#steel fabrication Auckland

Explore tagged Tumblr posts

Text

Discovery of the Versatility of Stainless Steel in Auckland

The unprecedented strength, flexibility, and glossy look have made stainless steel a fundamental element in the design and construction industry of Auckland. The need for quality steel products in the form of industrial, commercial, and residential sectors is continually on the rise. Right from customized stainless fabrication in Auckland to special products like stainless steel shelving and wash troughs, it meets many needs with perfection.

Precision in Steel Fabrication

There are many qualified fabricators in Auckland who can offer bespoke stainless steel solutions. Fabrication of stainless steel in Auckland means that there is stainless steel crafted in specific forms and structures to satisfy the specific needs of customers. These include structural components for construction works, designs of interior design, and industrial equipment among others. Advanced technology comes together with craftsmanship expertise in stainless steel fabrication. The outcome is a product that serves not only functional requirements but also adds a polished, modern look to its surroundings.

Effective Storage with Stainless Steel Shelving

Storage solutions are needed to ensure well-organized spaces, and the best durable, stylish, and hygienic solutions in Auckland are stainless steel shelving Auckland. Suitable for kitchen storage, warehouse shelving, retail shelving, and so much more, the shelves have been designed with durability in mind to stand against heavy loads and withstand corrosion, thus making it last longer. Stainless steel shelving is very much in demand by the industries that require hygiene of prime importance, such as food preparation and healthcare because of ease in cleaning and maintaining it. The stainless steel also provides a very sleek appearance, complementing any modern interior, making it not only practical but also pleasing.

Hygienic and Durable Stainless Steel Wash Troughs

In terms of hygiene and durability, no one tops the stainless steel wash troughs Auckland. Often used in schools, commercial kitchens, healthcare facilities, and other public places, these wash troughs are meant to be functional for a long period and still remain easy to clean. They are not porous, and neither do bacteria nor stains adhere to the surface, so their application in areas requiring significant hygiene is ideal. Auckland's suppliers of stainless steel wash troughs offer a variety of designs and sizes to ensure that there is an adequate number to fulfill the needs of every space.

Stainless Steel Advantages

Resistant to rust, corrosion, and weathering, these steel items are used both indoors and outdoors. Stainless steel can also be considered an ecologically friendly material since stainless steel is 100 percent recyclable. The other virtue which makes stainless steel cost effective for life is that it lasts really long and thus has limited replacement. Auckland fabricators ensure that all stainless steel productivities are of the highest level, hence reliable and effective for the customers.

Partner with Experts in Auckland

From bespoke steel fabrication in Auckland to practical stainless steel shelving and stainless steel wash troughs, for any of your requirements, there is a need to consult experienced experts. Local fabricators have end-to-end services ranging from design consultancy to installation and thus ensure quality completion of all projects.

Stainless steel, therefore, is still an all-around and reliable material for use in many applications in Auckland. With durability, hygiene, and modern aesthetic, stainless steel solutions, including shelving, wash troughs, and custom-fabricated structures, remain highly sought after in all sectors.

0 notes

Text

Steel Fabrication Innovations: Industry Update

Welcome to steel fabrication, where precision and ingenuity create a metalwork symphony. As technology advances rapidly, so does the art of shaping steel into spectacular structures that defy gravity and push the limits.

Latest Steel Fabrication Innovations

Steel has underpinned modern architecture from skyscrapers to intricate bridges. Steel manufacturing evolves with technology. Robotic welding is a recent breakthrough. These modern machines can weld complex structures with extreme accuracy, decreasing human error and enhancing efficiency.

3D printing is another intriguing steel fabrication trend. This cutting-edge technology lets architects and engineers develop elaborate designs layer by layer, expanding their options. From specialized components to distinctive architectural features, 3D printing is pushing steel fabrication limits.

In addition to robotic welding and 3D printing, CAD software has transformed steel fabrication in Auckland. Designers can construct detailed virtual prototypes before actual production using advanced modelling tools. Time is saved, stakeholder communication improves, and costly mistakes are reduced.

Modern steel fabrication emphasizes sustainability. Industry is always looking for solutions to cut waste and pollution. Innovative methods like cold-formed steel framing save material while retaining structural integrity.

We can see that innovation will continue to influence steel fabrication's dynamic future. Metal fabricators can push boundaries and create remarkable structures that last for generations using robotics, additive manufacturing technologies like 3D printing, or sustainable practices that prioritize environmental stewardship.

Steel fabrication method evolution

Over the years, technology and practices have transformed steel fabrication. Modern steel fabrication methods improve speed, precision, and quality.

CNC machining is a steel fabricating invention. This automated method programs machines to cut and shape steel precisely using CAD software. CNC machines have drastically decreased human error and enhanced production, making complicated designs possible.

Laser cutting is another steel fabricating innovation. Laser cutting allows elaborate patterns and forms to be generated rapidly and precisely with minimal heat distortion. This approach has expanded architectural metalwork, sculpture, and industrial applications.

Recent years have seen considerable changes in welding processes. Advanced welding methods include gas metal arc welding (GMAW) or MIG/MAG welding reduce spatter and improve weld pool management.

The speed and accuracy of robotic welding technologies make them popular in large-scale operations. These automated systems can do repetitive tasks without tiredness or errors.

Modern Steel Fabrication Benefits

Steel fabrication has transformed the construction business, offering many advantages over old methods. Enhanced efficiency is a major benefit. Steel fabrication is now speedier because to new technologies and automated procedures, lowering project durations.

Another benefit is precision. Measurements and computations are precise with CAD software, ensuring accurate manufacturing every time. This precision boosts product quality, cuts waste, and lowers expenses.

Furthermore, new steel construction technologies allow for greater customisation. Fabricators may easily produce complicated shapes and complex structures with powerful cutting and shaping tools. This lets architects and designers realize their ideas without sacrificing aesthetics or utility.

Modern steel fabrication technologies are eco-friendly in addition to these benefits. Recycled materials and efficient production cut carbon emissions and encourage sustainability in construction.

Modern steel fabrication technologies have many benefits. These advances have boosted efficiency, precision, and customisation, improving the industry. Modern steel fabrication gives construction experts worldwide infinite options for large-scale commercial projects and complicated architectural designs.

Avoid these aluminium welding mistakes

Aluminium welding in Auckland tasks is difficult for novices. You can succeed with the correct information and abilities. Avoiding typical aluminium welding mistakes is essential for success.

Not cleaning the metal before welding is a common mistake. Use a stainless steel brush or chemical cleaner to remove oxide from Aluminium surfaces. Neglecting this step might cause weak joints and poor welding.

Another error is using the wrong fillers. Aluminium welding projects require particular filler wires for different alloys. Incompatible fillers can break or weaken welds.

Incorrect heat control is another common aluminium welding mistake. Heat management is essential for robust welds. Overheating causes distortion and warping, whereas underheating causes partial penetration.

Any welding activity, particularly Aluminium fabrication, should never be done without safety precautions. Always wear gloves, goggles, and aprons to protect yourself from UV rays and sparks.

Being aware of these typical pitfalls and taking safeguards will improve your aluminium welding efforts!

Beginning Metal Fabrication: Essential Tools and Techniques

This ever-changing business has seen amazing steel fabrication breakthroughs. The field has evolved quickly from old methods to cutting-edge technologies. We examined the latest steel fabrication advances and how they are changing the industry.

We began by tracing steel fabrication from manual to highly automated. Metal fabrication initiatives are now more efficient, precise, and cost-effective.

Next, we explored modern steel fabrication's benefits. CAD software offers accurate measurements and comprehensive planning before physical work begins. This minimises project errors and rework.

Laser and robotic welding have also changed the sector by speeding up and improving welds. These innovations save time and strengthen structures.

We found typical aluminium welding faults during researching. Fabricators can avoid project failures by understanding certain dangers, such as inappropriate surface cleaning or filler metal selection.

Aluminium welding safety is paramount. Welders were given safety tips to avoid fumes and sparks. Safety protocols protect personal safety and project excellence.

We covered metal fabricating basics for novices, including tools and processes. Fabricators need a complete toolbox, from hammers and chisels to plasma cutters and TIG welders.

Metal fabrication beginners must master cutting, bending, drilling, and joining.

Practiced abilities and tool use build the groundwork for future mastery.

Professionals must keep up with metal fabrication trends and technologies as they change. Fabricators may execute high-quality projects faster and more accurately by adopting innovative methods and purchasing cutting-edge equipment.

0 notes

Text

AG Price Fabrication Shop | Experienced Metal Fabrication in New Zealand

AG Price Fabrication Shop offers a wide range of metal fabrication services for various industries. Their experienced fitters can weld, stress relieve, and perform NDT inspections on-site. They have a long history and a variety of equipment to meet your needs.to know more please visit us for more details: https://www.agprice.co.nz/fabrication-shop

#mining industry#foundry#metal fabrication New Zealand#fabrication shop Auckland#welding services New Zealand#NDT inspection#metal fabrication#custom metal fabrication#metal fabrication company#fabrication workshop#stainless steel fabrication#steel fabrication#aluminum fabrication

0 notes

Text

Shaping Steel in the City of Sails: Metal Fabrication in Auckland

Auckland, New Zealand's vibrant heart, thrums not just with commerce and culture, but also with the skilled hands of metal fabricators.

These artisans bend, weld, and shape steel, aluminium, and other metals into the lifeblood of the city's infrastructure, from towering skyscrapers to intricate railings.

From Blueprint to Bulwark: The Scope of Metal Fabrication

Metal fabrication in Auckland encompasses a diverse range of projects. Structural steel forms the bones of high-rise buildings, while architectural metals add elegant flourishes to facades and interiors.

Sheet metal finds its way into cladding, roofing, and bespoke creations like bespoke furniture and art installations.

Beyond the cityscape, metal fabrication plays a crucial role in industries like

Marine

Food processing

Transportation.

From sturdy boat hulls to gleaming food-grade tanks, Auckland's metalworkers craft essential equipment that keeps the city humming.

Precision and Passion: The Mark of a Skilled Fabricator

Metal fabrication demands not just technical expertise, but also a dedication to quality and safety. Welders wield torches with the focus of surgeons, ensuring every joint is strong and immaculate.

Sheet metal workers possess the keen eye of artists, transforming flat sheets into precise forms.

Auckland boasts a thriving community of metal fabrication companies, each with its specialities and strengths.

But what unites them is a commitment to excellence, passed down through generations and honed in dedicated workshops.

Investing in the Future: Metalskills Paves the Way

The future of metal fabrication in Auckland is bright, fueled by ongoing infrastructure projects and a growing appreciation for quality craftsmanship.

To ensure a steady stream of skilled professionals, organizations like Metalskills play a vital role.

Metalskills provides training and apprenticeship programs, nurturing the next generation of metalworkers.

Through hands-on learning and industry partnerships, they equip individuals with the knowledge and skills to thrive in this dynamic field.

So, the next time you admire the steel skeleton of a new building or marvel at the intricate metalwork adorning a local cafe, remember the quiet dedication of Auckland's metal fabricators.

Their skilled hands and unwavering commitment to quality shape not just the city's landscape, but also its future.

1 note

·

View note

Text

Structural Engineering Services in Auckland, New Zealand involve the precise application of engineering principles for accurate design and analysis. Provided by Silicon Engineering Consultants NZ, these services ensure excellence in structural solutions.

Take a visit:

#structuralengineeringservices#structuralconsultancy#StructuralShopDrawingServices#StructuralBIMServices#professionalstructuralengineer#civilstructuralengineer#structuralengineeringfirms#structuralconsultancyservices

2 notes

·

View notes

Text

Rebar Detailing CAD Services Provider in USA

Silicon Engineering Consultant Pvt. Ltd. gives high standard quality of Rebar Engineeering Outsourcing Services. Our Rebar Engineering Services typically include the design, detailing, and fabrication of Rebar elements such as beams, columns, walls, slabs, and foundations. Outsource Rebar Engineering Services, construction companies can save time and money while ensuring high-quality work. Rebar Detailing Companies typically employ skilled drafters and engineers who have a deep understanding of reinforced concrete design and fabrication processes. Connected with US for your next Rebar Engineering CAD Services Provider. Rebar Detailing Services are Below:

-Rebar Detailing

-Rebar Estimation

-Foundation Drawings

-Bar Banding Schedule

-3D Modeling of Rebar

More Information :

We provide Rebar Detailing Engineering Services in USA major cities like New York, Chicago, Houston, San Diego, Dallas, San Jose, San Antonio, Los Angeles, San Francisco, Boston, Dallas, Seattle, Washington

We provide Rebar Detailing Engineering Services in UK major cities like London, Liverpool, Newcastle, Bristol, Manchester, Sheffield, York, Cambridge, Norwich, Cardiff

We provide Rebar Detailing Engineering Services in New Zealand's major cities like Auckland, Christchurch, Dunedin, Rotorua, Whangarei, New Plymouth, Wellington, Dunedin, Rotorua, Tauranga

We provide Rebar Detailing Engineering Services in Australia's major cities like Sydney, Brisbane, Hobart, Newcastle, Canberra, Melbourne, Perth, Cairns, Gold Coast, Darwin, Brisbane

#RebarDetailingServices#ShopdrawingServices#3DRebarDetailingservice#RebarDetailingShopDrawingservice#RebarShopDrawingServices#rebardetailingcompanies#RebarDetailingOutsourcingServices#RebarDesignandDetailingServices#CADServices#CADD#SiliconEC#India#USA#UK#NewZealand#Australia

1 note

·

View note

Text

Metal Fabrication Auckland: Your Stainless Steel Specialists

Hey there! Are you seeking top-quality stainless steel fabrication Auckland services? Look no further than Otahuhu Engineering. We specialise in crafting custom stainless steel components and structures to meet your exact requirements.

Why Choose Stainless Steel?

Stainless steel is a popular choice for a variety of applications due to its exceptional properties:

Durability: Resistant to corrosion, rust, and staining.

Longevity: Maintains its appearance and functionality over time.

Hygienic: Ideal for food processing, healthcare, and pharmaceutical industries.

Versatility: Can be formed and shaped into various components.

Aesthetically Pleasing: Offers a sleek and modern appearance.

Our Stainless Steel Fabrication Auckland Services

Custom Fabrication: Creating bespoke stainless steel components tailored to your specifications.

Welding: Expert welding techniques for precise and durable joins.

Cutting and Forming: Using state-of-the-art equipment to shape stainless steel into desired forms.

Finishing: Applying coatings, finishes, and treatments to protect and enhance stainless steel surfaces.

Applications of Stainless Steel Fabrication

Stainless steel is used in a wide range of industries, including:

Construction: Structural components, railings, and cladding.

Food Processing: Equipment, tanks, and utensils.

Healthcare: Medical equipment, surgical instruments, and laboratory equipment.

Pharmaceutical: Manufacturing equipment and components.

Architectural: Decorative elements and sculptures.

Choose Otahuhu Engineering

At Otahuhu Engineering, we are committed to providing exceptional stainless steel fabrication services. Our team of skilled metalworkers has years of experience and expertise in working with this versatile material.

Contact us today for a free consultation and let us transform your vision into reality.

1 note

·

View note

Text

5 Surprising Facts About Metal Fabrication: From Ancient Origins to Modern Marvels in Auckland

Metal, that ubiquitous element shaping our world, owes its transformation to the fascinating art of metal fabrication. But beyond the sparks and clang of workshops, lies a history rich in surprising facts, some with applications even reaching beyond our planet!

1. Ancient Forerunners: Believe it or not, metalworking stretches back to a staggering 1,500 BCE.

The Iron Age saw humankind harnessing the power of smelting, birthing tools, weapons, and eventually, the foundations of our modern civilizations.

Even in Auckland, archaeological finds whisper tales of early Maori utilizing toki (chisels) and meres (hand weapons) crafted from meticulously shaped pounamu (jade).

2. Celestial Welding: While Earth may be our workshop, the boundaries of metalworking don't stop at the atmosphere.

Astronauts, those modern-day Hephaestuses, wield specialized tools to perform space welding, crucial for repairs and construction in the unforgiving vacuum.

Imagine, metalworking with Earth as your backdrop – a truly out-of-this-world feat!

3. Sustainable Shelters: In the fight against climate change, metal houses might be an unexpected hero. Steel-framed constructions boast quicker build times, reduced waste, and remarkable durability compared to traditional methods.

This eco-friendly approach aligns perfectly with Auckland's focus on sustainable living, with several companies specializing in crafting sturdy, stylish metal abodes.

4. The Puddling Revolution: Remember the blacksmiths of yore hunched over fiery furnaces? They weren't just heating metal; they were pioneering a technique called puddling.

This 18th-century innovation transformed impure pig iron into malleable wrought iron, fueling the Industrial Revolution and paving the way for the intricate metalwork gracing Auckland's historic buildings.

5. Ironclad Abundance: Our planet holds a surprising secret – iron is the most abundant metal on Earth! Comprising about 5% of the Earth's crust, this versatile element forms the core, and in turn, the magnetic field that safeguards us from harmful solar radiation.

So, the next time you admire the iconic Sky Tower or marvel at the intricate metal bridges spanning Auckland's harbor, remember, you're witnessing the transformative power of Earth's most common element.

From its ancient roots to its celestial applications, metal fabrication in auckland continues to surprise and shape our world. And in Auckland, this age-old craft thrives, breathing life into sustainable homes, iconic landmarks, and countless everyday objects, all testament to the enduring allure of bending metal to our will.

1 note

·

View note

Text

What Are the Benefits of Hiring Plastic Molding Services?

Plastic injection molding requires you to inject the molten plastic into a mold cavity. It hardens within the mold to fabricate Complex Moulded Products Wellington as per the spec. It is one of the most sought-after ways to produce parts and products at reasonable ranges. It is reliable and efficient enough to meet your requirements.

How effective are plastic molding and injection?

Plastic molding and injection are some of the most effective ways to construct Complex Moulded Products Wellington. The process involves an Injection molding machine, mold, and plastic material.

Since the molten plastic enters the mold, it cools and solidifies to produce the final product. The standard process entails the use of the aluminum mold, but it also involves steel mold. It saves time and produces durable molded products in Wellington.

The molding process involves four main stages. It includes clamping, injection, ejection, and cooling. A wide variety of products get produced using the molding process. It varies in terms of size, complexity, and type. Several industrial and commercial firms rely on custom plastic molding to meet the client's requirements. It is known for its potency in the mass production of plastic molded products at a time and hassle-free.

Why should you go for the plastic molding process?

You may wonder: Why should we go for Moulding Plastic Products Wellington. There are several benefits of the process. As stated before, it's known for producing varieties of parts rapidly. It has a high surface capacity and produces stools that last the test of time.

What are the benefits of using a plastic molding process?

One should understand that this process gets applied under pressure and increases the plastic to get pressed harder. You can expect to get high detailing in the designing process. In addition, it has the potential to produce the most intricate and complex molded products Wellington.

Increased strength of the product

Fillers used in the process reduce the thickness of the plastic in the molding process. It likewise helps to increase the density of the molded products. It furnishes the client with sturdy and durable products as per their requirement. You can say that it is the most appropriate molding process when compared to the alternatives. The best bit is that it's able to use different parts of plastic simultaneously.

Highly competent

When you put the mold in place, it takes less time to produce. Design the molded parts into a single mold. It is one of the specialties of the process, which gets recognized by the manufacturer.

As if the automated process gets conducted by a piece of missionary machinery, plastic molding injection saves you time. It reduces labor cost during manufacturing, cam and cad facilitates close tolerance. It makes the product precise and accurate.

If you want a custom prototype and molding Plastic Products Wellington, consider hiring plastic injection services. We are a global leader and manufacturer that provides you with high-grade plastic molding stock. For quotes on packaging tube Auckland, contact us today.

0 notes

Text

Premium Stainless Steel Solutions in Auckland

Stainless steel is where it's at for any type of project needing durability, function, and nice aesthetics. You have a commercial kitchen, want an upgrade at your home, or you're about to execute the industrial type-you name it – stainless steel fabrication in Auckland gives you top notch quality with unbeatable versatility, all by giving you a working design that lasts very long with it.

The stainless steel fabricators in Auckland are some of the most skilled ones, and their ability to tailor solutions to various needs is a hallmark. These professionals can help with kitchen benchtops and splashbacks as well as handrails, staircases, and industrial fittings, always bringing expertise, precision, and creativity to a project. If you’re after premium stainless steel products in Auckland, you’re in the right place.

Why Stainless Steel is a Top Choice

Stainless steel is known for its durability and resistance to corrosion. It is the perfect material for indoor and outdoor applications. It stands up rather well against the unpredictable Auckland weather, moisture, heat, and wear. It has, more than that, though, a contemporary, clean, modern look suited to fit many contemporary designs either in residential or commercial establishments.

Stainless steel is sustainable. It's 100% recyclable, hence requiring little to no maintenance. Individuals and businesses wishing to reduce their footprint, therefore, do not need to look any further than stainless steel. For projects big or small, this will be your material of choice due to the fact that it represents a perfect mix of strength and style.

Expectations of Fabricators in Auckland

Detail is everything when it comes to stainless fabrication in Auckland. The top fabricators make use of the best tools and techniques to ensure each product meets high standards of quality and precision. They specialize in a wide variety of projects-from small custom pieces to large industrial installations-and they ensure flexibility as well as expertise at every level.

In this process, discussion of your idea and needs happens, often in a consultancy session. Following the finalizing of the design, they apply the latest cutting-edge machinery that shapes the steel with great precision. From an easy kitchen bench to an advanced architectural feature, these stainless steel professionals in Auckland come back with results offering functionality combined with a polished finish.

Customized Stainless Steel Products

One of the major advantages of working with stainless steel fabricators in Auckland is the customized products. Ranging from custom furniture and decor elements to industrial equipment, fabricators customize their solutions according to a particular requirement. The customization is what makes each piece fit seamlessly into your space and also makes it a decorative feature of the design.

Change Your Space with Stainless Steel

Investing in stainless steel products is more than just a practical choice—it's an opportunity to elevate the look and functionality of your space. No project in Auckland has ever compared with stainless steel due to its unbeatable durability and timeless appeal. When you get into an experience with qualified fabricators, it is not about buying a product; you're investing in the quality craftsmanship of the end result.

Whether you need customized railings, kitchen surfaces, or industrial fittings, you are sure to have the best output from the experts in stainless steel in Auckland. Choose stainless steel to change your rooms with products that are as sturdy as they look beautiful.

#stainless fabrication Auckland#stainless steel fabricators Auckland#stainless steel products Auckland

0 notes

Text

Key Factors Influencing the Quality of Awnings: What to Consider When Choosing the Perfect Shade Solution

Awnings are not only functional but also add aesthetic appeal to your outdoor space. Whether you're looking to create a shaded area for your patio, protect your windows from harsh sunlight, or enhance the curb appeal of your home or business, choosing the right Awnings manufacturing Auckland approach is essential. To ensure you invest in a high-quality awning that meets your needs and stands the test of time, you must consider several key factors. In this blog, we'll explore these factors and guide you through the process of selecting the perfect shade solution for your space.

1. Material Matters

The first and most crucial aspect of awning quality is the material used in its construction. Awnings are typically made from various materials, including fabric, aluminum, and vinyl.

Fabric: Fabric awnings are popular for their versatility and aesthetics. However, the quality of the fabric matters significantly. Look for materials that are UV-resistant, weather-resistant, and easy to clean. Brands like Sunbrella are known for their durable, high-quality fabrics.

Aluminum: Aluminum Awnings manufacturing Auckland is durable and low-maintenance. Ensure that the aluminum is of a high gauge and has a protective coating to prevent rust.

Vinyl: Vinyl awnings are also durable and resistant to weather conditions. They are often used for commercial applications. Quality vinyl awnings should be reinforced and have strong seams to prevent tearing.

2. Frame and Structure

The frame and structure of an awning play a vital role in its longevity and stability. A sturdy frame is essential to withstand wind, rain, and snow. Look for awnings with frames made from materials such as steel, aluminum, or fiberglass. The design and engineering of the frame are equally important, as it should be able to support the weight of the awning material and any additional accessories like lights or fans.

3. Installation and Maintenance

Even the highest-quality Awnings manufacturing Auckland can underperform if it's not installed correctly. Proper installation by experienced professionals is crucial to ensure your awning functions as intended. Additionally, regular maintenance, including cleaning and inspections, can extend the lifespan of your awning.

4. Style and Design

Awnings come in various styles, including retractable, stationary, dome-shaped, and more. Consider the architectural style of your home or business and your specific shading needs when choosing the awning style. Quality awnings should also offer customization options, including color choices and accessories.

5. Warranty and Reputation

Reputable awning manufacturers and suppliers often provide warranties that reflect their confidence in the product's quality. Be sure to review the warranty terms and ask about the manufacturer's reputation.. For quotes on Marine Covers for Transport, contact us now.

6. Budget

A high-quality awning is an investment that pays off in terms of durability and performance.

In conclusion, the quality of an awning relies on various factors, including the choice of material, frame and structure, installation, maintenance, style, warranty, and budget considerations. By carefully evaluating these factors and choosing a reputable supplier, you can ensure that your awning not only enhances the functionality and aesthetics of your outdoor space but also provides long-lasting shade and protection. You can contact our experts if you’re hunting for the best Manufacturer of ziptrak Auckland.

0 notes

Text

Orams Marine Facility, Auckland, NZ

For every glamorous activity, there is some hard work behind the scenes – something that makes everything work seamlessly and look easy. This is the case with the new Orams Marine Facility in Auckland.

This huge new marine workshop is being constructed to provide increased maintenance facilities for Auckland’s ferries, fishing vessels and commercial vessels – and the occasional superyacht. It’s a large project, even involving a 110-tonne travelator to move the boats around. It’s due to be handed over on the first week of March 2023.

Why OrbiPlate™ was chosen

Main contractor of the project, MacRennie Construction, chose 20mm OrbiPlate connectors to connect the steel to the precast panels. Working with steel fabricator, Culham Engineering, and precast fabricator ConcreTec NZ, the OrbiPlate connectors were essential to the efficiency of the build.

“We piled first, then we added footings, structural steel, then precast,” explains site manager Tony Watson of MacRennie Construction. “And our services are going on now.”

MacRennie Construction discussed the precast panel installation process with Luke Price, the design engineer from Strata Group Consulting Engineers Ltd, because they wanted the maximum tolerance, they could get at the connection point of the structural steel and precast panels.

Price recommended OrbiPlate connectors, which are made of high tensile steel. The OrbiPlate system delivers 360 degrees connection tolerances of up to 20mm in structural connections. Quick and easy to install, it delivers fine locational accuracy when positioning steel members.

The OrbiPlate system streamlined the install process, reducing crane time and potential delays caused by misaligned connection points having to be remediated onsite while large panels were hanging on a crane.

This was the first time that MacRennie used the OrbiPlate system and after installing over #1000 units of them on this project, Watson said they were happy with the product and felt it was a good system.

“It was really effective,” he says. “Once the precasts were made, it was pretty straightforward.”

ReidBrace™ in action

MacRennie also used Ramset’s ReidBrace on the project, which is one of their favourite and most-used Ramset™ products. ReidBrace is an off-the-shelf system that provides design engineers and constructors with an economic solution for tension bracing of structures, tie-back applications and temporary works bracing.

“We use this product on 99% of our jobs and don’t have any issues with it,” says Watson. https://ramset.co.nz/orams-marine-facility-auckland-nz/

1 note

·

View note

Text

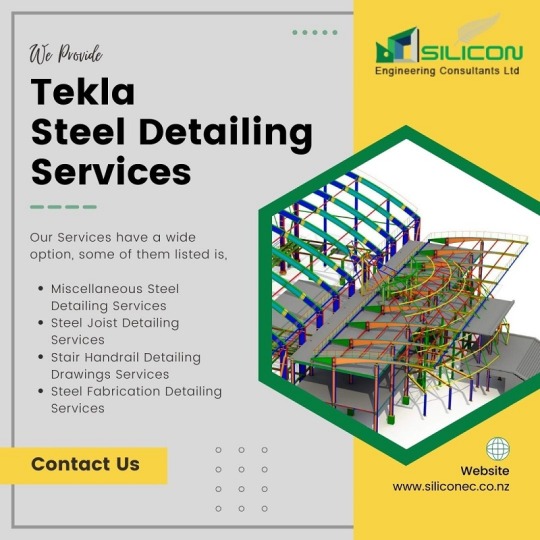

Get the best quality Steel Detailing Outsourcing Services in Auckland, New Zealand at very low price

Silicon Engineering Consultants Limited providing the best quality Engineering solutions for Steel Detailing and Steel Fabrication Drawings projects. Our team of experienced Steel Detailers utilize the latest software such as Tekla Structures, Advance Steel, and AutoCAD, ensuring efficient and accurate outputs. Our expertise lies in providing customized Joist Detailing Services that are tailored to the specific needs and requirements of our clients, making us stand out in the AEC industry.

Our main Tekla Steel Detailing Services are:

Steel Detailing Outsourcing Services

Steel Fabrication Detailing Services

Miscellaneous Steel Detailing Services

Joist Steel Detailing Services

Stair Handrail Detailing Services

Steel Detailing Drawings Services

Roof Truss Joist Drawing Services

Erection Drawings Services

We offer our Steel Detailing Services Auckland and covered other cities: Rotorua, Tauranga, Picton, Napier, Christchurch and Wellington.

License User AutoDesk AutoCAD, Revit, Tekla, STAAD.Pro, SOLIDWORKS, ZWCAD, AutoDesk Navisworks, 3Ds Max, Inventor, Showcase, ReCap, Infraworks 360, Civil 3D.

Contact Us Steel Detailing Consultant for your Steel Detailing Outsourcing Services requirement.

For More Details Website: https://www.siliconec.co.nz/detailing-services/steel-detailing.html

#SteelDetailing#DetailingServices#TeklaStructure#SiliconecNZ#StructuralServices#Auckland#NewZealand#Tekla#Detailing#Fabrication#CAD#CADDesign#CADDrafting#CADDrawings#AssemblyDrawing#ErectionDrawings#BIM#Engineering#Construction#B1M#ShopDrawing#CADD

1 note

·

View note

Text

Simplifying Your Cleaning Routine: A Guide on How to Buy Cleaning Products

Keeping our living spaces clean and tidy is essential for a healthy and comfortable lifestyle. However, with the vast array of Cleaning products New Zealand available on the market, choosing the right ones can be overwhelming. In this blog post, we will guide you through the process of buying cleaning products, making it simple and stress-free. By following these steps, you'll be equipped with the necessary tools to maintain a spotless home effortlessly.

Assess Your Cleaning Needs:

Before venturing into the world of cleaning products, it's important to evaluate your specific cleaning needs. Identify the surfaces, materials, and areas that require cleaning. Are you dealing with stubborn stains, delicate fabrics, or specific types of flooring? Understanding your requirements will help you choose the best Home cleaning product Auckland tailored to your needs, ensuring optimal results.

Research Product Types:

Once you've determined your cleaning needs, it's time to familiarize yourself with different types of cleaning products. Here are a few common ones to consider:

All-purpose cleaners: Versatile options suitable for most surfaces and areas.

Specialty cleaners: Designed for specific tasks, such as glass cleaners, stainless steel cleaners, or carpet cleaners.

Disinfectants: Effective for killing germs and bacteria, commonly used in bathrooms and kitchens.

Eco-friendly alternatives: For those seeking environmentally friendly options, look for products labeled as "green" or "eco-friendly."

Read Labels and Ingredients:

When selecting Dairy farm cleaning products Auckland, pay close attention to the labels and ingredients. Look for clear instructions on proper usage, precautions, and safety warnings. Avoid products with harsh chemicals that may pose health risks or damage surfaces. Opt for products with recognizable, non-toxic ingredients to minimize environmental impact.

Conclusion:

Choosing the right cleaning products doesn't have to be a daunting task. By assessing your needs, researching product types, and considering ease of use, you can make the process simpler and more enjoyable. Remember to read labels, compare prices, and test products before committing to a specific brand. With the right cleaning products in your arsenal, you'll be equipped to tackle any cleaning challenge and maintain a fresh and welcoming environment effortlessly.

0 notes

Text

Do you need high-quality custombuilt steel work in Northland, Auckland, Warkworth, Rodney, or Kaipara? Our expert fabricators offer customized steel solutions for all your needs. More info: https://mangawhaiengineeringmarineltd.co.nz/ns/custom-projects/

0 notes

Text

15 Remarkable Modern House Designs

Remarkable Modern House Designs there would always be updates when it comes to designs and eventually, house designs too. We’d always have our own preferences as to what type of house we’d want to be built. Some would prefer the contemporary way or classic perhaps. There are also those who would already prefer Modern House Designs applied to their dream houses. This type of design allows you to live in the modern era where minimalism is a hit, comfort is a plus and glass means elegance. Modern homes say goodbye to the typical colourful way of houses may it be the interior or the exterior part. Planning a modern house can be easy or hard depending on the owner requirements. Since a house is the very first extreme investment, there are standards to meet although it would still consider the modern taste of the owner. Here’s an overview of what you need to do when you want to plan a modern house: The first thing that you as the owner should consider is the available floor plan for your home. This includes new houses or for existing homes where owners wish to remodel. Here are some ways to finding floor plans for existing homes that needs remodeling: 1. Contact Your Local Permit Agency or Records Office. 2. Get in touch with the Builder or Architect of your home. 3. If bought, you may also check with your Real Estate Agent. 4. Inquire with Neighbours as you may have the same contractor. 5. Check out previous records and documents at home. There may be kept documents inside that were left. Before dwelling to the specifics of your desired design, you’ll need to consider your project budget to start it all out. Costs for building a modern house can be more expensive than other types of house design. But with the right architect, proper planning and right budgeting, an affordable house design can be achieved. For planning on your dream house, you may also want to check out modern house plans to keep increase your design options. Modern house plans are usually characterised by flat or shallow-pitched roofs, large expanses of glass, strong connections to outdoor space, and spare, unornamented walls. Materials for this type of houses usually features structure of steel, glass and concrete. As the owner, it’ll be your responsibility to look over the materials being used for your home. Make sure that all comply to standards and will work well with what you have envisioned and stay within the budget. Modern house interior generally has open layouts. This home design usually use wood, leather, wool, metal and textile. Walls are usually light colours and the floors are without carpets though some add some rugs of wool or another fabric. There are certain distinctions in modern home designs that you’ll notice in the following collection that we have compiled. From the lightings used, to the landscapes and even the peculiar shapes of the house exterior. The architecture of today has really evolved where there are already too many options to choose from to make that house look modern may it be made from wood or other architectural materials. Take a look and be amazed. If you think that having a small house can hinder you from having a modern house, then think again! Below are some pretty cool small modern houses! Brazil’s Piraja House

The Piraja House is an old house that has been passed through generations. Today, it stands as a three level home with a roof garden. Back Country Home

This small modern residence in New Zealand is a small home comprised of a single volume. The house is located in Auckland, New Zealand. Terrace House

This small terraced house in Australia has used bold black and wood exterior to create a stunning small modern

This small guest house in Russia is designed as a contemporary shed complete with everything one needs from a bedroom to a bathroom. Pool House

This pool house in New Delhi, India is a unique small house with a home theatre, lounge, pool area, changing room and gym. It features a curved concrete shell. Railway House

The Railway House is a semi-detached home seated in Singapore. It was designed by separating and pulling the main block away from the party wall, this semi-detached house breaks free. Ark House

This Ark House is a renewal and third interpretation of a holiday home. The design is a mix of materials and some glass windows that allow light to enter the interior. Mount Pleasant House

The Mount Pleasant House was converted into “two connected yet disparate buildings into a single cohesive new home with a focus on music and entertainment”. Maskiell Home

The Maskiell Home is a renovated home in Auckland, New Zealand with 4 bedrooms, a study and open-plan living area. The design was based on the form of a contemporary shipping container. Kew House

The Kew House is another unique renovation of a small house with its claw roof and folding theme of the house. If ‘Simple’ is what you have in mind for your modern house, the following design are great for inspiration:

The Theodore Wirth Ranch is a two-storey house in Minneapolis, Minnesota that is a fine example of a simple modern house. House In Messaria

The House In Messaria is a modern house which combines its design with traditional Greek architecture. Rough House The Rough House in Vancouver used carbonized cypress cladding, board-form concrete and repurposed board form boards white washed for exterior window surrounds and soffit. It also has an elevated exterior landscape which includes a green roof and a wall. Palma Plaza Spec

The Palma Plaza Spec in Texas used peaked roofs instead of a flat roof design. It started as a spec house and turned into a lovely house after construction. Mid-Block Contemporary House

This Mid-Block Contemporary House in Australia is a beautiful contemporary house with a black facade and a simple geometric design. Residencia Cumbaya

The Residencia Cumbayais a luxurious home that has an underground garage and a pivoting wooden door. Hayes Road

The Hayes Road is a simple modern residence made for a young family featuring geometric architecture and minimalist interiors. Modern Home in Toronto

This modern home in Toronto is a unique modern home with bright interiors as its windows bring in natural light into the home. It also used a combination of wood and concrete materials. 1653 Residence

This 1653 Residence is a simple modern home has 3 bedrooms & 2.5 baths with a compact but open floor plan. Villa Huizen

The Villa Huizen is a sustainably designed home that utilises glass materials to allow sustainable light in the interior. Somerset Renovation

The Somerset Renovation in Maryland is a renovated home that included an updated kitchen and bath and a living area with an open layout achieving a modern and airy space. 1930’s House in North London

The 1930’s House in North London is a house originally built in 1930 and was transformed into a spacious, light-filled home for the clients and their four children. Casa Bilbaina

The Casa Bilbaina in Spain is a 7,200 square feet home with a geometrical figure facade. Flip Flop House

The Flip Flop House in California is a home in Venice, Los Angeles that has a top-floor pivoting walls, elevator, wrap-around terrace and the oceanic view. Issaquah House

The Issaquah House is a house that combines sustainable materials and features while giving the homeowners a modern living. Eco-friendly homes are mostly preferred nowadays to help sustain the environment. Below are some example of an Modern Eco House. Green Home

The Green Home is a beautiful contemporary house that features solar panels and a green roof. Hoan House

The Hoan House is a home with a roof garden containing so many plants of various types. Pleated House

The Pleated House is a house with different volumes features a green roof and a clean interior. It is also located in a wooded area which brings more appeal to the home. Sun Path House

The Sun Path House is a three-storey extension with a solarium at the time. The design is based on the figure of the sun and has a sustainable design. Indochina Villa

The Indochina Villa Saigon is a house which focuses on the association of the interior design to the exteriors. It aims to integrate the surrounding that may complement with the lifestyle of the homeowner. Greenberg Green House

The Greenberg Green House is a house that forms a model for combining the state-of-the-art design together with the energy strategies that may certainly come up with a more well-organized and developed residence. Eco-Sustainable House

The Eco-Sustainable House is a house that is shaped by out-dated zoning regulations. It’s roof is shaped like a pergola that allows natural light and ventilation in the rooftop. For those who love the unusual and extraordinary, below are some unusual modern house designs for you to feast on! Flex House

The Flex House is a house has a distinct ribbon-like surface that defines the different levels and makes it appear totally unique. LA West Hollywood Modern Home

The LA West Hollywood Modern Home is a modern house features angular lines with charcoal and smoky orange color combinations both for the exterior and interior. Its unique facade sets it apart from other homes in the area. Sunflower House

The Sunflower House is a house is designed like a flower. It was able to identify each particularities of this magnificent landscape, with its geometry, the house frames a multiplicity of different and specific views and builds up content spaces that inhabit great big framed views. Scape House

The Scape House is a house built in the beach of Byron Bay, Australia. The house reveals the different amazing areas that also provide the luxurious experience with the members of the family. Tent House

The Tent House is a unique home that is inspired by a tent and it does look like a tent but it has a modern minimalist interior. The upper level can be accessed through a spiral staircase. Leaning House

The Leaning House is a zinc cladded house with a slanted design. It has an open floor plan and has more rooms too. Monteblanc House

The Monteblanc House is a structure with a gable-house-shape with a continuous exterior space from the 1st to the 3rd floor under large inclined roof.5 large openings in the inclined roof. Ga On Jai

The Ga On Jai is a contemporary residence that showcases an inner courtyard. It has a 3,541 square foot (329 square meters) of living space that allows home owners to enjoy both the indoor and outdoor areas. House in Kings Cross

The House in Kings Cross is a home with triple layered slate with stainless steel clips that are built to the last 100 years and the windows have wooden frames, indoor marble, stone, glass and wooden finishes on its facade. Caterpillar House

The Caterpillar House is the home of an art collector and his family. With the exceptional design and concept, the designer strategically made the proposed integration of the territory to the house. We know how important it is to have more design inspiration. As a bonus, we have more Modern House Design Ideas below: Modern House at Night

This was designed by Arch. Bienvenido Negradas Jr. an architect from Philippines and currently based in Doha, Qatar. House in Modern Style Read the full article

1 note

·

View note