#thermal analysis consultant

Explore tagged Tumblr posts

Text

Contact The Most Suitable Thermal Analysis Consultant At Thermal Design Solutions

Thermal management has become crucial in the electronic systems available today. So, you must consider it when it comes to design. People focus mainly on other aspects and just consider thermal management if there is an issue like excessive heating or malfunction. There can be various issues if the thermal management systems are not designed properly. These issues can be high failure rates or short lives of devices. To avoid all such problems, you should work with a thermal analysis consultant. Thermal Design Solutions is one of the most reliable companies that can help you with thermal analysis solutions. With extensive experience in this field, these experts will guide you in the right direction.

Helping clients with dedication

Thermal Design Solutions is one of the leading thermal management consulting firms. This company ensures that it guides clients from all around the world. This company has several decades of experience. So, the thermal consultant can handle several aspects, such as electronics cooling solutions, thermal interface solutions, phase change systems, and much more. So, when you choose Thermal Design Solutions, the solutions will match all your requirements and be dependable. These solutions are also available at reasonable prices.

Some examples

Thermal Design Solutions can help you with a variety of projects. It can guide you with smartphone thermal design, virtual reality devices, tablets, laptops, microprocessor design, liquid cooling systems, and a lot more. When you contact these professionals, they will seamlessly evaluate the systems. After this, these professionals will provide you with the most efficient suggestions. Along with this, it can also provide server thermal design, phase change energy storage, etc. With Thermal Design Solutions by your side, you can get the right assistance in selecting materials, testing, and prototyping.

Expertise

The team of professionals at Thermal Design Solutions has the right expertise in this industry. So, these professionals can take care of several thermal experiments. They can offer the most exceptional solutions if you need assistance with passive or active cooling solutions. Along with this, you can also get help with thermal interface material technologies. The team members at Thermal Design Solutions have experience with thermal ergonomics. So, no matter your needs, you can share them with the company. These professionals can easily help you using the most suitable techniques and methods.

To work with a thermal design consultant, contact the team at Thermal Design Solutions.

To learn more about the work of thermal analysis consultants, visit https://www.thermalds.com/

Original Source: https://bit.ly/4cgy2rK

0 notes

Text

fea fatigue analysis in hyderabad

thermal analysis services in hyderabad fatigue analysis services in hyderabad nonlinear analysis services in hyderabad fea for product development in hyderabad top fea consultants in hyderabad https://3d-labs.com/fea-services/ Comprehensive FEA Services for Enhanced Engineering Design and Analysis 3d-labs is an engineering consulting firm that provides full analysis using state-of-the-art FEA , CFD, and CAD/CAE tools. We help our clients reduce product development costs, decrease time-to-market , and improve product quality. We, offer not only reliable analysis results but also insight solutions to clients' projects….. We are from all sectors of the industry and have excellent analytical skills and knowledge. We have co-operation with universities, national laboratories, and other engineering firms, which enable us to address and solve clients' questions and problems simply and quickly. We solve a broad range of engineering analysis problems based on FEA techniques including stress analysis, fluid dynamics, kinematics, heat transfer, dynamics and vibration (seismic, harmonic), structural dynamics and electromagnetics. etc. Introduction Why Should we do Analysis Elastic Stress Analysis Method static Structural Analysis Engineering Data Geometry Model Setup Solution Results Fatigue Analysis Fatigue Tool Solution Results

https://3d-labs.com/

#thermal stress fea analysis services in hyderabad#fea consulting service provider in hyderabad#fea for civil engineering in hyderabad

0 notes

Text

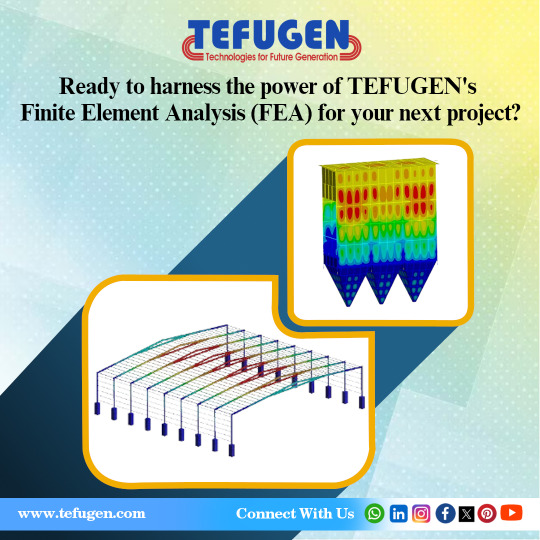

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

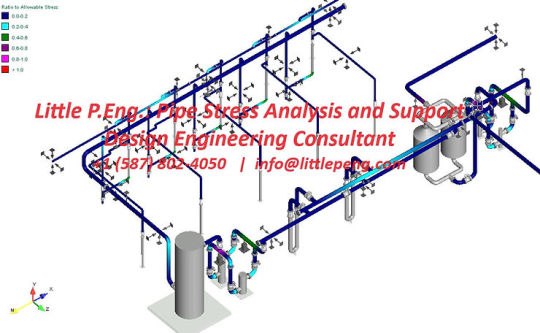

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

In the world of engineering, precision and safety are paramount, especially when it comes to piping systems. Any miscalculation or oversight can have severe consequences, ranging from safety hazards to costly downtime. This is where Little P.Eng. Engineering steps in as a trusted partner, providing expert pipe stress analysis and support design services to ensure the structural integrity and efficiency of piping systems across various industries.

With a reputation for excellence and a commitment to delivering tailored solutions, Little P.Eng. Engineering has established itself as a go-to engineering consultant for those seeking to optimize their piping systems.

Expertise in Pipe Stress Analysis

At the core of Little P.Eng.'s services is their expertise in pipe stress analysis. This crucial engineering discipline involves assessing the forces, stresses, and displacements acting on piping systems to ensure they operate safely and efficiently. Whether it's static stress analysis, dynamic stress analysis, thermal analysis, or seismic analysis, Little P.Eng. Engineering has a team of highly skilled engineers who are well-versed in these complex assessments.

Static stress analysis, for example, is employed to evaluate the stresses in stationary piping systems, ensuring they can withstand the pressures and loads they are subjected to during normal operation. Dynamic stress analysis, on the other hand, deals with transient conditions such as startup, shutdown, and water hammer, which can place additional stress on the system.

Ensuring Compliance with Standards

One of the hallmarks of Little P.Eng.'s services is their unwavering commitment to compliance with industry standards and codes. Piping systems must adhere to strict safety and regulatory guidelines, and Little P.Eng. Engineering ensures that all their analyses and designs meet or exceed these standards. Whether it's ASME, ANSI, API, ASTM, or local building codes, clients can trust that their projects are in full compliance.

Customized Solutions for Unique Needs

No two piping systems are identical, and Little P.Eng. Engineering understands this well. They excel in providing customized solutions that align with the specific needs and challenges of each project. Whether it's an oil refinery, a pharmaceutical facility, or a power plant, Little P.Eng.'s team tailors their services to ensure optimal results.

Support Design Expertise

In addition to pipe stress analysis, Little P.Eng. Engineering offers support design services that play a critical role in the stability and longevity of piping systems. Proper support design involves creating structures and supports that hold piping systems in place, preventing excessive movement, vibrations, and stress.

Little P.Eng. Engineering's support design services encompass a range of aspects, including pipe support design, structural analysis, material selection, and installation guidance. These services are crucial in preventing issues like excessive stress, vibrations, misalignment, and premature wear in piping systems.

Commitment to Safety and Quality

Safety is Little P.Eng.'s top priority. Their pipe stress analysis and support design services are driven by a deep commitment to ensuring the safety of people, the environment, and assets. They meticulously evaluate every aspect of a piping system to identify potential safety hazards and implement measures to mitigate them.

Quality assurance is woven into the fabric of Little P.Eng.'s services. They maintain rigorous quality control processes throughout the project lifecycle, from initial analysis to final implementation. This dedication to quality results in reliable and durable piping systems.

Client-Centric Approach

Little P.Eng. Engineering takes a client-centric approach, focusing on understanding the unique needs and goals of each client. They engage in open communication and collaboration, ensuring that clients are actively involved in the decision-making process. This approach fosters trust and transparency, key elements in successful engineering projects.

Timely and Efficient Service

In the world of engineering, time is often of the essence. Little P.Eng. Engineering understands the importance of meeting project timelines. Their streamlined processes and experienced team allow them to deliver timely and efficient services without compromising quality. This ensures that clients can rely on them to meet their project deadlines and objectives.

Continuous Improvement

In an ever-evolving field like engineering, staying current with the latest advancements is crucial. Little P.Eng. Engineering is committed to continuous improvement and invests in ongoing training and development for their team members. This dedication to staying at the forefront of technological advancements allows them to provide cutting-edge solutions to their clients.

Little P.Eng.: Pipe Stress Analysis and Support Design Engineering Consultant

A Pipe Stress Analysis and Support Design engineering consultant offers a range of services to ensure the structural integrity, safety, and efficiency of piping systems in various industries. These services may include:

1. Pipe Stress Analysis:

Static Stress Analysis: Evaluating stresses, forces, and displacements in stationary piping systems.

Dynamic Stress Analysis: Assessing the effects of transient conditions, such as startup, shutdown, and water hammer.

Thermal Stress Analysis: Analyzing the impact of temperature variations on piping materials and components.

Seismic Analysis: Evaluating the response of piping systems to seismic forces and designing for earthquake resistance.

Fatigue Analysis: Predicting the fatigue life of components subjected to cyclic loading.

2. Support Design Services:

Pipe Support Design: Designing supports, hangers, and restraints to prevent excessive movement and stress in piping systems.

Structural Analysis: Evaluating the structural integrity of support structures and ensuring compliance with safety codes.

Material Selection: Recommending suitable materials for support components based on factors like load-bearing capacity and corrosion resistance.

Installation Guidance: Providing recommendations and specifications for the proper installation of supports.

3. Compliance with Standards and Codes:

Ensuring that all designs and analyses meet relevant industry standards, codes, and regulations, such as ASME, ANSI, API, ASTM, and local building codes.

Assisting clients in obtaining necessary permits and approvals for piping system installations or modifications.

4. Customized Solutions:

Tailoring pipe stress analysis and support design services to the specific needs and requirements of each project.

Developing unique solutions for complex or challenging piping system configurations.

5. Failure Analysis and Troubleshooting:

Investigating and diagnosing issues related to piping system failures, leaks, or performance problems.

Recommending corrective actions and retrofits to address identified problems.

6. Hygienic Piping Design (in industries like pharmaceuticals and food production):

Designing piping systems that comply with stringent sanitary and hygiene standards to prevent contamination.

Implementing design solutions that minimize dead legs, reduce the risk of bacterial growth, and facilitate cleaning and sterilization.

7. Stress Testing and Simulation:

Conducting computer simulations and modeling to predict stress and strain behavior under different operating conditions.

Performing load testing to validate the performance of pipe supports and restraints.

8. Energy Efficiency Optimization:

Identifying opportunities to improve energy efficiency by optimizing piping system configurations and insulation.

Recommending modifications to reduce heat loss or improve heat transfer.

9. Retrofit and Upgrade Design:

Developing plans and designs for the retrofit or upgrade of existing piping systems to meet current safety and performance standards.

Incorporating advanced technologies and materials for improved reliability and efficiency.

10. Documentation and Reporting:

Generating comprehensive reports, including stress analysis reports, design drawings, specifications, and installation instructions.

Maintaining accurate records of all analyses, designs, and project documentation.

11. Consulting and Expert Witness Services:

Providing expert consulting services for legal matters, including expert witness testimony in cases involving piping system failures or disputes.

12. Project Management and Coordination:

Overseeing and coordinating the implementation of recommended design changes or support installations to ensure proper execution.

Pipe Stress Analysis and Support Design engineering consultants play a crucial role in ensuring the safe and efficient operation of piping systems across various industries, and their services are vital for preventing failures, reducing downtime, and maintaining regulatory compliance.

The listing below indicates a few of Meena Development’s most commonly served industries.

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

Tags:

Little P.Eng.

ASME standards

Engineering expertise

Thermal expansion

Structural integrity

Regulatory compliance

Pipe stress analysis

Documentation

Industrial processes

Engineering consultant

Advanced software

Pressure changes

API standards

Maintenance costs

Optimization

ISO standards

Seismic events

Oil and gas industry

Custom support systems

Inspection readiness

Load-bearing capacities

Compliance standards

Piping systems

Power generation

Fluid dynamics

Petrochemical industry

Support design engineering

Troubleshooting

Temperature fluctuations

Safety analysis

Pipe Stress Analysis Services

Engineering Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng.#ASME standards#Engineering expertise#Thermal expansion#Structural integrity#Regulatory compliance#Pipe stress analysis#Documentation#Industrial processes#Engineering consultant#Advanced software#Pressure changes#API standards#Maintenance costs#Optimization#ISO standards#Seismic events#Oil and gas industry#Custom support systems#Inspection readiness#Load-bearing capacities#Compliance standards#Piping systems#Power generation#Fluid dynamics#Petrochemical industry#Support design engineering#Troubleshooting#Temperature fluctuations

0 notes

Text

Revolutionizing Design and Analysis: Key Services for Modern Engineering

In the ever-changing fields of engineering and design, accuracy and efficiency are not only objectives; they are absolutely necessary.. Services like CFD Consulting Services and Cad Design Services are leading technological innovators and provide tools and expertise that propel industries toward more refined and sustainable solutions. This paper explores the transforming influence these services have on product development and system optimization, showcasing their critical role in advancing engineering disciplines.

The Power of CFD Consulting Services

CFD Consulting Services plays a crucial role in the engineering analysis realm, providing deep insights into fluid dynamics problems. These services utilize computational fluid dynamics (CFD) To replicate heat transfer, fluid transport, and related processes. within engineering designs. By applying CFD Consulting Services, companies can predict and enhance product performance, optimize processes, and innovate solutions that are both effective and environmentally sound. This predictive capability allows engineers to foresee complex fluid interactions and make informed decisions that refine product design and functionality.

Enhancing Engineering with Expertise

Expertise in fluid dynamics and thermal management directly supports more clever and environmentally friendly product innovations. . Consulting teams bring a wealth of knowledge, facilitating better design choices and offering solutions that balance performance with cost-effectiveness. This joint approach assures that projects are not only theoretically sound but also practically sensible.

Leveraging Technology for Better Outcomes

Technology plays a pivotal role in modern engineering, with advanced software and analytical tools shaping the future of design and manufacturing. These tools enable precise simulations and detailed analyses, speeding the development time and thereby lowering the demand for actual prototypes. This shift not only saves time and resources but also allows for greater experimentation and innovation within the design process.

Advantages of Cad Design Services

Cad Design Services are essential in transforming initial ideas into detailed plans and prototypes. These services facilitate the creation of precise 3D models that can be easily adjusted to test various design scenarios. By integrating Cad Design Services into the project workflow, engineers can achieve higher accuracy in their designs, ensuring that components fit perfectly and function as intended. The precision of CAD tools also enables the documentation of every detail, which is crucial for manufacturing and assembly processes.

Conclusion

To conclude, the integration of CFD Consulting Services and Cad Design Services marks a significant advancement in engineering and design practices. These services not only enhance the accuracy and efficiency of project outcomes but also empower industries to meet the challenges of modern engineering demands. For businesses looking to harness the full potential of these advanced services, the website FEAmax.com offers a gateway to expert advice and cutting-edge solutions. Embracing these innovative tools and services is essential for any company aiming to lead in the competitive landscape of engineering and manufacturing.

Blog Source Url:

https://feamax1.blogspot.com/2025/01/revolutionizing-design-and-analysis-key.html

0 notes

Text

Asus Service Center in Ranchi: Expert Laptop Repairs at Laptop Service Center Ranchi

Introduction

When it comes to laptops, Asus has built a strong reputation for innovation, quality, and performance. However, like any other electronic device, even the most reliable Asus laptops can encounter issues over time. If you're in Ranchi and facing problems with your Asus laptop, look no further than Laptop Service Center Ranchi. This blog delves into the comprehensive services offered by Laptop Service Center Ranchi and why it's the go-to destination for Asus laptop repairs.

Why Choose Laptop Service Center Ranchi?

Choosing a service center for your Asus laptop can be a daunting task. You need a trustworthy provider that offers professional expertise, genuine parts, and exceptional customer service. Here are some reasons why Laptop Service Center Ranchi stands out:

Certified Technicians: Our team comprises highly skilled and certified professionals who specialize in Asus laptops. From hardware repairs to software troubleshooting, they handle every issue with precision.

Genuine Parts: We use only authentic Asus components to ensure your laptop’s durability and performance are maintained.

Quick Turnaround Time: We value your time and strive to provide swift and effective repairs.

Affordable Pricing: Quality service doesn’t have to break the bank. We offer competitive pricing without compromising on quality.

Customer Support: Our friendly customer support team is always ready to assist you with any queries or concerns.

Common Asus Laptop Issues We Handle

At Laptop Service Center Ranchi, we cater to a wide range of Asus laptop issues. Here are some common problems we address:

Screen Damage: Cracked or malfunctioning screens are among the most frequent issues. We provide high-quality screen replacements for all Asus laptop models.

Battery Problems: Experiencing rapid battery drain or a laptop that won’t charge? We offer genuine battery replacements and power diagnostics.

Keyboard Malfunctions: Sticky keys, unresponsive buttons, or a non-functional keyboard? Our technicians can repair or replace the keyboard efficiently.

Overheating Issues: Overheating can lead to performance degradation. We clean internal components, replace thermal paste, and optimize cooling systems to resolve this issue.

Software Troubleshooting: Facing software crashes, virus infections, or OS issues? We provide software diagnostics, virus removal, and system optimization services.

Motherboard Repairs: Our experts handle complex motherboard repairs and replacements with utmost care.

Data Recovery: Lost important data? Our advanced data recovery services can retrieve your valuable files.

Services Offered

Laptop Service Center Ranchi offers a comprehensive range of services for Asus laptops:

Diagnostics and Consultation: We provide thorough diagnostics to identify the root cause of any issue. Our technicians explain the problem and suggest the best course of action.

Hardware Repairs and Replacements:

Screen and display repairs

Battery replacements

Keyboard repairs

Hard drive and SSD upgrades

Software Services:

OS installation and upgrades

Virus and malware removal

Performance optimization

Preventive Maintenance:

Cleaning and dust removal

Thermal paste replacement

Cooling system checks

Customization and Upgrades:

RAM upgrades

Storage enhancements

Graphics card installations (where applicable)

Emergency Services:

Same-day repairs for critical issues

Priority service for urgent requirements

The Repair Process at Laptop Service Center Ranchi

Our repair process is streamlined to ensure efficiency and transparency:

Problem Identification: Bring your Asus laptop to our center, and our technicians will conduct a detailed analysis.

Cost Estimation: Once the problem is identified, we provide a transparent estimate of the repair costs.

Repair or Replacement: After your approval, we proceed with the repair or replacement using genuine Asus parts.

Quality Check: Every repaired laptop undergoes rigorous testing to ensure optimal functionality.

Delivery: We hand over your laptop only after you’re fully satisfied with our service.

Customer Testimonials

Here’s what some of our satisfied customers have to say about Laptop Service Center Ranchi:

"I had a broken screen on my Asus laptop, and the team at Laptop Service Center Ranchi fixed it within a day. The quality of the replacement was excellent!"

– Rakesh Kumar

"The technicians are knowledgeable and friendly. They resolved my battery issue quickly and at a reasonable cost. Highly recommend!"

– Priya Sharma

"Great service and genuine parts. My laptop runs like new after the repair. Thank you, Laptop Service Center Ranchi!"

– Ankit Verma

Tips for Maintaining Your Asus Laptop

To ensure your Asus laptop remains in top condition, follow these maintenance tips:

Keep It Clean: Regularly clean your laptop to prevent dust buildup, especially around vents and the keyboard.

Avoid Overcharging: Overcharging can reduce battery lifespan. Disconnect the charger once the battery is full.

Use Antivirus Software: Protect your laptop from malware and viruses by installing reliable antivirus software.

Update Regularly: Keep your operating system and drivers up to date for optimal performance and security.

Handle with Care: Avoid rough handling to prevent physical damage to the screen, keyboard, and other components.

Contact Us

If you’re facing issues with your Asus laptop, don’t hesitate to reach out to us. Laptop Service Center Ranchi is committed to providing reliable, affordable, and high-quality services.

Contact Details:

Address: [Dangra Toli Chwok, 13A, Peace Rd, Lalpur, Ranchi, Jharkhand 834001]

Phone: [093349 87745]

Email: [[email protected]]

Working Hours: Monday to Saturday, 10:00 AM to 7:00 PM

Visit us today and experience exceptional laptop repair services tailored to your needs.

At Laptop Service Center Ranchi, your satisfaction is our priority. Whether it’s a minor repair or a major overhaul, we’re here to bring your Asus laptop back to life

#electronicsrepair#ranchi#laptoprepair#ranchitech#techsupport#laptopservice#ranchiservices#dellservicecenter#dellrepair#gadgetrepair

0 notes

Text

Comprehensive Guide to Choosing the Best Roofing Services

Your roof may not always show visible signs of damage, but there are subtle indicators that suggest it needs attention. Missing shingles, granules in the gutter, or water stains on ceilings are common red flags. A professional roofing contractor can assess these issues effectively and suggest timely repairs or replacements.

Searching for roofing company Miami ensures that you connect with experts who understand the unique weather challenges of the region, such as hurricanes and high humidity. Their local expertise is invaluable for providing tailored roofing solutions.

Benefits of Hiring a Professional Roofing Company

When it comes to roofing, DIY solutions can lead to more harm than good. Professional roofing companies possess the skills, tools, and experience necessary to handle a variety of roofing tasks. From basic maintenance to complete replacements, these experts ensure the job is done safely and efficiently.

A roofing company Miami can provide specialized services such as hurricane-proofing, energy-efficient roofing options, and advanced materials suited for tropical climates. They also offer warranties on their work, giving homeowners peace of mind.

How to Choose the Best Roofing Service

With so many options available, selecting the right roofing service can be daunting. Here are some factors to consider:

Experience and Expertise: Look for companies with years of experience and a strong track record. Customer reviews and testimonials can provide insights into their reliability and craftsmanship.

Licensing and Insurance: Verify that the company holds valid licenses and adequate insurance to protect both workers and homeowners.

Range of Services: Opt for a company that offers a comprehensive range of services, from roof inspection near me to emergency repairs and full installations.

Why Miami's Weather Demands Specialized Roofing Solutions

Miami’s tropical climate poses unique challenges for roofing systems. High humidity, intense UV rays, and frequent storms require durable materials and expert installation techniques. Local roofing companies are well-versed in these requirements, ensuring your roof remains resilient under extreme conditions.

Aroofing company Miami is also familiar with local building codes and regulations, ensuring that all work complies with legal standards. Their understanding of Miami’s climate helps in recommending the best materials, such as metal roofs or clay tiles, which are both durable and aesthetically pleasing.

Roof Maintenance Tips for Longevity

Regular maintenance can extend the life of your roof and save you money in the long run. Cleaning gutters, trimming overhanging branches, and inspecting for wear and tear are simple steps you can take. However, professional services remain indispensable for thorough assessments.

If you’re considering a roof inspection near me, choose a service provider that offers a detailed report on your roof’s condition. This report should include photographs, an analysis of problem areas, and recommendations for repairs or upgrades.

Common Roofing Materials and Their Benefits

Selecting the right material is crucial for durability and aesthetic appeal. Popular roofing materials include:

Asphalt Shingles: Affordable and versatile, suitable for most homes.

Metal Roofing: Long-lasting and resistant to extreme weather conditions.

Clay or Concrete Tiles: Ideal for Miami’s climate, offering excellent thermal performance.

Consulting aroofing company Miami ensures you choose the best material for your home, factoring in budget, design preferences, and environmental conditions.

The Cost of Neglecting Roof Repairs

Ignoring minor roofing issues can lead to significant problems, such as leaks, mold growth, and structural damage. These issues not only compromise the safety of your home but also reduce its market value. Regular inspections and timely repairs are a small investment compared to the potential cost of extensive damage.

For homeowners in Miami, searching forroof inspection near me ensures they find local experts who can address issues promptly. Don’t wait until water starts dripping from your ceiling; proactive care is key.

0 notes

Text

What to Do When SMART HDD Status Indicates Imminent Failure

Self-Monitoring, Analysis, and Reporting Technology (SMART) is an essential feature in modern hard disk drives (HDDs) and solid-state drives (SSDs). It monitors the health and performance of your storage device and provides early warnings of potential failures. When your system notifies you that the SMART status indicates "Imminent Failure," it’s a serious alert that requires immediate action to prevent data loss.

In this article, we’ll explore what SMART HDD failure warnings mean, the steps you should take when you encounter them, and how to safeguard your data effectively.

Understanding SMART HDD Warnings: Check Smart HDD

SMART technology monitors several parameters of your drive, including:

Reallocated Sectors: Tracks the number of bad sectors replaced with spare ones.

Read/Write Errors: Monitors issues with data transfer.

Temperature: Ensures the drive is operating within safe thermal limits.

Spin-Up Time: Tracks how quickly the drive reaches operational speed.

Power-On Hours: Logs the total time the drive has been in use.

A SMART failure warning means one or more of these parameters have exceeded the manufacturer’s defined thresholds, indicating the drive is likely to fail soon.

Steps to Take When You See a SMART Failure Warning

1. Do Not Ignore the Warning

SMART warnings are not false alarms. If you continue to use the drive without taking action, you risk catastrophic failure and permanent data loss.

2. Back Up Your Data Immediately

The first and most critical step is to back up all important files. Here’s how to do it:

Cloud Backup: Use cloud services like Google Drive, Dropbox, or OneDrive for urgent backups of essential files.

External Drives: Copy your data to an external HDD, SSD, or USB drive for safe storage.

Disk Imaging: Use software like Acronis True Image or Macrium Reflect to create a full image of your drive. This is especially useful for preserving the exact state of your system.

3. Verify the Warning

Sometimes, SMART warnings may be triggered by temporary issues or software errors. Use diagnostic tools to confirm the status:

Windows Users: Use built-in tools like CHKDSK or third-party software like CrystalDiskInfo or Hard Disk Sentinel.

Mac Users: Use Disk Utility to verify the drive’s health.

Linux Users: Run the smartctl command to check detailed SMART data.

4. Assess the Severity

Diagnostic tools will provide detailed SMART parameters. Pay attention to attributes like:

Reallocated Sector Count: High values indicate many bad sectors.

Pending Sector Count: Indicates sectors that are unstable and may fail.

Uncorrectable Errors: A high count suggests severe issues with data integrity.

If these parameters are critical, immediate replacement of the drive is necessary.

5. Avoid Heavy Usage

While the drive is failing, avoid intensive operations such as:

Installing or uninstalling software.

Running disk-intensive applications like video editing tools.

Performing defragmentation (especially for HDDs).

These activities can accelerate the failure process.

6. Replace the Drive

Once you’ve secured your data, the next step is to replace the failing drive. Options include:

Internal Drive Replacement: Purchase a new HDD or SSD that matches your system’s specifications.

Upgrade to SSD: If your failing drive is an HDD, consider upgrading to an SSD for faster performance and reliability.

Professional Help: If you’re not comfortable replacing the drive yourself, consult a technician.

7. Dispose of the Failing Drive Safely

After replacing the drive, securely erase all data on the failing disk to protect sensitive information. Use software like DBAN (Darik's Boot and Nuke) to perform a thorough wipe before recycling or disposing of the drive.

Preventive Measures to Avoid Future SMART Failures

Regular Backups: Implement a routine backup strategy. Automated backup tools like Acronis or Windows Backup can save you from data loss.

Monitor Disk Health: Use SMART monitoring tools regularly to check the drive’s status and address issues early.

Avoid Overheating: Ensure proper cooling for your system to prevent thermal damage.

Minimize Shocks: Handle external drives carefully to avoid physical damage, especially for HDDs.

Use Quality Power Supplies: Fluctuations in power can damage your drive. Use a reliable power supply or UPS.

When to Seek Professional Help

If the SMART warning persists after verifying the issue, or if you encounter problems like unreadable files or frequent crashes, professional data recovery services may be necessary. Companies like Seagate or Western Digital offer recovery solutions for failed drives, though costs can be high.

Conclusion

A SMART HDD status indicating imminent failure is a clear signal to act quickly. By backing up your data immediately, verifying the issue, and replacing the failing drive, you can minimize disruptions and avoid permanent data loss. Regular monitoring and preventive maintenance can help you stay ahead of potential failures and extend the lifespan of your storage devices. Remember, the best defense against data loss is a robust backup strategy—don’t wait for a warning to start protecting your data.

0 notes

Text

Understanding CFD in Heat Exchanger Design: A Case Study

In modern engineering, Computational Fluid Dynamics (CFD) is vital for optimizing thermal systems. This blog explores a recent CFD thermal analysis performed by Graphler Technology Solutions to evaluate a heat exchanger’s efficiency in transferring heat from a hot fluid (MSW slurry) to a cold fluid (DM water). Here’s what the study uncovered:

The Study Setup

The analysis simulated the heat transfer dynamics between two fluids using steady-state Conjugate Heat Transfer (CHT) analysis. Key parameters included:

Hot fluid (MSW Slurry): Initial temperature of 400°C, flow rate of 0.5 LPM, and inlet pressure of 300 Bar.

Cold fluid (DM Water): Initial temperature of 10°C, flow rate of 38.61 LPM, and inlet pressure of 2 Bar.

The system comprised four heat exchange passes, designed to ensure progressive heat transfer and achieve target temperature levels.

Key Findings

Temperature Distribution

In Pass 1, the hot fluid’s temperature dropped significantly from 400°C to 29.86°C.

Subsequent passes refined the output temperature, with Pass 4 reaching equilibrium at ~10°C.

Heat Transfer Efficiency

The cold fluid flow rate was 77 times higher than the hot fluid’s, driving an aggressive temperature drop.

The heat exchanger required approximately 9–10 meters to align the hot fluid’s temperature with that of the cold fluid.

Material Effectiveness

Stainless steel (Grade 304) and rockwool insulation ensured thermal integrity, with average heat transfer coefficients of:

Cold fluid side: 1027 W/m²-K

Outer insulation: 454 W/m²-K

Energy Implications

The design successfully minimized thermal losses while maintaining the structural and thermal stability of the exchanger.

Material Selection: The use of rockwool insulation and stainless steel proved effective. For future designs, these materials should remain standard, especially for similar operational conditions.

Flow Rate Optimization: High cold fluid flow rates were critical to achieving rapid heat exchange. Depending on energy costs, optimization between flow rates and exchanger length can be explored.

Length Considerations: A total pipe length of 18 meters, with four sequential passes, was adequate for the temperature targets. This insight aids in reducing unnecessary material and space usage in similar designs.

Reach out Graphler technology for a CFD Consulting Services .We are also specialized in Stress Analysis Services , Structural Design Services and more.

0 notes

Text

Design & Engineering: Shaping the Future of Innovation

The construction and infrastructure development industry is built on several specialized services that ensure projects are innovative, functional, and sustainable. Below, we explore key domains such as best Architecture in ghaziabad, Design, Mechanical, Electrical, and Plumbing (MEP) Design, Project Management Consultancy (PMC), and Building Information Modelling (BIM), which are essential for successful project execution.

1-Architecture

Architecture is the art and science of designing buildings and spaces. It involves creating functional, aesthetic, and sustainable designs that align with the client’s vision and the surrounding environment.Key Aspects of Architecture:Conceptual Design: Translating client ideas into preliminary layouts and designs.Space Planning: Efficiently utilizing available land and resources to create functional spaces.Sustainability: Incorporating eco-friendly materials, energy-efficient systems, and designs that harmonize with nature.Aesthetic Appeal: Balancing functionality with visually striking designs that enhance user experience.Architects play a crucial role in ensuring that designs comply with local regulations and meet safety standards, all while delivering innovative and iconic structures.

2. Structural Design

Structural design ensures that buildings, bridges, and other structures are safe, durable, and capable of withstanding environmental forces. It involves analyzing and designing the framework of a structure to support its intended load without failure.Key Components of Structural Design:Load Analysis: Calculating forces like gravity, wind, and seismic activity to ensure stability.Material Selection: Choosing materials such as steel, concrete, or timber based on the project's requirements.Structural Integrity: Designing frameworks that maintain strength and durability over time.Structural engineers work closely with architects to bring designs to life, ensuring that creative visions are supported by a solid and reliable foundation.

3. Mechanical, Electrical, and Plumbing (MEP) Design

MEP design focuses on the internal systems of a building, ensuring that it operates efficiently and meets the needs of its occupants.Mechanical Systems:HVAC (Heating, Ventilation, and Air Conditioning) systems for thermal comfort and air quality.Energy-efficient solutions to reduce operational costs.Electrical Systems:Designing power distribution networks, lighting systems, and backup power solutions.Incorporating smart technologies for automation and energy conservation.Plumbing Systems:Designing water supply, drainage, and sewage systems for efficiency and sustainability.Implementing rainwater harvesting and greywater recycling for green building certifications.MEP design is integral to creating functional and sustainable buildings, as it ensures optimal performance and comfort for occupants.

4. Project Management Consultancy (PMC)

PMC services ensure that construction projects are delivered on time, within budget, and to the highest quality standards.Responsibilities of PMC:Planning: Developing detailed project timelines and resource allocation strategies.Coordination: Facilitating communication between stakeholders, including architects, engineers, and contractors.Risk Management: Identifying potential risks and implementing strategies to mitigate them.Quality Control: Monitoring construction processes to ensure compliance with design specifications and industry standards.PMC professionals act as the backbone of a project, ensuring seamless execution and client satisfaction.

Architecture in ghaziabad

structural Design in delhi

Mechanical, Electrical, and Plumbing (MEP) in ghaziabad

Project Management Consultancy in ghaziabad

Building Information Modelling in ghaziabad

0 notes

Text

Thermal Design Solutions: Your One-Stop Shop For Thermal Management!

Are you looking for a thermal design consultant? Look no further than Thermal Design Solutions! They are a thermal management consulting firm offering services to clients related to the thermal design of electronics. With decades of experience in the field, they offer expertise in electronic cooling solutions, thermal interface solutions, and more.

The founders of Thermal Design Solutions are the two leading specialists in the thermal management of electronics. With fifty years of expertise in all areas of thermal design and engineering, they are well-equipped to provide their clients with the best services available.

Once the electronic design is complete, thermal analysis/thermal modeling should be taken into consideration. Thermal Design Solutions can help you as a thermal analysis consultant by offering a number of benefits:

Comprehensive Analysis

Thermal Design Solutions can provide a comprehensive analysis of the design by utilizing powerful software tools. This analysis helps ensure all engineering and manufacturing goals are met while staying within budget.

Expert Advice

With decades of experience in the field, Thermal Design Solutions can provide valuable advice on the best possible solutions for your specific project. Their expertise can save time and money by providing insight into potential areas of improvement before costly mistakes are made.

Cost Savings

Thermal Design Solutions can help you save money by providing cost-effective solutions tailored to your specific needs. They have access to the best suppliers and components, providing you with the most economical options when selecting components for your project.

Quality Control

By utilizing their expertise in thermal engineering, Thermal Design Solutions can provide quality control throughout the entire process. This helps to ensure that all aspects of your project meet industry standards and will operate as expected when completed.

Comprehensive Services

The range of services provided by Thermal Design Solutions includes finite element analysis, thermal interface materials selection, thermal system analysis, component specification and selection, and much more. Their comprehensive services ensure that all aspects of your project are covered, from initial conception to final product completion.

Conclusion

When looking for a thermal consultant, look no further than Thermal Design Solutions! With decades of experience in the field, they offer expertise in all areas of thermal engineering and design that is second to none. From comprehensive analysis to quality control, their services will ensure your project meets industry standards while staying within budget.

For more details, visit https://www.thermalds.com/

Original source: https://bit.ly/3MNfGVy

0 notes

Text

Premier Mold Inspection in Du

Expert Mold Inspection Services in Durham, NC

Welcome to SafeAir Mold Testing, the leading expert in mold inspection Durham, NC. Boasting decades of experience in the mold remediation industry, we are committed to providing detailed and precise assessments to ensure a healthy and safe environment for you and your family.

Why You Should Choose SafeAir Mold Testing for Your Mold Inspection Needs in Durham, NC

At SafeAir Mold Testing, we know how mold problems can be challenging and distressing. Our certified team of experts specializes in mold inspections in Durham, NC, offering a thorough approach to identify, assess, and address mold problems. Mold growth can pose significant health risks and structural damage if not managed properly. Hence, our goal is to provide you with detailed insights and effective solutions.

Comprehensive Mold Inspection Offerings

Our process for mold inspection in Durham, NC includes several critical steps designed to ensure an accurate diagnosis. Here?s what you can expect from our services:

Initial Consultation and Assessment: Starting with a detailed consultation to understand your concerns and any visible signs of mold. Our experts utilize cutting-edge tools and methods to evaluate the severity of the issue.

In-Depth Inspection: Our team conducts a thorough inspection of your property, including areas prone to moisture and mold growth. We use advanced equipment like moisture meters and thermal imaging cameras to identify concealed mold.

Testing Air Quality: Airborne mold spores and cause respiratory issues. We conduct air quality assessments to measure the mold spore levels in your indoor environment. This helps us gauge the level of contamination and recommend appropriate actions.

Surface Sampling: To determine the mold species, we gather samples from mold-affected areas. These samples are analyzed in a certified laboratory to guide our remediation strategy.

Comprehensive Reporting: After completing the inspection, we deliver a detailed report outlining our results. This report includes mold type assessment, contamination levels, and a remediation action plan.

The Importance of Mold Inspection in Durham, NC is Crucial

Opting for a professional mold inspection in Durham, NC is crucial for several reasons:

Precision: Professional mold inspectors use advanced technology and techniques to detect mold that might not be visible to the naked eye. This provides a comprehensive and accurate evaluation.

Protecting Your Health: Mold can lead to serious health issues, including respiratory issues, allergies, and compromised immune systems. Our expert mold inspection helps detect mold sources and offers health-protective recommendations.

Early Detection and Prevention: Early detection through mold inspection in Durham, NC helps avoid major property damage. Prompt action can prevent expensive repairs and protect your property.

Insurance and Compliance: A professional mold inspection provides documented evidence that can be crucial for insurance claims and compliance with local health and safety regulations.

Advanced Mold Detection Techniques

Our mold inspection services in Durham, NC employ cutting-edge detection methods to ensure no mold is left undetected. We use:

Thermal Imaging: This technology allows us to identify temperature variations in walls, ceilings, and floors, indicating potential mold growth behind surfaces.

Moisture Meters: Moisture meters are used to measure moisture levels in materials, which is essential for identifying mold-prone areas.

Airborne Mold Spore Analysis: By analyzing air samples, we determine the concentration of mold spores and assess the need for remediation.

Tailored Recommendations and Mold Removal

Once our mold inspection in Durham, NC is complete, we provide expert recommendations tailored to your specific situation. Our team will guide you through the remediation process, ensuring that all mold is effectively removed and that your property is restored to a safe and healthy condition. We also offer post-remediation verification to ensure that mold issues have been addressed and your property meets safety standards.

What Sets SafeAir Mold Testing Apart

SafeAir Mold Testing delivers exceptional mold inspection services in Durham, NC. Our experience, cutting-edge technology, and commitment to customer care distinguish us from other service providers. We focus on providing precise, reliable inspections to ensure your home remains safe and mold-free. We pride ourselves on our professionalism and attention to detail ensures that you get the highest quality service. Choosing SafeAir Mold Testing means choosing reassurance.

Get in Touch Today

To schedule your mold inspection in Durham, NC, contact SafeAir Mold Testing today. We are prepared to offer the professional assistance you require to ensure a safe and healthy living environment. Reach out to us at (404) 695-0673 or fill out our online contact form to schedule your mold inspection. Choose SafeAir Mold Testing as your trusted partner in ensuring a safe, mold-free environment.

https://premiermoldinspectio910.blogspot.com/2024/12/premier-mold-inspection-in-durham-nc.html https://topmoldinspectionser896.blogspot.com/2024/12/top-mold-inspection-services-in-durham.html https://businessreviews101.tumblr.com https://businessreviews101.tumblr.com/rss/ https://www.tumblr.com/businessreviews101/769874281519857664/ https://premiermoldinspectionindurhamnc.blogspot.com https://premiermoldinspectionindurhamnc.blogspot.com/2024/12/premier-mold-inspection-in-durham-nc.html https://meandmine2025.tumblr.com https://meandmine2025.tumblr.com/rss/ https://www.tumblr.com/meandmine2025/769874975945539584/

0 notes

Text

Top Mold Inspection Services

Premier Mold Inspection in Durham, NC

Welcome to the premier SafeAir Mold Testing, the leading provider in mold inspection Durham, NC. With extensive experience in the mold remediation industry, we focus on providing thorough and precise assessments to ensure a healthy and safe environment for your home and family.

Reasons to Choose SafeAir Mold Testing for All Your Mold Inspection in Durham, NC

Here at SafeAir Mold Testing, we know how mold issues can be challenging and distressing. Our certified team of experts specializes in mold inspections in Durham, NC, offering a thorough approach to detect, evaluate, and resolve mold problems. Mold growth presents significant health hazards and structural damage if not managed properly. Hence, our goal is to offer detailed insights and effective solutions.

Comprehensive Mold Inspection Offerings

Our process for mold inspection in Durham, NC includes several critical steps designed to ensure an accurate diagnosis. Here?s what you can expect from our services:

Initial Consultation and Assessment: We begin with a thorough consultation to discuss your concerns and identify visible mold signs. Our experts use advanced tools and techniques to assess the extent of the problem.

Detailed Inspection: Our team conducts a comprehensive inspection of your home, including high-risk areas such as basements, attics, and crawl spaces. We use advanced equipment like moisture meters and thermal imaging cameras to identify concealed mold.

Air Quality Testing: Mold spores can be airborne and can lead to respiratory problems. We conduct air quality assessments to measure the mold spore levels in your indoor environment. This helps us gauge the level of contamination and recommend appropriate actions.

Surface Sampling: To identify the type of mold present, we collect samples from affected surfaces. These samples are sent to a certified lab for analysis to guide our remediation strategy.

Comprehensive Reporting: After completing the inspection, we provide a comprehensive report outlining our findings. This includes an assessment of mold types, contamination levels, and a detailed action plan for remediation.

Why Professional Professional Mold Inspection in Durham, NC

Choosing a certified mold inspection in Durham, NC is crucial for several reasons:

Accuracy: Professional mold inspectors employ state-of-the-art technology to identify mold that?s not easily visible. This ensures a thorough and accurate assessment.

Health and Safety: Mold exposure can cause significant health problems, including respiratory problems, allergies, and weakened immune systems. Our expert mold inspection helps detect mold sources and offers health-protective recommendations.

Preventive Measures: Identifying mold early through our Durham inspection helps avoid major property damage. Prompt action can prevent expensive repairs and protect your property.

Insurance and Compliance: A professional mold inspection provides documented evidence that is essential for insurance claims and adherence to local regulations.

State-of-the-Art Detection Methods

Our mold inspection services in Durham, NC utilize advanced detection techniques to ensure no mold is left undetected. We use:

Infrared Technology: Thermal imaging helps us detect temperature changes in building materials, revealing possible hidden mold.

Moisture Detection Tools: Moisture meters are used to measure moisture levels in materials, which is critical for pinpointing areas at risk of mold.

Air Sampling: By analyzing air samples, we assess mold spore levels and evaluate remediation needs.

Tailored Recommendations and Mold Removal

Once our mold inspection in Durham, NC is complete, we offer customized recommendations based on our findings. Our team will guide you through the remediation process, ensuring that all mold is effectively removed and that your property is restored to a safe and healthy condition. We also offer post-remediation verification to confirm that the mold problem has been resolved and that your environment meets safety standards.

Why SafeAir Mold Testing Stands Out

SafeAir Mold Testing delivers exceptional mold inspection services in Durham, NC. Our expertise, advanced technology, and dedication to customer satisfaction set us apart from the competition. We prioritize providing precise, reliable inspections to ensure your home remains safe and mold-free. Our dedication to professionalism and attention to detail ensures that you receive the best possible service. When you choose SafeAir Mold Testing, you are choosing peace of mind.

Get in Touch Today

To schedule your mold inspection in Durham, NC, reach out to SafeAir Mold Testing. We are prepared to offer the professional assistance you require to maintain a healthy, mold-free environment. Reach out to us at (404) 695-0673 or complete our online form to schedule an inspection. Choose SafeAir Mold Testing as your trusted partner in ensuring a safe, mold-free environment.

https://topmoldinspectionser22.blogspot.com/2024/12/top-mold-inspection-services-in-durham.html https://expertmoldinspection759.blogspot.com/2024/12/expert-mold-inspection-services-in.html

0 notes

Text

Little P.Eng. Engineering for Nuclear Facilities Design Services

Little P.Eng. Engineering, a pioneer in the engineering consultancy domain, specializes in the design and analysis of nuclear facilities. Their expertise encompasses a broad spectrum of engineering services tailored to meet the stringent requirements of ASME Section III, Division 1, focusing particularly on Subsection ND (Class 3 Components) and Subsection NF (Supports). This specialization ensures that all designed components and supports within nuclear facilities not only comply with the highest safety standards but also embody efficiency and reliability.

Expertise in ASME Section III Compliance At the core of Little P.Eng. Engineering's services is a deep-rooted expertise in navigating the complexities of ASME Section III, Division 1 standards. These standards, essential for the nuclear power sector, dictate the design, fabrication, testing, and inspection criteria for nuclear facility components, ensuring they are capable of withstanding operational stresses without compromising safety.

Subsection ND: Class 3 Components

Subsection ND outlines the requirements for Class 3 components, which, although not directly involved in the reactor's primary cooling system, are crucial for the safe operation and shutdown of the reactor. Little P.Eng. Engineering's approach involves meticulous design and analysis to ensure these components can endure the operational environment, including handling stress, temperature variations, and potential seismic events.

Subsection NF: Supports

Subsection NF focuses on the design and integrity of supports for all classes of components within nuclear facilities. Little P.Eng. Engineering leverages advanced analytical methods to design supports that ensure structural stability under a variety of load conditions, including dead weight, live loads, thermal expansion, and earthquake forces.

Importance of ASME Section III, Division 1 Subsection ND and Subsection NF

Adherence to Safety and Quality Standards The use of ASME Section III, Division 1 standards in nuclear facility design is not merely a regulatory requirement but a cornerstone of safety and quality assurance. Subsections ND and NF are particularly significant for ensuring that all components and their supports are designed with an uncompromising focus on safety, taking into account normal operating conditions as well as potential emergency scenarios.

Engineering Excellence The application of Subsection ND and NF standards demands a high level of engineering expertise and precision. Little P.Eng. Engineering exemplifies this excellence, employing seasoned professionals and state-of-the-art tools to design, analyze, and validate the integrity of nuclear facility components and supports. Their work ensures that facilities are not only compliant with current standards but are also adaptable to future technological advancements and regulatory changes.

Piping Stress Analysis and Structural Design in Nuclear Facilities

Piping Stress Analysis: Ensuring System Integrity Piping systems in nuclear facilities are critical for the transport of coolant and other fluids essential to the reactor's operation. Piping stress analysis is a vital engineering task that assesses these systems' ability to withstand various stresses, including thermal expansion, pressure loads, and seismic events. Little P.Eng. Engineering employs sophisticated modeling and simulation tools to predict stress points and deformation, ensuring designs that maintain integrity under all operational conditions.

Structural Design: Foundation of Facility Safety The structural design of nuclear facilities encompasses the creation of buildings, supports, and containment structures capable of withstanding extreme conditions. This includes consideration for load-bearing capacities, resistance to seismic shifts, and the ability to endure environmental stressors. Little P.Eng. Engineering's structural design services ensure that every aspect of a nuclear facility's infrastructure is robust, resilient, and compliant with ASME and international safety standards.

Conclusion Little P.Eng. Engineering's dedication to excellence in nuclear facilities design, guided by ASME Section III, Division 1 standards, highlights their role in advancing nuclear safety and efficiency. Through meticulous attention to piping stress analysis and structural design, they ensure that nuclear facilities are not only safe and reliable but also prepared to meet the challenges of tomorrow's energy landscape. Their work underscores the critical importance of specialized engineering expertise in maintaining the high safety standards required in the nuclear power industry.

Tags:

Little P.Eng. Engineering

Structural design

Piping stress analysis

Thermal expansion

Engineering consultancy

Safety standards

Regulatory compliance

Project management

Nuclear facilities design

ASME Section III

Subsection ND

Subsection NF

Nuclear power sector

Class 3 components

Design criteria

Fabrication processes

Quality assurance

Advanced simulation tools

Seismic event resilience

Load-bearing capacity

Infrastructure robustness

Material selection

Innovative engineering solutions

Professional expertise

System integrity

Environmental stressors

Operational efficiency

Technological advancements

Energy landscape

Safety and reliability

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Piping stress analysis#Thermal expansion#Engineering consultancy#Safety standards#Regulatory compliance#Project management#Nuclear facilities design#ASME Section III#Subsection ND#Subsection NF#Nuclear power sector#Class 3 components#Design criteria#Fabrication processes#Quality assurance#Advanced simulation tools#Seismic event resilience#Load-bearing capacity#Infrastructure robustness#Material selection#Innovative engineering solutions#Professional expertise#System integrity#Environmental stressors#Operational efficiency#Technological advancements#Energy landscape

0 notes

Text

Engineering Precision: The Vital Role of FEA in Modern Design

In the intricate world of engineering, precision is not merely a goal—it is a necessity. Finite Element Analysis (FEA) has revolutionized how engineers approach complex problems, providing detailed insights that ensure safety, reliability, and efficiency. The innovative FEA Consulting Services and FEA Simulation Services play a pivotal role in transforming theoretical concepts into real-world applications across a myriad of industries.

Unlocking Capabilities with FEA Consulting Services

FEA Consulting Services is a cornerstone in the field of engineering, offering specialized expertise that aids firms in navigating the complexities of product and process design. These services provide access to experienced consultants who leverage FEA methodologies to analyze component behaviors under various conditions, such as mechanical stress, heat transfer, and fluid dynamics. Through this detailed analysis, companies can predict potential failures and optimize designs before any physical model is built, saving both time and resources.

Advancing Design and Innovation

FEA techniques enable engineers to enhance the design and innovation process significantly. By utilizing advanced modeling tools, engineers can create more accurate representations of products under real-world conditions. This ability to simulate and tweak designs iteratively leads to higher product quality and a greater understanding of potential design limitations and capabilities.

Streamlining Development and Testing

The integration of FEA also streamlines the product development process by reducing the reliance on physical prototypes. Simulation allows for extensive testing and modification without the costs associated with traditional prototyping methods. This not only speeds up the development cycle but also enables a more creative approach to problem-solving and design.

Refining Products with FEA Simulation Services

FEA Simulation Services extends its capabilities by offering more refined and specialized simulations. These services utilize state-of-the-art software tools to conduct stress analysis, dynamic analysis, and thermal simulations. By understanding how products will perform under different stresses and environments, engineers can make informed decisions to enhance durability, performance, and safety.

Conclusion

In conclusion, the integration of FEA Consulting Services and FEA Simulation Services represents a significant leap forward in engineering and design practices. These services empower companies to predict and solve complex design challenges with a level of precision previously unattainable. For businesses looking to leverage advanced FEA capabilities, visiting FEAmax.com provides invaluable resources and expert guidance. By embracing these sophisticated engineering tools, companies may make sure their creations are not simply novel. May make sure their creations are not simply original and reliable.

Blog Source Url:

https://feamax1.blogspot.com/2024/12/engineering-precision-vital-role-of-fea.html

0 notes

Text

Global Thermal Camera Market Overview 2025 and Forecast till 2037

Research Nester assesses the growth and market size of the global thermal camera market, driven by rising demand across security, surveillance, and industrial segments.

Research Nester’s recent market research analysis on "Global Thermal Camera Market: Supply & Demand Analysis, Growth Forecasts, Statistics Report 2025-2037" provides an in-depth competitor analysis and an extensive overview of the global thermal camera market, segmented by product type, technology, wavelength, application, end user, and region.

Increasing Adoption of Thermal Cameras in Security and Surveillance to Boost Global Market Growth

The global thermal camera market is expected to maintain its growth steadily during the forecast period. Thermal cameras have critical roles pertaining to predictive maintenance, fire detection, and environmental monitoring; therefore, demand from various industries continues to increase. Besides, with a greater focus on safety and automation, the cameras are in prime positions for smart city infrastructure and autonomous systems development. The ability of cameras to detect heat beyond visible light makes them invaluable in mission-critical environments, further propelling demand through 2037.

Request Free Sample Copy of this Report @ https://www.researchnester.com/sample-request-6418

Key Drivers and Challenges Influencing the Thermal Camera Market

Here are some of the drivers and challenges influencing thermal camera demand through 2037:

Growth Drivers:

Increasing demand for security and surveillance

Expanding adoption in the automotive sector

Challenges:

Technology limitations in thermal camera manufacture

Cost pressures and competition

By technology, the uncooled thermal camera segment is estimated to hold a significant share of 71.9% during the forecast period, driven by cost-effectiveness and low maintenance. Unlike cooled thermal cameras, uncooled variants do not require cryogenic cooling, making them more affordable and versatile for a variety of applications in security, surveillance, and industrial monitoring. Their suitability for wide deployment in multiple sectors further boosts their market dominance.

Request for customization @ https://www.researchnester.com/customized-reports-6418

By region, the thermal camera industry is seen as showing a sharp rise in APEJ due to rapid urbanization and industrial development, especially in India and China. The countries mentioned are investing heavily in smart city projects and industrial safety, which is boosting demand for thermal imaging solutions. India has deployed thermal cameras for urban surveillance in smart city initiatives, while China continues to expand into the nation's surveillance market with AI-powered thermal cameras.

The company profiles of major market players in the global thermal camera market that have been included in the report are Teledyne FLIR LLC, Hanwha Vision, Axis Communications AB, InfraTec GmbH, Leonardo DRS, Princeton Infrared Technologies, Inc., SATIR, Konica Minolta, Inc., Seek Thermal Inc., Sierra-Olympia Tech., Synectics plc, and InfiRay, among others. These companies are involved in research and development, strategic partnerships, and thermal imaging technology to leverage recent market dynamics.

Access our detailed report @ https://www.researchnester.com/reports/thermal-camera-market/6418

About Research Nester-

Research Nester Analytics is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates, and executives make wise decisions for their future marketing strategy, expansion, and investments. We believe every business can expand to its new horizon, provided the right guidance at the right time is available through strategic minds. Our out-of-the-box thinking helps our clients to make wise decisions to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes