#tefugen

Explore tagged Tumblr posts

Text

Leading CFD Analysis and Consulting Services in India

TEFUGEN, a leading consulting service provider in Computational Fluid Dynamics (CFD), has secured a distinguished position among India's top CFD companies. With a focus on precision in simulations and delivering valuable insights, we have earned the trust of businesses seeking CFD expertise. This highlights the company's capabilities, emphasising its unwavering commitment to excellence and substantial contributions to the CFD landscape in India.

Mastery in CFD Simulation:

Our dedicated team of highly skilled engineers excel in conducting various CFD simulations, analysing complex flow patterns, optimising designs, and addressing any problem in Fluid Dynamics.

Demonstrated Success Stories:

Through impactful case studies and client projects, we manifest how our advanced simulations and tailor-made solutions directly contribute to improved designs, heightened performance, and cost-effective solutions across diverse industries.

Tailored Solutions Across Varied Industries:

TEFUGEN caters to a broad spectrum of industries, tailoring CFD solutions to unique requirements, from Aerodynamic analysis to Thermal simulations and beyond.

Sophisticated Tools and Techniques:

Equipped with state-of-the-art CFD software such as ANSYS and OpenFOAM, we ensure the highest accuracy and efficiency in simulations. We stay abreast of the latest advancements in technology to address complex challenges with precision, providing detailed technical reports.

Integration Method and Client Satisfaction:

Emphasising collaboration and client satisfaction, TEFUGEN actively involves clients in the simulation process, ensuring alignment with expectations and providing actionable insights. Our goal is to exceed expectations at every project stage.

By prioritising collaboration and client satisfaction, Tefugen ensures clients achieve optimal designs, improved performance, and cost-effective solutions. For more information, contact us at [email protected].

#cfd#computationalfluiddynamics#cfdduct#ductoptimization#cfdconsultingservices#cfdanalysisserviceprovider#bestcfdservice#tefugen#bestengineeringserviceprovider#tefugentechnologies#cfdoptimization#ductflowoptimization#oilandgas#powerplant#refineries#automobile#airtransport#transportation#processindustries#chemicalindustries#buildingsandstructures#cfdservicesinindia#cfdaerospace#cfdpowersector#cfdautomobile#cfdoilandgas#cfdhvac#cfdturbomachinery#cfdelectronics

0 notes

Text

#cfd#fea#cad#performancetesting#fes#manufacturing#tefugen#engineeringserviceprovider#engineeringsolutionprovider#cfdconsultingservice#cfdanalysisservice#feaconsultingservice#cfddraftingservice#boiler#cleanairflowtest#dirtyairflowtest#gasdistribution#coldairvelocitytest#airpreheater#performance#airandgasanalysis#testing#boilertesting#boileroptimization#powerproductionoptimizaion#boilercapacityoptimization#fluegastesting#fluegasflowoptimization#ductoptimization#boilerducttesting

0 notes

Text

How Does Odoo Support Business Growth and Scalability?

Odoo is an excellent ERP solution for businesses seeking growth and scalability. Here’s how it supports your journey:

1. Integrated Applications Odoo offers an extensive suite of integrated tools that cover all key business functions, fostering seamless collaboration and driving efficiency across the entire organization.

2. Customization Options The platform offers extensive customization to fit your specific workflows, adapting as your business evolves.

3. Automation Capabilities Automate repetitive tasks to increase efficiency, allowing your team to focus on strategic initiatives that drive growth.

4. Data-Driven Insights Odoo’s reporting and analytics tools provide valuable insights, empowering informed decision-making and identifying growth opportunities.

5. Scalability Odoo is designed to grow with your business, accommodating new users and functionalities seamlessly.

As a trusted provider of Odoo development services in India, TEFUGEN helps businesses customize and implement Odoo to maximize the company's potential."

Conclusion With Odoo, your business can thrive through integrated solutions, customization, and scalability. Contact TEFUGEN today to learn how we can support your growth!

#businessautomation#businessgrowth#cad#cfd#cfdconsultingservice#digitaltransformation#engineeringsolutionprovider#erosioncontroldevice#erpsolutions#fea#feaconsultingservice#odoo#odoocommunity#odoocustomization#odoodevelopment#odooerp#odooexperts#odooimplementation#odoopartner#odooservices#odoosolutions#odoosupport#odoointegration#powerplantperformancetesting#guidevanes#tubularaph#tefugentechnologies

0 notes

Text

How Does Odoo Support Business Growth and Scalability?

Odoo is an excellent ERP solution for businesses seeking growth and scalability. Here’s how it supports your journey:

1. Integrated Applications Odoo offers an extensive suite of integrated tools that cover all key business functions, fostering seamless collaboration and driving efficiency across the entire organization.

2. Customization Options The platform offers extensive customization to fit your specific workflows, adapting as your business evolves.

3. Automation Capabilities Automate repetitive tasks to increase efficiency, allowing your team to focus on strategic initiatives that drive growth.

4. Data-Driven Insights Odoo’s reporting and analytics tools provide valuable insights, empowering informed decision-making and identifying growth opportunities.

5. Scalability Odoo is designed to grow with your business, accommodating new users and functionalities seamlessly.

As a trusted provider of Odoo development services in India, TEFUGEN helps businesses customize and implement Odoo to maximize the company's potential."

Conclusion With Odoo, your business can thrive through integrated solutions, customization, and scalability. Contact TEFUGEN today to learn how we can support your growth!

#businessautomation#businessgrowth#cad#cfd#cfdconsultingservice#digitaltransformation#engineeringsolutionprovider#erosioncontroldevice#erpsolutions#fea#feaconsultingservice#odoo#odoocommunity#odoocustomization#odoodevelopment#odooerp#odooexperts#odooimplementation#odoopartner#odooservices#odoosolutions#odoosupport#odoointegration#powerplantperformancetesting#guidevanes#tubularaph#tefugentechnologies

0 notes

Text

How Does Odoo Support Business Growth and Scalability?

Odoo is an excellent ERP solution for businesses seeking growth and scalability. Here’s how it supports your journey:

1. Integrated Applications Odoo offers an extensive suite of integrated tools that cover all key business functions, fostering seamless collaboration and driving efficiency across the entire organization.

2. Customization Options The platform offers extensive customization to fit your specific workflows, adapting as your business evolves.

3. Automation Capabilities Automate repetitive tasks to increase efficiency, allowing your team to focus on strategic initiatives that drive growth.

4. Data-Driven Insights Odoo’s reporting and analytics tools provide valuable insights, empowering informed decision-making and identifying growth opportunities.

5. Scalability Odoo is designed to grow with your business, accommodating new users and functionalities seamlessly.

As a trusted provider of Odoo development services in India, TEFUGEN helps businesses customize and implement Odoo to maximize the company's potential."

Conclusion With Odoo, your business can thrive through integrated solutions, customization, and scalability. Contact TEFUGEN today to learn how we can support your growth!

0 notes

Text

Comprehensive Field Engineering Services for Power Plants

TEFUGEN's Field Engineering Services (FES) team offers comprehensive solutions for the Installation, Supervision, Maintenance, and Renovation of various Non-Pressure parts within Power plants. Our expertise spans across a wide range of services aiming towards improving the efficiency, reliability, and safety throughout the plant's lifecycle.

Supervision, Installation & Maintenance Services Offered:

• Boiler Air and Gas ducts • Guide vanes for flow distribution • Expanded Metal Screen (EMS) • Electrostatic precipitator (ESP) • Air Preheaters (APH) • TALCON® Seal for Rotary Air Preheater

Approach:

At TEFUGEN, we take a holistic approach ensuring that every aspect of Field Engineering Service is executed with precision and efficiency. Our team of experienced engineers work closely with clients to understand their specific requirements and develop customized solutions that meet their objectives and site specific safety norms.

Key Benefits:

• Reduced downtime and maintenance costs • Increased lifespan of spares & components • End to End Support for turnkey projects • Compliance with safety norms as per industry standards • Liaising with advanced engineering team towards plant efficiency improvement

Commitment to Excellence:

TEFUGEN continuously invests in the latest technologies and training to ensure that our team stays at the forefront of the industry. Our dedication to safety, quality, and customer satisfaction is reflected in every project we undertake.

Conclusion:

As a leading provider of Field Engineering Services, TEFUGEN is well-equipped to handle all your needs. Our comprehensive solutions, combined with our commitment to excellence, make us the ideal partner for power plant operators looking to optimize their operations and maximize their return on investment.

0 notes

Text

Comprehensive Field Engineering Services for Power Plants

TEFUGEN's Field Engineering Services (FES) team offers comprehensive solutions for the Installation, Supervision, Maintenance, and Renovation of various Non-Pressure parts within Power plants. Our expertise spans across a wide range of services aiming towards improving the efficiency, reliability, and safety throughout the plant's lifecycle.

Supervision, Installation & Maintenance Services Offered:

• Boiler Air and Gas ducts • Guide vanes for flow distribution • Expanded Metal Screen (EMS) • Electrostatic precipitator (ESP) • Air Preheaters (APH) • TALCON® Seal for Rotary Air Preheater

Approach:

At TEFUGEN, we take a holistic approach ensuring that every aspect of Field Engineering Service is executed with precision and efficiency. Our team of experienced engineers work closely with clients to understand their specific requirements and develop customized solutions that meet their objectives and site specific safety norms.

Key Benefits:

• Reduced downtime and maintenance costs • Increased lifespan of spares & components • End to End Support for turnkey projects • Compliance with safety norms as per industry standards • Liaising with advanced engineering team towards plant efficiency improvement

Commitment to Excellence:

TEFUGEN continuously invests in the latest technologies and training to ensure that our team stays at the forefront of the industry. Our dedication to safety, quality, and customer satisfaction is reflected in every project we undertake.

Conclusion:

As a leading provider of Field Engineering Services, TEFUGEN is well-equipped to handle all your needs. Our comprehensive solutions, combined with our commitment to excellence, make us the ideal partner for power plant operators looking to optimize their operations and maximize their return on investment.

0 notes

Text

Comprehensive Field Engineering Services for Power Plants

TEFUGEN's Field Engineering Services (FES) team offers comprehensive solutions for the Installation, Supervision, Maintenance, and Renovation of various Non-Pressure parts within Power plants. Our expertise spans across a wide range of services aiming towards improving the efficiency, reliability, and safety throughout the plant's lifecycle.

Supervision, Installation & Maintenance Services Offered:

• Boiler Air and Gas ducts • Guide vanes for flow distribution • Expanded Metal Screen (EMS) • Electrostatic precipitator (ESP) • Air Preheaters (APH) • TALCON® Seal for Rotary Air Preheater

Approach:

At TEFUGEN, we take a holistic approach ensuring that every aspect of Field Engineering Service is executed with precision and efficiency. Our team of experienced engineers work closely with clients to understand their specific requirements and develop customized solutions that meet their objectives and site specific safety norms.

Key Benefits:

• Reduced downtime and maintenance costs • Increased lifespan of spares & components • End to End Support for turnkey projects • Compliance with safety norms as per industry standards • Liaising with advanced engineering team towards plant efficiency improvement

Commitment to Excellence:

TEFUGEN continuously invests in the latest technologies and training to ensure that our team stays at the forefront of the industry. Our dedication to safety, quality, and customer satisfaction is reflected in every project we undertake.

Conclusion:

As a leading provider of Field Engineering Services, TEFUGEN is well-equipped to handle all your needs. Our comprehensive solutions, combined with our commitment to excellence, make us the ideal partner for power plant operators looking to optimize their operations and maximize their return on investment.

#fieldengineeringservices #fesserviceproviders #fesconsultants #fesconsultingfirmsindia #fieldengineeringservicesinindia #installation #retrofitting #overhauling #siteengineeringservices #fieldengineeringservicesprovidersinindia #fesconsultantsandconsultingfirmsinindia #topfieldengineeringservicesproviderintiruchirappalli #TEFUGENfesservices #fieldengineeringservicesforpowerplants

0 notes

Text

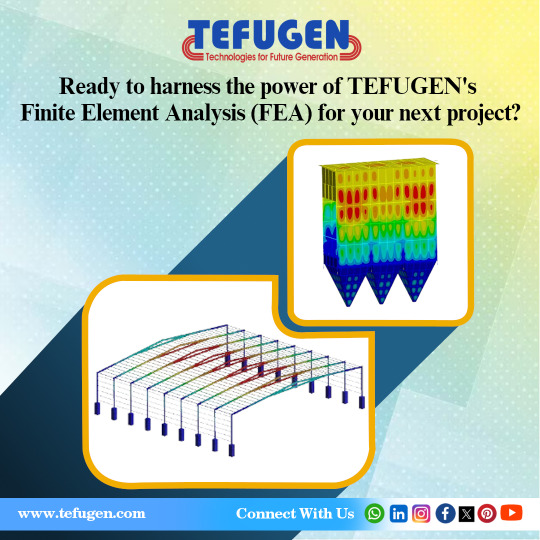

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

0 notes

Text

TEFUGEN: Redefining Engineering Excellence through Finite Element Analysis

WHY USE FEA IN YOUR ENGINEERING PROJECTS?

At the forefront of engineering excellence, TEFUGEN offers exceptional Finite Element Analysis (FEA) services in India. Utilizing FEA yields unparalleled benefits, offering profound insights into your project's performance prior to physical model construction. It aids in pinpointing stress points, identifying potential weaknesses, and assessing material durability under diverse conditions, effectively mitigating the risk of failure and associated costs. With its ability to conduct precise simulations, FEA empowers informed decision-making in design modifications, guaranteeing optimal performance and safety.

Structural Integrity Assessment:

In engineering, FEA, an indispensable method, meticulously assesses structural integrity by simulating material responses to diverse conditions. This predictive analysis is pivotal for guaranteeing the safety and reliability of designs. TEFUGEN, as a FEA consulting service in India, provides expert assistance, enabling engineers to identify potential weaknesses and optimize for durability.

Thermal stress analysis:

FEA analysis services play a key role in assessing heat distribution within structures or components. Engineers leverage this analysis to model and analyze thermal behavior meticulously. By doing so, they optimize designs for efficient heat dissipation or retention, ensuring the performance and reliability of the system. This detailed analysis enables engineers to make informed decisions regarding material selection, insulation, or heat management strategies, ultimately enhancing overall system efficiency and longevity.

Mechanical Component Design:

FE Analysis plays a crucial role in optimizing mechanical component design by accurately predicting stress, strain, and deformation. This ensures components can effectively withstand operational loads while minimizing material usage, thereby enhancing efficiency and cost-effectiveness.

Fatigue Analysis:

Engineers use FEA for fatigue analysis, predicting the lifespan of components subjected to cyclic loading. This is crucial in industries like aerospace and automotive, where understanding material fatigue is paramount.

Fluid Structure Interaction:

Fluid Structure Interaction (FSI) is a crucial aspect of FE Analysis, examining the dynamic interaction between fluids and structures. By simulating how fluids affect nearby structures and vice versa, FSI enables engineers to optimize designs for enhanced performance and durability across various industries.

Modal analysis Modal analysis using FEA techniques enables the simulation of eigenfrequencies and eigenmodes, revealing the vibrational characteristics of a structure. Meanwhile, harmonic analysis facilitates the emulation of peak responses to specific loads, offering insights into system behavior. These analyses are indispensable tools for understanding structural dynamics and optimizing performance.

Motion study Unlocking insights into structural behavior through Finite Element Analysis (FEA) motion studies. Discover the intricate dynamics of systems, optimize designs, and ensure structural resilience with FEA motion analysis.

#Finite Element Analysis Consulting Services in India#FEA Analysis Services#FEA Consulting Engineers#FEA Consultants in Trichy#FEA#Finite Element Method#Structural Analysis#Stress Analysis#Static Analysis#Dynamic Analysis#Thermal Analysis#Fluid Flow Analysis#Vibration Analysis#Fatigue Analysis#Buckling Analysis#Modal Analysis#Meshing#Boundary Conditions#Material Properties#Convergence#Post-processing#Optimisation#Mesh Generation#Simulation Software

0 notes

Text

Power Plant Performance Testing - TEFUGEN

0 notes

Text

Top Performance Testing for Power Plants - Tefugen

Introduction:

Performance Testing ensures that the plant operates according to its intended functionality and guaranteed parameters. It maximizes plant efficiency, reduces emissions, and minimizes operating costs by identifying any inefficiencies or capacity limitations and providing recommendations for recovery and performance improvement.

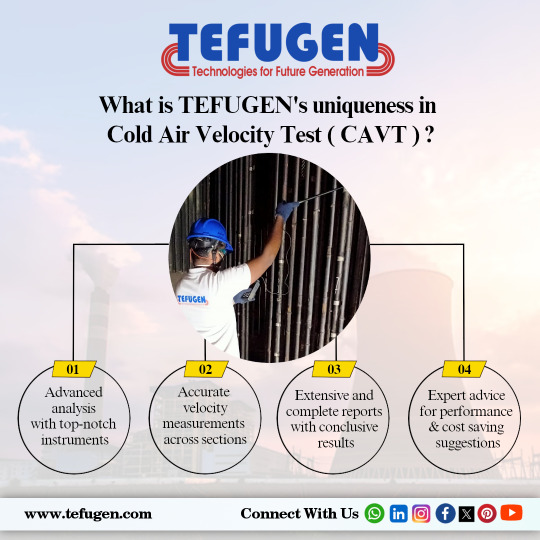

Cold Air Velocity Test (CAVT):

In boilers, the flue gas flow pattern in the second pass may lack uniformity due to combustion behavior, fouling tendencies, and configurations such as Gooseneck. This non-uniformity leads to uneven heat transfer in tube bundles and erosion of tube bundles in high-velocity zones. CAVT is conducted to assess the flue gas flow pattern by mapping the velocities measured across the top planes of different crosssections in the Boiler's second pass and the coefficient of variation (COV) in velocity is calculated to access the condition of the flow pattern.

Clean Air Flow Test (CAFT):

CAFT is performed as per the ASME-PTC 4.2 standard and it is performed in Coal Pulverizers outlet coal pipes by supplying only air as medium. In a variable orifice system, the velocity deviation among the pulverizers outlet coal pipes will be determined and an adjustment will be done in the orifice to restrict the deviations to the allowable limit. In a fixed orifice system, it ensures the correct orifice sizes are installed.

Dirty Air Flow Test (DAFT) and Iso Kinetic Sampling:

DAFT is carried out in Coal Pulverizers outlet coal pipes by following the ASME-PTC 4.2 standard in the presence of coal & air mixture inside the coal pipes.This test ensures the correct orifice sizes are installed in the case of a fixed orifice system. In the case of a variable orifice system, the velocity deviation among the pulverizer outlet coal pipes will be measured and an adjustment will be made to ensure the velocity deviations are within the allowable limit. Iso Kinetic Sampling systematically analyzes coal fineness.

Air and Gas Flow Test:

This testing measures the flow and velocity profiles in various streams of the boiler's air and gas circuits. Evaluating velocity profiles and pressure drops at different locations will show the current condition of the flow. Corrections can be made using CFD analysis to equalize flow and enhance system performance.

Air Pre Heater (APH) Performance Test:

APH performance testing, following the ASME-PTC 4.3 standard. Air leakage, pressure drop, temperature rise in air and temperature drop in flue gas will be identified. This test reveals the current condition of the APH which includes choking, seal surface clearances, and the effectiveness of the sealing system.

Flue Gas Analysis Test (NOx & SOx):

This test assesses the levels of oxides of nitrogen (NOx) and oxides of sulfur (SOx) emissions resulting from coal combustion. It ensures compliance with emission norms by evaluating the conversion of bound nitrogen and sulfur in coal.

Gas Distribution (GD) Test:

GD test is conducted as per the ICAC-EP-7 standard in electrostatic precipitator (ESP) to ensure uniform flow distribution across the ESP's cross-section. Over time, operating the boiler may disturb or erode guide vanes, flow splitters, etc., resulting in non-uniform flow distribution and increased emissions. The flow pattern will be assessed by calculating the coefficient of variation (COV) in velocity.

0 notes

Text

How does the Tubular Air Preheaters contribute to energy efficiency in Power sector?

Introduction:

In the realm of industrial heating, efficiency is key to both cost savings and environmental sustainability. Tubular Air Preheaters (TAPH), offering a range of benefits that significantly enhance the performance of heating systems. At the forefront of this technological advancement is TEFUGEN, a trusted provider delivering top-notch Tubular APH solutions.

Understanding Tubular Air Preheaters:

Before delving into their impact on performance, it's crucial to understand the fundamentals of Tubular APH. These heat exchangers are designed to recover heat from flue gases, preheating combustion air and boosting overall thermal efficiency.

Increased Energy Efficiency:

One of the primary advantages of Tubular APH is their ability to improve energy efficiency. By harnessing waste heat from flue gases, these preheaters elevate the temperature of incoming combustion air, reducing the workload on the Combustion chamber and subsequently lowering fuel consumption.

Enhanced Combustion:

The preheating of combustion air ensures a more consistent and optimal temperature for the combustion process. This, in turn, leads to improved flame stability, better control over combustion parameters, and ultimately, enhanced system performance.

Reduced Environmental Impact:

Tubular APH solutions contribute to environmental sustainability by minimizing greenhouse gas emissions. The efficient utilization of waste heat not only conserves energy but also aligns with eco-friendly practices, making it a win-win for both businesses and the planet.

TEFUGEN's Commitment to Excellence:

Amidst the myriad choices in the market, we stand out as a reliable provider of Tubular APH products. With a focus on quality, innovation, and customer satisfaction, we ensure that our Tubular APH solutions are tailored to meet the unique needs of diverse industries.

Customized Solutions for Varied Applications:

We take pride in offering Tubular APH solutions that are not one-size-fits-all. The company understands that different industries have distinct requirements, and therefore, provides customized products to optimize the performance of heating systems across various applications.

Conclusion:

The integration of Tubular Air Preheaters into heating systems is a strategic move toward achieving higher efficiency, reducing operational costs, and contributing to a greener future. With our commitment to excellence, businesses can trust in the reliability and effectiveness of their Tubular APH products for an optimized heating experience.

0 notes

Text

Elevate Your Designs with Best-in-Class CAD Services

Introduction:

In the fast-paced world of manufacturing and design, precision and efficiency are paramount. Tefugen stands as a beacon of excellence, providing unparalleled CAD services that redefine product development. With a keen eye on innovation and a commitment to excellence, we set the standard for CAD solutions.

Increased Efficiency with Work:

CAD services revolutionize design efficiency. By harnessing the power of cutting-edge CAD software, designers are empowered to fine-tune and optimize product designs with remarkable precision and speed. This not only saves time but also minimizes the margin for error, resulting in a more efficient and productive product development process.

Comprehensive Service:

As product designs continue to evolve in complexity, CAD software offers a comprehensive suite of tools to manage intricate details, assemblies, and precise measurements. This ensures that the resulting products are not only innovative but also entirely feasible for production.

Shorter Lead Time/Save Time:

Time is of the essence in today's dynamic market. CAD services streamline the design process, making it easier to meet tight deadlines without compromising on quality. This agility in design helps clients stay ahead of the curve and seize opportunities swiftly.

Improved Accuracy of Design:

Collaboration is at the heart of every successful design. CAD software facilitates seamless teamwork, allowing for real-time feedback and adjustments. This ensures that all stakeholders are aligned, leading to a more cohesive and successful end product.

Better Design Can Be Evolved:

The iterative nature of design is at the core of Tefugen's philosophy. With CAD services that allow for easy modifications and refinements, designs are enabled to evolve and reach their full potential. This commitment to continuous improvement ensures that the end product is nothing short of exceptional.

Conclusion:

CAD services are a testament to the dedication to excellence in product development. With an unwavering focus on precision, efficiency, and sustainability, Tefugen is poised to take your designs to new heights. Partner with us to experience the pinnacle of CAD services and unlock a world of design possibilities.

1 note

·

View note

Text

Exploring Tefugen's FEA Capabilities: Harnessing Advanced Analysis Techniques

FEA is a computer application that uses numerical techniques to assess systems and structures. When subjected to thermal and structural loads, it accurately predicts how components will react. Instead of needing to construct the actual component, using a virtual computer-based model makes it easier to check the design and integrity of a component and pinpoint important areas for development. TEFUGEN offers exceptional FEA analysis and consultancy services to help with simulation-based structural and thermal evaluation of mechanical systems.

In the field of engineering design, Finite Element Analysis (FEA) has developed into a highly promising computer-aided engineering technique for modeling and analyzing structures with complex geometries and changeable material properties. It is commonly used during the design phase of a range of engineering fields, such as automotive, aerospace, power plants, and production engineering, to optimize products that increase performance.

Advantages of FEA:

Minimize the product development cost

Reduce the product lead time into the market

Accurately predict components response to load

Unlimited level of detail in the system

Analyze difficult & dangerous experiments

Easy repeatability of simulation

Linear Analysis:

The branch of FEA known as linear static analysis is most typically used to evaluate the structural and thermal performance of mechanical structures. The applied forces and displacements have a linear connection in linear static analysis. Actually, where stresses remain within the material's linear elastic range, this is relevant to all structural components. In a linear static analysis, the model's stiffness matrix is constant, and the solving time is quicker than in a nonlinear analysis of the identical model. In order to obtain an initial estimate, linear static analysis is usually used before performing a full nonlinear analysis.

Static stress analysis is likely the most common type of structural analysis using the FE technique. Stress, strain, and deformation of a component or assembly can be assessed under various load scenarios to avoid expensive failures during the design stage.

Typically, structural loads consist of one or more of the following:

Outside forces, like the clamping force in subsea connectors.

Surface loads, such as the pressure inside pressure vessels

Body pressures (gravity, acceleration such as centrifugal force in rotating machines)

Dynamic Analysis :

The phrase "dynamic FEA" describes a number of dynamic simulation methods that can be used to analyze even complicated engineering systems. Dynamic analysis is used to design and analyze potential noise and vibration issues as well as to assess the effects of transient loads. As seasoned development engineers, we rarely end our involvement in a dynamic assessment with the analytical output. We frequently collaborate with customers to identify creative solutions that are practical and beneficial from a business standpoint.

Thermal Analysis :

Thermal analysis and FEA can be used to solve heat transmission in or between solids. Convection, conduction, and radiation are a few examples of heat transport mechanisms that can be calculated. However, the analyst directly estimates convection and radiation, not the FEA software. Heat transfer analysis with FEA is normally carried out when the heat convection coefficient can be assumed to be constant along the surface of the part or when the value is precisely known. FEA-based heat transfer analysis can also be used to determine structural stresses brought on by temperature gradients in the component, including thermal expansion.

Buckling Analysis:

By the use of buckling analysis, a structure's stability under compressive loading conditions is evaluated. To verify the stability of the construction, a weight-lifting device will need to be used under compressive loads. The kind of buckling analysis employed in FE analysis is called linear buckling analysis. A static structural study must be followed by a linear buckling analysis. The results of a linear buckling analysis are buckling load factors, which are scales of the loads employed in the static structural analysis. The structure will buckle when the aforementioned level of static loading is attained, according to the simulation's results. There are countless buckling load elements that might affect a building. Every load factor has a distinct instability pattern associated with it, similar to modal analysis. The bulk of us, however, are focused on the load factor that is the lowest.

Fatigue Analysis :

A fatigue analysis is used to determine if a structure would fail after a specific number of repeated loading and unloading, or "load cycles," as opposed to replicating one load cycle as in a static analysis.

0 notes

Text

Exploring Tefugen's FEA Capabilities: Harnessing Advanced Analysis Techniques

FEA is a computer application that uses numerical techniques to assess systems and structures. When subjected to thermal and structural loads, it accurately predicts how components will react. Instead of needing to construct the actual component, using a virtual computer-based model makes it easier to check the design and integrity of a component and pinpoint important areas for development. TEFUGEN offers exceptional FEA analysis and consultancy services to help with simulation-based structural and thermal evaluation of mechanical systems.

In the field of engineering design, Finite Element Analysis (FEA) has developed into a highly promising computer-aided engineering technique for modeling and analyzing structures with complex geometries and changeable material properties. It is commonly used during the design phase of a range of engineering fields, such as automotive, aerospace, power plants, and production engineering, to optimize products that increase performance.

Advantages of FEA:

Minimize the product development cost

Reduce the product lead time into the market

Accurately predict components response to load

Unlimited level of detail in the system

Analyze difficult & dangerous experiments

Easy repeatability of simulation

Linear Analysis:

The branch of FEA known as linear static analysis is most typically used to evaluate the structural and thermal performance of mechanical structures. The applied forces and displacements have a linear connection in linear static analysis. Actually, where stresses remain within the material's linear elastic range, this is relevant to all structural components. In a linear static analysis, the model's stiffness matrix is constant, and the solving time is quicker than in a nonlinear analysis of the identical model. In order to obtain an initial estimate, linear static analysis is usually used before performing a full nonlinear analysis.

Static stress analysis is likely the most common type of structural analysis using the FE technique. Stress, strain, and deformation of a component or assembly can be assessed under various load scenarios to avoid expensive failures during the design stage.

Typically, structural loads consist of one or more of the following:

Outside forces, like the clamping force in subsea connectors.

Surface loads, such as the pressure inside pressure vessels

Body pressures (gravity, acceleration such as centrifugal force in rotating machines)

Dynamic Analysis :

The phrase "dynamic FEA" describes a number of dynamic simulation methods that can be used to analyze even complicated engineering systems. Dynamic analysis is used to design and analyze potential noise and vibration issues as well as to assess the effects of transient loads. As seasoned development engineers, we rarely end our involvement in a dynamic assessment with the analytical output. We frequently collaborate with customers to identify creative solutions that are practical and beneficial from a business standpoint.

Thermal Analysis :

Thermal analysis and FEA can be used to solve heat transmission in or between solids. Convection, conduction, and radiation are a few examples of heat transport mechanisms that can be calculated. However, the analyst directly estimates convection and radiation, not the FEA software. Heat transfer analysis with FEA is normally carried out when the heat convection coefficient can be assumed to be constant along the surface of the part or when the value is precisely known. FEA-based heat transfer analysis can also be used to determine structural stresses brought on by temperature gradients in the component, including thermal expansion.

Buckling Analysis:

By the use of buckling analysis, a structure's stability under compressive loading conditions is evaluated. To verify the stability of the construction, a weight-lifting device will need to be used under compressive loads. The kind of buckling analysis employed in FE analysis is called linear buckling analysis. A static structural study must be followed by a linear buckling analysis. The results of a linear buckling analysis are buckling load factors, which are scales of the loads employed in the static structural analysis. The structure will buckle when the aforementioned level of static loading is attained, according to the simulation's results. There are countless buckling load elements that might affect a building. Every load factor has a distinct instability pattern associated with it, similar to modal analysis. The bulk of us, however, are focused on the load factor that is the lowest.

Fatigue Analysis :

A fatigue analysis is used to determine if a structure would fail after a specific number of repeated loading and unloading, or "load cycles," as opposed to replicating one load cycle as in a static analysis.

0 notes