#supercharging pile liquid cooling water pump

Explore tagged Tumblr posts

Text

TOPSFLO at 2024 Global Liquid Cooling System Innovation Conference

The 2024 (3rd) Global Liquid Cooling System Innovation Development and Application Technology Conference, a grand industry event that brings together global wisdom and innovation, was held in Suzhou on October 24-25. This conference is the largest and most professional liquid cooling industry event in China, with over 100 exhibitors from the liquid cooling field around the world. More than 70 industry experts shared their insights on the current status and development trends of liquid cooling technologies in mainstream industries such as EV fast charger, data centers, and energy storage.

As a global leader in pump technology and a key provider of liquid cooling pump solutions, TOPSFLO has been invited to attend the event, showcasing our cutting-edge liquid cooling system pump solutions, including the groundbreaking TA90E ultra-high-performance liquid cooling pump and a range of other innovative products.

As one of the few exhibitors showcasing liquid cooling pumps at the event, we successfully met with several partners and welcomed many new friends interested in liquid cooling pumps. We had in-depth discussions on liquid cooling system pump solutions. Our R&D engineers and sales engineers focused on high-power liquid cooling applications, providing detailed explanations to customers on the product features and model selection for pump systems.

The high-power liquid-cooled pumps we launched in this exchange meeting, condensing the deep technical precipitation of Topsflo��in the field of micro pumps and pump solutions for 20 years, representing the cutting-edge technology of China's liquid-cooled pump industry, delivering exceptional performance in ensuring stable and efficient operation, extending equipment lifespan, and improving energy utilization efficiency. It can accurately match the pump requirements of EV charger charging station, data center and energy storage liquid cooling system, and provide customers with one-stop liquid cooling solutions.

The liquid cooling industry is evolving rapidly. Through face-to-face communication with customers, we are able to directly address their pain points, better understand their needs, and gain a comprehensive understanding of the technical requirements of their industries. In response to the increasing demands for pumps across different application fields, TOPSFLO will rely on the strong R&D capabilities and technical expertise to provide customers with high-quality pumps and liquid cooling pump solutions.

In the future, TOPSFLO will actively respond to the national "Dual Carbon" strategy, continuously increasing investment in the R&D of liquid cooling pump technology, driving innovation and product upgrades in liquid cooling pump solutions. Together with global partners, we will open a new chapter in liquid-cooling technology, contributing TOPSFLO’s expertise and strength to building a green, low-carbon, safe, and efficient energy future.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ | http://www.topsflo.com/

Factory Tour

youtube

youtube

#liquid cooling sytem#liquid cooling pump#dcwaterpump#12vdcwaterpump#brushless dc water pump#brushless dc charging pile cooling circulating water pump#server liquid cooling pump#server cooling pump#supercharging pile liquid cooling water pump#coolingpump#coolingwaterpump#liquid cooling

0 notes

Photo

TOPSFLO high-efficiency liquid cooling water pump helps the well-known American company's supercharged piles sell well all over the world

http://www.topsflo.com/news/liquid-cooling-ev-charging-pump.html

2018년 충전기 업계는 "4분 충전 연속 주행 거리 100km"를 달성했습니다. 2021년 8월 "5분 충전 연속 주행 거리 200km" 달성; 2022년 4월 "5분 충전 연속 주행 거리 300km"를 달성했습니다. ... 최근 몇 년 동안 과급 말뚝 산업은 기술 혁신이 가속화되고 발전 추진력이 추진력을 얻으면서 발전의 빠른 차선에 진입했습니다. TOPSFLO Pumps와 전기 자동차용 DC 과급기 스택의 잘 알려진 제조업체인 American T Company 간의 파트너십은 2017년에 시작되었으며 우연히 업계의 성장을 동반하고 목격했습니다. 소규모 시험 생산에서 장기 전략적 협력에 이르기까�� 5년 이상의 협력 끝에 두 당사자의 관계는 오래된 포도주만큼 길고 향기롭다. 2021년에는 T사 과급 파일 프로젝트를 위해 TOPSFLO에서 제공한 수냉식 순환수 펌프가 공식 양산되어 양사 협력의 역사에 강력한 감동을 더했습니다.

협력 서곡 타이탄은 항상 같은 비전을 가지고 있습니다 2022년은 많은 사람들이 고전력 수냉식 장전말뚝 건설 원년이라고 합니다. 실제로 TOPSFLO Pumps는 수년 동안 장입 파일을 위한 액체 냉각 분야를 연구해 왔습니다. 이미 2015년에 Tesla에 냉각 순환 워터 펌프를 제공하기 시작했으며 업계에서 20개 이상의 성공적인 적용 사례를 보유하고 있습니다. 2017년 2월 전기 자동차(EV)용 DC 급속 충전 기술의 글로벌 리더인 T Company는 TOPSLO 엔지니어에게 접근하여 새로운 에너지 EV 충전기용 액체 냉각수 펌프에 대해 문의했습니다. 솔루션 제조업체는 상업용 쿨란스 회사에서 사용하는 TOPSFLO 펌프입니다. 고객의 요구에 따라 TOPSFLO 펌프 업계는 T사에 처음으로 소형 브러시리스 DC 냉각 펌프 TL-C01을 추천하고 테스트를 위해 샘플을 고객에게 보냈습니다. 몇 달 간의 검증 및 테스트 후 T 회사는 TOPSFLO 펌프가 프로젝트 요구를 완전히 충족할 수 있는 고효율, 긴 수명 및 안정적인 품질을 가지고 있다는 피드백을 받았습니다. 이에 양측은 수냉식 EV 충전 냉각 펌프와 협력하기 시작했다.

신뢰 업그레이드 효율적인 커스터마이징으로 새로운 프로젝트의 결실을 맺을 수 있습니다. DC 급속 충전기가 업데이트되고 반복됨에 따라 TOPSFLO는 자동차 전자 설계 전문가로 구성된 엄격한 팀을 구축하고 고객의 요구 사항에 맞게 시뮬레이션 및 맞춤화할 수 있는 다수의 국제 고급 장치를 도입한 완전한 개발 시스템을 구축하여 시장 변화에 적극적으로 대응했습니다. 효율적이고 정확한 개발을 달성하기 위해 새로운 개발 요구. 2019년 12월 T사는 새로운 프로젝트에 액체 냉각 순환 워터 펌프가 필요하다는 내용의 이메일을 TOPSFLO 엔지니어들에게 다시 보냈습니다. 고객사의 신제품은 350KW 슈퍼차저로 컴팩트한 디자인과 작은 풋프린트로 어떤 환경에도 적용 가능한 것으로 이해된다. 이 새로운 프로젝트에는 액체 최고 온도 85℃ 및 환경 최고 온도 70℃ 작업 조건에서 사용할 수 있는 소형, 고성능 안전 성능의 액체 냉각 순환 펌프가 필요합니다. 고객의 높은 요구에 부응하여 TOPSFLO 엔지니어는 테스트를 위해 TA60 EV 냉각수 펌프를 권장했습니다. 첫 번째 테스트에서 고객은 워터 펌프의 압력이 상대적으로 작아서 기대한 ��과를 얻지 못했다고 보고했습니다. 고객과의 심도 있는 커뮤니케이션 끝에 TOPSFLO의 구조 엔지니어는 고객 제품의 내부 파이프라인이 길고 굴곡이 많아 펌프가 최상의 성능을 발휘할 수 없음을 발견하고 즉시 고객에게 합리적인 구조 최적화를 제공했습니다. 제안 및 솔루션. 1년 이상의 테스트 후 고객은 피드백을 보냈습니다. TOPSFLO TA60 냉각수 펌프는 T 회사의 350KW 슈퍼 차징 파일의 애플리케이션 요구 사항과 성공적으로 일치했습니다! 2021년 2월 TOPSFLO TA60 워터 펌프가 대량 생산을 시작하여 고객 프로젝트에 사용되었습니다. 현재 T사의 제품은 41개국에 판매되고 있으며, TOPSFLO 펌프를 이용한 수만 개의 충전 파일이 전 세계에 서 있습니다. 고객은 TOPSFLO 펌프가 성능면에서 신뢰할 수 있을 뿐만 아니라 배치 일관성도 우수하다고 말했습니다. 그들은 아무 걱정 없이 TOPSFLO와 협력하기로 결정했습니다!

이점 복호화 자동차 산업에서 높은 기준을 가진 고품질 액체 냉각수 펌프 단조 갈수록 치열해지는 시장 경쟁 속에서 TOPSFLO Pumps가 두각을 나타낼 수 있는 이유는 끊임없는 기술과 품질 추구에 있습니다. TOPSFLO 충전기 액체 냉각 순환 펌프에 대한 연구 개발 프로세스는 자동차 산업의 가장 높은 IATF 16949 표준을 엄격히 따랐으며 자동차-

0 notes

Text

What Changes does "Liquid Cooling" Technology Bring to Charging Stations and How to Choose a Reliable Liquid Cooling Water Pump?

Recently, Have you noticed that Huawei's "liquid-cooled 600kW supercharger station" caused tremendous repercussions on the internet? It is said that this charging station can achieve a "one kilometer per second" charging speed, providing car owners with a charging experience of "having a cup of coffee and setting off fully charged". This resolves many of the core pain points such as range anxiety and charging anxiety for electric vehicle owners, bringing a completely new charging experience.

Huawei Technologies plans to install 100,000 EV DC fast charging stations in more than 340 cities and major highways across the country in China by 2024, leading the way in achieving "high-quality charging wherever you're"

What is the Liquid Cooling Fast Charging Station?

Different from traditional air-cooled charger, liquid cooling technology utilizes liquids to dissipate heat and maintain equipment temperature. Liquid-cooled ultra fast charging stations use this technology to charge electric vehicles in a shorter period, effectively improving charging efficiency and speed.

First, let's understand the basic principles of liquid cooling fast charging technology. According to the formula "power = voltage x current" (P = UI), we can see that when either the voltage (U) or the current (I) increases, the power (P) will increase, accelerating the charging speed and reducing the time required to fully charge.

Therefore, achieving high power fast charging mainly involves two methods. Firstly, increasing the vehicle's charging voltage—the charging voltage for electric vehicles has transitioned from the previous 400V to 800V and 1000V. Secondly, increasing the charging current. The majority of third-party universal fast chargers in China have achieved the 250A current limit recommended by the 2015 national standard. However, vehicle manufacturers' self-built super-fast chargers can successfully surpass the 250A current limit, achieving a higher 600A current output.

Why Do Electric Vehicle Charging Stations Heat Up So Much?

When the current passes through the resistor, all the electrical energy consumed on the resistor is converted into heat energy. According to Joule's law (Q=I²RT), the heat generated by the current through the conductor is proportional to the second square of the current, proportional to the resistance and power-on time, that is to say, the greater the current, the more heat generated by the charging pile.

Under the premise of the same resistance and equal time, when charging at 250A, a single charging cable or two charging cables can generate 62,500 joules of heat. And when charging at 600A will generate 360,000 joules of heat. Thus, how charging stations can withstand such high levels of heat has become a technical challenge that charging station manufacturers need to overcome.

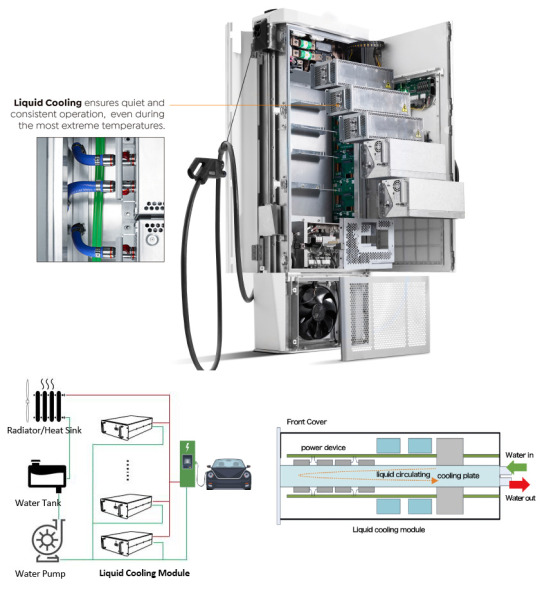

How to Achieve the "Black Technology" of Liquid Cooling EV Fast Charging?

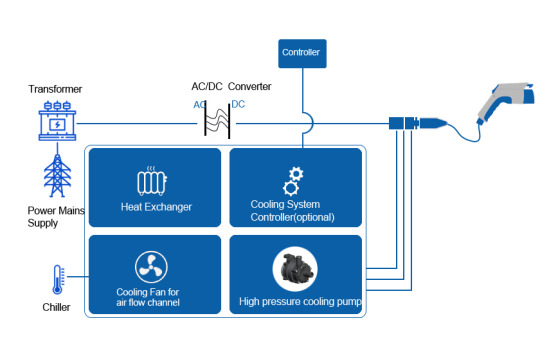

In the liquid cooling EV fast charging technology, the role of the liquid-cooled water pump is crucial.This is because the all-liquid-cooled charging station uses a liquid-cooled charging module, with no air ducts on the front and back of the liquid-cooled module. The module relies on the internal circulation of the coolant in the liquid cooling plate to exchange heat with the outside. The heat dissipation liquid is circulated between the charging host and other components to stabilize the temperature and ensure that the charging process is efficient and stable.

Meanwhile, the fully liquid-cooled charging pile has a special liquid circulation channel between cable and charging gun. Liquid coolant for heat dissipation is added to the channel, and the coolant is circulated through a liquid-cooled water pump, thereby dissipating the heat generated during the charging process. The liquid cooling system extends from charging station to charging cable and connector, enabling low-temperature operation of the entire charging system. This enhances the heat dissipation performance, increases the device power density and output power, and is significantly improved compared to traditional air-cooled heat dissipation technology.

How to Choose a Good and Reliable Water Pump Manufacturer?

1. Check the qualifications of pump manufacturers:

TOPSFLO has focused on micro pumps for 19 years. The industries we mainly serve are automobiles, charging station liquid cooling systems, home appliances, medical and ect.. 80% of our pumps are exported to European and American high-end markets, with international trademarks from the United States and the European Union. We has a modern factory with 16,000 square meters. Also has a patch factory and an injection molding factory with all imported equipment, an ESD anti-static control digital dust-free workshop, and fully automated electronic lines, motor lines, and water pump assembly and testing line and etc..

2. Whether the water pump has passed strict certification?

TOPSFLO is the only enterprise in China certified by German Rheinland TÜV double quality system of ISO 9001 and IATF:16949 in the micro pump industry. Based on this standard, TOPSFLO strictly controls all aspects of water pump R&D and design, raw material procurement, and production processes. Pursue and achieve "zero defects" in quality.

3. Successful customer cases

TOPSFLO is one of the earliest domestic micro-pump companies to enter the field of liquid-cooling applications for charging piles, and occupies a large market share in the field of liquid-cooled water pumps for charging piles. Since 2015, the company has provided 300,000 liquid-cooled water pumps to world-renowned electric vehicle and energy companies, and has professional and mature liquid-cooling solutions for fast charging piles.

Wanna to get pump solution or apply free sample? Contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Find more pumps: http://www.topsflo.com/

youtube

#ev charging station#liquid cooling sytem#liquid cooling#waterpump#water pump for ev charging#Youtube

0 notes

Text

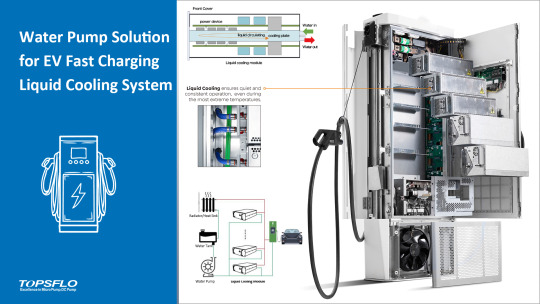

Water Pump Solution for EV Fast Charging Liquid Cooling System

Market Basics

"2021 China Electric Vehicle User Charging Behavior White Paper" released by the Charging Alliance shows that 99.3% of electric vehicle users prefer fast charging. And how can the charging pile realize faster charging? One is by increasing the output power (need to add module liquid cooling), the second is to increase the current (need to add gun line liquid cooling). At present, the liquid cooling system is the best solution for DC supercharging charging pile in the market, and the water pump, as an important part in the liquid cooling system, plays a key role in the cooling effect.

Market Pains

Charger Power Module Liquid Cooling

Superchargers generally consist of multiple DC:DC or AC:DC modules stacked on top of each other, and require a large flow rate to deliver coolant to each module for uniform heat dissipation;

EV Charging stations are equipped with intelligent management systems, which need to realize remote management, monitoring and data analysis, etc., and therefore cannot be subject to electromagnetic interference from other components.

Cable Liquid Cooling

Liquid-cooled charging cables are often thinned and lengthened to be more lightweight, thus adding a very large amount of drag to the liquid-cooled system;

The cable liquid cooling system generally uses glycol antifreeze or insulating oil as the medium. The viscosity of the liquid is different at different temperatures, especially the silicone oil, and the viscosity of the liquid will increase exponentially at low temperatures;

EV Fast Charging Water Pump Solution

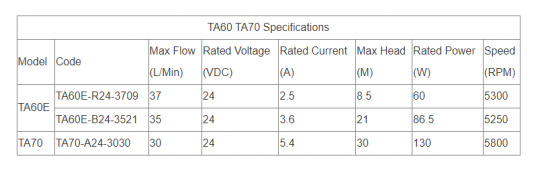

Charger Power Module Cooling Solutions

TOPSFLO water pump TA60/TA70 is designed to meet the needs of charging pile's multi-power module cooling, through the motor and fluid simulation, special design of high-efficiency motor and structural solutions, while minimizing power consumption, the maximum flow rate up to 60L/min, faster and better cooling so that there is no risk of overheating in the charging post module.

Charging pile liquid-cooled water pump is specially designed for low-temperature startup, and PWM intelligent speed regulation function. It can withstand low temperature -40℃, and adjust the motor speed according to the different viscosity of the liquid under different temperature conditions, which can solve the technical problem of not discharging liquid under low temperature due to excessive viscosity of the liquid.

TOPSFLO water pumps are designed with vehicle-grade electronic solutions, which can well meet the EMC specification requirements for charging piles. It will not cause interference to the electronic system of the charging pile, and at the same time, it can also resist electromagnetic interference from other equipment.

Cable Cooling Solutions

Cable Liquid cooling for coolant ( up to 400A )

Depending on the cable length and diameter, the resistance will vary and the cooling solution will be different. The smaller the cable diameter, the higher the resistance, and the longer the cable, the higher the resistance.

For low resistance, it is recommended to consider TOPSFLO centrifugal pump TA60E-B24-3521

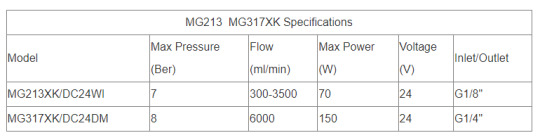

For high resistance, it is recommended to consider TOPSFLO gear pump MG213

Cable Liquid cooling for dimethyl silicone oil (over 400A)

For high current cables of more than 400A, silicone oil is usually chosen as the cooling medium, which has relatively higher resistance. For this kind of high resistance cable cooling application, TOPSFLO newly developed a high pressure liquid cooling gear water pump - MG317, the maximum water pressure up to 10bar, can meet 500-600A cable cooling of charging connector.

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#carwaterpump#microgearpump#evcharger#fastcharging#liquidcoolingsystem#waterpump12vdc#waterpumpmanufacture#water pumps

0 notes

Photo

Four departments issued documents to boost the 100 billion market

TOPSFLO high-quality supercharging pile liquid cooling water pump to seize the new track

In recent years, my country's new energy vehicle industry has developed vigorously, and the scale of production and sales has continued to grow rapidly. Recently, the Ministry of Transport, the National Energy Administration, the State Grid Corporation of China, and China Southern Power Grid Co., Ltd. jointly issued a document to fully mobilize the forces of all parties to promote the development of the electric vehicle industry.

It is estimated that the domestic charging market will exceed 200 billion in 2026

The charging pile is a device that supplements electric energy to new energy vehicles (including pure electric and plug-in hybrid). Its function is similar to the gas dispenser in the gas station. It can be installed in places such as roads, office buildings, shopping malls, public parking lots and residential parking lots. , charging various types of new energy vehicles according to different voltage levels.

With the continuous increase in the production, sales and ownership of new energy vehicles, the charging pile as an important supporting infrastructure has ushered in development opportunities. Up to now, among the 6,618 expressway service areas across the country, 13,374 charging piles have been built in 3,102 service areas, which basically meet the current electric vehicle charging requirements. According to statistics, the market size of the domestic charging pile industry will reach 41.87 billion yuan in 2021. The period from 2021 to 2026 is the period of rapid growth of the charging pile industry. It is estimated that the number of domestic charging facilities will reach 17.66 million units in 2026, and the market size will exceed 200 billion yuan.

The domestic charging pile market is promising, and the international market also has broad prospects. According to the latest "Global EV Outlook 2021" report released by the International Energy Agency (IEA), the scale of global charging piles in 2025 and 2030 is predicted: based on the latest national policies (SPS) and sustainable development scenarios (SPS), to In 2025, the global number of charging piles is expected to reach 45.8 million/65 million units respectively, of which the global private charging piles are expected to reach 39.70/56.7 million units respectively, and the global public charging piles are expected to hold 6.10/8.3 million units; by 2030 In 2018, the global number of charging piles is expected to reach 120.90/215.2 million units respectively, of which the global private charging piles are expected to have 104.70/189.9 million units respectively, and the global public charging piles are expected to reach 16.20/25.3 million units.

TOPSFLO pumps escort high-efficiency liquid-cooled supercharged piles

The explosion of the charging pile market has also intensified the competition in the upstream and downstream industries of charging piles. As the first domestic company to enter the field of micro-pump research, Changsha Duopule Pump has conducted in-depth research on the charging pile industry many years ago, and has reached long-term strategic cooperation with many well-known domestic and foreign companies. Among them, TOPSFLO has successfully provided 300,000 liquid-cooled circulating water pumps to Terras since 2015.

TOPSFLO brushless DC charging pile cooling circulating water pump can be used for different cooling applications such as supercharged liquid cooling module, gun line liquid cooling, etc. It is suitable for 100KW - 600KW, and can meet all the liquid cooling requirements of DC supercharged piles in the market. Each TOPSFLO water pump has undergone strict high and low temperature fast switching tests of the whole machine. It has a wide temperature resistance range to meet the needs of different working conditions of super charging piles, and adopts international well-known brand electronic components, with lower heat generation and reliability. High, truly empowering "cold and fast" charging piles.

Under the global wave of intelligence, TOPSFLO is committed to providing customers with products with strong competitiveness. TOPSFLO's brushless DC charging pile cooling and circulating water pump has 5V/PWM speed regulation and FG speed signal feedback functions, which can realize automatic intelligent detection , support failure alarm, real-time data feedback, etc., to escort high-efficiency liquid-cooled supercharged piles.

#supercharging pile liquid cooling water pump#brushless DC charging pile cooling circulating water pump#charging pile cooling circulating water pump#liquid-cooled supercharged piles pump

0 notes

Photo

TOPSFLO liquid cooling pump directly addressed the technical pain point of EV super charging pile, high-end quality has been certified by the authority

Reasons to choose TOPSFLO Liquid-cooled Water Pump Liquid cooling technology is the most practical solution in the visible range of the supercharged pile heat dissipation problem. The technical principle is to circulate the circulating liquid in a closed channel to dissipate heat. The liquid-cooled coolant pump, as the power source, its high efficiency, safety and reliability are the keys to the choice of new energy vehicle companies. As a global professional micro-pump solution supplier - TOPSFLO, its brushless DC liquid-cooled circulating coolant pump can be used in different cooling applications, such as high-power charging pile liquid-cooling modules, gun line liquid-cooling, etc. also applicable to the large power of 600 kw. It can meet the liquid cooling requirements of all DC supercharged pile on the market, and can provide professional customization according to customer needs.

More details: http://www.topsflo.com/news/high-power-ev-charging-pump.html

#DC liquid-cooled circulating coolant pump#TOPSFLO Liquid-cooled Water Pump#liquid-cooled coolant pump

0 notes

Photo

Topsflo, the Pioneer of Ultra-fast Charging Era, Redefines Liquid-cooled Water Pump for Charging Piles

With the rapid development of new energy electric vehicles, the demand for capacity of power battery is increasing, and the requirements for charging time is also getting shorter and shorter. DC high-power charging has become an inevitable trend in the future development of the new energy vehicle industry. On August 30, Sinopec's first community super charging station in the country was completed and put into use. It can charge 24 vehicles at the same time, and can charge an ordinary family car with an endurance of about 400 kilometers in 25 minutes as fastest. Meanwhile, traditional energy companies such as BP and Shell, as well as car companies such as Li Auto Inc. And XPeng Motors, are also accelerating the deployment of super fast charging. The slogan of “5 minutes of charging continued calling 2 hours”used to be catchy, but now the slogan of “5 minutes of charging continued driving mileage 200km”has almost become a standard of every 800V new energy vehicle, which proving that the era of ultra-fast charging has arrived. Topsflo, the Pioneer of Liquid Cooling Mature Solutions for Super Charging Piles In order to adapt to the ultra-fast charging era and the development of electric vehicle technology, charging pile equipment is changing with each passing day, and its technological innovation and iteration speed are even at the forefront of the development of electric vehicle technology. Among them, liquid-cooled supercharging technology is even more optimistic in the industry, and has become the development trend of a new generation of DC fast charging equipment. At the beginning of September, thousands of liquid cooling water pumps supplied by Topsflo to American T companies were shipped out as usual. According to the representative of Topsflo, T company is a world-renowned manufacturer of DC fast charging piles for electric vehicles, and Topsflo provides liquid-cooled circulating water pumps for their 350KW super charging piles, mass production starting from February 2021. At present, the 350KW super charging piles from T company have been sold to 41 countries, and tens of thousands of super charging piles using Topsflo pumps are standing all over the world. In fact, the founder of Topsflo, Richard Wang, has awared of the huge potential of the new energy vehicle charging pile market many years ago. Mr. Wang entered the micro pump industry since 2005, and he is one of the experts who engaged in the research and development of brushless DC pumps in China at the earliest time. Mr. Wang is also a researcher who is fully proficient in micro pumps in Europe, America and Japan. Perennial attention to the European and American markets made him aware the situation early: The US electric vehicle charging pile market, which started at the end of the 20th century, has developed steadily and received strong support from all aspects of the government. In China, although the electric vehicle industry started late, development is inevitable. Seizing the opportunity is the way to develop. Therefore, Topsflo is the first to enter the market, and it has laid out the charging pile cooling application field with an advanced vision. In 2015, Topsflo became the pump supplier of TESLA, and has provided 250,000 liquid-cooled circulating pumps for them. On the busy streets of Wall Street, Topsflo pumps are behind the rows of charging piles. Up to now, Topsflo has successfully provided high-efficiency liquid cooling solutions for more than 20 well-known enterprises in the charging pile industry. Topsflo Redefines Liquid Cooled Charging Pile Water Pump As the power source of the supercharged pile cooling module, the liquid cooling water pump plays a very important role in the safety and reliability of the supercharged pile. As the pioneer of the mature solution provider for supercharged liquid cooling system, Topsflo liquid-cooled circulating water pumps are suitable for different cooling applications such as supercharged liquid-cooled cooling modules, cable liquid cooling system, etc. The high quality presented is favored by customers in the charging pile industry. First, 100KW-600KW are applicable, which truly empowers "cool and fast" charging piles. Topsflo adopts electronic components from internationally renowned brand, with uniquely designed PCB board, sufficient margin design for electronic solutions, low temperature rise, fast heat dissipation, and remarkable cooling effect. At present, the maximum output power of supercharged piles on the market is 600KW. Over the years, Topsflo has been continuously researching and making breakthroughs to fully meet the liquid cooling needs of all supercharged piles in the market. Second, it can meet the needs of different working conditions of super charging piles, no matter it’s freezing or high temperature. Charging piles are generally installed outdoors, thus they must be able to withstand a variety of extreme weather. Each Topsflo water pump has undergone strict high and low temperature fast switching tests of the whole machine, and has a wide temperature resistance range, which can easily meet the ambient temperature requirements of -30°C to 70°C for supercharged piles on the market. Third, intelligent control can be realized. Intelligent interaction is one of the key selling points of super charging piles. Topsflo is committed to providing customers with liquid-cooled water pumps with strong competitiveness, supporting 5V/PWM speed regulation, FG speed signal feedback, matching with different power charging piles, realizing automatic intelligent detection function, supporting failure alarm, real-time data feedback etc.。 Fourth, the life span exceeds 30,000 hours and is maintenance-free. Charging piles arranged along expressways, highways and in remote areas require long-distance maintenance, and it is difficult for personnel to be in place in time. Therefore, the advantages of Topsflo liquid-cooled water pump, which is maintenance-free and has a lifespan much longer than that of ordinary water pumps on the market, can be fully utilized. Fifth, multiple protections make charging more stable. TA60 coolant pump has six safety protection functions, such as dry-running protection, blocked protection, overcurrent protection, polarity protection, overvoltage protection, and constant power output, escorting high-efficiency liquid-cooled super charging piles. Everything is ready, and the first year of ultra-fast charging is finally here. Focusing on the field of micro-pumps for seventeen years, Topsflo insists on independent research and development and technological innovation, based on long-term development, and constantly develops new application fields. The era of ultra-fast charging is both an opportunity and a challenge. Topsflo will continue to improve, keep up with the times and the pace of industry development, and provide customers in the charging pile industry with higher-quality micro-pump products and efficient solutions.

0 notes

Photo

Which brand of charging pile water pump is good?

Charging pile liquid cooling water pump producted by TOPSFLO is suitable for different cooling applications such as supercharging pile liquid cooling heat dissipation modules 、liquid cooling gun line. Various pumps can be choosen and professional customized can be provided according to customer needs which can meet all needs in dc supercharging liquid cooling on the market.The advantages of TOPSFLO charging pile liquid cooling water pump is below:

1、Choosing imported materials.Electronic scheme margin design is sufficient.low temperature rising,fast heat dissipation.

2、After strict high and low temperature fast switching test of the whole machine, there is no fear of extreme temperatures in severe cold and heat

3、Then lifetime is over 30000 hours,maintenance-free,meet the need of long lifetine of high-quality charging piles.

4、Idling protection, locked-rotor protection, overcurrent protection, polarity protection, overvoltage protection, and constant power output six-fold safety protection.

5、Intelligent control,support 5V/PWM speed regulation, FG speed signal feedback, etc.

0 notes

Photo

TOPSFLO high-efficiency liquid cooling water pump helps the well-known American company's supercharged piles sell well all over the world

In 2018, the charger industry achieved "4 minutes of charging continued driving mileage 100km"; in August 2021, it achieved "5 minutes of charging continued driving mileage 200km"; in April 2022, it achieved "5 minutes of charging continued driving mileage 300km"; ... In recent years, the supercharging pile industry has entered the fast lane of development, with technological innovation accelerating and the development momentum gaining momentum. The partnership between TOPSFLO Pumps and American T Company, a well-known manufacturer of DC supercharger stacks for electric vehicles, began in 2017 and just happened to accompany and witness the rise of the industry. After more than five years of cooperation, from small-batch trial production to long-term strategic cooperation, the relationship between the two parties is as long and fragrant as old wine. In 2021, the liquid-cooled circulating water pump provided by TOPSFLO for the T Company's super-charging pile project was officially mass-produced, which added a powerful touch to the history of cooperation between the two parties. Cooperation prelude The titans always have the same vision 2022 is called the first year of construction of high-power liquid-cooled charging piles by many people. In fact, TOPSFLO Pumps has been researching the field of liquid cooling for charging piles for many years. As early as 2015, we started to provide cooling circulating water pump for Tesla and have more than 20 successful application cases in the industry. In February 2017, T Company, a global leader in DC fast charging technology for electric vehicles (EVs), approached a TOPSLO engineer to inquire about a liquid cooling water pump for new energy EVs charger, because it learned that the well-known liquid cooling solution manufacturer is the TOPSFLO pump used by the commercial koolance company. According to the customer's demand, the TOPSFLO Pump industry recommended the miniature brushless DC cooling pump TL-C01 for T company for the first time, and sent samples to the customer for testing. After several months of verification and testing, T company feedback that the TOPSFLO pump has high efficiency, long life and reliable quality, which can fully meet their project needs. Thus, the two parties began to cooperate with the liquid-cooled EV charging cooling pump. Trust upgrade Efficient customization helps new projects come to fruition As DC fast chargers have been updated and iterated, TOPSFLO has actively responded to market changes by building a rigorous team of automotive electronics design experts and a complete development system that has introduced a large number of international advanced devices that can simulated and tailored to the customer's new development needs, to achieve efficient and accurate development. In December 2019, T company sent an email to TOPSFLO engineers again, saying that its new project needed a liquid cooling circulating water pump. It is understood that the customer's new product is a 350KW super-charger , which has a compact design, a small footprint, and can be applied to any environment. This new project needs a small size, high safety performance liquid cooling circulating pump that can be used in the liquid maximum temperature of 85℃ and the environment maximum temperature of 70℃ working condition. In response to the high demand of customers, TOPSFLO engineers recommended TA60 EV coolant water pump for its testing. In the first round of tests, the customer reported that the pressure of the water pump was relatively small, which did not achieve the expected effect. After in-depth communication with the customer, the structural engineer of TOPSFLO found that the internal pipeline of the customer's product is long and there are many bends, which cannot make the pump perform at its best, and immediately provided the customer with reasonable structural optimization suggestions and solutions. After more than a year of testing, the customer sent feedback: TOPSFLO TA60 cooling water pump successfully matched the application requirements of T company's 350KW super charging pile! In February 2021, TOPSFLO TA60 water pumps began mass production and were used in customer projects. At present, T company's products have been sold to 41 countries, and tens of thousands of charging piles using TOPSFLO pumps are standing all over the world. The customer said that TOPSFLO pumps are not only reliable in performance, but also have good batch consistency. They choose to cooperate with TOPSFLO without any worries! Advantage decryption Forging high-quality liquid cooling water pumps with high standards in the automotive industry The reason why TOPSFLO Pumps can stand out in the increasingly fierce market competition stems from the unremitting pursuit of technology and quality. The research and development process for TOPSFLO charger liquid cooling circulating pump strictly followed the automotive industry's highest IATF 16949 standards and selected automotive-grade electronic components to meet the cooling application requirements of high-power charge piles. 1. Environmental adaptability - with good temperature resistance. According to the technical requirements of charging piles, most of the working environment temperature is required to be between -20 °C and 50 °C. At present, the ambient temperature requirements of most powerful charger on the market are basically between -30 °C and 70 °C. The TOPSFLO TA60 E-car circulation pump can be started at an extremely low temperature of -45°C and is resistant to a high temperature of 100°C. TOPSFLO has four major professional and precision laboratories that meet the national CNAS standards. It performs reliability verification that is stricter than industry standards, and conducts cold and thermal shock tests for the whole machine and extreme temperature and temperature rise tests to ensure the excellent high and low temperature resistance of the pump. 2. Product reliability - with a long life. A high-quality charging pile can be used for 10 years or even longer, so the life expectancy of the water pump is also higher. Topsflo charging pile liquid cooling circulating water pump uses high efficiency DC brushless motor, korean-branded PPS housing, imported chips, high-precision silent rotors and a 30,000-hour lifespan, which is significantly higher than the average water pump on the market. Using internationally renowned brand name electronic components and uniquely designed PCB boards, professional high-temperature electronic solutions are designed for lower temperature rises and higher reliability. In addition, TOPSFLO is one of the few companies in the domestic micro brushless DC pump industry that has obtained the international authoritative TÜV Rheinland ISO 9001 & IATF 16949 dual quality system certification. "Let every pump be used with absolute confidence". 3. Batch consistency - with high quality control standards. The charging pile industry has grown rapidly and has entered the mass production phase, so the requirements for product batch consistency are very high. TOPSFLO adopts the most advanced static management system in the industry to prevent, detect and eliminate static electricity, and avoid product electronic failure caused by potential static electricity; Only well-known suppliers were selected for key raw materials to ensure batch consistency across different batches of material; Automated equipment has been introduced from Japan, United States, Germany and other countries to build intelligent production lines where batch consistency of the process is highly efficient and guaranteed; it adopts 6 full inspection processes that are stricter than national standards, strictly follows the international quality system standards, and pursues quality "zero defect". Product defect rates can be as low as 1 in 1,000,000. Under the global wave of intelligence, TOPSFLO is committed to providing its customers with products that are highly competitive, support 5V/PWM speed regulation, FG speed signal feedback, and can be matched with charging stacks of different powers, enabling automatic intelligent detection capabilities, support for failure alarms, real-time data feedback etc. Epilogue Since its establishment for 17 years, TOPSFLO Pumps has won a good reputation from customers for its high quality, and has reached stable and long-term cooperation with hundreds of well-known companies around the world, such as Tesla, Whirlpool, Flex, Kohler, GE, Roca, KTM, Geberit, etc. In the future, TOPSFLO will continue to conduct in-depth research and improve quality, provide more high-quality assured pumps for our customers, and escort high-efficiency liquid-cooled super charging piles and more industries!

0 notes

Photo

Focusing on the field of liquid cooling of charging pile cables for many years, TOPSFLO Pump Co., Ltd. is calmly responding to the era of supercharging.

Many people have to consider the issue of charging when buying new energy vehicles. Compared with the slow charging of "small water and long flow", convenient and efficient super charging piles are more in line with the needs of car owners, which has also become the focus of competition between car companies and charging pile companies. Electric vehicles are moving towards the era of super fast charging, which has also driven the use of liquid-cooled charging cables.

The layout of super charging is the general trend

Once, OPPO's slogan "charge for 5 minutes, talk for two hours" opened up the era of super fast charging of mobile phones. Now, this phrase is used in the field of new energy vehicles.

On August 15, Xiaopeng Motors released the S4 super charging technology, which can charge for 5 minutes and have a range of 200 kilometers. At the same time, it was announced that 1,000 self-operated charging stations will be launched, which is also the first station in the country equipped with the latest generation of ultra-fast charging pile S4. Xiaopeng plans to build another 2,000 ultra-fast charging stations by 2025.

On August 30, Sinopec's first community super charging station in China, Lotus Super Charging Station, was completed and put into use in Longyan City, Fujian Province. It can charge 24 vehicles, integrating refueling, charging, photovoltaics, and rest. An ordinary family car with a range of about 400 kilometers can be filled in as little as 25 minutes.

With the continuous improvement of the market's requirements for the charging capacity of electric vehicles, high-power fast charging and super fast charging have become an inevitable option for car companies to improve their advantages, which also means that the utilization rate of liquid-cooled charging cables will be greatly improved.

Liquid-cooled cables solve the problem of charging thermal damage

For ordinary car charging cables, the increase of charging current and voltage is bound to increase the wire diameter and insulation thickness of the cable to ensure the smooth transmission of high-power current, but this also makes the cable thick and hard, and the charging gun is cumbersome and difficult. In addition, the high-power current transmission will inevitably dissipate more heat. During the charging period, the charging gun contacts the car at a high temperature, which will easily increase the risk of spontaneous combustion of the car.

The use of liquid-cooled high-power charging cables can alleviate the above problems. The liquid cooling cable is a special cable used for high-current heating equipment. A special circulation channel is set between the cable and the charging gun. The heat dissipation effect is more suitable for high-power charging of electric vehicles, which can reduce the thermal damage caused by high-power charging to the charging gun, charging cable, and charging pile.

As the first car company in the world to adopt liquid-cooled charging, Tesla has been developing a charging station with a new liquid-cooling system in 2015. In March 2019, Tesla V3 supercharger appeared in the world, using a liquid-cooled charging cable. The diameter of the charging cable is about 44% smaller than that of the V2 supercharger, which is only 23.87mm. The maximum peak power of the supercharger can reach 250kW.

With the continuous adjustment and upgrading of the electric vehicle industry, the hardware requirements of high-power charging and fast charging will continue to drive the electric vehicle charging connection device. Products must master cooling technology. Liquid-cooled circulating water pumps have also become the focus of liquid-cooled charging cables and even charging pile manufacturers. one of the focal points.

TOPSFLO provides mature solutions for liquid cooling of supercharged cable

As a company with nearly 20 years of experience in the R&D and production of micro-pumps,TOPSFLO Pumps is far-sighted and has carried out in-depth research on charging pile cooling applications many years ago. Since 2015, it has successfully provided 300,000 liquid pumps to Terra Cold circulating water pump. TOPSFLO charging pile liquid-cooled circulating water pump has the advantages of small size, good cooling effect, high and low temperature resistance, long life, maintenance-free, intelligent control and many other advantages that ordinary water pumps in the market cannot compare with, and can provide professional customization according to customer needs, including EMC electromagnetic compatibility scheme, etc.

"Let every pump of TOPSFLO be used with absolute confidence", TOPSFLO has practiced this quality concept for many years, and strictly controls the quality according to the TÜV Rheinland IATF 16949 quality management standard. More than 90% of TOPSFLO pump parts and electronic components are from world-renowned brands, and do not use mixed materials and any recycled materials; equipped with a series of advanced production equipment imported from the United States, France, Japan and other countries that are in line with international standards, to carry out high-level Precision and high-efficiency production; 38 all-round performance in-depth tests that are stricter than industry standards, and each pump must undergo a comprehensive performance test before leaving the factory to ensure product reliability. As a global high-quality supplier of miniature brushless DC pumps, TOPSFLO will continue to provide excellent products and services to customers around the world.

0 notes