#stainless steel cables

Explore tagged Tumblr posts

Text

Orion Ropes provides top-grade stainless steel cables designed for strength, flexibility, and corrosion resistance. Ideal for various applications, from marine to architectural use, Orion's stainless steel cables offer reliable performance in even the harshest environments.

0 notes

Text

Landscape Retaining Walls in New York

Ideas for a sizable, traditional, fully-shaded backyard with a stone retaining wall in the spring.

0 notes

Photo

New York Retaining Walls Landscape Design ideas for a large traditional full sun backyard stone retaining wall landscape in spring.

#landscape designer#ny#new york#onandoga#aj miller landscape architecture#stainless steel cables#landscape

0 notes

Text

🥇 Elevate your projects with Asia's Leading Stainless Steel Railing Manufacturer, Rinox Engineering! Quality, innovation, and craftsmanship at its finest. Connect with us today! 🚀 #StainlessSteel #NumberOneInAsia #BusinessSolutions #InnovationInMetal

#architecture#business#design#architecture design#aestheitcs#stainless steel#cable railing#glass railing

2 notes

·

View notes

Photo

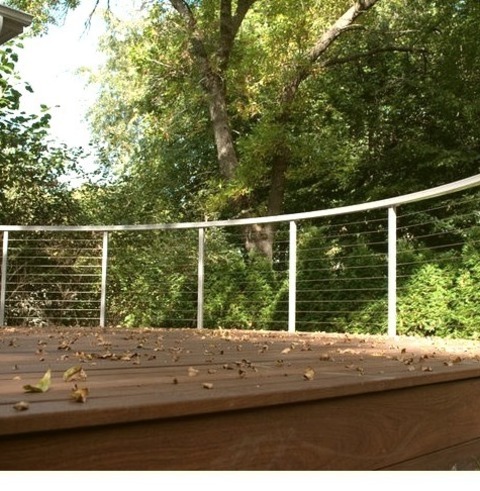

Modern Deck Here is an illustration of a medium-sized minimalist backyard deck.

2 notes

·

View notes

Text

We manufacture a variety of Cable Glands Accessories, including blanking plugs, locknuts, earth tags, entry thread seals, and stopper plugs.

#blanking plugs#adaptors and reducers#stopper plugs#stainless steel locknuts#earth tags#entry thread seals#pvc shrouds#cable glands accessories

1 note

·

View note

Photo

An illustration of a small side yard deck in the mid-century modern style

2 notes

·

View notes

Photo

Uncovered in Milwaukee Mid-sized 1950s backyard dock photo with no cover

#waukesha wi#stainless steel cable railing#wisconsin#decks#cable railing#brookfield wi#waukesha wi cable railing

2 notes

·

View notes

Photo

Lap Orange County Example of a large minimalist backyard concrete and rectangular lap pool fountain design

2 notes

·

View notes

Text

Raceway Cable Tray Manufacturer in Hyderabad

Raceway Cable Tray Manufacturer in Hyderabad – Aparna Rollform

Aparna Rollform is a leading Raceway Cable Tray Manufacturer in Hyderabad, offering high-quality cable management solutions for commercial and industrial applications. Our raceway cable trays are designed to provide a secure, organized, and efficient way to route electrical and communication cables while ensuring safety and durability.

Why Choose Aparna Rollform?

Premium Quality: Manufactured using high-grade steel with corrosion-resistant coatings.

Customizable Solutions: Available in different sizes, thicknesses, and finishes to meet client requirements.

Easy Installation: Designed for quick assembly with minimal effort.

Durability & Strength: Engineered to withstand heavy cable loads and harsh environments.

Industry Compliance: Adheres to national and international safety standards.

Applications

Raceway cable trays are widely used in IT companies, data centers, commercial buildings, manufacturing units, and infrastructure projects to ensure safe and efficient cable management.

At Aparna Rollform, we prioritize innovation, quality, and customer satisfaction, making us the preferred choice for raceway cable trays in Hyderabad.

For inquiries, visit aparnarollform.com.

#Solid Bottom Type Cable Trays#solid bottom cable trays#solid bottom tray#Cable Tray Manufacturer#cable tray manufacturer in Hyderabad#Cable Tray Covers#cable tray cover types#ladder type cable tray with cover#perforated cable tray cover#ladder cable tray cover#perforated cable tray with cover#cable tray manufacturers#cable tray manufacturers in Hyderabad#Raceway Cable Tray Manufacturer in Hyderabad#raceway cable tray#electrical cable tray#cable tray covers#solar module mounting structures#false ceiling sections#stainless steel grating manufacturers#steel reinforcement manufacturers#false ceiling channels types#Types of Ceiling Channels Used In False Ceiling

1 note

·

View note

Text

Say Goodbye to Bird Infestations: Industrial Bird Net Installation in Gurugram by Experts!

As one of the top providers of industrial bird netting in Gurugram Networks Birds Net Solution delivers adaptable bird control solutions to keep industrial and commercial spaces clear of bird disturbances. We operate with superior product and service recognition to create lasting bird netting systems which serve multiple industrial requirements.

We deliver stainless steel bird netting and industrial netting solutions ensuring both premise protection and creation of safe clean hygienic conditions. This extensive manual explains our expert abilities as the leading provider of Gurugram industrial bird net design services.

Top Reasons Industrial Bird Net Installation in Gurugram is a Game-Changer!

Multiple challenges face industrial facilities because they struggle with bird infestations. Industrial equipment faces detrimental consequences from nesting bird populations alongside product contamination and safety concerns when sparrows and pigeons inhabit machinery systems. Installing industrial bird netting in Gurugram ensures:

Protection of Assets: The installation of industrial bird netting stops birds from entering restricted sites which protects both machinery infrastructure and untreated resources along with produced end products.

Enhanced Safety: Birds create obstacles in vents and airways while creating safety risks in the process. Netting solutions prevent such occurrences.

Hygienic Environment: Droppings from birds attack surfaces and introduce health concerns along with surface damage. The solutions we provide guarantee clean environments throughout your facility.

Cost Efficiency: A single purchase of industrial bird netting price in Gurugram will enable businesses to avoid spending money on ongoing cleaning efforts and structural repairs.

Our Expertise in Industrial Bird Netting Installation in Gurugram

Networks Birds Net Solution delivers premium flexible stainless steel cable mesh and other extended-life materials to construct lasting solutions through flexible deployment. Our industrial bird netting manufacturer in Gurugram offers the following benefits:

Customized Solutions: We conduct premises analysis to engineer custom-made netting solutions that integrate perfectly within your building infrastructure.

High-Quality Materials: Stainless steel bird netting from our company demonstrates excellent resistance to corrosion while having outstanding durability for industrial applications.

Expert Installation: Our staff of trained engineers guarantees both safe and quick implementation of bird netting systems.

After-Sales Support: Our maintenance services along with support functions work to preserve the long-term life of your installations.

youtube

Our industrial bird netting solutions in Gurugram offer the following vital characteristics.

1. Durability and Strength

Industrial netting solutions from our company use high-grade stainless steel bird netting and steel bird netting materials because they provide superior strength and durability against harsh conditions. Our nets demonstrate sturdiness in demanding weather circumstances maintaining operational effectiveness throughout several years.

2. Flexibility and Adaptability

The adaptable stainless steel cable mesh frameworks from our system can provide customized protection for any site configurations including hard-to-defend structures and expansive open areas as well as elevated boundaries. Proper protection extends to all sensitive areas which bird interference attempts to target.

3. Eco-Friendly Approach

We maintain a strong dedication to following environmentally friendly practices. Our netting solutions block birds with no negative impact to them while following ethical bird control procedures.

4. Cost-Effective Pricing

We provide industrial bird netting solutions for Gurugram businesses at competitive prices that enable any enterprise to access our high-quality protection systems.

5. Quick Turnaround Time

Our dedicated team and state-of-the-art tools make sure that full installation work progresses with maximum efficiency and causes minimal operational disturbances.

Applications of Industrial Bird Netting in Gurugram

Our industrial bird net installation in Gurugram is suitable for a wide range of industrial and commercial facilities, including:

Warehouses: Your stored items require protection from bird droppings while nesting occurs.

Factories: The netting system prevents birds from accessing production facilities which protects finished products from contamination.

Airports: Aircraft conduct and maintenance operations can run smoothly when birds stay away from vital operation areas.

Parking Lots: The installation of your bird netting system helps businesses protect all open areas from bird nesting activities and ensures safety through cleanliness.

Commercial Complexes: Install discreet netting solutions to create appealing and secure environments for your premises.

Knowledge about stainless steel bird netting matters significantly because of its application potential

Our stainless-steel bird netting is highly sought after due to its superior features:

Corrosion Resistance: This material excels when deployed outdoors within industrial complexes.

High Tensile Strength: The product maintains its strength under heavy weight combined with substantial pressure.

Longevity: Offers a durable solution with minimal maintenance requirements.

Aesthetic Appeal: The solution integrates easily with architectural designs while maintaining visual quality.

Using the following steps anyone can get in contact with the leading bird netting provider operating in Gurugram

Seeking a dependable Gurugram industrial bird netting provider contact number has become an easy process for everyone. Our team at Networks Birds Net Solution remains available to help you with advanced services. The customer-first system at our company allows prompt response to your requests and successful attainment of your requirements.

FAQs About Industrial Bird Net Installation in Gurugram

1. Industrial bird netting in Gurugram comes at what expense?

Regular industrial bird netting costs in Gurugram become established by measuring the area dimensions and material selection together with setup complexity level. Reach out to us right now for a complimentary evaluation of your site and we will provide you with a personalized quote.

2. The process of industrial bird netting setup requires what amount of time?

The duration of installation runs from straightforward to intricate installations depending on how large the area is and how challenging its installation details are. Our implementation team works to maintain rapid installations without affecting business operations.

3. Which offers better protection against bird’s stainless steel bird netting or plastic alternatives?

Stainless steel bird netting succeeds as an excellent choice for industrial applications because it offers enhanced durability alongside extreme strength along with remarkable resistance against environmental stressors.

What Our Customer Says About Us:

"Finding a trustworthy industrial bird netting manufacturer in Gurugram was challenging until we came across Networks Birds Net Solution. Their products are of premium quality, and the pricing was within our budget. The installation team was efficient, and the results were beyond our expectations. Thanks for such an outstanding job!" — Anil Gupta, Operations Head, Gurugram

"We contacted Networks Birds Net Solution for bird net installation at our factory, and the service exceeded our expectations. The team assessed the area, provided a customized solution, and installed the netting within the promised time. We haven’t had any bird-related issues since. I recommend them to anyone looking for reliable industrial bird netting in Gurugram." — Divyanshi Verma, Plant Supervisor, Gurugram

"The team from Networks Birds Net Solution was prompt, professional, and detail-oriented. They installed a flexible stainless steel cable mesh in our industrial unit that not only solved our bird problem but also blended seamlessly with the facility’s aesthetics. Thank you for a job well done!" — Simran Kaur, Logistics Manager, Gurugram

"It’s been over a year since we had industrial bird netting installed by Networks Birds Net Solution, and we couldn’t be happier. The nets are strong, weather-resistant, and have completely eliminated the bird menace from our premises. Exceptional service!" — Vikram Singh, CEO, Manufacturing Unit, Gurugram

Networks Birds Net Solution stands as the most optimal solution for your needs

We have established ourselves as Gurugram's premier industrial bird netting installation provider because of the relentless dedication we demonstrate toward high quality solutions alongside professional workmanship and exceptional customer service. Transaction with our company ensures both protective and clean conditions alongside complete bird management inside your industrial space.

Networks Birds Net Solutions represents your leading choice for dependable industrial bird netting production in Gurugram. Reach out to our team for a free consultation while starting your journey toward securing your industrial facilities.

#Industrial Bird Net Installation in Gurugram#Industrial Bird Netting in Gurugram#Industrial Bird Netting Manufacturer in Gurugram#industrial bird netting price in Gurugram#Gurugram industrial bird netting provider contact number#Industrial Bird Netting Installation in Gurugram#stainless steel bird netting#steel bird netting#industrial netting#industrial net#flexible stainless steel cable mesh#Youtube

0 notes

Text

High-Quality Stainless Steel Cable Railing

https://sightlinesmn.com/products/stainless-steel-cable/ : Streamline your cable railing projects by assessing your needs, choosing durable stainless steel components, and using custom preassembled kits for easy installation and lasting results.

0 notes

Text

How Polishing Stainless Steel Differs from Other Metals

Not all metals are the same, each one of them was different in its quality and textures whereas its refining methods also vary from one another. It is better to polish metals frequently to maintain their shininess and smoothness to use them on a long-term basis. Compared to other metals like Aluminium, Brass, copper, silver etc. stainless steel and its polishing methods is something different. It contains the alloy of nitrogen, carbon, manganese, silicon and nickel that helps to resist erosion and rust. It contains a stable passivation layer to defend it from moisture and air. Here we Gonna discuss how polishing stainless steel differs from other metals.

Read more: https://hicareqatar.com/?blog=how-polishing-stainless-steel-differs-from-other-metals

0 notes

Text

Hot-Dip Galvanized Earthing Flats: Ensuring Safety and Longevity ?

In today’s world, where safety, reliability, and durability are paramount, hot-dip galvanized earthing flats emerge as an indispensable component in ensuring the safety of electrical systems and infrastructure. From industrial setups to residential complexes, these galvanized components are designed to offer optimal performance, corrosion resistance, and an extended lifespan.

What Are Hot-Dip Galvanized Earthing Flats?

Hot-dip galvanized earthing flats, also known as earthing GI strips or earthing patti, are flat steel components coated with a protective layer of zinc through the hot-dip galvanization process. The hot-dip galvanization process ensures that the steel is resistant to environmental factors such as moisture, heat, and chemicals, making it ideal for electrical grounding and earthing systems.

The earthing system plays a critical role in protecting electrical installations by providing a safe path for excess electrical energy to safely drain into the ground. Use of galvanized components such as galvanized beams, galvanized steel beams, and galvanized c channels ensures that these systems are durable and efficient.

Benefits of Hot-Dip Galvanizing for Earthing Flats

The hot-dip galvanization process provides various benefits for earthing flats, including:

1. Corrosion Resistance

One of the most significant advantages of hot-dip galvanizing is its ability to resist corrosion. The zinc coating acts as a barrier, protecting the underlying steel from rust, even in harsh environmental conditions. This ensures the galvanized steel grating and earthing flats maintain their integrity for decades.

2. Cost-Effectiveness

Although the initial investment for hot-dip galvanized products may be more compared to non-galvanized options, reduced maintenance and replacement costs make them a cost-effective solution in the long run.

Steel and zinc have a high recycling rate. Once galvanized iron or steel has served its lifetime, it can be collected, melted, and then reused. This makes such construction projects an eco-friendly method.

3. Safety

Hot-dip galvanized steel has a life expectancy greater than 50 years within any environment, making it fit to be used for integral structural components of stainless-steel cable trays and earthing systems.

Uses of Galvanized Earthing Flats

Galvanized earthing flats are one of the most versatile and commonly utilised products in many industries with wide applications, including:

1. Industrial Plants

Factories and processing plants require reliable earthing systems to protect the machinery and personnel. In addition to earthing flats, there are components such as galvanized c channels and chequered plates that are applied to ensure an all-rounded safety solution.

2. Power Transmission

Power generation and distribution requires reliable earthing systems to avoid faults and guarantee smooth running. Galvanized steel beams and earthing flats are the pillars of these systems.

3. Renewable Energy Systems

Solar farms and wind turbines necessitate efficient grounding systems to protect against lightning or electrical surges. Stainless steel cable trays and galvanized checker plates along with earthing GI strips enhance the durability of these systems.

4. Infrastructure Projects

Large construction projects involving bridges and buildings make use of hot-dip galvanized earthing components for safety and structural stability.

Hot-Dip Galvanized Earthing Flats’ Contribution to Sustainability

Sustainability is one of the growing concerns in modern construction and manufacturing. Hot-dip galvanization is an eco-friendly process that supports sustainable practices in the following ways:

1. Recyclability

Galvanized steel, including chequered plates and earthing strips, is 100% recyclable, which reduces waste and conserves resources.

2. Reduced Maintenance

The long life of galvanized products means less frequent replacement, saving resources and energy in the manufacturing process.

3. Energy Efficiency

Hot-dip galvanized earthing flats reduce the probability of system failures, thus avoiding downtime and saving energy in industrial processes.

Comparison with Other Coating Methods

Hot-dip galvanization is compared to other coating methods, for example, paint or electroplating, on the following grounds:

1. Durable

Paint may only offer a temporary protective covering, but it is not as durable as that of a galvanized zinc coating, especially in demanding environments.

2. Thorough Coverage

The galvanization process ensures full coverage of the steel surface, including corners and edges, which are often missed by other coating methods.

3. Low Maintenance

Unlike paint, which may require frequent touch-ups, the galvanized coating remains intact for decades, offering superior performance with minimal upkeep.

Why Choose Parco Engineers?

At Parco Engineers, we are committed to meeting the highest industry standards, and our hot-dip galvanized products are of good quality. Our product categories include galvanized steel beams, galvanized steel gratings, and checkered plates, all designed for safety, durability, and performance.

1. Galvanization Expertise

With years of experience and expertise, Parco Engineers mastered the art of galvanization, providing good quality products which are long-lasting.

2. Extensive Product Line

From stainless steel cable trays to galvanized c channels, we provide a wide variety of products to suit different applications.

3. Sustainability

Through our practice of sustainable manufacturing, we are contributing to a greener future while still producing top-quality products.

Galvanized earthing flats, a part of the modern system used for safety, efficiency, and durability, are indeed widely used in many other areas like power transmission or renewable energy. Hot-dip galvanized earthing components from Parco Engineers have the right durability and are cost-effective, sustainable products that can serve your purposes. Depend on Parco Engineers for innovative products that would pass the test of time and assure the safety and efficiency of your systems.

#hot-dip galvanized earthing flats#earthing GI strips#galvanized beams#galvanized c channels#galvanized steel grating#hot-dip galvanized#chequered plates#stainless steel cable trays

0 notes

Text

Stainless Steel Bands: The Unsung Heroes of Strength, Durability, and Versatility

When it comes to ensuring the strength, security, and longevity of structures, equipment, and installations, the stainless steel band stands as one of the most reliable and versatile solutions. While often overlooked, stainless steel bands play a crucial role in a wide range of industries and applications—from cable management and construction to automotive and packaging.

In this blog post, we’ll take a deep dive into what stainless steel bands are, their key benefits, common uses, and why they are often the go-to choice for many professionals.

What is a Stainless Steel Band?

A stainless steel band is essentially a strip or band made from stainless steel, a corrosion-resistant alloy primarily composed of iron, chromium, and, in some cases, nickel or molybdenum. These bands are manufactured in a range of widths, thicknesses, and lengths, and can be either flexible or rigid depending on the intended application.

Stainless steel bands are often used for fastening, bundling, or securing items in place. They are highly resistant to corrosion, making them suitable for use in harsh environments where durability and long-term performance are required.

The most common type of stainless steel used in these bands is grade 304 (general-purpose stainless steel), but in more demanding environments, grade 316 (marine-grade stainless steel) might be used for even higher resistance to corrosion, especially in coastal or industrial settings.

Key Benefits of Stainless Steel Bands

1. Exceptional Durability

The standout feature of stainless steel bands is their strength and durability. Stainless steel is inherently resistant to corrosion, rust, and staining, making it the perfect material for use in outdoor, industrial, and marine environments. Whether used in high-temperature conditions, humid spaces, or environments exposed to chemicals or salts, stainless steel bands hold up much better than other materials like plastic, aluminum, or iron.

This durability means stainless steel bands provide long-lasting performance even in harsh environments. They won’t degrade or lose their strength over time, ensuring a reliable and secure connection for years.

2. Corrosion and Weather Resistance

One of the most significant advantages of stainless steel is its corrosion resistance. The chromium content in stainless steel forms a passive layer of oxide on the surface of the metal that protects it from rust and corrosion. This makes stainless steel bands ideal for outdoor and marine applications, as they won’t rust or degrade when exposed to moisture, rain, snow, or salt.

For industries that require continuous exposure to chemicals, oils, or extreme weather conditions—such as agriculture, construction, or marine transportation—stainless steel bands provide peace of mind by maintaining their integrity despite the tough conditions.

3. High Tensile Strength

Stainless steel bands possess excellent tensile strength, meaning they can handle high amounts of stress without breaking or losing their shape. This makes them ideal for applications that require tightness and pressure, such as securing cables, pipes, or heavy equipment in place.

In industries like electrical infrastructure, stainless steel bands are commonly used to secure and bundle power cables, ensuring they stay in place even when subjected to environmental forces like wind, temperature changes, or mechanical stress.

4. Versatility in Use

Stainless steel bands are incredibly versatile and can be used in a wide array of industries and applications. They can be used to secure, fasten, bundle, or attach items to structures. Their versatility extends beyond just mechanical tasks—these bands also have aesthetic appeal in some design and architectural projects, where a sleek, metallic look is desired.

5. Ease of Installation and Adjustment

Stainless steel bands are typically easy to install, and many types come with adjustable tensioning systems or tools, which allow for a snug, secure fit. Depending on the application, you can use manual tools, tensioning tools, or even automated machines to adjust the band for precise fitting.

Once installed, stainless steel bands stay in place without requiring constant adjustments or maintenance. This makes them ideal for securing cables, pipes, or even as part of a larger fastening system.

Common Uses of Stainless Steel Bands

1. Cable Management and Securing

One of the most common applications for stainless steel bands is in cable management. In both residential and commercial settings, stainless steel bands are used to secure and bundle power cables, telecommunications cables, and other types of wiring.

The durability and strength of stainless steel bands prevent cables from sagging, rubbing against surfaces, or getting tangled, ensuring a tidy and organized installation. Stainless steel bands are also used in electrical infrastructure, such as power grids, to secure cables and keep them in place against wind, temperature changes, or mechanical stress.

2. Pipe Securing

In plumbing, construction, and industrial settings, stainless steel bands are frequently used to secure pipes. Whether it’s securing pipes to beams or mounting them to walls, stainless steel bands provide the tensile strength needed to hold pipes in place, even in heavy-duty applications.

Their resistance to corrosion also makes them ideal for use in plumbing systems exposed to moisture, chemicals, or varying temperatures.

3. Automotive and Mechanical Uses

In the automotive and mechanical industries, stainless steel bands are used to fasten components, such as exhaust systems, fuel lines, or hoses, ensuring that all parts remain securely attached and functional over time. The bands can withstand the high heat, vibrations, and pressure found in automotive applications.

In addition, stainless steel bands are used in various machinery and equipment to hold parts together, bundle wires, or attach components to structures, helping maintain the integrity and performance of machines in industries ranging from manufacturing to aerospace.

4. Construction and Engineering

In construction and engineering, stainless steel bands are used for securing heavy equipment, reinforcing structures, and bundling materials. They’re also used in architectural projects, for example, to fasten or secure elements in bridges, buildings, and large infrastructure projects.

For example, stainless steel bands are often used to secure structural components in concrete or steel frameworks, where they can maintain tightness and stability under high stress.

5. Marine and Coastal Applications

In coastal and marine environments, stainless steel bands are essential for keeping equipment, cables, and pipelines secure and resistant to the corrosive effects of saltwater. This includes use in marinas, docks, ships, and offshore oil rigs, where high-strength, corrosion-resistant bands prevent deterioration of cables and structures.

Stainless steel bands are also used to secure sails, rigging, and other critical elements on boats, where strength and durability are paramount for safe operations.

6. Packaging and Bundling

Stainless steel bands are commonly used in industrial packaging to securely bundle products or materials. They can hold heavy packages or pallets tightly together during storage or transportation, ensuring that items don’t shift, move, or get damaged.

This type of packaging is particularly beneficial for goods that will be transported over long distances or that require extra protection from external forces.

How to Choose the Right Stainless Steel Band

When selecting a stainless steel band for a specific application, there are several factors to consider:

Grade of Stainless Steel: Choose a grade based on the level of corrosion resistance you need. For general applications, 304 stainless steel works well, while more demanding environments (marine or highly corrosive environments) may require 316 stainless steel.

Band Width and Thickness: Choose the appropriate width and thickness for the task. A wider, thicker band is necessary for securing heavier items, while a narrower band might be better for lighter-duty applications.

Tensioning Tools: Consider whether you will need tensioning tools to install the band. Some bands come with built-in tensioning systems for easy installation.

Environmental Factors: Think about the environment in which the stainless steel band will be used. High temperatures, exposure to chemicals, or constant moisture could all influence the choice of material and band design.

Stainless steel bands are incredibly versatile, durable, and essential Aerial Cable Connectors components in a wide range of industries and applications. From securing power cables to bundling materials in construction or even managing automotive parts, these bands provide strength, reliability, and corrosion resistance that are hard to beat. Whether you're working in an industrial setting, managing infrastructure projects, or simply organizing cables at home, the stainless steel band is one tool that can ensure long-lasting performance and security. By choosing the right stainless steel band for your needs, you can maximize efficiency, safety, and durability in your projects for years to come.

#Stainless steel band for power cable networks#Stainless steel band#Stainless Steel Band Manufacturer#Aerial Cable Connectors#Underground Cable Connectors#Aerial Cable Connectors Factory#Aerial Cable Connectors Factory China

1 note

·

View note

Text

How to Choose the Right Accessories for Your Wire Mesh Cable Tray Installation by Madewithless

Installing a wire mesh cable tray system is a reliable way to organize and protect your cables. But to ensure it functions at its best, choosing the right accessories is essential. The right accessories can make installation smoother, enhance system durability, and add layers of protection for cables in various environments. Here’s a guide from Madewithless to help you choose the best accessories for your wire mesh cable tray installation.

Wire Mesh Cable Tray

1. Know Your Installation Environment

The environment where the wire mesh cable tray will be installed impacts which accessories you’ll need. Consider:

Corrosive environments (like factories and outdoor installations) where stainless steel accessories or corrosion-resistant finishes may be necessary.

High-temperature areas may require heat-resistant materials.

Moisture-prone areas benefit from galvanized or coated accessories to prevent rusting.

Choosing accessories tailored to your installation environment improves the system's resilience and lifespan.

2. Choosing the Right Support Brackets

Support brackets are essential to keep your wire mesh cable tray securely in place. At Madewithless, we recommend:

Wall-mounted brackets for easy access along walls.

Ceiling-mounted brackets if the cable tray is overhead.

Floor-mounted brackets for raised floors.

By selecting the right support brackets for your setup, you create a stable system that prevents sagging and protects your cables from strain.

Wire Cable Tray

3. Connectors and Splice Plates for Stronger Joints

Splice plates connect tray sections and create smooth transitions:

Straight splice plates join trays in a straight line.

Angle splice plates allow for 90° and other turns.

Look for high-quality plates that reduce vibration and securely link each tray section for a seamless connection, which also minimizes strain on cables.

4. Dropouts for Better Cable Flow

Dropouts are essential accessories that let cables enter and exit trays smoothly. These help to:

Organize cables at entry and exit points.

Reduce wear and tear by preventing sharp bends.

Minimize strain, prolonging cable life.

Properly placed dropouts prevent tangled cables, ensuring easier access when updates or maintenance are needed.

Wire Cable Tray Manufacturer

5. Cover Plates for Added Protection

Cover plates are a must for installations where cables need extra protection from dust, debris, or moisture. They also:

Improve safety by keeping cables covered, reducing risks of accidental contact.

Enhance appearance for professional, finished setups in offices or commercial areas.

Choose cover plates that fit snugly and provide a sturdy shield for your cables.

6. Compatibility and Quality Standards

Make sure all accessories are compatible with your tray system and meet industry standards. Quality accessories:

Fit securely without gaps.

Enhance load-bearing capacity for larger cable bundles.

Comply with safety regulations to ensure reliable performance.

At Madewithless, our accessories are designed to be fully compatible with our wire mesh cable trays, offering customers a high-quality, consistent solution.

SS Wire Cable Tray

7. Easy Installation Accessories

Select accessories that are easy to install, as they save on both time and labor costs. Quick-mount or pre-assembled options can make your project go more smoothly and reduce the chance of installation errors.

Conclusion

Selecting the right accessories for your wire mesh cable tray installation can transform your setup from standard to exceptional. By taking the time to choose support brackets, splice plates, dropouts, and cover plates that fit your environment and installation style, you’ll create a safer, more efficient cable management system. At Madewithless, our high-quality accessories ensure that your wire mesh cable tray installation is built to last, meeting the unique needs of every workspace.

#wire mesh cable tray#stainless steel wire mesh cable tray#wire mesh cable tray manufacturer#wire cable trays

0 notes