#store hazardous substances on a construction site

Explore tagged Tumblr posts

Text

How to store hazardous substances on a construction site has been published on CivilDigital By Kevin Rowe, Managing Director of SafetyBuyer.com Construction is historically one of the most dangerous industries in the UK in terms of workplace safety is why construction companies must maintain the highest level of health and safety standards. A critical component is ensuring that your workplace has sufficient safety precautions in place for the safe … Read more , Read More..

New Post has been published on https://civildigital.com/how-to-store-hazardous-substances-on-a-construction-site/

How to store hazardous substances on a construction site

0 notes

Text

50 Liter Industrial Oil Spill Kit Bag (USK-50LO)

The universal spill kit contents in the 50 Liter Industrial Oil Spill Kit Bag (USK-50LO) include absorbent pads, socks, and disposal bags for efficient waste management. These tools are essential for handling spills quickly, minimizing risks, and preventing contamination. The chemical spill kit equipment is specifically selected to ensure safety when managing hazardous spills, offering protection to workers and the environment.

Applications of Oil and Chemical Spill Kits

An 50 Liter Industrial Oil Spill Kit Bag(USK-50LO) and chemical spill kit like this one is perfect for various industrial settings, including manufacturing plants, warehouses, laboratories, and construction sites. The kit is not only designed to manage oil spills but also to address chemical spills, making it a reliable solution for workplaces that handle a diverse range of substances. A chemical spill kit used for hazardous materials ensures that spills are contained safely, avoiding long-term damage or costly cleanups.

Portable and Practical Oil Spill Kit Bags

The 50 LiterIndustrial Oil Spill Kit Bag(USK-50LO) is compact and lightweight, making it easy to store and transport. This portability ensures that the spill kit is always accessible in case of emergencies, helping teams respond faster. The oil spill kit bags are also built for durability, ensuring they can withstand industrial environments while keeping the contents secure and ready for use.

Specifications

Model USK-50LO

Portable Bag 1 pc

Absorbent Pad 25 pieces (50 × 40)cm

Absorbent Pillow 2 pieces

Absorbent Socks 3 pieces (7.6 × 120)cm

Hazmat Disposal Bag 2 piece

Cable Tie 2 piece

Safety Goggles 1 piece

Safety Gloves 1 pair

Cleaning Powder 1 Box

User Manual 1 piece

2 notes

·

View notes

Text

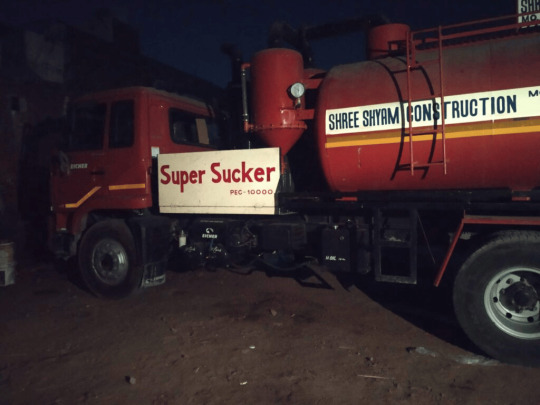

SUPER SUCKER MACHINE

The Super Sucker Machine is a heavy-duty industrial vacuum cleaner used to suck up large volumes of solids, liquids, and sludges from a variety of industrial settings. It is an extremely powerful and efficient machine that is used to clean up a range of substances, including oil spills, sewage, and hazardous waste. The machine is particularly useful in environments where traditional cleaning methods are not practical or effective.

The Super Sucker Machine is a self-contained unit that is mounted on a truck or trailer. It consists of a large vacuum pump, a high-pressure water pump, and a storage tank for the collected materials. The machine is typically operated by a crew of two or more people who are trained in the use of the equipment.

One of the key features of the Super Sucker Machine is its powerful vacuum pump. This pump is capable of creating a vacuum that is strong enough to lift heavy materials such as rocks and bricks. It is also capable of sucking up large volumes of liquids and sludges. The pump is driven by a powerful diesel engine that provides the necessary power to operate the machine.

SUPER SUCKER MACHINE

In addition to the vacuum pump, the Super Sucker Machine also has a high-pressure water pump. This pump is used to spray water onto surfaces to help loosen and remove stubborn materials such as grease and oil. The water pump is also used to clean up spills and to flush out pipes and tanks.

The collected materials are stored in a large tank on the Super Sucker Machine. The tank is designed to hold large volumes of solids, liquids, and sludges. Once the tank is full, the crew can transport it to a disposal site where the materials can be safely disposed of or recycled.

The Super Sucker Machine is used in a variety of industries, including oil and gas, mining, and construction. In the oil and gas industry, the machine is used to clean up oil spills and to remove solids and sludges from storage tanks and pipelines. In the mining industry, the machine is used to clean up tailings ponds and to remove solids and sludges from mining operations. In the construction industry, the machine is used to clean up construction sites and to remove debris from demolition projects.

If you have any query please free to ask:

Supertechengineer

Contact No:09910715032, 09311309436

Email: [email protected]

Address: MORTA INDUSTRIAL AREA, MORTA GHAZIABAD, Ghaziabad, Uttar Pradesh, India.

18 notes

·

View notes

Text

Chemical Additives for Concrete Durability: Building Resilience and Longevity

Concrete ranks as one of to-day's most commonly utilized construction materials because of its strength and wide-ranging applications. The durability of concrete in different environmental situations represents an essential requirement for modern construction methods. The introduction of chemical additives for concrete has transformed construction practices through their ability to extend concrete structure durability and improve their performance characteristics.

Understanding Chemical Additives for Concrete

During concrete mixing procedures manufacturers incorporate specialized compounds known as chemical additives which influence the material characteristics. Additives modify concrete properties through designed features so developers achieve better workability and stronger results with durability against environmental exposures. The decision about additives depends on assessing project-specific requirements including weather conditions and structural design requirements and environmental exposure contexts.

Types of Chemical Additives for Concrete Durability

Water-Reducing Agents: Water-reducing concrete additives minimize mixture water content which in turn improves concrete strength combined with reduced potential for material contraction and associated damage.

Plasticizers and Superplasticizers: The additive systems provide better workable concrete and reduced water usage which results in improved placement methods before compacting concrete.

Air-Entraining Agents: The addition of these chemical elements forms microscale air bubbles in concrete which make it more resistant to freezing vibrations and diminishes its moisture permeability.

Corrosion Inhibitors: These protective substances shield concrete-reinforced steel bars from corrosion damages that occur in structures at risk from moisture exposure and chloride conditions.

Shrinkage-Reducing Additives: These additives reduce concrete shrinkage along with decreases in cracking which results in strengthened structural composition.

Pozzolanic Materials: Mineral admixtures such as fly ash and silica fume and slag improve concrete structural strength and reduce permeability and extend lifetime performance.

Benefits of Using Chemical Additives for Concrete

Enhanced Strength: Building materials (additives) enhance both concrete's compression strength and tensional strength to perform well with heavy loads.

Improved Durability: Concrete materials achieve much better protection against weather-induced breakdown alongside damage from chemicals and environmental hazards.

Better Workability: The additives make mixes easy to blend while enabling smooth placement procedures and optimal finishing outcomes regardless of project site complexity.

Reduced Permeability: The addition of such additives produces a protective effect by blocking pores and cracks which prevents destructive water passage.

Cost Savings: Such structures retain their integrity for longer time spans thereby decreasing future repair expenses.

Applications of Durable Concrete with Additives

Bridges and Highways: The additives improve resistance to both heavy loads and weathered conditions as well as chloride exposure resulting in corrosion damage.

Marine Structures: Substances have been developed to protect structures from saltwater intrusion while keeping them safe in dangerous maritime climates.

Industrial Floors: Additives enhance concrete properties by increasing its performance against heavy machinery and chemical spills and abrasion effects.

Residential Buildings: Ensuring long-lasting and low-maintenance structures.

Dams and Reservoirs: The combination of additives elevates both impermeability and structural strength for structures that store water.

The usage of chemical additives in construction requires builders to evaluate two main factors.

Compatibility: The selected additive must show compatibility to the particular cement mixed with the specified design.

Dosage: Manufacturers provide exact dosage information to achieve the best results.

Quality Assurance: All manufacturers should obtain chemicals for additives from respected professionals who ensure correct measurements while adhering to all applicable stand

Environmental Impact: Buildings require chemical additives which combine sustainability with green construction solutions.

Conclusion

The advantages provided by chemical additives to enhance concrete durability revolutionize construction practices across the industry. These innovations address concrete structural issues by providing solutions against corrosion and breaking while fighting against environmental damage thus maintaining concrete structures durable for many years. Engineers and builders achieve exceptional strength alongside sustainable construction while gaining cost efficiency through the implementation of these advanced materials into their projects.

0 notes

Text

Finding Spill Kits Near You: A Guide To Locating The Right Spill Response Supplies

When it comes to managing spills in your workplace or facility, having a spill kit on hand is essential for safety and compliance. Whether you're dealing with hazardous chemicals, oils, or other liquids, having the right spill response materials can prevent significant damage to the environment and your employees. But what happens when you need a spill kit urgently? In this guide, we’ll explain how to find spill kits near you and what to consider when purchasing one.

Why You Need a Spill Kit

Spill kits are crucial tools that allow you to respond quickly to hazardous spills. They contain absorbents, tools, and protective equipment designed to contain, clean up, and dispose of hazardous materials safely. Having a spill kit nearby ensures you're prepared for a variety of accidents and are able to mitigate risks associated with chemical, oil, or other harmful substance spills.

How to Find Spill Kits Near You

Finding spill kits locally can be a simple task if you know where to look. Here are some methods to help you locate spill kits near your location:

1. Search Online Retailers and Suppliers

One of the easiest ways to find spill kits near you is by searching online. Many suppliers and retailers offer direct sales of spill kits, and some even provide same-day or next-day delivery depending on your location. Simply search for terms like “spill kits near me” or “spill kit suppliers near [your location]” to find local vendors. Popular websites like Amazon, Grainger, and ULINE often have spill response products readily available and can help you find what you need quickly.

2. Local Industrial Supply Stores

Industrial supply stores often carry safety equipment, including spill kits. These stores serve businesses in manufacturing, construction, and other industries where spills are common. Local hardware or safety supply stores can be a good option for purchasing spill kits without waiting for delivery. They may also offer custom spill kits tailored to your specific needs.

3. Contact Emergency Response Companies

Some companies specialise in spill response and environmental safety. These businesses may offer on-site delivery, emergency spill response services, and maintenance of spill kits. If you need a spill kit in a hurry or require a kit designed for a specific type of spill, contacting a local emergency response company can help. They may even provide training on how to use the spill kit effectively.

4. Check with Local Waste Management and Environmental Services

Waste management and environmental service companies often provide spill kits to ensure compliance with environmental regulations. If you’re located near an area with a focus on environmental protection, these businesses can be a helpful resource for purchasing or renting spill kits.

5. Ask for Recommendations

Another way to find spill kits near you is by asking others in your industry or network for recommendations. Businesses dealing with hazardous materials or those in highly regulated industries often work with specific suppliers for their spill response needs. Connecting with local professionals or colleagues may help you identify trusted vendors and sources for spill kits in your area.

What to Look for When Choosing a Spill Kit

When purchasing a spill kit, it’s important to consider the type of spills you’re likely to encounter and the size of the kit you need. Here are a few factors to keep in mind:

1. Type of Spill

Different spill kits are designed to handle different types of materials. Be sure to choose a kit based on the liquids or chemicals commonly found in your workplace:

Oil Spill Kits: Ideal for dealing with oils and petroleum-based substances.

Universal Spill Kits: Suitable for a wide variety of liquids, including oils, coolants, and non-corrosive chemicals.

Chemical Spill Kits: Designed for hazardous chemicals, acids, or bases.

Biohazard Spill Kits: Designed for handling biological spills, such as bodily fluids.

2. Size and Capacity

Consider the size of your facility or work area and the volume of spills you may need to handle. Spill kits come in a range of sizes, from small kits that are suitable for individual workstations to larger, more comprehensive kits for industrial settings. A larger facility may need multiple kits in various locations.

3. Ease of Use

Look for spill kits that are easy to use and contain clear instructions. Ideally, the kit should include absorbents, protective gloves, disposal bags, and tools like scoops or shovels to make the cleanup process easier. A well-organised kit ensures your team can act quickly and efficiently in case of a spill.

4. Compliance with Regulations

Ensure that the spill kit complies with local regulations and industry standards. Many industries are required by law to have spill response equipment, and failure to comply can result in fines or other penalties. Check if the kit meets guidelines set by OSHA, EPA, or other regulatory bodies relevant to your business.

Conclusion

Having a spill kit nearby is crucial for managing spills effectively and maintaining safety and compliance in your workplace. By using the methods outlined above, you can easily find a spill kit supplier near you and ensure your business is prepared for any spill-related emergency. Whether you need a simple universal kit or a specialised chemical spill response solution, having the right materials at hand can make a big difference in minimising harm and ensuring your team’s safety. Don’t wait until an accident happens—be proactive and invest in a spill kit today.

0 notes

Text

Understanding Stormwater: Infrastructure, Pollution, and Solutions

Stormwater management is a critical aspect of urban planning and environmental protection. Recently, Arch Environmental Group held a presentation for high schoolers at Southfield High School for The Arts to shed light on the intricacies of stormwater, its infrastructure, and the various types of pollutions that impact stormwater.

Stormwater is the runoff generated from precipitation events, such as rain or snowmelt, that flows over land surfaces. Unlike natural landscapes, urban areas with impervious surfaces like roads and buildings prevent water from infiltrating the ground, leading to increased runoff.

Effective stormwater management relies on a well-designed infrastructure. The presentation highlighted several key components:

Drainage Systems: These include gutters, storm drains, and culverts that collect and convey stormwater away from urban areas to prevent flooding.

Retention and Detention Basins: These structures temporarily store stormwater, allowing it to infiltrate into the ground or be released at a controlled rate.

Green Infrastructure: This includes permeable pavements, green roofs, and rain gardens that mimic natural processes to manage stormwater sustainably.

Stormwater can carry various pollutants as it flows over surfaces. The presentation categorized stormwater pollution into three main types:

Sediment Pollution: Erosion from construction sites and urban landscapes can introduce large amounts of sediment into water bodies, affecting aquatic habitats and water quality.

Nutrient Pollution: Runoff can carry fertilizers and organic matter, leading to nutrient overloads in water bodies. This can cause algal blooms and oxygen depletion, harming aquatic life.

Chemical Pollution: Stormwater can pick up oils, heavy metals, and other toxic substances from roads, industrial sites, and residential areas, posing significant risks to both human health and the environment.

Solutions and Best Practices

The presentation also discussed various strategies to mitigate stormwater pollution and improve infrastructure:

Implementing Green Infrastructure: Encouraging the use of green roofs, rain gardens, and permeable pavements to reduce runoff and filter pollutants.

Regular Maintenance: Ensuring that stormwater systems are regularly inspected and maintained to function effectively.

Public Education: Raising awareness about the impacts of stormwater pollution and promoting practices like proper disposal of hazardous materials and reducing the use of fertilizers.

Conclusion

Understanding stormwater and its management is crucial for creating sustainable and resilient urban environments. By investing in robust infrastructure, educating the public, and adopting best practices, we can mitigate the adverse effects of stormwater pollution and protect our water resources for future generations.

0 notes

Text

Construction sites are inherently challenging environments. With large machinery, hazardous materials, and numerous workers navigating the space, the potential for accidents is always present. However, beyond the physical hazards, maintaining cleanliness and sanitation is equally critical to ensuring a safe and healthy working environment.

A well-maintained site not only reduces the risk of accidents but also boosts productivity, protects workers’ health, and improves the overall morale of the workforce.

1. Implement Strict Safety Protocols

Safety starts with establishing and adhering to a robust set of guidelines. All workers should be properly trained in safety practices, including the correct use of machinery, handling of hazardous materials, and emergency response protocols. Daily safety briefings should be conducted to remind workers of essential practices and highlight any site-specific hazards that might arise. Clear signage must be placed in areas where hazards are more likely, such as near large equipment, electrical installations, and locations with restricted access.

Personal protective equipment (PPE) is non-negotiable. Every worker must wear the required PPE, including hard hats, gloves, high-visibility vests, and safety goggles, depending on the task at hand. Supervisors should conduct regular inspections to ensure that workers are following these guidelines.

2. Manage Waste Properly

Construction activities generate a considerable amount of waste, including scrap materials, packaging, and potentially hazardous substances like chemicals and asbestos. Waste mismanagement can lead to environmental contamination and workplace injuries. A solid waste management plan helps prevent the accumulation of debris that can lead to trips, falls, or more serious incidents.

Segregating waste materials by type such as recyclable, hazardous, and non-recyclable facilitates efficient waste disposal. Properly marked bins should be placed in accessible areas, and waste should be removed from the site regularly to avoid build-up. Hazardous waste, in particular, must be stored and disposed of following strict regulatory guidelines to minimize risk to both workers and the environment.

3. Maintain Cleanliness in High-Traffic Areas

Construction sites often have areas where workers frequently move, such as entrances, exits, pathways, and break areas. These high-traffic zones can quickly become cluttered with dirt, debris, and equipment if not properly managed. A cluttered or dirty environment significantly increases the risk of accidents like slips, trips, and falls.

Establishing a routine for cleaning these areas is essential. Sweeping or power washing walkways, removing unnecessary tools, and regularly emptying trash receptacles are simple measures that can greatly reduce the chances of an accident. In addition, these clean, organized areas allow workers to focus on their tasks without unnecessary distractions.

Read more

1 note

·

View note

Text

Why Construction SWMS Are Essential for Project Safety and Legal Compliance

A Safe Work Method Statement (SWMS) is vital for maintaining safety and ensuring legal compliance in construction settings. Given the inherent risks associated with the construction industry, SWMS serve as a fundamental resource for detailing safety protocols and minimizing the chances of accidents or injuries on-site. Additionally, they assist in fulfilling legal requirements, thereby making them an essential element of any construction endeavor. This article will examine the reasons why SWMS are essential for both project safety and compliance.

A Construction SWMS is a comprehensive document that delineates the procedures necessary for the safe execution of high-risk construction activities. It highlights potential hazards, evaluates the associated risks, and specifies the control measures required to mitigate them. Crucially, it serves as a clear reference for workers, guiding them on how to carry out their tasks in a manner that safeguards their safety as well as that of their colleagues on-site. In numerous jurisdictions, the creation of such documents is mandated by law, particularly in contexts involving high-risk work.

One of the key reasons that Safe Work Method Statements (SWMS) are crucial is their status as a legal obligation for construction projects that involve high-risk activities. Such activities may encompass tasks like working at elevated heights, managing hazardous substances, or operating heavy machinery. In numerous countries, governmental regulations require businesses to develop and implement a SWMS to showcase their dedication to health and safety standards.

By implementing SWMS, construction firms ensure compliance with the legal frameworks that govern workplace safety. The absence of a SWMS for specific high-risk tasks can lead to significant legal repercussions, including fines or even the halting of the project. Adhering to SWMS requirements also mitigates the risk of legal liabilities in the event of an incident, as it provides documented evidence that safety measures were established and adhered to.

A well-designed Safe Work Method Statement (SWMS) offers straightforward and succinct guidance that is easily comprehensible for workers. These guidelines ensure that all personnel are aware of the precise procedures to follow in order to execute tasks safely, thereby minimizing confusion and misinterpretations on the worksite. In scenarios where multiple workers are engaged in various activities concurrently, SWMS act as a uniform reference, ensuring that all individuals are aligned regarding safety protocols.

Effective communication through SWMS significantly reduces the likelihood of errors, which is crucial in environments with high risks. When workers have a definitive set of instructions available, they are less inclined to engage in unnecessary risks. Consequently, this approach diminishes the potential for accidents, injuries, or expensive errors that could hinder project timelines.

Risk management is fundamental to ensuring safety in the workplace, and SWMS play a crucial role in identifying, managing, and mitigating risks on construction sites. By documenting potential hazards linked to each task along with the corresponding control measures, SWMS empower project managers and workers to proactively tackle risks before they lead to incidents.

For example, a SWMS may highlight the risk of falling objects on a construction site and specify measures to alleviate this danger, such as mandating the use of hard hats and ensuring that materials are securely stored. Adhering to the SWMS allows workers to carry out their responsibilities with greater safety, confident that adequate safety protocols are established.

In the dynamic setting of a construction project, maintaining safety hinges on consistency. Safe Work Method Statements (SWMS) establish uniform safety protocols across all tasks and personnel, ensuring adherence to the same standards by everyone involved. This uniformity mitigates the likelihood of miscommunication or errors, especially in larger projects that engage multiple workers and contractors.

For a deeper understanding of construction SWMS, read the complete article.

0 notes

Text

Enhancing Industrial Safety with Gas Grab: The Ultimate Hands-Free Tool

Industrial environments pose numerous safety risks, especially when dealing with hazardous materials like gas cylinders. Handling such equipment with precision and care is crucial to avoid accidents and ensure workplace safety. The Gas Grab tool, designed specifically for industrial applications, offers a hands-free solution that improves both safety and efficiency. Here’s how this innovative tool plays a pivotal role in industrial settings.

Key Features of the Gas Grab

Hands-Free Operation The primary advantage of the Gas Grab is its hands-free functionality. It allows workers to securely maneuver gas cylinders without direct hand contact, significantly reducing the risk of injuries, such as crushing or pinching. This is particularly useful in industries where gas cylinders are frequently moved or handled, ensuring that workers maintain a safe distance from potentially hazardous materials.

Enhanced Worker Safety By eliminating the need for manual handling of gas cylinders, the Gas Grab minimizes the chances of accidents. Workers are less likely to be exposed to dangerous situations like falling cylinders or sudden gas leaks. This tool is essential in high-risk environments such as oil and gas, chemical plants, and other industrial facilities where gas cylinders are part of daily operations.

Ergonomic Design The Gas Grab tool is designed with worker comfort in mind. Its ergonomic build ensures that workers can lift and transport gas cylinders with ease, minimizing strain on the body. This feature helps prevent long-term injuries that often result from repetitive manual handling tasks in industrial settings.

Durability for Industrial Use Built to withstand the demanding conditions of industrial environments, the Gas Grab is made from durable materials that ensure it can handle the weight and size of various gas cylinders. Its robust construction means it is a reliable tool for long-term use in industries like manufacturing, construction, and chemical processing.

Applications of the Gas Grab in Various Industries

Oil and Gas Industry In the oil and gas sector, gas cylinders are a common sight. The Gas Grab tool allows workers to safely transport and store cylinders without coming into direct contact with them. This reduces the risk of accidents and ensures a safer working environment, especially in high-pressure settings.

Manufacturing and Chemical Processing Industries that deal with volatile gases or hazardous chemicals benefit greatly from using the Gas Grab. The tool’s ability to securely handle gas cylinders minimizes the risk of exposure to harmful substances, protecting both the workers and the facility.

Construction and Engineering In construction, the need for gas cylinders arises frequently, whether for welding or other technical operations. The Gas Grab ensures that these cylinders are moved safely across job sites, contributing to better workflow efficiency and improved safety protocols.

Conclusion

The Gas Grab tool is an essential addition to any industrial safety toolkit. Its hands-free operation, ergonomic design, and ability to enhance safety in hazardous environments make it a must-have for industries where gas cylinders are regularly used. By minimizing the risks associated with manual handling and offering a reliable, durable solution, the Gas Grab ensures a safer, more efficient workplace.

For more details on the Gas Grab and how it can improve your industrial safety standards, visit here.

0 notes

Text

Safety bunding is a critical practice in various industries, particularly those dealing with hazardous materials. This safety measure involves creating physical barriers, or "bunds," to contain spills and leaks, preventing them from causing harm to people, the environment, and property. This article explores the importance of safety bunding, its applications, and best practices for implementation.

Understanding Safety Bunding

Safety bunding, also known as secondary containment, refers to the construction of containment areas around storage tanks, chemical drums, and other vessels holding hazardous substances. These bunds are typically made of concrete, plastic, or earthen materials and are designed to capture and contain any spills or leaks that may occur.

The primary purpose of safety bunding is to prevent hazardous materials from escaping into the environment, where they can cause significant damage. This includes preventing contamination of soil and water sources, reducing fire and explosion risks, and protecting personnel and equipment from exposure to dangerous substances.

Importance of Safety Bunding

Environmental Protection: One of the most critical functions of safety bunding is to protect the environment. Containing spills and leaks prevents hazardous substances from contaminating soil and groundwater, which can have long-term detrimental effects on ecosystems and human health.

Regulatory Compliance: Many industries are subject to stringent regulations regarding the storage and handling of hazardous materials. Safety bunding is often a legal requirement to ensure compliance with environmental and safety regulations. Non-compliance can result in hefty fines and legal action.

Risk Mitigation: Safety bunding helps mitigate the risks associated with handling hazardous materials. By containing spills and leaks, bunding reduces the likelihood of accidents, such as fires and explosions, that can occur when hazardous substances come into contact with incompatible materials or ignition sources.

Operational Continuity: Implementing effective safety bunding measures can help ensure the continuity of operations. By preventing spills and leaks from causing significant disruptions, businesses can maintain productivity and avoid costly downtime.

Applications of Safety Bunding

Safety bunding is employed in various industries where hazardous materials are stored, processed, or transported. Some common applications include:

Chemical Manufacturing and Storage: Chemical plants and storage facilities use bunding to contain spills of toxic, flammable, or corrosive substances. Proper bunding is essential to prevent environmental contamination and protect workers.

Oil and Gas Industry: In the oil and gas sector, bunding is used around storage tanks, pipelines, and drilling sites to contain spills of crude oil, refined products, and other hazardous materials. This is crucial for preventing large-scale environmental disasters.

Mining and Mineral Processing: Mining operations often involve the use of chemicals for ore processing. Bunding is used to contain spills from chemical storage areas and prevent contamination of surrounding land and water sources.

Agriculture: In agriculture, bunding is used to contain spills of pesticides, herbicides, and fertilizers. This practice helps protect soil health and prevent runoff into nearby water bodies.

Waste Management: Facilities that handle hazardous waste use bunding to contain leaks and spills from storage containers, ensuring that dangerous materials do not escape into the environment.

Best Practices for Safety Bunding

To ensure the effectiveness of safety bunding, it is important to follow best practices in design, construction, and maintenance:

Design Considerations: The design of bunds should take into account the type and volume of hazardous materials being stored. Bunds must be large enough to contain at least 110% of the volume of the largest container within the bunded area. They should also be constructed of materials that are resistant to the substances being contained.

Regular Inspections: Regular inspections are essential to ensure that bunds remain in good condition. Inspections should check for cracks, leaks, and other signs of wear and tear. Any damage should be repaired promptly to maintain the integrity of the bunds.

Proper Drainage: Bunds should be equipped with proper drainage systems to remove rainwater and prevent overflow. However, drainage systems must include mechanisms to prevent the release of hazardous materials, such as shut-off valves or treatment facilities.

Training and Awareness: Personnel working with hazardous materials should be trained in spill response procedures and the importance of safety bunding. Regular training and drills can help ensure that everyone knows how to respond in the event of a spill.

Emergency Response Plans: Facilities should have comprehensive emergency response plans in place that include procedures for dealing with spills and leaks. These plans should be regularly reviewed and updated to reflect changes in operations and regulations.

Documentation and Record Keeping: Maintaining detailed records of bunding inspections, maintenance, and incidents is important for regulatory compliance and continuous improvement. Documentation helps identify recurring issues and track the effectiveness of safety measures.

Conclusion

Safety bunding is a fundamental practice for managing the risks associated with hazardous materials. By containing spills and leaks, bunding protects the environment, ensures regulatory compliance, mitigates risks, and supports operational continuity. Implementing best practices in design, construction, and maintenance of bunds, along with proper training and emergency preparedness, is essential for maximizing the effectiveness of safety bunding. As industries continue to evolve and new hazards emerge, safety bunding will remain a crucial component of comprehensive risk management strategies.

0 notes

Text

Center Enamel Provides Top-Quality External Floating Roofs for Storage Tanks

Center Enamel Provides Top-Quality External Floating Roofs for Storage Tanks

When it comes to innovative storage solutions, Center Enamel stands at the forefront, offering unparalleled expertise and a commitment to quality that sets us apart in the industry. Among our diverse product offerings, our external floating roofs for storage tanks are a testament to our dedication to excellence and innovation.

Why Choose External Floating Roofs?

External floating roofs are designed to float directly on the surface of the stored liquid, rising and falling with the liquid level. This design minimizes the space between the roof and the liquid, significantly reducing the evaporation of volatile organic compounds (VOCs). By limiting the exposure of the liquid to the atmosphere, external floating roofs provide a safer and more environmentally friendly solution for storage.

Superior Design and Engineering

At Center Enamel, our external floating roofs are engineered with precision and built to the highest standards. We utilize advanced materials and manufacturing techniques to ensure durability, reliability, and optimal performance. Our floating roofs are designed to handle a variety of liquids, including oil, chemicals, and other volatile substances, making them suitable for a wide range of industrial applications.

Aluminum dome roof, also known as an aluminum space truss roof, refers to a fully triangular aluminum space truss with support nodes distributed on the surface of a sphere. The aluminum cladding panels are securely connected to the frame structure, supported and fixed by evenly distributed support points on the top of the tank.

The Aluminum dome roof is a prefabricated, on-site assembled, fast construction, and construction quality controllable solution for tank roofs. It is of significant importance for improving the service life of tanks and reducing construction time. Made from high-strength aluminum alloy material, it features reasonable stress distribution, high rigidity, lightweight, large roofage area, low cost, good corrosion resistance, and long-term maintenance-free use. It inherits the inherent characteristics of both rod system structure and thin-shell structure, showcasing an elegant and artistic appearance that highlights structural beauty.

Center Enamel's Aluminum dome roof complies with API 650 and AWWA specifications, suitable for very large diameter storage tanks without the need for intermediate supports. The roof design exhibits excellent resistance to weather conditions, with the ability to withstand extremely high wind loads and snow loads, making it adaptable to various weather conditions.

Specification Parameters

Category

Specification Parameters

Load

0.75 kPa

Aluminum Bracket Model

5754-H22/F24

Corrosion Resistance

Excellent, maintenance-free for extended periods

Weight

One-third of the weight of steel with the same cross-section

Key Features and Benefits

Enhanced Safety: Our external floating roofs significantly reduce the risk of fire hazards by minimizing the presence of flammable vapors. This makes them an ideal choice for storing volatile liquids.

Environmental Protection: By reducing VOC emissions, our floating roofs help in protecting the environment and complying with stringent environmental regulations.

Cost Efficiency: Lower evaporation rates mean less product loss, leading to substantial cost savings over time. Additionally, the maintenance and operational costs are reduced, offering a more economical storage solution.

Durability: Built with high-quality materials, our floating roofs are resistant to corrosion and wear, ensuring a long service life even in the harshest conditions.

Tailored Solutions for Every Need

Understanding that each project has unique requirements, Center Enamel provides customized solutions tailored to meet specific needs. Our team of experts works closely with clients to design and manufacture external floating roofs that perfectly align with their operational demands.

Proven Track Record

Center Enamel has a proven track record of successful projects worldwide, with our external floating roofs being a preferred choice for many leading industries. Our commitment to quality and customer satisfaction has earned us a reputation as a trusted partner in the storage solutions industry.

Comprehensive Support

From initial consultation and design through to installation and after-sales support, Center Enamel offers comprehensive services to ensure the successful implementation and operation of our storage solutions. Our dedicated support team is always available to address any concerns and provide the necessary assistance.

With Center Enamel’s external floating roofs, you get more than just a storage solution—you get a commitment to quality, safety, and efficiency. As we continue to innovate and expand our product offerings, we invite you to explore the benefits of our external floating roofs and see how they can enhance your storage operations. Contact us today to learn more about our products and services, and let us help you find the perfect solution for your storage needs.

Center Enamel is a comprehensive high-tech enterprise that focuses on the research, development, manufacturing, and sales of GFS tanks, diversified environmental protection equipment, as well as undertaking environmental EPC projects and anaerobic process segments. In its long-term service and engineering practice, the company adheres to a technology-centric approach, not only ensuring the high-quality completion of project construction but also dedicating itself to achieving breakthrough innovations in the field of wastewater treatment.

On one hand, Center Enamel, through a deep understanding of the needs of clients in various sectors, meticulously plans and designs rational solutions for sewage collection, transportation, treatment, and discharge. The company provides comprehensive wastewater treatment solutions to clients, ensuring the safe and stable operation of each wastewater treatment project.

On the other hand, leveraging advanced core technologies, Center Enamel has developed numerous environmentally friendly devices that are highly competitive in the market. These devices have received significant recognition from the market and clients for their operational stability, effectiveness in water environmental governance, cost-effectiveness, and more. In this batch of new projects, the company customizes the design of equipment based on project requirements, not only reducing investment costs but also improving construction efficiency. This approach enables projects to be delivered on time and with high quality, meeting the demands of clients within specified timelines.

0 notes

Text

The Challenges and Solutions for Fly Ash Manufacturers in India

When coal combustion occurs in the thermal power plants, it produces a byproduct named fly ash. Owing to its ability and high potential, it has varied applications. it can be used in the construction industries as well as to create environmental impact.

However, despite the numerous advantages, there are several challenges that fly ash manufacturers in India face. This article will look into these challenges and help understand the best way to overcome them. 1. The most important issue that fly ash manufacturers face is the storage of this product. As the byproduct is produced in large quantities, it needs to be stored in maximum containers. However, if you end up storing it using improper methods, you might cause environmental hazards. There are fine particles within the fly ash that can become airborne, which can increase the pollution in the air. This results in increased health risks to the people nearby. Moreover, if you store the fly ash in open ponds or landfills, it can increase the quantity of harmful substances in the air. This can cause contamination. That’s why the storage is a big challenge. a. To overcome the storage issue, most power plants and the fly ash supplier in India implement the improved storage solutions. They use enclosed silos and covered facilities to store the fly ash. This way there are fewer chances of it becoming airborne and causing environmental risks. Moreover, they tend to adopt the best practices to store and handle the fly ash. 2. The other major challenge that most manufacturers face is transporting the fly ash to the utilization sites. This impacts the logistics and planning. In case of bulk fly ash, there is a need for specialized equipment that can handle the transportation without spilling it over. In case the transportation causes spillage, it can cause dust. Again, the cost of transportation can also increase if the distance is huge. Lastly, the infrastructure could also pose to be an issue causing delays in transport. a. When you want to effectively use the fly ash, you must acknowledge and implement efficient transportation methods. You can use dust suppression systems within the transport vehicles. Moreover, you can also use dedicate corridors for transportation so that fly ash manufacturers in India can safely transport the byproduct. Lastly, you can use the rail transport as it is a great way to ensure dust free transportation. 3. You may be faced with quality and consistency issues when you are planning to use the fly ash. The quality depends on the coal and the combustion process used by the plants. In case the coal is of low quality, it can impact the performance of the fly ash you are planning to use. if there are quality issues, you may face strength and durability issues as well. a. When you use stringent quality control measures, you can ensure the consistent quality of the product. It also helps if you have a standardized process for testing and certification. This would ensure that the fly ash can be used by the industry for the specific solution. it can impact the reputation of the fly ash supplier in India positively.

0 notes

Text

Understanding FIBC Bulk Bags: A Comprehensive Guide

Flexible Intermediate Bulk Containers 1 Ton Bag Manufacturers in Gujarat, commonly known as bulk bags, are essential tools in the storage and transportation of various goods. These large, flexible bags are designed to handle and transport bulk materials, making them indispensable in numerous industries. In this guide, we will explore the features, benefits, and applications of FIBC bulk bags, along with answering some frequently asked questions about these versatile containers.

What are FIBC Bulk Bags?

FIBC bulk bags are made from woven polypropylene and are designed to carry bulk quantities of products, ranging from food and pharmaceuticals to chemicals and construction materials. These bags can handle weights ranging from 500 to 2,000 kilograms, depending on their size and design. FIBCs are widely appreciated for their durability, flexibility, and cost-effectiveness.

Key Features of FIBC Bulk Bags

Material: Most Bulk Bag Manufacturers in Ahmedabad are made from woven polypropylene, which provides excellent strength and durability. This material is resistant to moisture, chemicals, and UV rays, making it suitable for a wide range of applications.

Design: FIBCs come in various designs, including U-panel, circular, and baffle bags. Each design caters to specific needs, such as maximizing storage space or improving stability during transport.

Capacity: The capacity of FIBC bulk bags can vary significantly, typically ranging from 0.5 to 2 cubic meters. The weight capacity also varies, with some bags capable of carrying up to 2,000 kilograms.

Handling: FIBCs are equipped with lifting loops, making them easy to handle with forklifts or cranes. This feature is particularly useful in industrial settings where large quantities of materials need to be moved efficiently.

Customization: Many FIBC manufacturers offer customization options, allowing businesses to specify size, material, and additional features such as liners, coatings, and printing.

Benefits of Using FIBC Bulk Bags

Cost-Effective: FIBC Bags Manufacturers in India are a cost-effective solution for transporting and storing bulk materials. Their reusable nature and large capacity reduce the need for multiple smaller containers, thereby lowering overall costs.

Versatility: FIBCs can be used across various industries, including agriculture, pharmaceuticals, chemicals, and construction. They can carry a wide range of materials, from fine powders to granular substances.

Space-Saving: When not in use, FIBCs can be folded and stored compactly, saving valuable storage space. This feature is particularly beneficial for businesses with limited storage facilities.

Ease of Handling: The integrated lifting loops make FIBCs easy to handle with standard lifting equipment, enhancing operational efficiency and reducing the risk of workplace injuries.

Environmental Impact: Many FIBCs are recyclable and can be reused multiple times, making them an environmentally friendly option compared to single-use containers.

Applications of FIBC Bulk Bags

Agriculture: FIBCs are widely used in the agricultural sector to transport and store grains, seeds, fertilizers, and animal feed. Their large capacity and durability make them ideal for handling bulk agricultural products.

Pharmaceuticals: In the pharmaceutical industry, FIBCs are used to transport raw materials and active pharmaceutical ingredients (APIs). The bags can be customized with liners to ensure the materials remain uncontaminated.

Chemicals: FIBCs are commonly used to transport chemicals, including powders, granules, and pellets. The chemical-resistant properties of polypropylene make these bags suitable for handling hazardous materials.

Construction: In the construction industry, FIBCs are used to transport sand, gravel, cement, and other building materials. Their robust design ensures that they can withstand the rough handling typical of construction sites.

Food Industry: The food industry utilizes FIBCs for transporting bulk food products such as sugar, flour, salt, and spices. Food-grade FIBCs are designed to meet stringent hygiene standards to ensure the safety of the contents.

Conclusion

FIBC bulk bags are a vital component in the efficient storage and transportation of bulk materials. Their durability, versatility, and cost-effectiveness make them an ideal choice for various industries. By understanding the features, benefits, and applications of FIBCs, businesses can make informed decisions about how to best utilize these containers to enhance their operations. With proper use and handling, FIBC bulk bags can provide a reliable and sustainable solution for managing bulk materials.

Frequently Asked Questions (FAQs) About FIBC Bulk Bags

What are the types of FIBC bulk bags available?

FIBCs come in various types, including U-panel bags, circular bags, and baffle bags. U-panel bags are constructed from two side panels and a single base panel, offering a stable and cost-effective option. Circular bags are made from a single piece of fabric, providing excellent structural integrity. Baffle bags include internal baffles that help maintain the bag’s shape, optimizing space usage during storage and transport.

Are FIBC bulk bags reusable?

Yes, many FIBCs are designed for multiple uses. Reusability depends on the bag’s condition and the nature of the materials it has carried. Bags used for non-hazardous and non-contaminating substances can often be cleaned and reused. However, bags used for hazardous materials or food products may have restrictions on reuse due to safety and contamination concerns.

How are FIBC bulk bags tested for safety?

FIBCs undergo rigorous testing to ensure they meet safety standards. Tests typically include load testing, where the bag is filled to its maximum capacity and lifted repeatedly to check for strength and durability. Additional tests may assess resistance to UV light, moisture, and chemicals. Certified bags are labeled with safety ratings indicating their load capacity and usage conditions.

Can FIBC bulk bags be customized?

Yes, FIBCs can be highly customized to meet specific needs. Customization options include different sizes, materials, coatings, and liners. Businesses can also choose to have their logo or other information printed on the bags. Custom features like spouts, filling and discharge mechanisms, and anti-static properties can also be added to enhance functionality.

What are the environmental benefits of using FIBC bulk bags?

FIBCs offer several environmental benefits. Their reusability reduces the need for single-use packaging, cutting down on waste. Many FIBCs are also recyclable, allowing the materials to be repurposed after the bag’s lifecycle ends. Additionally, the efficient design of FIBCs can reduce the number of trips needed for transportation, leading to lower carbon emissions.

0 notes

Text

The U Panel Advantage: Your Guide to Bulk Packaging

Introduction:

U panel bulk bags, also known as U panel FIBC (Flexible Intermediate Bulk Containers), are versatile and efficient packaging solutions used across various industries for transporting and storing bulk materials. In this blog, we will delve into the features, benefits, and applications of U panel bag manufacturers, as well as how Singhal Industries, a leading manufacturer of flexible packaging products, excels in providing innovative solutions in this field.

Understanding U Panel Bulk Bags:

U panel bulk bags are large, flexible containers made from woven polypropylene fabric, featuring a distinctive U-shaped panel on each side. This panel design provides additional strength and stability, making U panel bulk bags ideal for handling and transporting heavy or irregularly shaped materials. These bags typically have four lifting loops for easy handling with forklifts or cranes, and they come in various sizes and configurations to suit different applications.

Applications of U Panel Bulk Bags:

Construction: U panel bag manufacturers India are commonly used in the construction industry for transporting and storing materials such as sand, gravel, and aggregates. Their sturdy construction and large capacity make them ideal for handling heavy loads on construction sites.

Agriculture: In the agricultural sector, U panel bulk bags are utilized for storing and transporting crops, seeds, and fertilizers. Their breathable fabric construction allows for proper airflow, helping to preserve the quality of agricultural products during storage and transportation.

Chemicals and Pharmaceuticals: U panel bulk bags are suitable for handling and transporting chemicals, pharmaceuticals, and other hazardous materials. Their durable construction and secure closures ensure safe containment and handling of sensitive substances.

Food and Beverage: U panel bulk bags are used in the food and beverage industry for packaging and transporting ingredients such as grains, flour, sugar, and spices. Their food-grade fabric and hygienic design make them suitable for handling food products safely.

Benefits of U Panel Bulk Bags:

Strength and Durability: U panel bag supplier are constructed from high-quality woven polypropylene fabric, providing exceptional strength and durability. This ensures that the bags can withstand the rigors of transportation and storage without tearing or breaking.

Space Efficiency: U panel bulk bags are designed to maximize storage space, allowing for efficient use of warehouse and transportation space. Their stackable design and ability to be transported in bulk reduce the need for additional packaging and handling, saving time and resources.

Customization Options: U panel bulk bags can be customized to meet specific requirements, including size, capacity, lifting options, and printing options. This allows for branding opportunities and ensures that the bags meet the unique needs of each application.

Environmental Sustainability: U panel bulk bags are reusable and recyclable, making them an environmentally friendly packaging solution. By reducing the need for single-use packaging and minimizing waste, U panel bulk bags contribute to sustainable practices in various industries.

Singhal Industries: Providing Innovative Solutions:

Singhal Industries is a trusted manufacturer of flexible packaging products, including high-quality U panel bulk bags. With a focus on innovation and quality, Singhal Industries offers a range of U panel bulk bags designed to meet the specific needs of various industries. Their bags are manufactured using premium materials and state-of-the-art technology, ensuring durability, reliability, and customization options to suit different applications.

Conclusion:

In conclusion, U panel bulk bags are versatile and efficient packaging solutions used across various industries for transporting and storing bulk materials. With their strength, durability, space efficiency, and customization options, U panel bulk bags offer numerous benefits for businesses seeking reliable packaging solutions. Singhal Industries' commitment to innovation and quality ensures that their U panel bulk bags meet the highest standards of performance and reliability, making them a trusted choice for businesses worldwide.

FAQS

What are U panel bulk bags, and how are they different from other types of bulk bags? U panel bulk bags, also known as U panel FIBC (Flexible Intermediate Bulk Containers), are large, flexible containers made from woven polypropylene fabric. They feature a distinctive U-shaped panel on each side, providing additional strength and stability compared to other types of bulk bags. This design makes them ideal for handling and transporting heavy or irregularly shaped materials.

What are the main applications of U panel bulk bags? U panel bulk bags are used across various industries for transporting and storing bulk materials such as sand, gravel, aggregates, crops, seeds, fertilizers, chemicals, pharmaceuticals, food ingredients, and more. They are commonly utilized in construction, agriculture, chemical, pharmaceutical, food and beverage, and other industries that require efficient and reliable packaging solutions for bulk materials.

What are the key benefits of using U panel bulk bags? Some of the key benefits of U panel bulk bags include their strength and durability, space efficiency, customization options, and environmental sustainability. They offer exceptional strength and durability, maximizing the safety and security of transported materials. Their space-efficient design allows for efficient storage and transportation, while customization options ensure they meet specific application requirements. Additionally, their reusable and recyclable nature contributes to environmental sustainability.

How can U panel bulk bags be customized to meet specific requirements? U panel bulk bags can be customized in various ways to meet specific requirements, including size, capacity, lifting options, and printing options. Businesses can choose the appropriate dimensions and lifting configurations based on the type and weight of the materials being transported. Printing options allow for branding opportunities and the inclusion of essential information such as product details, handling instructions, and safety warnings.

How does Singhal Industries ensure the quality and reliability of its U panel bulk bags? Singhal Industries is committed to providing high-quality U panel bulk bags manufactured using premium materials and state-of-the-art technology. Their bags undergo rigorous quality control measures to ensure they meet the highest standards of performance and reliability. With a focus on innovation and customer satisfaction, Singhal Industries offers customized solutions tailored to the specific needs of various industries, ensuring maximum efficiency and satisfaction.

0 notes

Text

How to Handle Hazardous Waste in Waste Water Treatment

Hazardous waste management is an integral part of industrial waste management. Right handling, storage, treatment and disposal of these hazardous substances are vital. Otherwise, problems like spills, leakages, fires and the pollution of soil and drinking water may happen.

Different types of hazardous waste

According to the EPA, hazardous waste is any waste with possibly harmful effects on the human health or the environment. It may come from different sources, like farming, manufacturing, laboratory, construction and health care amenities. Hazardous waste also comes in different forms, including sludge, gases, liquids and solids which can be analyzed during Waste soil solid sludge analysis in Dubai.

How do you handle hazardous materials in wastewater?

Hazardous and waste liquid chemicals analysis send water based wastes, like oils, paint, bases, acids and coolants, through a special treatment process causing neat and usable water extraction. Amenities can reuse the treated water on-site or discharge it to the environment.

Hazardous waste management can look a bit different depending on the amenity and waste type. Nonetheless, it generally involves these steps:

Transportation

First of all, a hazardous waste disposal company transports the hazardous waste to a treatment plant. The plant gets the waste in tankers, drums and totes.

Disposal

After being stored in a tank or any other unit, the treated waste water by the EIAC Emirates International Accreditation Center approved Laboratory is ready for on-site use, like hydraulic fracturing or cooling tower. Or else, the water can be discharged back into the environment.

Moreover, the plant should properly dispose the hazardous wastes. Landfills are commonly used as disposal sites. The disposal company will generally place the substance in a mindfully constructed unit to safeguard surface water and groundwater. Then, the waste is ready to be discarded into the landfill.

#Water soil sludge analysis in Dubai#EIAC Emirates International Accreditation Center approved Laboratory#Waste Soil Solid Sludge analysis in Dubai

0 notes

Text

Enhancing Kitchen Safety: The Importance of Safety Shoes and Boots in Singapore

In bustling Singaporean kitchens, where the aroma of sizzling spices fills the air and culinary creations come to life, safety is paramount. Amidst the whirlwind of activity, chefs and kitchen staff navigate a landscape filled with potential hazards, from slippery floors to sharp utensils. In such an environment, the right protective gear can make all the difference, and safety shoes and boots play a crucial role in ensuring the well-being of kitchen workers.

Safety shoes designed specifically for kitchen environments offer a range of features tailored to address the unique challenges faced in culinary settings. These shoes are engineered to provide maximum traction on slippery surfaces, helping to prevent slips and falls, which are among the most common accidents in kitchens. With specialized outsoles that offer superior grip and stability, chefs can move confidently even on wet or greasy floors.

Moreover, safety shoes for kitchens are equipped with reinforced toe caps to protect against impact injuries from heavy objects such as pots, pans, or crates. In a fast-paced kitchen where utensils are wielded with precision and haste, the risk of accidentally dropping or kicking objects is ever-present. The presence of protective toe caps can significantly reduce the likelihood of foot injuries, safeguarding the well-being of kitchen staff.

In addition to physical hazards, kitchens are also prone to spills and splatters, exposing workers to the risk of burns and scalds. Safety shoes designed for the kitchen environment often feature water-resistant materials that provide a barrier against hot liquids and steam, minimizing the risk of burns to the feet. Furthermore, some models incorporate heat-resistant soles that can withstand high temperatures, offering an added layer of protection in busy kitchen settings.

Beyond the kitchen, in industries such as construction, manufacturing, and logistics, safety boots are indispensable for ensuring the safety of workers in diverse environments. In Singapore, where workplace safety regulations are stringent, employers prioritize the well-being of their employees by providing appropriate protective gear, including safety boots.

Safety boots in Singapore are designed to meet rigorous safety standards, offering protection against a wide range of hazards commonly encountered in industrial settings. From heavy machinery to hazardous substances, workers face numerous risks that necessitate the use of robust protective footwear. Safety boots are typically constructed with durable materials such as steel toe caps and puncture-resistant soles, providing comprehensive protection against impact, compression, and penetration injuries.

In Singapore's construction sector, where workers are exposed to hazards such as falling objects and sharp debris, safety boots are essential for safeguarding against foot injuries. The sturdy construction of safety boots ensures that workers can navigate construction sites with confidence, knowing that their feet are adequately protected against potential dangers.

Moreover, in warehouses and logistics facilities where heavy loads are transported and stored, safety boots play a vital role in mitigating the risk of foot injuries caused by crushing or puncture accidents. By investing in high-quality safety boots, employers demonstrate their commitment to workplace safety and employee well-being, fostering a culture of responsibility and care.

In conclusion, safety shoes and boots are indispensable tools for promoting workplace safety in Singaporean kitchens and industrial environments alike. By providing chefs, kitchen staff, and workers in various industries with the appropriate protective footwear, employers can mitigate risks, prevent injuries, and create safer work environments for all. In a nation known for its commitment to excellence and innovation, prioritizing safety is not just a legal requirement but a fundamental aspect of responsible business practices. As Singapore continues to thrive and grow, let us ensure that safety remains at the forefront of our efforts, protecting the lives and livelihoods of our workforce.

0 notes