#stability chamber manufacturer in india

Explore tagged Tumblr posts

Text

Stability Chamber Supplier in India

Are you looking for Stability Chamber Manufacturer in India? Look no further than Effem Technologies , We are a leading manufacturer, supplier and exporter of Stability Chamber in India.

For more details, please contact us!

#Stability Chamber Manufacturer#Stability Chamber Manufacturers#Stability Chamber Supplier#Stability Chamber Manufacturer in India#Stability Chamber Supplier in India#Stability Chamber Manufacturer in Delhi NCR#Stability Chamber Exporter in India

1 note

·

View note

Text

Stability Chamber Manufacturer in India

Are you looking for Stability Chamber Manufacturer in India, look no further than Ferrotek Equipments. We are a leading manufacturer and supplier of Stability Chamber in India, For more details, please contact us!

#Stability Chamber Manufacturer in India#Stability Chamber Supplier in India#Stability Chamber Manufacturer in Ghaziabad#Stability Chamber Supplier in Ghaziabad#ferrotek equipment

1 note

·

View note

Text

Stability Test Chamber Manufacturer

Yatherm Scientific offers high-quality stability test chambers especially designed for stability testing, drug stability, expiration date testing, package testing & accelerated aging.

0 notes

Text

What is the purpose of Stability Test Chamber?

Stability test chambers are specialized environments designed to mimic real-world conditions such as temperature, humidity, and light exposure, allowing manufacturers to simulate the aging process of their products over time. These chambers provide a controlled setting where researchers can monitor how different factors impact the stability and integrity of their creations.

Understanding Stability Testing

Before delving into the intricacies of stability test chambers, it’s essential to grasp the significance of stability testing itself. This process involves subjecting products to various environmental conditions to evaluate their stability and shelf life. By doing so, manufacturers can assess how factors like temperature fluctuations, humidity levels, and light exposure affect the product’s chemical composition, efficacy, and physical attributes.

The Role of Stability Test Chambers

Stability test chambers serve as the backbone of stability testing, offering precise control over environmental parameters. These chambers come in various sizes and configurations, ranging from small benchtop units to large walk-in chambers, catering to the diverse needs of different industries.

• Controlled Environmental Conditions

One of the primary functions of stability test chambers is to create and maintain specific environmental conditions required for testing. Temperature and humidity control are critical aspects, as slight variations can significantly impact test results. Advanced chambers feature programmable controllers that allow researchers to set precise parameters and replicate real-world conditions accurately.

• Accelerated Aging Studies

In addition to simulating real-time storage conditions, stability test chambers enable accelerated aging studies. By subjecting products to elevated temperatures and humidity levels, researchers can expedite the aging process, obtaining valuable insights into long-term stability in a fraction of the time it would take under normal storage conditions.

• Light Exposure Testing

For products sensitive to light, such as pharmaceuticals and certain chemicals, stability test chambers equipped with light exposure capabilities are indispensable. These chambers simulate different lighting conditions, including UV and fluorescent light, allowing researchers to assess the effects of photodegradation on product quality and stability.

Applications Across Industries

Stability test chambers find applications across a wide range of industries, each with its unique testing requirements.

• Pharmaceuticals

In the pharmaceutical industry, stability testing is mandated by regulatory agencies to ensure the safety, efficacy, and quality of drugs. Stability test chambers play a crucial role in these tests, helping pharmaceutical companies determine the shelf life of their products and identify potential degradation pathways.

• Food and Beverage

For food and beverage manufacturers, maintaining product quality and freshness is paramount. Stability test chambers allow researchers to simulate storage conditions and evaluate the stability of food products over time, ensuring they meet quality standards and regulatory requirements.

• Electronics

Electronics undergo rigorous testing to assess their reliability and performance under various environmental conditions. Stability test chambers provide controlled settings for evaluating the effects of temperature, humidity, and vibration on electronic components, helping manufacturers design more durable and resilient devices.

Conclusion

In an era where product reliability and quality are non-negotiable, stability test chambers emerge as indispensable tools for manufacturers across industries. By providing controlled environments for conducting stability testing, these chambers enable researchers to assess the long-term stability and performance of their products with precision and confidence. As technology advances and regulatory standards evolve, the role of stability test chambers in ensuring product integrity will only continue to grow, driving innovation and fostering consumer trust in the products we rely on every day.

Best Stability Test Chamber Manufacturer in India

If you are looking for a Best Stability Test Chamber Manufacturer and Supplier in India, look no further than Roch Mechatronics INC, We are a leading manufacturer and supplier of Stability Test Chamber in India.

For more details, please contact us!

Website — https://www.rochmechatronics.com/test-chamber/

Contact No. — +91–7011654652

Email — [email protected]

#Stability Test Chamber Manufacturer#Stability Test Chamber Manufacturer in India#Stability Test Chamber supplier#Stability Test Chamber Manufacturer in noida#Stability Test Chamber Manufacturer in Ghaziabad#Best Stability Test Chamber Manufacturer in India#Top Stability Test Chamber Manufacturer Supplier in India#Best Stability Test Chamber Companies in India#Roch Mechatronics

1 note

·

View note

Text

stability chambers manufacturers

#stability chambers#stability chambers manufacturers#stability chambers manufacturers in Mumbai#stability chambers manufacturers in India#Climate Chamber#Climate Chamber manufacturers#Climate Chamber manufacturers in Mumbai#Climate Chamber manufacturers in India#Environmental Test Chamber#Environmental Test Chamber manufacturers#Environmental Test Chamber manufacturers in Mumbai#Environmental Test Chamber manufacturers in India

0 notes

Text

Compressor Oil Market - Forecast(2024 - 2030)

Overview

Sample Report Request :

With rising concerns about energy consumption and environmental impact, there is a heightened focus on developing compressor oils that contribute to energy efficiency and environmental sustainability. Manufacturers are innovating with low-viscosity oils and formulations with reduced frictional losses to optimize compressor performance and minimize energy consumption. Additionally, there is a shift towards eco-friendly compressor oil formulations that comply with environmental regulations and promote sustainable practices in industrial operations.

By Base Oil Type: Synthetic Oils (Polyalkylene Glycols (PAGs), Polyalphaolefins (PAOs), Diester and Polyolesters, Phosphate Esters, Silicone Based), Mineral Oil, and Others

By Compressor Type: Positive Displacement Compressor (Rotary Compressor and Reciprocating), Dynamic Compressor (Centrifugal Compressor and Axial Compressor).

By End-Use Industry: Chemical & Petrochemical, Transportation, Food & Beverages, Oil & Gas, Marine, Pharmaceutical, Metal Fabrication, Mining, Energy, and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, ANZ, Indonesia, Taiwan, Malaysia, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific region dominated the compressor oil market, due to the high consumption of compressor oil in emerging and developing Asian countries such as India, China, Japan, Malaysia, South Korea, and others.

Growing demand for compressor oil as they help to reduce production cost in various end-use industries such as chemical & petrochemical, oil & gas, and others. According to the American Chemistry Council (ACC), in the United States, chemical exports are expected to grow by US$ 134.5 billion in 2021.

Increasing demand for synthetic lubricants as they have various properties such as anti-oxidation, excellent thermal stability, excellent viscosity index, and others is estimated to growing the compressor oil market size.

Compressor Oil Market Segment Analysis — by Type

The synthetic oil segment is projected to witness the highest share of 55% in the compressor oil market in 2023 as it comes with excellent properties such as anti-oxidation and thermal stability. Polyalphaolefins synthetic oil can contribute to an extended service life of machine parts at a low cost. Synthetic oil provides outstanding viscosity index, high flash point, low pour point, and excellent hydrolytic stability, thus it is widely required in air compressors especially vane and screw compressors. Furthermore, synthetic lubricant improves the fuel efficiency of machine parts and reduced operating costs. Hence, the consumption of synthetic base oil is estimated to influence the market for compressor oil

Compressor Oil Market Segment Analysis — By Compressor Type

Positive displacement compressor type segment held the largest share of 56% in the compressor oil market in 2023 as they have excellent operational efficiency. Positive displacement compressors capture the volume of air in a chamber. They help to reduce the volume of the chamber to compress the air. This type of compressor uses vanes instead of helical blades on a rotor to compress air that enters the cavity. Positive displacement compressor uses a piston for air compression that moves backward and forward. A rotary compressor is a very required positive displacement air compressor type. It sucks air into the cylinder, then closes the valve, and compresses the air with two rotors. These rotors rotate regularly and run through the chamber. Compressor oils lower the temperature of the operation during the mixture of air and oil. The maximum output of a rotary compressor is mostly 600 horsepower and 1000 horsepower of the reciprocating compressor. Hence, the growing demand for positive displacement compressors is estimated to grow the consumption of compressor oil.

Schedule A Call:

Compressor Oil Market Segment Analysis — By End-Use Industry

Chemical & petrochemical sector held the largest share in the compressor oil market in 2023 and is growing at a CAGR of 4.6% during this forecast period of 2024–2030, as compressor oil increases the service of machine, reduces operational cost & power consumption during operation. Thus, the increasing chemical & petrochemical industry is estimated to grow the consumption of compressor oil. Apart from this, according to the U.S. Energy Information Administration, the total natural gas production is projected to contribute 30% and more than 75% in Canada & Mexico, respectively by 2040. Hence, all factors are estimated to grow the consumption of compressor oil. The use of compressor oils in the chemical and petrochemicals industry is to guarantee the untroubled functioning of the machine parts and also help in minimizing the expenses and increasing the lifetime of the machine.

By Geography — Segment Analysis

Asia Pacific dominated the compressor oil market in 2023 with a share of more than 45%. China and India are expected to witness high demand for compressor oil during the forecast period, with the growing need from the oil & gas industry, automotive industry, chemical & petrochemical industry, and others. Compressor oils provide different advantages such as reduces energy consumption, reduces operational cost, longer life, corrosion resistance, synthetic solvency, and others. Thus, these lubricants are widely consumed by end-use sectors. According to the U.S. Energy Information Administration, the total natural gas production is projected to contribute more than 40% in China by 2040. As compressor oils are used in power transmission to machines and engines, so the increasing automotive industry is also estimated to grow the consumption of compressor oil. Additionally, according to the Association of Automobile Manufacturers, China has become a world leader in the electric bus segment which grows in production of electric buses at 34% by 2025. Hence, such factors are estimated to grow the demand for compressor oil in the region.

For More Details on This Report — Request for Sample

Drivers — The Compressor Oil Market

Increasing Consumption of Compressor Oil from Automotive Industry

Compressor oil lubricants are used for inflating vehicles, cars, and motorcycle tires. These air compressor oil used to transfer power to the machine and engines. Compressor oil is used in the production cycle of the automotive industry due to its ease of maintenance and reduction in operative costs. Thus, increasing automotive production is estimated to grow the consumption of compressor oil. In 2023, the Australian car market experienced growth despite widely publicized supply issues. A total of 1,081,429 new cars, SUVs, and commercial vehicles were delivered, marking the best result since 2018 when 1,153,111 vehicles were sold. Toyota secured the top spot in annual sales, achieving its best result in 14 years. Mazda followed in second place, while Kia achieved its best-ever result for a third-place finish. Notably, battery electric vehicles accounted for 3.1% of sales, and this trend is expected to continue in 2023 with more affordable models from China entering the market1.

Fast forward to 2023, and the Australian new vehicle market has rebounded significantly in the first half of the year, showing 8.2% growth compared to the same period in 2023. Some interesting developments include, Hence, such factors are expected to grow the compressor oil market size

Growing Demand for Positive Displacement Air Compressor

Buy Now :

Positive air compressors such as rotary compressors and reciprocating compressors are widely used as they require a low cost of production. The positive air compressor has a high-pressure ratio, thus it is widely used in refrigerators, chemical plants, automotive cylinders, and hydraulic cylinders. Reciprocating positive displacement air compressors are designed for the double or single chamber, as they use the piston for the constant movement of air in the chamber. Apart from this, rotary compressor such as screw compressor has safety devices that are fully packaged and pre-installed. Hence, as it reduce the production cost, the demand for positive displacement air compressor is estimated to boost from the chemical industry which, in turn, is expected to grow the compressor oil market size.

Challenges — Compressor Oil Market

Volatility in Raw Material Prices

Synthetic oils are typically created from chemically modified materials such as petroleum components but the base material is always distilled crude oil. Although polyalphaolefin is produced through a synthetic chemical process that originated from ethylene. Ethylene is produced by cracking crude oil. Hence, fluctuation in crude oil prices may hamper market growth. The U.S. Energy Information Administration (EIA) projected that Brent crude oil prices would average $83 per barrel in 2023, down from $101/b in 2022. This decline was mainly due to expectations of global oil production outpacing consumption. Another forecast indicated that the Brent price would stay relatively flat through the second quarter of 2023, averaging $85/b, and then decline through the end of the year.

Compressor Oil Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Compressor Oil Market. Major players in the Compressor Oil Market are Chevron U.S.A. Inc, Croda International Plc, Eurol, Exxon Mobil Corporation, FUCHS, HP Lubricants, LUKOIL Marine Lubricants DMCC, OMSC, Royal Dutch Shell plc, Sasol and among others.

Developments:

In February 2023, Chevron Shipping Company LLC, a subsidiary of Chevron Corporation, announced an agreement with Sembcorp Marine Repairs & Upgrades Pte. Ltd. to install new technologies to support the energy transition goals and lower carbon footprint of Chevron vessels

For More Information about Compressor Oil Market report click here

0 notes

Text

What are Stability Chambers and their uses?

Stability chambers are controlled environments used to test the durability and shelf life of products, typically in industries like pharmaceuticals, food, and cosmetics. They simulate different conditions of temperature, humidity, and light exposure to determine how materials or products respond over time. Microsil India, a leading suction apparatus manufacturer, delivers high-quality medical suction devices. Their innovative technology ensures reliable performance, catering to hospitals, clinics, and healthcare professionals for efficient patient care.

0 notes

Text

Inconel 600 Flanges

In the realm of industrial engineering, materials that can withstand extreme conditions while maintaining structural integrity are invaluable. Among these, Inconel 600 stands out as a superalloy renowned for its exceptional properties, making it a prime choice for critical components like flanges in various industries.

Understanding Inconel 600

Inconel 600 is a nickel-chromium alloy known for its high strength and resistance to corrosion, oxidation, and high temperatures. These properties stem from its composition, which includes approximately 72% nickel, 14% chromium, and smaller amounts of iron, making it highly durable and suitable for demanding environments.

Unique Properties of Inconel 600 Flanges

1. Corrosion Resistance: Inconel 600 flanges exhibit outstanding resistance to corrosion in both reducing and oxidizing environments. This makes them ideal for applications involving acids, alkalis, and salt solutions, where other materials might corrode over time.

2. High Temperature Stability: One of the most notable characteristics of Inconel 600 is its ability to maintain strength and structural integrity at high temperatures. Flanges made from this alloy can withstand temperatures ranging from cryogenic levels up to 2000°F (1093°C), making them suitable for use in heat exchangers, furnace components, and jet engine parts.

3. Oxidation Resistance: Inconel 600 flanges form a dense oxide layer when exposed to high temperatures, which enhances their resistance to oxidation. This property ensures longevity and reliability in applications where prolonged exposure to heat and oxygen is expected.

4. Mechanical Strength: The alloy's combination of nickel and chromium provides excellent mechanical strength and toughness, allowing Inconel 600 flanges to withstand high pressures and mechanical stresses without deformation or failure.

5. Weldability: Despite its robust nature, Inconel 600 maintains good weldability, allowing for easy fabrication and assembly of flanges into complex structures. This enhances its versatility in manufacturing processes.

Applications of Inconel 600 Flanges

The unique properties of Inconel 600 make it indispensable in various industries:

Chemical Processing: Used in reactors, piping systems, and valves where resistance to corrosive chemicals is crucial.

Aerospace and Defense: Employed in gas turbine components, jet engine exhaust systems, and rocket engine thrust chambers due to its high temperature capabilities.

Heat Treatment Industry: Utilized in furnace components and radiant tubes where oxidation resistance and thermal stability are paramount.

Nuclear Power: Found in reactor core components due to its resistance to nuclear radiation and high-temperature environments.

Technolloy Inc. is one of the most Manufacturers, Exporters & Stockists of Inconel 600 Flanges in India. These flanges are in peril from pushing, breaking in hot water, and consuming alkalies. These UNS N06600 flanges have an obliging explanation: they dry out HCl and Cl2 gases at sensibly raised temperatures. Inconel 600 Flanges is a nickel-base thing in the sense of having stunning carburization and hosing oxidation hindrance at raised temperatures.

1 note

·

View note

Text

Test Chambers Manufacturer in India

Elevate your testing capabilities to new heights with our cutting-edge Test Chambers, designed to meet the diverse needs of industries ranging from pharmaceuticals to electronics. Our Test Chambers offer precise and controlled environments for conducting a wide range of tests, ensuring the reliability, safety, and quality of products and materials. With advanced temperature, humidity, and pressure control systems, our Test Chambers provide unparalleled accuracy and consistency, enabling manufacturers to simulate real-world conditions with precision. Whether it's testing the durability of electronics, evaluating the stability of pharmaceutical formulations, or assessing the performance of automotive components, our chambers deliver reliable results that meet regulatory standards and industry requirements. Our Test Chambers are engineered for versatility, offering customizable configurations to accommodate various test parameters and sample sizes. From small bench top chambers to large walk-in chambers, we have solutions to suit every testing need. Additionally, our chambers feature user-friendly interfaces and intuitive controls, making them easy to operate and monitor, even for novice users.

For more details clicks here - https://www.indiantradebird.com/product/test-chambers

0 notes

Text

0 notes

Text

Stability Chamber Manufacturer

Are you looking for Stability Chamber Manufacturer in India? Look no further than Effem Technologies, We are a leading manufacturer and supplier of Stability Chamber in India. For more in info please contact us!

#stability chamber#effem technologies#stability test chamber manufacturer in india#stability test chamber manufacturer in ghaziabad

1 note

·

View note

Text

Stability Test Chambers: Everything You Need to Know

Ferrotek Equipments is a leading manufacturer and supplier of high-quality stability chambers in India, specializing in advanced environmental control solutions for diverse industries. Their stability chambers are designed to provide precise temperature and humidity control, essential for testing and maintaining the stability of pharmaceuticals, chemicals, and other sensitive products.

With a focus on reliability and accuracy, Ferrotek Equipments employs cutting-edge technology and robust materials to ensure optimal performance and durability. Their stability chambers feature user-friendly interfaces, programmable controls, and consistent environmental conditions to meet stringent regulatory standards. Committed to excellence and customer satisfaction, Ferrotek Equipments offers tailored solutions and comprehensive support to address specific testing requirements, making them a trusted partner in ensuring product integrity and compliance across various sectors.

For more details, please contact us!

Website :- https://www.ferrotekequipments.com/

Contact No. :- +91–9811576010

Email :- [email protected]

0 notes

Text

Dual Chamber Glass Cartridges are essential for ensuring the stability and separation of sensitive medications. We provide these high-quality cartridges, which are ideal for pharmaceuticals requiring compartmentalization. As India’s leading manufacturer and exporter of high-quality glass ampoules, tubular vials, Insulin & dental cartridges, perfume samplers, and laboratory test tubes, we guarantee superior performance and reliability. Our Dual Chamber Glass Cartridges are meticulously crafted to meet the highest industry standards, ensuring that your products are stored safely and effectively. Trust Kapoor Glass for all your specialized glass container needs.

0 notes

Text

Everything You Need To Know About Lab Test Chamber In India?

Roch Mechatronics Inc. is a leading manufacturer and supplier of high-quality Test Chambers in India, renowned for its precision engineering and advanced technology. Specializing in environmental test chambers, Roch Mechatronics provides solutions that cater to various industries such as automotive, electronics, pharmaceuticals, and aerospace. These chambers simulate a wide range of environmental conditions, including temperature, humidity, and vibration, enabling rigorous testing of products and materials.

Product Range:

Roch Mechatronics offers a diverse selection of test chambers, including temperature and humidity chambers, thermal shock chambers, and stability chambers. Each product is designed to meet specific testing needs, whether it is for quality control, product development, or research purposes. The chambers are equipped with state-of-the-art control systems that ensure accurate and repeatable results, making them ideal for high-stakes testing environments.

Features and Benefits:

These test chambers are built with robust construction, ensuring durability and long-lasting performance. They feature user-friendly interfaces with digital control panels for easy monitoring and precise adjustments of test parameters. Energy-efficient designs help reduce operational costs, while built-in safety features protect both the user and the test materials. Roch Mechatronics also provides customization options to tailor the chambers to specific testing requirements, ensuring maximum flexibility.

Quality and Compliance:

All products from Roch Mechatronics are manufactured in compliance with international standards, ensuring reliability and accuracy. The company is committed to quality assurance and continuous improvement, delivering solutions that meet the highest standards of performance and safety.

With its strong commitment to innovation and customer satisfaction, Roch Mechatronics Inc. is a trusted partner for industries across India, delivering top-tier test chambers for all your testing needs.

For more details, please contact us!

Website :- /https://www.rochmechatronics.com/

Contact No. :- +91–7011654652

Email :- [email protected]

0 notes

Text

Walk in Stability Chambers suppliers

#Walk-In Stability Chamber#Walk-In Stability Chamber manufacturers#Walk-In Stability Chamber manufacturers in Mumbai#Walk-In Stability Chamber manufacturers in India#walk in stability chamber manufacturers#walk in stability chamber manufacturers in mumbai#walk in stability chamber manufacturers in India#Walk In Humidity Chamber#Walk In Humidity Chamber Manufacturers#walk In Humidity Chamber Manufacturers in Mumbai#Walk In Humidity Chamber Manufacturers in India#Photo Stability Chamber with Temperature and Humidity Control#Walk In Environmental Chamber#Walk In Environmental Chamber manufacturers#Walk In Environmental Chamber manufacturers in Mumbai#Walk In Environmental Chamber manufacturers India#walk in stability chamber exporters in Algeria

0 notes

Text

Compressor Oil Market - Forecast(2024 - 2030)

Overview

Compressor Oil Market size $9.5 billion in 2023, and the total revenue is expected to grow at a CAGR of 6.6% through 2024 to 2030, reaching nearly $ 21.19 Billion. It Compressor oil offers various properties such as viscosity, chemical stability, dielectric strength & moisture, and others which are expected to grow the demand from end-use industries. These oils are used for lubrication, removal of heat, and for sealing.

Sample Request :

Manufacturers are increasingly developing advanced synthetic formulations to meet the evolving requirements of modern compressors, driving the uptake of synthetic compressor oils in various industrial applications. With rising concerns about energy consumption and environmental impact, there is a heightened focus on developing compressor oils that contribute to energy efficiency and environmental sustainability. Manufacturers are innovating with low-viscosity oils and formulations with reduced frictional losses to optimize compressor performance and minimize energy consumption. Additionally, there is a shift towards eco-friendly compressor oil formulations that comply with environmental regulations and promote sustainable practices in industrial operations.

Inquiry Before Buying :

By Base Oil Type: Synthetic Oils (Polyalkylene Glycols (PAGs), Polyalphaolefins (PAOs), Diester and Polyolesters, Phosphate Esters, Silicone Based), Mineral Oil, and Others

By Compressor Type: Positive Displacement Compressor (Rotary Compressor and Reciprocating), Dynamic Compressor (Centrifugal Compressor and Axial Compressor).

By End-Use Industry: Chemical & Petrochemical, Transportation, Food & Beverages, Oil & Gas, Marine, Pharmaceutical, Metal Fabrication, Mining, Energy, and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, ANZ, Indonesia, Taiwan, Malaysia, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

Asia-Pacific region dominated the compressor oil market, due to the high consumption of compressor oil in emerging and developing Asian countries such as India, China, Japan, Malaysia, South Korea, and others.

Growing demand for compressor oil as they help to reduce production cost in various end-use industries such as chemical & petrochemical, oil & gas, and others. According to the American Chemistry Council (ACC), in the United States, chemical exports are expected to grow by US$ 134.5 billion in 2021.

Increasing demand for synthetic lubricants as they have various properties such as anti-oxidation, excellent thermal stability, excellent viscosity index, and others is estimated to growing the compressor oil market size.

Schedule a Call:

Compressor Oil Market Segment Analysis — by Type

The synthetic oil segment is projected to witness the highest share of 55% in the compressor oil market in 2023 as it comes with excellent properties such as anti-oxidation and thermal stability. Polyalphaolefins synthetic oil can contribute to an extended service life of machine parts at a low cost. Synthetic oil provides outstanding viscosity index, high flash point, low pour point, and excellent hydrolytic stability, thus it is widely required in air compressors especially vane and screw compressors. Furthermore, synthetic lubricant improves the fuel efficiency of machine parts and reduced operating costs. Hence, the consumption of synthetic base oil is estimated to influence the market for compressor oil

Compressor Oil Market Segment Analysis — By Compressor Type

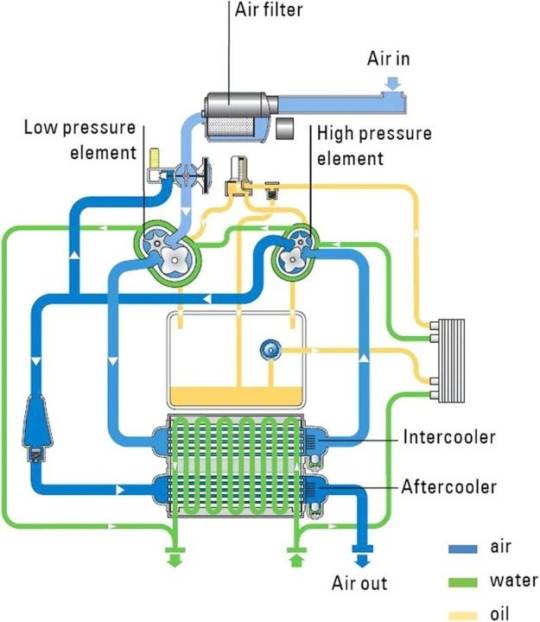

Positive displacement compressor type segment held the largest share of 56% in the compressor oil market in 2023 as they have excellent operational efficiency. Positive displacement compressors capture the volume of air in a chamber. They help to reduce the volume of the chamber to compress the air. This type of compressor uses vanes instead of helical blades on a rotor to compress air that enters the cavity. Positive displacement compressor uses a piston for air compression that moves backward and forward. A rotary compressor is a very required positive displacement air compressor type. It sucks air into the cylinder, then closes the valve, and compresses the air with two rotors. These rotors rotate regularly and run through the chamber. Compressor oils lower the temperature of the operation during the mixture of air and oil. The maximum output of a rotary compressor is mostly 600 horsepower and 1000 horsepower of the reciprocating compressor. Hence, the growing demand for positive displacement compressors is estimated to grow the consumption of compressor oil.

Compressor Oil Market Segment Analysis — By End-Use Industry

Chemical & petrochemical sector held the largest share in the compressor oil market in 2023 and is growing at a CAGR of 4.6% during this forecast period of 2024–2030, as compressor oil increases the service of machine, reduces operational cost & power consumption during operation. Thus, the increasing chemical & petrochemical industry is estimated to grow the consumption of compressor oil. Apart from this, according to the U.S. Energy Information Administration, the total natural gas production is projected to contribute 30% and more than 75% in Canada & Mexico, respectively by 2040. Hence, all factors are estimated to grow the consumption of compressor oil. The use of compressor oils in the chemical and petrochemicals industry is to guarantee the untroubled functioning of the machine parts and also help in minimizing the expenses and increasing the lifetime of the machine.

Buy Now:

By Geography — Segment Analysis

Asia Pacific dominated the compressor oil market in 2023 with a share of more than 45%. China and India are expected to witness high demand for compressor oil during the forecast period, with the growing need from the oil & gas industry, automotive industry, chemical & petrochemical industry, and others. Compressor oils provide different advantages such as reduces energy consumption, reduces operational cost, longer life, corrosion resistance, synthetic solvency, and others. Thus, these lubricants are widely consumed by end-use sectors. According to the U.S. Energy Information Administration, the total natural gas production is projected to contribute more than 40% in China by 2040. As compressor oils are used in power transmission to machines and engines, so the increasing automotive industry is also estimated to grow the consumption of compressor oil. Additionally, according to the Association of Automobile Manufacturers, China has become a world leader in the electric bus segment which grows in production of electric buses at 34% by 2025. Hence, such factors are estimated to grow the demand for compressor oil in the region.

For More Details on This Report — Request for Sample

Drivers — The Compressor Oil Market

Increasing Consumption of Compressor Oil from Automotive Industry

Compressor oil lubricants are used for inflating vehicles, cars, and motorcycle tires. These air compressor oil used to transfer power to the machine and engines. Compressor oil is used in the production cycle of the automotive industry due to its ease of maintenance and reduction in operative costs. Thus, increasing automotive production is estimated to grow the consumption of compressor oil. In 2023, the Australian car market experienced growth despite widely publicized supply issues. A total of 1,081,429 new cars, SUVs, and commercial vehicles were delivered, marking the best result since 2018 when 1,153,111 vehicles were sold. Toyota secured the top spot in annual sales, achieving its best result in 14 years. Mazda followed in second place, while Kia achieved its best-ever result for a third-place finish. Notably, battery electric vehicles accounted for 3.1% of sales, and this trend is expected to continue in 2023 with more affordable models from China entering the market1.

Fast forward to 2023, and the Australian new vehicle market has rebounded significantly in the first half of the year, showing 8.2% growth compared to the same period in 2023. Some interesting developments include, Hence, such factors are expected to grow the compressor oil market size

Growing Demand for Positive Displacement Air Compressor

Positive air compressors such as rotary compressors and reciprocating compressors are widely used as they require a low cost of production. The positive air compressor has a high-pressure ratio, thus it is widely used in refrigerators, chemical plants, automotive cylinders, and hydraulic cylinders. Reciprocating positive displacement air compressors are designed for the double or single chamber, as they use the piston for the constant movement of air in the chamber. Apart from this, rotary compressor such as screw compressor has safety devices that are fully packaged and pre-installed. Hence, as it reduce the production cost, the demand for positive displacement air compressor is estimated to boost from the chemical industry which, in turn, is expected to grow the compressor oil market size.

Challenges — Compressor Oil Market

Volatility in Raw Material Prices

Synthetic oils are typically created from chemically modified materials such as petroleum components but the base material is always distilled crude oil. Although polyalphaolefin is produced through a synthetic chemical process that originated from ethylene. Ethylene is produced by cracking crude oil. Hence, fluctuation in crude oil prices may hamper market growth. The U.S. Energy Information Administration (EIA) projected that Brent crude oil prices would average $83 per barrel in 2023, down from $101/b in 2022. This decline was mainly due to expectations of global oil production outpacing consumption. Another forecast indicated that the Brent price would stay relatively flat through the second quarter of 2023, averaging $85/b, and then decline through the end of the year.

Compressor Oil Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Compressor Oil Market. Major players in the Compressor Oil Market are Chevron U.S.A. Inc, Croda International Plc, Eurol, Exxon Mobil Corporation, FUCHS, HP Lubricants, LUKOIL Marine Lubricants DMCC, OMSC, Royal Dutch Shell plc, Sasol and among others.

Developments:

In February 2023, Chevron Shipping Company LLC, a subsidiary of Chevron Corporation, announced an agreement with Sembcorp Marine Repairs & Upgrades Pte. Ltd. to install new technologies to support the energy transition goals and lower carbon footprint of Chevron vessels

For More Information about Compressor Oil Market click here

0 notes