#steel pipes manufacturing process

Explore tagged Tumblr posts

Text

Proper maintenance and inspection of steel pipes are essential to ensure their safety, longevity, and optimal performance. Steel Pipes and Tubes are widely used in various industries and applications, and their failure can have significant consequences.

#steel pipes manufacturers#stainless steel pipes suppliers#steel pipes and tubes#steel pipes manufacturing process#steel pipes industry#steel pipes producers

1 note

·

View note

Text

kitchen Equipment Manufacturers Chennai

Best kitchen equipment manufacturers in Chennai offering high-quality, durable, and innovative solutions for your kitchen set-up needs. Upgrade your kitchen with the best equipment today!

#kitchen Equipment Manufacturers Chennai#heavy steel fabrication services#piping engineering in chennai#piping design engineering services#skid package design services#skid mounted process plant design#piping engineering#skid fabrication solution chennai#piping design and engineering#technical manpower supply#skid mounted process plant design chennai

0 notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

16 - 17 October 2024, Houston, Texas USA

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#16 - 17 October 2024#Houston#Texas#USA#HEAT EXCHANGER WORLD AMERICAS - 2024#Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024#Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions#Duplex#Super Duplex#Nickel Alloy#and Exotic-Grade Material Tubes#Pipes#and U-Tubes.#Event Details:#•#Date: 16 – 17 October 2024#Venue: Houston#Booth Number: Stand 2110#Event Hours: 10:00 AM – 5:00 PM#Event Link: https://heat-exchanger-world-americas.com#KRYSTAL X HEAT EXCHANGER#2024#Manufacturer and Exporter of Seamless Stainless Steel#Nickel Alloy Tubes#Pipes & U Tubes.#At the trendsetting#ultimate networking event for the process industry#you will have an opportunity to connect with Krystal experts#tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics in#the latest decarbonization innovations

0 notes

Text

hot take but like why are we as a society still using lead in manufacturing processes in 2024...

anyway tldr of this is that you are not being exposed to lead unless the circular piece on the bottom of the cup is damaged. so, owning a cup like this will likely not result in lead exposure. this is similar to the fact that in older housing where lead paint has been painted over in subsequent decades, and that paint is in good condition, then it is not a risk. lead based paint only becomes an issue when it is deteriorating (chipping, cracking, peeling, chalking, etc) or being turned into dust during renovation activites. so yeah, in a similar way--you aren't going to get lead poisoning unless the steel compontent on this water bottles comes off.

but also this article says that these lead pellets that are used in the cups are an "industry standard" and i'm like: why? WHY is it industry standard in 2024? at least with lead pipes and lead based paint, we're just dealing with issues from prior decades. but this is current so there is a conscious decision to still use lead in products. also, i don't know enough about this subject (bottle manufacturing) to know why they prefer to use lead for this step, or where in the world they manufacture the cups, but my other concern is that even though the general public will likely not be exposed if it's covered, there are still workers who have to handle it during production.

anyway, i just find that i am constantly learning about more places that lead gets found and it's just. sigh. i know lead has many appealing properties which is why it is constantly found everywhere in everything but at this point it's incredibly clear that no benefits outweigh its risks....

#anyway. assimilating this into brain so that the next time i do public outreach i can answer this question lmao#it pays (quite literally for me) to learn as many of these sources as possible#so now i also get to tell parents they should be careful about their steel tumbler bottles getting damaged...#havent done enough research yet to determine if this is All brands or just stanley & the ones mentioned in the consumer product safety site#but it seems to be a common component of steel insulated bottles#will have to do more research later

66 notes

·

View notes

Text

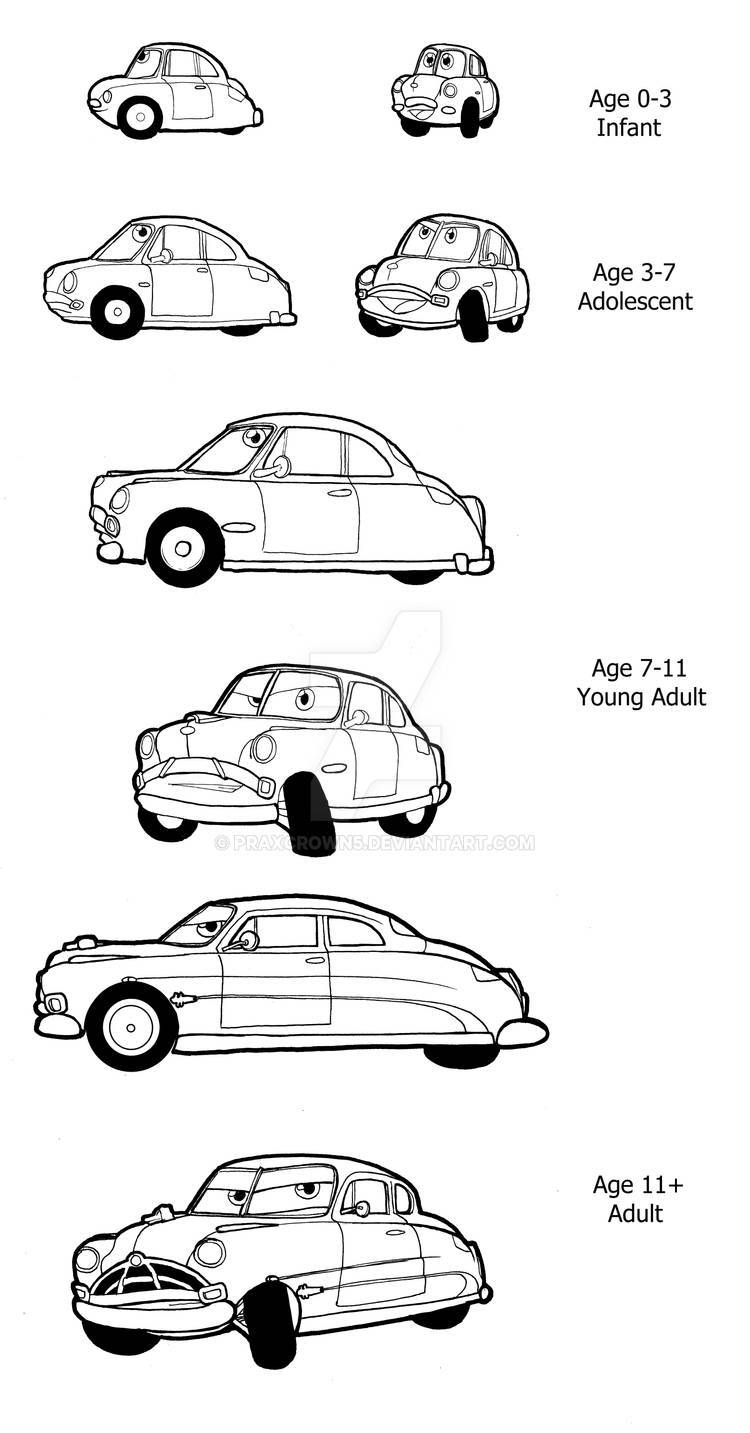

Cars Headcanon: Vehicle Growth and Development

*note: this Headcanon is for civilian-class vehicles, only. The process is slightly different for carrier and combat class vehicles...as is the siring process.*

Following the events of the Factory Wars (1819-1864, Cycle 9), most newborn, sapient vehicles are manufactured in factories. The long and the short of things is that vehicles actually do "grow up," after they are manufactured, and have distinct phases of development between infancy and adulthood.

*I used Doc as an example...because it gave me an excuse to draw him as an adorable babeh.*

A vehicle wanting to procreate must go through the siring process with a partner of the opposite gender (see my post on reproduction). Recently, some factories (Chrysler, Jeep, Chevrolet, Stellantis, and Mazda) have allowed people to petition them directly if they are unable to create a flame due to injury, manufacturing defect and/or sexual orientation.

Once a flame is sired, the female carrier will begin receiving internal notifications with instructions on what factory they'll need to report to. If she can't get to the factory right away, she can maintain the flame for three weeks by doubling her food intake. After this time, the energy is reabsorbed, and she'll have to go through the siring process if she wants to try again.

No one outside of a factory knows how a newborn is actually manufactured. In conversations with an angel at the Hudson Motor Car Factory, Doc's mother and grandfather learn that there are at least two processes involved beyond the initial "harvesting" (the operation that extracts the flame from the female's body): "grafting" and "nurturing." The time between harvesting and being introduced to the family is, on average, three and a half days…though it can take as long as seven if the flame splits, resulting in twins.

A newborn is always the same make as their factory of origin, and the type of vehicle created is dependent on the vehicles involved in the siring process. If both parents are one type of vehicle (a car, for example), the child will be that type of vehicle. If the parents are two, different types of vehicle (a car and a plane, for example), the resulting child has a 50% chance of being one or the other. Gender is random. Twins are always the same gender and model.

When newly manufactured, a vehicle begins life with a simple, two-cycle engine and are capable of self-locomotion. The moment a child emerges from the factory, they memorize their parents UV patterns, and the sound of their parent's voices on the way home initiates their natal learning software. By the end of their first day, the newborn can speak in complete sentences and will spend every waking moment asking questions and generally absorbing as much information as their budding minds can handle. This period of hyper information gathering, known as the Infant Period, lasts until the child's third birthday…and the dreaded First Appetency Phase.

In preparation for their most intense growth spurt, the child develops an insatiable appetite for metal, especially objects made of iron, copper and lead. And…much to the horror of those around them, they're not picky about where the metal comes from. Non-sapient machines, road markers, pipes, unattended parts, steel bridge supports, power poles, tools, cooking utensils…really anything that the child can stuff into their crop whole or tear apart with their incredibly strong teeth is fair game. It's not uncommon for children, during the height of the phase, to attempt to eat their parents and/or siblings. They do not attend school during this phase for obvious safety reasons.

The excess metals are stored within the child's body, melding with existing metals in the frame, engine, and mechanical components. The infant eventually becomes so dense and heavy that they can't move; eleven hours later the spurt begins. The child's body metals "slacken," taking on a texture similar to the metals around and inside the mouth. Stored metals from the Appetency Phase are re-mobilized, and the child's body begins to slowly grow. It's a painful period fraught with danger, and many parents don't leave their children unattended for even a minute.

Manufacturing defects (misshapen wheels, bent frames, UV blindness, etc) manifest during this growth spurt. Many can be corrected, especially with modern technology…but some cannot.

After two weeks, the growth spurt runs its course and the infant vehicle matures into an adolescent. They are now about half the size of an adult with a four cycle engine. Adolescents are much more mobile than infants, and this is the age when they really began to interact with the world around them. They are still insanely curious and learning rapidly, and this is when most parents start teaching them a trade…or at the very least the life skills that they'll need to survive on their own.

Almost immediately after their seventh birthday, the adolescent enters their Second Appetency Phase…though by this point, they tend to have enough self-control that they're not eating their family out of literal house and home. This time around, they crave rarer metals, like titanium, palladium, and magnesium, and they're taking in almost triple the amount of food as an adult. The slackening phase of this spurt is more dangerous than the first due to the fact that the child's engine is powerful enough to allow mobility, despite the increase in weight. Most families opt to keep their children confined to the house until the spurt runs its course, as even a minor fender-bender during this time can be lethal.

After two weeks, the adolescent matures into a young-adult. They are now about 75% the size of an adult, with a significantly more powerful engine and a greater capacity for strategic problem-solving, deductive reasoning, and information processing. They are strong enough to work and participate in competitive sports, though there is mounting evidence that overtaxing the body and engine too much during this phase can cause developmental issues during their 11th year growth spurt.

Upon reaching their eleventh birthday, a vehicle experiences their Third, and final, Appetency Phase. While they still need extra metal in their diet (copper and aluminum, especially) they find themselves craving organic materials like peat, kerogen, coal and, oddly enough, crab meat. The final growth spurt takes three weeks…but once a vehicle's body metals harden, they are considered an adult, socially and legally. They can drink, get married, live independent of their parents, own property, run for public office, and work full-time somewhere other than a family-owned business.

Probably the most important physical change is the development of reproductive hardware. The ability to hook up with another vehicle for pleasure usually drives the first two or three years of adulthood as a vehicle figures out, not only out how their own hardware works, but what preferences they have in terms of sexuality, foreplay, and hook up configurations. Because there's an extra step involved in actually siring a child, accidental children aren't really a thing, and most vehicles (in the modern era) don't even think about parenthood until their late twenties/early thirties.

Now, that's not to say there aren't risks involved with casual hookups. Vehicles are immune to most of the organic viruses left over from the Great Dying and The Return, but they can be susceptible to digital viruses…and the easiest way for a virus to transfer between vehicles is during physical intimacy. Outbreaks can occur suddenly and spread rapidly, devastating populations…and even disrupting the factories, themselves. Cycle 8, for example, was rocked by a powerful, almost sapient, computer virus…and the resultant hardware crashes wiped out 60% of all bio-mechanical life on the planet, necessitating a full recall.

In 1900 (Cycle 9), the global, average life expectancy of a vehicle was 32 years. By 2017 this had more than doubled to 65 years. Advances in bio-mechanics, public health, automation, safety standards, and a more robust biosphere have led to decreases in mortality, for all age groups, in much of the world. Part obsolescence, usually caused by political infighting between factories, is the major limiting factor to longevity, though the advent of 3D printing is helping to counteract it.

#cars fandom#pixar cars#cars#cars pixar#doc hudson#cars 2006#disney cars#disney pixar cars#cars headcanons#fabulous hudson hornet#hudson hornet#cars fanart#Cars reproduction#woc#world of cars

40 notes

·

View notes

Text

Carbon Pipe Fittings : Astm A234 WPB Pipe Fittings Manufacturers

Introduction:

ASTM A234 WPB pipe fittings, also known as carbon steel pipe fittings, have largely become standard parts in many industries. The fitting elements will be used to adapt straight pipe or tubing sections, to maintain different size or shape, and to control the rate of flow of liquids.

Always resistant to strength and versatile, ASTM A234 WPB fittings play a critical role in industries dealing with oil, gas, petrochemicals, and power generation.

What are ASTM A234 WPB Pipe Fittings?

They are used to connect pipes in shapes such as elbows, tees, reducers, and caps. The prime factors that make the use of these fittings highly prevalent are their excellent mechanical properties, like high tensile strength and resistance to corrosion. They are very important in ensuring the integrity and efficiency of piping systems across industries.

Manilaxmi Industrial also supplies Carbon ASTM Pipe Fittings around the globe.

Real-Time Advancements in Industries

Ranging from new manufacturing technologies and materials science to improved performance and reliability, these fittings have carved out a niche in use. Applications of the ASTM A234 WPB carbon steel pipe fitting have greatly improved in the industrial sector.For example, refined heat treatment processes leave behind fittings that are easier to manipulate and work under higher pressure and temperature conditions.

Besides, numerous coating and lining innovations provide improved corrosion resistance and give extended life expectancy.

Manilaxmi Industrial the Indian manufacturers, suppliers, and exporters have been among the most active adopters of these developments to ensure that the country is retained as a main supplier of quality pipe fittings in the global market.

Technology and Need in Various Countries

Demands for ASTM A234 WPB carbon steel pipe fittings are ever-increasing in the global scenario. This demand has been hastened further by the requirement of strong, efficient piping systems in the developing countries and renovated or rejuvenated ones in the developed nations.

Such as setting up power plants and oil refineries. In contrast, developed nations always require update works and servicing of already existing facilities. Equipped with state-of-the-art technology in the manufacturing process, these fittings comply with strict standards that make them very important and cardinal for maintaining efficiency and safety during industrial operations.

Conclusion

In conclusion, ASTM A234 WPB pipe fittings are the most essential material in the industrial market, possessing qualities of high durability, adaptability, and tolerance toward extreme situations. With relentless development in the manufacturing technologies, further improvements are made in their performances, making them trustworthy for different applications.

#innovation#management#technology#metalfabrication#metalwork#supplychain#manufacturers#exporters#suppliers

9 notes

·

View notes

Text

Stainless Steel 317/317L Seamless Tubes Exporters In India

Introduction :

Metinox Overseas is a renowned manufacturer, supplier, and stockist of SS 317L Seamless Tubes. The SS 317L alloy is distinguished by its molybdenum-bearing austenitic stainless steel composition, featuring lower carbon content compared to alloy 317. These Stainless Steel ASTM A213 TP 317L Seamless Tubes not only offer impressive tensile and stress-to-rupture strength but also exhibit enhanced creep resistance at elevated temperatures.

Product Overview :

With high chromium content, Stainless Steel 317L Seamless Square Tubes demonstrate excellent oxidation resistance; however, they are susceptible to embrittlement beyond temperatures of approximately 350 degrees Celsius, thus their application is limited to lower temperature environments. Both martensitic and precipitation hardening families of Stainless Steel 317L Rectangular Tubes boast high strengths achievable through thermal treatments.

Stainless Steel 317/317L Tubes Standard Specifications :

Specifications :ASTM A213 / ASME SA213

Outside Diameter :1/8″ OD TO 2″OD 3MM OD TO 38 MM OD

Thickness :1MM TO 3 MM 0.028 TO 0.156 IN, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size :1/2″ NB — 24″ NB

Type :Seamless / Capillary Tubes

Form :Round Tubes, Square Tubes, Rectangular Tubes.

Length :Single Random, Double Random & Required Length

End :Plain End, Beveled End, Treaded

Finish :Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Application of Stainless Steel 317/317L Seamless Tubes :

1. Chemical and Petrochemical Industry

· Used for handling corrosive chemicals, acids, and solvents.

· Common in heat exchangers, condensers, and piping systems.

2. Pharmaceutical and Food Processing

· Ideal for cleanroom applications and processing environments due to hygienic and non-reactive properties.

3. Marine and Coastal Structures

· Suitable for seawater and saline environments due to enhanced resistance to chloride corrosion.

Conclusion :

Stainless Steel 317/317L seamless tubes offer a superior combination of corrosion resistance, mechanical strength, and durability, making them a reliable choice for demanding applications across various industries

#Stainless Steel 317/317L Seamless Tubes#Stainless Steel 317/317L Seamless Tubes Manufacturers#Stainless Steel 317/317L Seamless Tubes Suppliers#Stainless Steel 317/317L Seamless Tubes Stockists#Stainless Steel 317/317L Seamless Tubes Exporters#Stainless Steel 317/317L Seamless Tubes Manufacturers In India#Stainless Steel 317/317L Seamless Tubes Suppliers In India#Stainless Steel 317/317L Seamless Tubes Stockists In India#Stainless Steel 317/317L Seamless Tubes Exporters In India

2 notes

·

View notes

Text

Do you have HMS1 and HMS2 steel scrap?

EDELSTAHL VIRAT IBERICA is an emerging importer - exporter, supplier of tool steels, mold steels from various countries. We are also engaged in the trade of ferrous, alloy steel, etc., with a network of partners all over the world, we are able to quickly meet customer needs.

HMS-1, HMS-2, and ferrous scrap are terms commonly used in the scrap industry to classify and describe different types of steel and iron scrap.

Here's what each of these terms means:

HMS-1 (Heavy Fusion Scrap 1):

HMS-1 is a designation for heavy, bulky scrap, composed primarily of wrought iron and steel.

It typically includes scrap metal from a variety of sources, such as demolished buildings, old machinery, and industrial equipment.

HMS-1 is relatively clean and free of excessive contaminants, making it suitable for recycling into new steel products.

It usually consists of thick and heavy items such as beams, pipes, and plates.

HMS-2 (heavy melt scrap 2):

HMS-2 is another scrap category, but it may contain a slightly higher percentage of contaminants compared to HMS-1.

Includes items such as smaller structural steel parts, miscellaneous steel parts, and lighter gauge materials.

While still suitable for recycling, HMS-2 may require further processing to remove impurities and contaminants before it can be used in steel production.

We are looking for all wholesale scrap metal manufacturers and suppliers such as #HMS1, #HMS2, ferrous scrap, electronic motor scrap and shredded scrap in #Portugal…

Learn more: https://moldsteel.eu/recycling-products/

WhatsApp Chat: +351-920016150 E-mail: [email protected]

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura

2 notes

·

View notes

Text

Buy MS Blind Flange – Affordable & Ready to Ship

Finding reliable components at affordable prices is crucial for the success of any industrial project. MS Blind Flanges are essential for securely sealing the ends of pipes, ensuring safety and efficiency in various applications. At Udhhyog, we offer a wide selection of MS Blind Flanges that combine affordability with superior quality. Our products are always ready to ship, allowing you to maintain your project timelines without delays.

Explore our complete range of Flanges for diverse applications and ensure you have the best materials for your operations.

Why Udhhyog is Your Best Choice for MS Blind Flanges

Choosing Udhhyog for your MS Blind Flange needs comes with several advantages:

Affordable Prices: We are committed to offering competitive pricing without compromising quality.

High-Quality Materials: Our flanges are manufactured from premium mild steel to ensure durability.

Quick Shipping: We guarantee fast processing and shipping, so your order arrives on time.

Versatile Applications: Suitable for various industries, our flanges meet different specifications and requirements.

For a reliable supply, shop our MS Blind Flanges today.

Considerations When Purchasing MS Blind Flanges

When selecting the right MS Blind Flange, keep the following factors in mind:

Material Quality: Ensure the flange is made from durable mild steel for maximum longevity.

Size Compatibility: Verify that the dimensions match your piping system for a proper fit.

Pressure Requirements: Choose flanges that can withstand the necessary pressure ratings for your application.

Supplier Reliability: Trust Udhhyog for quality assurance and exceptional service.

Visit our Flanges category for a variety of options that meet your specifications.

Benefits of Using MS Blind Flanges

Utilizing MS Blind Flanges in your projects provides numerous benefits:

Effective Sealing: These flanges create a secure seal, preventing leaks and enhancing system integrity.

Durable Performance: Built to last, our flanges reduce the need for frequent replacements, saving costs.

Compliance with Standards: Our products adhere to industry regulations for safety and reliability.

Easy Installation: Designed for straightforward installation, they help save time on project execution.

For affordable prices and quick shipping, choose Udhhyog for your MS Blind Flange needs.

The Udhhyog Advantage

Udhhyog is dedicated to providing:

Unbeatable Pricing: We focus on keeping our prices competitive in the market.

Quality Products: Each MS Blind Flange undergoes strict quality checks to ensure reliability.

Fast Shipping Options: We prioritize fast processing and delivery to meet your project timelines.

Customer Support: Our expert team is always available to assist you with any queries or needs.

Explore our MS Blind Flanges and experience the quality and service that Udhhyog provides.

2 notes

·

View notes

Text

Stainless steel pipes manufacturers and Steel Pipes Suppliers play an important role in maintaining the quality of steel pipes, and regular inspection and maintenance are crucial to detecting and addressing any issues.

#steel pipes and tubes#stainless steel pipes manufacturers#steel pipes suppliers#types of steel pipes#steel pipes manufacturing process

1 note

·

View note

Text

MS Blind Flange at Lowest Price in India

In industrial systems, MS Blind Flanges play a crucial role in closing off pipe ends, ensuring safety and system efficiency. Udhhyog offers high-quality MS Blind Flanges at the lowest prices in India. Whether you're a contractor or an industry professional, we make purchasing flanges more affordable and efficient.

Benefits of MS Blind Flange

An MS Blind Flange (Mild Steel) is renowned for its versatility and affordability, making it suitable for various industrial applications. Here’s why it’s a popular choice:

Durable & Cost-Effective: MS Blind Flanges are sturdy, offering durability at competitive pricing.

Corrosion Resistance: With the right coating, these flanges perform well in demanding environments.

Easy to Install: Mild steel flanges are lightweight, making installation and maintenance easier.

Lowest Price Guarantee on MS Blind Flange

Udhhyog is committed to providing MS Blind Flanges at the lowest price without compromising on quality. As a leading supplier and manufacturer in India, we ensure that our customers get the best value. Browse our offerings and Buy MS Blind Flange at the Lowest Price with ease.

Applications of MS Blind Flanges

MS Blind Flanges are widely used in industries that require efficient flow control and safety:

Water Treatment Plants

Oil and Gas Refineries

Chemical Processing

Shipbuilding

The adaptability of these flanges across different environments makes them an essential component in many industrial systems.

Why Choose Udhhyog for MS Blind Flanges?

Competitive Prices: We offer the best rates on MS Blind Flanges, ideal for bulk orders.

Fast Delivery: Timely delivery across India ensures your projects run smoothly.

Quality Assurance: All our products meet high standards, ensuring reliability and performance.

Ready to make a purchase? Buy MS Blind Flange at the Lowest Price from Udhhyog and experience unmatched service and quality.

#MSBlindFlange#LowestPrice#BuyNow#IndustrialSupplies#Udhhyog#FlangeSupplier#DelhiSuppliers#BulkOrders#MildSteelFlange

2 notes

·

View notes

Text

kitchen Equipment Manufacturers Chennai

kitchen equipment manufacturers in Chennai providing high-quality, durable solutions for all your kitchen set up needs. Explore our range of innovative and reliable kitchen products. Get in touch now!

#kitchen Equipment Manufacturers Chennai#piping engineering#piping engineering in chennai#heavy steel fabrication services#piping design engineering services#skid package design services#skid mounted process plant design#skid fabrication solution chennai#piping design and engineering#technical manpower supply#skid mounted process plant design chennai

0 notes

Text

MS ERW B/Weld Reducer Eccentric at Best Price in India

In the dynamic world of industrial piping, efficiency and reliability are paramount. The MS ERW (Electric Resistance Welded) Butt Weld Eccentric Reducer plays a crucial role in connecting pipes of different diameters while ensuring optimal fluid flow. If you're in search of the best prices for MS ERW B/Weld Eccentric Reducers in India, look no further than Udhhyog, your trusted supplier.

What is an MS ERW B/Weld Eccentric Reducer?

An MS ERW B/Weld Eccentric Reducer is a specialized fitting designed to connect pipes of varying sizes. Unlike concentric reducers, which maintain a circular profile, eccentric reducers feature a flat edge on one side. This design is essential for preventing sedimentation in applications where solids may accumulate, making them ideal for use in wastewater systems and other similar setups. The robust construction and butt-welded design provide a secure, leak-proof connection suitable for high-pressure environments.

Key Features of MS ERW B/Weld Eccentric Reducers

Efficient Fluid Flow: The eccentric design minimizes turbulence and ensures a smooth transition between pipe sizes, facilitating better flow rates.

Durable Material: Crafted from high-quality mild steel, these reducers are built to withstand harsh operating conditions, including high pressures and temperatures.

Leak-Proof Connections: The butt weld design ensures a secure joint that significantly reduces the likelihood of leaks.

Versatile Applications: Suitable for a range of industries, including oil and gas, water treatment, and chemical processing.

Cost-Effective Solution: Offering exceptional quality at competitive prices, these reducers are an economical choice for industrial applications.

Applications of MS ERW B/Weld Eccentric Reducers

Wastewater Management: Eccentric reducers are particularly useful in wastewater applications, where preventing sediment buildup is crucial for maintaining system efficiency.

Oil and Gas Pipelines: These fittings provide seamless transitions in pipelines, ensuring pressure integrity and fluid management.

Chemical Processing: In chemical plants, they help maintain efficient fluid transitions, facilitating various processes with minimal disruption.

HVAC Systems: Eccentric reducers are often used in HVAC systems to ensure balanced airflow and effective pressure control.

Why Choose Udhhyog for MS ERW B/Weld Eccentric Reducers?

At Udhhyog, we pride ourselves on being a leading supplier of MS ERW B/Weld Eccentric Reducers at the best prices in India. Here’s why you should partner with us:

Quality Manufacturing: Our reducers are produced under strict quality control measures to meet industry standards, ensuring you receive top-tier products.

Affordable Pricing: We are committed to providing high-quality products without breaking your budget, making us the go-to supplier for industrial fittings.

Prompt Delivery: Located in Delhi, we offer timely delivery services across India, ensuring your projects remain on schedule.

Extensive Product Range: Beyond eccentric reducers, we offer a wide selection of industrial fittings, flanges, and valves to cater to all your piping needs.

Dedicated Customer Support: Our team is focused on understanding your specific requirements and delivering tailored solutions to enhance your operational efficiency.

Order Your MS ERW B/Weld Eccentric Reducers Today

Choosing Udhhyog as your supplier for MS ERW B/Weld Eccentric Reducers means gaining access to high-quality products at the best prices in India. Whether you're involved in large-scale industrial projects or specific applications, we are here to support your needs with reliable and effective solutions.

#MSErwEccentricReducer#PipeFittings#IndustrialPiping#Udhhyog#EccentricReducerIndia#BestPriceIndia#DelhiSupplier#SteelPipeFittings#CostEffectiveSolutions#MSPipeFittings

2 notes

·

View notes

Text

MS ERW Butt Weld Reducer Concentric-India Supplier

An MS ERW Butt Weld Concentric Reducer is an important pipe fitting used to connect two pipes of different diameters while maintaining the centerline alignment. These reducers are widely used in industries like oil & gas, chemical processing, water treatment, and power generation. The concentric design ensures smooth fluid flow, making them suitable for vertical and fluid transport pipelines. The use of Electric Resistance Welding (ERW) in these reducers guarantees strong, durable, and seamless joints.

Key Features of MS ERW Butt Weld Concentric Reducers

Material: Constructed from mild steel (MS), which offers excellent strength and durability.

ERW (Electric Resistance Welded): ERW welding provides a strong, uniform weld that enhances the overall durability and integrity of the reducer.

Butt Weld Connection: Ensures a seamless, leak-proof, and permanent joint between pipes, making it highly reliable for industrial applications.

Concentric Design: Aligns the centerlines of the pipes, making it ideal for vertical pipelines and for applications where maintaining uniform flow is essential.

Benefits of Using MS ERW Butt Weld Concentric Reducers

Durability: The mild steel construction ensures long-lasting performance, even in challenging industrial environments.

Leak-Proof Joints: Butt weld connections provide strong, leak-free joints that prevent any leakage, ensuring safe and efficient operation.

Efficient Fluid Flow: The concentric design reduces the risk of turbulence, ensuring smooth and uninterrupted fluid flow in the pipeline.

Cost-Effective: MS ERW butt weld concentric reducers offer a cost-effective solution for connecting pipes of varying diameters without sacrificing performance or durability.

Finding a Reliable Supplier of MS ERW Butt Weld Concentric Reducers in India

When searching for a reliable supplier for MS ERW Butt Weld Concentric Reducers in India, consider the following factors:

Quality Assurance: Ensure that the supplier provides reducers that meet industry standards and are manufactured using high-grade materials.

Competitive Pricing: Look for suppliers that offer the best balance of price and quality.

Timely Delivery: Reliable and prompt delivery is key to avoiding project delays.

Customer Support: Opt for suppliers who offer comprehensive customer service and after-sales support.

Udhhyog – Your Trusted Supplier for MS ERW Butt Weld Concentric Reducers

At Udhhyog, we are dedicated to providing high-quality MS ERW Butt Weld Concentric Reducers at competitive prices across India. Our expertise in industrial steel products and our commitment to customer satisfaction make us the go-to supplier for businesses in need of reliable and durable piping solutions.

High-Quality Products: Our reducers are manufactured using top-grade mild steel and precision welding processes to ensure durability and long-term reliability.

Affordable Pricing: We offer some of the most competitive prices in the market without compromising on product quality.

Reliable Delivery: Udhhyog ensures prompt and efficient delivery to meet your project timelines.

Exceptional Customer Service: Our team is always ready to assist with any inquiries or after-sales support, ensuring a smooth purchasing experience.

To buy MS ERW Butt Weld Concentric Reducers and explore other industrial fittings, visit Udhhyog's website and browse our wide selection of industrial products at affordable prices.

#MSErwReducer#ButtWeldFittings#ConcentricReducer#IndustrialFittings#Udhhyog#IndiaSuppliers#PipeFittings

2 notes

·

View notes

Text

MS Concentric Reducer at Lowest Price in India: Key Uses and Benefits

Mild Steel (MS) concentric reducers play a crucial role in industrial piping systems, offering efficient transitions between different pipe diameters. Whether you're dealing with fluid flow or gas transportation, these reducers help ensure smooth operations by maintaining system integrity. In India, MS concentric reducers have gained prominence for their durability, corrosion resistance, and cost-effectiveness. At Udhhyog, we supply MS concentric reducers at the lowest price, ensuring that industries get reliable products without compromising on quality.

Key Benefits of MS Concentric Reducers

Versatility: MS concentric reducers are compatible with a wide range of piping systems, including water supply, oil and gas, and chemical processing industries. This makes them a preferred choice across various sectors.

Durability: Made from high-quality mild steel, these reducers exhibit excellent resistance to wear and tear, ensuring long service life even in harsh environments.

Corrosion Resistance: Mild steel concentric reducers are designed to withstand corrosion, making them ideal for industries exposed to water or chemicals.

Cost-effective: Being highly affordable, MS concentric reducers offer excellent value for money, especially for industries seeking durable yet economical solutions.

Applications of MS Concentric Reducers

Industrial Piping: MS concentric reducers are widely used in piping systems to ensure smooth transitions between pipes of different diameters.

Petrochemical Industry: They are crucial in fluid and gas transportation systems, ensuring safe and efficient operations.

Water Treatment Plants: These reducers help maintain consistent water flow while reducing pressure buildup, making them ideal for treatment plants.

HVAC Systems: MS concentric reducers are commonly used in HVAC systems to regulate airflow between different duct sizes.

Why Choose Udhhyog for MS Concentric Reducers?

Udhhyog is a leading manufacturer and supplier in India, providing MS concentric reducers of the highest quality at the most competitive prices. We ensure that our products meet international standards, offering reliable and durable solutions for all your industrial needs. With our technology-driven platform, we help MSMEs streamline their procurement process, saving time and money.

By choosing Udhhyog, you benefit from:

Affordable pricing: We offer the lowest prices for MS concentric reducers in India without compromising on quality.

Quick delivery: We ensure fast and efficient shipping across the country, including major industrial hubs like Delhi, Mumbai, and Chennai.

Quality assurance: Our products undergo stringent quality checks to guarantee that they meet the highest industry standards.

#MSConcentricReducer#MildSteelFittings#IndustrialFittings#PipeReducer#BestPriceIndia#MSMEsupplier#LowestPriceIndia#Udhhyog#IndustrialSteel#DelhiManufacturer

2 notes

·

View notes

Text

Buy Mild Steel Flange from Manufacturer at Best Price

When it comes to purchasing Mild Steel (MS) Flanges, buying directly from a reliable manufacturer like Udhhyog ensures you get the best price and superior quality. MS Flanges play an essential role in various industrial applications, making it crucial to find a trusted source for your procurement.

Why Choose Udhhyog for MS Flanges?

As a leading manufacturer and supplier in India, Udhhyog offers an extensive range of MS Flanges tailored to meet diverse industrial needs. Here’s why we are the preferred choice:

Direct Manufacturer Pricing: Avoid middlemen and buy directly from the manufacturer, ensuring the lowest price on all MS Flanges.

High-Quality Products: Our flanges are built to last, using high-grade materials to ensure durability in demanding environments.

Fast and Reliable Delivery: We prioritize quick delivery times, so your project can stay on schedule.

Types of MS Flanges Available at Udhhyog

Udhhyog provides a wide range of Mild Steel Flanges, including options that meet various standards and specifications:

MS Flange ISI 1538: Known for its reliability and adherence to industry standards, this flange is suitable for multiple industrial uses.

MS Flange ASA 150: Ideal for applications requiring flanges with ASA 150 standards.

MS Flange – Table E: Offering durability and strength, this flange is perfect for high-pressure systems.

MS Flange – Table D: Suitable for medium-pressure piping systems and well-suited for industrial use.

MS Dummy Plate – 6mm Thickness: This precision-engineered dummy plate is perfect for sealing and closing applications.

Applications of MS Flanges

MS Flanges are essential components in various industries due to their strength, durability, and affordability. Some common applications include:

Industrial Piping Systems: Ensuring secure connections in fluid transportation systems.

Construction Projects: Providing structural stability in heavy-duty construction and fabrication projects.

Machinery and Equipment: Used in mechanical systems to maintain high-pressure integrity.

Benefits of Buying from Udhhyog

Competitive Pricing: By purchasing directly from Udhhyog, you benefit from manufacturer prices, which guarantees the lowest cost for premium-quality flanges.

Customization Options: We offer the flexibility to manufacture custom sizes and specifications, ensuring you get the exact flange needed for your project.

Commitment to Quality: All of our flanges are manufactured according to industry standards, ensuring maximum safety and performance.

How to Order MS Flanges from Udhhyog

Buying MS Flanges from Udhhyog is a seamless process. Follow these steps:

Browse Our Selection: Visit our website to explore our range of MS Flanges.

Select Your Product: Choose the MS Flange that meets your specifications.

Place Your Order: Benefit from our lowest price guarantee by purchasing directly from the manufacturer.

Enjoy Quick Delivery: We provide fast shipping across India, ensuring that your flanges arrive on time.

At Udhhyog, we pride ourselves on offering the best MS Flanges at the most competitive prices, backed by excellent customer service.

#MSFlanges#FlangeSupplier#BuyFlanges#FlangesIndia#IndustrialProducts#Udhhyog#MildSteelFlange#LowestPriceFlanges#MSFlangeManufacturer#FlangeDeals

2 notes

·

View notes