#microgearpump

Explore tagged Tumblr posts

Text

What Are the Advantages and Disadvantages of Different Coffee Machine Water and Milk Pump?

Pump, the core power system of coffee machine, is crucial for ensuring the smooth flow of water and milk during the brewing process. In a coffee machine, the water pump is primarily responsible for extracting coffee, while milk pumps are mainly used in automatic milk frothing systems to draw milk from storage tanks, heat it, and create foam.These two types of pumps have different application requirements in various coffee machine models, with common pump types including vibration pumps, rotary vane pumps, and gear pumps. Below, we will analyze the advantages and disadvantages of different pumps in the context of home and commercial coffee machines.

Household Coffee Machines

Household coffee machines are divided into regular and high-end types based on user needs. Their pump requirements vary, with regular models focusing on price and basic functionality, while high-end models prioritize performance and coffee taste.

1.1 Standard Household Coffee Machines

Water Pump: Vibratory Pump

Advantages

Low Cost: Vibratory pumps are relatively inexpensive, suitable for budget-conscious home users.

Compact Design: Vibratory pumps are small in size and take up little space, fitting well into the compact design of household coffee machines.

Disadvantages

Unstable Pressure: The pressure output of vibratory pumps fluctuates, potentially leading to inconsistent coffee extraction quality.

High Noise: Vibratory pumps produce noticeable noise during operation, affecting the user experience.

Milk Pump: Manual or Basic Automatic System

Advantages

Low Cost: Most ordinary household coffee machines use manual steam wands or basic automatic milk frothing systems, which are cost-effective.

Disadvantages

Inconsistent Milk Foam Quality: Manual systems rely on user operation, easily resulting in unstable milk foam quality.

High-End Household Coffee Machines

Designed for family users who pursue coffee quality and experience, high-end household coffee machines typically use better-performing pumps, such as vane pumps or high-performance vibratory pumps, and are equipped with advanced automatic milk frothing systems.

Water Pump: Vane Pump

Advantages

Stable Pressure Output: Vane pumps provide consistent and stable pressure, ensuring uniform coffee extraction quality each time.

Low Noise: Compared to vibratory pumps, vane pumps operate with less noise, enhancing the user experience.

Disadvantages

High Cost: Vane pumps are more expensive, increasing the overall cost of the coffee machine.

Larger Size: Vane pumps are bulky, occupy more space, and increase design complexity.

Milk Pump: Coffee Machine Milk Pump (Gear Pump)

Advantages

High-end household machines are equipped with automatic milk frothing systems containing adjustable-speed milk pumps, ensuring evenly textured and delicate milk foam for milk-based drinks like lattes and cappuccinos.

Disadvantages

Complex Maintenance: Automatic milk frothing systems require regular deep cleaning to prevent milk residue buildup.

Commercial Coffee Machines

The pump system design of commercial coffee machines is intended to handle high-intensity work demands, divided into regular commercial automatic coffee machines and high-end commercial automatic coffee machines. Commercial machine pumps need higher durability, efficiency, and stability.

Standard Commercial Automatic Coffee Machines

Standard commercial automatic coffee machines are commonly used in small to medium-sized cafes or dining establishments. To balance cost and performance, they often use vane pumps or high-durability vibratory pumps.

Water Pump: Vane Pump

Advantages

Efficient and Stable: Vane pumps provide stable pressure output for long periods in commercial settings, suitable for continuous high-frequency coffee production.

Strong Durability: Vane pumps have a long lifespan and can withstand the production demands of numerous orders.

Disadvantages

Higher Cost: Compared to household vibratory pumps, vane pumps are more expensive but more economically beneficial in long-term use.

Milk Pump: Coffee Machine Milk Pump (Gear Pump)

Advantages

High Consistency: Commercial automatic milk frothing systems with adjustable-speed milk pumps ensure stable milk foam quality, reducing the impact of operator skill differences on product quality.

Disadvantages

Complex Equipment: Commercial milk frothing systems have complex structures and high maintenance costs, requiring regular maintenance by professionals.

High-End Commercial Automatic Coffee Machines

High-end commercial automatic coffee machines are often used in high-end hotels, boutique cafes, and other venues requiring extremely high efficiency and stability. They commonly use vane pumps and gear pumps, equipped with advanced milk frothing systems.

Water Pump: High-Performance Vane Pump or Gear Pump

Advantages

Extremely High Stability: High-performance vane pumps or gear pumps excel in high-intensity commercial use scenarios, providing consistent high pressure.

Precise Control: Gear pumps can precisely control flow rates, suitable for making high-end coffee, enhancing coffee taste and texture.

Disadvantages

Expensive: These pump systems are costly, suitable for high-end commercial venues with sufficient budgets.

High Maintenance Requirements: High-end pump systems require regular maintenance to ensure long-term efficient operation.

Milk Pump: Advanced Intelligent Milk Frothing System

Advantages

Intelligent Adjustment: Advanced milk frothing systems can automatically adjust the thickness and temperature of milk foam based on different beverage needs, providing a perfect user experience.

Fast and Efficient: Suitable for handling large order demands during peak times.

Disadvantages

Complex and Costly Maintenance: The cleaning and maintenance of advanced systems are complex, requiring ensuring no milk residue blocks the system.

Summary

Different types of coffee machines have varying requirements for pump systems. Home machines tend to use more affordable vibration pumps, while high-end home and commercial machines opt for higher-performing rotary vane pumps or gear pumps to meet the demands for better quality and stability. The pumps for water and milk serve distinct functions, and the choice of pump system not only affects the quality of coffee extraction but also directly impacts the overall user experience and maintenance costs. When selecting a coffee machine, the type of pump is a key factor in determining its performance and durability.

Wanna to get custom pump service? Feel free to contact us now:

Email: [email protected]

Whatsapp/Wechat:+86-19376691419

Visit our Web: https://www.topstec.com/ | http://www.topsflo.com/

youtube

Factory Tour

youtube

0 notes

Text

TOPSFLO Automatic Commercial Coffee Machine Milk Pump

☕️Give your automatic commercial coffee machine a competitive edge with TOPSFLO Food Grade Micro Gear pumps—milk pump!

We understand your systems, challenges and market situation. That's why TOPSFLO are the preferred choice for addressing common problems of your products. Let's explore the issues and discover how our milk pump solutions can improve the automatic commercial coffee machine experience for your customers:

1️⃣ Milk Frothing Temperature Issue: Problem: Coffee shops and businesses often require flexibility in milk foam texture and temperature that traditional venturis cannot provide. ✅Solution: TOPSFLO automatic commercial coffee machine milk pump can froth both cold and hot milk, allowing users to customize the coffee experience to meet customer preferences.

2️⃣Inconsistent Milk Frothing: Problem: Traditional pumps may struggle to achieve consistent milk frothing, leading to variations in beverage quality. ✅Solution: TOPSFLO milk pumps ensure stable pressure and precise flow, guaranteeing uniform and high-quality milk froth for every cup of coffee.

3️⃣Operational Noise: Problem: Noisy water pumps can disrupt the ambiance in coffee shops and businesses, impacting the overall customer experience. ✅Solution: TOPSFLO milk pumps operate quietly, providing a peaceful environment for customers and maintaining the ideal atmosphere.

4️⃣Maintaining Hygiene Standards: Problem: Residue and bacterial growth in pumps handling milk or other dairy-based beverages can pose hygiene concerns, especially in high-usage environments. ✅Solution: TOPSFLO milk pumps are made with materials that meet hygiene standards, featuring a simple internal structure designed to minimize the risk of milk residue buildup, making them easy to clean and maintain.

5️⃣Electronic Compatibility Challenge ✅Solution: TOPSFLO Micro Gear Pump TG-01 motor design fully takes into account the European electrical electromagnetic compatibility standards (EMC), which can reduce interference, ensure the stable operation of the equipment and seamless integration.

⚙Versatility Beyond Coffee Machines: 🍹 Beverage Dispensers and Vending Machine 🍯 Food Processing ...

TOPSFLO Gear Pumps offer a comprehensive solution to the challenges faced by customers in the context of fully automatic commercial coffee machines. With features such as precise flow control, quiet operation, durability, compact design, temperature resilience, our milk pumps provide a reliable and efficient solution for the demanding requirements of the coffee industry.

👉 Welcome to share your machines and talk the problems you're facing with us. http://www.topsflo.com/

0 notes

Text

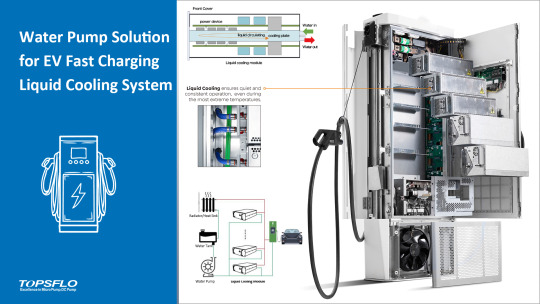

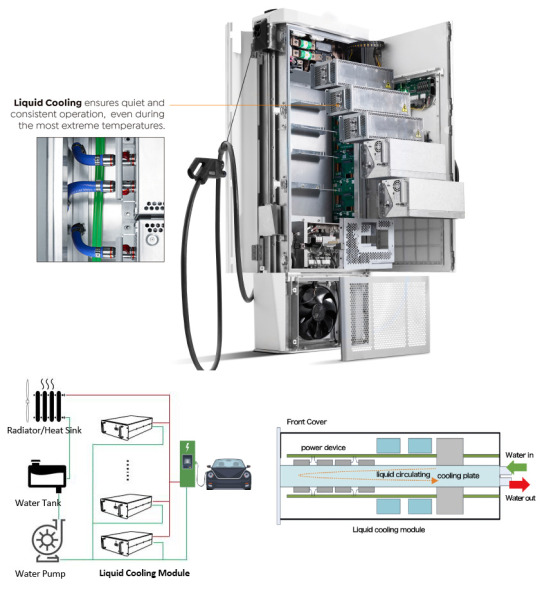

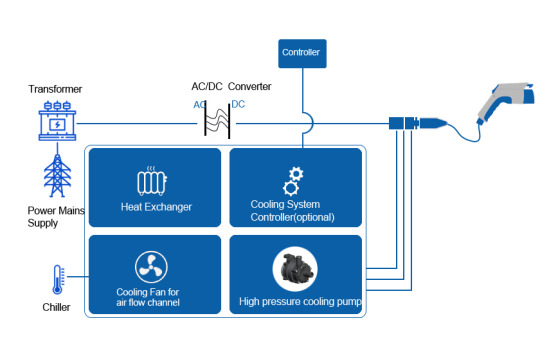

Water Pump Solution for EV Fast Charging Liquid Cooling System

Market Basics

"2021 China Electric Vehicle User Charging Behavior White Paper" released by the Charging Alliance shows that 99.3% of electric vehicle users prefer fast charging. And how can the charging pile realize faster charging? One is by increasing the output power (need to add module liquid cooling), the second is to increase the current (need to add gun line liquid cooling). At present, the liquid cooling system is the best solution for DC supercharging charging pile in the market, and the water pump, as an important part in the liquid cooling system, plays a key role in the cooling effect.

Market Pains

Charger Power Module Liquid Cooling

Superchargers generally consist of multiple DC:DC or AC:DC modules stacked on top of each other, and require a large flow rate to deliver coolant to each module for uniform heat dissipation;

EV Charging stations are equipped with intelligent management systems, which need to realize remote management, monitoring and data analysis, etc., and therefore cannot be subject to electromagnetic interference from other components.

Cable Liquid Cooling

Liquid-cooled charging cables are often thinned and lengthened to be more lightweight, thus adding a very large amount of drag to the liquid-cooled system;

The cable liquid cooling system generally uses glycol antifreeze or insulating oil as the medium. The viscosity of the liquid is different at different temperatures, especially the silicone oil, and the viscosity of the liquid will increase exponentially at low temperatures;

EV Fast Charging Water Pump Solution

Charger Power Module Cooling Solutions

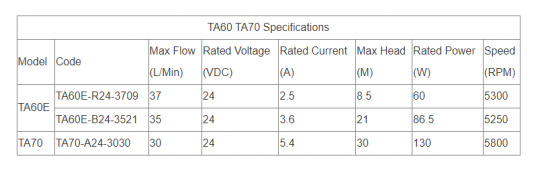

TOPSFLO water pump TA60/TA70 is designed to meet the needs of charging pile's multi-power module cooling, through the motor and fluid simulation, special design of high-efficiency motor and structural solutions, while minimizing power consumption, the maximum flow rate up to 60L/min, faster and better cooling so that there is no risk of overheating in the charging post module.

Charging pile liquid-cooled water pump is specially designed for low-temperature startup, and PWM intelligent speed regulation function. It can withstand low temperature -40℃, and adjust the motor speed according to the different viscosity of the liquid under different temperature conditions, which can solve the technical problem of not discharging liquid under low temperature due to excessive viscosity of the liquid.

TOPSFLO water pumps are designed with vehicle-grade electronic solutions, which can well meet the EMC specification requirements for charging piles. It will not cause interference to the electronic system of the charging pile, and at the same time, it can also resist electromagnetic interference from other equipment.

Cable Cooling Solutions

Cable Liquid cooling for coolant ( up to 400A )

Depending on the cable length and diameter, the resistance will vary and the cooling solution will be different. The smaller the cable diameter, the higher the resistance, and the longer the cable, the higher the resistance.

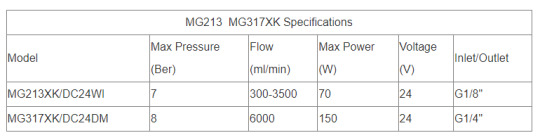

For low resistance, it is recommended to consider TOPSFLO centrifugal pump TA60E-B24-3521

For high resistance, it is recommended to consider TOPSFLO gear pump MG213

Cable Liquid cooling for dimethyl silicone oil (over 400A)

For high current cables of more than 400A, silicone oil is usually chosen as the cooling medium, which has relatively higher resistance. For this kind of high resistance cable cooling application, TOPSFLO newly developed a high pressure liquid cooling gear water pump - MG317, the maximum water pressure up to 10bar, can meet 500-600A cable cooling of charging connector.

#dcwaterpump#waterpump#brushlessdcpump#topsflopump#12vdcwaterpump#12vwaterpump#24vdcwaterpump#bldcpump#dc water pump#carwaterpump#microgearpump#evcharger#fastcharging#liquidcoolingsystem#waterpump12vdc#waterpumpmanufacture#water pumps

0 notes