#stator

Explore tagged Tumblr posts

Text

Part No:- 1T2052 Description:- Stator AS Application Bulldozer:- D6D, D6E, D6G, D6H, D6R, D6T, D7G, D7R . Contact: +91-9999978975 or email - [email protected] https://www.dozerspares.in . Bulldozer Spare Parts | Excavator Spare Parts| Motor Grader Spare Parts | Caterpillar | Komatsu | BEML | Bharat Earth Movers Limited

#HeavyEquipmentParts#dozerspares#earthmover#bulldozerparts#dozerparts#heavymachineryparts#excavatorparts#1T2052#StatorAS#Stator#Pad#dayacharansons#DCPL#dayacharan#dcaspl#spareparts#dozer#bulldozer#cat#caterpillar#beml#PipeLayer#komatsu

0 notes

Text

Rotor blade tooth cutting is a common machining process primarily used for manufacturing rotors in various mechanical devices. Rotor blades are usually made of metal materials, commonly used materials including aluminum alloys, carbon ste

Email:[email protected]

Website: https://www.east-asia-motor.com/

TEl: +8613621756475

Whatsapp: +86 13621756475

how many ohms should a stator have, stepping motor code, shrink fit kit, k industrial co. ltd, how do traction motor work , portable generator rotor/stator resistance tables, wound rotor motor frequency drive, industrial motor installation, high speed motor water pump , 1 rotor rotary engine, zd motor, o motor central não está sendo executado,

1 note

·

View note

Text

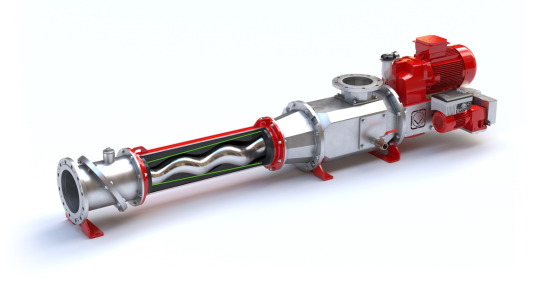

Conical rotor-stator geometry in a progressive cavity pump

At Ifat exhibition in Munich (May 13-17, 2024), the German company Vogelsang GmbH & Co. KG will be showing the conical HiCone progressive cavity pump for use in wastewater treatment plants and pump stations. Additionally, a 3D model of a small, compact version of the HiCone will be on display at booth 347/446 in hall B1. “Wastewater treatment plants that consume large amounts of power in the municipal area owing to their demanding process steps depend on technologies that are both energy efficient and powerful,” says Michael Brinkmann, Director of Global Sales at Vogelsang. He also says: “The HiCone gives wastewater treatment plant operators a durable, highly efficient pumping technology that can be flexibly readjusted to different pumping tasks and operating parameters.”

The HiCone features a conical rotor-stator geometry and a clever adjustment system. Precise readjustment of the rotor compensates for wear. This ensures constant pumping performance at a high level of effectiveness – without costly and time-consuming parts replacement. At the same time, the product has a status display that informs users about the pump’s condition continuously and in real time. The HiCone thus requires maintenance less often, and it can be planned better. If the HiCone is equipped with the automatic adjustment option and connected to remote maintenance, the rotor can be readjusted as needed from the control room – with no time-consuming travel and maintenance. Wastewater treatment plant operators with pumps in remote use benefit from this in particular, at pump stations, for instance, which usually are not monitored by specialists on site. Conical pump for high pressures up to 12 bar The HiCone is also designed for higher pressures of up to 12 bar. For wastewater treatment plant operators, that means the HiCone can even handle process applications with high pressures that usually require a long, two-stage progressive cavity pump. www.vogelsang.info Read the full article

0 notes

Text

The Benefits Of Ordering Custom Stator Rotors Online

When you order custom stator rotors online, you open the door to a range of benefits:

Convenience: Online ordering simplifies the procurement process, saving you time and effort.

Customization: You can tailor the stator rotor to your exact specifications, ensuring it perfectly suits your machinery.

Access to Expertise: Reputable manufacturers have experienced professionals who can provide guidance and recommendations to ensure optimal results.

Top-Quality Performance: Custom stator rotors are crafted with precision and undergo rigorous testing, ensuring top-tier performance.

In Conclusion

Ordering custom stator rotors online is your gateway to achieving machinery that operates at peak efficiency. The customization options available ensure that your stator rotors are perfectly aligned with your machinery’s unique requirements. So, explore the world of custom stator rotor manufacturing, and take the first step towards enhancing your machinery’s performance today. Customize your stator rotors with precision, and see the difference it makes in your operations.

0 notes

Text

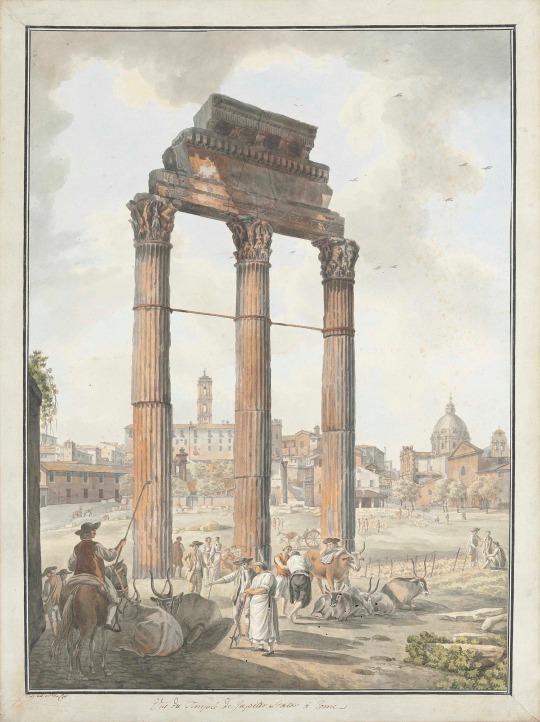

A Student on a ladder measuring a Corinthian order at the Temple of Jupiter Stator in Rome

by Henry Parke (Sir John Soane’s Museum, London.)

#architecture#architect#student#henry parke#john soane#sir john soane#corinthian order#neoclassical#neoclassicism#british#english#art#europe#european#italy#columns#rome#watercolour#roman forum#temple of jupiter stator#temple of castor and pollux#temple#temples#roman#greek#britain#england#ancient greek#ancient greece#ancient rome

254 notes

·

View notes

Text

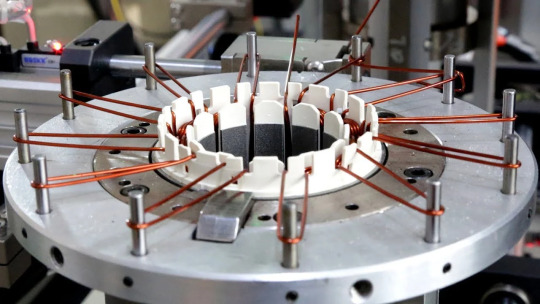

Design and manufacture of axial flux permanent magnet motors

Axial flux motors are extremely high efficiency motors where low form factor is essential. The applications for such stators are in Elevator Traction Motors (Roomless elevator design), Direct Drive Appliance Motors, EV Motor Applications,etc.

YOUYOU has developed a unique technology to manufacture axial flux motor cores.

Diameter range:20mm to 2 meter.

Email: [email protected]

Whatsapp:086-18826897469

Web: https://www.istator.com/axial-flux-stator.html

2 notes

·

View notes

Text

Sparrow Series APM40 KV380 Brushless Motor | High-Efficiency UAV Motor

Discover the Sparrow Series APM40 KV380 Brushless Motor by ePropelled, designed for high-efficiency UAV propulsion. Lightweight, powerful, and optimized for drone applications.

#Brushless Motor#APM40 brushless motor#Sparrow Series APM40#UAV motor#drone propulsion#high-efficiency motor#lightweight brushless motor#electric propulsion#ePropelled UAV motor#430W Drone Motor Replacement#Air Propulsion Motors for Drones#Propellers#APM40 Sparrow Series motor#ePropelled APM40 Sparrow Series motor#frameless stators and rotors#Drone Motor Replacement

0 notes

Text

Stator Winding Process A Comprehensive Guide

One of the most important concepts in electrical engineering is stator winding, which describes the painstaking process of creating coils inside the stator, which is an essential part of electric motors. Electromechanical systems rely heavily on these complex windings to transform electrical energy into mechanical power.

0 notes

Text

Magnetic Stator Assemblies

Magnetic stator assemblies is also a representatives magnetic assembly,consisting of housing and permanent magnet which similar like magnetic rotor assembly. Permanent magnets are mounted on the housing, then housing working as the magnetic yoke to a form a magnetic circuit.

Contact With Us Call Anytime: +86-191 0672 9372 Send Email: [email protected]

0 notes

Text

Temperature Condition for Brushless Motor Magnets

Temperature Condition for Brushless Motor Magnets Brushless motors use permanent magnet as one of their key components. These magnets usually use high-performance permanent magnet materials, such as rare earth neodymium strong magnets, mainly arc-shaped, fan-shaped, wedge-shaped, and rectangular. Today, this article mainly introduces the temperature requirements of brushless (DC) motor…

#AC motors#bonding neodymium iron boron#Brushless motor magnets#DC motors#Embedded Permanent Magnets#Ferrite magnet#high-performance permanent magnet motors#interior permanent magnet motors#IPM motors#magnet working temperature#Magnetic alloy#magnetic field#magnetic fields#magnetic flux density#magnetic forces#magnetic parameters#magnetic properties#Magnetic stators#Magnetic torque#magnetization direction#Magnets Temperature#motor magnets#permanent magnet motors#Permanent Magnets#PM Motors#rotor and stator#SPM motors#surface permanent magnet motors#Surface Permanent Magnets

0 notes

Text

What are the functions of stator core laminations

The stator core laminations play a vital role in the operation of electrical machines, particularly in motors and generators. These laminations are not just an insignificant component but have several key functions that contribute to the overall performance and efficiency of the device.

One of the primary functions of stator core laminations is to reduce eddy current losses. When a magnetic field changes within a solid piece of conducting material, such as a stator core, it induces circulating currents known as eddy currents. These eddy currents result in energy dissipation in the form of heat, which not only wastes energy but can also cause overheating and potential damage to the stator core. By laminating the stator core into thin sheets, the electrical resistance along the direction of the induced currents is increased, effectively minimizing the formation and magnitude of eddy currents. This reduction in energy loss leads to improved efficiency and better heat management within the machine.

Stator core laminations also enhance the magnetic flux path within the stator. The laminations are made of materials with high magnetic permeability, such as silicon steel, which allows for a more concentrated and directed magnetic field. This ensures that the magnetic flux generated by the stator windings interacts optimally with the rotor, maximizing the torque production or electrical output depending on whether it's a motor or a generator. A well-defined and efficient magnetic flux path leads to better performance and more reliable operation of the device.

Another important function is to improve the mechanical strength and stability of the stator core. The individual laminations are stacked and held together, providing a rigid structure that can withstand the mechanical stresses and vibrations during operation. This helps to prevent deformation or damage to the stator core, ensuring its longevity and consistent performance over time.

For example, in large industrial motors that operate continuously under heavy loads, the mechanical integrity provided by the stator core laminations is crucial. Even minor deformations in the core can lead to misalignment of the magnetic fields, increased noise, and reduced efficiency. The laminations act as a reinforcing structure, maintaining the precise alignment and functionality of the stator.

In addition, stator core laminations contribute to reducing magnetic hysteresis losses. Hysteresis occurs when the magnetic material of the stator core undergoes repeated magnetization and demagnetization cycles. The laminated structure helps to minimize the energy expended during these cycles, further enhancing the overall efficiency of the machine.

To illustrate the significance of these functions, consider an electric vehicle motor. The efficient operation of the stator core laminations ensures that the motor delivers maximum power while minimizing energy consumption, extending the driving range of the vehicle. Without the proper design and quality of the laminations, the motor's performance would suffer, resulting in shorter battery life and compromised driving experience.

In conclusion, the functions of stator core laminations are multi-faceted and essential for the optimal performance, efficiency, and reliability of electrical machines. Their role in minimizing eddy current and hysteresis losses, enhancing the magnetic flux path, and providing mechanical stability makes them a critical component in the design and operation of motors and generators in a wide range of applications, from industrial machinery to modern transportation systems.

0 notes

Video

youtube

Customer in Vietnam inspected a 220-ton high-speed press for stamping a ...

#youtube#Customer in Vietnam inspected a 220-ton high-speed press for stamping a stator for a ceiling fan.

0 notes

Text

Ordering Custom Stator Rotors Online

From the last article, now that you understand the significance of custom stator rotors, you might be wondering how to go about ordering them online. Here’s a step-by-step guide:

1. Identify Your Needs: Start by assessing the specific requirements of your machinery. Consider factors like the power output, size, and voltage to determine the exact specifications you need for your custom stator rotor. Youwei welcome any consulting and customization.

2. Consult with Experts: Many manufacturers offer consultation services to help you choose the best custom stator rotor design for your needs. Take advantage of these consultations to ensure you make an informed decision. Youwei has the whole expert team with 20+ years experience to help you achieve what you want!

3. Place Your Order: Once you’re satisfied with the design and specifications, place your order online through our website:https://ywxyouwei.com/contact/

Make sure to provide all necessary details to ensure the production process is accurate.

4. Quality Assurance: Reputable manufacturers will have stringent quality control processes in place. We provide testing and inspection to guarantee the stator rotors meet the highest industry standards.

5. Installation Support: We offer installation support or guidance to ensure your custom stator rotor is seamlessly integrated into your machinery.

Table of Contents

The Benefits of Ordering Custom Stator Rotors Online

In Conclusion

0 notes

Text

View of the Temple of Jupiter Stator in Rome by Abraham-Louis-Rodolphe Ducros and Giovanni Volpato

#abraham louis rodolphe ducros#giovanni volpato#rome#art#temple of jupiter stator#architecture#ruins#marble#columns#antiquity#ancient rome#roman#louis ducros#landscape#city#temple#temples#history#italy#europe#european#cityscape#du cros#romans

129 notes

·

View notes

Text

Torque test of Magnetic Coupling

[email protected] WhatsApp: 0086 15257962734 www.wallymagnet.com

#magnet#permanent magnets#holding magnet#pot magnet#hook magnet#magnetic assembly#magnetic coupling#inner rotor#out stator

0 notes

Text

RWO AEP5 STATOR-5460402EP5, pos 402, New original RWO oily water separator parts

Qty 2pcs

Condition New

Worldwide delivery

also we sale : RWO 2WAY -3WAY VALVES, COALESCER, ADSORBER

AND ORIGINAL PRODUCTS OTHER PARTS ALSO AVAILABLE

we are stockist of all types of marine approved ows parts

IDEAL DIESEL MARINE E-MAIL: [email protected] [email protected] ( cc email) [email protected] ( cc email) City : Bhavnagar 364001 Gujarat INDIA

#IDEAL DIESEL MARINE#pos 402#rwo stator pos 402#rwo stator aep5#AEP5 RWO STATOR#RWO AEP5 STATOR-5460402EP5-POS 402#RWO AEP5 STATOR POS 402- New original RWO oily water SEPARATOR#RWO AEP5 STATOR- -POS 402- New original RWO oily water separator parts#Qty 2pcs#RWO OWS 5.0#RWO OILY WATERSEPARATOR TYPE 5

0 notes