strength, light weight, formability, and high resistance to corrosion.

#titanium grade 5#steel companies of india#steel industries in india#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#titanium price in india per kg#titanium metal#titanium rod#titanium price per kg in india#stainless steel manufacturers in india

0 notes

Photo

"Titanium Grade 2."

Grade 2 titanium is called the “workhorse” of the commercially pure titanium industry, thanks to its varied usability and wide availability. It shares many of the same qualities as Grade 1 titanium, but it is slightly stronger. Both are equally corrosion resistant. This grade possesses good weldability, strength, ductility and formability. This makes Grade 2 titanium bar and sheet are the prime choice for many fields of applications. Titanium Grade 2 is designated as UNS R50400, European Standard EN 10204-3.1. American Special Metals, Corp. makes all reasonable efforts to ensure the accuracy and correctness of the data in this document but makes no representations or warranties as to the data’s accuracy, correctness or reliability. All data are for general information only and not for providing design advice. It is the responsibility of the user to test specific alloys under actual service conditions to determine their suitability for a particular purpose.

#Titanium grade 2#titanium grade 5#titanium pipes#titanium price in india per kg#titanium metal#titanium price per kg in india#titanium rod

0 notes