#supplier of quartz sand

Explore tagged Tumblr posts

Text

High-Quality Talc Powder Supplier for Industrial and Specialized Applications

Pratibha Refractory Minerals is a trusted Supplier of Talc Powder in India, offering premium-grade talc powder that meets the highest industry standards. With a commitment to quality, we source talc from the finest mines, ensuring purity and consistency in every batch. Our talc powder is widely used in various industries, including cosmetics, ceramics, plastics, and pharmaceuticals, providing superior performance and reliability. At Pratibha Refractory Minerals, we focus on customer satisfaction, delivering products that meet specific requirements. Whether you need talc powder for industrial applications or specialized uses, we are your reliable partner for all talc powder needs. Trust us for excellence and quality.

#talc#manufacturer#indonesia#exporter#supplier#supplier of dolomite#kaolin#supplier of quartz sand#dolomite

0 notes

Text

Raj Global Ramming Mass (RGR) is a reliable manufacturer and supplier of Silica Ramming Mass sourced from Rajasthan, India. As a crucial component of our mini conglomerate, RGR, along with our affiliated companies, offers a comprehensive package encompassing mining, processing, and marketing. Our integrated approach guarantees steady quality and enhances the performance of our products. Our track record of reliability makes us the trusted choice for high-quality ramming mass.

#White Ramming Mass Manufacturer#Premixed Ramming Mass Supplier#.SILICA RAMMING MASS#ACIDIC RAMMING MASS#NOZZLE FILLING COMPOUND#QUARTZ LUMPS#QUARTZITE LUMPS#BOILER SAND#SILICA SAND

0 notes

Text

Discover the Top AAC Block Dealers in Pune

Discover the Top AAC Block Dealers in Pune.

When embarking on construction projects, the choice of building materials is pivotal. Among the diverse options available, AAC (Autoclaved Aerated Concrete) blocks stand out for their exceptional qualities. These blocks are fire and pest resistant, and they surpass traditional materials like concrete, wood, brick, and stone in terms of economic and environmental benefits. Evergreen Enterprises, a leading manufacturer and supplier of AAC blocks in Pune, exemplifies the superior quality and sustainability of these materials. In Pune, several AAC block dealers, including Evergreen Enterprises, offer top-quality products that cater to various construction needs. This blog delves into the premier AAC block dealers in the area, focusing on their offerings and the advantages of choosing AAC blocks.

The Superiority of AAC Blocks

Before we explore the leading dealers, it’s essential to understand why AAC blocks are increasingly favored in construction. AAC blocks are known for their light weight, which reduces the overall dead load of a structure. They offer excellent thermal insulation, ensuring energy efficiency in buildings by maintaining indoor temperatures. Moreover, AAC blocks are highly durable, providing long-term structural stability with minimal maintenance.

From an environmental perspective, AAC blocks are manufactured using fly ash, a byproduct of coal combustion, thus recycling waste material. Their production process emits fewer greenhouse gases compared to traditional building materials, making them a sustainable choice.

Evergreen Enterprises

Overview: As renowned AAC block manufacturers in Pune, we at Evergreen Enterprises Productions are renowned for producing AAC blocks using premium materials. Additionally, we are a top supplier, manufacturer, and dealer of AAC blocks. For building needs, we provide a large selection of AAC blocks. You can use our AAC blocks for exterior and interior construction. For side walls, these AAC blocks are utilized. The greatest quality concrete was used to create the AAC block. We provide these AAC blocks of the greatest quality at affordable costs, with prompt delivery. Therefore, we are recognized in the industry as a leading supplier and manufacturer of AAC blocks. Because we employ rounded, sanded materials, our AAC blocks are lightweight and easy to install. High-rise structures with significant temperature fluctuations can use these AAC blocks. Few steel, concrete, and other building supplies are needed to construct the walls in our AAC block. We use sand, quartz sand, water, calcined gypsum, lime (mineral), or cement to make AAC blocks. SIZE �� 3X8X24, 4X8X24, 5X8X24, 6X8X24, 8X8X24, ALL SIZES AVAILABLE

COLOUR- GREY

Key Features:

Require less Materials

Light Weight

Quick and Easy Installation

Costs Saving

Used for Interior and Exterior Constructions

High Thermal Efficiency

Other Specifications:

Color: Gray

Sizes: 12 In. X 4 In. X 2 In.

Shape: Rectangular

Materials Used: sand, quartz sand, calcined gypsum, lime (mineral) or cement and water

Why Choose AAC Blocks?

Choosing AAC blocks for your construction projects in Pune, offers several advantages:

Fire and Pest Resistance: AAC blocks are non-combustible and highly resistant to pests, enhancing the safety and longevity of structures.

Economic Efficiency: These blocks are lightweight, reducing the transportation and handling costs. They also cut down on the structural load, leading to savings in steel and concrete usage.

Environmental Benefits: AAC blocks are made from recycled materials and have a lower environmental footprint compared to traditional building materials. Their production emits fewer pollutants, aligning with sustainable construction practices.

Thermal Insulation: AAC blocks provide excellent thermal insulation, which helps in reducing heating and cooling costs in buildings.

Conclusion

For those in Pune, looking to source AAC blocks, Evergreen Enterprises and the other mentioned dealers provide excellent options. These dealers not only offer top-quality products but also contribute to sustainable and efficient building practices. By choosing AAC blocks, you ensure that your construction projects are safer, more durable, and environmentally friendly. Whether you are a builder, contractor, or individual embarking on a construction project, these dealers in Pune, are your go-to for all your AAC block needs.

0 notes

Text

Metal Disc Filters, Metal Disc Filter Manufacturer, Supplier, India

Metal Disc Filters : We are Metal Disc Filter Manufacturer, Metal Disc Filter Supplier, Sangli, Maharashtra, India.

Filter System, Filter Systems, Screen Filter, Screen Filters, Metal Disc Filter, Metal Disc Filters, Gravel Filter, Gravel Filters, Media Filter, Media Filters, Fertilizer Tank, Fertilizer Tanks, Hydrocyclone Filter, Hydrocyclone Filters, Drip Irrigation Filter, Drip Irrigation Filters, Micro Irrigation Filter, Micro Irrigation Filters, Allied Agro Equipment, Allied Agro Equipments, Drip Filter Spare, Drip Filter Spares, Quartz Sand, Quartz Sands, Plastic Screen Filter, Plastic Screen Filters, Micro Irrigation Filter System, Micro Irrigation Filter Systems, Metal Screen Filter, Metal Screen Filters, Sand Filter, Sand Filters, Fertigation System, Fertigation Systems, Hydro Cyclone, Hydro Cyclones, Manufacturer, Sangli, Maharashtra, India.

0 notes

Text

crystal quartz singing bowls : beautiful addition to any meditation or sound healing practice

Crystal quartz singing bowls are a unique type of musical instrument known for their pure, resonant sound. They are crafted from pure quartz crystal and are believed to have various healing properties. Here's what you need to know about them:

Composition: Crystal quartz singing bowls are made from 99.8% silicon quartz and sand, heated to about 4000 degrees in a process that removes most impurities .

Appearance: They come in clear or frosted varieties and in sizes ranging from 5 to 24 inches. Clear bowls are lighter and can be played while being held in hand .

Sound: These bowls produce a vibrational sound that is thought to resonate with the body's chakras. They are used in sound therapy and meditation to promote relaxation and healing .

Healing Properties: Crystal quartz singing bowls are believed to help balance the body's energy centers, support an improved state of consciousness, and promote physical and mental well-being .

Usage: They are played by gently tapping the outer rim and then gliding a mallet around the rim to produce a sustained ringing sound .

Choosing a Bowl: Consider the size, tone, and color of the bowl. It's important to choose a bowl that resonates with you personally .

Care: Crystal quartz singing bowls should be handled with care to avoid damage. They should be cleaned gently with a soft cloth and stored in a protective case when not in use .

Purchase: When purchasing crystal quartz singing bowls, ensure you are buying from a reputable supplier to guarantee quality and authenticity .

Crystal quartz singing bowls are a beautiful addition to any meditation or sound healing practice, and they can also serve as a decorative piece when not in use. Their ethereal tones and potential healing properties make them a sought-after tool for spiritual and personal growth.

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

The Allure of Soapstone Kitchen Countertops: A Comprehensive Guide

In the quest for the perfect kitchen countertop, soapstone has emerged as a popular choice for homeowners seeking a blend of elegance, durability, and low maintenance. With its unique characteristics and timeless appeal, soapstone countertops offer a distinctive alternative to more common materials like granite or quartz. If you’re considering soapstone for your kitchen renovation, here’s everything you need to know about its benefits, installation, and maintenance.

What is Soapstone?

Soapstone is a metamorphic rock primarily composed of talc, chlorite, pyroxenes, and carbonates. Its name is derived from its soapy feel, which comes from the high talc content. Soapstone is known for its smooth texture and rich, often veined appearance, which can range from light grays and blues to deep greens and browns.

Benefits of Soapstone Kitchen Countertops

Aesthetic Appeal

Soapstone’s unique visual characteristics make it a standout choice for kitchen countertops. Its natural veining and varied color palette create a sophisticated look that adds warmth and character to any kitchen. The stone’s subtle, muted tones can complement a range of kitchen designs, from modern to rustic.

Durability

One of soapstone’s key advantages is its durability. It is a dense, non-porous material that resists scratches, stains, and heat. This makes it ideal for the high-traffic environment of a kitchen. While it’s not completely impervious to damage, it can withstand daily use without significant wear.

Low Maintenance

Unlike some other countertop materials, soapstone requires minimal maintenance. Its non-porous surface doesn’t need to be sealed regularly, unlike granite or marble. A simple routine of cleaning with mild soap and water is usually sufficient to keep it looking its best. Additionally, soapstone’s ability to withstand heat means you can place hot pots and pans directly on the surface without worrying about damage.

Aging Gracefully

Soapstone develops a patina over time, which many homeowners find appealing. This natural aging process enhances the stone’s character, giving it a unique, lived-in look. The patina can range from a slight darkening to more pronounced color changes, depending on the level of use and exposure.

Considerations Before Installing Soapstone Countertops

Cost

Soapstone can be more expensive than some other countertop materials, such as laminate or tile. The cost varies based on the stone’s quality, color, and origin, as well as the complexity of the installation. It’s essential to factor in both the material and installation costs when budgeting for your project.

Softness

While soapstone is durable, it is softer than granite or quartz, which makes it more susceptible to scratches and dents. However, many homeowners appreciate that minor scratches can be easily sanded out or blended into the stone’s surface.

Color Variations

Soapstone’s natural color variations can be both a blessing and a challenge. While the variations add beauty and uniqueness, they can also mean that the stone’s appearance may not be entirely uniform. It’s important to view samples or slabs in person and discuss your preferences with your supplier.

Installation Process

Choosing a Supplier

Start by selecting a reputable supplier who specializes in soapstone. They can provide you with various slabs to choose from and offer guidance on color selection and matching. Ensure that the supplier has experience in handling and installing soapstone to avoid any potential issues.

Template and Fabrication

Once you’ve selected your soapstone, a professional will take precise measurements of your kitchen to create a template for the countertop. The soapstone will then be cut and fabricated according to your specifications. During this process, you can also choose edge profiles and other custom features.

Installation

Soapstone countertops are typically installed by experienced professionals. The installation involves securing the countertops in place and ensuring that seams and joints are properly aligned. The stone’s natural density and weight can make it challenging to handle, so professional installation is recommended to achieve a flawless finish.

Maintaining Your Soapstone Countertops

Regular Cleaning

Keep your soapstone countertops clean by wiping them down with a damp cloth and mild soap. Avoid harsh chemicals or abrasive cleaners that can damage the stone’s surface.

Dealing with Stains

While soapstone is resistant to most stains, oils and acidic substances can sometimes cause discoloration. For stubborn stains, use a mixture of baking soda and water to gently scrub the affected area. Always rinse and dry thoroughly after cleaning.

Enhancing the Patina

If you prefer a darker patina, you can apply mineral oil periodically to the surface. This will accentuate the stone’s natural color and help maintain its appearance.

0 notes

Text

Fused Silica Prices Trend | Pricing | Database | Index | News | Chart

Fused Silica Prices, also known as fused quartz, is a high-purity, non-crystalline form of silicon dioxide that finds applications across various industries due to its unique properties such as high thermal resistance, low thermal expansion, and excellent optical clarity. The pricing of fused silica can be influenced by several factors, including production methods, raw material costs, and market demand. Fused silica is produced through the melting of high-purity quartz sand in an electric furnace, and its production process is complex and energy-intensive, which significantly impacts its cost. The global market for fused silica is influenced by supply and demand dynamics, technological advancements, and fluctuations in the cost of raw materials. In recent years, the demand for fused silica has been driven by its use in the semiconductor industry, solar panel production, and high-precision optics, all of which require materials with exceptional purity and performance characteristics.

The semiconductor industry, in particular, is a major consumer of fused silica due to its use in photomasks and other high-precision components. As technology continues to advance and the demand for more sophisticated electronic devices grows, the need for high-quality fused silica also rises. Similarly, the expansion of the solar energy sector has contributed to increased demand for fused silica, as it is used in the production of photovoltaic cells and other solar panel components. This rising demand can lead to price increases, especially when production capacity struggles to keep pace with market needs.

Get Real Time Prices for Fused Silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591Another factor affecting fused silica prices is the cost of raw materials and energy. The production of fused silica requires high-quality quartz sand and significant amounts of electricity, both of which can be subject to price volatility. Changes in the cost of these inputs can directly impact the final price of fused silica. For instance, if there is a rise in the price of electricity or a shortage of high-purity quartz sand, manufacturers may need to adjust their prices to maintain profitability. Moreover, environmental regulations and policies aimed at reducing carbon emissions can influence production costs and, consequently, the pricing of fused silica.

Technological advancements in the production of fused silica can also affect pricing. Innovations that improve production efficiency or reduce energy consumption can lead to lower costs and more competitive prices. Conversely, the need for more advanced production techniques or equipment can drive up costs if these technologies are not widely adopted. The balance between these factors can result in fluctuating prices for fused silica, making it essential for buyers and suppliers to stay informed about industry trends and market conditions.

Market dynamics play a significant role in shaping fused silica prices. The interaction between supply and demand often dictates price levels, with periods of high demand potentially leading to price increases if supply cannot keep up. Conversely, if there is an oversupply or reduced demand, prices may stabilize or even decrease. Seasonal variations, economic conditions, and global events can also impact market dynamics and, consequently, the pricing of fused silica.

The global nature of the fused silica market means that prices can vary by region. Different regions may experience varying levels of demand, production costs, and availability of raw materials, which can lead to regional price differences. For instance, regions with abundant quartz sand and lower energy costs may see lower prices for fused silica compared to areas where these resources are more expensive. Additionally, trade policies and tariffs can influence regional pricing by affecting the cost of importing or exporting fused silica.

In conclusion, the pricing of fused silica is a multifaceted issue influenced by production methods, raw material costs, market demand, and technological advancements. As the demand for high-quality fused silica continues to grow in industries such as semiconductors and solar energy, prices may experience fluctuations based on supply and demand dynamics. Buyers and suppliers should remain aware of these factors to navigate the market effectively and make informed decisions regarding the procurement and pricing of fused silica.

Get Real Time Prices for Fused Silica: https://www.chemanalyst.com/Pricing-data/fused-silica-1591

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Fused Silica#Fused Silica Prices#Fused Silica Price#Fused Silica News#Fused Silica Monitor#Fused Silica Market

0 notes

Text

Top Talc Powder Exporter in India - Pratibha Refractory Minerals, premium quality

When it comes to high-quality talc powder, Pratibha Refractory Minerals stands out as the leading Talc powder exporter in India . With a reputation built on excellence and reliability, we pride ourselves on delivering top-tier talc powder that meets the diverse needs of various industries.

About Pratibha Refractory Minerals

Pratibha Refractory Minerals is synonymous with superior talc powder production. Our commitment to quality and customer satisfaction has made us the preferred choice for businesses seeking the best talc powder exporter in India. We offer talc powder that is smooth, slippery, and soapy to the touch, with a white color, dull, pearly, and greasy luster.

Applications of Talc Powder

Talc powder, known for its softness and chemical inertness, is a versatile mineral with a wide range of applications across multiple industries. Here are some key sectors where talc powder plays a crucial role:

1. Paper Industry

In the paper industry, talc powder is used as a filler to improve the quality and printability of paper. It enhances the smoothness, opacity, and brightness of the paper while also reducing the consumption of expensive pulp.

2. Paint Industry

Talc powder is an essential ingredient in the paint industry. It acts as a filler, improving the paint’s texture and consistency. Additionally, it enhances the paint's durability, providing a smoother finish and better coverage.

3. Plastic Industry

In the plastic industry, talc powder is used as a reinforcing filler to enhance the mechanical properties of plastic products. It improves stiffness, impact resistance, and dimensional stability, making it ideal for various plastic applications.

4. Rubber Industry

Talc powder is widely used in the rubber industry as a processing aid. It prevents rubber compounds from sticking to molds and rollers, facilitating the manufacturing process. Talc also improves the performance and durability of rubber products.

5. Cosmetics Industry

In the cosmetics industry, talc powder is a popular ingredient in products such as foundation, face powder, and blush. Its smooth texture and ability to absorb moisture make it ideal for enhancing the feel and finish of cosmetic products.

6. Pharmaceutical Industry

Talc powder is used in the pharmaceutical industry as an excipient in tablet formulations. It helps in improving the flow properties of powders, ensuring uniformity in tablet production and preventing sticking during the manufacturing process.

Why Choose Pratibha Refractory Minerals?

As the best Talc powder exporter in India, Pratibha Refractory Minerals offers several advantages:

1. Superior Quality:

We ensure that our talc powder is of the highest quality, meeting stringent industry standards. Our talc is characterized by its smooth, slippery texture and consistent white color.

2. Extensive Industry Experience:

With years of experience in the industry, we understand the specific requirements of different sectors and tailor our products to meet those needs.

3. Customized Solutions:

We offer customized talc powder solutions to cater to the unique requirements of our clients. Whether you need talc powder for paper, paint, plastic, or any other application, we have you covered.

4. Reliable Supply Chain:

Our robust supply chain ensures timely delivery of talc powder to our clients, regardless of their location. We maintain consistent inventory levels to meet demand without delays.

ConclusionPratibha Refractory Minerals is the trusted choice for businesses seeking the best Talc powder exporter in India. Our high-quality talc powder, extensive industry experience, and commitment to customer satisfaction make us the preferred partner for your talc powder needs. Contact us today to learn more about our products and how we can help your business thrive.

#manufacturer#exporter#supplier#business#dolomite#talc#kaolin#supplier of quartz sand#talc powder exporter in india#indonesia

0 notes

Text

Luverre Quartz produce and sell various kinds of high quality quartz glass including quartz tube, quartz plate, quartz rod, quartz sand, quartz window, quartz crucible, quartz boat, quartz flange, quartz beaker, quartz glass instruments and so on. We can meet our customers all kinds of custom requirements for quartz glass products.

#QuartzTube#QuartzPlate#QuartzRod#QuartzIngot#QuartzBoat#QuartzLabware#QuartzCrucible#QuartzFlange#Quartzproduct

0 notes

Text

Discover the Top AAC Block Dealers in Pune

Discover the Top AAC Block Dealers in Pune.

When embarking on construction projects, the choice of building materials is pivotal. Among the diverse options available, AAC (Autoclaved Aerated Concrete) blocks stand out for their exceptional qualities. These blocks are fire and pest resistant, and they surpass traditional materials like concrete, wood, brick, and stone in terms of economic and environmental benefits. Evergreen Enterprises, a leading manufacturer and supplier of AAC blocks in Pune, exemplifies the superior quality and sustainability of these materials. In Pune, several AAC block dealers, including Evergreen Enterprises, offer top-quality products that cater to various construction needs. This blog delves into the premier AAC block dealers in the area, focusing on their offerings and the advantages of choosing AAC blocks.

The Superiority of AAC Blocks

Before we explore the leading dealers, it’s essential to understand why AAC blocks are increasingly favored in construction. AAC blocks are known for their light weight, which reduces the overall dead load of a structure. They offer excellent thermal insulation, ensuring energy efficiency in buildings by maintaining indoor temperatures. Moreover, AAC blocks are highly durable, providing long-term structural stability with minimal maintenance.

From an environmental perspective, AAC blocks are manufactured using fly ash, a byproduct of coal combustion, thus recycling waste material. Their production process emits fewer greenhouse gases compared to traditional building materials, making them a sustainable choice.

Evergreen Enterprises

Overview: As renowned AAC block manufacturers in Pune, we at Evergreen Enterprises Productions are renowned for producing AAC blocks using premium materials. Additionally, we are a top supplier, manufacturer, and dealer of AAC blocks. For building needs, we provide a large selection of AAC blocks. You can use our AAC blocks for exterior and interior construction. For side walls, these AAC blocks are utilized. The greatest quality concrete was used to create the AAC block. We provide these AAC blocks of the greatest quality at affordable costs, with prompt delivery. Therefore, we are recognized in the industry as a leading supplier and manufacturer of AAC blocks. Because we employ rounded, sanded materials, our AAC blocks are lightweight and easy to install. High-rise structures with significant temperature fluctuations can use these AAC blocks. Few steel, concrete, and other building supplies are needed to construct the walls in our AAC block. We use sand, quartz sand, water, calcined gypsum, lime (mineral), or cement to make AAC blocks. SIZE – 3X8X24, 4X8X24, 5X8X24, 6X8X24, 8X8X24, ALL SIZES AVAILABLE

COLOUR- GREY

Key Features:

Require less Materials

Light Weight

Quick and Easy Installation

Costs Saving

Used for Interior and Exterior Constructions

High Thermal Efficiency

Other Specifications:

Color: Gray

Sizes: 12 In. X 4 In. X 2 In.

Shape: Rectangular

Materials Used: sand, quartz sand, calcined gypsum, lime (mineral) or cement and water

Why Choose AAC Blocks?

Choosing AAC blocks for your construction projects in Pune, offers several advantages:

Fire and Pest Resistance: AAC blocks are non-combustible and highly resistant to pests, enhancing the safety and longevity of structures.

Economic Efficiency: These blocks are lightweight, reducing the transportation and handling costs. They also cut down on the structural load, leading to savings in steel and concrete usage.

Environmental Benefits: AAC blocks are made from recycled materials and have a lower environmental footprint compared to traditional building materials. Their production emits fewer pollutants, aligning with sustainable construction practices.

Thermal Insulation: AAC blocks provide excellent thermal insulation, which helps in reducing heating and cooling costs in buildings.

Conclusion

For those in Pune, looking to source AAC blocks, Evergreen Enterprises and the other mentioned dealers provide excellent options. These dealers not only offer top-quality products but also contribute to sustainable and efficient building practices. By choosing AAC blocks, you ensure that your construction projects are safer, more durable, and environmentally friendly. Whether you are a builder, contractor, or individual embarking on a construction project, these dealers in Pune, are your go-to for all your AAC block needs.

0 notes

Text

Swimming Pool Interior Finishes

When it comes to transforming your Swimming Pool Interior Finishes into a luxurious oasis, choosing the right interior finish is crucial. Sunstate Sands offers a diverse range of options that blend durability with aesthetic appeal. Whether you prefer the timeless elegance of polished pebbles or the smooth texture of quartz, Sunstate Sands ensures your pool reflects your style and lasts for years to come. Dive into unparalleled craftsmanship and quality with Sunstate Sands, where every detail is crafted to perfection.

0 notes

Text

Metal Disc Filters, Metal Disc Filter Manufacturer, Supplier, India

Metal Disc Filters : We are Metal Disc Filter Manufacturer, Metal Disc Filter Supplier, Sangli, Maharashtra, India.

Filter System, Filter Systems, Screen Filter, Screen Filters, Metal Disc Filter, Metal Disc Filters, Gravel Filter, Gravel Filters, Media Filter, Media Filters, Fertilizer Tank, Fertilizer Tanks, Hydrocyclone Filter, Hydrocyclone Filters, Drip Irrigation Filter, Drip Irrigation Filters, Micro Irrigation Filter, Micro Irrigation Filters, Allied Agro Equipment, Allied Agro Equipments, Drip Filter Spare, Drip Filter Spares, Quartz Sand, Quartz Sands, Plastic Screen Filter, Plastic Screen Filters, Micro Irrigation Filter System, Micro Irrigation Filter Systems, Metal Screen Filter, Metal Screen Filters, Sand Filter, Sand Filters, Fertigation System, Fertigation Systems, Hydro Cyclone, Hydro Cyclones, Manufacturer, Sangli, Maharashtra, India.

0 notes

Text

Top-Quality Soapstone Powder: Leading Manufacturers and Suppliers in India

Zillion Sawa Minerals Pvt. Ltd. stands out as a premier Soapstone Manufacturer in India, offering high-quality soapstone powder at competitive prices. As a leading Soapstone Supplier in India, our diverse range of products includes cosmetic-grade soapstone powder, body-grade soapstone powder, and industrial-grade soapstone powder, catering to various industry needs.

Why Choose Soapstone?

Soapstone, known for being one of the softest minerals, is a vital component in many everyday products. While all soapstone shares properties like softness, platy structure, water repellence, and chemical inertness, each type of soapstone is unique. Soapstone plays a crucial role in enhancing the quality of items such as magazines, automotive plastics, household paints, and floor tiles.

Our Expertise

We procure soapstone from the top soapstone powder manufacturers in India. Soapstone, or Mg3Si4010(OH)2, is a hydrated magnesium sheet silicate, known for being insoluble in water, mild acids, and alkalis. It is also non-explosive and non-flammable, with a strong affinity for organic compounds despite its low chemical reactivity.

Soapstone in Various Forms

Lumps Form: Found in the mountainous regions of India, soapstone is an excellent building material due to its durability, natural insulating properties, and acid resistance.

Powder Form: Pulverized soapstone powder serves multiple industrial purposes. It is used as a filler in rubber, textiles, plastics, linoleum, asbestos products, polishes, and soaps; as a loading agent in paper; as a carrier for insecticidal and pesticidal dust; and as a coating for calcium ammonium fertilizer. Additionally, soapstone powder acts as a lubricant to prevent ungalvanized rubber goods from sticking. Calcined steatite, known as ‘Lava,’ is used in low-loss ceramic materials for high-frequency insulation in electronic devices.

Applications in Cosmetics and Pharmaceuticals

In cosmetics, soapstone is utilized as a thickening agent, lubricant, and filler. It is also a popular filler in the paper industry and serves as a tablet binder in pharmaceuticals. Zillion Sawa Minerals offers some of the purest, most affordable soapstone available.

Product Variety and Quality

We provide a wide range of soapstone powders, including cosmetic, body, and industrial grades. Our soapstone, sourced from leading manufacturers, includes silicone-talc available in granules, powder, and flakes, suitable for various industries such as cosmetics, pharmaceuticals, and construction.

Your Trusted Supplier

As a renowned Soapstone Manufacturer in India and Soapstone Supplier in India, Zillion Sawa Minerals also supplies kaolin, quartz, and silica sand. We ensure safe and timely doorstep delivery of products through our dedicated logistic partners, providing a seamless experience from order placement to delivery.

Choose Zillion Sawa Minerals Pvt. Ltd. for top-quality soapstone powder and experience unparalleled service and reliability.

1 note

·

View note

Text

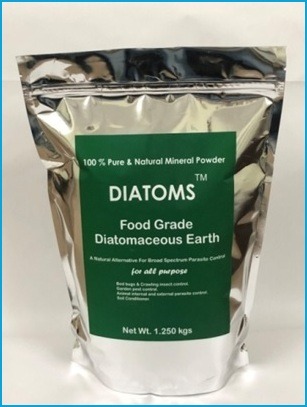

Practical Uses and Benefits of Food-Grade Diatomaceous Earth

Food Grade Diatomaceous Earth from Seema Minerals & Metals stands out as a versatile, natural product. Seema Minerals & Metals is a renowned name in the mining and processing of various industrial minerals. The company ensures high-quality DE by adhering to stringent quality control measures and using advanced processing techniques. Known for reliable and consistent product quality, it is a trusted supplier in the industry.

Introduction to Diatomaceous Earth

Diatomaceous Earth (DE) is a naturally occurring, soft sedimentary rock that is easily crumbled into a fine white to off-white powder. Mainly composed of silica, which is a common component in sand and quartz. Food-grade DE typically contains 85-90% amorphous silica. There are two main types of DE: food-grade and industrial-grade. Food-grade DE is safe for human and animal consumption.

Benefits of DE Food Grade

Health Supplement:

Acts as a detoxifying agent, absorbing toxins, heavy metals, and parasites. It promotes a healthy digestive system by cleansing the digestive tract. Provides a natural source of silica, essential for healthy hair, skin, nails, and bones.

Pest Control:

Effective against a variety of pests, including fleas, ticks, bed bugs, and ants. Works by dehydrating and killing insects without the use of harmful chemicals. Non-toxic to humans and pets when used properly, making it a preferred choice for organic pest control.

Animal Health:

Acts as a natural dewormer for pets and livestock. It enhances the overall health of animals by improving digestion and nutrient absorption.

Household Uses:

Absorbs odours in trash cans, refrigerators, and pet areas. Mild abrasive properties make it an excellent cleaner for sinks, tiles, and other surfaces. Helps to control moisture in the home, preventing mold and mildew growth.

Applications of DE Food Grade

In Agriculture:

Improves soil structure and promotes healthy plant growth by increasing aeration and water retention. Used as a natural pesticide in organic farming, protecting crops from pests without harmful residues.

In Food Industry:

Used as an anti-caking agent in food products to prevent clumping. Effective in filtering impurities from beverages, including wine, beer, and juices.

In Cosmetics:

Used in facial scrubs and toothpaste for its gentle abrasive properties. Common in makeup and deodorants for its absorbent qualities.

In Pharmaceuticals:

Acts as an inert carrier for drugs and supplements. Used in the formulation of pills and capsules for its absorbent properties.

Environmental Benefits

The DE Food Grade provided by Seema Minerals & Metals benefits the environment in various ways:

Eco-Friendly:

DE is a natural and sustainable resource, causing minimal environmental impact during extraction and processing.

Biodegradable:

Fully biodegradable and does not contribute to pollution.

Inhalation Risk:

While food-grade DE is safe for consumption, inhalation of fine DE dust can cause respiratory issues. Proper protective equipment like masks should be used during handling.

Storage:

Should be stored in a cool, dry place to maintain its efficacy and prevent clumping.

Purchasing and Availability

Packaging Options:

Available in various sizes, from small consumer packages to bulk industrial quantities.

Distribution:

Widely distributed through various channels, including online platforms and physical stores.

Conclusion

DE Food Grade from Seema Minerals & Metals stands out as a versatile, natural product with numerous applications across health, agriculture, and household maintenance. Its effectiveness, combined with the company’s commitment to quality, makes it a valuable addition to any home or business focused on natural and eco-friendly solutions.

Experience the remarkable benefits of Food Grade Diatomaceous Earth in your health, home, and garden today. Discover how this versatile and natural product can transform your life with its multitude of applications. Whether you’re looking to improve your digestive health, tackle pest problems, or enhance your agricultural practices, our high-quality Food Grade Diatomaceous Earth is the perfect solution. Contact us now for your needs!

0 notes