#strain gauge transducer

Explore tagged Tumblr posts

Text

Hire a Strain Gauge Transducer at Affordable Prices

Enhance operational efficiency with Belcur's sophisticated condition monitoring equipment. Our strain gauge transducers offer unparalleled precision in data collection, enabling proactive maintenance strategies to optimise performance. Count on Belcur for state-of-the-art condition monitoring solutions that contribute to the longevity and reliability of your assets.

0 notes

Text

single point alminium alloy load cell weighing sensor

A load cell sensor is a device used to measure force or weight in various applications. It is a type of transducer that converts a mechanical force into an electrical signal that can be measured and interpreted by electronic instruments.

Load cell sensors typically consist of several components: Strain Gauges: Load cells often use strain gauges, which are small electrical resistance elements, as the primary sensing element. Strain gauges are bonded or attached to a metal structure within the load cell. When a force is applied to the load cell, it causes the metal structure to deform, resulting in a change in the electrical resistance of the strain gauges.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us

Office +256 (0) 705 577 823, +256 (0) 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

#Crane (hanging) scales#Whole sale scales#Baby scales#Mini palm scales#Industrial platforms#assorted weighing brands including Avery#Salter#Health ( height and weight ) scales#Precision scales Analytical/Laboratory scales#Moisture meters#Temperature gauges#Pallet trolleys#kitchen scales#Animal scales#Bag closers-stitching machine#Plastic bag sealers#Plastic foot sealers#Batch sealers#Table top scales#Counter scales#Barcode readers/printer#Waterproof scales#Axle weigh bridge#Mini and full Weigh bridges among others.

0 notes

Text

Shear Web Load Cells: The Key to Accurate Force Measurement

Shear web load cells are critical in a wide range of industrial and scientific applications where precise force measurement is essential. These advanced devices offer unparalleled accuracy and durability, making them a go-to solution in environments where high precision and robustness are required. In this blog, we’ll dive deep into the mechanics of shear web load cells, their benefits, and their applications in various industries.

What is a Shear Web Load Cell?

A Shear Web Load Cell is a type of force transducer that measures force or load by detecting the shear strain in a load-bearing structure. The load cell typically consists of a thin metal web or element that deforms slightly when a force is applied. Strain gauges are strategically placed on the web to measure the resulting deformation, which is directly related to the applied force.

Unlike other load cells that measure compressive or tensile forces, shear web load cells detect forces based on shear stress. This unique property allows for higher accuracy and stability in measuring forces.

How Shear Web Load Cells Work

When a force is applied to a shear web load cell, the structure within the cell experiences deformation. This deformation causes a strain, which is measured by strain gauges bonded to the surface of the load cell. These strain gauges detect the slight changes in electrical resistance caused by the deformation. This change in resistance is then converted into a measurable electrical signal, which corresponds to the magnitude of the applied force.

The key advantage of shear web load cells is that they isolate shear forces from other types of forces (e.g., bending or torsional forces), leading to highly accurate and repeatable measurements.

Benefits of Shear Web Load Cells

High Precision: One of the most significant benefits of shear web load cells is their precision. Because they measure shear strain, they eliminate many of the inaccuracies that can arise from other types of load cells.

Durability: These load cells are constructed with robust materials that make them suitable for heavy-duty industrial applications. Their resistance to environmental factors such as moisture, temperature variations, and mechanical shock ensures longevity.

Compact Design: The design of shear web load cells is often more compact compared to other load cells, making them ideal for applications where space is a premium.

Excellent Linearity and Stability: Shear web load cells offer linear outputs and excellent long-term stability, which are crucial for applications that demand consistent accuracy over time.

Reduced Sensitivity to Misalignment: Because these load cells are designed to isolate shear forces, they are less affected by side loads or misalignments, further enhancing accuracy.

Applications of Shear Web Load Cells

Shear web load cells are used across various industries, especially in environments that require precise force measurement. Below are some common applications:

Aerospace: In the aerospace industry, shear web load cells are used to measure the forces applied to aircraft components during testing. The high precision of these load cells ensures accurate data, which is critical for safety and performance evaluations.

Automotive: Shear web load cells are used in the automotive industry for crash testing, engine dynamometers, and fatigue testing of components. Their high precision ensures that the force measurements are reliable and consistent.

Manufacturing: In industrial manufacturing, shear web load cells are integrated into machines to monitor the forces applied during production processes, such as stamping, pressing, and assembly.

Testing and Calibration: These load cells are ideal for testing and calibration equipment, where precise force measurements are essential for ensuring the accuracy of other instruments.

Weighing Systems: Shear web load cells are also found in high-precision weighing systems, such as those used in laboratory or industrial settings.

Choosing the Right Shear Web Load Cell

When selecting a shear web load cell for your application, several factors should be considered:

Capacity: Ensure that the load cell’s capacity matches the forces you need to measure. Load cells are available in a wide range of capacities, from small measurements for laboratory use to large-scale industrial applications.

Environment: Consider the environmental conditions in which the load cell will be used. Factors such as temperature, humidity, and exposure to chemicals may affect the performance of the load cell. Choose a load cell that can withstand these conditions.

Accuracy: Depending on the application, you may need a load cell with ultra-high precision. Ensure that the load cell meets the necessary accuracy requirements for your specific needs.

Size: If space is limited, you may need to select a compact shear web load cell. Be sure to verify the dimensions to ensure the load cell fits within your design constraints.

Maintenance and Calibration

To ensure the ongoing accuracy and reliability of a shear web load cell, regular maintenance and calibration are essential. Over time, environmental factors and mechanical wear can affect the accuracy of the load cell. Scheduled calibration checks ensure that the load cell remains accurate and performs optimally. Additionally, it is important to follow the manufacturer’s guidelines for proper installation and handling to prevent damage.

Conclusion

Shear web load cells are a highly reliable and accurate solution for force measurement in demanding industrial and scientific applications. Their ability to isolate shear forces, combined with their durability and compact design, makes them ideal for environments where precision is essential. Whether you’re working in aerospace, automotive, or manufacturing, choosing the right shear web load cell can significantly enhance your force measurement capabilities.

0 notes

Text

Understanding Intracranial Pressure Monitoring Devices and its Versatile Uses

What are Intracranial Pressure Monitoring Devices? Intracranial pressure (ICP) monitoring devices are medical instruments used to measure pressure inside the skull and brain. As the brain is contained within a rigid skull, any swelling or hemorrhage can quickly raise intracranial pressure which can potentially lead to brain damage or death if not treated. ICP monitoring devices provide clinicians real-time data to help diagnose and treat conditions that affect brain pressure. Types of Intracranial Pressure Monitoring Devices There are a few main types of Itracranial Pressure Monitoring Device monitoring devices currently used in hospitals: External Ventricular Drainage (EVD) Catheter: This device consists of a thin cylindrical catheter inserted into one of the brain's ventricles. The catheter is connected to an external drainage and monitoring system. It allows both drainage of cerebrospinal fluid to reduce pressure and monitoring of ICP levels. EVD is considered the gold standard for invasively measuring ICP. Intraparenchymal ICP Probe: This minimally invasive probe is directly inserted into the brain tissue, most commonly in the white matter of the frontal lobe. It contains a pressure transducer at the tip that is connected to an external monitor. Intraparenchymal probes provide a slightly less accurate ICP reading compared to EVD but with less risk of complications. Subdural Screw or Bolt: A small screw or bolt containing a strain gauge pressure sensor is surgically implanted through a burr hole in the skull and positioned between the dura membrane and skull. It directly measures pressure on the brain surface and is well-tolerated by most patients.

Get more insights on Intracranial Pressure Monitoring Devices

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Load Cell Controller Suppliers In Ahmedabad

Introduction

Load cell technology is critical in many industries, providing accurate weight measurement and control. These devices convert force or weight into an electrical signal, allowing data to be collected in real time. Industries such as manufacturing, logistics, automotive and healthcare rely heavily on load cells for efficient operations and quality assurance.

Significance of Load Cells

Accuracy: Load cells ensure reliable measurements, minimizing errors that can lead to costly mistakes.

Versatility: Available in different types like strain gauge and pressure transducers, they can adapt to diverse operational needs.

Efficiency: Streamlined processes improve productivity and resource management across sectors.

Choosing the right supplier for load cells and controllers is crucial for optimal performance. In Ahmedabad, there are many suppliers offering a variety of products designed to meet specific industrial needs. Selecting a reputable supplier not only guarantees high-quality equipment but also provides valuable support and expertise to improve your operations.

Taking the time to understand the available options will greatly impact your success in implementing effective weighing systems.

Understanding Load Cells and Their Applications

Load cells are essential components in measuring weight and force across various industries.

Definition and Function

A load cell is a type of force sensor that converts a force into an electrical signal. This transformation allows for accurate measurements of weight, which can be displayed digitally or used in control systems.

Working Principle

The most common type of load cell employs the strain gauge principle. When a load is applied, the strain gauge deforms, altering its electrical resistance. This change is measured and converted into a readable output, providing precise weight data.

Types of Load Cells

Several types of load cells cater to different industrial needs:

Load Cells: Widely used due to their accuracy and reliability in static and dynamic applications.

Pressure Transducers: Often utilized in hydraulic systems, converting pressure into an electrical signal for monitoring fluid levels or forces.

Industrial Applications

Load cells find applications in numerous sectors:

Manufacturing: Used in assembly lines for quality control and inventory management.

Logistics: Essential for weighbridges and shipping scales to ensure compliance with regulations.

Automotive: Employed in testing vehicles for performance metrics and safety standards.

Advantages of Using Load Cells

Incorporating load cells into operational processes offers several benefits:

Accuracy: Ensure precise weight measurements critical for quality assurance.

Efficiency: Streamline operations by automating weight checks, reducing manual errors.

Versatility: Adaptable to various applications, from small-scale laboratory settings to large industrial operations.

With their variety of types and extensive applications, load cells play a vital role in enhancing operational efficiency across diverse industries.

The Role of Load Cell Controllers in Weighing Systems

Load cell controllers are essential for weight measurement systems to work properly. They act as the link between load cells and users, converting the mechanical force applied to a load cell into an electronic signal that can be shown, recorded, or processed.

Enhancing Performance

Load cell controllers enhance overall system performance by:

Accuracy: Load cell controllers ensure precise readings by filtering out noise and compensating for environmental factors that could affect measurement.

Reliability: Consistent performance is vital in industrial settings. A quality controller guarantees stable operation under various conditions.

The significance of load cell controllers becomes evident in their ability to enhance overall system performance. They provide features such as:

Weighing Indicators: Display real-time weight data clearly for immediate interpretation.

Calibration Options: Allow users to calibrate the system easily, ensuring accuracy over time.

Tare Functionality: Facilitates the subtraction of container weight, providing net weight directly.

Key Features to Consider

When selecting a load cell controller, several important features should be assessed:

Input Compatibility: Ensure compatibility with existing load cells in your application.

Display Type: Choose between digital or analog displays based on visibility requirements and user preference.

Power Supply Options: Evaluate voltage requirements; options typically include 230V AC or 24V DC depending on your operational environment.

User Interface: An intuitive interface simplifies setup and operation, enhancing usability for technicians and operators alike.

Incorporating these elements into your choice will significantly impact the effectiveness of your weighing system. Load cell controllers not only improve measurement accuracy but also contribute to streamlined operations across diverse OEM applications.

Top Load Cell Suppliers in Ahmedabad You Can Trust

1. Sensor techniques (loadcell techniques)- Your Reliable Partner for Load Cell Solutions

Stands out as a prominent load cell supplier in Ahmedabad, known for its quality products and commitment to customer satisfaction. With a focus on innovative solutions, they cater to various industrial needs, making them a trusted partner for businesses seeking reliable load cell technology.

One of their flagship products is the Load Cell Indicator Controller (model LCC-961). This model is particularly popular among users for its robust features and performance capabilities. Here’s an in-depth analysis of the LCC-961:

Specifications:

Load Range: Capable of handling weights from 100 gm to 50,000 kg

Display: Features a 5-digit dual display, which enhances visibility and allows for easy monitoring of weight measurements.

Design: Constructed with an ABS plastic body, ensuring durability and resistance to environmental factors.

Key Features:

Tare Facility: This function allows users to subtract the weight of containers or packaging, ensuring accurate net weight readings.

Software Calibration: Users can easily calibrate the controller through software, providing flexibility and ease of use.

Pricing Details:

The LCC-961 is competitively priced at approximately making it an economical choice for businesses looking to invest in high-quality weighing solutions without breaking the bank.

This combination of advanced features and affordability makes the LCC-961 a popular choice among industries requiring precision in weight measurement. When you choose Sensor techniques as your load cell supplier, you gain access not only to exceptional products but also to knowledgeable support that can assist you in optimizing your load cell applications.

With their dedication to quality and innovation, Sensor techniques is indeed a reliable partner for all your load cell needs in Ahmedabad.

Sensor techniques stands out in the competitive landscape of load cell suppliers in Ahmedabad, specializing in advanced weighing solutions. Their extensive experience positions them as a key player for industries seeking reliable load cell products.

Product Range Highlights:

Batch Controllers: Designed for precise measurements, ideal for applications requiring controlled batching.

Weigh Feeder Controllers: Perfect for continuous weighing and feeding operations.

Digital Displays: Available with various voltage options, including both 230V and 24V, catering to diverse operational needs.

Key Features:

Automatic Types: Simplifies the weighing process, enhancing efficiency.

Manual/Auto Tare Facilities: Provides flexibility, allowing for accurate readings by zeroing out weights as needed.

When choosing a supplier for your load cell requirements, consider factors such as product variety, reliability, and customer support. Sensor techniques presents a robust option with their innovative technologies and comprehensive offerings tailored to meet industry demands. Whether you need to buy load cells or find load cell suppliers, Sensor techniques ensures quality solutions that enhance operational efficiency.

4allbiz.in serves as a comprehensive platform for sourcing digital load cell controllers in Ahmedabad. This marketplace features a variety of suppliers, enabling you to compare prices and specifications easily. Some notable models include:

When selecting a load cell supplier, consider the following key points:

Reliability of the supplier

Product warranty and support

Customer reviews and ratings

This competitive landscape allows you to explore options that best fit your needs while ensuring you make informed purchasing decisions. With numerous suppliers available, maximizing value through price comparison is crucial for ensuring optimal performance in your weight measurement systems.

Specialized Manufacturers Pioneering Quality Load Cells in Ahmedabad

Sensor Techniques

Sensor Techniques is a specialized manufacturer that focuses on producing strain gauge-based load cells. With a wide range of products designed for various applications, they ensure high accuracy and reliability in weight measurement.Sensor techniques

Sensor techniques stands out with its diverse offerings, including a wide range of load cells and weighing controllers. They also provide innovative solutions tailored to meet specific industrial needs, improving operational efficiency across different sectors.

Both companies are known for their dedication to quality and precision, making them important players in the load cell market in Ahmedabad. Their expertise in specialized manufacturing plays a significant role in advancing weight measurement technology.

Industries Benefiting from Load Cell Technology: A Closer Look at OEM Applications

Load cell technology plays a crucial role in enhancing operational efficiency across various sectors. Here are specific examples of how different industries utilize load cells for their OEM applications:

1. Manufacturing

Load cells ensure precise weight measurements during production processes, aiding in quality control and minimizing material waste.

2. Logistics

In warehousing and distribution, load cells provide accurate weight data for inventory management, ensuring compliance with shipping regulations.

3. Automotive

Load cells are employed in assembly lines to monitor component weights, contributing to safety and performance standards.

4. Food and Beverage

Accurate weight measurement is vital for portion control and regulatory compliance, which load cells effectively facilitate.

These applications illustrate the versatility of load cell technology and its significance in streamlining operations across diverse industries.

Conclusion: Making an Informed Choice for Your Load Cell Needs in Ahmedabad

Quality equipment is vital for industrial success. Choosing the right supplier for load cells can significantly impact operational efficiency and accuracy in weight measurement systems. Reliable suppliers ensure that you receive products that meet industry standards and specifications.

Consider the following when selecting a supplier:

Reputation: Look for established suppliers with positive testimonials.

Product Range: A diverse range of products indicates expertise and adaptability.

Support Services: Assess the availability of customer support and after-sales service.

Explore the trusted suppliers mentioned in this article, such as Sensor techniques, and others on platforms like 4allbiz.in. These options provide robust solutions tailored to your specific needs. Investing time to choose wisely will yield long-term benefits for your organization's weighing requirements.

Ahmedabad has many reputed suppliers of load cells catering to the diverse needs of industries like manufacturing, construction and transportation. These suppliers offer a comprehensive range of load cells designed to meet the highest standards of quality and performance. Whether you need tensile, compression or shear load cells, a reliable supplier in Gujarat can provide you with the right solutions to optimize your operations and achieve your business goals. By partnering with a trusted supplier, you can benefit from their experience and commitment to providing high-quality products that meet your specific requirements.

Free feel to contact us

#artists on tumblr#clouds#manufacturer#india#ahmedabad#loadcell#supplier#gujarat#rajkot#saurashtra#mumbai#baroda

1 note

·

View note

Text

Essential Tools for Monitoring Clamping Force on Birla Precision.

In the area of engineering and production, precision is paramount. Whether it's aerospace components, car elements, or elaborate clinical gadgets, the reliability and functionality of the stop product depend heavily at the precision with which it's crafted. One essential element of making sure precision in manufacturing processes is tracking clamping pressure. In this weblog post, we delve into the importance of clamping force monitoring and explore crucial tools to gain it, all through the lens of Birla Precision Technologies Limited, a pioneering business enterprise within the engineering area.

Understanding Clamping Force: The Backbone of Precision

Clamping force refers back to the force carried out to preserve or extra items together to save you motion between them. In manufacturing, specifically in machining methods, clamping force plays a critical position in securing workpieces firmly in location for the duration of slicing, milling, drilling, or grinding operations. Insufficient clamping force can result in workpiece slippage, inaccuracies in machining, and even catastrophic failure of the component being synthetic.

The Significance of Clamping Force Monitoring

Monitoring clamping pressure during the machining system is critical for several motives:

Precision Assurance: Consistent and adequate clamping pressure guarantees specific machining, resulting in accurately dimensioned components.

Safety: Proper clamping force prevents workpiece ejection, minimizing the threat of accidents and accidents in the workshop.

Tool Life Optimization: By keeping most effective clamping pressure, device wear and breakage can be minimized, extending device life and decreasing manufacturing downtime.

Cost Efficiency: Accurate clamping force monitoring facilitates in decreasing material wastage and transform, mainly to fee savings in production.

Essential Tools for Monitoring Clamping Force

Now that we recognize the importance of tracking clamping pressure, allow's explore some crucial system and techniques hired for this cause:

Torque Wrenches: Torque wrenches are flexible tools used to apply a selected quantity of torque to fasteners which include bolts and nuts. By measuring the torque done throughout the clamping approach, the clamping stress can be indirectly monitored.

Load Cells: Load cells are transducers that convert stress or weight into an electrical sign. They can be protected into clamping systems to without delay diploma the stress applied all through clamping.

Strain Gauges: Strain gauges are sensors used to degree stress (deformation) on an item subjected to pressure. By attaching strain gauges to clamping elements, modifications in pressure can imply versions in clamping force.

Ultrasonic Measurement Systems: Ultrasonic length structures employ sound waves to hit upon changes inside the elasticity of substances. These systems may be hired to display changes in clamping stress through measuring the acoustic homes of the clamped additives.

Pressure Sensors: Pressure sensors can be installed inside hydraulic or pneumatic clamping systems to without delay degree the fluid stress, which correlates with clamping force.

Setting the Standard

In the realm of precision engineering, Birla Precision Technologies Limited stands as a beacon of excellence. With a legacy of innovation and a commitment to quality, they manufacture and resources excessive-speed steel cutting gear to domestic and international markets. Their determination to precision engineering is clear in each side of their operations, from design to production to customer support.

By leveraging contemporary technology and a crew of skilled specialists, they ensure that their products meet the very best standards of fine and reliability. From CNC machining facilities to automotive manufacturing plant life, their reducing tools play a pivotal role in enhancing productivity and performance throughout diverse industries.

For groups seeking to enhance their production techniques and obtain extraordinary precision, they give a complete range of answers tailor-made to meet their particular desires. Whether it's optimizing clamping pressure, improving device life, or enhancing machining accuracy, Birla Precision is synonymous with excellence in engineering.

In conclusion, monitoring clamping pressure is crucial for retaining precision and safety in manufacturing processes. By employing critical tools and techniques, producers can ensure regular and dependable clamping force in the course of the production cycle. And in relation to precision engineering answers, they stand at the forefront, prepared to exceed expectancies and drive innovation inside the enterprise.

For extra information and their variety of engineering solutions, go to their website or contact them without delay. Experience the difference precision makes.

0 notes

Text

Pressure Sensors: 7 Important Types, Working & Applications

Since the 1590s, humanity’s fascination with measuring pressure changes has evolved from simple glass tubes to sophisticated pressure sensors. These advanced devices play a crucial role in modern industries, offering unparalleled precision in monitoring pressure fluctuations. In this article, we delve into the world of pressure sensors, exploring their functions, types, and the transformative impact they have on maintenance strategies.

Understanding Pressure Sensors:

A pressure sensor, in its essence, is a device designed to sense and measure pressure. In the context of these sensors, pressure refers to the force exerted over an area. These devices have become integral for specialized maintenance strategies, such as predictive maintenance. By collecting real-time data on equipment conditions, pressure sensors enable teams to predict and address potential failures.

For instance, a transducer, a common pressure sensor in maintenance, picks up signals when pressure is applied, allowing teams to respond promptly. These sensors act as vigilant guardians, ensuring the smooth operation of pressurized assets.

How Pressure Sensors Work:

Pressure sensors operate by measuring physical changes in response to pressure differences. The most common type employs a strain gauge — a mechanical apparatus that undergoes deformations as pressure is applied. This gauge converts these changes into electrical signals, providing real-time, interpretable data for maintenance teams.

The process involves the strain gauge converting pressure into electrical signals, which are then measured, recorded, and sent to a Computerized Maintenance Management System (CMMS). The CMMS receives these signals and alerts maintenance teams in case of abnormal pressure readings, allowing for timely intervention and prevention of potential issues.

Types Of Pressure Sensors

Pressure sensors are crucial devices that measure and monitor pressure changes in various applications. These sensors come in different types, each designed to suit specific requirements and operating conditions.

Read More: Pressure Sensors

0 notes

Text

Website: http://www.loadcellsensor.com/

Address: Rm 1605, Ho King Commercial Center, 2-16 Fa Yuen St., Mongkok, Kowloon 999077, Hong Kong China

Phone: +86-19956502838

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

#load cell sensor#tension compression load cell#multi-axis force sensor#rotary torque sensor#reaction torque transducer

1 note

·

View note

Text

Vibration Sensor Market Size, Share, Trends, Outlook, Forecast 2024-2032

According to IMARC Group latest report titled “Vibration Sensor Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on vibration sensor market forecast. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The global vibration sensor market size reached US$ 4.5 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.4 Billion by 2032, exhibiting a growth rate (CAGR) of 5.4% during 2024-2032.

Request a Free Sample Report: https://www.imarcgroup.com/vibration-sensor-market/requestsample

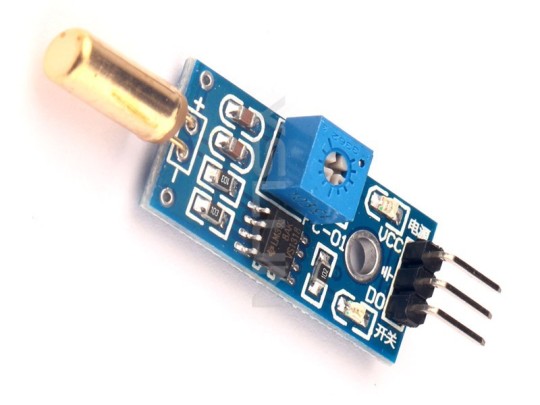

A vibration sensor, also known as an accelerometer or vibration transducer, is a device designed to detect and measure vibrations in machinery or structures. It converts mechanical vibrations into electrical signals, providing valuable data for monitoring equipment health and identifying potential issues. Vibration sensors are widely used in various industries, including manufacturing, aerospace, automotive, and infrastructure. They help prevent equipment failure, reduce maintenance costs, and enhance overall operational efficiency by detecting abnormal vibrations that may indicate misalignments, imbalance, or wear. The collected data aids in predictive maintenance strategies, ensuring timely intervention and preventing unexpected breakdowns in machinery or structural components.

Market Trends:

The global market is majorly driven by the increasing emphasis on predictive maintenance. In line with this, industries worldwide are increasingly adopting predictive maintenance strategies, leveraging vibration sensors to monitor equipment health. These sensors play a pivotal role in detecting abnormalities in machinery early on, reducing downtime, and optimizing maintenance schedules. Furthermore, the rise of Industry 4.0 and the broader trend of industrial automation contribute significantly to the market's growth. Vibration sensors are integral components of smart manufacturing systems, enabling real-time monitoring and control of machinery. This facilitates data-driven decision-making, improves overall equipment effectiveness, and supports the transition toward more efficient and connected industrial processes. Besides, the expanding use of vibration sensors in diverse applications, including automotive, aerospace, healthcare, and infrastructure, drives market diversification. In the automotive sector, for example, vibration sensors contribute to vehicle safety and performance monitoring. In healthcare, they play a role in medical diagnostics and monitoring equipment. Additionally, rapid technological advancements, particularly in sensor design and data analytics, enhance the capabilities of vibration sensors. Integrated wireless communication and Internet of Things (IoT) connectivity enable seamless data transmission and remote monitoring, fostering the adoption of these sensors across various industries.

View Full Report with TOC & List of Figure: https://www.imarcgroup.com/vibration-sensor-market

Competitive Landscape

The competitive landscape of the industry has also been examined along with the profiles of the key players operating in the market.

Analog Devices Inc.

Bosch Sensortec GmbH (Robert Bosch GmbH)

Dytran Instruments Inc.

Emerson Electric Corp.

FUTEK Advanced Sensor Technology Inc.

Hansford Sensors Ltd.

Honeywell International Inc.

National Instruments Corporation

NXP Semiconductors N.V.

Rockwell Automation

Safran Colibrys SA

SKF

TE Connectivity Ltd.

Texas Instruments Incorporated.

Key Market Segmentation:

Our report has categorized the market based on region, product, technology, material, and end-use industry.

Breakup by Product:

Accelerometers

Velocity Sensors

Non-Contact Displacement Transducers

Others

Breakup by Technology:

Piezoresistive

Strain Gauge

Variable Capacitance

Optical

Others

Breakup by Material:

Doped Silicon

Piezoelectric Ceramics

Quartz

Breakup by End-Use Industry:

Automotive

Healthcare

Aerospace and Defence

Consumer Electronics

Industrial Machinery

Others

Breakup by Region:

North America (United States, Canada)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Asia Pacific (China, Japan, India, Australia, Indonesia, South Korea, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Key Highlights of the Report:

Market Performance (2018-2023)

Market Outlook (2024-2032)

Porter’s Five Forces Analysis

Market Drivers and Success Factors

SWOT Analysis

Value Chain

Comprehensive Mapping of the Competitive Landscape

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

0 notes

Text

Website: http://www.loadcellsensor.com/Products

LCS Tech Co., Ltd is a Chinese manufacturer for strain gauge type load cell sensors,tension compression force transducers, reaction and rotary torque sensors.

1 note

·

View note

Text

Force Sensor Market Expected to Reach $3.30 Billion, Globally, by 2027 at 5.3% CAGR: Allied Market Research

The force sensor industry in Asia-Pacific is expected to grow at the highest rate during the forecast period, owing to enormous development of manufacturing, automotive, assembling, and bulk material handling industries in arising economies. Moreover, economically developed nations tend to witness high penetration of force sensor technology in various vehicle segments, which is projected to significantly contribute to the growth of the market.

Wilmington, Delaware

According to a new report published by Allied Market Research, titled, “Force Sensor Market By Operation, Force Type, Technology, and End User: Opportunity Analysis and Industry Forecast, 2020–2027”, the global force sensor market size was valued at $2.16 billion in 2019, and is projected to reach $3.30 billion by 2027, registering a CAGR of 5.30%. The Asia-Pacific region is expected to be the leading contributor to the global force sensor market analysis during the forecast period, followed by North America and Europe.

Download Research Report Sample & TOC: https://www.alliedmarketresearch.com/request-sample/9097 (We look forward to moving quickly to provide the Report Analysis needed for your Business Success) •135 – Tables •73 – Charts •287 – Pages

The overall working principle of force sensors is that they react to the applied force & change the value into a quantifiable figure. There are different kinds of force sensors available in the market dependent on different detecting components. The majority of force sensors are designed by utilizing force-sensing resistors. These sensors comprise electrodes & sensing film.

Prime determinants of growth:

The prominent factors that impact the market growth are increase in demand for automotive products, growing adoption of force sensor in manufacturing application, rapidly rising adoption of advanced driver assistance systems (ADAS), and growing safety regulations. However, volatility in demand restricts the market growth. On the contrary, adoption of internet of things (IoT) technology and rising robot application in industries are expected to create lucrative opportunities for the market. These factors are likely to have a definite impact on the growth of the global force sensor market during the forecast period.

Report Coverage and Details:

Aspects

Details

By Operation

Analog

Digital

By Force Type

Compression & Tension

Compression

Tension

By Technology

Strain Gauge

Load Cell

Force Sensitive Resistors

Others

By End Use

Automotive

Locomotive

Manufacturing

Mining

Aerospace & Defense

Construction

Healthcare

Others

COVID-19 Scenario:

The COVID-19 pandemic is impacting the society and overall economy across the global. The impact of this outbreak is growing day-by-day as well as affecting the supply chain. The crisis is creating uncertainty in the stock market, falling business confidence, massive slowing of supply chain, and increasing panic among the customer segments.

A force sensor is an instrument that measures the amount of force between two surfaces. Force sensors or force transducers translate an input mechanical force into electrical signal at output. Basically, it works as a force sensing resistor in an electric circuit. These force measurement instruments have varying working principles based on factors considered during designing process. They are used to measure weight, mass, pressure, and torque. These sensors can be used over a wide range of temperature. These are used in industries, such as electronics, robotics, chemical, agricultural sector, paper & print, for various purposes.

Inquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/9097

Leading Market Players:

SENSATA TECHNOLOGIES,

ABB LTD,

FUTEK ADVANCE SENSOR TECHNOLOGY,

TE Connectivity Ltd,

HOTTINGER BALDWIN MESSTECHNIK,

Honeywell International,

ATI Industrial Automation,

SIEMENS AG,

Tekscan Inc,

VISHAY PRECISION GROUP

The report provides a detailed analysis of these key players of the global force sensor market. These players have adopted different strategies such as product development and product launch to increase their market share and maintain dominant shares in different regions. The report is valuable in highlighting business performance, operating segments, product portfolio, and strategic moves of market players to showcase the competitive scenario.

Key Benefits for Stakeholders:

In 2019, analog force sensor accounted for the maximum revenue, and is projected to grow at a notable CAGR of 3.8% during the forecast period.

North America and APAC collectively accounted for more than 58% of the force sensor market share in 2019.

China is anticipated to witness highest growth rate during the global force sensor market forecast.

By Region:

North America (U.S., Canada, and Mexico)

Europe (U.K., Germany, France, Italy, Spain, Russia, Netherlands, Belgium, Poland, and Rest of Europe)

Asia-Pacific (China, Japan, India, South Korea, Australia, Malaysia, Thailand, Philippines, Indonesia, and Rest of Asia-Pacific)

LAMEA (Latin America, Middle East and Africa)

Trending Reports in Semiconductor and Electronics Industry (Book Now with Up to 20% Discount + COVID-19 Scenario):

Antenna Market size is projected to reach $40.1 billion by 2032, growing at a CAGR of 9.1% from 2023 to 2032.

Image Sensor Market size is projected to reach $87.5 billion by 2032, growing at a CAGR of 12.9% from 2023 to 2032.

Superconductors Market share is projected to reach $17.4 billion by 2032, growing at a CAGR of 10% from 2023 to 2032.

Power Cable Market size is projected to reach $277.8 billion by 2031, growing at a CAGR of 6.4% from 2022 to 2031

Embedded Systems Market size is projected to reach $163.2 billion by 2031, growing at a CAGR of 6.5% from 2022 to 2031.

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports Insights" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Allied Market Research CEO Pawan Kumar is instrumental in inspiring and encouraging everyone associated with the company to maintain high quality of data and help clients in every way possible to achieve success. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA.

Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285

UK: +44-845-528-1300

India (Pune): +91-20-66346060 Fax: +1-800-792-5285 [email protected]

0 notes

Text

strain gauge type transducer force sensor pocket scale loadcell.

Electrical Circuitry: Load cell sensors have electrical circuitry that connects the strain gauges to form a Wheatstone bridge configuration.

This configuration enables the measurement of the small changes in resistance caused by the deformation of the strain gauges.

The electrical circuitry also includes amplification and conditioning circuits to convert the small resistance changes into a usable electrical signal.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us

Office +256 (0) 705 577 823, +256 (0) 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

0 notes

Text

Unveiling the Versatility of Universal Load Cells: Revolutionizing Diverse Applications with Precision and Reliability

Load cells are essential devices used to measure force or weight in various industries and applications. Their versatility makes them a crucial component in fields ranging from manufacturing and transportation to healthcare and research. In this article, we will delve into the world of versatile universal load cells, exploring their functionalities, applications, benefits, and the reasons behind their widespread use.

Introduction to Load Cells

Load cells are transducers that convert a mechanical force into an electrical signal. They play a pivotal role in measuring force or weight accurately across various applications. Load cells have evolved significantly over the years, leading to the development of universal load cells that can cater to a wide range of applications.

Understanding Universal Load Cells

Universal load cells are designed to be versatile and adaptable to different measurement requirements. They are capable of measuring force in multiple directions and can handle dynamic as well as static loads. This versatility stems from their design and the technology they employ.

Types of Universal Load Cells

There are several types of universal load cells, each utilizing different principles for force measurement. Some common types include:

Strain Gauge Load Cells

Strain gauge load cells are widely used and operate based on the principle that the electrical resistance of a material changes when subjected to mechanical stress. They are suitable for various applications due to their accuracy and cost-effectiveness.

Hydraulic Load Cells

Hydraulic load cells utilize the pressure of a hydraulic fluid to measure force. They are known for their high accuracy and durability, making them ideal for heavy-duty industrial applications.

Pneumatic Load Cells

Pneumatic load cells measure force by analyzing the air pressure changes in an enclosed chamber. They are often used in applications where cleanliness and safety are crucial.

Capacitive Load Cells

Capacitive load cells measure force by detecting changes in capacitance between two plates. They offer excellent precision and are often used in laboratory and research settings.

Applications of Universal Load Cells

Universal load cells find applications in various industries, including:

Industrial Manufacturing

In manufacturing, universal load cells are used to monitor the quality and safety of products during production. They ensure that machines operate within safe load limits, preventing accidents and optimizing production processes.

Transportation and Logistics

Load cells are integrated into transportation systems to measure the weight of cargo and ensure compliance with weight regulations. This is crucial for maintaining road safety and preventing overloading.

Healthcare and Medical Devices

Universal load cells play a role in medical devices such as hospital beds and rehabilitation equipment. They assist in ensuring patient comfort and safety.

Research and Development

In research, load cells are used to collect data in fields like material testing, structural analysis, and biomechanics. Their accuracy and versatility make them invaluable tools in various experiments.

Benefits of Using Universal Load Cells

Universal load cells offer several benefits, including:

Precision and Accuracy

These load cells provide accurate and reliable measurements, ensuring the quality of processes and products.

Durability and Reliability

Universal load cells are built to withstand harsh conditions, making them suitable for demanding environments.

Easy Integration

They can be easily integrated into existing systems, reducing downtime and the need for extensive modifications.

Wide Measurement Range

These load cells can measure both small and large forces, making them versatile across applications.

Factors to Consider When Choosing Universal Load Cells

When selecting universal load cells, consider factors such as:

Load Capacity

Choose load cells with the appropriate capacity for your application's maximum force requirements.

Environmental Conditions

Consider the operating environment, including temperature, humidity, and exposure to chemicals or contaminants.

Cost and Budget

Balance the features and quality of load cells with your budget constraints.

Mounting and Installation

Ensure the load cells can be properly installed and mounted in your specific setup.

Maintenance and Calibration of Load Cells

Regular maintenance and calibration are crucial to ensure the accuracy and reliability of load cell measurements. Follow manufacturer guidelines and industry best practices.

Future Trends in Load Cell Technology

The load cell industry continues to evolve, with advancements in materials, wireless technology, and data analytics. Expect more accurate, efficient, and interconnected load cells in the future.

Conclusion

Universal load cells are indispensable devices that have revolutionized force measurement across diverse industries. Their versatility, precision, and reliability make them vital tools for ensuring safety, quality, and efficiency in various applications.

#sensomaticloadcell#universalloadcell#VersatileUniversalLoad CellsforMultipleApplications#loadcell#sensomatic

0 notes

Text

trucks scales weighing loadcells from turkey at affordable prices Wandegeya

A load cell sensor is a device used to measure force or weight in various applications. It is a type of transducer that converts a mechanical force into an electrical signal that can be measured and interpreted by electronic instruments.

Load cell sensors typically consist of several components:

Strain Gauges: Load cells often use strain gauges, which are small electrical resistance elements, as the primary sensing element. Strain gauges are bonded or attached to a metal structure within the load cell. When a force is applied to the load cell, it causes the metal structure to deform, resulting in a change in the electrical resistance of the strain gauges.

Metal Structure: Load cell sensors are constructed with a metal structure that deforms under the applied force. The metal structure may have different shapes and designs, such as an S-beam, a disk, or a bending beam, depending on the specific load cell type.

Mounting Elements: Load cell sensors are designed with mounting elements or attachments to allow them to be securely connected to the object or system where force measurement is required. These mounting elements ensure proper alignment and transfer the applied force to the load cell.

Electrical Circuitry: Load cell sensors have electrical circuitry that connects the strain gauges to form a Wheatstone bridge configuration. This configuration enables the measurement of the small changes in resistance caused by the deformation of the strain gauges. The electrical circuitry also includes amplification and conditioning circuits to convert the small resistance changes into a usable electrical signal.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

0 notes

Text

3000kg capacity industrial floor weighing scale best prices from supplier uganda

Weighing Accuracy of Accurate Weighing Scales in Uganda

A brief insight for weighing Accuracy for scales buyers in Uganda

Weighing accuracy

By scientific definition, the accuracy of a measurement system is how close a result comes to the true value or a standard.

In our daily life, when we see a measurement like a speed of 25 kmph on a speedometer, or a weight of 12.2 kg on a weighing scale, we regard this value as correct without thinking about the errors those values may have. It is a common perception that ‘what we SEE is the CORRECT & ACCURATE value’.

This perception is further strengthened in today’s ‘digital’ indication age, where instruments produce a direct readout of numeric values, removing the ambiguity of analogue indication such as needle/pointer of earlier times. However the fact remains that each measurement, whether done by an analog or a digital instrument, has an error and we cannot say how accurate a measurement is unless we know the true value to compare it with.

Weighing equipment as a ‘system’

A measurement system can have many components, but there is always at least one critical component which dictates and limits the overall accuracy of the measuring system.

In modern day electronic weighing systems, this most critical measuring component is the transducer which converts applied load into a proportionate electrical signal. The majority of weighing machines used for commercial purposes have strain-gauge based Load Cells as the transducer. The voltage signal generated is processed and converted into digital form by the weighing instrumentation, commonly known as ‘digitizer’, for displaying the weight and further use. The weighing system needs to be calibrated using standard weights before putting to use.

A weighing system cannot have accuracy more than the accuracy of load cell/s used in it.

The role of least count

All measuring instruments have a calibrated range known as ‘span’, with a Min. and a Max. limit. This range or span is a graduated scale and the minimum value of displayed graduation is the ‘least count’ or ‘resolution’ of the instrument.

For example: a weighing scale with a least count of 10 kg will show weight only in steps of 10 kg, i.e. if the weight of an object is measured as 1016 kg, the scale can show it either as 1010 kg or 1020 kg. Here it does not have any relation whether the measurement of 1016 kg was correct or not. It is only about displaying the result. The least count of a scale can only be 1, 2, 5, 10 and their multiples.

The least-count/resolution relates more to readability of a weighing instrument, rather than accuracy.

The Legal Metrology perspective

The majority of scales which we see and use everyday, such as weighbridges, platform scales, bench / counter scales etc, are classified as non-automatic weighing machines by Indian Legal Metrology. These are further classified into four accuracy classes – I, II, III and IV depending on permissible errors for a measurement, with class I being most accurate and class IV the least.

Most of the scales used for ‘legal for trade’ purpose are certified for min. class III.

All weighing machines used for trade purposes are required to be verified and stamped every year by Legal Metrology, according to their accuracy class.

The accuracy classes for scales

One important specification valid for class I and II only is that the accuracy of the scale can be 1, 2, 5 or 10 times the least count of the scale. For example: a scale of 10 kg x 0.1 g can have accuracy 10 times the resolution which is 1 g (10 x0.1 g) i.e. a reading of 5000.1 g may have an error of up to 1 g.

This specification is not applicable to Class III and Class IV machines. For these machines, the accuracy of readings is between 0.5x to 1.5x of the scale resolution, or 1x as an average (simplified for ease of understanding). For example: in a scale with 50000 kg x 10 kg, a reading of 25050 may have maximum error of 10 kg, i.e. the object’s true weight could be anywhere from 25040 to 25060 kg.

For class III machines, the accuracy is generally considered as +/- 1 division (least count).

International standards

OIML (International Organization of Legal Metrology) is the most followed standard internationally, subscribed officially by more than 120 countries including India. Additionally, there is NTEP (National Type Evaluation Program) standard which is primarily followed by USA & Canada.

OIML has defined accuracy classes for load cells (OIML R-60) as well as weighing instruments (OIML R-76) with their relationship as below –

Load cell accuracy class (R-60)

Weighing Instrument accuracy class (R-76)

Number of scale divisions

A

I

> 50,000

B

II

5,000 ~1,00,000

C

III

500 ~10,000

D

IV

50 ~ 1000

OIML stipulations attribute 50% of the error in a weighing system to the error in the load cells.

For a weighing instrument, the OIML compatibility checks between load cells and weighing scale include:

a) No. of certified load cell divisions are >= the weighing scale divisions

b) Load cell accuracy class corresponds to above table or higher

The international guidelines on weighing accuracy stress on importance to verify load cell accuracy to ensure that desired overall accuracy is achievable.

The practical application and ethical aspects

By now it should be amply clear that the load cell(s) used in a weighing scale should be able to deliver the accuracy in terms number of divisions, equal to or better than weighing scale divisions, to achieve desired accuracy.

Taking an example for a weighbridge of 50 t x 10 kg (i.e. 50000/10 = 5000 divisions), the load cell should be at least accurate and certified to 5000 divisions (OIML R-60 C5) or higher accuracy class. Similarly a platform scale of 60 kg x 20 g (i.e. 60000/20 = 3000 divisions) should be using a load cell certified for 3000 divisions (OIML R-60 C3) or higher.

Unfortunately the Indian Legal metrology, despite following OIML guidelines, is yet to specify rules for load cell certification. As a result, the market is brimming with cheap weighing scales using unapproved load cells and the least count of scale being often projected as ‘accuracy’.

However, companies in India with global standards and ethical practices, use OIML approved load cells for weighbridge applications corresponding to accuracy classes of scales manufactured by them.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

https://hansonscales.wordpress.com/category/crane-scales/

https://averyweighingscalesuganda.wordpress.com/sinar-weighing-scales/

https://averyweighingscalesuganda.wordpress.com/draminski-weighing-scales/

https://averyweighingscalesuganda.wordpress.com/diweigh-weighing-scales/

0 notes

Text

2000kg capacity industrial platform scale interior ramps prices Kampala

Weighing Accuracy of Accurate Weighing Scales in Uganda

A brief insight for weighing Accuracy for scales buyers in Uganda

Weighing accuracy

By scientific definition, the accuracy of a measurement system is how close a result comes to the true value or a standard.

In our daily life, when we see a measurement like a speed of 25 kmph on a speedometer, or a weight of 12.2 kg on a weighing scale, we regard this value as correct without thinking about the errors those values may have. It is a common perception that ‘what we SEE is the CORRECT & ACCURATE value’.

This perception is further strengthened in today’s ‘digital’ indication age, where instruments produce a direct readout of numeric values, removing the ambiguity of analogue indication such as needle/pointer of earlier times. However the fact remains that each measurement, whether done by an analog or a digital instrument, has an error and we cannot say how accurate a measurement is unless we know the true value to compare it with.

Weighing equipment as a ‘system’

A measurement system can have many components, but there is always at least one critical component which dictates and limits the overall accuracy of the measuring system.

In modern day electronic weighing systems, this most critical measuring component is the transducer which converts applied load into a proportionate electrical signal. The majority of weighing machines used for commercial purposes have strain-gauge based Load Cells as the transducer. The voltage signal generated is processed and converted into digital form by the weighing instrumentation, commonly known as ‘digitizer’, for displaying the weight and further use. The weighing system needs to be calibrated using standard weights before putting to use.

A weighing system cannot have accuracy more than the accuracy of load cell/s used in it.

The role of least count

All measuring instruments have a calibrated range known as ‘span’, with a Min. and a Max. limit. This range or span is a graduated scale and the minimum value of displayed graduation is the ‘least count’ or ‘resolution’ of the instrument.

For example: a weighing scale with a least count of 10 kg will show weight only in steps of 10 kg, i.e. if the weight of an object is measured as 1016 kg, the scale can show it either as 1010 kg or 1020 kg. Here it does not have any relation whether the measurement of 1016 kg was correct or not. It is only about displaying the result. The least count of a scale can only be 1, 2, 5, 10 and their multiples.

The least-count/resolution relates more to readability of a weighing instrument, rather than accuracy.

The Legal Metrology perspective

The majority of scales which we see and use everyday, such as weighbridges, platform scales, bench / counter scales etc, are classified as non-automatic weighing machines by Indian Legal Metrology. These are further classified into four accuracy classes – I, II, III and IV depending on permissible errors for a measurement, with class I being most accurate and class IV the least.

Most of the scales used for ‘legal for trade’ purpose are certified for min. class III.

All weighing machines used for trade purposes are required to be verified and stamped every year by Legal Metrology, according to their accuracy class.

The accuracy classes for scales

One important specification valid for class I and II only is that the accuracy of the scale can be 1, 2, 5 or 10 times the least count of the scale. For example: a scale of 10 kg x 0.1 g can have accuracy 10 times the resolution which is 1 g (10 x0.1 g) i.e. a reading of 5000.1 g may have an error of up to 1 g.

This specification is not applicable to Class III and Class IV machines. For these machines, the accuracy of readings is between 0.5x to 1.5x of the scale resolution, or 1x as an average (simplified for ease of understanding). For example: in a scale with 50000 kg x 10 kg, a reading of 25050 may have maximum error of 10 kg, i.e. the object’s true weight could be anywhere from 25040 to 25060 kg.

For class III machines, the accuracy is generally considered as +/- 1 division (least count).

International standards

OIML (International Organization of Legal Metrology) is the most followed standard internationally, subscribed officially by more than 120 countries including India. Additionally, there is NTEP (National Type Evaluation Program) standard which is primarily followed by USA & Canada.

OIML has defined accuracy classes for load cells (OIML R-60) as well as weighing instruments (OIML R-76) with their relationship as below –

Load cell accuracy class (R-60)

Weighing Instrument accuracy class (R-76)

Number of scale divisions

A

I

> 50,000

B

II

5,000 ~1,00,000

C

III

500 ~10,000

D

IV

50 ~ 1000

OIML stipulations attribute 50% of the error in a weighing system to the error in the load cells.

For a weighing instrument, the OIML compatibility checks between load cells and weighing scale include:

a) No. of certified load cell divisions are >= the weighing scale divisions

b) Load cell accuracy class corresponds to above table or higher

The international guidelines on weighing accuracy stress on importance to verify load cell accuracy to ensure that desired overall accuracy is achievable.

The practical application and ethical aspects

By now it should be amply clear that the load cell(s) used in a weighing scale should be able to deliver the accuracy in terms number of divisions, equal to or better than weighing scale divisions, to achieve desired accuracy.

Taking an example for a weighbridge of 50 t x 10 kg (i.e. 50000/10 = 5000 divisions), the load cell should be at least accurate and certified to 5000 divisions (OIML R-60 C5) or higher accuracy class. Similarly a platform scale of 60 kg x 20 g (i.e. 60000/20 = 3000 divisions) should be using a load cell certified for 3000 divisions (OIML R-60 C3) or higher.

Unfortunately the Indian Legal metrology, despite following OIML guidelines, is yet to specify rules for load cell certification. As a result, the market is brimming with cheap weighing scales using unapproved load cells and the least count of scale being often projected as ‘accuracy’.

However, companies in India with global standards and ethical practices, use OIML approved load cells for weighbridge applications corresponding to accuracy classes of scales manufactured by them.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance.

For inquiries on deliveries contact us

Office +256 705 577 823, +256 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

https://electronicbalanceug.wordpress.com/about-us/

https://portablemoistureanalysers.wordpress.com/why-accurate-weighing-scales/

https://portablemoistureanalysers.wordpress.com/clients-reviews/

0 notes