#stainless steel threaded pipe fitting dimensions

Explore tagged Tumblr posts

Text

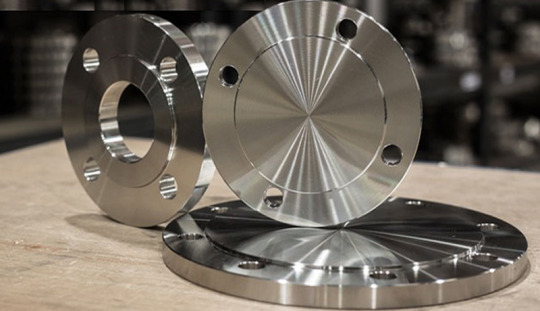

SS 304 Flanges Q&A - Everything You Need to Know

What is an SS 304 flange?

An SS 304 flange is a type of flange made from 304 stainless steel, one of the most widely used and versatile types of stainless steel. It is known for its excellent corrosion resistance, strength, and durability, making it ideal for industrial applications.

What is the SS 304 flange price list?

The SS 304 flange price list varies depending on the size, type, and quantity of the flanges. Udhhyog offers competitive pricing for all types of SS 304 flanges. To view our price list, please visit our SS 304 flange page.

What is a 304 stainless steel flange?

A 304 stainless steel flange is a pipe fitting made from 304 stainless steel. It is commonly used in piping systems for its resistance to rust and corrosion, ensuring longevity in harsh environments.

What is the F304 stainless steel grade?

F304 stainless steel refers to the forged version of 304 stainless steel, often used in the production of high-strength components like flanges. It offers enhanced toughness and resistance to high temperatures.

What is a flange AISI 304?

A flange AISI 304 is a flange made according to the American Iron and Steel Institute (AISI) 304 standard. This designation ensures that the flange meets the chemical composition and mechanical property requirements for 304 stainless steel.

What are SS 304 flange dimensions?

SS 304 flange dimensions vary depending on the type and standard (e.g., ANSI, DIN, JIS). Dimensions include outer diameter, inner diameter, bolt circle diameter, and thickness. For detailed SS 304 flange dimensions, please refer to our product specifications or technical datasheets on our website.

What are the specifications for SS 304 flanges?

The SS 304 flanges specification includes:

Material: 304 stainless steel

Corrosion resistance: Excellent in most industrial environments

Temperature range: -100°C to 800°C

Standards: ANSI, DIN, JIS, etc. For more detailed specifications, visit our product page for SS 304 flanges.

What are the types of SS 304 flanges?

At Udhhyog, we offer various types of SS 304 flanges, including:

SS 304 Slip-On Flanges

SS 304 Weld Neck Flanges

SS 304 Blind Flanges

SS 304 Threaded Flanges

SS 304 Socket Weld Flanges

Who is the best SS 304 flange manufacturer?

Udhhyog is a leading SS 304 flange manufacturer, providing high-quality flanges for a variety of industrial uses. We ensure all our flanges meet international standards for safety and performance.

Where can I find SS 304 flanges at the lowest price?

You can find SS 304 flanges at the lowest price directly at Udhhyog. We offer competitive prices for all types of stainless steel 304 flanges. Visit our SS 304 flange page for more information.

How can I buy SS 304 flanges from Udhhyog?

You can easily buy SS 304 flanges from Udhhyog by visiting our website and selecting the required flange type and size. For bulk orders or inquiries, contact our sales team for personalized assistance.

#SS304Flange#304StainlessSteelFlange#BuySS304Flange#F304StainlessSteel#FlangeAISI304#StainlessSteelFlanges#SSFlangePrice#Udhhyog#FlangeManufacture#IndustrialFlanges#PipeFittings#SteelFlanges#FlangeTypes#StainlessSteelFittings#FlangeSpecifications#FlangesAndFittings

5 notes

·

View notes

Text

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Supplier of Stainless Steel Flanges in Maharashtra

Arisa Impex is a Manufacturer and supplier of Stainless Steel Flanges in Maharashtra. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter, and Supplier of stainless steel products, including stainless steel round bars, wires, rods, sheets, coils, pipes, flat bars, square bars, hexagonal bars, angles, flanges, and alloy steel. Arisa Impex is a leading manufacturer, supplier, and exporter of high-quality stainless steel flanges designed to meet the needs of a variety of industries. We engineer our flanges to provide reliable and durable connections for piping systems, ensuring seamless performance in demanding applications. We commit to excellence and guarantee producing each flange with precision, adhering to stringent quality standards and customer specifications. Types of Flanges: Blind Flange Weld Neck Flange Slip-on Flange Socket Weld Flange Threaded Flange Lap Joint Flange Specifications: Material Standards: ASTM A182 / ASME SA182 Size Range: 1/2" (15 NB) to 48" (1200 NB) Dimensions: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS10, EN-1092, DIN, and other industry standards. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges. Class / Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. Flange Face Types: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ). Stainless Steel Flanges Grades: 304, 304L, 304H, 310, 310S, 310H, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L Flanges are produced in size ranges: ½” to 40" What is the most common type of SS flange used in high-pressure applications? Weld neck flanges are most commonly used for high-pressure applications. Their tapered hub design provides additional reinforcement, making them suitable for high-stress environments. How do I choose the correct size of an SS flange? The size of an SS flange depends on the pipe size, pressure rating, and application requirements. It’s best to refer to relevant industry standards and consult a professional to ensure the right fit. Arisa Impex is a Supplier of Stainless Steel Flanges in Maharashtra including locations like Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#Aurangabad#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#Dhule#Flanges#Gondia#Gujarat#Hinganghat#Ichalkaranji#India#Jalgaon#Jalna#Kalyan-Dombivli#Kolhapur#Latur#Maharashtra#Malegaon#Manufacturer#ManufacturerofStainlessSteelFlanges#Mira-Bhayandar

0 notes

Text

Difference Between Carbon Steel Flanges And Duplex Flanges

Flanges are versatile parts of piping where pipes, valves, and equipment are joined. While carbon steel flanges and duplex stainless steel flanges are quite popular in industries ranging from oil and gas through chemical processing to water treatment, international standards, grades, types, and testing methods applied to carbon steel and duplex flanges.

Carbon Steel Flanges Manufacturers In India produce products of superior quality and up to international standards, including ASME, ANSI, and ISO. A variety of grades like A105, A350 LF2, A182 F11 accommodate the products to specific pressure and temperature requirements. Indian manufacturers are preferred for reliability, durability, and cost-effectiveness using advanced manufacturing techniques combined with rigorous processes for quality control, making them the first choice among the discerning global clients who seek robust piping solutions.

Duplex Flanges Manufacturers In India are superior strength and corrosion resistance. DUPLEX FLANGES India manufactures in various grades, such as UNS S31803 and UNS S32750, under international standards of ASTM, ASME, and ISO. Indian duplex flanges are designed for critical applications in oil and gas, petrochemicals, and marine engineering through state-of-the-art manufacturing processes and rigid quality control procedure

International Standards for Flanges

International Standards about flanges are followed so that the flanges are of certain quality, safety, and interoperability. The most recognized standards are as follows:

ASME

ASME B16.5 : It comprises pipe flanges and flanged fittings for NPS 1/2 to NPS 24.

ASME B16.47: For larger flanges, from NPS 26 to NPS 60.

ASME B31.3: This standard deals with process piping and therefore requires a description of flanged connections.

ANSI (American National Standards Institute)

ANSI/ASME standards often overlap when assuring the flanges are designed in specific pressure classes.

API (American Petroleum Institute)

ISO 7005 Deals with general requirements for pipe flanges and flanged fittings, looking at various materials

EN 1092-1 Deals with specification for metallic flanges, dimensions and pressure ratings

Grades of Carbon Steel and Duplex Flanges

Carbon Steel Flanges

Carbon steel flanges are categorized based on their chemical composition and mechanical properties. There are, for example, several grades of carbon steel as follows:

A105: General-purpose carbon steel for forged flanges, used at ambient and at higher temperature.

A350 LF2: Carbon steel flanges for low-temperature applications when low-temperature conditions arise.

A182 F11/F22: Alloy steel for high-temperature and also high-pressure applications.

Duplex Stainless Steel Flanges

Duplex stainless steel flanges, high-strength corrosion-resistant, mostly come under:

UNS S31803: The most widely available duplex grade: providing a perfect balance of strength and corrosion resistance.

UNS S32205: The superior variant of S31803: superior pitting resistance compared to S31803

UNS S32750 (Super Duplex): Higher strength and corrosion resistance with higher strength compared to S31803; in excellent performance in the presence of chlorides

Flange Types

Flanges differ in various types. Some common are as follows:

Weld Neck Flanges: They can be used in high pressure applications and bear a long neck which takes care of welding to the pipe.

Slip-On Flanges: They are easier in alignment and installation; merely slide onto the pipe to be welded on the place.

Blind Flanges: It is used for closing a piping system. It does not contain any bore.

Socket Weld Flanges: It is used with small-sized pipes, where the pipe is inserted into the flange, which is then welded.

Threaded Flanges: These flanges have the internal threads, and hence screw onto the pipes suitable for low-pressure applications.

Testing Methods for Flanges

Quality assurance is an important element during the production of flanges. Among some common testing methods for them are:

Dimensional inspection of the dimensions of flanges with respect to these standards.

Pressure Test: Pressure test on flanges is tested under a predetermined pressure for tests to ensure the flanges have been designed to withstand operational conditions.

Chemical Analysis: The material composition is checked to meet the required standards.

Understanding the international grades types of testing applicable for carbon steel and duplex flange is important, which could allow it to achieve a piping system with reliability and safety.

#Carbon Steel Flanges Manufacturers In India#Duplex Flanges Manufacturers In India#Rishabh steel industries#Ramesh group

0 notes

Text

Get High Quality Stainless Steel Pipe Nipple From Right Manufacturer in India

Indeed, this new industrial landscape has placed a great importance on stainless steel pipe nipples in almost all areas: plumbing to construction work, from the oil and gas sector and so forth. One of the largest Indian manufacturers for ss pipe nipples, we emphasize quality and innovation as to why we are considered the best business partner for companies in search of solutions for their piping needs.

SS Pipe Nipples What are they?

It is a short piece of pipe having threads on both ends, used to connect two other fittings or pipes. Fittings are extremely essential to any system as it forms a strong, leak-tight connection. The material used in pipe nipple applications holds a prominent position within stainless steel, especially in hostile environments due to their high strength and its corrosion resistance and durability properties.

Why Stainless Steel?

The main difference is excellent corrosion, rusting, and staining resistance. This factor has made it to be applied in many industries. The class of tensile strength can handle the burden of high-pressure and high-temperature conditions; therefore, stainless steel pipe nipples are applicable in pharmaceutical, food processing, and chemical manufacturing among others. Moreover, stainless steel is recyclable; thus, it is very amiable for a sustainable company.

Excellence in Indian Manufacturing

We are Stainless Steel Pipe Nipple Manufacturer in India. Our pipe nipples are made from our own premises with great craftsmanship and high technology. We follow all international standards and certifications and never leave anything behind to fulfill the rigid requirements given by our customers.

We offer wide ranges of pipe nipples in various sizes, dimensions, and grades in stainless steel with grades 304, 316, and duplex grades. We maintain very close follow-ups with our clients to understand what they actually require so that we can offer solutions accordingly based on the requirement.

Quality Assurance and Customer Satisfaction

Quality assurance is the foundation for our production process. Every ss pipe nipple is subject to a test in terms of durability and reliability in performance. Quality assurance gives rise to long-term relations, and we provide excellence in each order.

Conclusion

We are the leading manufacturers of stainless steel pipe nipples in India, enabling us to deliver quality products and services towards success for our customers. This mark of commitment to quality, innovation, and customer satisfaction marks out our difference in this world. From a construction site to a manufacturing site, or whatever it may be, we cater to all of you for piping needs.

0 notes

Text

The Top Reasons to Choose Ananka Group for High-Quality U Bolts

If you're looking for high-quality and reliable U Bolts, Ananka Group is one of the top U Bolts manufacturers in India. With decades of experience as well as cutting-edge technology and a dedication to excellence, Ananka Group ensures that its U Bolts meet the highest industry standards, providing robust and well-engineered solutions for a variety of uses.

What Are U Bolts?

U Bolts are fasteners with a specialization designed to look like letters like "U." Their unique design makes them able to fix poles, pipes as well as any other cylindrical items to a variety of frames or surfaces. They are used extensively in plumbing, construction automotive, marine, and construction applications because of their flexibility and long-lasting nature.

It is the U Bolt is a key component in a wide range of industries where a strong, durable fastening is needed. The curved design provides great strength and support, which makes them a crucial tool for many industries.

An Overview of U Bolts Specifications

In the Ananka Group, U Bolts are manufactured in many dimensions and specifications that satisfy the needs of various industries. Here are a few most commonly used specifications:

Size Variation The U Bolts made by Ananka Group are available in various sizes, from large to small diameters. This means that customers will get the best fit to their specific needs.

Thread types U Bolts are available in a variety of thread types, such as metric and imperial to satisfy the particular requirements of different industries and markets.

Optional Coatings: Ananka Group offers U Bolts with different types of coatings like zinc-plated, galvanized, or stainless steel for enhancing the durability and resistance to corrosion particularly in extreme environments.

Materials & Grades of U Bolts

The strength and endurance that comes from U Bolts are heavily dependent on the type of material employed. Ananka Group manufactures U Bolts with high-quality components, making sure U Bolts that are durable robust, durable, and immune to wear and corrosion. Here are the most frequently utilized materials used for U Bolts:

Carbon Steel: U Bolts made of carbon steel is well known for its strength and durability. They are ideal for use for applications that require high tension force.

The Stainless Steel U Bolts provide excellent resistance to corrosion and are ideal for outdoor and marine applications in which exposure to moisture and chemicals is very high.

Alloy Steel: Alloy steel U Bolts are superior for high-temperature applications. They provide strength and durability in extreme conditions.

Galvanized Steel Galvanized U Bolts are coated with a coating of zinc to stop rust from forming and make them ideal to be used in damp or harsh environments.

Ananka Group offers U Bolts in various grades to satisfy the particular demands for strength and durability of different industries. The grades are:

Grade 4.6

Grade 8.8

Grade A2-70 (stainless steel)

Grade A4-80 (stainless steel)

Applications of U Bolts

U Bolts are commonly employed in industries where high-end fastening is needed. Here are a few typical applications:

Piping Systems: U Bolts are used to keep pipes in place securely to stop them from bouncing or vibrating.

Automotive Industry: U Bolts are used in automobiles for securing leaf springs onto the axles. They provide stability and security.

Construction U Bolts are used in construction structures to hold poles, beams and other building substances.

Marine Industry: Due to their resistance against corrosion stainless steel U Bolts are utilized in vessels, boats and various marine structures.

Why Choose Ananka Group as Your U Bolt Manufacturer?

Finding the top U Bolt manufacturer is crucial to ensure the quality and durability of the bolts used to complete your job. Here are some reasons to consider why Ananka Group is the most suitable choice

Highest Quality: Ananka Group uses only the finest raw materials and imposes strict quality control procedures throughout the manufacturing process to ensure that every U Bolt meets international standards.

custom manufacturing If you require traditional U Bolts or customized solutions, Ananka Group offers flexible manufacturing options to meet your needs.

Price Competitive By using the latest manufacturing techniques, Ananka Group offers high-quality U Bolts at competitive prices without compromising quality.

Speedy Delivery With a solid distribution channel, Ananka Group ensures timely delivery of U Bolts across India and internationally.

expert support with a team of highly skilled professionals, Ananka Group offers excellent customer service, assisting customers to choose the appropriate U Bolts for their applications.

Conclusion

If you are in need of sturdy and reliable U Bolts to suit any purpose you can count on Ananka Group to supply. Being one of the most renowned U Bolts producers in India They offer the widest selection of high-quality U Bolts with different dimensions and materials to meet the various requirements of different industries. No matter if you're in construction or marine or automotive, Ananka Group has the experience and capability to supply you with the highest quality U Bolts in the market.

For more details about Our U Bolts and to place your order, please visit our Ananka Group website today!

When it comes to protecting your projects with stability and strength, selecting the best hardware is essential. Join Ananka Group, where quality meets technology within the realm of U bolts! No matter if you're in construction or manufacturing, or automotive choosing durable and reliable fasteners can make a huge difference. FAQ

What industries benefit from using U Bolts from Ananka Group?

Ananka Group’s U bolts are used in a variety of industries, including construction, automotive, agriculture, and manufacturing. Their high-quality U bolts provide the strength and durability needed for critical applications across these sectors.

What customization options are available for U Bolts?

Ananka Group offers a range of customization options, including different sizes, materials (like stainless steel, carbon steel, galvanized steel), and coatings. They also provide tailored solutions for specific project needs, ensuring that the U bolts meet your exact requirements.

How does Ananka Group ensure the quality of their U Bolts?

Ananka Group follows strict adherence to international quality standards throughout their production process. They use advanced technology for precision manufacturing and conduct thorough testing to ensure every U bolt meets rigorous specifications.

Are Ananka Group’s U Bolts suitable for outdoor or marine applications?

Yes, Ananka Group offers stainless steel and galvanized U bolts that provide excellent corrosion resistance, making them ideal for outdoor and marine environments where exposure to moisture and harsh conditions is common.

How competitive are the prices for U Bolts at Ananka Group?

Ananka Group offers competitive pricing for their high-quality U bolts. Despite their commitment to superior manufacturing and customization, they ensure affordability, making them an excellent choice for businesses operating within tight budgets.

How quickly can I expect my order of U Bolts to be delivered?

Ananka Group prioritizes timely delivery. Thanks to their efficient production processes and dedicated logistics team, they ensure that your U bolts are delivered as per schedule, helping you meet your project timelines without delays.

0 notes

Text

Stainless Steel Flanges Manufacturers in India: The Ultimate Guide for Buyers

India has firmly established itself as one of the leading global suppliers of stainless steel flanges. These essential components are critical in industries such as oil and gas, petrochemicals, power generation, and construction. Stainless steel flanges are not only versatile but also provide corrosion resistance, durability, and reliability in high-pressure and high-temperature environments.

In this comprehensive guide, we will explore the manufacturing landscape of stainless steel flanges in India, highlighting the factors that make Indian manufacturers a preferred choice worldwide. Whether you’re a buyer seeking to source from India or an industry professional looking to deepen your understanding, this guide offers everything you need to know.

Why Choose Stainless Steel Flanges from Riddhi Siddhi Metal Impex?

Indian manufacturers are renowned for their quality, cost-effectiveness, and timely delivery. The country has a well-established stainless steel industry, supported by an abundance of raw materials and advanced production techniques. Indian manufacturers adhere to stringent international standards such as ASME, ASTM, ANSI, DIN, and JIS, ensuring their flanges meet the highest global requirements.

Some key reasons to choose stainless steel flanges from India include:

High-quality raw materials: Indian manufacturers use premium-grade stainless steel, sourced domestically or internationally, to produce durable and corrosion-resistant flanges.

Technological advancements: Indian factories are equipped with state-of-the-art machinery that enables precision engineering and consistent production.

Skilled workforce: The availability of skilled labour, coupled with decades of experience, ensures Indian manufacturers consistently deliver top-notch products.

Competitive pricing: Indian manufacturers offer cost-effective solutions without compromising on quality, making them a highly attractive option for buyers worldwide.

Types of Stainless Steel Flanges Manufactured in India

Indian manufacturers produce a wide variety of stainless steel flanges to cater to different industries and applications. Some of the most common types include:

1. Weld Neck Flanges

Weld neck flanges are designed to transfer stress to the pipe, minimising high-stress concentrations at the base of the flange. These are ideal for high-pressure applications and are commonly used in the oil and gas industry. Indian manufacturers offer weld neck flanges in various sizes, pressure ratings, and materials, ensuring versatility in use.

2. Slip-On Flanges

Slip-on flanges are easy to install and weld, making them a popular choice in lower-pressure systems. These flanges are slipped over the pipe and welded both inside and outside to provide strength. Indian manufacturers offer slip-on flanges in multiple dimensions, with smooth and durable finishes.

3. Blind Flanges

Blind flanges are used to close off the ends of piping systems, providing a strong seal. They are ideal for pressure testing and maintenance purposes. Manufacturers in India produce blind flanges in various diameters and pressure classes, ensuring compatibility with diverse piping systems.

4. Socket Weld Flanges

Socket weld flanges are typically used for smaller pipes in high-pressure systems. The pipe is inserted into the socket and welded, providing a smooth bore that enhances flow. Indian manufacturers produce socket weld flanges with precision machining, ensuring they meet critical application standards.

5. Threaded Flanges

Threaded flanges, also known as screwed flanges, are used in systems where welding is not an option. These flanges are screwed onto the pipe and are suitable for low-pressure applications. Indian manufacturers offer a wide range of threaded flanges with strong threads for secure connections.

6. Lap Joint Flanges

Lap joint flanges are used with stub-end fittings and are ideal for systems requiring frequent disassembly. Indian manufacturers produce lap joint flanges that provide a smooth surface for the gasket to ensure a tight seal.

Stainless Steel Flanges Manufacturers in India: Leading Suppliers of High-Quality Flanges

India has a robust stainless steel flanges manufacturing business that produces high-quality goods for both domestic and international markets. Riddhi Siddhi Metal Impex has become a prominent player in the stainless steel industry, with SS Flanges Manufacturers in India delivering high-quality products to various industries. Stainless steel flanges are critical components in a variety of sectors, including oil and gas production, power generating, and chemical processing. Indian manufacturers are known for their modern production processes, adherence to international standards, and competitive pricing.

The future of stainless steel flange manufacturers in India looks promising, with increasing demand from both domestic and international markets. With a focus on quality, cost-effectiveness, and innovation, Indian manufacturers are expected to maintain their position as global leaders in this sector

India is a major supplier of premium stainless steel flanges, providing a variety of goods for a range of industrial uses. Indian producers are in a strong position to satisfy the demand for stainless steel flanges around the world because of their affordable pricing, adherence to international standards, and dedication to innovation. India's producers are capable of providing weld neck, slip-on, blind, or socket weld flanges, depending on your needs.

The goal of our business has been to provide our customers with high-quality stainless steel flanges and pipe fittings, rather than EIL Approved Pipe Fittings Manufacturer in India & IBR Approved Pipe Fittings Manufacturer in India.

For More Detail

Website: riddhisiddhimetal.com

Product: Stainless Steel Flanges Suppliers in India

Other Product: EIL Approved Pipe Fittings Suppliers in India.

#Stainless Steel Flanges Manufacturer in India#EIL Approved Flanges Manufacturers#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges

0 notes

Text

Pipe End Caps in the Manufacturing Industry: A Crucial Component

Pipe end caps are essential components in manufacturing industries, used to seal or terminate the ends of pipes. These fittings play a vital role in ensuring the integrity and safety of piping systems.

Types of Pipe End Caps Used in Manufacturing

A variety of pipe end caps are employed in manufacturing, including:

Flat end caps: These are the most common type, used to simply seal off the end of a pipe.

Beveled end caps: These have a beveled edge for welding or threading.

Blind end caps: These are used to completely seal off a pipe, often used for storage or testing.

Plug end caps: Similar to blind end caps but with a threaded connection.

Applications of Pipe End Caps in Manufacturing

Pipe end caps are used in numerous applications within manufacturing facilities, such as:

Process Lines: Sealing the ends of pipes that transport materials through the manufacturing process.

Utility Lines: Sealing the ends of pipes used for water, steam, or other utilities.

Wastewater Lines: Sealing the ends of pipes used for handling and transporting wastewater.

Compressed Air Lines: Sealing the ends of pipes used for distributing compressed air.

Hydraulic Lines: Sealing the ends of pipes used for transporting hydraulic fluids.

Benefits of Using Pipe End Caps in Manufacturing

Pipe end caps offer several advantages in manufacturing:

Safety: They prevent leaks and spills, which can pose safety hazards.

Efficiency: They help to maintain system pressure and prevent loss of materials.

Durability: Pipe end caps are designed to withstand the demands of manufacturing environments, ensuring long-term performance.

Versatility: They are available in a wide range of sizes and materials to suit different applications.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including pipe end caps. These fittings are manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company.

Platinex pipe end caps are ideal for the manufacturing industry due to their:

Corrosion resistance: Stainless steel provides excellent resistance to corrosion, making it suitable for various materials and chemicals.

High-temperature resistance: Platinex end caps can withstand high temperatures, making them suitable for processes involving hot materials or fluids.

Precision manufacturing: RMTL ensures precise dimensions and tolerances in Platinex fittings, guaranteeing proper fit and function.

Customizable solutions: Platinex can provide customized end caps to meet specific requirements.

Conclusion

Pipe end caps are essential components in manufacturing industries, playing a vital role in ensuring the safety, efficiency, and reliability of piping systems. Platinex piping solutions offer high-quality stainless steel end caps that are well-suited for the demanding requirements of manufacturing processes. By selecting the appropriate pipe end caps and ensuring proper installation, manufacturers can enhance the performance and longevity of their piping systems.

0 notes

Text

Choosing Between Socket Weld And Threaded Fittings With Their Applications

Selecting the appropriate pipe fittings is crucial in industrial systems, particularly when dealing with high-pressure or corrosive environments. Socket weld and threaded fittings are two commonly used types, each with unique characteristics that make them suitable for specific applications.

What Are Socket Weld and Threaded Fittings Each Good At?

Socket Weld Fittings

Socket weld fittings are engineered for systems that require strong, reliable connections. The process involves inserting the pipe into a socket and applying a fillet weld, which creates a seamless, uniform joint. This method is especially useful in situations where preventing leaks and maintaining strength are crucial. For example, in industries like oil and gas, socket weld fittings are often used because even a small leak could lead to serious problems. Similarly, in high-pressure steam systems, these fittings help ensure that connections stay solid and safe. Standards like ASTM A105 and ASTM A182 ensure that these fittings are tested and manufactured to be reliable and durable.

High Pressure Tolerance: Socket weld fittings are designed to withstand high-pressure environments, often exceeding 2000 psi. The welded joint provides best mechanical strength, making them ideal for high-stress applications.

Corrosion Resistance: The welded connection lowers the risk of corrosion at the joint, which is essential in handling aggressive chemicals or steam.

Thermal Stability: Socket welds maintain their strength under fluctuating temperatures, making them suitable for thermal cycling processes commonly found in petrochemical and power generation industries.

Threaded Fittings

Threaded fittings are easy to assemble and disassemble, making them great for systems that require regular maintenance. These fittings use a helical thread pattern to create a pressure-tight seal between the pipe and fitting. Standards like ANSI B16.11 and ASME B16.5 guide the production of these fittings, ensuring they meet exact specifications for dimensions and performance. These fittings are usually used in systems with lower-pressure systems, where the connection doesn’t need to be as strong. For example, in home plumbing, threaded fittings are common because they allow for quick repairs. In heating, ventilation, and air conditioning (HVAC systems), they are also used because the fittings may need to be adjusted or replaced over time.

Pressure Rating: Threaded fittings are generally used in systems with pressures under 150 psi. They are not recommended for high-pressure applications due to the potential for thread wear and leakage.

Material Versatility: Threaded fittings can be manufactured from a variety of materials, including stainless steel, brass, and PVC, allowing them to be adjusted to specific environmental and chemical conditions.

Ease of Installation: Threaded connections are straightforward to install and do not require special equipment, making them cost-effective for small-scale operations or temporary setups.

Comparing Socket Weld and Threaded Fittings to Make the Right Choice

Socket Weld, Threaded Fittings

1. Joint Reliability

a. Socket weld fittings provide a solid, permanent joint.

b. Offer a less secure connection that is prone to loosen under vibration or thermal expansion.

2. Installation Requirements

a. Requires accurate welding, which often involves skilled labour and quality control measures.

b. Threaded fittings, on the other hand, can be installed with basic hand tools.

3. Hydrodynamic Efficiency

a. Creates a smooth internal surface that reduces turbulence and pressure drop.

b. Creates flow restrictions and potential points for particulate accumulation.

Where Each Fitting Type Works Best

Socket Weld: Commonly used in high-pressure steam lines, oil and gas transmission pipelines, and in chemical processing plants where leak prevention is risky.

Threaded: Often found in potable water systems, HVAC setups, and other low-pressure applications where ease of maintenance and flexibility are priorities.

Strengthen Your Customer Relationships with the Right Fittings

While selecting the right fittings is crucial for performance and safety, it is even more important to ensure that these fittings meet the highest Manufacturing Standards and Types. By understanding the specific needs of your customers, you can ensure they receive the best solutions for their operations. We are committed to providing fittings that not only meet but exceed industry standards, ensuring that your customers’ systems are built to last. Serving businesses across the UAE, Saudi Arabia, Kuwait, Oman, and beyond, we deliver products that your customers can trust.

Explore our catalogue at Online Fittings and partner with us to provide your customers with fittings that meet the highest industry benchmarks.

0 notes

Text

Threaded Flanges Exporters in Mumbai

About The Product

It is similar to a slip-on flange or a socket weld flange, equipped with a tapered thread (screw) in the flange hole and attached to the pipe with a corresponding external thread.

Threaded pipe flanges manufacturers are available in a variety of dimensions, but threaded connections are most often used on small diameter pipelines.

On the other hand, thin-walled pipe systems do not have space for threads and are therefore not compatible.

Grades in Threaded Flanges

Stainless Steel Flanges

Carbon Steel Flanges

Alloy Steel Flanges

Monel Flanges

Inconel Flanges

Hastelloy Flanges

Nickel Alloy Flanges

These are commonly paired with externally threaded pipes, finding applications across industries such as shipbuilding, power generation, petrochemicals, and more. Our threaded flanges boast comprehensive specifications, ranging from 1/2″ to 48″ in size, and adhere to ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, and other standards. Pressure ratings span Class 150 to Class 2500, and PN6 to PN64, offering flexibility for diverse project requirements. With materials including ASTM A105/A105N, A350 LF1/2, ASTM A182 stainless steel grades, and various alloy steels, our threaded flanges ensure reliability and durability in demanding environments.

0 notes

Text

Stainless Steel 316 Flanges Exporters in India

Introduction

Stainless Steel 316 Flanges, renowned for their exceptional resistance to corrosion and high temperatures, are a cornerstone in various industrial applications. These flanges are particularly favored in environments where superior resistance to chlorides and acids is required, making them indispensable in industries such as chemical processing, petrochemical, and marine engineering. At Universe Metal & Alloys, we pride ourselves on being leading Manufacturers, Suppliers, Stockists, and Exporters of top-quality Stainless Steel 316L Flanges, ensuring that our clients receive only the best in durability and performance.

Description

Universe Metal & Alloys specializes in manufacturing stainless steel 316 flanges, designed to meet the rigorous demands of industries such as petrochemical, oil and gas, power generation, and more. Stainless steel 316 is a highly sought-after material due to its superior corrosion resistance, strength, and durability. These flanges are produced using state-of-the-art technology and adhere to stringent international standards to ensure optimal performance and reliability.

The flanges are available in various types, including slip-on, weld neck, blind, socket weld, and threaded, catering to the diverse needs of different applications. Each flange is meticulously crafted to ensure a perfect fit and seal, providing long-lasting and leak-free connections in piping systems.

Benefits

Choosing stainless steel 316 flanges from Universe Metal & Alloys comes with a multitude of benefits:

Excellent Corrosion Resistance: Stainless steel 316 flanges offer superior resistance to corrosion, especially in harsh environments and chemical exposure, ensuring longevity and reliability.

High Strength and Durability: The mechanical properties of stainless steel 316 make these flanges exceptionally strong and durable, capable of withstanding high pressure and temperature conditions.

Versatility: Available in various types and sizes, these flanges can be used in a wide range of applications, from industrial piping systems to specialized equipment.

Hygiene and Cleanliness: The smooth surface finish of stainless steel 316 ensures easy cleaning and maintenance, making these flanges ideal for applications in the food and pharmaceutical industries.

Compliance with Standards: Universe Metal & Alloys ensures that all its products meet international standards and certifications, providing customers with confidence in the quality and safety of their products.

Specification

Stainless Steel 316L Flanges Specification:

Stainless Steel 316 Flange Specification

ASTM A182 / ASME SA182

Stainless Steel 316 Flange Manufacturing Process

Hot Forging / Rolling / Machining

Stainless Steel 316 Flange Other Grades

202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539

Stainless Steel 316 Flange and Flanges Pipe Fittings Outer Diameter

1/2" NB TO 64" NB

Stainless Steel 316 Flange Pressure Class

Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement PN 6, PN 10, PN 16, PN 25 and PN 40 etc

Stainless Steel 316 Flange Schedule

Sch 10s TO Sch XXS or As Per Custom Requirement

Stainless Steel 316 Flange Facing

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Stainless Steel 316 Flange Dimension

ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631--2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc..

Stainless Steel 316 Flange Other Testing

NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc.

Stainless Steel 316 Flange Value Added Services

Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Stainless Steel 316 Flange Packaging

Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps

Stainless Steel 316 Flange Shipment & Transportation

By Road - Truck / Train Partial Load, Full Load, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes

Stainless Steel 316 Flange Material Test Certificate

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of stainless steel 316 flanges in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their products are trusted by industries worldwide for their superior performance, durability, and compliance with stringent standards.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788. Experience the excellence of working with a premier manufacturer of stainless steel 316 flanges.

0 notes

Text

A guide to choosing the right pipe fittings for your project

When embarking on a piping assignment, whether or not it's far for business, business, or residential functions, choosing the right pipe fittings is vital for the success and toughness of the system. Pipe fittings feature the connective tissue of any piping community, ensuring seamless go along with the glide and structural integrity. However, with a myriad of options available within the market, choosing the suitable fittings can be overwhelming.

In this guide, we are capable of delve into the critical aspect factors to maintain in thoughts at the same time as selecting pipe fittings on your challenge, ensuring advanced ordinary normal performance and efficiency.

Understanding Pipe Fittings:

Pipe fittings are additives used to connect, terminate, control flow, or change the path of piping structures. They are available numerous shapes, sizes, and substances to cope with precise packages and environments. Common kinds of pipe fittings encompass elbows, tees, reducers, couplings, valves, and flanges, each serving a selected feature within the piping tool.

Factors to Consider When Selecting Pipe Fittings:

Material:

The preference of fabric for pipe fittings relies upon at the character of the fluid being transported, temperature, pressure, and environmental elements. Common substances embody chrome steel, carbon metal, brass, PVC, and copper. Stainless metallic fittings are wonderful for corrosive environments, on the identical time as PVC fittings are suitable for water and chemical applications.

Size and Dimensions:

Pipe fittings have to be healthful the dimensions and dimensions of the pipes they may be connecting. It's critical to bear in mind factors together such as nominal pipe size (NPS), outdoor diameter (OD), wall thickness, and threading specifications to make certain compatibility and proper fitment.

Pressure Rating:

Different pipe fittings have diverse pressure ratings, indicating their functionality to stand as much as inner pressure without failure. It's essential to pick fittings with a strain score appropriate for the running situations of your device to prevent leaks, bursts, or different screw ups.

End Connections:

Pipe fittings encompass numerous cease connections, together with threaded, socket weld, butt weld, and flanged. The preference of give up connection relies upon the set up method, accessibility, and necessities of the piping device.

Application and Functionality:

Consider the particular application and capability requirements of your project while selecting pipe fittings. Factors which consist of float route, fluid compatibility, temperature range, and environmental conditions need to manual your preference method to ensure highest nice overall performance and reliability.

Codes and Standards Compliance:

Ensure that the pipe fittings you pick observe applicable enterprise necessities and codes, together with ASTM, ANSI, ASME, DIN, and API. Compliance with those requirements guarantees nice, protection, and interoperability of the fittings inner your piping device.

Durability and Longevity:

Invest in notable pipe fittings from actual manufacturers to make certain sturdiness and durability of your piping machine. Quality fittings are much much less vulnerable to corrosion, erosion, and mechanical failure, reducing renovation charges and downtime in the long run.

Choosing the Right Pipe Fittings Manufacturer:

Selecting a dependable and first rate pipe fittings manufacturer is vital to make certain the great, consistency, and universal performance of your piping device. When evaluating producers, bear in mind the subsequent factors:

Experience and Expertise:

Choose a producer with sizable experience and information within the manufacturing of pipe fittings. Look for an enterprise that has an established single document of turning in extraordinary merchandise and solutions to clients across diverse industries.

Product Range and Customization:

Opt for a producer that offers a various range of pipe fittings in exclusive materials, sizes, and configurations to satisfy your assignment requirements. Additionally, inquire about their capability to customize fittings in keeping with your particular desires and specs.

Quality Assurance:

Ensure that the producer adheres to stringent nice manipulation measures and standards for the duration of the manufacturing method. Look for certifications consisting of ISO 9001, API Q1, and ASME accreditation, which reveal a dedication to quality and excellence.

Technical Support and Customer Service:

Choose a producer that provides comprehensive technical assistance, guidance, and assistance in the course of the undertaking lifecycle. A responsive customer support group can cope with any queries, issues, or troubles right away, ensuring an easy and problem-free experience.

Competitive Pricing and Value:

While fee is an essential aspect, prioritize fee over price when selecting a pipe fittings producer. Consider the general great, reliability, and performance of the goods, at the side of competitive pricing and favorable phrases.

Conclusion:

In conclusion, choosing the right pipe fittings for your mission is critical for ensuring the performance, reliability, and longevity of your piping system. By thinking about elements including fabric, length, strain rating, application, and compliance, you can make knowledgeable choices and select fittings that meet your specific necessities.

Additionally, partnering with a reputable manufacturer like Bu-Lok can offer you the right of entry to extraordinary, dependable pipe fittings sponsored by means of sizable experience, information, and customer support. Contact Bu-Lok these days to explore their complete variety of pipe fittings and answers on your undertaking needs.

0 notes

Text

Zeron 100 Flanges Exporters In India

Zeron 100, also known as UNS S32760, is a high-performance super duplex stainless steel. It is widely used in flanges due to its excellent mechanical properties and resistance to corrosion in aggressive environments. Here is some information about exporters of Zeron 100 flanges in India:

Aspirinox Alloys Inc.: They offer a variety of Zeron 100 flanges, including slip-on, weld neck, blind, threaded, socket weld, and reducing flanges. These flanges are available in various pressure classes and dimensions, adhering to standards such as ANSI, ASME, BS, DIN, and EN. Their products are noted for high strength and corrosion resistance, suitable for demanding applications (Aspirinox Alloys Inc).

Amigo Impex: Located in Mumbai, Amigo Impex provides Zeron 100 flanges in types such as weld neck, slip-on, blind, threaded, socket weld, lap joint, long weld neck, and spectacle blind flanges. They follow ASTM and ASME standards and offer these flanges in sizes ranging from 1/8" to 24" NB, with various pressure ratings. The company emphasizes quality and provides custom packaging to ensure safe delivery (Amigo Impex India) (Amigo Impex India).

Rely Metalloys Inc.: This company supplies and exports a comprehensive range of Zeron 100 super duplex steel flanges, including buttweld and forged fittings. They offer these flanges in numerous configurations and sizes, adhering to international standards. Rely Metalloys Inc. highlights the durability and robust design of their flanges, making them suitable for connecting pipes in various industrial applications (Rely Metalloys).

These companies are known for their commitment to quality and customer satisfaction, ensuring that their Zeron 100 flanges meet rigorous industry standards and client specifications.

0 notes

Text

Threaded Equal Tee Exporters in India

INTRODUCTION:- Shasan Piping Solution was founded by a group of many years of experienced specialists in product developing, designing, producing management, and quality control. Our Organisation is ISO 9001:2015. We supply only good quality, traceable inspection, and reliable delivery with excellent customer service.

We are professionals and specialize in manufacturing, stockist, importing, and export of Pipe Fittings, Flanges, Fasteners, Instrumentation Fittings, Hammer Union, Valves, Gaskets, Pipes and Tubes, Sheet, Plates, Coils, Bars & Structural Steel Products as per customer’s projects, drawings, standards, and specifications. The most popular kind of pipe fitting that can be used to combine or divide liquid streams is a threaded tee fitting. The ASTM A182 SS Threaded Tees can be accessed via a female-threaded side outlet and female thread sockets, solvent-weld sockets, or solvent-weld sockets.

Threaded Equal Tees can be used to divert a pipe run, connect pipes of different diameters, or do both. A stock list of forged threaded tees made in various materials, sizes, and wraps is available at Shasan Piping Solution. Additionally, the screwed tee made of alloy steel can also be used to transfer two liquid combinations. Based on their three connections, tees can be classified as equal or unequal in size, with equal tees being the most often produced kind.

DESCRIPTION:- These threaded tee fittings have undergone additional treatments, one of which includes surface treatments, to improve their outer layer. The threaded tee ASME B16.11 is available in several completions. Typical finishes for the outer layer of the threaded tee include electroplating, nickel plating, white coating, dark cast, gold plating, excited finish, and so forth. While these treatments provide an external advantage to the ASME B16.11 threaded tee features, there should occasionally be an opportunity to further enhance its mechanical qualities, such as by boosting its resistance to and tensile strength of erosion.

Most commonly, cast metal or bronze, forged alloy and carbon steel, or cast dark or flexible iron could be used to make threaded screwed tee fittings. Alternatively, alternative materials such as stainless steel, aluminum, nickel, cast iron, bronze, plastic, elastic, copper, metal, polypropylene, etc. might also be used to make the ASTM A182 SS Threaded Tees. There are three tension ratings available for the ASME B16.11 threaded tee fitting aspects: Class 2000, Class 3000, and Class 6000.

Presumably, the earliest technique for connecting pipe systems is represented by the threaded tee fitting characteristics of ASME B16.11. The ASME B16.11 threaded tee fittings, often called little drag pipework, are mostly used for small pipe diameters, much as socket weld fittings. Little drag pipe is typically defined as piping with an apparent diameter of NPS 2 or less.

SPECIFICATIONS:- 1. Specifications- Forged Threaded equal tee 2. Dimension Specification- ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 3. Threaded equal tee Forged Fittings Thread- NPT, BSPT, BSPP 4. Threaded equal tee FittingsType- DN15-DN1200 5. End- Threaded, Welding, JIC 6. Threaded equal tee Fittings Pressure Rating- Threaded end-2000lb/ 3000lb/ 6000lbs Threaded equal tee, Connection, Welding 7. Bending Radius- R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom 8. Threaded equal tee 8. Size Range- 1/8" NB TO 4" NB 9. Manufacturing process- Push, Press, Forge, Cast, etc. 10. Threaded equal tee Test Certificates- EN 10204/3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third Party Inspection Report, etc 11. Origin & Mills - Japanese, Indian, USA, Korean, European, Ukraine, Russian 12. Key markets and industries for Threaded equal tee Fittings- Bitumen upgraders, Heavy oil refineries, Nuclear power (mostly seamless), Petrochemicals and acids. 13. Application - Threaded equal tee To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc.

BENEFITS:- High-Quality Products: Threaded equal tee exporters provide products that meet international standards such as ASME 16.11, MSS SP-79, and BS 3799. This ensures that the tees are of superior quality and suitable for various industrial applications.

Wide Range of Options: Exporters offer a diverse range of threaded equal tees, including different sizes, pressure ratings, and materials. This variety allows customers to find the perfect fit for their specific requirements, enhancing flexibility and compatibility with existing systems.

Ease of Installation: Threaded connections offer ease of installation, allowing for quick and hassle-free assembly of piping systems. Threaded equal tees provide a secure and reliable connection without the need for specialized tools or welding, saving time and labor costs during installation.

Versatility: Threaded equal tees are versatile components that can be used in a wide range of industries and applications, including petroleum, chemical, construction, and shipbuilding. Their ability to connect three pipes of equal diameter at right angles makes them essential for branching and distributing fluid flow in piping systems.

Customization Options: Exporters often offer customization options for threaded equal tees, allowing customers to tailor the fittings to their specific needs. Whether it's a particular size, material, or threading requirement, exporters can accommodate various customization requests to meet customer specifications.

Reliable Supply Chain: Exporters ensure a reliable supply chain, ensuring timely delivery of threaded equal tees to customers worldwide. With a robust manufacturing infrastructure and efficient logistics network, exporters can fulfill orders promptly, minimizing downtime and maximizing operational efficiency for businesses.

CONCLUSION:- In conclusion, threaded equal tee exporters play a crucial role in providing high-quality fittings for industrial piping systems. By offering a wide range of options, ease of installation, versatility, customization capabilities, and a reliable supply chain, exporters empower businesses to optimize their piping systems for enhanced efficiency and performance. Threaded equal tees serve as integral components in various industries, facilitating the distribution and control of fluid flow in piping networks. With a commitment to quality, reliability, and customer satisfaction, threaded equal tee exporters contribute to the success and competitiveness of industries worldwide.

CONTACT US:- Phone :+91-88797-09191 Phone :+91-22-6651 8642 E-mail : [email protected]

#Threaded Equal Tee Manufacturers#Threaded Equal Tee Suppliers#Threaded Equal Tee Stockists#Threaded Equal Tee Exporters#Threaded Equal Tee Manufacturers in India#Threaded Equal Tee Suppliers in India#Threaded Equal Tee Stockists in India

0 notes

Text

Firefighting Pipes Manufacturers

Firefighting pipes are a specialized category of steel pipes used primarily in fire protection systems. They are designed to transport water and other extinguishing agents safely and efficiently to necessary points in a building or structure in case of fire. These pipes are subject to stringent manufacturing standards to ensure their reliability, durability, and resistance to heat and pressure.

Overview of Firefighting Pipe Manufacturing

1. Material Selection: Firefighting pipes are typically made from carbon steel or stainless steel, materials known for their high strength and resistance to heat. The choice of material often depends on the specific requirements of the fire protection system and the environment in which they will be installed.

2. Pipe Forming: Steel coils are uncoiled and flattened. The flat steel is then formed into pipe shapes using a process called Electric Resistance Welding (ERW). In this process, the edges of the steel are fused together using electric current and pressure.

3. Seam Welding: For firefighting pipes, the longitudinal seams are continuously welded to ensure watertight connections and to maintain the structural integrity under high pressure during use.

4. Galvanizing: To protect against rust and corrosion, which are critical in fire protection environments, the pipes are often galvanized. This involves dipping the formed pipes into a bath of molten zinc, creating a robust protective layer on the exterior and interior surfaces.

5. Threading and Grooving: Once the pipes are galvanized, they are threaded, grooved, or plain-ended depending on the connection method used in the installation. Threading and grooving are crucial for the secure attachment of fittings and couplings in fire protection systems.

6. Pressure Testing: To ensure that the pipes can withstand the operational pressures of firefighting systems, they undergo hydrostatic pressure tests. This test checks for leaks and verifies the strength and durability of the pipe.

7. Quality Control: Throughout the manufacturing process, quality control measures are strictly enforced. This includes checks on dimensions, material composition, and coating thickness to ensure that all specifications are met.

Applications of Firefighting Pipes

Fire Sprinkler Systems: These are the most common applications of firefighting pipes, used in residential, commercial, and industrial buildings to deliver water to sprinklers in the event of a fire.

Standpipe Systems: Used in large buildings, standpipe systems allow firefighters to connect hoses directly to a water supply, providing a consistent flow of water to combat fires on multiple floors.

Water Supply Lines: Firefighting pipes are also used in the external water supply lines that connect fire protection systems to public water sources.

Specialized Firefighting Systems: In facilities where standard water-based systems are not suitable, such as in chemical plants or data centers, firefighting pipes may carry other extinguishing agents like foam or gases.

Advantages of Firefighting Pipes

High Durability and Strength: Essential for withstanding the high pressures involved in firefighting applications.

Corrosion Resistance: Galvanizing provides protection against corrosion, crucial for maintaining the integrity and longevity of fire protection systems.

Safety and Reliability: Manufactured to meet strict standards, ensuring that they perform reliably in emergency situations.

Leading Firefighting Pipe Manufacturer: Hi-Tech Fire Pipes

Hi-Tech Fire Pipes is a prominent manufacturer known for producing high-quality firefighting pipes that meet or exceed international safety standards. With advanced manufacturing processes and a commitment to quality, Hi-Tech Fire Pipes ensures that its products provide maximum reliability and performance in fire protection systems. Their extensive range of firefighting pipes is designed to cater to various requirements, making them a trusted choice for builders, architects, and safety engineers worldwide.

More Read: Best Firefighting Pipes

0 notes

Text

Unveiling the Secret: How to Select the Best Flange for Your Project

Metalica Forging Inc. is a leading Flanges Manufacturer in India. A flange is a projecting rim or edge that is commonly utilized for strength, alignment, or connection in engineering and building applications. Flanges are widely utilised in pipeline systems to help with the assembly and disassembly of pipes, valves, and other components.

Flange Supplier in India may seem like simple components in the grand scheme of engineering projects, but their importance cannot be overstated. They serve as crucial connectors, joining pipes, valves, and other equipment in a wide array of industries, from oil and gas to manufacturing and construction. However, choosing the right Flange Suppliers for your project is not always a straightforward task. With numerous types, materials, and specifications available, the selection process can be daunting. But fear not, for in this blog post, we will unveil the secrets to selecting the perfect flange for your specific needs.

Understanding Flanges:

Before diving into the selection process, it's essential to have a basic understanding of what flanges are and how they function. Essentially, a flange is a protruding rim or edge that is used to connect two objects, often by bolting them together. In the context of piping systems, flanges are used to join pipes, valves, fittings, and other components, allowing for easy assembly, disassembly, and maintenance.

Types of Flanges:

Flanges come in various types, each designed for specific applications and requirements. Some common types of flanges include:

Plate Flanges: are flat, circular flanges with bolt holes drilled directly into the flat surface, commonly used in low-pressure applications for connecting pipes, valves, and fittings. They offer a simple and cost-effective solution for joining components in systems where high pressure and temperature are not critical factors.

Slip-On Flanges: These flanges slide over the pipe and are then welded in place. They are relatively easy to install and are suitable for low-pressure applications.

Blind Flanges: As the name suggests, blind flanges are used to seal the end of a pipe or vessel. They are commonly used for pressure testing or when the end of the pipe needs to be closed off.

Socket Weld Flanges: Similar to slip-on flanges, socket weld flanges are welded to the pipe. However, they feature a recessed area (socket) into which the pipe fits, providing additional strength and stability.

Threaded Flanges: These flanges have threaded holes, allowing them to be screwed onto the pipe without the need for welding. They are commonly used in low-pressure, non-critical applications.

Hub Flanges: Hub Flanges can be customised to meet specific customer requirements and come in an assortment of sizes, dimensions, and forms. Being a top manufacturer of hub flanges, we supply them to a broad range of industries, including transportation, paper & pulp, plumbing, food processing and others. We are renowned for the outstanding quality, dependability, and durability of our goods. There are several different kinds of hub flanges that we offer, such as carbon steel, copper nickel, stainless steel, monel, inconel, and more. The International Quality Standards (IQS) are followed in the design and development of hub flanges. In accordance with the needs of the customer, we also provide customised Hub Flanges.

Factors to Consider:

When choosing the perfect flange for your project, several factors should be taken into consideration:

Pressure and Temperature: One of the most critical factors is the pressure and temperature conditions the flange will be subjected to. Different flange materials and designs have varying pressure and temperature ratings, so it's essential to select a flange that can withstand the operating conditions of your system.

Material Compatibility: Flanges are available in a wide range of materials, including carbon steel, stainless steel, and various alloys. The material chosen should be compatible with the fluid being transported and resistant to corrosion, erosion, and other forms of degradation.

Flange Facing and Gasket Material: The flange facing and gasket material play a crucial role in ensuring a reliable seal between flange joints. Factors such as the type of fluid, operating temperature, and pressure should be considered when selecting the appropriate facing and gasket material.

Size and Dimensions: Flanges come in various sizes and dimensions to accommodate different pipe sizes and pressure ratings. It's essential to select a flange that matches the size and specifications of your piping system to ensure proper alignment and functionality.

Consultation and Expertise:

While understanding the basics of flanges is essential, choosing the perfect flange for your project may require consultation with experts in the field. Engineers, manufacturers, and suppliers with experience in flange selection can provide valuable insights and recommendations based on your specific requirements and constraints.

We produce flanges in several Indian cities.

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Ahmedabad

Flange Manufacturer In Surat

Flange Manufacturer In Bhavnagar

Flange Manufacturer In Pune

For More Detail

Website: metalicaforginginc.com

Other Product: JIS Flanges Manufacturer in India.

0 notes