#metal fabrication New Zealand

Explore tagged Tumblr posts

Text

AG Price Fabrication Shop | Experienced Metal Fabrication in New Zealand

AG Price Fabrication Shop offers a wide range of metal fabrication services for various industries. Their experienced fitters can weld, stress relieve, and perform NDT inspections on-site. They have a long history and a variety of equipment to meet your needs.to know more please visit us for more details: https://www.agprice.co.nz/fabrication-shop

#mining industry#foundry#metal fabrication New Zealand#fabrication shop Auckland#welding services New Zealand#NDT inspection#metal fabrication#custom metal fabrication#metal fabrication company#fabrication workshop#stainless steel fabrication#steel fabrication#aluminum fabrication

0 notes

Text

#metal skills#welding engineering#metal fabrication#hardware insertion#metal skills in new zealand#steel fabrication

0 notes

Text

RAH

introductory

so, for those of you who dont know, electio ace is someone who is ace but still desires a sexual relationship. Same thing for electio aro but its romance not sex

quinn doesn't use this blog anymore

Ki's tags: "ki posting" "ki reblogging" "ki answers" "ki's questions" (she/they)

Tag lissttt

@bisexual-airforce @obviously-enby-airforce @actual-transgender-navy @queer-military-treasury @sam-the-skelepun

@bored-dromaeosaur @thealphabetcultleader @hold-my-dr-pepper @femboy-hooters-real @duothelingo

@operagxreal @i-say-ok @gimmick-theif @gimmick-theif-theif @post-uwuifier

@firehouse-subs-fr @realsafari @totallyoperagx @truly-bath-and-body-works

@truly-jcjenson @unofficially-joann-fabric @unofficialvine @walmart-the-official @yahooo-official

@yamaha-official @yes-im-youtube-kids @ymca-for-realzies @youtubefr @actually-alberta

@antarcitica-official @definitely-brasil

@definitely-canada @definitelytherepublicofireland @denmark-forreal @denmark-official

@forever-scotland @france-unofficial @germany-official @guatemala-official @india-official

@massachusetts-official @new-york-for-real @non-tyrannical-usa @official-denmark @official-ireland

@official-new-zealand @official-the-united-states @pakistan-official @quebec-official @republic-of-molossia

@russia-totallyofficial @sovereign-state-of-alaska @spain-unofficial @telangana-official @texas-real

@the-principality-of-sealand @totally-brazil @totally-france @totally-germany @totally-italy

@same-pic-of-venus-everyday @same-pic-of-the-earth-everyday @same-pic-of-the-moon-everyday @same-pic-of-mars-everyday @same-pic-of-jupiter-everyday

@same-pic-of-saturn-everyday @the-real-uranus @same-pic-of-neptune-everyday @steve-not-anon @metal-frisbee

@earth-fan @not-10-salmon-in-a-png @same-pic-of-halleys-comet @same-pic-of-callisto-everyday @same-pic-of-eris-everyday

42 notes

·

View notes

Text

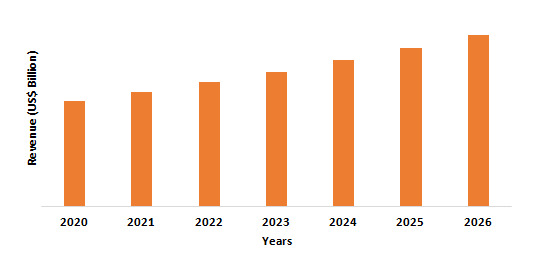

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes

Text

VOY: Caretaker (Part 1)

Just like its predecessor, Deep Space Nine, Voyager opens with an expository text crawl explaining the current galactic situation. We learn about the Maquis – a plucky, non-Federation rebel group fighting the Cardassian occupation – then jump right into a heated space battle!

Fire! Raise shields! And somebody turn off that damned smoke machine!

As one would expect from a ragtag group of resourceful underdogs, the Maquis wear mismatched outfits made for trouble; we’re introduced to Chakotay and B’Elanna, both sporting rolled-up sleeves and tough leather vests.

Forearms mean business.

Tuvok is here too, although we don’t get a good look at his outfit from any of the angles in this scene. Chakotay makes up for it, however, by giving us a bit of a catwalk look at his duds: the patterned shirt is lovely, and probably meant to evoke his Native American heritage.

Actually, this may be the least problematic reference to his “heritage.”

Next, we’re taken to a sunny, verdant New Zealand penal colony, where Captain Janeway is busy picking out a boy toy. Unsurprisingly, we’re working with the same Starfleet uniforms currently in use on DS9, with a coloured section on the shoulders indicating department, and a grey turtleneck with rank pips underneath.

Get used to it – Voyager won’t be receiving wardrobe updates for about the next seven years.

Janeway finds the man she’s looking for – the boyishly handsome Nick Locarno Tom Paris – and hands him a “get out of jail free” card in the form of an invitation to join her crew. Tom considers her offer, weighing the excitement of adventure against having to give up his stylish prison coverall; the garment is concrete grey, with subtle shade differences across the chest and shoulders, not unlike a Starfleet uniform. I appreciate the asymmetry of the dark grey extending down the left sleeve, but not the right. The flap closure at the front is a little bit sexy, too, and along with the rolled-up sleeves, gives a “greasemonkey” vibe we’ll come to see a lot of from Tom.

The ankle monitor makes a nice accessory, too.

Meanwhile, Voyager is docked at Deep Space Nine, and we cut to a character we all know and love: Quark! …In the process of ripping off young Harry Kim. Although Quark’s ensemble technically belongs to another show, I still have to award it “best outfit” for the episode. The matching teal hues in the pants, shirt, and jacket is a beautiful bit of coordination, and it’s obvious the costume department has had a few seasons to perfect the character design. It’s not unusual for a Ferengi to dress so lavishly, but Harry should probably take it as a warning sign that he’s about to be ripped off.

I’m sure he’ll be fine.

Up on the ship, Janeway has a chat with her fiancé Mark, who’s sporting a handsome wool-looking jacket in a dark mustard colour. Mark only gets about six lines and thirty seconds of screen time, so his outfit has to really pull its weight here building a character: handsome but approachable, smart but unpretentious, still shops at GAP in his 50s.

Sensible. I meant sensible.

There are no new costumes for a while as we meet the ship and crew, but we do get a few nice close-ups of Janeway’s lovely, elaborate updo – a more complicated style than the “bun of steel” she’ll wear in coming episodes.

Ignore the wig glue. It’s just… space sweat.

I suspect the stylist wanted all those extra swirlies in there because, once the action begins and our crew gets roughed up a bit, Action-Tousled Janeway looks amazing.

Slay, girl.

Harry and Tom go to sickbay, which is going to be full of patients very soon, and is also on fire. It’s hard to get a good look, but Harry puts on a cool Starfleet-issue oven mitt with metallic fabric to extinguish the fire.

Was that hole always there?

The least visible costume prop of all time.

In all the commotion, the crew realizes they’ve been zooped across the galaxy – 75,000 lightyears from home. But just when you thought we’d be stuck on a spaceship with one set of clothes for the next seventy years, we’re zooped again… to a southern country farm?! It looks exactly like Earth, and what looks like a perfectly human grandma comes out with cookies and lemonade to greet Janeway and co.

Floral fabric, ivory cameo, plate of cookies… yep, that’s a grandma.

She’s not alone, and soon the farm is full of completely “normal” “humans” having a good time, dancing and playing music. It’s literally the friendliest alien welcome party in history, but the Voyager crew are spooked. Moreover, they seem confused by the folksy straw hats and denim overalls.

Highly suspicious flannel.

With one exception: Tom Paris has quickly made friends with one of the illusory farm girls, a young woman in a cute printed dress with a belt, mary janes, and bright white ankle socks.

First contact: cottagecore edition.

However, Paris’ new friend gets a bit upset when they turn down her extremely tempting offers of a “real private” root cellar, a duck pond, and deviled eggs, and suddenly the farm folk aren’t so welcoming. The crew is zooped back to the ship – mostly. Harry Kim is missing.

Get outta here! And take your synthetic fabrics with you!

Discovering a similar absence on the Maquis ship – B’Elanna is also missing – the two crews decide to work together to track down their people.

As they discuss plans, we finally get a good look at Tuvok’s Maquis disguise: he wears a cropped, open jacket made from a textured brown-green fabric, with sleeves in a lovely deep blue. The trim between the different fabrics is subtly shiny, giving the impression of leather straps. More importantly though, he wears an orange shirt underneath that appears to be stained at the collar – is that greenish hue Vulcan blood??

What happened to you in the Maquis, Tuvok?!

The episode isn’t out of costumes for us yet, though, and it’s a hard pivot from the dirty, worn-in clothes of the Maquis – as the viewpoint switches to that of our missing crewmembers, we find them in white clothing that resembles hospital gowns, albeit with an awkward strap closure that goes all the way around the back.

You know that strap has come undone and dipped in the toilet at LEAST once.

We also get our first look at the Ocampa, who at the moment are also clad in white, gauzy outfits. Unlike the “patients,” they wear strange fruit-netting-ish infinity scarves around their neck and head.

Keeps their melon safe.

The mesh fabric looks like it might be some kind of protective gear, but no, as we explore more of the compound, we see the truth: Ocampans just don’t know how to wear a scarf.

So close…

9 notes

·

View notes

Link

0 notes

Text

Electroactive Polymers Market — By Type , By Application , By Geography — Global Opportunity Analysis & Industry Forecast, 2024–2030

Electroactive Polymers Market Overview

Request Sample :

Electroactive Polymers Market COVID-19 Pandemic

The outbreak of Covid-19 is having a huge impact on the economy of electronic devices. The COVID-19 pandemic caused an unprecedented increased demand for some medical devices, as well as significant disruptions in the manufacturing and supply chain operations of global medical devices. The FDA monitors the supply chain of medical products and works closely with producers and other stakeholders to assess the risk of disruption and to prevent or reduce its impact on patients, health care providers, and the general public’s health. In addition, there is a delay in imports and exports of medical devices due to the import-export restriction by the governments in various regions. All these factors are having a major impact on the Electroactive Polymers Market during the pandemic.

Report Coverage

The report: “Electroactive Polymers Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the electroactive polymers Industry.

By Type: Ionic Electroactive Polymers (Ionic Polymer Gels (IPG), Ionic Polymer Metal Composites (IPMC), Conductive Polymers (CP), and Carbon Nanotubes (CNT)), Electronic Electroactive Polymers (Ferroelectric Polymers, Electrostrictive Graft Elastomers, Dielectric Elastomers, Electro VIscoelastic Elastomers, Liquid Crystal Elastomer (LCE), and Others), and Others.

By Application: Actuators, Sensors, Plastic, Aviation Technology, Energy Generation, Automotive Devices, Prosthetics, Robotics, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the Electroactive Polymers Market owing to the increasing demand for the electroactive polymers industry in the region. The increasing urbanization coupled with the rising population in APAC is the major factor driving the demand for electroactive polymers.

Electroactive polymers are extensively used for corrosion-preventing coatings in ferrous and non-ferrous alloys, actuators, damped harmonic oscillator, metamorphic biomaterials, and protective fabrics points. These properties of electroactive polymers are projected to increase market growth.

Electroactive polymers due to its unique properties find application in different end-use industries. These are lighter in weight, more durable, and have better conductive properties, unlike conventional materials (metals). During the forecast period, this factor is anticipated to drive the market.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which the projects and operations of various industries such as energy generation and automotive are disruptively stopped, which is hampering the Electroactive Polymers Market growth.

Electroactive Polymers Market Segment Analysis — By Type

The conductive polymers segment held the largest share in the Electroactive Polymers Market in 2020 and is growing at a CAGR 8.10% over 2024–2030. The significant class of functional materials that have certain useful properties of both organic polymers (such as strength, plasticity, flexibility, strength, elasticity) and semiconductors (such as electric conductivity) are conducting polymers (CPs). The conductive polymers are often used in miniature boxes that have the ability to open and close, micro-robots, surgical tools, surgical robots that assemble other micro-devices. In addition, conductive polymers (CPs) are extensively used as an alternative to metallic interfaces within biomedical devices as a way of imparting electroactivity to normally passive devices such as tissue scaffolds. Thus, all these extensive characteristics of conductive polymers are the key factor anticipated to boost the demand for conductive polymers in various regions during the forecast period.

Schedule A Call :

Electroactive Polymers Market Segment Analysis — By Application

The actuator segment held the largest share in the Electroactive Polymers Market in 2020 and is expected to grow with a CAGR of 7.2% for forecast period. To maximize the actuation capability and durability, effective fabrication, shaping, and electrode techniques are being developed. Many engineers and scientists from many different disciplines are attracting attention with the impressive advances in improving their actuation strain. Due to their inherent piezoelectric effect, ferroelectric polymers, such as polyvinylidene fluoride (PVDF), are largely used in manufacturing electromechanical actuators. For biomimetic applications, these materials are especially attractive, as they can be used to make intelligent robots and other biologically inspired mechanisms. To form part of mass-produced products, many EAP actuators are still emerging and need further advancements. This requires the use of models of computational chemistry, comprehensive science of materials, electro-mechanical analytical tools, and research into material processing. Which will eventually drive is the Electroactive Polymers Market during the forecast period.

Electroactive Polymers Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the Electroactive Polymers Market in 2020 up to 38%, owing to the escalating medical device industry in the region. A key factor behind the growth of the region’s electroactive polymer market is the large demand for electroactive polymers for the manufacture of advanced implant devices for medical conditions. According to Invest India, the Indian medical device sector is projected to register a CAGR of 14.8% and is expected to reach $11.9 billion in 2021–22, and the sector is projected to reach $ 65 bn industry by 2024. According to the most recent official figures from the Ministry of Health, Labour and Welfare (MHLW), the Japanese medical devices market in 2018 was roughly $29.3 billion, up about 6.9 percent from 2017 in yen terms. And from 2018 to 2023, the medical device market in Japan is estimated to show an increment of 4.5% CAGR in yen terms. Furthermore, North America also holds a prominent market share of the Electroactive Polymers Market due to the escalating medical device industry. According to the Select USA, the United States medical device market is anticipated to rise to $208 billion by the year 2023. Thus, with the expanding medical device industry, the demand for electroactive polymers will also subsequently increase, which is anticipated to drive the Electroactive Polymers Market in the Asia Pacific and North America during the forecast period.

Electroactive Polymers Market Drivers

Increasing Automotive Production

In the automotive industry, electroactive polymers are used as actuators and sensors. For materials that are light in weight but strong and durable such as an electroactive polymer, there is high demand. By using modern electroactive polymers in numerous automotive electronic components, such as multiple sensors, accelerometers, and accelerator pedal modules, car manufacturers are attempting to achieve lightweight properties. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects the production of cars to reach 35 million by 2025. According to the International Trade Administration (ITA), in 2019 the Mexican market for electric, plug-in vehicles, and hybrid vehicles reached 25,608 units, representing a 43.8% growth over 2018. Thus, increasing automation production will require more electroactive polymers for manufacturing various automotive components, which will act as a driver for the Electroactive Polymers Market during the forecast period.

Increasing Application of Electroactive Polymers

Textiles called sensing and actuating microfibers can be directly woven into electromechanical systems such as sensors, actuators, electronics, and power sources. They can be used as smart fabrics because of the flexibility and low cost of electroactive polymers. In developing intelligent fabrics, polypyrrole and polyaniline are used. In addition, using electroactive polymers in robotics for muscle development is better, as it is more cost-effective than the semiconductor and metal materials. And robotics is widely used; hence the demand for electroactive polymers will also positively affect the market growth. Furthermore, Electroactive Polymers Market growth is increasing owing to its wide usage in areas such as medical devices, damped harmonic oscillator, electric displacement field, electrostatic discharge/electromagnetic interference, high-strain sensors, and biomimetic. Hence, the increasing application of electroactive polymers acts as a driver for the Electroactive Polymers Market.

Buy Now :

Electroactive Polymers Market Challenges

Environmental Hazards Related to the Electroactive Polymers

Raw materials which are used to produce electroactive polymers (EAPs) are difficult to extract and often harmful to the environment. The disposal of waste generated by electroactive polymers is one of the major concerns (EAPs). Improper disposal of EAP products could harm the environment and ultimately impact the food chain. Manufacturers of EAPs may experience increased costs associated with the disposal of certain electroactive polymers (EAPs) that cannot be disposed of by biodegradation. The government has, therefore, enforced strict regulations on the use of such polymers. Besides, the environmental regulations on the use of petroleum products restrict the growth of the EAPs market. These factors are hampering the electroactive polymer market growth.

Electroactive Polymers Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Electroactive Polymers Market. Major players in the Electroactive Polymers Market are Solvay, Parker Hannifin, Agfa-Gevaert, 3M, Merck, Lubrizol, Novasentis, Premix, PolyOne Corporation, Celanese Corporation, and KEMET Corporation.

Key Market Players:

The Top 5 companies in the Electroactive Polymers Market are:

Merck

3M

Solvay

Parker Hannifin

Agfa-Gevaert

For more Chemicals and Materials Market reports, Please click here

#ElectroactivePolymers#SmartMaterials#ConductivePolymers#FlexibleElectronics#ShapeMemoryAlloys#PolymersInElectronics#SoftRobotics

0 notes

Text

Enhancing Productivity: The Surging Demand for Metalworking Fluids

Metalworking Fluids Industry Overview

The global metalworking fluids market size is expected to reach USD 17.45 billion by 2030, as per the new report by Grand View Research, Inc., registering a CAGR of 4.9% in the forecast period. The demand is attributed to arise in demand for automotive and industrial machinery. Individual end-use sectors, such as machinery, metal fabrication, and transportation equipment, are driving the expansion of the market.

The market is also expected to be driven by strong development in the machinery and transportation equipment end-use industries over the projected period. Manufacturing is one of the core industries in North America and Europe. Advances in the manufacturing methods for the production of sophisticated end-use products, coupled with the increase in the exports of construction machinery and power, agricultural, and automotive equipment, have fueled the market growth.

Gather more insights about the market drivers, restrains and growth of the Metalworking Fluids Market

The sector is expected to benefit from increased production of construction machines and related parts for industrial, residential, and commercial construction. The rise in public-private partnerships is expected to boost the demand for a variety of construction components that use MWFs during their production. Because of the expanding building activities in these nations, emerging economies are likely to be critical for product growth.

The increasing demand for electricity and upgrading of the existing infrastructure for electricity generation, transmission, and distribution, is anticipated to fuel the market for electrical & power equipment and related components. These components are manufactured using ferrous and non-ferrous metal parts, which consume MWFs during manufacturing.

Browse through Grand View Research's Petrochemicals Industry Research Reports.

The global chemical distribution market size was estimated at USD 268.9 billion in 2024 and is anticipated to grow at a CAGR of 7.3% from 2025 to 2030.

The global biolubricants market size was valued at USD 2.95 billion in 2024 and is projected to grow at a CAGR of 13.7% from 2025 to 2030.

Metalworking Fluids Market Segmentation

Grand View Research has segmented the global metalworking fluid market report based on product, application, end-use, industrial end-use, and region:

Metalworking Fluids Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Mineral

Synthetic

Bio-Based

Metalworking Fluids Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Neat Cutting Oil

Water Cutting Oil

Corrosion Preventive Oil

Others

Metalworking Fluids End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal Fabrication

Transportation Equipment

Machinery

Others

Metalworking Fluids Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 – 2030)

Construction

Electric & Power

Agriculture

Automobile

Aerospace

Rail

Marine

Telecommunications

Health Care

Metalworking Fluids Regional Outlook (Volume, Kilotons; Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

UK

Russia

Italy

Spain

Turkey

Switzerland

Denmark

Norway

Belgium

Poland

Czech Republic

Sweden

Finland

Asia Pacific

China

Japan

South Korea

India

Singapore

Malayasia

Thailand

Australia

New Zealand

Central & South America

Brazil

Middle East & Africa

Key Companies profiled:

Houghton International, Inc.

Blaser Swisslube AG

BP plc

Exxon Mobil Corp.

Total S.A.

FUCHS

Chevron Corp.

China Petroleum & Chemical Corp.

Kuwait Petroleum Corp.

Key Metalworking Fluids Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as capacity expansion, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

On January 2023, Univar Solutions B.V. entered a distribution agreement with Graphics Services Ltd. for their products such as inks, rust preventive oils, coatings, lubricants, and metalworking fluids in Europe.

On September 2022, Clariant announced the extension of support for metalworking fluid manufacturers globally by offering their additives to develop high lubricity and fully-synthetic metalworking fluids.

Order a free sample PDF of the Metalworking Fluids Market Intelligence Study, published by Grand View Research.

0 notes

Text

Transforming the Industry: The Impact of Ultra High Power Laser Cutting on New Zealand Sheet Metal Fabrication

In the realm of manufacturing and fabrication, technological advancements continually reshape the landscape, driving efficiency, precision, and capability to new heights. One such transformative innovation making waves globally and specifically in New Zealand is Ultra High Power laser cutting machines. This cutting-edge method has revolutionized sheet metal fabrication processes, offering unprecedented speed, accuracy, and versatility.

Evolution of Laser Cutting Technology

Laser cutting itself has been a pivotal technology in sheet metal fabrication for decades, offering advantages over traditional methods such as plasma and mechanical cutting. Initially, CO2 lasers dominated the scene, providing excellent precision but with limitations in cutting speed and thickness. However, with advancements in fiber laser technology and the introduction of UHP lasers, the industry has witnessed a significant leap forward.

youtube

What is Ultra High Power Laser Cutting?

Ultra High Power (UHP) laser cutting involves the use of fiber lasers with power levels ranging from 10 kW to 50 kW and beyond. These lasers generate intense beams of light that can effortlessly slice through thick sheets of metal with incredible speed and accuracy. This capability extends the boundaries of what was previously possible in sheet metal fabrication, enabling manufacturers to handle thicker materials and produce intricate designs at unprecedented speeds.

Impact on New Zealand Sheet Metal Fabrication Industry

The adoption of UHP laser cutting technology has had profound implications for the sheet metal fabrication industry in New Zealand:

Increased Productivity

UHP lasers can cut materials significantly faster than traditional methods, reducing lead times and increasing throughput. This enhanced productivity allows manufacturers to fulfill orders more efficiently, meeting customer demands with greater agility.

Enhanced Precision

The high power and advanced control systems of UHP lasers ensure precise cutting, even for complex geometries and fine details. This level of precision is crucial for industries requiring exact specifications, such as aerospace and electronics.

Expanded Material Capabilities

UHP lasers can cut a wide range of materials beyond traditional metals, including composites and reflective materials. This versatility opens new avenues for innovation and product development in diverse sectors.

Cost Efficiency

While initial investments in UHP laser systems can be substantial, the long-term cost benefits are significant. Reduced operating costs, minimal material wastage, and lower maintenance requirements contribute to overall cost efficiency over the equipment’s lifespan.

Competitive Edge

Companies adopting UHP laser cutting gain a competitive edge by offering faster turnaround times, higher quality products, and the ability to take on more complex projects. This positions them strongly in both local and global markets.

Future Outlook

Looking ahead, the trajectory of UHP laser cutting technology in New Zealand appears promising. As advancements continue to refine laser systems and drive down costs, more businesses are expected to integrate this technology into their operations. This trend will likely spur further innovation in manufacturing processes and product design, reinforcing New Zealand’s reputation as a hub for advanced manufacturing solutions.

SLTL is Excited to Connect with Florida's Growing Manufacturing Base

This year, we can't wait to bring SLTL’s Ultra High-Powered Laser Innovations to Orlando and provide the expanding Florida manufacturing sector with another opportunity to witness SLTL's cutting-edge laser technology up close. Manufacturers from all over the world will gather in Orlando for FABTECH 2024 to witness innovative solutions and remain ahead of the curve in manufacturing technology.

SLTL is going to offer attendees the opportunity to witness live equipment demonstrations, build strategic partnerships, identify solutions, and stay ahead of the curve in the ever-evolving manufacturing landscape.

Knowledge Hub at SLTL’s Booth

The 2024 SLTL booth will be a knowledge hub for attendees, featuring demonstrations and insights into laser cutting, laser marking, laser welding, automation, smart manufacturing, and much more. In addition, attendees will gain knowledge about IoT-integrated machinery and witness live demonstrations of them.

Prepare for the Groundbreaking Experience

Get ready because SLTL is prepared to have an amazing time with the attendees at this event, which promises to be an incredible experience in its own way. Come see us in Hall No – S31150 at Orange County Convention Center in Orlando, Florida, from October 15-17, 2024.

Conclusion

Ultra High Power laser cutting represents a pivotal advancement in the sheet metal fabrication industry of New Zealand. Its transformative impact on productivity, precision, material capabilities, and overall competitiveness underscores its importance in shaping the future of manufacturing. As businesses embrace these technologies, they pave the way for a more efficient, agile, and dynamic industrial landscape.

Stay tuned for more updates on how technological innovations are reshaping industries around the globe. Subscribe to our newsletter for the latest insights and trends in manufacturing and beyond.

0 notes

Text

Powder Coating is a high-performance, eco-friendly finishing process in which a dry, fine powder made from pigments, resins, and additives is electrostatically applied to a surface and then cured under heat to form a hard, durable, and smooth coating. Unlike traditional liquid paints, powder coating does not use solvents, making it an environmentally friendly option with minimal volatile organic compound (VOC) emissions. This process is widely regarded for its ability to provide exceptional resistance to chipping, scratching, fading, and corrosion and its versatility in producing a wide range of textures, colors, and finishes. For more information about Powder Coating, visit: https://www.metalskills.co.nz

0 notes

Text

Unlocking Creativity: The Power of NEWMAT Stretch Ceilings 🎨💡

NEWMAT AUSTRALIA leverages its vast global expertise to provide incomparable service and reliability to clients across Australia and New Zealand – drawing from the expertise of a team who have been driving the charge towards stretch membrane design since 2002.

Integrating seamlessly into the overall design, our premium stretch ceilings are fast and clean to install, maintenance free, and safe. They are suitable for virtually any application, from wall and ceiling through to 3D shaped forms.

The experienced team at NEWMAT AUSTRALIA has worked on small-scale and major projects in the commercial, hospitality, retail, education, healthcare and residential sectors, working closely with the region’s leading architects, designers, acousticians and builders.

We supply and install membranes, tracking and complete backlighting systems, and our industrial designers assist with fast design development, prototyping, and documentation. Our extensive in-house capabilities include the fabrication of custom light boxes and framing, CNC machining and welding. We are proudly Australian owned.

As Australia’s largest stretch ceiling company, with the combined experience of over 95 years just in our Sydney office, you have no better place to start your journey but with us.

With our dedicated team of designers, fabricators, project managers and installers, we pride ourselves on setting the standard, this allows for efficient design development, prototyping, lighting supply, metal fabrications, installation and maintenance.

We assist clients not only on design development and documentation but provide specifications for fabrication, detail drawings, rapid quotations, site surveys, architectural metal work and delivery of finished goods.

Get In Touch With Us:

Address: 84 Hotham Parade, Artarmon NSW 2064, Australia 📍

Phone: +61 1300 047 047 ☎️

Email Id: [email protected] 📧

1 note

·

View note

Text

Changes to Work to Residence and Occupations on the Green List

Changes to Work to Residence and Occupations on the Green List

Starting from April 7, 2024, there are significant changes in the eligibility criteria for Transport Sector Work to Residence visas. Specifically, bus and truck drivers who apply for an Accredited Employer Work Visa (AEWV) or start working as bus or truck drivers on an open work visa after this date will no longer be eligible for a Transport Work to Residence visa. However, those who currently hold an AEWV, have already applied for one (and got approved), or are already working on open work visas will still be eligible for a Transport Work to Residence visa. Green List Updates Exciting news for skilled professionals! As of April 8, 2024, six new roles are being added to the Green List, covering nine ANZSCO occupations. These additions open up promising pathways to residency for you:Straight to Residence Aviation Engineer (Avionics, Aeronautical, Aerospace Engineer) Naval Architect (also known as Marine Designer) ICT Database and Systems Administrator Mechanical Engineering Technician Aircraft Maintenance Engineer Work to Residence Corrections Officer However, it's worth noting that previously announced roles will not be included in the Green List: Paving Plant Operator Metal Fabricator Pressure Welder Welder Fitter (General) Fitter and Turner Fitter-Welder Metal Machinist (First Class) Panel Beater Vehicle Painter Road Roller Operator Construction and Infrastructure Sector Agreement Additionally, plans to integrate seven roles into the Construction and Infrastructure Sector Agreement will not proceed: Driller's Assistant Earthmoving Labourer Earthmoving Plant Operator (general) Linemarker Machine Operators (not elsewhere classified) Mechanic's Assistant Road Traffic Controller These changes reflect the evolving landscape of New Zealand's immigration policies, which emphasise addressing skill shortages while ensuring a streamlined visa application process. The aim is to attract and retain skilled professionals in sectors with a high worker demand. By staying informed, you can navigate your immigration journey effectively and understand the government's efforts to balance the needs of the economy and the interests of the local workforce. Reference https://www.mbie.govt.nz/ https://www.immigration.govt.nz/ About ICL Immigration ICL Immigration is a 20-year-old licensed immigration adviser based in Auckland, dedicated to making your dream of settling in New Zealand a reality. With a 97% approval rate, we offer specialized services in skilled migration visa, family reunification, student visas, and business immigration, guiding you seamlessly through every step of your journey. Disclaimer: For the latest information, always refer to the official Immigration New Zealand or New Zealand government websites. Do You Have Any Question? JTNDZGl2JTIwY2xhc3MlM0QlMjJlbWJlZHNvY2lhbC1oYXNodGFnJTIyJTIwZGF0YS1yZWYlM0QlMjIxOTE5ZGNlOTE1NTNlMTQxZWUyZGQ4M2IyNWUxMTdkY2I2M2ZjYzhhJTIyJTNFJTNDJTJGZGl2JTNFJTIwJTNDc2NyaXB0JTNFJTIwJTI4ZnVuY3Rpb24lMjhkJTJDJTIwcyUyQyUyMGlkJTI5JTIwJTdCJTIwdmFyJTIwanMlM0IlMjBpZiUyMCUyOGQuZ2V0RWxlbWVudEJ5SWQlMjhpZCUyOSUyOSUyMCU3QnJldHVybiUzQiU3RCUyMGpzJTIwJTNEJTIwZC5jcmVhdGVFbGVtZW50JTI4cyUyOSUzQiUyMGpzLmlkJTIwJTNEJTIwaWQlM0IlMjBqcy5zcmMlMjAlM0QlMjAlMjJodHRwcyUzQSUyRiUyRmVtYmVkc29jaWFsLmNvbSUyRmNkbiUyRmh0LmpzJTIyJTNCJTIwZC5nZXRFbGVtZW50c0J5VGFnTmFtZSUyOCUyMmhlYWQlMjIlMjklNUIwJTVELmFwcGVuZENoaWxkJTI4anMlMjklM0IlMjAlN0QlMjhkb2N1bWVudCUyQyUyMCUyMnNjcmlwdCUyMiUyQyUyMCUyMkVtYmVkU29jaWFsSGFzaHRhZ1NjcmlwdCUyMiUyOSUyOSUzQiUyMCUzQyUyRnNjcmlwdCUzRQ==JTNDZGl2JTIwY2xhc3MlM0QlMjJlbWJlZHNvY2lhbC1oYXNodGFnJTIyJTIwZGF0YS1yZWYlM0QlMjIyMTU1NDFlYjc0YTNiY2ZjODU2MTkwMzZmM2M3NmE0ZGVhNTE1ZTk5JTIyJTNFJTNDJTJGZGl2JTNFJTIwJTNDc2NyaXB0JTNFJTIwJTI4ZnVuY3Rpb24lMjhkJTJDJTIwcyUyQyUyMGlkJTI5JTIwJTdCJTIwdmFyJTIwanMlM0IlMjBpZiUyMCUyOGQuZ2V0RWxlbWVudEJ5SWQlMjhpZCUyOSUyOSUyMCU3QnJldHVybiUzQiU3RCUyMGpzJTIwJTNEJTIwZC5jcmVhdGVFbGVtZW50JTI4cyUyOSUzQiUyMGpzLmlkJTIwJTNEJTIwaWQlM0IlMjBqcy5zcmMlMjAlM0QlMjAlMjJodHRwcyUzQSUyRiUyRmVtYmVkc29jaWFsLmNvbSUyRmNkbiUyRmh0LmpzJTIyJTNCJTIwZC5nZXRFbGVtZW50c0J5VGFnTmFtZSUyOCUyMmhlYWQlMjIlMjklNUIwJTVELmFwcGVuZENoaWxkJTI4anMlMjklM0IlMjAlN0QlMjhkb2N1bWVudCUyQyUyMCUyMnNjcmlwdCUyMiUyQyUyMCUyMkVtYmVkU29jaWFsSGFzaHRhZ1NjcmlwdCUyMiUyOSUyOSUzQiUyMCUzQyUyRnNjcmlwdCUzRQ== Read the full article

0 notes

Link

0 notes

Text

Hydrogen Market: Global Industry Analysis and Forecast 2023 – 2030

The Global Hydrogen Market Size Was Valued at USD 225.35 Billion In 2022 And Is Projected to Reach USD 407.93 Billion By 2030, Growing at A CAGR of 7.7% From 2023 To 2030.

Hydrogen plays a vital role in the chemicals and oil & and gas industry. Hydrogen extracted from various processes is classified into three types—blue hydrogen, grey hydrogen, and green hydrogen. Grey hydrogen is hydrogen produced from fossil fuel resources where the carbon capture and storage process are not implemented. Furthermore, this type of hydrogen releases carbon dioxide into the environment as a by-product.

The industry is seeing a lot of growth in the development of environmentally friendly industrial technologies including photobiological processes and photobioreactors, etc. The development of the current hydrogen manufacturing process in a carbon-free manner is also being pursued by several businesses, which is anticipated to accelerate the growth of the hydrogen industry shortly.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart) @

https://introspectivemarketresearch.com/request/16711

The latest research on the Hydrogen market provides a comprehensive overview of the market for the years 2023 to 2030. It gives a comprehensive picture of the global Hydrogen industry, considering all significant industry trends, market dynamics, competitive landscape, and market analysis tools such as Porter's five forces analysis, Industry Value chain analysis, and PESTEL analysis of the Hydrogen market. Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years. The report is designed to help readers find information and make decisions that will help them grow their businesses. The study is written with a specific goal in mind: to give business insights and consultancy to help customers make smart business decisions and achieve long-term success in their particular market areas.

Leading players involved in the Hydrogen Market include:

Oxygen Service Company, Inc. (OSC) (US), Plug Power Inc (US), Quantum Fuel Systems LLC (US), Teledyne Technologies Incorporated (US), Weldship Corporation (US), Worthington Industries (US), Air Products and Chemicals, Inc. (US), BayoTech (US), Chart Industries (US), Chevron Corporation (US), Air Liquide(France), AMS Composite Cylinders (UK)

If You Have Any Query Hydrogen Market Report, Visit:

https://introspectivemarketresearch.com/inquiry/16711

Segmentation of Hydrogen Market:

By Type

Grey

Blue

Green

By Production Source

Natural gas

Coal

Other hydrocarbons

Electrolysis & other sources

By Application

Refineries

Ammonia

Methanol & Other Chemicals

Metals & Fabrication

Electronic Food & Beverage

Glass & Ceramics

Others

By Mode of Delivery

Merchant

Captive

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

What to Expect in Our Report?

(1) A complete section of the Hydrogen market report is dedicated for market dynamics, which include influence factors, market drivers, challenges, opportunities, and trends.

(2) Another broad section of the research study is reserved for regional analysis of the Hydrogen market where important regions and countries are assessed for their growth potential, consumption, market share, and other vital factors indicating their market growth.

(3) Players can use the competitive analysis provided in the report to build new strategies or fine-tune their existing ones to rise above market challenges and increase their share of the Hydrogen market.

(4) The report also discusses competitive situation and trends and sheds light on company expansions and merger and acquisition taking place in the Hydrogen market. Moreover, it brings to light the market concentration rate and market shares of top three and five players.

(5) Readers are provided with findings and conclusion of the research study provided in the Hydrogen Market report.

Our study encompasses major growth determinants and drivers, along with extensive segmentation areas. Through in-depth analysis of supply and sales channels, including upstream and downstream fundamentals, we present a complete market ecosystem.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Acquire This Reports: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16711

About Us:

We are technocratic market research and consulting company that provides comprehensive and data-driven market insights. We hold the expertise in demand analysis and estimation of multidomain industries with encyclopedic competitive and landscape analysis. Also, our in-depth macro-economic analysis gives a bird's eye view of a market to our esteemed client. Our team at Pristine Intelligence focuses on result-oriented methodologies which are based on historic and present data to produce authentic foretelling about the industry. Pristine Intelligence's extensive studies help our clients to make righteous decisions that make a positive impact on their business. Our customer-oriented business model firmly follows satisfactory service through which our brand name is recognized in the market.

Contact Us:

Office No 101, Saudamini Commercial Complex,

Right Bhusari Colony,

Kothrud, Pune,

Maharashtra, India - 411038 (+1) 773 382 1049 +91 - 81800 - 96369

Email: [email protected]

#Hydrogen#Hydrogen Market#Hydrogen Market Size#Hydrogen Market Share#Hydrogen Market Growth#Hydrogen Market Trend#Hydrogen Market segment#Hydrogen Market Opportunity#Hydrogen Market Analysis 2023#US Hydrogen Market#Hydrogen Market Forecast#Hydrogen Industry#Hydrogen Industry Size#china Hydrogen Market#UK Hydrogen Market

0 notes

Text

Insight into the Custom Molding and Extrusion Service Providers in NZ

Did you know that you can take your productivity to the next level with Custom Mouldings and Extrusions services? Yes, that’s true. Several sectors rely on custom extrusions. Whether it’s the manufacturing or production process, extrusion is versatile.

Custom extrusion gained demand and popularity over time. Firms produce customizable products depending on the needs of customers. But, plastic or custom molding isn’t free of challenges.

Whether it’s a standard profile or aluminum molding, challenges come along the way. In general; Fabricators design Complex Molded Products in New Zealand using accurate graphs. A single error might get the entire process ruined.

What is custom extrusion?

Custom extrusion is a process that works with items or raw materials. It can come up with unique Shapes and Designs using a die. It allows them to create an end product. Custom molding and extrusion permit you to work with hollow and solid dimensions. There are several types of plastic extrusion: friction, extrusion, cold and hot.

Hot extrusion allows fabricators to use a die with a ram. Cold extrusion, on the other side, lets you realize a die at room or standard temperature.

Cold molding and extrusion allow you to work with metals as follows:

Aluminum

Lead

Copper

Steel

Tin

Niobium

When the designers cast the materials into forms, the elements heat up to one hundred degrees. This temperature change gets termed as deformation heating.

Friction Custom molding and extrusion let the metal expand in temperature as it contracts. It is fundamental to comprehend this cycle. This adjustment of temperature can change the creation of the crude material.

Benefits touted by Custom Moldings and Extrusions

Custom Mouldings and Extrusions offer a couple of advantages. For instance, fabricators can use Custom Mouldings to make a vast range of intricate items. Dies or shapes utilized for expulsion fabrication are simple to make and create. Custom Extrusion sallows you to design extrusion items using a single pass.

As it utilizes a single pass, expulsion offers a distinctive benefit over rolling metals to design an item. Besides, extrusions exhibit less erosion when contrasted with other processes.

The molding and extrusion process produces clean surfaces that emerge to an incredible extent. The best part of the Custom Molding and Extrusion cycle is that it is dimensional. Likewise, it offers precision. It is prevalent among ventures that need to mass-produce an item in specific proportions.

Things to consider when employing Custom Moldings And Extrusions process

One should focus on the task that should get performed. How will the extruded plastic get used? What are the properties of Complex Molded Products New Zealand? Will the process get conducted in a corrosive environment? Will load-bearing be part of custom molding? Is weight an important factor? Know your requirements and needs from the metal. Only then it becomes easy to choose the metal that is the best fit for your specifications.

With our experience in Custom Mouldings and Extrusions, our firm has overcome even the most complicated design challenges. If you’ve queries related to Moulding Plastic Products New Zealand, contact us today.

#Custom Mouldings and Extrusions#Moulding Plastic Products New Zealand#Complex Molded Products New Zealand

0 notes

Text

Metalworking Fluids Market Size, Share, Trends And Forecast 2030

The global metalworking fluids market size is expected to reach USD 15.1 million by 2030, as per the new report by Grand View Research, Inc., registering a CAGR of 3.8% in the forecast period. The demand is attributed to arise in demand for automotive and industrial machinery. Individual end-use sectors, such as machinery, metal fabrication, and transportation equipment, are driving the expansion of the market.

The market is also expected to be driven by strong development in the machinery and transportation equipment end-use industries over the projected period. Manufacturing is one of the core industries in North America and Europe. Advances in the manufacturing methods for the production of sophisticated end-use products, coupled with the increase in the exports of construction machinery and power, agricultural, and automotive equipment, have fueled the market growth.

The sector is expected to benefit from increased production of construction machines and related parts for industrial, residential, and commercial construction. The rise in public-private partnerships is expected to boost the demand for a variety of construction components that use MWFs during their production. Because of the expanding building activities in these nations, emerging economies are likely to be critical for product growth.

The increasing demand for electricity and upgrading of the existing infrastructure for electricity generation, transmission, and distribution, is anticipated to fuel the market for electrical & power equipment and related components. These components are manufactured using ferrous and non-ferrous metal parts, which consume MWFs during manufacturing.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

Metalworking Fluids Market Report Highlights

Mineral-based MWFs accounted for a revenue share of 48.1% in 2021 due to the increased consumption owing to their low cost

Water cutting oils application is anticipated to grow at the fastest CAGR over the forecast period due to product usage in operations, such as drilling, milling grinding, and mainly in heat dissipation for the proper machining process

The machinery segment dominated the market in 2021 due to the high demand for construction equipment and increased infrastructural development activities

The automobile industry is anticipated to witness a significant CAGR over the forecast period due to the high demand for automobile machinery

The growth of the construction and electrical & power equipment sectors in emerging economies is also expected to drive the product demand

Synthetic and mineral-based products aid in better tool performance, which has led to their high demand

Metalworking Fluids Market Segmentation

Grand View Research has segmented the metalworking fluids market report on the basis of product, application, end-use, industrial end-use, and region:

MWFs Product Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Mineral

Synthetic

Bio-based

MWFs Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Neat Cutting Oils

Water Cutting Oils

Corrosion Preventive Oils

Others

MWFs End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Metal Fabrication

Transportation Equipment

Machinery

Others

MWFs Industrial End-use Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Construction

Electrical & Power

Agriculture

Automobile

Aerospace

Rail

Marine

Telecommunication

Healthcare

MWFs Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

Russia

France

Spain

Italy

U.K.

Switzerland

Denmark

Norway

Belgium

Poland

Czech Republic

Turkey

Sweden

Finland

Asia Pacific

China

India

Japan

South Korea

Singapore

Malaysia

Thailand

Australia

New Zealand

Central & South America

Brazil

Middle East & Africa

List of Key Players in Metalworking Fluids Market

Houghton International, Inc.

Blaser Swisslube AG

BP plc

Exxon Mobil Corp.

Total S.A.

FUCHS

Chevron Corp.

China Petroleum & Chemical Corp.

Kuwait Petroleum Corp.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/metalworking-fluids-market

#Metalworking Fluids Market#Metalworking Fluids Market Size#Metalworking Fluids Market Trends#Metalworking Fluids Market Forecast

0 notes