#stepper vs servo

Explore tagged Tumblr posts

Text

Perbedaan Motor Stepper dengan Servo Motor untuk Mesin CNC dan Robotika

Dalam dunia industri khususnya untuk mesin otomasi, CNC dan Robotika memilih motor penggerak harus mempertimbangkan banyak hal. Baik itu dari sisi akurasi, biaya, dan efisiensi. Motor stepper dan servo keduanya merupakan pilihan populer untuk berbagai aplikasi di industri seperti robotika, otomasi, dan manufaktur. Motor-motor ini bekerja sangat berbeda dan menawarkan kelebihan dan kekurangan yang…

0 notes

Text

All We Need To Know About Oem Pumps - Zaxis Inc.

An OEM pump is created by a producer with the see to be it being utilized as a component inside a framework by the client for the deal to a conclusion client. Ordinarily, the pumps will be bought in amount and be of indistinguishable or comparable determination. In numerous cases, the producer and conclusion client may create or institutionalize a portfolio of items for their particular utilize or indeed for an extraordinary competitive advantage.

OEM Pump can be typically used by the following firms:

1. Medical: for heating and cooling blankets.

2. Technology: for cooling computer mainframes and in x-ray machines.

3. Commercial: for ice machines and beverage dispensing equipment.

These are the few points you have to keep in mind before considering OEM Pump:

1. Will the pump fit into the OEM component?.

2. What noise level is tolerable?

3. Will the OEM operate within the existing base?

4. Will it overheat within the assembly? How many amps and watts will the system tolerate?

BENEFITS OF OEM PUMP:

An advantage for OEMs working with Walk Pump is working with another manufacturer-there is no agent. This permits for coordinated communication, which in turn guarantees issues are illuminated more effectively and private data can be shared safely and with ease. Sometimes an engine is as well hot or as well boisterous, or as well costly, and a alter ought to be made. Not at all like other producers, Walk Pump will attempt its hardest to discover an arrangement for the client.

SERIES OF OEM PUMPS:

(2.5μL/rev – 100μL/rev) Microliter Heads .

1. M-Series Microliter Pumps (2.5μL/rev – 100μL/rev)

a) Microliter Heads

Designed primarily for ultra-low volume metering and dispensing, providing high precision and accuracy. If you are looking to meter under 100 mL/min or dispense from 2.5 µL to 100 µL per revolution, then the M0 or M1 head is perfect. Standard with low flow, low dead volume ¼ -28 female ports. The PVDF (Kynar®) pump body, and the wetted path can be configured for Kynar®, PTFE, and Rulon® AR. Select the piston size closest to your maximum volume for the best accuracy and precision.

b) Microliter Drive

The eVmP Micro is our stepper motor drive, designed for the Micro Series pump heads. Micro Pumps are ideal for neat chemistry, with flow rates under 100 mL/min, and pressure less than 100 PSIG. Each Micro Drive is standard with RS485, PLC I/O, and Ethernet connections.

2. V-Series Milliliter Pumps (25μL/rev – 1.28mL/rev)

a) Milliliter Heads

The V6SAN-W Pump head offer one of the largest fill volumes per stroke and metering rate in the industry, providing larger flow rates with a valve-less piston design. It features 316SS and PTFE wetted parts, as well as sanitary features such as tri clamp/sanitary fittings designed to meet FDA and 3A standards. Wash glands are optional(-w) as well as numerous fitting configurations to meet your application needs.

b) VMP-OEM-V Drive

The VMP-OEM-V is our stepper–driven motor drive, designed for V series pump heads. VMP-OEM-V Pumps are ideal for a very wide range of applications, including neat chemistry, and some slurries, pastes, gels, or creams. Flow rates are typically less than 1000 mL/min, and under 100 PSI, making the V Series is one of our most popular pumps. Each VMP-OEM-V Drive is standard with RS485, PLC I/O, and Ethernet connections.

c) VMP-OEM-VS Drive

The VMP-OEM-VS is our servo-driven motor drive, designed for V series pump heads. The Servo Drive is ideal for more demanding applications with higher flow rates, higher pressure, or higher viscosity applications. With nearly 4 times the torque, the VS series drive can handle flow rates near 2,000 mL/min and backpressure up to 200 psi, while accepting common V series pump heads. Each VMP-OEM-V Drive is standard with RS485, PLC I/O, and Ethernet connections.

3. VS10-Series Milliliter Pumps (0.5mL/rev – 10mL/rev)

a) Milliliter Heads

The V6SAN-W Pump head offer one of the largest fill volumes per stroke and metering rate in the industry, providing larger flow rates with a valve-less piston design. It features 316SS and PTFE wetted parts, as well as sanitary features such as tri clamp/sanitary fittings designed to meet FDA and 3A standards. Wash glands are optional(-w) as well as numerous fitting configurations to meet your application needs.

b) Milliliter Drive The VMP-OEM-VS10 is our specialty, servo-driven motor drive, designed to accept to V6SAN Pump Head. Using a powerful servo motor and extra-large flow capacity, the VMP-OEM-VS10 can accomplish an amazing 10L/min and nearly 10mL/stroke, at a maximum of 25 PSI. Each VS10 Drive is standard with RS485, PLC I/O, and Ethernet connections.

0 notes

Text

Texas Driver Certificate Demands for Mopeds and Motorized Bicycles

Deciding which type generator you'll need may possibly not be a straightforward task. There are many different kinds accessible today. Before you buy, you will find a number of variables that need to be addressed. So how can you effectively achieve this? This article is published to help you in deciding which generator is better for your application.

First and foremost you will have to know very well what voltage supply comes in your application. Electrical engines may be classified as possibly AC (Alternating Current) or DC (Direct Current). Switching current types just run on AC Voltage and primary current types just run on DC Voltage. There's also a widespread generator that could run on equally AC and DC voltages.

After you have recognized which energy supply you have you will have to decide which fashion works for your application. AC engines may be sub-divided into these: Single Period Induction, Three Period Induction, Two Period Servo, and Hysteresis Synchronous. DC engines may be sub-divided into: Brushless DC, Comb DC, and Stepper types.

Next we have to understand the various traits of each type in order to effectively match a generator to their application.

An individual period induction generator is linked to an individual voltage line. An additional capacitor is needed to get this to generator operate. The several types of simple period induction engines are distinguished where technique they are started. The four fundamental types are: separate period, capacitor start, lasting separate capacitor, and capacitor start/capacitor run.

A separate period generator uses a changing system to disconnect the start turning once the generator reaches 75% of their ranked speed. While this sort has a simple design rendering it more affordable for commercial use, it also has reduced beginning torques and large beginning currents.

The capacitor start generator is simply a separate period capacitor generator with a capacitor in line with the beginning turning to create more beginning torque. That generator is more expensive on bill of the changing and capacitor requirement.

A lasting separate capacitor generator does have no staring switch. For this sort, a capacitor is forever linked to the beginning winding. Since this capacitor is needed for constant use, it doesn't provide beginning energy, thus beginning torques are typically low. These engines aren't proposed for large beginning load applications. However, they do have reduced beginning currents, quieter function, and higher life/reliability, thereby making them a good choice for large period rates. They are also the most trusted capacitor generator on bill of not having a beginning switch. They can be created for higher efficiencies and energy factor at ranked loads.

The capacitor start/capacitor work generator has equally a start and work capacitor in the circuit. The start capacitor is turned out once reaching start-up. This kind of generator has higher beginning, decrease packed currents, and higher efficiency. The problem is the trouble that's expected for just two capacitors and a changing device. Consistency also plays an issue on bill of the changing mechanism.

The three period induction generator is injure for three period switching voltage. They're the simplest and many robust electrical engines available. The generator could be created for possibly DELTA or WYE hook-up. This sort is made for constant use and large beginning torques. Generator speed is relatively constant. If three period voltage can be acquired here is the generator to choose.

Two period servo engines are used in servo methods, hence the name. They are very painful and sensitive to voltage modifications on the get a grip on phase. That fashion needs two currents in 90 degrees period change from each other so as to make a twisting magnetic field. Servo engines have large torque to inertia ratio, top speed and works well for speed get a grip on applications. Tachometer feedback units may be given these motors.

Hysteresis synchronous engines are ostensibly induction engines that work at synchronous speed. As soon as your application needs synchronous speeds that is the best choice. These engines may be created for possibly simple period or three phase. For simple period voltage a capacitor will be required. Hysteresis synchronous engines develop what's called pull-out and pull-in torques. Pull-out torque is the total amount of torque/load the generator are designed for only since it grab of synchronous speed. Pull-in torque is the total amount of torque on the production base that enables the generator to draw into synchronism and stay there. Both pull-in and grab torques are very similar. These engines have reduced beginning currents and reduced vibration. Because the rotor assembly is made from a cobalt product, that is hard ahead by, this kind of generator is expensive.

The primary current (DC) engines that are accessible are brushless DC (BLDC), brush, and stepper motors. Once you just have DC voltage accessible then one of these simple engines must certanly be used. Brushless DC engines do have no brushes thus there aren't any concerns of brush use or sparking. Stable state regulates and feedback devises are required for operation. These engines have predicable performance, large beginning torques, and are capable of large speeds. While more energy production may be performed in an inferior package, the electric regulates get this to fashion generator expensive.

Unlike brushless engines, brush DC engines don't require any get a grip on electronics. Comb engines use commutator and brushes to produce a magnetic field. While these engines are usually low priced, brush and commutator use limits their consistency and longevity.

Stepper engines are DC engines that make step-by-step steps. If you require base placing to be predicable then stepper engines might be an option. These engines are trusted and lower in cost. They are nevertheless, confined in their ability to take care of large inertia loads.

After you have determined the voltage and volume supply your system has accessible you can determine the number of stages and type generator to look at. Next you would have to know these to ensure that your generator design engineer to help select the very best generator:

(1) Energy Output/Horsepower: The designer will have to know very well what the ranked speed and torque parameter that your process requires motovario redüktör.

(2) Frame Measurement: It's ideal for the designer to know the technical constraints in order to effectively measurement the motor.

(3) Work Cycle/Time standing: The total amount of time the generator is operating vs. time it's perhaps not is an essential conditions when planning the warmth methods of the motor.

(4) Environmental Situations: It is always very important to recommend the generator designer what situations the generator may see. This is crucial so the correct box is determined.

As you can see there are many several types of engines to decide on from. There's also many facets used in the choice. By working with a style engineer you can guarantee to have the best generator for your application. For this reason it is very important to search for a manufacturer before finalizing any methods design.

0 notes

Text

Stepper Motor

- Parts used

UNO R3

Breadboard

Power Supply Module

ULN2003 Stepper Motor Driver Module

Stepper Motor

7x Wire

Video:

youtube

Circuit diagram:

(Taken from https://www.tinkercad.com/things/jsXkBTAsRVu-stepper-motor-4-pairs-and-l293d since they have no driver module (ULN2003AN) and is a H-bridge but this is kind of the closest thing so it is not accurate to the real world, but works in a similar way.)

Code:

#include <Stepper.h> const int stepsPerRevolution = 200; Stepper myStepper(stepsPerRevolution, 8, 9, 10, 11);

void setup() { myStepper.setSpeed(60); Serial.begin(9600); }

void loop() { Serial.println("clockwise"); myStepper.step(stepsPerRevolution); delay(500); Serial.println("counterclockwise"); myStepper.step(-stepsPerRevolution); delay(500); }

Explanation: The inclusion of stepper.h allows control of the stepper motor and the accompanying controller board

Troubleshooting required: Initially i had my own 9v battery around so i had used that, before embarking on any project, it’s best to make sure batteries you use actually work. Took me a while to figure it out too.

Evaluation: Interesting introduction to stepper motors, something that could have been improved is either learning how to use more than one stepper at the same time to create some kind of simple moving car, or learning more about the applications of stepper motors vs servos

Difficulties others may encounter: Getting the input pins could be confusing to people new to Arduinos, along side making sure you use a separate power supply to drive the motors because if you don't it will not work.

0 notes

Text

3 Axis vs 4 Axis CNC Router

What is the difference between a CNC 3-axis and a 4-axis machine? I found this question on Quora.

I know that there are many friends will be often confused with this two kind of CNC routers. Today FORSUN CNC will be showing you the difference that exists between the three-axis and four-axis engraving machines. In 5 different parts, including what is it, what they can do, some considerations for selecting a CNC machine, what are the differences in configurations, what industries they apply to. Choosing the CNC machine that is more suitable for your processing needs is what you do. Join us as we share in detail.

1. What is 3 Axis / 4 Axis CNC router?

3 axis CNC router

The entry-level engraving machine for the engraving machine industry that is what 3 axis CNC router is. It performs intelligent cutting, milling, engraving, drilling, and grooving functions in different materials by moving a tool bit on the three-axis. As a basic machine, an upgrade to other machines like multi-process CNC router,multi-head CNC router, and other CNC machines is vital.

4 Axis CNC router

4 axis CNC router generally can be divided into a 4th axis CNC router and rotary axis CNC router. Comparing the 4 Axis CNC router to the 3 axis CNC router, the 4th axis engraving machine is special in its spindle which can swing 180 degrees in both positions – left and right. The 4 axis CNC router can realize plane processing and also make work possible on both sides. It does some surface processing of 3D workpieces.

Another 4 axis CNC router is also called a rotary axis CNC router. Compared with the 3 axis CNC router, this type of CNC machine includes adding a rotary device to the 3 axis CNC router. The rotary device majorly realizes the machining of cylindrical workpieces. It should be noted that the rotary device can be placed in any position you want to either in the X-axis direction or the Y-axis direction of the machine.

Similarly, the rotary device can not only be placed on the machine but also function independently of the machine. It is easier to operate, transport, and maintain. Therefore this type 4 axis CNC router can realize processing cylindrical workpieces and the plain engraving.

2. The differences of 3 Axis & 4 Axis CNC Router in Configurations

· Machine bed: The bed of the 4-axis engraving machine is thicker, which ensures the machine is more stable at high speed and also ensures the accuracy of the machine, compared with that of a 3-axis engraving machine. This ensures that the service life of the machine is extended accordingly.

· Motor: Three-axis CNC router can choose between stepper motors and servo motors depending on the customer requirements. But this does not apply to 4-axis CNC router which is recommended to choose servo motors above 850 watts, and they must be equipped with a reducer. The greater the motor power, the greater the torque provided with the accuracy of the machine better guaranteed.

· Guide rail: The recommended guide rail for the four-axis engraving machine is 25 mm or more. But the commonly used guide rail sizes are 20mm, 25mm, 30mm. Rails of these sizes have a strong carrying capacity, which not only helps to increase the processing efficiency but also increases the speed of the machine accordingly.

· Control system: The four-axis machine is to choose the control system with faster processing speed and higher control precision such as Syntec, Baoyuan, Siemens. While the conventional 3-axis engraving machine chooses Mach3, DSP, and NK105.

· Cooling method: The three-axis engraving machine generally adopts manual spray cooling, and a four-axis engraving machine uses automatic oil mist/water spray cooling to facilitate the processing of stone metals.

3. CNC Router Functions

What can a 3 axis CNC machine do?

The 3 Axis CNC Router has limitations of the working direction and as such, it only can realize the plane engraving. The 3 axis engraving machine has only three working directions as X, Y, and Z-axis. Achieving complicated hollowing out and 3D engraving is not possible. These three-axis machines can meet your machining requirements if you want to achieve simple flat machining in advertising, wooden furniture, and other industry.

Examples of what is achievable include shoe polishers, cabinet doors, mahjong tables, solid wood doors, craft doors, panel furniture products’ auxiliary processing, paint-free doors, screens, craft window processing, game cabinets and panels, three-dimensional wave board processing and computer tables.

What can a 4 axis CNC machine do?

4 axis engraving machine has four processing directions of A, X, Y, and Z-axis. It includes both a three-dimensional CNC router and a rotary CNC router. The four-axis engraving machine can realize the processing of three-dimensional workpieces such as Buddha statue, Dragon pillar column, Roman column, Guanyin statue, gourd and so on, and other cylindrical workpieces like Corel, chair leg, turned and box newel posts, handrail, door, and window frame based on the plane engraving machine.

4. What Industries Use CNC Machines?

CNC router applies to various industries. It is widely used in electronics, printing and packaging, furniture, advertising, crafts, molds, construction, crystal products, wood, tombstone, and decoration industry. As mentioned earlier, the four-axis engraving machine is an upgrade of the 3-axis CNC router. Therefore, the application range of the four-axis engraving machine is more extensive, compared with the 3 axis CNC router.

5. How to choose a right CNC router?

Choosing an engraving machine is important for users because there are various types of engraving machines. FORSUN will show you how to choose between three-axis and four-axis engraving machines. Depending on your goals, you will choose the machine that fits your purpose. For simple plane processing, the three-axis engraving machine can meet your needs. And to perform complex, three-dimensional, and diverse processing, the four-axis engraving machine is the best choice.

How to choose the four-axis engraving machine with two linkage modes?

Next we shall discuss the rotary engraving machine. How do users choose a machine based on where the rotary device is placed? The precautionary measures when purchasing a four-axis engraving machine.

When the rotary device is directly placed on the machine table, it does not affect the processing size. The rotary device can be inserted and taken off at any time, which is more convenient for users. This is suitable for users with small workpieces. We need to consider the size of the workpiece to be processed and the effective processing size of the machine when inserting the rotary device on the side of the machine.

The user needs to have a clear understanding of the size of the workpiece to be machined and that of the processing machine when choosing. This will help to decide on the position where the rotary device is placed because the diameter of the rotary device affects whether the gantry is raised.

Some users are suitable for the case where the rotary device is independent of the machine bed, and what are the benefits? It is recommended that the rotary shaft be placed independently of the machine, if the width of the machine is greater than 2 meters and the diameter of the rotary shaft is greater than 200 mm. This will not only affect the effective processing size of the user but will also benefit the packaging and transportation of the machine.

The above is a different case of a 4-axis engraving machine with a rotary device. We shall proceed to discuss how users choose a four-axis CNC router whose spindle can be swung? The machining size of the workpiece in the transverse direction will be reduced to a certain extent because the spindle can swing left and right. The machining accuracy will be affected too when the spindle is swung. The accuracy of the machine’s parts and that of the machine’s assembly are particularly important here.

So the user must choose a manufacturer with sufficient production strength like FORSUN, a professional in technology and assembly to reduce the error range and achieve satisfactory processing results.

6. What can FORSUN provide for you?

Complete CNC machine types:

In Part 7, we shall discuss the selection guide for our 3 axis CNC router and 4 axis CNC router. Depending on your production volume, if it is relatively large and you want higher processing efficiency, you can choose both an ATC engraving machine and a multi-process engraving machine. But If your processing workpiece is relatively small, you can choose our mini engraving machine.

You can choose our stone engraving machine if you mainly process in the stone industry. If your focus is to process large molds, you can choose the EPS engraving machine. As a professional engraving machine manufacturer, we are committed to helping you choose the most cost-effective machine that will meet your diverse processing needs and we provide customized services.

Perfect after-sales service:

Our professional after-sales service team provides you with 24-hour online and offline services. Regardless of the challenges you have with either machine selection, installation, maintenance, repair operation, and much more, you can always reach out to us. Prompt response to our customers has always been our commitment. Because we have a dedicated technical team that visits customers every year to solve any problems related to the CNC engraving machine according to customer needs.

0 notes

Text

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Cop 200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes 200pcs Heat Shrink Butt Connectors Terminals. Beetrie 260pcs Insulated FemaleMale Bullet Butt Connector wire Crimp Termin. Sopoby Solder Seal Heat Shrink Butt Connectors, crimp free connectors with built in low melt solder. 250 PCS Insulated Heat Shrink Electrical Wire Terminals Crimp Connectors Spade Set. Solder Seal Heat Shrink Butt Connectors. Heat Shrink Butt Connectors Kit JACKYLED 200pcs Waterproof. No solder? No problem! Butt Connectors!. 200PCS Electrical Crimp Butt Connector Insulated Terminals. Sealey Heat Shrink With Solder. Heat Shrink Butt Connectors Terminals. Find great deals on eBay for wiring butt connectors. 200Pcs Heat Shrink Insulated Butt 100 3M Heat Shrink Butt Connectors Marine Electrical Wiring Waterproof. . 560PCS Heat Shrink Tubing 2-1, Eventronic Electrical Wire Cable Wrap Assortment Electric Insulation. РекламаЛицензия The Connector. Доставка на Email. · пн-пт 10:00-18:00. . Solder vs. Butt connector ohms. 200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Copper Wire Electrical Kits (3 …. . Free delivery and returns on all eligible orders. Shop 200PCS Heat Shrink Butt Connectors Terminals, Aribest Insulated Waterproof Marine Automotive Copper Wire. . Heat Shrink Connectors & Terminals. electrical training heat shrink high voltage underground connection. РекламаБолее 30 тысяч товаров: одежда, товары для дома и др. Заходи на сайт и выбирай! · круглосуточно. . Free delivery and returns on all eligible orders. Shop 200PCS Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine …. . Wirefy Solder Seal Wire Connectors Review | Is It Worth It?. amazon heat shrink review 612. Butt connector compound injector and capping machine. Find great deals for 200pcs Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine AU N4m3. Shop with confidence on eBay!. . URLWALL 900PCS Mixed Electrical Wire Connector Crimp Insulated Spade Butt Splice Male Female Termina. 200pcs Heat Shrink Butt Connectors Terminals, Eventronic Insulated Waterproof Marine Automotive Cop. Heat Shrink Butt Connectors. Electralink Heat Shrink Connectors. 50pcs Solder Seal Wire Connector, Sopoby Solder Seal Heat Shrink Butt Connectors Terminals Electrical Waterproof Insulated Marine Automotive Copper(23Red 12Blue. . How to Use Heat Shrink Butt Splices.

200PCS Heat Shrink Butt Connectors Terminals Insulated Waterproof Marine Automotive Electrical Kits 3 colors 3 sizes

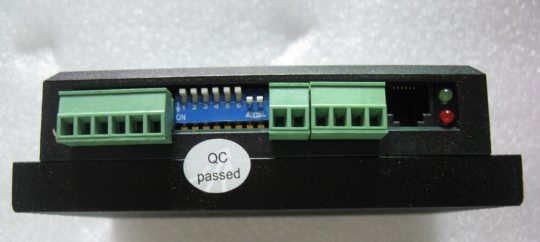

New Leadshine DM556 2-phase Digital Stepper Drive work 36-60 VDC 2.1A to 5.6A for Associated products NEMA23 motor

New Leadshine DM556 2-phase Digital Stepper Drive work 36-60 VDC 2.1A to 5.6A for Associated products NEMA23 motor

120Pcs Waterproof Butt Terminal Connectors Heat Shrink Solder 1.5/3/5/6mm Set Tinned Copper Four Sizes Heat Shrink Connector Kit

120Pcs Waterproof Butt Terminal Connectors Heat Shrink Solder 1.5/3/5/6mm Set Tinned Copper Four Sizes Heat Shrink Connector Kit

HGM1750 Genset Controller

HGM1750 Genset Controller

10/20M high temperature PT100 compensation wire PT100 PTFE silver plated shielded wire 3 core 4 Core 6core cable for sensor

10/20M high temperature PT100 compensation wire PT100 PTFE silver plated shielded wire 3 core 4 Core 6core cable for sensor

ET6415BND 60A solar control mppt charge, 48V solar charge controller, 60A 24V solar control

ET6415BND 60A solar control mppt charge, 48V solar charge controller, 60A 24V solar control

Free shipping 21in = 525mm stroke 24v electric linear actuator, the maximum load 1000N 12v linear actuator

Free shipping 21in = 525mm stroke 24v electric linear actuator, the maximum load 1000N 12v linear actuator

Promotion! Red Wire White Screw Type Cap Inline 6mm x 30mm Tube Fuse Holder 5Pcs

Promotion! Red Wire White Screw Type Cap Inline 6mm x 30mm Tube Fuse Holder 5Pcs

Free Shipping DC 12V / 24V 5inch / 125mm Linear Actuator, 1000N / 100kgs / 225lbs Thrust Load Line Actuator Actuator

Free Shipping DC 12V / 24V 5inch / 125mm Linear Actuator, 1000N / 100kgs / 225lbs Thrust Load Line Actuator Actuator

100Pcs Reusable Hook and Loop Fastening multifunction PC TV Computer Wire Cable Ties Organizer (5 color)

100Pcs Reusable Hook and Loop Fastening multifunction PC TV Computer Wire Cable Ties Organizer (5 color)

ECMA-C31010ES+ASD-A1021-AB DELTA 1kw 3000rpm 3.18N.m ASDA-AB AC servo motor driver kits with 3m power and encoder cable

ECMA-C31010ES+ASD-A1021-AB DELTA 1kw 3000rpm 3.18N.m ASDA-AB AC servo motor driver kits with 3m power and encoder cable

China 2 Phase NEMA34 86mm 4.8NM Closed Loop Stepper Motor & Driver kits Encoder 10000P/R 40~70VDC 5.6A 86SMA-HA+86SDA-H

China 2 Phase NEMA34 86mm 4.8NM Closed Loop Stepper Motor & Driver kits Encoder 10000P/R 40~70VDC 5.6A 86SMA-HA+86SDA-H

Fast free shipping, 2848A278 Skid Steer Diesel Solenoid CAT 246 Fuel Shutoff Stop Shut Off

Fast free shipping, 2848A278 Skid Steer Diesel Solenoid CAT 246 Fuel Shutoff Stop Shut Off

Aiyima 68KTYZ AC220V Synchronous Motor High Toque Permanent Magnet Gear Reduction Motors Reversible Controllable Micro Moteur

Aiyima 68KTYZ AC220V Synchronous Motor High Toque Permanent Magnet Gear Reduction Motors Reversible Controllable Micro Moteur

0 notes

Text

Step to Step to Build a Home DIY CNC Router

One of the aspects of any home built CNC Router machine is the use of each material in the construction of the machine vs the quantity of that material you have to buy. You are only building one machine so you don’t want have to buy more material than you need to build that machine. You especially need to consider this when deciding the length of travel you want for each axis, because this decision effects almost every other part of the machine. This was the general design process I went through for my CNC machine.

1. Decide what length of travel you need for each axis (if you have a specific project in mind for your cnc then start with it’s sizes requirements)

2. Decide what type of linear motion system you will use for the machine

3. Decide what kind of linear drive you will use for each axis

4. Decide what type of drive motor and controller you will use

5. Decide the material you will use to construct the machine

6. Based on the previous decisions, design a machine on paper or a CAD software of you choice (this does not have to be a complete design, just enough so you know the total quantity of the materials you’ll need)

7. Determine if you will need any special tools for your design

8. Determine the overall cost of your design, which includes the cost of tools you may not have

9. Decide that you can’t spend that much money on the machine and return to step 1

I went through this process 5 times before coming to a final design. The pictures show the different versions of the router as my design progressed. I know most people would consider this to be overkill but for me doing all this important. I knew that once I finished actually building the machine I would have something that fit my needs and my budget without any headaches do to poor planning. Here is my thinking for each one of the design steps I outlined:

1. Travel: My first thought for a CNC Router machine was to build molds for the vacuum forming machine I have already built. So I decided to build the machine with roughly 12”x24”x6" of travel because that how big the forming platen is on my vacuum forming machine.

2. Linear Motion: There are many options to choose from for linear motion. Commonly used methods for CNC routers include, drawer slides, skate bearings, v-groove bearings, round linear rail and profile linear rail. These are ordered in terms of cost, I would recommend going the best system you can afford. You can save some money in other areas of the machine but getting a good motion system will pay off in cutting quality. I chose to use round linear rail. This system uses precision ground and hardened steel shafts and linear bearings that use small steel balls that roll on the shaft and re-circulate through channels within the bearing. This offers smooth low friction movement and has good resistance to forces placed on the bearing in any direction. There are many different manufactures of these types of rails and bearings and costs can vary quite a bit. I got my rails and bearings from a reseller in China on ebay. The ebay store is linearmotionbearings and the prices were the best I found online. They often sells kits with three sets of rails and two bearings for each rail, which is what is needed for a 3-axis CNC. The kit I got uses 20mm x 800mm long rails for the x-axis, 16mm x 500mm long rails for the y-axis and 12mm x 300mm long rails for the z-axis. This kit cost me $223 dollars shipped.

3. Linear Drive: The three basic options to drive each axis of a CNC router are ribbed belts, screws, and a rack and pinion. The most common on DIY CNC routers are ACME screws, ball screws and rack and pinion setups. Screw drive systems work by attaching a nut to the movable part of each axis, a threaded rod is then fed through the nut and locked into position at both ends. The screw is turned by the drive motors and the nut moves along the screw. ACME screws have trapezoidal threads that are either cut or rolled into a steel rod. ACME screw threads are used on common C-clamps. Their thread shape makes the screw stronger than the threads on standard bolts. When these threads are precision cut they are perfectly suited to drive a CNC router. Probably the most common and cheapest ACME thread size is 1/2"-10. That means1/2” in diameter and 10 threads per inch. Ten threads per inch means that if the screw in spun around 10 times the attached nut will move 1 inch along the screw. For any screw size multiple individual threads can be cut on the screw, this is referred to as the number of starts the screw has. A single start screw has one thread a 2-start has two threads and a 5-start has five threads. What is the significance of multiple threads on a screw? Well there are two things that make multiple start screws better for CNC machines. First multiple start screws are more efficient at turning the rotational force on the screw into linear force on the nut. This means it takes less torque for the drive motors to move each axis. Second, multiple start screws increase the lead of the screw, which is how far a nut would move if the screw was rotated once. To determine the lead for a screw divide the number of starts by the number of threads per inch. For example, a 1/2”-10, 5 start, ACME screw would have a 5/10 or 1/2” lead. This means for every rotation of the screw the nut moves 1/2”. This is important because the electric drive motor can produce the most torque at low speeds, and with a higher lead the nut will move farther per revolution of the screw and that means the motor can spin at a lower speed to move the axis of the machine. For my machine I chose to use a 1/2”-10, 5 start, precision ACME screw from Mcmaster Carr for all 3 axis.

Another important thing to note is how precise the fit between the nut and the screw is. A standard nut on a bolt will wiggle a small amount back and forth and in CNC terms this is known as backlash. You want to reduce the amount of backlash you have between the nut and the screw because every time the screw changes rotation direction that small amount of play in nut will throw of your CNC position off and your parts might not come out correctly sized. There are ways with both hardware and the software you use to reduce the amount of backlash you have. On the software side there are simple settings that can compensate for backlash and on the hardware side you can use an anti-backlash nut. I purchased anti-backlash nuts from dumpsterCNC and again you can find part numbers on the parts list. Typically the effects of backlash can be reduced to the point that parts can be made to within a few thousands of an inch.

1. Drive Motor: For CNC routers two basic options exist, stepper motors or servo motors. Stepper motors are used in the vast majority of DIY CNC routers. CNCroutersource has some excellent information comparing these two types of motors. The key difference in these motors is servo motors provide position feedback to ensure proper positioning while stepper motors do not. I chose to use stepper motors for my machine mainly due to cost. Servo motors are more expensive and require more expensive controllers then comparable stepper motors for the sizes that are commonly used on CNC routers. Also stepper motors are highly supported in the DIY router community and are available from many different retailers. When looking in to stepper motors and controllers I found many options and price ranges from less than $100 to more than $500. When deciding what to get for my machine I came to the conclusion that these systems are so universal that I could use my controller and even steppers for other CNC projects in the future. Knowing that I wanted to get good performance and long term reliability I decided to go with American made components from Gecko. I purchased a Gecko G540 stepper controller which can control up to 4 stepper motors at once and connects to a computer through a parallel port. I also purchased 4 280oz-in, NEMA 23 stepper motors from Gecko which are also made in America. The control software I decided to use is called Mach3 and it uses a computer’s parallel port to send signals to the G540 which controls the stepper motors. Mach3 CNC control software can be downloaded and used for free, but is limited until you buy the software for $150. Mach3 is probably the most widely used software for DIY CNC machines and is well supported.

2. Construction Material: Most DIY CNC routers are built using either MDF, aluminum extrusion, or steel. MDF can be easy to work with and cheap to buy and many first time builders use this material. Slotted aluminum extrusion, commonly from a company called 80/20, is used on many DIY CNC router design plans available on the internet. It offers many design options due to the large amount on mounting brackets and configurations the slotted design allows. Aluminum extrusion would also be the most expensive of the three methods I listed. Steel is also used to construct many DIY routers. Square tubing, angle, and flat stock are common and can usually be locally sourced. In most cases steel machines are welded together so a welder and the ability to weld are necessary. Steel is generally going to be less expensive per foot than aluminum extrusion. I chose to use 1”x2”x0.065” steel tubing to construct my CNC router. I was able to purchase a single 24ft piece from a local steel supplier, Industrial Tube and Steel. They even cut it in half so I could load it in my car. If you don’t have a local steel supplier I would suggest looking at speedymetals, I have purchased from them before and they have good prices and deliver fast. I have experience welding and a flux core welder, which is similar to MIG welder but doesn’t require shielding gas. If you want to get more information about welding take a look at this great instructable from Phil B, Learning to Weld. Using steel also requires the use of metal working tools. I used a small horizontal band saw to cut the tubing and a small bench top drill press to drill holes. I have included a few tips about working with metal and some tools that make life a lot easier in this instrucable.

3. Design: You can use what ever software you are comfortable with when designing the machine. You could even just draw your machine on paper. 123D from Autodesk and SketchUp from Google are both free 3D modeling software programs you could use. Many of the parts I used on this machine came from McMaster-Carr. Their website provides drawings for many of the items they sell including 3D models which can be downlaoded for free.

4. Tools: I used a number of tools to build my CNC machine and they are listed on the Tools step. Some of the tools are specific to working with metal and are essential to getting the best results. I also made a few of my own tools to make building this machine much easier.

5. Cost: I estimated my cost for the complete machine and electronics around $1500.

You now know my decisions and hopefully understand my reasoning. I think I have a pretty good combination of parts that has exceeded my expectations. If you decide to build a machine based on my plans I have everything laid out in the following steps.

wood CNC router CNC router machine CNC Router 4 axis CNC Router 3 axis cnc router 5 axis CNC Router

#cnc wood carving machine price#cnc wood carving machine reviews#cnc router machine price in india#cnc drilling machine price#cnc drilling machine wiki

0 notes

Text

Deciding Which Generator is Right For You

Deciding which type generator you'll need may not be a simple task. There are lots of different kinds accessible today. When you buy, you can find a number of parameters that have to be addressed. So how could you precisely attempt? This short article is written to help you in determining which generator is most beneficial for the application.

First and foremost you will have to know very well what voltage source will come in your application. Electric engines could be classified as either AC (Alternating Current) or DC (Direct Current). Switching current types only operate on AC Voltage and primary current types only operate on DC Voltage. There's also a widespread generator that may operate on both AC and DC voltages.

Once you've recognized which power source you have you will have to decide which design works for the application. AC engines could be sub-divided in to these: Single Phase Induction, Three Phase Induction, Two Phase Servo, and Hysteresis Synchronous. DC engines could be sub-divided in to: Brushless DC, Brush DC, and Stepper types.

Next we need to realize different characteristics of every type to be able to precisely match a generator to their application.

An individual phase induction generator is connected to just one voltage line. An external capacitor must make this generator operate. The different types of single phase induction engines are famous by which technique they are started. The four fundamental types are: split phase, capacitor start, permanent split capacitor, and capacitor start/capacitor run.

A split up phase generator runs on the switching device to remove the start winding once the generator reaches 75% of their scored speed. Even though this sort has a easy design which makes it more affordable for commercial use, it also offers minimal beginning torques and large beginning currents.

The capacitor start generator is actually a divided phase capacitor generator with a capacitor in series with the beginning winding to create more beginning torque. This generator is more costly on bill of the switching and capacitor requirement.

A lasting split capacitor generator does have no looking switch. For this sort, a capacitor is forever connected to the beginning winding. Because this capacitor is necessary for continuous use, it doesn't offer beginning power, thus beginning torques are usually low. These engines are not advised for large beginning fill applications. But, they do have minimal beginning currents, quieter function, and larger life/reliability, thereby creating them a good choice for large routine rates. They are also the absolute most trusted capacitor generator on bill of devoid of a beginning switch. They can also be designed for larger efficiencies and power component at scored loads.

The capacitor start/capacitor run generator has both a start and run capacitor in the circuit. The start capacitor is turned out once reaching start-up. This sort of generator has larger beginning, decrease loaded currents, and larger efficiency. The disadvantage is the trouble that is required for just two capacitors and a switching device. Consistency also plays one factor on bill of the switching mechanism.

The three phase induction generator is injure for three phase changing voltage. These are the easiest and many rugged electrical engines available. The generator might be designed for either DELTA or WYE hook-up. This type is made for continuous use and large beginning torques. Generator speed is somewhat constant. If three phase voltage is available this is the generator to choose.

Two phase servo engines are used in servo systems, hence the name. They are really sensitive to voltage modifications on the get a grip on phase. This design involves two currents in 90 levels phase shift from one another so as to produce a rotating magnetic field. Servo engines have large torque to inertia percentage, high speed and is useful for velocity get a grip on applications. Tachometer feedback units could be supplied with these motors.

Hysteresis synchronous engines are ostensibly induction engines that run at synchronous speed. Whenever your application involves synchronous rates that is the best choice. These engines could be designed for either single phase or three phase. For single phase voltage a capacitor is going to be required. Hysteresis synchronous engines build what's called pull-out and pull-in torques. Pull-out torque is the total amount of torque/load the generator are designed for only as it pull out of synchronous speed. Pull-in torque is the total amount of torque on the productivity base that allows the generator to take in to synchronism and remain there. Equally pull-in and pull out torques are very similar. These engines have minimal beginning currents and minimal vibration. Since the rotor assembly is manufactured out of a cobalt material, that is hard to come by, this form of generator is expensive.

The primary current (DC) engines which can be accessible are brushless DC (BLDC), comb, and stepper motors. Once you only have DC voltage accessible then one of these simple engines should be used. Brushless DC engines do have no brushes thus there aren't any issues of comb use or sparking. Solid state controls and feedback devises are required for operation. These engines have predicable performance, large beginning torques, and are designed for large speeds. Even though more power productivity may be performed in an inferior offer, the digital controls make this design generator expensive.

Unlike brushless engines, comb DC engines don't involve any get a grip on electronics. Brush engines use commutator and brushes to produce a magnetic field. Even though these engines are often low priced, comb and commutator use limits their reliability and longevity.

Stepper engines are DC engines that create step-by-step steps. In the event that you involve base positioning to be predicable then stepper engines may be an option. These engines are trusted and reduced in cost. They are nevertheless, restricted in their ability to handle big inertia loads.

Once you've established the voltage and volume source the body has accessible you are able to determine the amount of phases and type generator to check at. Next you would have to know these to ensure that your generator design manufacture to greatly help pick the very best generator:

(1) Energy Output/Horsepower: The designer will have to know very well what the scored speed and torque parameter that your system requires motovario redüktör

(2) Figure Measurement: It is great for the designer to learn the physical limitations to be able to precisely size the motor.

(3) Duty Cycle/Time ranking: The amount of time the generator is functioning vs. time it is maybe not is a significant standards when developing the padding systems of the motor.

(4) Environmental Conditions: It is definitely vital that you advise the generator designer what environments the generator will see. That is essential therefore the correct housing is determined.

As you can see there are numerous different types of engines to decide on from. There's also several facets used in the choice. By dealing with a style manufacture you are able to assure to obtain the best generator for the application. This is why it is very important to look for a manufacturer before finalizing any systems design.

0 notes