#substrate compatibility

Explore tagged Tumblr posts

Text

How to Choose the Right Printable Electronic Ink for Your Application

Discover how to select the best printable electronic ink for your application by considering conductivity, substrate compatibility, printing methods, and environmental stability. Ensure optimal performance and reliability in your electronic devices. Contact A-Gas Electronic Materials for expert guidance today.

#printable electronic ink UK#conductive ink UK#dielectric ink UK#substrate compatibility#electronic printing UK#flexible displays UK#wearable electronics UK#PCB ink#A-Gas Electronic Materials#electronic manufacturing UK

0 notes

Note

Hi, out of curiosity...can we actually propagate lichens in our backyards? Is it feasible? It seems like a good idea to help or allow them thrive in residential areas

ok ive gotten asks like this before and the answer is that like... unless you're a lichen researcher person and youre gathering existing lichens of the species you want outside and culturing them on plates in a lab for an experiment (how lichens are grown in a lab if i remember correctly because growing one from scratch with a fungal spore and a compatible algal spore still doesnt work, you still need the sourdough starter, and even then it takes a long time and is really hard), for the most part the lichens, they command respect in a way that plants dont, you see. the lichen chooses to grow where it wants, when it wants. it chooses the substrate and conditions and sticks to it. those microhabitats are hard to replicate and they take so long to grow and are so variable in their preferences, my advice is that if you want to have more lichens in your life, look into what organic substrates you want to attract wants, and leave those substrates lying around or growing in your backyard untouched for 10+ years. or alternatively find a patch and visit them. or alternatively move to a coastline if you havent already because they love the mist that rolls in and the temperate temperatures.

may i suggest visiting an old graveyard that doesnt scrape them off regularly? because they are loving graveyards let me tell you. perhaps an old retaining wall or big tree that for some reason has a lot of them on there while the other trees don't have as much. lichens are the kings of seeing one hyperspecific substance and going I Sleep and then seeing the same substance 4 feet to the left and going oh nevermind the 17-year-4-month-old-cinderblock-remnants-with-a-ittle-bit-of-dirty-water-dribbling-on-them-enjoyers have logged tf on actually

885 notes

·

View notes

Text

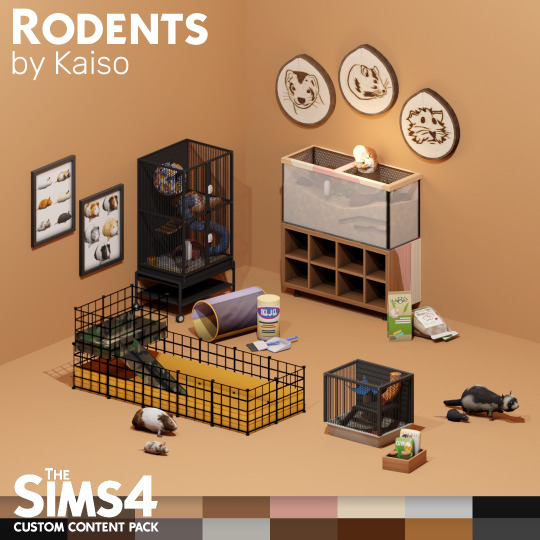

The Sims 4 Rodents CC Pack

The Sims 4 Rodents CC Pack

Add four new decorative small pets to your game with 5+ hand-painted fur variations each and 4 new respective pet enclosures, along with other rodent themed items for your pet-loving Sims to decorate with.

- Base Game Compatible

- Custom tuned enclosures allow for naming your pet.

- 6+ enclosure swatches give plenty of customization for your Sims to choose from when placing enclosures in their spaces.

- 5+ hand-painted fur variations per animal allow plenty of choice when deciding to “adopt” a pet from the buy catalog.

- Pets are placed into enclosures via slots, except for the Guinea Pig Enclosure, which is placed with bb.moveobjects on.

Recommended Enclosure Use:

Play with these items as you wish, but my intention was to provide as accurate of a CC Pack as I can for realism and storytelling purposes.

Hamster Cage – Perfect for 1 hamster with deep substrate to encourage natural burrowing behavior for optimal enrichment. Place on HMSTR table for optimal fit and swatch combinations.

Large Rodent Cage – Provides space for 2 ferrets or 4 rats. Place on a Cage Stand or on a stable table surface. Ferrets are largely free roam animals but should have an enclosure for when they are unsupervised or sleeping.

Small Rodent Cage – Suitable for 2 rats.

Guinea Pig Enclosure – Place any pet objects you would like within your guinea pig’s enclosure with bb.moveobjects on, such as a litter box, food bowl, or Rodent Play Tube. Place the Guinea Pig Enclosure Upper Tier in the provided slot to give your little friends more room to play.

Search Rodents or Kaiso to find the items from this CC pack.

20 Items total:

Cute Critters Print | 4 swatches

Cage Stand | 2 swatches

Cleaning Supplies | 7 swatches

Ferret | 5 swatches

Rodent Food | 5 swatches

Guinea Pig | 5 swatches

Guinea Pig Enclosure | 6 swatches

Guinea Pig Enclosure Upper Tier | 6 swatches

Hamster | 6 swatches

Hamster Cage | 6 swatches

Hamster Lampster | 4 swatches

HMSTR Table | 9 swatches

Rat | 7 swatches

Large Rodent Cage | 6 swatches

Small Rodent Cage | 6 swatches

Substrate Bags | 3 swatches

Once-In-A-While Treats | 4 swatches

Rodent Play Tube | 6 swatches

Wooden Friends | 5 swatches

Zoom-Zoom Pet Toy | 3 swatches

All items have all LODs and are as low poly as possible. (Largest item is the Guinea Pig Enclosure at 2.1k polys).

DOWNLOAD (FREE) on Patreon: https://www.patreon.com/posts/sims-4-rodents-76397251

#sims 4 cc#sims 4 cc pack#mm cc#ts4 cc#ts4 cc pack#ts4cc#s4cc#kaisosims#s4 buy#s4mm#ts4 buy mode#ts4 build buy cc#ts4 furniture cc#ts4 object cc#ts4 mm cc#ts4 maxis match cc#maxis match cc#sims 4 custom content#sims 4 maxis match#kaiso#sims 4 mod#sims 4 terrariums#sims 4 small pets#sims 4 rodents#sims 4 rats#sims 4 hamsters#sims 4 guinea pig#sims 4 ferret#ts4 small pets#ts4 rats

6K notes

·

View notes

Text

One of the things enterprise storage and destruction company Iron Mountain does is handle the archiving of the media industry's vaults. What it has been seeing lately should be a wake-up call: Roughly one-fifth of the hard disk drives dating to the 1990s it was sent are entirely unreadable.

Music industry publication Mix spoke with the people in charge of backing up the entertainment industry. The resulting tale is part explainer on how music is so complicated to archive now, part warning about everyone's data stored on spinning disks.

"In our line of work, if we discover an inherent problem with a format, it makes sense to let everybody know," Robert Koszela, global director for studio growth and strategic initiatives at Iron Mountain, told Mix. "It may sound like a sales pitch, but it's not; it's a call for action."

Hard drives gained popularity over spooled magnetic tape as digital audio workstations, mixing and editing software, and the perceived downsides of tape, including deterioration from substrate separation and fire. But hard drives present their own archival problems. Standard hard drives were also not designed for long-term archival use. You can almost never decouple the magnetic disks from the reading hardware inside, so if either fails, the whole drive dies.

There are also general computer storage issues, including the separation of samples and finished tracks, or proprietary file formats requiring archival versions of software. Still, Iron Mountain tells Mix that “if the disk platters spin and aren’t damaged," it can access the content.

But "if it spins" is becoming a big question mark. Musicians and studios now digging into their archives to remaster tracks often find that drives, even when stored at industry-standard temperature and humidity, have failed in some way, with no partial recovery option available.

“It’s so sad to see a project come into the studio, a hard drive in a brand-new case with the wrapper and the tags from wherever they bought it still in there,” Koszela says. “Next to it is a case with the safety drive in it. Everything’s in order. And both of them are bricks.”

Entropy Wins

Mix's passing along of Iron Mountain's warning hit Hacker News earlier this week, which spurred other tales of faith in the wrong formats. The gist of it: You cannot trust any medium, so you copy important things over and over, into fresh storage. "Optical media rots, magnetic media rots and loses magnetic charge, bearings seize, flash storage loses charge, etc.," writes user abracadaniel. "Entropy wins, sometimes much faster than you’d expect."

There is discussion of how SSDs are not archival at all; how floppy disk quality varied greatly between the 1980s, 1990s, and 2000s; how Linear Tape-Open, a format specifically designed for long-term tape storage, loses compatibility over successive generations; how the binder sleeves we put our CD-Rs and DVD-Rs in have allowed them to bend too much and stop being readable.

Knowing that hard drives will eventually fail is nothing new. Ars wrote about the five stages of hard drive death, including denial, back in 2005. Last year, backup company Backblaze shared failure data on specific drives, showing that drives that fail tend to fail within three years, that no drive was totally exempt, and that time does, generally, wear down all drives. Google's server drive data showed in 2007 that HDD failure was mostly unpredictable, and that temperatures were not really the deciding factor.

So Iron Mountain's admonition to music companies is yet another warning about something we've already heard. But it's always good to get some new data about just how fragile a good archive really is.

67 notes

·

View notes

Text

Flexible, permeable and 3D integrated electronic skin combines liquid metal circuits with fibrous substrates

In recent years, research teams worldwide have been trying to develop new flexible and soft electronics. These devices could have various potential applications, for instance helping doctors to monitor their patients' health conditions or supporting rehabilitation and performance sports. To be safely and comfortably worn by users daily, these devices should be permeable (i.e., based on breathable materials that allow liquids and gases to pass through them). They should also be bio-compatible (i.e., safe to be worn on the human body for long periods of time) and strain resistant, meaning that they do not break easily when stretched or pulled in a specific direction. Researchers at the Hong Kong Polytechnic University and other institutes in China recently developed a new intrinsically permeable, 3D integrated and flexible electronic skin. This e-skin, presented in a paper in Nature Electronics, is based on high-density inorganic electronic components placed on organic stretchable fibrous substrates.

Read more.

12 notes

·

View notes

Text

I have no idea why I am so proud of this simple creature. I just love it. No shading. No texture. Just block color and yet... it is just lovely. In retrospect I probably should have painted its horn gold instead of silver but you know what? It's my art project I will do whatever I want and then sell it here... https://www.ebay.com/usr/willowwind78.

This thing took me forever. Not because it was difficult mind you just because... well I have a focusing issue. Yes, just add it to my list of problems. It's fine. Once again, the Hobby Lobby grass just fits.

I bought a new grass substrate off Amazon not long ago that has purple flowers in it and I think it would look fantastic as the base to another one of these rainbow unicorns. I have more. You get a bunch of them when you buy the Monster Miniature set off Amazon: Amazon.com: Monster Fantasy Creature Mini Action Figure Playset - 98pcs Toy Miniatures with 14 Unique Designs - Dragons,Wizards,Orcs, & More- XL 1/32 Scale Compatible with Dungeons and Dragons and other RPG Games : Toys & Games

#miniature painting#how not to paint miniatures#painting miniatures#dungeons and dragons#unicorn#rainbow#rainbow unicorn

10 notes

·

View notes

Text

Printing Custom Mylar Bags: An In-Depth How to Exploration of Digital and Flexo Printing Techniques

Custom Mylar bags are a stellar choice for brands looking to combine robust packaging with eye-catching design, especially prevalent in sectors like food, cannabis, and health care products. In the world of printing on these durable, barrier-enhancing bags, two primary technologies reign supreme: digital printing and flexographic (flexo) printing. This extensive guide delves into each method, detailing their processes, benefits, and when to use one over the other.

Decoding Mylar Bags

Mylar, technically known as biaxially-oriented polyethylene terephthalate (PET), is favored for its excellent protective qualities, including moisture resistance and durability. It’s a go-to for products needing a longer shelf life and consistent freshness.

Before You Print: Key Steps

Before setting the printing wheels in motion, consider these critical steps:

Design Mastery: The right design transcends aesthetics, reflecting your brand’s ethos and meeting packaging specifications with flair.

Choosing the Right Bag: Factor in the product’s needs—size, features like zip-locks or clear windows, and the overall style of the bag.

Prep the Material: Mylar often requires specific treatments to ensure ink adherence during printing.

Digital Printing on Mylar Bags

Digital printing impresses with its direct approach, where designs from digital files spring to life on the substrate through inkjet or laser technology.

Step-by-Step Process

Digital Design: Transform your creative vision into a digital file compatible with the printing machinery, using tools like Adobe Illustrator.

Set Up: Position the Mylar bags in the printer, tuned to accommodate the material’s specifics.

The Printing Dance: The printer interprets the digital file, meticulously layering CMYK inks to recreate your design on the bag.

Ink Setting: Post-printing, some inks may need curing to secure their bond with the Mylar.

Why Go Digital?

Quick Turnaround: Skip the setup complexities and dive straight into printing.

Small Batch Friendly: No hefty setup fees, making it perfect for limited runs or bespoke orders.

Precision and Color: Achieve sharp, vibrant prints that catch the eye.

Adaptable: Easily tweak designs between runs without financial heartache.

Potential Drawbacks

Ink Stability: May require additional protective measures to enhance durability.

Cost Efficiency: Larger orders can become costly compared to flexo printing.

Flexographic Printing on Mylar Bags

Flexo printing, a sophisticated evolution of letterpress, uses flexible plates to apply ink onto materials like Mylar, marrying old-school technique with modern efficiency.

How It Works

Plate Crafting: Each color in your design calls for its own flexible plate.

Inking Up: Plates kiss the ink rollers, transferring the design sequentially to the Mylar as it moves through the press.

Curing the Print: A drying phase ensures the ink melds flawlessly with the Mylar.

Flexo’s Strengths

Bulk Efficiency: Once the setup is complete, flexo churns out large volumes swiftly, making it cost-effective.

Lasting Impressions: Uses robust inks that endure, ideal for long-term display and functionality.

Material Versatility: Adapts to a wide range of inks and materials.

Considerations

Upfront Investment: Initial costs can be high due to the need for custom plates.

Rigidity: Switching designs or running small batches can be economically impractical.

Which Printing Path to Take?

Your choice between digital and flexo printing will hinge on several factors:

Volume: Digital suits low quantities, while flexo excels at high-volume orders.

Budget: Consider digital for minimal upfront costs; flexo for larger investments but lower costs over time.

Design Complexity: Digital is king for intricate, colorful designs.

Durability Demands: Opt for flexo when longevity and wear resistance are paramount.

Wrapping Up

Printing on custom Mylar bags is not just about aesthetics; it’s a strategic choice that enhances product integrity and elevates brand presence. Whether opting for the swift adaptability of digital or the enduring power of flexo, aligning your method with your project’s needs ensures your product stands out beautifully and effectively.

2 notes

·

View notes

Text

Bug's RWBY Worldbuilding Series 2:

Have been cooking up ideas in my head about Aura/Semblances/Dust/Magic, and clarifications and differentiation for each. So finally, Part 2, Dust, which will also need its own sub-parts. First, an overview of what it actually *is*, and then we'll get to the rest. Part 1: Aura Part 1-B: Active Aura Part 2: Dust, A General Overview <- You are here.

Dust in this AU is now not some mysterious independent entity, it's a transmutation of minerals caused by a build-up of condensed Aura, to put it simply. To be more detailed, it's a very slow accumulation of "spent" or "background" Aura within the mineral substrate. That's Aura after it radiates away from living things and loses most of its energy to "cooling". This Aura is very persistent in the atmosphere. Its rate of energy loss eventually hits equilibrium with the energy the system gains as new Aura is released, which creates a sort of constant, low level "background radiation" of Aura across the entire world. This Aura need not be sourced from those with "active" Aura, as every living thing produces Aura particles, and "active" Aura is only the same thing on a much more energetic wavelength. In essence, compared to normal light terminology, most lifeforms are infrared, and "active" Aura is like jumping up to ultraviolet. Meanwhile, "spent" Aura drops down to something like a radio wave. To condense, it then needs a pre-existing, compatible mineral or Dust deposit that will slowly attract it and accumulate it, eventually being transmuted into Dust and then transmuting more pre-existing, surrounding mass into new Dust. Because the particles are ubiquitous, but individually extremely weak, this is the main reason that Dust accumulation takes a long time. ""Renewable"", but on a rather impractically slow scale. A pre-existing deposit steadily increases in mass faster, proportional to available outer surface area, but for each given bit of surface area, maximum accretion rate is only about 1 cm of further buildup per century. Minerals associated with biological sources also seem to be the most "compatible" with the initial transmutation into Dust, but in practice, this does not mean that limestone deposits become giant Dust expanses, or that all coal is replaced with Dust, or that nobody in Remnant knows what diatomaceous earth is. That's because the invisible, uneven "pull" of so many different Dust deposits creates an endless "tug-of-war" that keeps background Aura constantly in flux, instead of always being free to settle and accumulate. Therefore, areas can be considered "saturated" with all the Dust they can form long, long before a full conversion. This phenomenon on a worldwide scale also contributes to background Aura creating vast, worldwide "currents", "eddies", and "jetstreams", which also leads to different areas having different thresholds at which they become "saturated", and these thresholds being subject to gradual change over time. Continuous Aura circulation is also the main reason why someone will not accumulate Dust in their bones as they age. However, ancient remains can transmute, inspiring a great deal of this Remnant's spirituality and mythology. Stories of clams that develop "Dust pearls" are a dime a dozen, as well as tales of legendary creatures and nature spirits born with Dust for bones. Beyond remains, perhaps there is a grain of truth to this... Beautiful as they are, "Dust fossils" are only a rare minority of all fossils found. Not only can they become the nucleus of further Dust growth and become indistinguishable from regular Dust deposits, but many fossils end up in areas that are already too "saturated" with other deposits. However, what kind of Dust you get can be rather complicated. It depends on the environment, depth/elevation, surrounding mineral strata, and the contributing Aura, meaning that it also depends a lot on the local *and* historical ecosystem of an area. So, yes, because it's cold, modern Solitas is currently forming a lot of Ice Dust, but it ends up being much more dynamic and complicated than "Solitas cold, so just Ice Dust".

#rwde#mainly just to be safe#Bug's RWBY Worldbuilding Series#rwby worldbuilding#rwby#for some reason tumblr doesn't remember and autocomplete the specific tag i use for this so that's Fun

10 notes

·

View notes

Text

VICTORIAN FISH TANK

VICTORIAN FISH TANK

Creating a Victorian-style fish tank involves blending the elegance and aesthetics of the Victorian era with the practicalities of modern aquarium keeping. The Victorian era, characterized by ornate designs and a fascination with nature, can inspire a captivating and unique fish tank. Here's a guide to crafting a Victorian-inspired aquarium that harmonizes historical charm with contemporary fish-keeping principles.

1. Aesthetic Elements: Victorian design is known for its opulence and intricate detailing. Incorporate elements such as ornate frames, detailed moldings, and elegant furniture-style aquarium stands. Consider wooden or metal frames with decorative embellishments to capture the essence of Victorian aesthetics.

2. Tank Selection: Choose a tank that complements the Victorian theme. Rimmed tanks with dark, ornate frames or even custom-designed tanks that mimic antique furniture can be excellent choices. Select a size that suits the available space and allows for the comfortable accommodation of the chosen fish species.

3. Decorative Substrate: For a Victorian fish tank, consider using a substrate that reflects the elegance of the era. Dark gravel or sand can provide a classic backdrop for the aquarium. Substrate materials like crushed coral or natural gravel can enhance the visual appeal while promoting a healthy environment for the aquarium's inhabitants.

4. Victorian-Inspired Décor: Integrate Victorian-inspired décor elements such as faux coral, classical sculptures, or miniature replicas of Victorian artifacts. Porcelain figurines, small vases, or even miniature sculptures reminiscent of the Victorian period can be strategically placed to create a visually appealing underwater landscape.

5. Plant Selection: Incorporate aquarium plants that align with the Victorian theme. Anacharis, java fern, or other plants with a lush and slightly wild appearance can evoke a sense of the Victorian fascination with nature. Ensure that the selected plants are suitable for the fish species and tank conditions.

6. Lighting: Victorian-era interiors were often characterized by soft, warm lighting. Mimic this ambiance with subdued aquarium lighting. Use fixtures with warm-toned bulbs or consider incorporating dimmable LED lights to create different moods within the tank. Ensure that the lighting is suitable for both the aesthetic appeal and the well-being of the fish and plants.

7. Fish Selection: Choose fish species that thrive in the aquarium conditions and are compatible with the Victorian aesthetic. Species like angelfish, guppies, or gouramis can add elegance to the tank. Research the specific care requirements of the chosen fish to ensure their well-being.

8. Filtration and Heating: Modern filtration and heating systems are essential for maintaining a healthy aquarium environment. While the equipment itself may not be visually Victorian, it should be discreetly placed and hidden behind decorative elements or within the aquarium stand. Prioritize the well-being of the fish by providing stable and suitable water conditions.

9. Maintenance: Regular maintenance is crucial to keep the Victorian fish tank thriving. Perform water changes, clean the substrate, and trim plants as needed. Incorporate maintenance activities seamlessly into the overall aesthetic by using Victorian-style tools and accessories.

3 notes

·

View notes

Text

Custom DTF Transfers: A Game Changer for Bronx Businesses

In the bustling borough of the Bronx, businesses are constantly looking for new ways to stand out and appeal to their target market. One of the most innovative methods for customizing apparel and products is through Direct-to-Film (DTF) transfers. As the demand for Custom Dtf Transfer Bronx grows, DTF transfers have emerged as a popular choice for entrepreneurs, fashion designers, and small business owners in the Bronx looking to create high-quality, durable, and vibrant prints on a variety of items.

What is DTF Transfer?

DTF (Direct-to-Film) transfer is a relatively new printing technique that involves printing designs onto a special film and then transferring that design onto various substrates like fabrics, bags, or even hard surfaces. Unlike traditional screen printing or heat transfer methods, DTF allows for high-quality prints with intricate details and vibrant colors, while being cost-effective for small and medium-sized runs.

The process starts with printing a design on a special transfer film using eco-solvent inks. The film is then coated with a powder adhesive and cured under heat to make it ready for transfer. Afterward, the printed design is applied to the fabric or other material using heat and pressure. This method is known for producing sharp, vibrant images with excellent color accuracy, making it ideal for custom t-shirts, hoodies, tote bags, and even promotional products.

Why Choose Custom DTF Transfers?

High-Quality Prints DTF transfers provide a superior print quality compared to other methods like vinyl or screen printing. The color depth and resolution of DTF prints are exceptional, making them perfect for designs with intricate details, gradients, and photographic images. The versatility of DTF allows for full-color prints with minimal setup, providing exceptional clarity and crispness on a variety of materials.

Durability and Longevity One of the standout features of DTF transfers is their durability. Unlike other methods that may fade or crack over time, DTF prints are designed to be long-lasting and resistant to wear and tear. The ink used in the process bonds well with fabrics and materials, ensuring that your custom designs stay vibrant even after multiple washes. This makes DTF a great choice for apparel that will see frequent use, such as uniforms, fashion items, and custom merchandise.

Cost-Effective for Small Runs Traditional screen printing often requires expensive setup costs, including screens and large quantities of ink. DTF transfers, on the other hand, offer a cost-effective solution for small and medium production runs. Whether you're printing one custom shirt or 100, DTF provides flexibility without compromising on quality. This makes it especially appealing for local businesses and entrepreneurs in the Bronx who are looking to provide personalized products without breaking the bank.

Quick Turnaround Time For Bronx-based businesses that require fast production, DTF transfers are a great option. The setup time for DTF printing is quick, and the transfer process itself is fast and efficient. As a result, businesses can offer rapid turnaround times to customers, making it easier to meet deadlines or fulfill last-minute orders.

Versatility DTF transfers are compatible with a wide range of materials, including cotton, polyester, leather, and even hard goods like ceramics and wood. This versatility allows businesses to offer a diverse array of Custom Vinyl Decals Printing. Whether you're in the fashion, promotional merchandise, or home décor industry, DTF transfers can be adapted to suit your needs.

0 notes

Text

Top 5 Reasons to Use a Chemical Etching Service in Your Manufacturing Process

Chemical etching is a highly efficient and precise manufacturing process that has gained popularity across various industries. As a leading chemical etching company, OTOEL specializes in providing high-quality chemical etching services that cater to diverse manufacturing needs. Here, we discuss the top five reasons why utilizing a chemical etching service can significantly enhance your manufacturing process.

1. Precision and Accuracy

One of the most compelling reasons to opt for a chemical etching service is the unmatched precision it offers. The process allows for the creation of intricate designs and patterns with tight tolerances, often achieving features as small as 0.01 mm. This level of accuracy is difficult to attain with traditional manufacturing methods such as stamping or laser cutting.

Tight Tolerances: Chemical etching can maintain tolerances of ±10% of the metal thickness or ±0.020 mm, ensuring that every part produced meets exact specifications.

Complex Geometries: The ability to create complex shapes and fine details makes chemical etching ideal for applications in industries like aerospace, electronics, and medical devices.

2. Cost-Effectiveness

Utilizing a chemical etching company can lead to significant cost savings in your manufacturing process. The efficiency of chemical etching reduces waste and minimizes the need for extensive tooling, which can be costly.

Reduced Tooling Costs: Unlike traditional machining methods that require specific tools for each part, chemical etching utilizes photoresist masks, which can be easily modified for different designs.

Lower Material Waste: The subtractive nature of chemical etching means that only the necessary material is removed, resulting in less scrap compared to other processes.

3. Speed and Efficiency

In today's fast-paced manufacturing environment, speed is crucial. A chemical etching service can dramatically shorten lead times compared to conventional machining methods.

Rapid Prototyping: Chemical etching allows for quick iterations during the design phase, enabling manufacturers to test and refine their designs faster.

Shorter Production Cycles: With lead times measured in days rather than weeks or months, companies can respond quickly to market demands and reduce time-to-market for new products.

4. Versatility in Material Use

Chemical etching is compatible with a wide range of materials, making it a versatile option for various applications. A reputable chemical etching company can work with metals such as:

Stainless steel

Copper

Brass

Nickel alloys

Titanium

5. Quality and Consistency

Quality control is paramount in manufacturing, and chemical etching excels in producing consistent results across large production runs.

Uniformity: The controlled nature of the chemical etching process ensures that each part produced is identical to the last, minimizing variations that could affect performance.

No Mechanical Stress: Unlike mechanical processes that can introduce stress into materials, chemical etching does not deform the substrate, resulting in burr-free components with smooth edges.

Suitable Metals for Chemical Etching

1. Stainless Steel

Stainless steel is one of the most popular materials for chemical etching due to its corrosion resistance and mechanical strength.

Types: It includes various grades such as austenitic (300 series), ferritic/martensitic (400 series), and duplex stainless steels.

Applications: Commonly used in medical devices, automotive components, and architectural features.

Advantages: The etching process produces burr-free parts, maintaining the integrity of the material without introducing mechanical stress.

2. Titanium

Titanium is renowned for its lightweight properties, high strength, and excellent corrosion resistance.

Challenges: While titanium can be etched, it requires specialized processes due to its tendency to form a protective oxide layer when exposed to air.

Applications: Frequently used in aerospace, medical implants, and high-performance engineering applications.

Advantages: Chemical etching allows for the production of complex shapes that would be difficult to achieve through traditional machining.

3. Aluminum

Aluminum is another metal that benefits from chemical etching, particularly due to its favorable strength-to-weight ratio.

Challenges: The heat generated during the etching process can lead to rough edges if not managed properly.

Applications: Widely used in aerospace components and electronic housings.

Advantages: Offers excellent corrosion resistance and is malleable, making it suitable for intricate designs.

Conclusion

Incorporating a chemical etching service into your manufacturing process offers numerous advantages, including precision, cost-effectiveness, speed, versatility, and consistent quality. As an established chemical etching company, OTOEL is dedicated to providing exceptional service tailored to meet your specific needs. By choosing chemical etching, you not only enhance your production capabilities but also position your business for success in an increasingly competitive market.

Why Choose OTOEL?

At OTOEL, we pride ourselves on our expertise in chemical etching technology and our commitment to customer satisfaction. Our state-of-the-art facilities and experienced team ensure that we deliver high-quality products that meet stringent industry standards. Whether you require prototypes or large-scale production runs, we have the capabilities to support your manufacturing goals effectively.

For more information about our services or to discuss your project requirements, please contact us today!

0 notes

Text

How to Choose the Right Sealants for Your Project

Selecting the appropriate sealant is crucial for any construction project. The right sealant can significantly enhance a structure's durability, water resistance, and overall aesthetics. However, with numerous options available, it can be overwhelming to make an informed decision.

Understanding Your Project's Specific Needs

Before diving into the selection process, it's essential to assess the specific requirements of your project. Consider the following factors:

Substrate Material: The type of material you're sealing, whether it's concrete, metal, wood, or glass, will determine the suitable sealant type.

Environmental Exposure: The level of exposure to weather conditions, such as UV rays, moisture, and temperature fluctuations, will influence the sealant's durability.

Movement and Stress: The amount of movement or stress the joint or crack will experience will affect the sealant's flexibility and ability to accommodate expansion and contraction.

Aesthetic Requirements: The desired appearance of the sealed joint, whether it should be visible or invisible, will impact the choice of sealant.

Key Types of Sealants

Silicone Sealants: Highly versatile, weather-resistant, and UV-stable. They are ideal for sealing joints around windows, doors, and bathroom fixtures.

Polyurethane Sealants: Offer excellent adhesion, flexibility, and durability. They are suitable for sealing joints in concrete, metal, and masonry.

Acrylic Sealants: Paintable and easy to apply, acrylic sealants are commonly used for interior applications, such as sealing gaps around trim and molding.

Butyl Sealants: Highly adhesive and water-resistant, butyl sealants are often used for roofing applications and sealing joints in metal and plastic.

Tips for Selecting the Right Sealant

Consult with Experts: Seek advice from experienced professionals at ADT Industries Pvt. Ltd., a leading Sealants Suppliers in Mumbai. They can guide you in choosing the right sealant based on your project's specific needs.

Read Product Labels Carefully: Pay attention to the product's technical data sheet, which provides information on its application, curing time, and performance characteristics.

Consider the Manufacturer's Reputation: Opt for reputable brands known for their quality and reliability.

Prepare the Surface Properly: Ensure the surface is clean, dry, and free from contaminants before applying the sealant.

Follow Application Instructions: Adhere to the manufacturer's recommended application techniques to achieve optimal results.

Test in an Unconspicuous Area: Before applying the sealant to the entire project, test it in a small, inconspicuous area to ensure compatibility and desired results.

By carefully considering these factors and following these tips, you can select the right sealant for your project, ensuring its longevity and performance.

0 notes

Text

The Science Behind Mushroom Growth: From Spores to Harvest

Mushroom cultivation is a fascinating journey rooted in biology, sustainability, and meticulous care. Unlike plants, mushrooms are fungi, thriving without chlorophyll and relying on organic matter for nourishment. From a single microscopic spore to a fully developed fruiting body ready for harvest, the mushroom life cycle is a process of transformation. This blog explores the science behind mushroom growth, emphasizing the stages from spore germination to harvest.

1. The Mushroom Life Cycle Begins: Spores

Mushrooms begin their life as tiny, microscopic spores. These spores are analogous to seeds in plants but much smaller. Produced in the gills, pores, or teeth of the mushroom cap, spores are dispersed by wind, water, or animals. Each spore contains genetic material but requires specific conditions to germinate.

Spores are haploid, meaning they carry only half the genetic information needed to form a new organism. For growth to occur, two compatible spores must meet and fuse, creating a mycelium—a network of thread-like structures essential for mushroom development.

2. Mycelium Development: The Foundation of Growth

The mycelium, often referred to as the vegetative body of the fungus, is the engine of mushroom cultivation. It consists of hyphae, which are thin, tubular filaments that spread through a substrate like soil, wood, or organic waste. The mycelium absorbs nutrients from its environment, breaking down complex organic materials through enzymes.

Mycelium performs critical roles:

Nutrient Absorption: It acts as the digestive system of fungi, extracting essential nutrients from decaying matter.

Colonization: The mycelium colonizes the substrate, forming a dense network that prepares the environment for fruiting.

Cultivators pay close attention to the substrate's composition and moisture levels to ensure robust mycelial growth. Popular substrates include straw, sawdust, coffee grounds, and agricultural waste.

3. Environmental Triggers for Fruiting

Mycelium can remain dormant until environmental conditions trigger fruiting. Factors influencing this include:

Temperature: Specific mushroom species require particular temperature ranges.

Humidity: High humidity levels, often above 85%, are crucial for fruit body formation.

Light: While mushrooms do not photosynthesize, some species require light to signal the start of fruiting.

Carbon Dioxide Levels: A drop in CO2 concentration often stimulates fruiting.

These environmental cues signal the mycelium to shift from vegetative growth to reproductive growth, producing the fruiting bodies we recognize as mushrooms.

4. Primordia Formation: The First Signs of Mushrooms

Once conditions are favorable, the mycelium begins to form knots, known as primordia. These tiny clusters represent the early stage of mushrooms. At this point, the fungi redirect energy from expanding the mycelium to developing fruiting bodies.

Primordia are extremely sensitive to their environment. Any fluctuation in temperature, humidity, or airflow can impact their growth, making this stage critical for cultivators.

5. Mushroom Development: Rapid Growth

Mushrooms are among the fastest-growing organisms. After primordia appear, they develop into pinheads, which quickly expand into mature mushrooms. This rapid growth is driven by water absorption and cell enlargement rather than cell division, making consistent humidity vital.

The mushroom's structure includes:

Cap (Pileus): Protects the spore-producing surfaces underneath.

Stem (Stipe): Supports the cap and elevates it for better spore dispersal.

Gills or Pores: Located beneath the cap, these structures produce and release spores.

The growing mushroom absorbs nutrients stored in the substrate, which must be replenished in large-scale cultivation systems.

6. Harvesting Mushrooms: Timing is Key

Timing is everything in mushroom cultivation. Harvesting too early can result in underdeveloped mushrooms, while waiting too long can cause them to deteriorate or release spores, reducing the substrate's productivity.

Key indicators of readiness include:

The cap is fully expanded but not overly flat.

Gills or pores are visible but not releasing spores excessively.

The stem is firm and unblemished.

Different mushroom species have varying harvesting requirements, but careful observation ensures maximum yield and quality.

7. Sustainability in Mushroom Cultivation

Mushroom cultivation is inherently sustainable. The process utilizes agricultural waste as a substrate, reducing environmental impact. Additionally, spent mushroom substrate (SMS), the leftover material after harvest, is rich in nutrients and can be repurposed as compost or animal feed.

Moreover, mushrooms grow efficiently, requiring less water, land, and energy compared to traditional crops. This makes them an eco-friendly option for food production.

8. Common Challenges in Mushroom Growth

While mushroom cultivation is rewarding, it comes with challenges:

Contamination: Competing fungi or bacteria can colonize the substrate, hindering growth.

Inconsistent Conditions: Variations in temperature or humidity can disrupt the growth cycle.

Pests: Insects like fungus gnats can damage mycelium and fruiting bodies.

To overcome these challenges, cultivators use sterilized equipment, controlled environments, and regular monitoring.

9. Advances in Mushroom Cultivation

Recent innovations have revolutionized mushroom cultivation. Techniques like vertical farming, automated climate control, and genetic optimization are increasing yields and reducing costs. Additionally, researchers are exploring new substrates, such as bioplastics, to further enhance sustainability.

Medicinal mushrooms like Reishi and Cordyceps are also gaining popularity for their health benefits, driving interest in specialty cultivation methods.

10. The Fascination of Fungi

The journey from spore to harvest showcases the complexity and beauty of fungal life. Beyond their culinary and medicinal uses, mushrooms contribute to ecological balance by decomposing organic matter and recycling nutrients.

For growers, understanding the science behind mushroom growth is the key to success. By mastering each stage of the lifecycle, from nurturing mycelium to perfecting harvest timing, cultivators can produce high-quality mushrooms while contributing to a sustainable future.

0 notes

Text

Selecting the Right Access Flooring Solution

Access flooring is a hugely popular flooring used in commercial buildings all over the world. It is so common that a number of times, we don’t even realize that the floor we are on is built following the access flooring method.

Why is it a raised surface?

In office buildings, data centers, computer rooms, and shopping complexes, there is an excess of wires, ducts, cables, and pipes that should be kept hidden from common sight to support an aesthetically pleasing ambiance.

It is placed at a higher elevation from the actual subfloor surface, and that’s the reason it is called raised flooring. The flooring material is laid on a platform built with metallic pedestals installed vertically. Raised floors are incredibly convenient.

Cables and wires can be run all over the floor area without rendering any mess on walls or ceilings. Access flooring allows for easy repairs and efficient management of cables, ducts, and pipes in the space between the substrate and the flooring panel.

You can remove and reinstall flooring panels whenever required. You don’t have to demolish and remove the entire flooring. This helps commercial space owners save big on floor maintenance.

Choosing the Right Access Floor Supplier:

The raised flooring system is compatible with almost all tiling materials, including ceramic tiles, porcelain tiles, natural stones, laminates, luxury vinyl tiles, and carpet tiles – which you can select as per your design preferences and predetermined budget. However, raised flooring is not wholly about the flooring materials or panels.

It is crucial that the platform on which panels are to be installed is robust and durable. The platform for installing access flooring should be built using metallic pedestals and stringers from a trusted access floor supplier.

Here are the key considerations when you are looking to build access flooring in your commercial space –

Substrate –

The surface on which the pedestals will be bonded has a major role to play in the performance and longevity of your raised flooring. It should be strong and level. If not, the platform will not be stable; it will be shaky and have a shorter lifespan.

Additionally, if there is moisture content in the soil beneath the subfloor, it should be sealed before the commencement of the project to prevent rusting and other potential issues that might arise with time.

Safety Provisions –

The presence of cabling, wires, pipes, and ducts may sometimes cause a hot and moist environment under the access flooring panels. You must take fire safety measures and implement airflow management tools to fend off the likelihood of such events.

Last but not least, the pedestals, nuts and bolts, stringers, and sealants – every piece of accessory should be able to handle the expected load or foot traffic on the floor. Discuss this with your access floor supplier.

0 notes

Photo

Vertically aligned single-walled carbon nanotubes for energy storage and the electronics industry

Lawrence Livermore National Laboratory (LLNL) scientists have created vertically aligned single-walled carbon nanotubes on metal foils that could be a boon for energy storage and the electronics industry.

Vertically aligned carbon nanotubes (VACNTs) have exceptional mechanical, electrical and transport properties in addition to an aligned architecture, which is key for applications such as membrane separation, thermal management, fiber spinning, electronic interconnects and energy storage.

To date, widespread integration of VACNTs into next-generation technologies is thwarted by a lack of compatible, economic, mass-production capabilities. High-quality VACNTs are typically made on substrates such as silicon (Si) or quartz wafers that are rigid, expensive and electrically insulating.

After exploring metal foil options in scientific literature, the LLNL team turned to Inconel metal substrates allowing them to integrate VACNTs into flexible devices, eliminate a transfer step from Si to other substrates and minimize electrical or thermal transport resistances at the interface between CNTs and the substrate, which is critical for electronic and energy storage applications. Inconel is a family of nickel-chromium-based superalloys that are oxidation-corrosion-resistant materials well-suited for service in extreme environments subjected to pressure and heat.

Read more.

#Materials Science#Science#Carbon nanotubes#Electronics#Energy storage#Carbon#Nanotechnology#Nanotubes#Inconel#Alloys#Superalloys

16 notes

·

View notes

Text

How Leveling Agents Improve Surface Smoothness in Coatings

Achieving a smooth and even surface finish is a critical requirement in the coatings industry, whether for automotive paints, architectural finishes, industrial coatings, or printing inks. Surface imperfections such as brush marks, craters, orange peel textures, and pinholes can significantly impact the aesthetics, durability, and performance of coatings. This is where leveling agents play a crucial role. By enhancing the flow and uniformity of coatings, leveling agents ensure that the applied surface is smooth, defect-free, and visually appealing.

What are Leveling Agents?

Leveling agents are specialty additives used in coatings, paints, inks, and other related materials to improve the uniformity and smoothness of applied layers. They work by influencing the surface tension of the coating, promoting an even distribution during and after application. This leads to better surface leveling, minimizing defects such as brush strokes, roller marks, and other irregularities.

Mechanism of Leveling Agents in Surface Smoothness

To understand how leveling agents improve surface smoothness, it's important to explore their working mechanism. When a coating is applied, it must spread evenly across the substrate. However, surface tension gradients can cause uneven spreading, leading to visible defects. Leveling agents modify the surface tension of the liquid coating, ensuring uniform distribution over the substrate. Here’s how they work:

Reducing Surface Tension Gradients: Leveling agents lower surface tension gradients within the coating film, reducing the tendency for surface irregularities to form during application and drying.

Promoting Uniform Flow: By enhancing the flow and mobility of the coating material, leveling agents ensure a more even spread, reducing the appearance of brush marks and other texture variations.

Improving Wetting Properties: Leveling agents enhance the wetting properties of coatings, enabling them to cover substrates more effectively. This reduces the risk of pinholes, craters, and other surface defects.

Controlling Drying Dynamics: Some leveling agents help regulate the drying dynamics of coatings, allowing sufficient time for the film to level out before curing or solidifying. This minimizes surface imperfections and promotes a smoother finish.

Key Benefits of Using Leveling Agents

Enhanced Aesthetics

One of the primary advantages of leveling agents is their ability to enhance the visual appeal of coatings. By creating a uniform and smooth surface, they eliminate unsightly defects such as brush strokes, roller marks, and sagging. This is particularly important in applications where appearance is critical, such as automotive coatings, consumer goods, and high-end furniture finishes.

Improved Durability

Surface imperfections can weaken the structural integrity of coatings, making them more susceptible to wear, abrasion, and environmental damage. By promoting smoothness, leveling agents contribute to a more uniform film thickness, which enhances the protective properties and durability of the coating.

Better Performance in Industrial Applications

In industrial settings, the performance of coatings often depends on their ability to create a consistent barrier. Leveling agents improve the coating’s ability to cover surfaces evenly, which is essential for achieving desired performance characteristics such as corrosion resistance, chemical resistance, and adhesion.

Compatibility with Various Coating Systems

Leveling agents are available in different formulations to suit a wide range of coating systems, including water-based, solvent-based, and UV-curable coatings. This versatility allows formulators to select the right leveling agent for their specific application needs, ensuring optimal performance across different substrates and environmental conditions.

Choosing the Right Leveling Agent

Selecting the appropriate leveling agent depends on factors such as the type of coating, the application method, the desired finish, and environmental considerations. Some leveling agents may be more effective for high-gloss finishes, while others are designed for matte or textured surfaces. Additionally, formulators must consider the compatibility of the leveling agent with other components in the coating formulation, such as pigments, binders, and solvents.

Challenges in Using Leveling Agents

While leveling agents offer numerous benefits, their use must be carefully managed to avoid potential issues. Overuse or improper selection of a leveling agent can lead to problems such as reduced adhesion, surface contamination, or foaming. It is essential to strike the right balance and test formulations thoroughly to achieve optimal results.

Conclusion

Leveling agents play a vital role in enhancing surface smoothness in coatings by improving flow, reducing surface tension gradients, and promoting uniform distribution. Their ability to minimize surface defects and create visually appealing finishes makes them indispensable in industries ranging from automotive to architectural coatings. By carefully selecting and applying the right leveling agents, manufacturers can achieve superior quality, durability, and performance in their coatings, ultimately delivering a better experience for end-users.

0 notes