#the torque output will increase; if the drive increases speed

Explore tagged Tumblr posts

Text

#indiasbestgearboxdealers#bestoffersindia#Qualitygearbox#trustedsellerGearbox#Gearboxbestoffersindia#Gearboxontimeservice#RoadSafetyFirst

#gearboxspecialoffers#savewater#planttreessavelife#DrugfreeNation#SaveEnergy#Gearboxdealers#Gearboxmanufacturer#IndustrialGearboxdealers

#Industrialgearboxmanufacturer#Industrialgearboxdistributer

The purpose of a gearbox is to increase or reduce speed. As a result, torque output will be the inverse of the speed function. If the enclosed drive is a speed reducer (speed output is less than speed input), the torque output will increase; if the drive increases speed, the torque output will decrease.

It allows the driver to manually change the gear ratio as per the speed and road conditions. Transfer power to the wheels: The gearbox transfers the required amount of power from the engine to the wheels at different speeds. This allows for optimising fuel efficiency and performance.

there are three different types of gearboxes: concentric, parallel, and right angle

Speed. Different sized gears can be used to efficiently change the speed of a system. ...

Force. In a similar setup, you can use gears to increase the force of a system; that extra speed doesn't appear out of nowhere. ...

Rotation direction. ...

Movement.

A gearbox is a mechanical method of transferring energy from one device to another and is used to increase torque while reducing speed. Torque is the power generated through the bending or twisting of a solid material. This term is often used interchangeably with transmission

Set the Playback Speed. The main function of the gear is to regulate the rotational speed of a power. ...

Transmitting Power. Another function of the gears can be used to transmit power with the gears that are interconnected without causing slippage. ...

Changing Torque. ...

Changing Power Direction.

#indiasbestgearboxdealers#bestoffersindia#Qualitygearbox#trustedsellerGearbox#Gearboxbestoffersindia#Gearboxontimeservice#RoadSafetyFirst#gearboxspecialoffers#savewater#planttreessavelife#DrugfreeNation#SaveEnergy#Gearboxdealers#Gearboxmanufacturer#IndustrialGearboxdealers#Industrialgearboxmanufacturer#Industrialgearboxdistributer#The purpose of a gearbox is to increase or reduce speed. As a result#torque output will be the inverse of the speed function. If the enclosed drive is a speed reducer (speed output is less than speed input)#the torque output will increase; if the drive increases speed#the torque output will decrease.#It allows the driver to manually change the gear ratio as per the speed and road conditions. Transfer power to the wheels: The gearbox tran#there are three different types of gearboxes: concentric#parallel#and right angle#Speed. Different sized gears can be used to efficiently change the speed of a system. ...#Force. In a similar setup#you can use gears to increase the force of a system; that extra speed doesn't appear out of nowhere. ...#Rotation direction. ...#Movement.

0 notes

Text

AMG G63 4x4² „Nuthin but a G thang“.

The AMG G63 4x4² brings driving performance to the segment of unadulterated off-road vehicles in unexpected form.

The AMG 4.0-litre V8 biturbo engine generates 430KW (585HP) in this model, and delivers a maximum torque of 850Nm. This is available across a wide rev range between 2.500 and 3.500 rpm, and provides a sense of effortless superiority. It absolves a sprint from zero to 100 km/h in 5 seconds.

The two turbochargers are not positioned on the outside of the cylinder banks, but inside the cylinder „V“. Advantages: a compact engine design, spontaneous response of the turbochargers and low exhaust emissions thanks to optimal airflow to the near-engine catalysts. The eight-cylinder delivers its power with muscular torque in all engine speed ranges, combined with maximum efficiency for low fuel consumption and emission figures.

Two twin scroll turbochargers are used for optimal response.

The housing is divided into two parallel flow channels. Combined with two separate exhaust ducts in the exhaust manifold, this makes it possible to control the exhaust gases on the turbine wheel separately. The exhaust gas from the first and fourth cylinders of the cylinder bank is fed into one duct, that from the second and third cylinders to the other duct.

The aim is to prevent the individual cylinders from having mutually adverse effects on the gas cycle. This reduces the exhaust gas back pressure and improves gas exchange. The results are increased output, more torque at low revs and very fast response times.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

#amg#gclass#gwagon#g634x4amg#g634x4#g63amg#g63#mercedesamg#mercedes#mercedesbenz#mercedesgclass#affalterbach#onemanoneengine#pagani

13 notes

·

View notes

Text

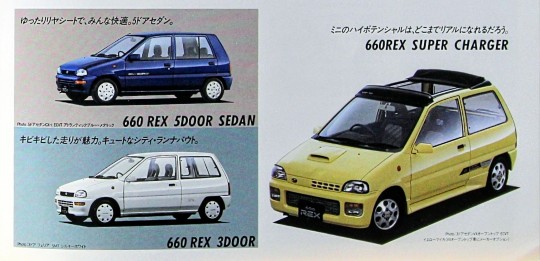

Subaru REX

Let's go to Rex.

REX 660

In 1990, the engine grew to 660cc, ushering in a new era for minicars. The Rex decided to use this new spaciousness as "high-quality spaciousness" that would energize all its occupants and make daily life more comfortable. It is fun, gentle, and makes you want to drive it every day. It is a car that is more appropriately described as "good performance" than high performance. Although it is small, the "660 Rex, a sedan-made car" offers the comfort of a full-fledged passenger car. This is the kind of shape that the future Mini should have.

660 REX 3DOOR SEDAN

Photo: 3-door sedan Feria!! ECVT Noble Cute Metallic

We love people. That's why the 660 Rex is designed to be "perfect for everyday life."

660 REX

Amazingly smooth. 3 valve 4-cylinder "CLOVER4".

660cc CLOVER4

A representative example of the Clover 4. It has the quietness and smoothness that only a 4-cylinder can offer. The smoothness at high revolutions is something that can only be achieved with a 4-cylinder. The ease of use in the practical range has also been further improved with the 660cc engine.

Maximum output (net): 42ps/7000rpm

Max torque 5.3kg-m/4500rpm

660cc EMPI CLOVER4

EMPi (Electronic Multi-Point Fuel Injection) is used. It realizes more powerful driving that allows you to ride comfortably even on fast-moving highways. Another point not to be overlooked is its good fuel economy.

Maximum output (5MT vehicle, net): 48ps/7200rpm

ECVT vehicle: 46ps/6400rpm

Maximum torque (5MT) 5.4 kg-m/5600 rpm

ECVT vehicle 5.5kg-m/4000rpm

660cc EMPI SUPER CHARGER CLOVER4

Equipped with a supercharger that provides excellent response and mid-range torque. With EMPI and an intercooler, the power is an undeniable 64ps. It has a sports heart that allows you to enjoy driving to the fullest.

Maximum output (net): 64ps/6400rpm

Max torque 8.6kg-m/4400rpm

Subaru is the only light car with a 4-cylinder engine. The Clover 4 is a 4-cylinder engine that is even more attractive now that it is 660cc. The increase in displacement is not a simple bore increase, but an increase in stroke with an emphasis on ease of handling in the mid-range. Experience the greatness of the 4-cylinder 660cc when starting off in the city or driving at high speeds on the highway.

*660cc class as of January 1990

The smooth and powerful four-cylinder engine is best paired with the smooth and easy-to-use super automatic ECVT.

ECVT is a mechanism that automatically changes gears infinitely using a pair of variable diameter pulleys and a special steel belt. There is absolutely no unpleasant gear change shock. With the same easy operation as a normal automatic transmission, you can enjoy an incomparably comfortable ride.

There is no creep phenomenon, where the car starts moving on its own even when the driver is not in the car. Low fuel consumption. The fuel consumption is so good that you would never think it was an automatic. Excellent reliability and durability. The steel belt is guaranteed for 5 years or 100,000 km.

For more reliable operation of ECVT vehicles, the following features are provided: ●Key interlock ●Shift lock ●Reverse alarm ●ECVT select indicator.

●Smooth ride. There are absolutely no unpleasant gear shift shocks, so it's smooth from starting to top speed.

● Sharp start. Powerful driving with direct acceleration. Selecting the Ds range makes it even sportier. ● Safety is also a big plus. When waiting at a traffic light, etc.,

ECVT Electro-Continuously Variable Transmission

Electronically controlled electromagnetic clutch type automatic variable speed transmission

A high-grade mechanism that greatly increases your sense of security.

●In accordance with the new standard of an overall length of 100 mm more, not only the bumper but also the bonnet has been enlarged. The strength of the side doors has also been increased. A highly rigid body that gives a sense of trust in the way it drives. ●High-quality ride comfort, four-wheel independent suspension. ●All vehicles have front disc brakes and radial tires.

Two 4WD options that greatly increase your sense of security.

All Easy Drive ECVT vehicles are equipped with Subaru's original Twin Visco full-time 4WD system, which provides a stable driving experience. Selective 4WD is also available, allowing you to easily switch between 2WD and 4WD with the push of a button.

Subaru REX

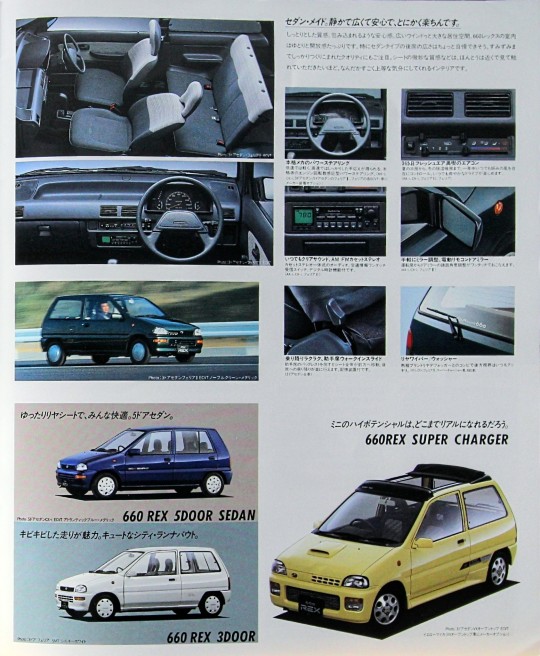

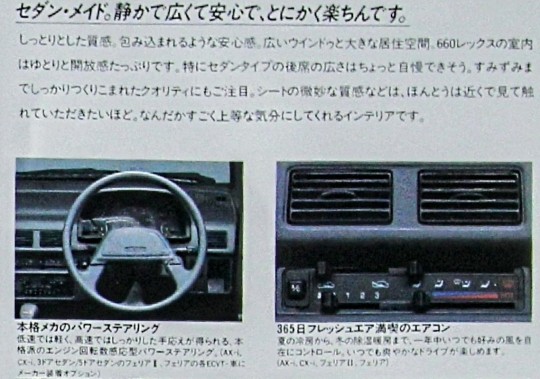

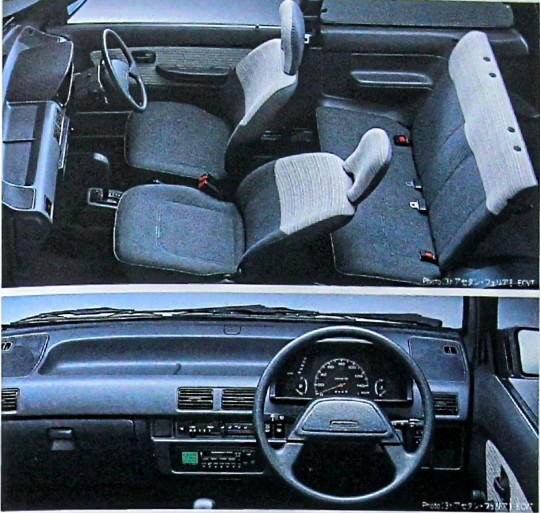

Sedan - Made. It's quiet, spacious, safe, and just so comfortable.

A soft texture. A sense of security that wraps you up. Wide windows and a large living space. The interior of the 660 Rex is spacious and open. The spaciousness of the rear seats in the sedan in particular is something to be proud of. Note also the quality that has been carefully crafted down to the last detail. The subtle texture of the seats is so beautiful that you'll want to get up close and touch them. It's an interior that makes you feel extremely high-class.

PIC CAPTIONS

Fully mechanical power steering

Genuine engine speed-sensitive power steering that is light at low speeds and provides firm feedback at high speeds. (Factory option on AX-i CX-i, 3-door sedan/5-door sedan Feria, and Feria ECVT models)

Air conditioning that lets you enjoy fresh air 365 days a year

From cooling in the summer to dehumidifying heating in the winter, you can freely control the airflow to your liking any time of the year. You can enjoy a refreshing drive at any time. (AX-i, CX-i, Feria)

Clear sound at any time, AM FM cassette stereo

It is equipped with a cassette stereo audio system, a one-touch traffic information receiving switch, and a digital clock function.

(AX-i, CX-i, Feria)

Easy mirror adjustment, electric remote control door mirror

The door mirror angle can be adjusted with a single touch from the driver's seat.

(AX-i, CX-i, Feria)

Easy entry and exit with passenger seat walk-in slide

When the passenger seat backrest is folded down, the entire seat moves forward, making it easier for passengers to get in and out of the rear seat. Equipped with a memory device.

(All 3-door sedans)

Rear wiper/washer

Combined with a heated printed rear defogger, rear visibility is always clear. (AX-i, CX-i, Feria, Supercharger, 4WD)

16 notes

·

View notes

Text

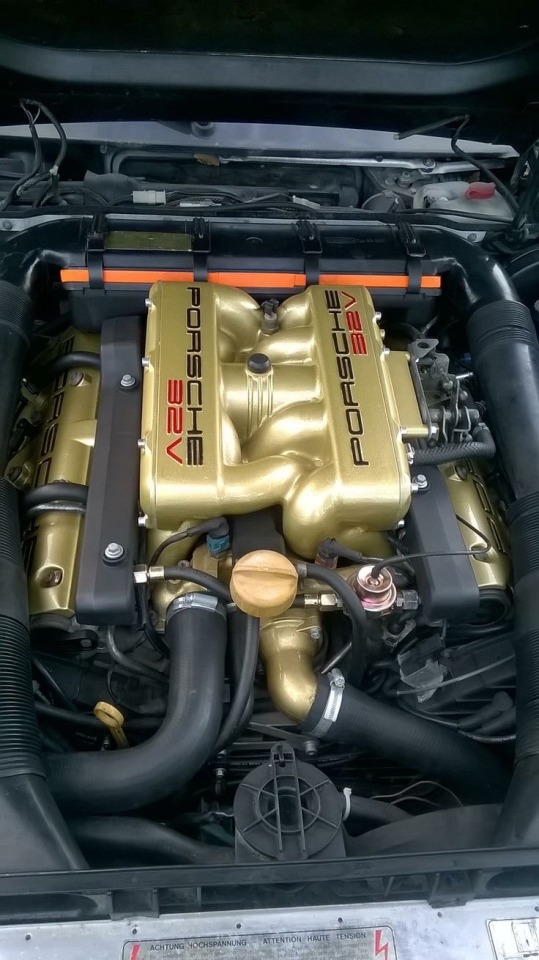

Porsche Panamera

The presentation of the first generation (code name 970), which took place in April 2009 in China, revealed only part of the model range (3 versions), later expanded to 9 (including a diesel and a hybrid). Furthermore, there is a version with a 15cm longer wheelbase, called Executive.

In April 2013, a restyling was presented which, in addition to modifications to the headlights and bumpers, introduced some new engine features.

The 400 HP 4.8 V8 was replaced by the more powerful and high-performance 420 HP 3.0 V6 biturbo for the S version.

Car body

edit

The Panamera is a 4-door coupé approximately 5 meters long, with top speeds ranging between 259 km/h for the Diesel version and 310 km/h for the Turbo S version. The four seats consist of single seats; the external style deliberately recalls that of the Porsche 911, especially at the front, so as to make the Panamera immediately recognizable as a Porsche.

Production takes place in the Leipzig plant, the same one where the Porsche Cayenne is assembled, demonstrating the presence of many points in common between the two models (starting from the engines and the integral transmission on the 4S and Turbo models).

The markets for which the model is intended are, in addition to Europe and the USA, above all the emerging markets (Russia, China, Middle East): for this reason the presentation took place at the Chinese show in Shanghai.

In April 2013, the restyled version of the Panamera was announced, which then made its debut at the Shanghai Auto Show. The plug-in hybrid version, called Panamera S E-Hybrid, was introduced on the US market in November 2013.

The second generation Panamera was unveiled on 28 June 2016 at an event held in Berlin. The code name is Type 971; the car, built on the VW Group's new Porsche MSB (Modular Standard Drive) platform, is 35 millimeters longer and 5 mm wider than the first generation, with 30 millimeters more wheelbase. The interior features a redesigned dashboard, with center console instrumentation made up of touch-sensitive surfaces replacing the previous generation with physical buttons. The tachometer, the only analogue instrument, is mounted centrally on the instrument panel and recalls that of the 1955 Porsche 356 A. The new car is equipped with two seven-inch displays instead of the classic pointer dials in the dashboard, with another screen 12.3-inch touchscreen that also acts as a satellite navigator with Apple CarPlay integration present in the center console. The new instrumentation is called Advanced Cockpit. Under the bonnet is a new range of engines, with only the Panamera 4S, 4S Diesel and Turbo versions available at launch.

In March 2017 Porsche presented the Panamera Turbo S E-Hybrid, a plug-in hybrid car. The Turbo S E-Hybrid features the 4.0-liter V8 engine from the Panamera Turbo, but it comes paired with an electric motor. The total system output is 680 hp, making it the second most powerful production Porsche ever built, after the 918 Spyder.

In this new model the torque of the overall system rises to 850 Nm, reaching the torque level of the Diesel version. Performance also increases, 0-100 is covered in 3.4 and 0-200 in 8.2 seconds.

The new Panamera aesthetically no longer features the rounded tailgate that had divided automotive critics of the previous series, but now the tail with a more tapered and squared style recalls that of the 991 through the headlights and the longitudinal rear LED strip. This improvement in design helped clarify the model's identity as a touring-oriented sports car.

In March 2017 at the Geneva Motor Show, a shooting brake version of the Panamera II series built on the same base, called Panamera Sport Turismo, was presented.

The restyling of the second generation Panamera was presented on August 26, 2020.

10 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/139824-2/

In 2022, car enthusiasts all over the United States were anxiously awaiting the arrival of the Nissan Z. In the new Z, not 400Z, it seems Nissan answered all of our prayers. Equipped with a 3.0L VR30DDTT Twin Turbo V6 and a 6 speed FS6R31 manual transmission, the new Z34 (Kouki Z34) seemed to fill all the gaps Nissan left in the Zenki Z34 and R35 that left true drivers wanting more. With a power output at an even 400hp (298kw; 406ps) and 350 ftlbs (475 N-m 48 kg-m) of torque, the new Z34 was unlike any of its predecessors and a breath of fresh air in the middle of the ‘Sports Car Electrification Movement’. Nissan then broke some hearts, mine included, when they announced the 420hp, 384ftlb Z34 Nismo would be equipped with a rebadged Mercedes 9G-Tronic automatic transmission manufactured under Jatco as the JR913E and that there would be no manual option for the Nismo Z. Their reasoning: Even with more power, the automatic sport model would be faster in the ¼ mile than a manual Nismo, and they feared consumers would care.

Fast forward to release day, and the reasonably priced Nissan Z saw dealer markups of over $70,000 over MSRP on what could be Nissan’s final true sports car. Somehow, clout and fear of missing out beat common sense and they sold like hotcakes. So much so, that as of the writing of this article, the least expensive USED Nissan Z on the market is being offered at $7,000 above NEW MSRP. Now to bring it all into perspective, if you were an early buyer of a Nissan Z, you’re punching in Audi RS5 Coupe, BMW M4 Competition xDrive, and C8 Corvette territory price-wise, except you likely have cloth seats, less power, and are a good deal slower from 0-60 than your newly priced out competition… and the EFI scientist here at Vivid Racing just can’t let you go out like that.

Interested in this Nissan Z Tuning Box? Order Here

While we have options for your interior woes, and styling upgrades that make the car look the part of the markup, we were focused on two things and two things only: horsepower and torque… and drivability (I’m aware that’s three things). When this Two-tone Ikazuchi Yellow Tricoat / Super Black Kouki Z34 rolled into our dyno lab, we were impressed. It put down an underrated 405hp and 475ftlbs of torque through the automatic transmission, which was more than we all expected. Immediately wanting to unlock the ECU and start our flash process, the customer let us know the factory warranty was very important to him and that he would like to keep it. Luckily here at VR Tuned, we have developed a Warranty-safe tune with our VR Tuned Tuning Box. Basically, this system acts as a piggy back. It requires no cutting or splicing and does not modify the way any of the factory sensors work. Instead, through science and electrical engineering and magic, it provides safe, modified data to the factory ECU, allowing us modify boost, fuel and spark strategies that ultimately results in a 65hp increase over stock and 85 more ftlbs or torque through our VR Forged wheels.

To make it more user-friendly for the driver, we included optional Bluetooth control for both iOS and Android platforms, allowing the user to quickly change between 7 performance maps, or simply turn the tuning box off for emissions purposes from their phone. With 3 active drive modes (Race, Sport, and Eco) included, and German tuning box construction, we feel Vivid Racing has crafted the ultimate tuning solution for Nissan Z owners looking to retain their factory warranty. We also found the best exhaust system for making big power, and the best suspension system to keep it all under control, so there’s no need to take it one step at a time. The next stop for us and the Z should be a track day, so subscribe if you want to see more.

So whether you want to be the talk of the town at the next local cars and coffee, or you want to take a few hot laps around the track in extreme comfort, shoot me an email at [email protected] to get your Z right.

Product Featured: VR Tuned ECU Tuning Box Kit V2 Nissan Z | 400Z

2 notes

·

View notes

Text

''Understanding Their Key Functions"

Introduction

Small gear motors are essential components used in various industries and applications. These compact devices play a crucial role in converting electrical energy into mechanical power, enabling precise and controlled motion. In this blog, we will explore the primary function of small gear motors and their significance in modern-day technology.

Function of Small Gear Motors

Power Transmission: The primary function of small gear motors is to transmit power from the input source (typically an electric motor) to the output shaft. The motor generates rotational energy, which is then transmitted to the gear assembly. The gears inside the motor are designed to mesh with each other, creating a mechanical advantage that enables the motor to deliver higher torque at reduced rotational speeds. This power transmission allows small gear motors to efficiently drive various mechanisms and devices.

Speed Reduction: Another critical function of small gear motors is speed reduction. By using gears with different numbers of teeth, the rotational speed of the output shaft can be reduced relative to the input shaft speed. This feature is particularly useful in applications that require slower, controlled movements, such as robotics, automated systems, and precise machinery.

Torque Amplification: Gear motors are also known for their ability to amplify torque. The gear assembly increases the torque output, making it easier for the motor to overcome resistance or load in the system. This torque amplification ensures that the motor can perform tasks that would be challenging or impossible with a direct drive system.

Directional Control: Small gear motors offer precise directional control. By reversing the rotation of the input motor or changing the gear arrangement, the output shaft can rotate in the opposite direction. This capability is crucial in applications where bidirectional motion is required, like in the operation of conveyor belts, valves, and actuators.

Compact Size and Efficiency: The compact size of small gear motors makes them ideal for applications with limited space. Their efficiency in converting electrical energy into mechanical power also contributes to their widespread use. They can achieve efficiency levels of 70-90%, making them highly energy-efficient solutions.

Conclusion

In conclusion, small gear motors play a pivotal role in modern engineering and technology. Their primary functions include power transmission, speed reduction, torque amplification, directional control, and efficiency. As these devices continue to evolve and improve, we can expect them to remain a key component in various industries, ranging from robotics and automation to automotive and aerospace.

2 notes

·

View notes

Text

Discover the 2023 Chevy Silverado 1500

What You Need To Know

This versatile, well-built half-ton truck is perfect for daily use, engineered to work hard while regularly carrying light loads. Available since the end of 2022, this is a durable and resilient five-person truck with optimum power and increased efficiency that drives extremely well on challenging roads and can tackle off-road journeys with ease, too.

New Features

This version of the Silverado has increased power with its reformed turbocharged 3.0 liter Duramax engine, increasing output to 305 horsepower and 495 pound-feet of torque. It also boasts a modified combustion bowl, updated fuel injectors, and different pistons, which aid strength and create a more dynamic truck altogether.

The interior has benefitted from a 10-way power driver’s seat and power lumbar control. It now has the option for a crew cab and an adult-length bed to provide optimum comfort for passengers and increased space for cargo. The new option of a 5.3-liter V-8 engine gives more speed and increased efficiency. If you pick this engine, you can then add the upgraded Z71 off-road package, which turns tough journeys into an absolute pleasure.

How Safe Is It?

Every model is fitted with several excellent driver-assistance features like Adaptive Cruise Control and Park Assist. The top-tier High Country model offers the addition of both GM hands-free driver technology and Super Cruise. Its safety is increased by the forward collision warnings and an automated emergency braking system.With this in mind, the technology can also monitor blind spots, alert you to traffic at the rear, and warn you if you drift lanes.

Engine and Performance

The Silverado is blessed with many engine/transmission combinations, the most impressive being the 6.2-liter, which can thrust the vehicle from 0 to 60 mph in less than 6 seconds. Its 420 horsepower and 460 pound-feet of torque make it a real force to be reckoned with. Other engines available include two V-8s, the turbocharged four-cylinder, and the Duramax diesel 3-liter inline-six, allowing the powerful Silverado to provide an effortless, smooth ride.

Comfort

The soft padding and support maintain comfort even on long journeys and while driving off-road, plus you can barely feel any small impacts from uneven surfaces. Climate Control allows you to alter the temperature inside the cabin, with the addition of ventilated, split-headed front seats if you wish.

Any truck including the LT trim and upwards has a sleek, updated dashboard with a gigantic 12.3-inch, accessible touchscreen. The High-Country is especially attractive with its leather interior and wood trim. The crew cab is adorned with a spacious back seat and compact storage is scattered throughout the cabin. Bed lengths vary from 5.8-to-8.1 feet, providing comfortable rest when needed.

#Chevy#Silverado 1500#2023 Models#Truck Features#New Trucks#Auto Technology#Vehicle Reviews#Pickup Trucks#Chevy Silverado 1500 Features#2023 Chevy Silverado 1500

6 notes

·

View notes

Text

1968 Mustang GT 2+2 Fastback Cobra Jet: A Muscle Car Legend

The 1968 Mustang GT 2+2 Fastback Cobra Jet is more than just a car; it’s an icon of American muscle car history. With its aggressive styling, powerful engine, and track-ready performance, this Mustang has cemented its place among the greatest muscle cars of all time. For enthusiasts and collectors alike, the 1968 Mustang GT Fastback Cobra Jet represents the pinnacle of Ford’s engineering and innovation during the golden era of muscle cars.

A Brief History of the 1968 Mustang GT

The Ford Mustang made its debut in 1964, creating a new category of performance cars known as “pony cars.” By 1968, Ford had refined its design and performance to keep up with the growing competition from Chevrolet, Dodge, and Pontiac. The introduction of the GT package, along with the availability of the Cobra Jet engine, elevated the Mustang to an entirely new level.

In 1968, the Mustang underwent some key design changes, including revised side scoops, new grille patterns, and safety features like energy-absorbing steering columns and side marker lights. However, the most significant upgrade came in the form of the 428 Cobra Jet engine, a high-performance powerhouse that transformed the Mustang into a true muscle car.

Design and Styling: A Timeless Classic

The 1968 Mustang GT 2+2 Fastback is a masterpiece of automotive design. The fastback styling, characterized by its sloping rear roofline, gave the Mustang a more aggressive and aerodynamic look compared to the coupe and convertible versions. The GT package added distinctive elements such as:

Fog lights integrated into the grille

GT badging and stripes

Styled steel wheels

Dual exhaust with chrome quad tips

Sporty handling suspension

Inside, the Mustang GT offered a driver-focused cabin with a woodgrain-trimmed dashboard, deluxe bucket seats, and an optional center console. The interior could be customized with various trim options, adding to the appeal for buyers looking for a personalized driving experience.

The Powerhouse: 428 Cobra Jet Engine

The highlight of the 1968 Mustang GT 2+2 Fastback was undoubtedly its engine. Ford introduced the 428 Cobra Jet in response to increasing demand for higher performance in the Mustang lineup. This engine was developed to compete with the Chevrolet Camaro Z/28 and Pontiac Firebird 400, both of which were making waves in the muscle car market.

Key Specs of the 428 Cobra Jet Engine:

Displacement: 428 cubic inches (7.0L)

Horsepower: Officially rated at 335 HP (but actually closer to 400 HP)

Torque: 440 lb-ft

0-60 MPH: Approximately 5.5 seconds

Quarter-Mile Time: Around 13.5 seconds @ 105 mph

The Cobra Jet engine featured a heavy-duty crankshaft, strengthened connecting rods, larger intake ports, and a performance-tuned Holley 735 CFM carburetor. These enhancements allowed the engine to produce massive power, making the Mustang a dominant force on both the streets and the drag strip.

Performance and Handling: Built for Speed

The 1968 Mustang GT Fastback Cobra Jet wasn’t just about straight-line speed; it also featured upgraded suspension and braking systems to handle the increased power. The GT package came with:

Stiffer suspension with heavy-duty shocks

Upgraded front disc brakes for better stopping power

Quick-ratio steering for improved handling

Wider tires for enhanced grip

Despite its high power output, the Cobra Jet-equipped Mustang remained relatively easy to drive, making it an attractive option for both seasoned racers and casual enthusiasts. Whether on the track or the highway, the 1968 Mustang GT delivered a thrilling driving experience that few other cars could match.

Racing Success and Legacy

The introduction of the Cobra Jet engine immediately made the 1968 Mustang a force to be reckoned with in racing circles. Ford entered the 428 Cobra Jet Mustang in the 1968 NHRA Winternationals, where it stunned the competition by securing a first-place finish in the Super Stock class. This victory solidified the Mustang’s reputation as a serious contender in drag racing.

Over the years, the 1968 Mustang GT Fastback Cobra Jet has become a highly sought-after collector’s car. Its combination of aggressive styling, raw power, and historical significance has made it one of the most iconic muscle cars ever produced. Original models with matching numbers and factory documentation can fetch six-figure prices at auctions, reflecting their desirability among collectors.

The 1968 Mustang GT in Pop Culture

The Mustang Fastback has been featured in countless movies, TV shows, and music videos, further cementing its legendary status. One of the most famous appearances was in the 1968 movie Bullitt, where Steve McQueen drove a Highland Green Mustang GT 390 Fastback in one of the most iconic car chases in cinematic history. While the Bullitt Mustang was not a Cobra Jet model, its popularity helped boost the appeal of all 1968 Fastback Mustangs, including the 428 Cobra Jet.

Additionally, the Mustang has made appearances in modern films such as John Wick, Gone in 60 Seconds, and Need for Speed, ensuring that its legacy continues to inspire new generations of car enthusiasts.

Owning a 1968 Mustang GT 2+2 Fastback Cobra Jet Today

For those lucky enough to own a 1968 Mustang GT Cobra Jet, maintaining and restoring the car is both a passion and an investment. Here are some key tips for owners and buyers:

Authenticity Matters

When purchasing a 1968 Mustang GT Cobra Jet, verifying authenticity is crucial. Look for VIN numbers, engine codes, and original factory documentation to ensure you’re getting a genuine Cobra Jet model.

Restoration vs. Original Condition

Some collectors prefer fully restored models, while others seek well-preserved original cars. Restorations can add value, but an all-original, well-maintained Cobra Jet is often the most desirable.

Availability of Parts

Fortunately, the Mustang’s popularity means that reproduction parts are widely available. Companies specialize in restoring classic Mustangs, making it easier to keep these cars in top condition.

Investment Potential

The 1968 Mustang GT Fastback Cobra Jet has consistently appreciated in value over the years. Well-maintained models with original components can command premium prices at auctions and private sales.

Conclusion

The 1968 Mustang GT 2+2 Fastback Cobra Jet remains one of the most revered muscle cars of all time. Its combination of stunning design, incredible power, and racing pedigree make it a true automotive legend. Whether you’re a collector, a classic car enthusiast, or someone who simply appreciates American muscle, the 1968 Mustang GT Cobra Jet stands as a timeless symbol of performance and style.

From its dominance on the drag strip to its enduring presence in pop culture, this Mustang continues to capture the hearts of car lovers worldwide. Owning one isn’t just about having a classic car—it’s about being part of a legacy that represents the golden age of American muscle cars. If you ever get the chance to drive one, be prepared for an experience that’s as exhilarating today as it was back in 1968.

FAQs

1. How rare is the 1968 Mustang GT 2+2 Fastback Cobra Jet?

The 1968 Mustang GT Cobra Jet is considered a rare collector’s car, especially in original condition with factory documentation.

2. How much does a 1968 Mustang GT Cobra Jet cost today?

Prices vary depending on condition and originality, but well-maintained models can sell for over $100,000 at auctions.

3. What makes the Cobra Jet engine special?

The 428 Cobra Jet engine was built for high performance, featuring heavy-duty components and high torque output, making it one of the most powerful engines of its time.

4. Can I still find parts for restoration?

Yes, many aftermarket companies produce high-quality reproduction parts for classic Mustangs, making restoration possible.

5. Is the 1968 Mustang GT Cobra Jet a good investment?

Yes, due to its historical significance and limited production, the 1968 Mustang GT Cobra Jet has strong investment potential.

1 note

·

View note

Text

Choosing the Right Timing Belt Pulley for Your Vehicle

Your vehicle engine depends on selecting an appropriate timing belt pulley for proper engine functioning. A timing belt pulley serves a crucial function by linking the engine components together as it provides proper power transmission while maintaining peak operational efficiency. Recipients must examine multiple elements before making their selection including the material type and dimensions and tooth design as well as performance compatibility with existing engine systems.

A clear comprehension of Timing Belt Pulley operations reveals its purpose.

Operation of the timing belt pulley depends on the timing belt to manage rotation between crankshaft and camshaft. A proper timing operation between the engine valves leads to correct valve movements for both functional efficiency and better engine output. The combination of durable operation and longer component lifespan stems from right engine timing that a premium pulley system allows.

Factors to Consider When Choosing a Timing Belt Pulley

1. Material Quality

Horizontal shaft position sensors play an essential role in the efficiency and durability of a timing belt pulley since the chosen material determines both attributes. Common materials include:

Aluminum serves as an excellent material because it provides lightweight characteristics together with resistance against corrosion which makes it ideal for fast performances.

Steel: Offers superior strength and durability, ideal for heavy-duty engines.

Modern engines use plastic for weight reduction and noise reduction purposes yet this component does not match the longevity of metal counterparts.

2. Tooth Profile and Pitch

Timings elements on the timing belt connect to matching features on the timing belt pulley in order to achieve proper engagement and operational function. Common profiles include:

Traditional engines use the trapezoidal design as their timing pulley configuration.

The HTD - High Torque Drive architecture of curvilinear timing belts distributes load effectively while decreasing wear on the belt.

A modified version of curvilinear design creates better grip and efficiency with reduced slippage between belt and pulley.

3. Size and Fitment

A correctly sized pulley leads to both optimal engine timing and appropriate tension of the belt. Your vehicle requires the correct pulley dimensions which you need to acquire through your manufacturer's guidelines or professional advice. A timing belt drives the engine poorly and causes excessive wear that can end in component failure when it has an improper size.

4. Load Capacity and Performance Requirements

Your selection of a timing belt pulley depends on both the load requirements of your engine and its operational demands. Pulleys that serve high-performance engines must have specifications for increased torque together with elevated speeds to handle tough operating environments.

5. Compatibility with Your Vehicle’s Engine

Check that the timing belt pulley matches the specifications of your engine model. A wrong pulley selection may produce alignment issues which can subsequently trigger belt slippage or result in engine destruction. Your reference point for correct timing belt pulley selection should start with the vehicle manual or by contacting Makhija International Private Limited because they provide reliable expertise.

Why Choose Makhija International Private Limited?

Makhija International Private Limited specializes in the manufacturing of high-quality durable precision engineering timing belt pulleys for all applications. Makhija International Private Limited creates its products through the combination of premium materials with advanced engineering techniques to provide best-in-class performance across different automotive applications. Our team possesses the capability to develop both generic and tailored pulley solutions to meet every customer requirement.

Conclusion

Engine efficiency and reliability along with longevity depend on making the correct selection of timing belt pulleys. The correct selection of material together with tooth profile and size and load capacity and compatibility will ensure your vehicle operates optimally. Choose Makhija International Private Limited for high-quality timing belt pulleys which they produce according to your specific requirements.

0 notes

Text

The Chevrolet C8 Corvette

The Chevrolet C8 Corvette, also known simply as the C8, marks a dramatic and exciting chapter in the long history of America’s iconic sports car. Introduced in 2020, the C8 Corvette is the eighth generation of the Corvette lineup and brings with it a major departure from tradition. For the first time in over 60 years, Chevrolet decided to break from the Corvette’s front-engine layout and transition to a mid-engine design, a move that has stirred both excitement and curiosity among automotive enthusiasts.

The C8’s mid-engine design is a bold statement in the performance car world. For decades, the Corvette had been known for its front-engine, rear-wheel-drive configuration, which offered excellent handling and performance for its price. But with the C8, Chevrolet sought to take performance to the next level by improving weight distribution, agility, and overall driving dynamics. The decision to place the engine in the middle of the car allows for better balance and more responsive handling, creating a car that competes with some of the world’s best sports cars, including those from Europe.

Under the hood of the C8 Corvette sits a 6.2-liter V8 engine, the same engine used in the previous generation, but now with improvements to increase power output. The naturally aspirated V8 produces 495 horsepower and 470 lb-ft of torque in the standard Stingray model. This performance is impressive, but the true magic of the C8 lies in its driving experience. The engine is paired with an 8-speed dual-clutch transmission, which provides quicker gear shifts, enhancing the overall responsiveness and speed of the car. This combination allows the C8 to go from 0 to 60 mph in under 3 seconds, making it one of the fastest cars in its class.

The exterior design of the C8 is unmistakably Corvette, with a sharp, aggressive stance that conveys power and performance. The mid-engine layout allowed designers to lower the car’s profile and create a more aerodynamic shape. The car’s wide rear fenders, aggressive front end, and sleek, sculpted lines give it a futuristic look that stands out in any crowd. The C8 is also available in a variety of colors, allowing owners to customize their cars to their preferences.

Inside, the C8 Corvette is designed with a driver-focused cockpit that blends high-tech features with luxury. The cabin is filled with premium materials, such as leather and suede, and the center-mounted digital display makes it easy for drivers to monitor vehicle performance and navigation. The seats are comfortable, offering excellent support for spirited driving, yet also provide a level of comfort for long drives. The dashboard layout is clean and modern, and the design is focused on maximizing driver experience while still maintaining a high level of comfort.

The C8 Corvette is not just about performance; it’s also about value. Chevrolet managed to price the C8 Corvette aggressively, starting at around $60,000 for the base Stingray model. This pricing puts it in direct competition with some of the world’s best exotic cars, but with a distinct American flavor and performance at a fraction of the price of European rivals.

One of the most exciting aspects of the C8 is its performance potential. While the base model offers incredible power and handling, the Corvette lineup has historically been known for offering higher-performance variants. With the mid-engine architecture in place, future iterations of the C8, including potential Z06, Grand Sport, and ZR1 models, are expected to push the limits of the Corvette's performance even further.

Overall, the Chevrolet C8 Corvette represents the future of the iconic American sports car. With its mid-engine layout, cutting-edge technology, and incredible performance at an accessible price point, the C8 has redefined what it means to own a Corvette. Whether you’re a longtime Corvette fan or a newcomer to the brand, the C8 is a car that’s impossible to ignore and promises to be a major player in the sports car world for years to come.

0 notes

Text

How Permanent Magnet Machines Improve Energy Efficiency in Industrial Applications

Energy efficiency has become a key focus for industries looking to reduce operational costs, minimize energy waste, and meet sustainability goals. One of the most effective ways to enhance energy efficiency in industrial applications is through the use of permanent magnet machines. These machines, including Permanent Magnet Synchronous Machines (PMSMs) and Brushless DC Motors (BLDCs), offer superior performance, higher efficiency, and reduced energy consumption compared to traditional induction motors.

In this article, we will explore how permanent magnet machines contribute to energy efficiency in industrial applications and why they are becoming the preferred choice in modern manufacturing and automation systems.

1. Higher Efficiency Compared to Induction Motors

Why It Matters

Traditional induction motors are widely used in industrial settings, but they lose energy through electrical resistance and rotor slip. This inefficiency increases energy consumption and operational costs.

How Permanent Magnet Machines Help

Elimination of Rotor Losses – Permanent magnet machines do not require electrical current to excite the rotor, reducing energy losses.

Higher Power Density – They provide more power output for the same size compared to induction motors.

Improved Load Efficiency – These machines maintain efficiency even at partial loads, making them ideal for variable-speed applications.

The improved energy efficiency of permanent magnet motors results in lower electricity bills, reduced heat generation, and longer operational life of industrial equipment.

2. Reduced Power Consumption in High-Torque Applications

Why It Matters

Many industrial processes require high torque at low speeds, such as conveyor belts, extruders, and material handling equipment. Induction motors often consume excess energy in these conditions due to their dependency on high currents.

How Permanent Magnet Machines Help

Higher Torque Density – These machines generate higher torque per unit of electric power.

Lower Current Requirements – They require less electrical current to achieve the same torque output.

No Need for Gearbox Systems – Direct-drive permanent magnet motors eliminate mechanical inefficiencies in transmission systems.

By optimizing power consumption in high-torque applications, permanent magnet machines enable industries to reduce energy waste and increase overall productivity.

3. Enhanced Performance in Variable-Speed Operations

Why It Matters

Many industrial processes require variable-speed operations to optimize performance and energy consumption. Traditional motors suffer from efficiency losses when operated at varying speeds.

How Permanent Magnet Machines Help

Precise Speed Control – With advanced motor control technology, these machines adjust speed efficiently without excess energy loss.

Smooth Acceleration and Deceleration – Unlike traditional motors that require additional control mechanisms, permanent magnet motors respond quickly and smoothly.

Integration with Smart Drives – These machines work seamlessly with variable frequency drives (VFDs) and intelligent motor controllers for optimized energy usage.

Industries using variable-speed systems such as pumps, compressors, and HVAC systems benefit greatly from permanent magnet machines due to their dynamic efficiency and adaptive energy consumption.

4. Lower Maintenance and Longer Lifespan

Why It Matters

Frequent maintenance of industrial machinery increases downtime, reduces productivity, and adds to operational costs. Traditional motors with brushes, slip rings, and bearings require regular servicing and replacements.

How Permanent Magnet Machines Help

Brushless Design – BLDC motors and PMSMs eliminate brushes, reducing wear and tear.

Minimal Heat Generation – Lower energy losses mean cooler operating temperatures, which extends motor lifespan.

Less Mechanical Wear – Fewer moving parts lead to less friction and lower maintenance costs.

Industries relying on continuous operations, such as manufacturing, packaging, and assembly lines, can reduce maintenance costs and extend machine life by switching to permanent magnet machines.

5. Energy Savings in Renewable and Sustainable Applications

Why It Matters

Industries are shifting towards energy-efficient and sustainable solutions to meet global carbon reduction targets. Traditional motors often consume more energy than necessary, leading to excess CO₂ emissions.

How Permanent Magnet Machines Help

Higher Efficiency in Wind and Hydro Power Systems – These motors are widely used in renewable energy systems for power generation.

Integration with Smart Grids – Permanent magnet motors work efficiently with energy storage and grid balancing systems.

Reduction in CO₂ Emissions – Lower energy consumption directly translates to reduced environmental impact.

By adopting permanent magnet machines, industries contribute to sustainability efforts while improving their own operational efficiency.

6. Compact and Lightweight Design for Space Efficiency

Why It Matters

Industrial spaces are often limited, and bulky machines can create inefficiencies in factory layouts. Traditional motors require large cooling systems and additional space for auxiliary components.

How Permanent Magnet Machines Help

Smaller Footprint – Higher power density means compact motor designs, freeing up valuable floor space.

Lighter Weight – Reducing weight allows for easier installation and mobility.

Flexibility in Industrial Layouts – Compact machines enable optimized factory and plant layouts.

Industries with limited space, such as robotics, automation, and electric vehicle (EV) manufacturing, benefit significantly from compact and efficient motor solutions.

Conclusion

Permanent magnet machines are revolutionizing industrial applications by providing higher efficiency, lower energy consumption, reduced maintenance, and superior performance. Industries adopting these motors benefit from cost savings, better productivity, and sustainability.

As businesses focus on energy efficiency and long-term savings, transitioning to permanent magnet machines is an investment that delivers both economic and environmental benefits.

0 notes

Photo

New Post has been published on https://fastmusclecar.com/new-ford-mustang-shelby-gt350-with-old-school-799bhp/muscle-cars/

New Ford Mustang Shelby GT350 with old-school 799bhp

The old-school muscle car template still thrives, this time in the form of the newly released Shelby GT350 and track-ready GT350R. Both cars will be built by Shelby America featuring a 5.0-litre ‘Coyote’ V8, good for 473bhp. With the addition of a Whipple supercharger, the power output can be increased to 799bhp when using 93, 98 or 99 octane fuel. both vehicles can be ordered with either a 6-speed manual with short throw shifter or a 10-speed automatic transmission.

Raw Power Under the Hood: The Heart of the Shelby GT350

The power output is backed by 670 lb-ft of torque, ensuring that the Mustang GT350 can deliver the goods in straight line or on the track. The new Shelby GT350 boasts enhanced engine cooling and advanced fuel injection technology, allowing the car to maintain its impressive performance over long drives or under intense acceleration.

Performance and Handling: Built for Precision

Beyond its raw power, the Shelby GT350 delivers an extraordinary driving experience thanks to its tuned suspension system. Ford has equipped the Mustang with an enhanced suspension, lowering the car by one inch, with adjustable sway bars all around, and 20-inch alloy wheels and Michelin pilot sport tires.

The Mustang Shelby GT350 is not just about power; it’s about handling. The car features improved braking systems with large, carbon-ceramic disc brakes, providing exceptional stopping power. With a robust and lightweight chassis, the Shelby GT350 maintains a low center of gravity, which enhances the car’s cornering agility and overall stability.

Design: familiarity without being overt

There’s just enough on the exterior of the GT350 to let people know it’s a cut above the average Mustang. The prerequisite Shelby stripes run the length of the car, with a redesigned front grille, enhanced bumpers and huge brake docs. The aluminium hood features central vents, while there is a three-piece splitter for a track-ready look.

A Legacy of Performance: The Shelby Heritage

The Shelby Mustang lineage is one of the most storied in automotive history. Originally introduced in the 1960s by automotive legend Carroll Shelby, the Shelby Mustang quickly gained a reputation for both style and performance. With each iteration, Shelby has pushed the boundaries of performance, blending raw power with innovative engineering.

The GT350 name is particularly iconic, symbolizing the very best in American muscle car design. Ford continues to honor this legacy with the latest iteration of the Mustang Shelby GT350, infusing it with a combination of traditional muscle car elements and modern technology. This muscle car not only delivers performance but also embraces the heritage of a legendary nameplate.

Safety Features: Built for Confidence

The Shelby GT350 does not compromise on safety. It comes equipped with a host of driver assistance features designed to keep both the driver and passengers safe on the road. Features such as lane departure warning, blind-spot monitoring, and adaptive cruise control make everyday driving safer without sacrificing performance.

The interior features a half-roll cage, 4-point seat harnesses, and an extra stiff chassis. if that’s not enough for most, there are further upgrades such as the aero package which adds lots of carbon fibre appointments such as Sparco carbon fibre racing seats.

Pricing and Availability: A True Investment in Performance

While pricing of the Shelby GT350 and the Shelby GT350R may vary when it hits the shelves, according to the official Shelby website, ‘the MSRP starts at $109,999 for the supercharged version, including the car.’

Only 562 Shelby GT350s, including the R models were built in 1965, including only 36 Shelby GT350R models. Ford intend to produce the same amount of models for this production year. Each vehicle will be documented in the Shelby registry, with a three-year/36,000-mile warranty.

Conclusion: A Timeless Classic Reinvented for the Modern Age

There are also plans to enter a Trans Am spec’ed version of the Shelby for the 2026 race season, in association with Turn Key Automotive/Motorsports.

Find out more here about the cars from the Shelby website – https://www.shelby.com/multimedia/News/ArtMID/5059/ArticleID/141/Shelby-GT350-and-Shelby-GT350R-Return#:~:text=The%20Shelby%20GT350%20offers%20significant,supercharged%20version%2C%20including%20the%20car.

0 notes

Text

AMG G63 4x4² „Nuthin but a G thang“.

The AMG G63 4x4² brings driving performance to the segment of unadulterated off-road vehicles in unexpected form.

The AMG 4.0-litre V8 biturbo engine generates 430KW (585HP) in this model, and delivers a maximum torque of 850Nm. This is available across a wide rev range between 2.500 and 3.500 rpm, and provides a sense of effortless superiority. It absolves a sprint from zero to 100 km/h in 5 seconds.

The two turbochargers are not positioned on the outside of the cylinder banks, but inside the cylinder „V“. Advantages: a compact engine design, spontaneous response of the turbochargers and low exhaust emissions thanks to optimal airflow to the near-engine catalysts. The eight-cylinder delivers its power with muscular torque in all engine speed ranges, combined with maximum efficiency for low fuel consumption and emission figures.

Two twin scroll turbochargers are used for optimal response.

The housing is divided into two parallel flow channels. Combined with two separate exhaust ducts in the exhaust manifold, this makes it possible to control the exhaust gases on the turbine wheel separately. The exhaust gas from the first and fourth cylinders of the cylinder bank is fed into one duct, that from the second and third cylinders to the other duct.

The aim is to prevent the individual cylinders from having mutually adverse effects on the gas cycle. This reduces the exhaust gas back pressure and improves gas exchange. The results are increased output, more torque at low revs and very fast response times.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

#amg#gclass#gwagon#g634x4amg#g634x4#g63amg#g63#g636x6amg#g636x6#mercedesamg#mercedes#mercedesbenz#mercedesgclass#affalterbach#onemanoneengine#pagani

11 notes

·

View notes

Text

Article comparing the Mazdaspeed A-spec and B-spec Eunos Roadsters. Translation of pages below.

How to enjoy the Mazdaspeed Roadster

Let's start with Aspec

test drive

MAZDASPEED EUNOS Roadster

A spec(1.8ℓ)

B spec(1.6ℓ)

The A-Spec is focused on the suspension. The B-Spec is its higher-end version with increased power. These two kits will greatly expand the range of driving capabilities of the Roadster. They will be released by Mazdaspeed, who knows Mazda cars inside and out.

report: Satoshi Saito

Photo: Hideyo Komine

Contact:

mazdaspeed

03-3533-6496

Runs and turns just the way you want it to

Let's start by getting straight to the point. Which one is more fun? It's definitely the B-spec. Although the displacement is different, the two cars have engines with similar characteristics. Since one of them has been tuned, it's only natural that it's fun. If it wasn't fun, it wouldn't be worth paying a high price for. The 102 isn't a bad car either. It will cost a fair amount of money, but if you know how, you can make a 1.6 -liter model that exceeds the 1.8.

Now, the B-Spec. The power specs are maximum output 144/6500 rpm, maximum torque 17.0 kgm/5700 rpm. Compared to the standard model, the power is up by 24 horsepower and the torque by 3 kgm.

In terms of speed, it's not as fast as VTEC, and if they were going to do it, I would have preferred it to be tuned to about 100 horsepower per 1L. That's my honest opinion. However, compared to a normal engine, it's still much more pleasant and powerful. Of course, even compared to the 1.8 -liter engine.

Perhaps it's because of the lighter flywheel, but the engine response is really good. Even when heel-and-toeing, you don't have to hold down the accelerator with your heel and wait for the rotations to pick up. Just give it a gentle jerk and it responds properly.

The more you increase your pace, the more you get into the rhythm. From braking to downshifting, and then cornering. Gradually open the throttle as you accelerate, then upshift. It's a certain pleasure, as if the car and your hands and feet are one.

This is due not only to the engine, but also to the well-balanced suspension. The springs are not set too hard, but the A-spec stabilizers on the front and rear and the 8-stage adjustable shock absorbers help the car turn just as you want it to.

Although it had been a while since I last drove on the Izu Skyline, I felt as if it were a familiar road.

If you are dissatisfied, just change it.

On the other hand, the 1.8 -liter A-spec car is not boring; that is not the case at all. If you want to enjoy driving, it is several times more fun than the normal 1.

Compared to the B-spec, the stock engine feels rough when revving up, but perhaps because the intake and exhaust systems have been replaced, the revving up is smoother and the torque is stronger at around 2000-5000 rpm. Since it already has torque in the low rpm range, there is no need to be fussy about keeping it at high rpm.

You can run fast and without stress without having to try too hard.

The handling is still incomplete. Only the front and rear shocks and the rear stabilizer have been changed, and the front stabilizer is still standard. The handling is unsettled, and when you turn the steering wheel, the nose turns in more than you would expect. There is a lack of stability.

So I changed the shock initials from 2 for both the front and rear to 3 for the front and 2 for the rear. This significantly increased stability, but the rear still lacked stability. So I boldly changed the rear to 1 (the softest). This calmed down the car's sharp cutting movements, and made it much easier to drive.

The A-Spec shock has eight adjustable settings, and each initial setting produces a clear difference in damping characteristics, so you can play around with the settings like this. In fact, I was playing around on winding roads trying out different initial settings on this A-Spec to see what kind of handling it would give me.

I wrote at the beginning that the B-Spec is by far the more interesting car, but that is only if you look at it as a completed car. If you change your perspective to enjoying the car, both are enjoyable enough to never disappoint you. This is no lie. If you are not satisfied with the engine, you can just tune it. There is no need to put up with anything and drive a ready-made car, as the A-Spec and B-Spec teach us.

_______________________________________________________________________

MAZDASPEED

EUNOS Roadster B spec(NA6CE)

144 horsepower and the response you expect

B-spec is, simply put, a tuned, complete engine.

It is set to 1.6L Roadster, and includes a stepped cylinder head port, high compression piston (compression ratio 10.5:1), eight-speed cam, reinforced valve springs, computer, lightweight flywheel (40%), reinforced clutch, reinforced clutch cover, octopus legs, muffler, air cleaner, head cover with Mazdaspeed logo, oil filler cap, and special ornament.

For the B-spec, a modified vehicle inspection is required, and the car will be delivered after passing this procedure. There are only 80 units available, and the price is 680,000 yen (excluding modification application fees, etc.).

Also available are radiators that increase heat dissipation by 100% and springs.

●15-inch wheels, 20mm lowered ride height, original nose beads, etc. give it a more dynamic image.

★The only difference in appearance is the stainless steel exhaust manifold and head cover, but the inside has been significantly improved.

★The test vehicle is equipped with a radiator (98,000 yen) that dissipates twice as much heat, and an oil cooler.

●To accommodate the strengthened suspension, the wheels are Mazdaspeed original 15-inch. The tires are 195/50 size W-1 Spec R.

●The already familiar Mazdaspeed rear spoiler. Compared to the standard version, it creates a much more aggressive rear view.

●The stainless steel sports muffler (76.3mm) is included in the standard tuning of the B-spec. It has a slightly thicker sound that is appealing.

●The buckskin bucket seats (68,000 yen each) that were installed in the test vehicle. They offer high levels of support and comfort, and are highly recommended.

_______________________________________________________________________

MAZDASPEED

EUNOS Roadster A spec(NA8C)

"The joy of finishing the suspension

●Although the A-Spec is centered on the suspension, there are also a wide variety of parts available for the exterior, interior, drivetrain, etc. You can choose your favorite parts from among them.

A-spec parts are developed for use on public roads and are in compliance with safety standards. The selling point is that you can wear them and pass vehicle inspections with confidence.

Although there are many exterior and interior dress-up parts on the market, the main products are suspension and engine-related parts.

The suspension-related parts include shock absorbers, stabilizers, and bushings, and their development and settings are handled directly by drivers Yojiro Terada and Takashi Yorino.

As for the engine, an air cleaner, a sports sound muffler, and octopus legs were added. Although the inside of the engine was not touched, the aim was to bring out the engine's inherent performance by tuning the intake and exhaust systems.

Other drive system parts available include a reinforced clutch and clutch cover, and a mechanical 1.5-way LSD.

PIC CAPTIONS

●The interior is slightly dressed up with 360mm leather-wrapped steering (35,000 yen) and aluminum and carbon shift knob (8,400 yen).

● The damping force adjustable shock absorbers are priced at 18,000 yen each for the front and rear. In addition to stabilizers, bushes and pads are also available.

The wheels are Mazdaspeed MS-01R 7JJ x 15 inches (35,000 yen per wheel). The test car is fitted with Dunlop W-1 tyres.

●Aero board combined with a four-point roll bar (48,000 yen). The streamlining effect and rear visibility are not very satisfactory.

10 notes

·

View notes

Text

The M3 Touring is already an exceptional machine, but that hasn't stopped BMW's M division from turning up the heat. Over the weekend, BMW officially teased the highly anticipated M3 CS Touring, giving enthusiasts a glimpse of what promises to be an even more thrilling version of the high-performance wagon. Accompanied by the tagline ‘Fast is about to meet faster,’ the teaser makes it clear that the CS variant is all about pushing the limits. The standard M3 Touring is already capable of hitting 62 mph in under four seconds, and the Competition Sport version, which has been seen undergoing rigorous testing, is expected to shave a fraction more off that time. The updates reflect those applied to the saloon variant back in 2023, so the CS treatment should make both aesthetics and performance better. One of the most striking updates is a more aggressive stance, but BMW has applied signature CS elements such as yellow-tinted daytime running lights and a distinctive front splitter that peeks through even the heavy camouflage. The rear seems to be largely unaltered, although it would be surprising if forged wheels and an open carbon-fiber bonnet did not make an appearance. The extensive use of lightweight materials should save some weight, but if the saloon's CS model is any guide, the savings may be relatively modest - probably in the order of 10-15kg. M(e)ister Eiskalt, CC BY-SA 3.0 https://creativecommons.org/licenses/by-sa/3.0, via Wikimedia Commons From an engineering perspective, the M3 CS Touring will be no less potent than its saloon cousin, with outputs of 550hp. Here, torque increases weren't accompanied by any changes but the boost pressure lift that was carried over from said power increase before did yield notational improvements in longitudinal performance. Perhaps the most compelling changes, then, will actually take place in areas of chassis preparation; BMW's outgoing CS models garnered auxiliary springs plus reinforced anti-roll bars, thus it should allow for a pointier handling ride and a very dynamic drive, too. With any special-edition M car, exclusivity and high price tag come as part of the package. The entry price for the M3 Touring starts at £87,945, while the M3 CS saloon debuted with a £115,955 sticker. Because the Touring variant will likely have low production volumes, a starting price north of £125,000 is a reasonable assumption. The car maker hasn't said when it will reveal the car, but now that we have a teaser out, it can't be far away. Might it finally appear at the Festival of Speed this year? It is still a bit early to tell, but based on BMW's previous record, one would not be surprised if it makes a massive splash in something as iconic as that event to launch the latest performance jewel from the stables. Read the full article

0 notes

Text

Why Is Electric Motor Rewinding Important for Industrial Applications?

Electric motors are essential components in almost every industrial operation. From powering conveyor belts to running pumps and fans, these motors play a critical role in keeping operations running smoothly. However, like any machine, electric motors are subject to wear and tear over time, which can lead to decreased performance or even complete failure. One way to extend the life of an electric motor and ensure it continues to work efficiently is through a process known as motor rewinding. This blog will explore why electric motor rewinding is so important for industrial applications.

What Is Electric Motor Rewinding?

Electric motor rewinding is the process of removing the old windings (the coils of wire inside the motor that carry electrical current) and replacing them with new ones. This helps restore the motor’s performance to like-new condition. It is commonly done when a motor’s windings become damaged, worn, or overheated. The rewinding process can involve cleaning, inspecting, and repairing the motor’s components, ensuring everything is in proper working order.

Reasons for Electric Motor Rewinding

Rewinding an electric motor can bring many benefits, and it is an important part of maintaining industrial machinery. Here are the primary reasons why rewinding is essential:

1. Restores Motor Efficiency

Over time, electric motor windings can become damaged due to factors such as overheating, mechanical stress, or exposure to contaminants like dust and moisture. When the windings are compromised, the motor can lose its efficiency, leading to higher energy consumption and increased operating costs. Rewinding helps restore the motor to its original condition, improving its efficiency and reducing energy waste.

2. Extends Motor Life

Electric motors are a significant investment for industrial facilities. Instead of replacing a worn-out motor, rewinding can extend its life and delay the need for costly replacements. Proper rewinding and maintenance can keep the motor running for many additional years, making it a cost-effective solution.

3. Prevents Further Damage

When an electric motor experiences issues with its windings, it can cause other components to fail as well. For instance, a short-circuited winding can lead to overheating, which could damage the motor’s bearings or insulation. Rewinding addresses these problems before they escalate, helping prevent more expensive repairs or a complete motor failure.

4. Improves Motor Performance

Electric motor rewinding is an effective way to restore motor performance. Worn or damaged windings can lead to irregular operation, such as a decrease in speed or torque. Rewinding can bring the motor back to its optimal performance, ensuring it operates at the required speed and power output for its specific application.

5. Reduces Downtime

In industrial settings, downtime can be costly. If a motor fails, it can stop an entire production line or process. Rewinding helps ensure the motor continues to function efficiently, reducing the risk of unexpected breakdowns and the downtime that follows. A well-maintained motor is less likely to break down, leading to more reliable operations.

Key Benefits of Electric Motor Rewinding for Industrial Applications

The advantages of electric motor rewinding are significant for industrial applications. Here are some key benefits:

1. Cost-Effectiveness

Replacing an electric motor can be a significant expense. However, motor rewinding offers a more affordable alternative, especially when the motor is still in good physical condition. By investing in rewinding, businesses can save on the cost of buying a new motor while still getting the performance they need.

2. Energy Savings

Rewinding a motor can improve its efficiency, reducing the amount of energy it consumes. An inefficient motor can consume much more electricity than necessary, driving up operating costs. After rewinding, the motor’s energy usage will be reduced, resulting in long-term savings on electricity bills.

3. Environmental Benefits

By extending the life of an electric motor through rewinding, businesses can reduce waste and minimize the environmental impact associated with manufacturing and disposing of motors. Rewinding helps ensure that fewer motors need to be discarded and replaced, making it a more sustainable solution.

4. Better Performance and Reliability

Rewinding restores the motor to its full capacity, ensuring that it runs smoothly and consistently. Industrial operations rely on machinery that works without interruption, and rewinding helps keep motors in peak condition. This leads to greater reliability in production processes and improved overall productivity.

How Is Electric Motor Rewinding Done?

The rewinding process involves several steps, which are carried out by skilled technicians to ensure the motor is properly restored:

1. Disassembly and Inspection

The first step in rewinding is to disassemble the motor. This involves removing the motor’s outer casing, bearings, and other components. The windings are then inspected for damage. Any parts that are worn or damaged beyond repair are replaced.

2. Cleaning the Motor

Once the motor is disassembled, it is thoroughly cleaned to remove any dirt, debris, or dust that has accumulated over time. This helps ensure that there is no contamination that could interfere with the rewinding process.

3. Rewinding the Motor

The old windings are carefully removed, and new copper wire is wound into the motor’s stator and rotor. The technician ensures the new windings are properly insulated and positioned for optimal performance.

4. Testing the Motor

After the rewinding is complete, the motor is tested to ensure that it is functioning correctly. The technician will check for proper voltage, current, and resistance, as well as the motor’s ability to handle the required load.

5. Reassembly and Installation

Once the motor has passed all tests, it is reassembled and ready to be installed back into its industrial application.

When Should You Consider Electric Motor Rewinding?

It’s important to monitor your motors for signs of damage and wear to determine when rewinding may be necessary. Some common indicators that a motor might need rewinding include:

Decreased motor efficiency or performance

Excessive overheating

Unusual noises or vibrations

Frequent motor breakdowns or failures

If you notice any of these issues, it’s a good idea to consult a professional to assess whether rewinding could be a solution.

Conclusion

Electric motor rewinding is a vital process for ensuring the efficiency, performance, and longevity of motors used in industrial applications. By restoring damaged windings, this process can help prevent expensive replacements, reduce downtime, and improve overall motor performance. For industrial businesses, motor rewinding offers an affordable, sustainable, and effective solution to maintaining crucial equipment and keeping operations running smoothly.

0 notes