#Stability Chamber Manufacturer

Explore tagged Tumblr posts

Text

Environmental Chamber Manufacturer

#Stability Chamber#Stability Chamber Manufacturer#Environmental Test Chamber#Humidity Chambers#Humidity Chambers Manufacturers#Walk In stability Chamber#Walk in Chamber#BOD Incubators#Walk-In Incubators#Humidity Oven#Humidity Oven manufacturer#Laboratory Oven#Bacteriological Incubator#vacuum ovens#Autoclave Laboratory Vertical#Ultra Low Deep Freezer manufacturer#Walk-In Cooling Chambers#Walk-In Incubator Chambers#Rotary Shaker#Rotary Shaker Manufacturer#Blood Bank Refrigerator#Blood Bank Refrigerator manufacturer

0 notes

Text

Stability Chamber Supplier in India

Are you looking for Stability Chamber Manufacturer in India? Look no further than Effem Technologies , We are a leading manufacturer, supplier and exporter of Stability Chamber in India.

For more details, please contact us!

#Stability Chamber Manufacturer#Stability Chamber Manufacturers#Stability Chamber Supplier#Stability Chamber Manufacturer in India#Stability Chamber Supplier in India#Stability Chamber Manufacturer in Delhi NCR#Stability Chamber Exporter in India

1 note

·

View note

Text

Importance of Stability Test Chamber in Industries

What is Stability Test Chamber?

In industries where precise environmental conditions are paramount, Stability Test Chambers play a crucial role. These chambers provide controlled settings for testing and storing products, ensuring their stability and integrity over time. However, with a myriad of stability chamber manufacturers in the market, choosing the right one can be a daunting task. In this blog post, we delve into the realm of stability chamber manufacturers, exploring key considerations and tips to help you find the perfect fit for your specific requirements.

Importance of Stability Test Chambers:

Before delving into manufacturers, it’s essential to grasp the significance of stability chambers in various industries:

1. Pharmaceutical: Stability chambers are vital for pharmaceutical companies to assess the stability of drugs and ensure their efficacy and safety over their shelf life.

2. Food and Beverage: In the food and beverage industry, stability chambers help maintain product quality by simulating storage conditions and evaluating shelf-life parameters.

3. Research and Development: Stability chambers are indispensable in research laboratories for conducting experiments and studies that require precise temperature and humidity control.

Key Considerations When Choosing a Manufacturer:

When evaluating stability chamber manufacturers, consider the following factors to make an informed decision:

1. Reputation and Experience: Opt for manufacturers with a proven track record and extensive experience in designing and producing stability chambers. Look for testimonials, reviews, and case studies to gauge their reputation and reliability.

2. Customization Options: Assess the manufacturer’s ability to tailor stability chambers to meet your specific needs. Look for flexibility in terms of chamber size, temperature range, humidity control, and additional features.

3. Quality and Compliance: Ensure that the manufacturer adheres to industry standards and regulations, such as FDA, ICH, and GMP guidelines. Look for certifications and quality assurance processes to guarantee the reliability and accuracy of their chambers.

4. Technical Support and Service: Choose a manufacturer that offers comprehensive technical support, training, and after-sales service. Consider factors such as warranty coverage, maintenance plans, and availability of spare parts.

Top Stability Test Chamber Manufacturer:

While numerous manufacturers specialize in stability chambers, several industry leaders stand out for their quality, reliability, and innovation:

1. Ferrotek Equipment: Ferrotek Equipment is recognized for its high-performance stability chambers featuring innovative design, precise control, and user-friendly interface, catering to the stringent requirements of pharmaceutical and research laboratories.

2. ESPEC North America: With a legacy of over 60 years, ESPEC is renowned for its precision-engineered stability chambers, offering a wide range of models tailored to diverse industries and applications.

3. Weiss Technik: As a global leader in environmental testing solutions, Weiss Technik delivers cutting-edge stability chambers known for their advanced technology, accuracy, and durability.

Conclusion:

Choosing the right stability chamber manufacturer is paramount to ensuring the integrity and reliability of your testing and storage processes. By considering factors such as reputation, customization options, quality, and technical support, you can make an informed decision that aligns with your specific needs and objectives. Whether you prioritize precision, reliability, or versatility, partnering with a trusted manufacturer is the first step towards achieving optimal results and compliance in your industry.

#stability chamber manufacturer#stability chamber manufacturer in India#stability test chamber#stability test chamber manufacturer#stability test chamber manufacturer in India#Top supplier of stability test chamber#stability chamber supplier#ferrotek equipment

1 note

·

View note

Text

#BOD Incubator Manufacturer#Cold Chamber Manufacturer#Stability chamber#Stability Chamber Manufacturer#Walk in Stability Chamber Manufacturer#Walk in stability chamber#Humidity chamber#Humidity chamber Manufacturer#Photostability chamber#Photostability chamber Manufacturer#BOD Incubator#Cold Chamber

0 notes

Text

A permanent place to call my own and help others .

1 note

·

View note

Text

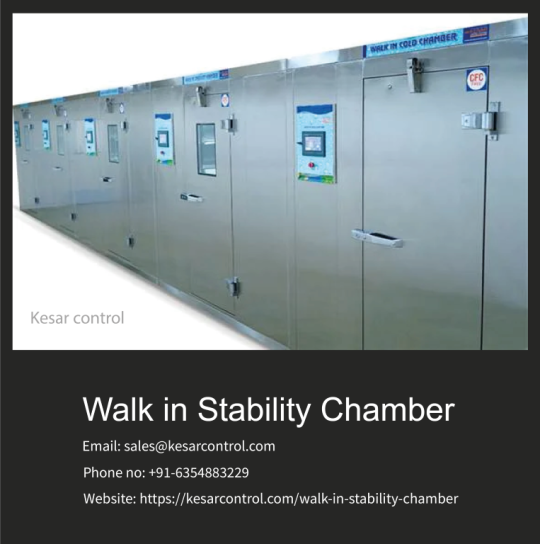

Elevate Your Stability Chamber Needs with Kesar Control – Leading Stability Chamber Manufacturer

Welcome to Kesar Control, your trusted partner in precision and reliability when it comes to stability chambers. As a renowned stability chamber manufacturer, we take pride in presenting our flagship product, the Eco-Smart Walk-In Stability Chamber.

1 note

·

View note

Text

Leading Humidity Chamber Manufacturer in India – Kesar Control Systems

Kesar Control Systems is a trusted Humidity chamber manufacturer in India, specializing in high-precision chambers designed for controlled humidity and temperature conditions. Our humidity chambers are ideal for pharmaceutical, biotech, and research applications, ensuring accurate environmental simulation for product testing and stability studies. Built with advanced technology and compliance with international standards, our chambers offer reliability and efficiency. Choose Kesar Control Systems for premium humidity chambers. Contact us today! https://www.kesarcontrol.com/humidity-chamber.php

#Walk in stability chamber manufacturer in India#Stability chamber manufacturer in India#Cold chamber manufacturer in India#BOD incubator manufacturer in India#Photostability chamber manufacturer in India#Humidity chamber manufacturer in India

0 notes

Text

Science Behind Stability Test Chamber: How Acmas Technologies Help Businesses Quality Control

In industries such as chemicals, food, electronics, and pharmaceuticals, ensuring product longevity and quality is essential. Stability test chambers play a crucial role in verifying product reliability under different environmental conditions. Acmas Technologies, a prominent manufacturer, supplier, and exporter of test chambers, offers high-precision solutions tailored to various industry requirements. This article explores the science behind stability test chambers and how Acmas Technologies supports businesses in upholding stringent quality control standards.

Understanding Stability Test Chambers

A stability test chamber is a specialized environmental chamber that simulates real-world conditions—such as temperature, humidity, and light—to assess a product’s performance over time. Various industries rely on these chambers to ensure their products remain stable and functional throughout their intended shelf life.

Science Behind Stability Testing

Stability testing involves subjecting a product to controlled environmental conditions to predict its behavior over time. This process includes:

Temperature Control: One of the primary factors affecting product stability is temperature variation. Stability test chambers can simulate extreme heat and cold conditions, helping manufacturers determine how their products react to different climates and seasonal changes. Temperature control ensures that electronic devices, pharmaceuticals, and packaged foods maintain their integrity during storage and transportation.

Humidity Regulation: Humidity can significantly impact the stability of products, particularly pharmaceuticals and food items. Excessive moisture can lead to microbial growth, corrosion, or degradation of active ingredients. Stability test chambers regulate humidity levels to mimic various environmental conditions, helping manufacturers determine safe storage conditions.

Light Sensitivity Analysis: Certain products, such as medicines and cosmetics, degrade when exposed to light. Stability test chambers simulate UV and visible light exposure to assess the impact of prolonged light exposure on products. This testing ensures that packaging and formulation provide adequate protection.

Why Businesses Need Stability Test Chambers

For businesses, investing in high-quality stability test chambers is crucial to ensure regulatory compliance and customer satisfaction. Key benefits include:

1. Ensuring Regulatory Compliance: Industries such as pharmaceuticals and food manufacturing must adhere to stringent regulatory standards, including WHO, FDA, and ICH guidelines. Stability test chambers help businesses meet these requirements by providing accurate data on product stability.

2. Enhancing Product Quality: By identifying potential stability issues early, manufacturers can modify formulations, packaging, and storage recommendations to enhance product quality.

3. Reducing Product Failures: Stability testing minimizes the risk of product recalls and failures, preventing financial losses and reputational damage.

Acmas Technologies: Leading Test Chambers Manufacturer and Supplier

Acmas Technologies is a renowned test chamber manufacturer, supplier, and exporter, providing cutting-edge solutions for various industries. The company offers a wide range of stability test chambers tailored to specific industry requirements. Here’s how Acmas Technologies stands out:

Advanced Technology Integration: Acmas Technologies incorporates the latest technology in its stability test chambers, ensuring precision control of temperature, humidity, and light exposure.

Customization Options: Acmas Technologies provides test chambers that may be customized to meet the individual needs of various industries because it understands that every industry has different requirements.

Compliance with Global Standards: Acmas Technologies manufactures stability test chambers that comply with international regulatory standards, making them a trusted choice for businesses across the globe.

Competitive Test Chambers Price: Despite offering top-tier quality and advanced technology, Acmas Technologies ensures competitive pricing, making its test chambers accessible to small and large businesses alike.

Key Features of Acmas Technologies Stability Test Chambers

Precision Temperature and Humidity Control: Ensuring accurate simulation of environmental conditions.

Energy-Efficient Design: Reducing operational costs while maintaining performance.

User-Friendly Interface: Simplifying operation and monitoring.

Durability and Reliability: Long-lasting performance for continuous testing.

Comprehensive After-Sales Support: Assisting businesses with maintenance and troubleshooting.

Conclusion: Stability test chambers are indispensable for businesses that prioritize product quality and regulatory compliance. Acmas Technologies, a trusted test chamber manufacturer, supplier, and exporter, provides high-quality solutions tailored to various industries. With advanced technology, customization options, and competitive test chamber prices, Acmas Technologies helps businesses achieve superior quality control and product stability.

By investing in reliable stability test chambers, businesses can ensure their products remain effective, safe, and durable, ultimately leading to customer satisfaction and industry compliance.

Get in Touch with Acmas Technologies Today!

Are you looking for high-quality stability test chambers at competitive prices? Contact Acmas Technologies, a leading test chamber manufacturer, supplier, and exporter, to find the perfect solution for your business.

Call us at: 8069186503 Email us at: [email protected] Visit our website: https://www.acmasindia.co.in/ Location: Plot No. 126, Sector-56 Phase- IV Kundli, Sonepat, Haryana-131028

#Stability Test Chamber#Test Chambers#Test Chambers Manufacturer#Test Chambers Supplier#Test Chambers exporter#Test Chambers Price

0 notes

Text

#navsarjants#stability-chamber-manufacturer#humidity-chamber-manufacturer-in-ahmedabad#walk-in-stability-chamber-manufacturer#laboratory-instruments-manufacturers-in-ahmedabad#laboratory-instruments-supplier-in-ahmedabad#pharmaceutical-turnkey-project-consultants-in-ahmedabad#pharma-turnkey-projects-in-ahmedabad#pharma-project-consultants-in-gujarat#pharma-project-consultant#drug-license-consultant-in-ahmedabad#WHO-GMP-consultant-in-ahmedabad#SOP-preparation-consultant-in-ahmedabad

0 notes

Text

Understanding the Role of Environmental Test Chambers Manufacturers in Advanced Testing

In today’s fast-paced industrial and technological advancements, reliable testing solutions are critical for ensuring the quality and durability of products. Environmental test chambers manufacturers, such as Tunix, play a pivotal role in providing cutting-edge solutions for various industries. These chambers simulate real-world environmental conditions, making them essential for testing product reliability under extreme conditions.

What Are Environmental Test Chambers?

Environmental test chambers are specialized equipment designed to simulate a wide range of environmental conditions, such as temperature, humidity, altitude, and vibration. They are used extensively across industries, including automotive, electronics, aerospace, and pharmaceuticals, to test the endurance and performance of products.

Types of Environmental Test Chambers

Temperature and Humidity Test Chambers: These are the most common types and are used to simulate varying temperature and humidity conditions.

Thermal Shock Chambers: Ideal for testing a product’s resistance to sudden changes in temperature.

Altitude Chambers: Designed for testing the performance of products in high-altitude conditions.

Vibration Chambers: Simulate mechanical stresses caused by vibrations during product transportation or usage.

Why Choose Tunix for Temperature and Humidity Test Chambers?

Tunix stands out among environmental test chambers manufacturers due to its commitment to quality and innovation. The company’s temperature and humidity test chamber are designed to deliver precise, reliable, and repeatable results, ensuring that your products meet the highest quality standards.

Key Features of Tunix Test Chambers

Precision Control: Tunix chambers offer accurate temperature and humidity control for consistent testing.

Durability: Built with high-quality materials, these chambers ensure long-lasting performance.

Customizability: Tunix provides tailored solutions to meet specific testing requirements.

Energy Efficiency: Designed to consume less energy, reducing operational costs.

Applications of Environmental Test Chambers

Automotive Industry: Testing vehicle components for heat resistance and durability.

Electronics: Ensuring circuit boards and devices can withstand extreme conditions.

Aerospace: Testing materials and equipment used in high-altitude and temperature-variable conditions.

Pharmaceuticals: Simulating storage conditions to test drug stability.

Frequently Asked Questions (FAQs)

1. What industries benefit the most from environmental test chambers?

Industries like automotive, electronics, aerospace, and pharmaceuticals rely heavily on environmental test chambers for product testing and quality assurance.

2. How do temperature and humidity test chambers work?

These chambers create controlled environments by regulating temperature and humidity levels to simulate real-world conditions for testing product performance.

3. Why is Tunix a trusted name among environmental test chambers manufacturers?

Tunix is renowned for its high-quality, innovative solutions that cater to diverse industry needs, ensuring precise and reliable testing.

Conclusion

Environmental test chambers manufacturers, like Tunix, are integral to advancing product quality and reliability across various industries. Their temperature & humidity test chamber provide the precision and versatility required for rigorous testing standards. For more information, Tunix and explore their range of advanced testing solutions.

#Environmental Test Chambers Manufacturer#About Tunix Corporation#Temperature and Humidity Test Chamber#Mini Environmental Test Chamber#Industrial Hot Air Oven Manufacturers#Climatic Simulation Chamber manufacturer#Careers at Tunix Corporation#Tunix Environmental Test Chambers#Altitude Test Chamber#Thermal Shock test Chamber#Dust Test Chambers Manufacturer#Cyclic Salt Fog Test Chamber#Walk in Environmental Test Chamber#Vibration Test Chamber Manufacturer in India#Water Bath & Oil Bath Equipment#Vacuum Ovens#Stability Test Chambers#Premium Accuracy Dew Point Hygrometers#High-Accuracy Thermo Hygrometer#High-Accuracy Digital Pressure Indicator#Pressure Screw Pump#Ultra Cool Dry Block Temperature Calibrator#Oil Liquid Temperature Calibrator#Dry Block Temperature Calibrator#Temperature & Humidity Calibration Chamber

1 note

·

View note

Text

What is a Stability Chamber and what are its uses?

A stability chamber is crucial in various industries, particularly pharmaceuticals, biotechnology, food, and cosmetics. Stability chambers are designed to create controlled environmental conditions, allowing for the precise regulation of temperature and humidity, simulating different storage environments. These chambers are essential for assessing the shelf life, quality, and durability of products under varying conditions. In this blog, we’ll explore the principle behind stability chambers and their many applications across industries.

In the manufacturing of pharmaceuticals, food, medical devices, or chemical engineering, stability chambers are important. Businesses can use it to model and assess a product's stability and durability in various environmental settings.

We go into every aspect of stability chambers in this piece. from the foundational to the essential components. Regardless of your level of experience, we will provide in-depth explanations and thorough insights to help you gain more understanding of and use stability chambers.

What is a Stability chamber?

A stability chamber is an intricate, independent device. They can be employed to simulate particular environmental circumstances. The ambient conditions can be controlled to very close tolerances with the correct equipment.

Stability chambers, sometimes referred to as stabilisation chambers, are perfect for evaluating a product's longevity. These consist of pharmaceuticals, electronic parts, and building supplies. They let the user adjust parameters like humidity and temperature. It enables carrying out a thorough analysis of various circumstances. Different testing conditions are needed for different items. It's almost impossible to get around the entire world and experience different climate conditions. Stability chambers are particularly useful in this situation, facilitating better control and a smoother finish.

Usually made of strong materials like stainless steel, a stability test chamber is a sealed space. It features built-in hardware that enables adjustments to the interior environment. It indicates that the chamber will be equipped to dry the air, raise humidity, and heat or cool as needed. Several environmental variables can be tested through a well-designed stability test chamber. Timer elements in a sound stability chamber allow testing to take place at scheduled times.

Working Principle of a Stability Chamber:

The basic principle of a stability chamber is to maintain consistent environmental conditions (usually temperature and humidity) for extended periods while exposing products to these controlled environments. The chamber’s conditions simulate real-world environmental factors that a product may face during its storage and use.

Here’s how it works:

1. Temperature Control

Stability chambers have heating and cooling systems (typically using refrigeration cycles or heaters) to maintain constant temperature ranges, as specified by the user.

The typical temperature ranges for testing could be 25°C, 30°C, 40°C, or higher, depending on the product and regulatory guidelines (such as ICH guidelines in the pharmaceutical industry).

The temperature inside the chamber is continuously monitored by sensors, and adjustments are made to maintain the desired set point.

2. Humidity Control

Humidity control systems ensure that the chamber maintains a specified relative humidity (RH) level.

To increase humidity, water vapour is injected into the air inside the chamber. Conversely, to reduce humidity, dehumidifiers or refrigeration systems condense moisture out of the air.

Stability chambers typically operate at RH levels such as 40%, 60%, or 75%, depending on the testing requirements.

3. Uniformity

The chamber must maintain uniform conditions throughout the space. This is critical because any variation in temperature or humidity could affect the results of the stability test.

To ensure uniformity, stability chambers use air circulation systems (fans, blowers) to evenly distribute air throughout the chamber, so the conditions remain consistent at all points inside.

4. Sensors and Monitoring

Stability chambers are equipped with sensors that continuously monitor both temperature and humidity.

Data logging systems are also integrated, which record the environmental conditions over time, ensuring the test parameters are maintained and allowing for later analysis of the data.

5. Alarms and Safety Mechanisms

Stability chambers include alarms that notify operators if the conditions inside deviate from the set parameters, allowing for quick corrective action to be taken.

Backup systems may also be included to maintain conditions in case of a power failure or system malfunction.

Uses of Stability Chamber

You know that a stability chamber can be used to evaluate the condition of different products and materials under different humidity and temperature conditions:

Evaluating food and beverage products

The food and beverage industries test product quality and shelf life using stability chambers. It helps businesses in this industry to track how their products respond to temperature, light, and humidity so that preventive measures can be taken to keep germs away.

Analysing the package

Product and material conditions are significantly impacted by packaging. It tests the ability of packaging to withstand different conditions and evaluates how well it protects contents from outside influences.

Testing of electronic components

Temperature and humidity variations can affect electronic materials and devices. For this reason, the electronics industry makes investments in stability chambers to verify that various components function properly in real-world scenarios and to evaluate their operation under a variety of climatic circumstances.

Monitoring medical devices

Medical equipment dependability testing is essential for medical clinics to be able to treat patients. Stability chamber testing proves the effectiveness and durability of these devices.

Pharmaceutical assessment

To ensure that drugs are safe for use and that their responses to temperature, light, and humidity are as expected, they are tested for stability and shelf life under a range of environmental conditions.

Key Factors of A Stability Chamber

Temperature Control

Control of Humidity

Light Regulating

Control of Vibrations

Air Flow

Observation and Data Recording

Inside Area

Verification of Stability

Stability chambers play an integral role in ensuring the quality and reliability of products by providing accurate, controlled environmental conditions for testing. Whether in pharmaceuticals, food, or cosmetics, they help companies predict product behaviour over time, meet regulatory standards, and ensure customer safety. Understanding the principles and uses of stability chambers is vital for industries focused on long-term product stability and compliance.

A stability chamber plays a crucial role in industries like pharmaceuticals, cosmetics, and food by providing a controlled environment to test products' stability under various temperature and humidity conditions. This testing ensures that products maintain their quality, efficacy, and safety throughout their shelf life. Whether it’s for accelerated ageing tests or long-term stability studies, stability chambers are essential for meeting regulatory standards and ensuring product reliability.

Mack Pharmatech is a high-quality stability chamber manufacturer designed for precise environmental control and reliable performance. Our chambers are equipped with advanced features like uniform air distribution, accurate sensors, and customizable settings, ensuring you get the most accurate data for your stability testing needs. With a commitment to quality and innovation, we are your trusted partner in providing state-of-the-art stability chambers that meet the stringent demands of modern industry testing.

1 note

·

View note

Text

Blood Bank Refrigerator Manufacturer

#Stability Chamber#Stability Chamber Manufacturer#Environmental Test Chamber#Humidity Chambers#Humidity Chambers Manufacturers#Walk In stability Chamber#Walk in Chamber#BOD Incubators#Walk-In Incubators#Humidity Oven#Humidity Oven manufacturer#Laboratory Oven#Bacteriological Incubator#vacuum ovens#Autoclave Laboratory Vertical

0 notes

Text

What are the Functionalities of Stability Chamber?

Functionality of Stability Chambers

Stability chambers are designed with precision to maintain constant and accurate conditions:

Temperature Control: Chambers can simulate a wide range of temperatures, from extreme cold to high heat, depending on the product being tested. Temperature stability is crucial for assessing how heat-sensitive products will behave in different climates.

Humidity Control: Some products, like electronics or certain pharmaceuticals, are sensitive to moisture. Stability chambers can replicate different humidity levels to assess product stability under varying moisture conditions.

Lighting Conditions: In industries where exposure to light can degrade products (such as food and pharmaceuticals), stability chambers can simulate various lighting conditions to test product stability against light exposure.

Stability chambers are controlled environments used primarily in industries like pharmaceuticals, food, cosmetics, and even in scientific research. Their primary function is to replicate and maintain the environmental conditions under which a product is expected to be stored or used. This replication allows researchers and manufacturers to predict the product’s shelf life, efficacy, and safety under various environmental conditions.

Importance of Stability Chambers

Product Safety and Efficacy: For pharmaceuticals and biotech products, stability chambers help determine how temperature and humidity variations affect chemical composition and effectiveness. This information is critical for ensuring product safety and efficacy.

Regulatory Compliance: Regulatory bodies like the FDA (Food and Drug Administration) require stability testing as part of the approval process for drugs and medical devices. Stability chambers provide the necessary data to meet these regulatory standards.

Quality Assurance: Manufacturers use stability testing to guarantee product quality throughout its intended shelf life. It helps identify potential issues like degradation, contamination, or packaging failures that could affect product performance.

Research and Development: In research settings, stability chambers are essential for studying how environmental factors impact materials and products. This information guides the development of improved formulations and packaging.

Types of Stability Chambers

Stability chambers come in various types depending on the specific needs of the industry and the product being tested:

Walk-in Chambers: Large chambers that can accommodate substantial quantities of test samples or products.

Reach-in Chambers: Smaller chambers designed for easier access and monitoring of samples.

Environmental Chambers: Designed to replicate extreme conditions such as arctic cold or desert heat, useful for testing products intended for harsh environments.

Conclusion

Stability chambers are indispensable tools in ensuring product quality, safety, and regulatory compliance across industries. By replicating and controlling environmental conditions, these chambers provide valuable data that guide product development, quality assurance, and regulatory submissions. As technology advances, so too does the precision and capabilities of stability chambers, enabling industries to innovate and deliver safer, more effective products to consumers worldwide. Whether in pharmaceutical research labs or food manufacturing facilities, stability chambers remain a cornerstone of modern quality control and product development processes.

Top Stability Test Chamber Manufacturer in India

If you are looking for Best Stability Test Chamber Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Stability Test Chamber in India.

#Stability Chambers#Stability Chamber manufacturer#Stability Chambers manfuacturer in India#Stability Chambers Supplier in India#Effem Technologies

0 notes

Text

Are you Looking for Stability Chamber Manufacturers in India?

A stability chamber is a controlled environment used in scientific and industrial settings to simulate and maintain specific conditions such as temperature, humidity, and light, among others. These chambers are designed to test the stability and shelf life of products, including pharmaceuticals, food, cosmetics, and other materials, by subjecting them to controlled environmental conditions over a period of time. This helps researchers and manufacturers assess the effects of different environmental factors on the quality and durability of their products.

Features of Stability Chamber:

Precise Environmental Control

Stability Testing

Shelf Life Evaluation

Compliance Standards

Easy Operation

Data Monitoring and Logging

Safety Features

Uniformity and Consistency

Customizable Configurations

Accelerated Aging Studies

Uses of Stability Test Chamber in Industries

Pharmaceuticals: Stability chambers are extensively used in the pharmaceutical industry to assess the stability of drugs and pharmaceutical products under different environmental conditions. This helps ensure the efficacy and safety of medications over their intended shelf life.

Food and Beverages: In the food and beverage industry, stability chambers are employed to test the shelf life and quality of perishable goods, including packaged foods, beverages, and dietary supplements. They help identify optimal storage conditions and packaging materials to maintain product freshness and safety.

Cosmetics and Personal Care Products: Stability testing chambers are utilized to evaluate the stability and performance of cosmetics, skincare products, and toiletries. This includes assessing factors such as color, texture, fragrance, and chemical stability over time.

Chemicals and Materials: Stability chambers are used to test the stability and durability of various chemical compounds, industrial materials, and specialty products. This includes assessing resistance to degradation, corrosion, and other environmental factors.

Environmental Research: Researchers use stability chambers to simulate specific environmental conditions for studying the effects of temperature, humidity, light exposure, and other factors on materials, organisms, and ecosystems. This facilitates environmental monitoring, conservation efforts, and climate change research.

Electronics and Components: Stability testing chambers are employed in the electronics industry to evaluate the reliability and performance of electronic components, circuits, and devices under different temperature and humidity conditions. This helps ensure product quality and durability in various operating environments.

Automotive and Aerospace: In automotive and aerospace industries, stability chambers are used to test the stability and durability of vehicle components, materials, and aerospace equipment under extreme conditions, including temperature fluctuations, vibration, and humidity levels.

Research and Development: Stability chambers play a crucial role in research and development across industries by providing controlled environments for studying the stability, degradation mechanisms, and performance characteristics of various products and materials.

Top 5 Stability Chamber Manufacturer in India

Thermolab Scientific Equipments Pvt. Ltd.: Thermolab is known for its wide range of stability chambers, including walk-in stability chambers, photostability chambers, and environmental chambers. They offer precise temperature and humidity control for various testing applications.

2. Remi Elektrotechnik Limited: Remi manufactures high-quality stability chambers suitable for pharmaceutical, biotechnology, and research laboratories. Their chambers are designed to meet international standards and offer advanced features for stability testing.

3. Ferrotek Equipment.: Ferrotek Equipment specializes in manufacturing stability chambers with precise control over temperature, humidity, and light conditions. They offer both standard and custom-designed chambers to meet specific testing requirements.

4. HMG (India) Pvt. Ltd.: HMG is a leading manufacturer of stability chambers used in pharmaceutical, food, and research industries. Their chambers are known for their reliability, accuracy, and compliance with regulatory standards.

5. Everest Instruments Pvt. Ltd.: Everest Instruments offers a range of stability chambers with advanced features such as microprocessor-based controllers, data logging, and alarm systems. Their chambers are widely used for stability testing and shelf life determination in various industries.

Conclusion

Stability chambers are vital for industries like pharmaceuticals, food, and research, offering precise control over environmental conditions for accurate stability testing. They ensure product quality, safety, and regulatory compliance. Choosing a reputable manufacturer is key to acquiring reliable chambers tailored to specific needs. With stability chambers, industries can confidently develop high-quality products meeting consumer expectations.

For more information, please contact us!

Website — https://www.ferrotekequipments.com/

Contact No. — +91–9811576010

Email — [email protected]

#Stability chambers#Stability chamber#Stability chamber manufacturer#Stability chamber manufacturer in India#Stability chamber manufacturer in Delhi NCR#Stability chamber manufacturer in Ghaziabad#Stability chamber manufacturer in Noida#Stability chamber supplier in India#Stability chamber supplier in Ghaziabad#Stability chamber supplier in Noida#Stability chamber supplier in Gurugram#Best Stability chamber manufacturer in India

0 notes

Text

#Walk in Stability Chamber Manufacturer#Walk in stability chamber#Humidity chamber#Humidity chamber Manufacturer#Photostability chamber#Photostability chamber Manufacturer#BOD Incubator#BOD Incubator Manufacturer#Cold Chamber#Cold Chamber Manufacturer#Stability chamber#Stability Chamber Manufacturer

0 notes

Text

What are Stability Chambers and their uses?

Stability chambers are controlled environments used to test the durability and shelf life of products, typically in industries like pharmaceuticals, food, and cosmetics. They simulate different conditions of temperature, humidity, and light exposure to determine how materials or products respond over time. Microsil India, a leading suction apparatus manufacturer, delivers high-quality medical suction devices. Their innovative technology ensures reliable performance, catering to hospitals, clinics, and healthcare professionals for efficient patient care.

0 notes