#slurry pumps high chrome suppliers

Explore tagged Tumblr posts

Text

We have high chrome investment castingup upto 90 kg, shaft sleeve sl100, shaft sleeve sl150, shaft sleeve sl200, shaft sleeve sl250, shaft sleeve sl50, shaft sleeve sl750, slurry pump sl100, slurry pump sl250, slurry pump sl200, slurry pump spares job work, oem shaft sleeve for slurry pumps.

#slurry pumps high chrome#slurry pumps high chrome manufactures#slurry pumps high chrome manufactures in india#slurry pumps high chromes exports#slurry pumps high chrome exports in india#slurry pumps high chrome suppliers#slurry pumps high chrome suppliers in india

0 notes

Link

End suction pumps are one of the main common types of centrifugal pumps. Cost-effective and reliable, they are suitable for a variety of pumping applications. They’re nearly always single stage pumps, meaning they need only one impeller. Available in an exceedingly big selection of sizes, construction materials, and styles, they will be accustomed to pump a range of fluids from ambient-temperature water to high-pressure and high- temperature viscous oils, abrasive slurries, and corrosive chemicals. Betting on the top pumping application, they will be constructed from plastic, standard iron, hardened iron, chrome steel, or more exotic alloys. End suction pumps are found across the spread of commercial facilities and water treatment and processing plants. They’re also commonly used for fire fighting and protection systems, HVAC systems, and pressure boosting large-scale plumbing systems for giant buildings like office buildings, shopping malls, and stadiums. Working of end-suction pumps Centrifugal pumps in general work by forcing the pumping fluid through one or more rapidly rotating impellers, thereby increasing the fluid’s velocity and pressure. End suction pumps usually contain just one impeller and a volute type casing. Volute casings have an offset impeller, which creates a curved funnel with the area increasing towards the pump outlet or discharge. This helps to increase the fluid pressure towards the outlet. The pumped fluid enters the impeller at its rotating axis or the eye of the impeller. The

rotation of the impeller then accelerates the liquid. It flows radially outward into the volute casing, where the high velocity is converted to high pressure through a diffusion process. An alternating current electric motor usually drives them. However, direct current motor driven ones are available and pump driven by air motors, hydraulic motors, steam turbines, and diesel and petrol engines. Applications & Services: ● Circulating Water System ● Power plants ● WTP & STP ● Fire Fighting ● HVAC ● Irrigation / Sprinkler service ● General Services

Types of End Suction Pumps

End suction pumps are useful in many types of residential, commercial, and industrial applications. Since they are so common and available from so many pump suppliers, they are often offered at very attractive prices. Standard water pumps are often close coupled and made of traditional iron or various plastics for a low cost. For more heavy-duty industrial applications, the pumps are usually mounted on a bedplate with a coupling separating the pump and motor. These are often supplied in stainless steel or more exotic alloys or plastics for corrosion resistance or made of hardened iron for slurry applications in mining, dredging, and minerals processing. End suction pumps can be fitted with open impellers for chemical or food processing applications that contain solids or have closed impellers for relatively clean water and oil services. The pump shaft is sealed from the

environment with conventional packing, mechanical seals, or the pump may be a magnetic drive or canned motor pump type. The best manufacturer of end-suction pumps, the FLOW MORE PUMPS, based in Gurugram, provides the best pumps. If you are looking for high- quality end-suction pumps at reasonable prices, then visit flowmorepumps.com today!

1 note

·

View note

Text

Sand suction dredge pump factories

#Sand suction dredge pump factories portable

#Sand suction dredge pump factories series

We are looking for pump dealers all over the world. They are widely used in mining, metallurgy, coal washing, power plants, sewage water treatment and dredging in such industries as mine, chemical and petroleum.

#Sand suction dredge pump factories portable

Our main products include centrifugal portable sand pump, marine sand pump, slurry pump, gravel pump, submersible slurry pump, vertical sand pump, simple small sand pump dredger, submersible dredger, mini dredge for sale, small dredging equipment, small pond dredging equipment, sand suction dredger, suction dredging equipment, cutter suction dredger, sewage submersible pump, lake dredging equipment, mini dredges for sale, sand dredging machine, river dredging equipment and other parts like discharging sand pipe, floater, rubber hose. W e provide our customers with a complete set of sand, slurry, gravel pumping solutions and related parts. Specially designed for mining, with large flow. OCEAN Pump is the Certification of New Hi-tech Enterprises by the Government. Industrial Horizontal High Chrome Centrifugal Rriver Sand Suction Gravel Dredge Pump Machine for Mining. Product innovation and customer satisfaction are our continuous commitment to all our partners.

#Sand suction dredge pump factories series

More than 4 series 20 kinds of sand pumps, slurry pumps, sand dredgers and related parts had been manufactured to satisfy your pumping requirements. China 900m3/H Jet Suction Dredger for Sea & River, Find details about China Sand Ship, Jet Boat from 900m3/H Jet Suction Dredger for Sea & River - Qingzhou Yongsheng Dredging Equipment Co., Ltd. English Sourcing Solutions Services & Membership Help & Community Ready to Ship Trade Shows. Find high quality Sand Dredge Pump Suppliers on Alibaba. There are 1,056 OEM, 968 ODM, 356 Self Patent. dredger, equipped with high-pressure water jet and water pump, pumps sand and then. Alibaba offers 1,680 Sand Dredge Pump Suppliers, and Sand Dredge Pump Manufacturers, Distributors, Factories, Companies. We have more than 30 talented sand pump experts and 15,000 square meters factory. Manufacturer of Dredger & Other Marine Machine - Jet Suction Dredger. is the leading dredge pump and sand dredger solutions manufacturer, supplier and exporter in China. Over size bearings and shaft for longer life.Our main products include ship (tug boat, yacht, passenger boat, etc. is a multiple industrial chain enterprise with more than 10 years export experience. Knock out ring for easy impeller removal. Weifang Auspiciousness Economic Commerce Co., Ltd.Optional rotation – Right or left hand rotation.Easily adapted for submersible applications.Speed and power to suit your service conditions.Custom design and fabrication available.Most efficient volute and impeller designs.Capable of handling sand and slurry with maximum size and percentage of solids.Suction Dredge Pump is single stage single suction horizontal centrifugal dredging pump system consists of the pump head, reduction gear box, flexible couplings, gearing marine monitoring system, it has a good overall structure of marine dredging excellent performance, high rate of long-term life, seal, reliable, comprehensive and significant economic benefits etc., WN series dredge pump can fully meet all requirements for various dredgers.Dredge pump can create a vacuum that sucks the slurry from the bed up into a suction pipe and pushes it to the discharge pipeline.

0 notes

Text

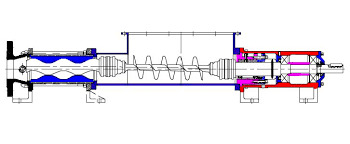

Introduction to Wide Throat Progressive Cavity Pump

Wide Throat Progressive Cavity Pump (WTPCP) is a centrifugal pump that has a progressive cavity along with a wide throat and low shear. It is designed to handle difficult fluids and slurries with high solids content. It is the most efficient way to move liquids and solids because it can handle high viscosities without clogging. With this pump, you can move more products faster with less effort. Wide Throat Progressive Cavity creates a strong suction force to draw in the liquid which makes this pump perfect for moving thick or sticky products like honey, molasses, peanut butter, and other viscous liquids. It can also handle grainy or fibrous materials like cornmeal and flour with ease without damaging them or the pump.

This pump has a wide throat that allows large chunks to pass through without getting stuck. The progressive cavity design ensures that the material is moved smoothly and efficiently from beginning to end. Then the wide throat allows for easy passage of the fluid, while the low shear prevents damage to the fluid. The WTPCP is also great for pumping viscous liquids with high solids content. Because of the wide throat and progressive cavity, this pump can handle these types of liquids without any problems. Wide Throat Progressive Cavity Pump in India are available in both electric and hydraulic versions, so they can be used in a variety of applications.

Component configuration

Wide Throat Progressive Cavity Pump consist of the following components as follows,

Wettable Housing can be made of materials like cast iron, cast stainless steel, fabricated steel, etc.

Stator

Rotor, commonly used material are alloy steel, stainless steel or few other kinds of steel/ material depending upon the use.

Coupling Rod and the shaft is commonly made from alloy steel or stainless steel

Other Exotic Materials such as duplex, super duplex, alloy 20, haste alloy

Rotor Surface Coatings are manufacture of ceramic coating, tungsten carbide, hard chrome plating, etc.

Protective Coatings: rubber lining, epoxy coatings.

Working of WTPCP

Wide Throat Progressive Cavity Pump in India employs the latest technology that helps in pumping viscous and shear sensitive fluids, it has a wide throat or inlet to accommodate large size particles. The pump operates by using an expanding and contracting cone-shaped eccentric rotor that moves within a stationary casing to create a pumping action. This action creates pockets of air and liquid which are drawn into the pump and expelled out the discharge port to the desired container or place

Advantages and Characteristics

Wide Throat Progressive Cavity Pump in India has plenty of advantages some of them are mention in the given list,

It’s self-priming rate is high.

A variety of installation positions are available.

It is possible to reverse the direction of rotation and, therefore, reverse the flow of delivery.

It is possible to handle suspensions with a high solids percentage without clogging a non-clogging system.

Inherently self-priming, it can be used to eliminate Snore

It’s NPSH(R) is low, can withstand high vacuum conditions, and is effective at high suction lift.

Due to the low internal velocity, products that are shear sensitive and abrasive are handled gentle and do not experience excessive internal wear.

Easily interchangeable: by simply switching the rotation direction of the prime mover, the suction and delivery ends can be interchanged.

For more information on Submerged P.C Pumps Supplier in Uttar Pradesh & Barrel Pumps Manufacturer in Uttar Pradesh , please visit : Deepa Pumps.

1 note

·

View note

Text

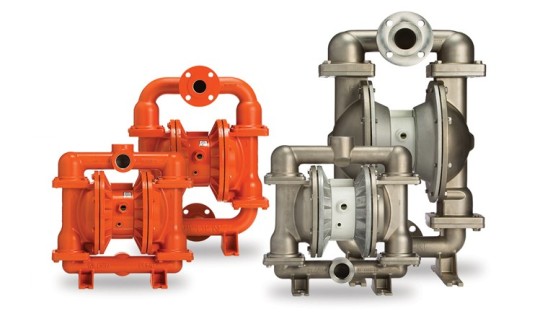

TEN REASONS YOU MUST USE ENGINEERED AODD PUMPS

Oil rigs, midstream production and refineries are dangerous places where one spark during a highly combustible environment can mean disaster.

When you’re working within the oil and gas industry, you don’t have time to fiddle with unreliable equipment. Whether onshore or offshore, you would like machinery you'll trust to try to do the work the primary time.

Air-operated double-diaphragm (AODD) pumps are one among the foremost critical pieces of kit to the industry. Oil and gas workers calculate AODD pump to not only keep their production moving smoothly, but also to stay them safe.

In fact, there are many reasons you ought to use engineered AODD pumps in critical applications, like those within the oil and gas industry.

1. AODD pumps are safe in potentially explosive environments.

AODD pumps by their nature don't use electricity and are fully groundable. This is often important because groundable equipment prevents static discharge from igniting a combustible environment.

2. Gas powered pumps are available.

Traditional AODD pumps are designed to be used with air only. Over the years, oil and gas operators have opted to power their diaphragm pumps with easily accessible gas .This g-series pump line is csa certified to be operated with either sweet/sour gas or instrument air. AODD Pump Suppliers provide safety features and help standardize inventory for multiple locations.

3. GODD pumps are versatile.

Gas or air operated heavy-duty flap valve pumps can safely carry the abrasive slurries, suspended and non-suspended solids and enormous line-size solids found within the oil and gas market. Gas/oil field pumps are often utilized in a good range of applications, including:

• lube oil transfer

• Glycol recirculation/heat trace

• flare knockout

• Glycol transfer/water make-up

• Sump/general transfer

• Tank bottom recirculation/transfer

• Utility/general transfer

• Separators and knockout drums

• General-duty spill cleanup

• Diesel fuel transfer

• Seawater pump for drilling fluid make-up

• produced water/condensate transfer

• cellar pump-out and dirt transfer

4. AODD pumps are often utilized in flare knockout applications.

AODD pumps can pump liquids with entrained gasses while many other pump designs will air bind thanks to excessive amounts of gasses present. The liquid and gas mixture can then be disposed of or reprocessed.

5. Different porting options are available.

Look for AODD Pump manufacturers who offer bottom discharge porting, which prevents settling, solids from shortening pump life and provides superior suction lift.

6. Flap valve pumps offer superior solids handling.

Flap valve pumps with top suction configurations are designed to pump solids without causing damage to pump internals caused by solids build up.

7. AODD pumps are portable.

Safely and simply transported, double diaphragm pumps are made for tough environments. Some are made with roll cages or skid bases, in order that they are often thrown within the back of a truck and brought from one site to a different.

8. AODD pumps work consistently despite the temperature.

AODD pumps can operate within the freezing and very high temperatures encountered on oil rigs or in gas fields.

9. Containment-duty AODD pumps help prevent leaks.

Metallic and non-metallic containment-duty pumps are ideal for pumping highly corrosive and unsafe chemical fluids. These are often constructed of aluminum, cast iron, chrome steel, alloy c, polypropylene and pvdf bodies with elastomeric and ptfe options for diaphragms and check valves. Unlike a standard AODD, the planning of the pump will prevent fluid from leaking within the event of a diaphragm failure. It'll also prevent instrument air powering the pump, from entering the method fluid when the diaphragm fails.

10. Accessories can improve pump efficiency/lifespan.

Accessories, like filter regulators and liquid level control, are often purchased and installed to extend the method control of the method and lengthen the lifespan of the pump.

0 notes

Photo

Hebei jishiyu Pump Co., Ltd. is the leading manufacturer and supplier of slurry pumps, desulfurization pumps, dredge pumps,multistage pumps, sewage pumps in China. The main product slurry pumps is of 20 series, 80 varieties and more than 400 specifications. The products are widely used in metallurgy, mining, petrochemical, coal, electricity, building materials, municipal, environmental protection departments. Mainly used for transport of solid particles with a strong abrasive, high-concentration slurry. We have exported our products to Canada, Russia,Japan,Vietnam, India,Ethiopia,Malaysia,Singapore,Chile, Zambia,Bolivia and other countries and regions. Ensure the highest efficiency and lowest operation costs; we help our customers to maintain industry leading advantage.

We have pattern workshop,foundries, rubber plant, machining workshop, assembly workshop and testing station. With rich experience in production of high chrome wear resistant white iron material. From the vital casting process to machining and assembly, we insist strict process technology and continuous improvement to ensure the high quality products as customers expect.

Strictly follow and continuously improve & strengthen the ISO quality control , become our highest quality control guiding principle. Not only does JISHIYU PUMP offer pump products, we also provide pre-sales solution, on-site service, spares and after-sale support.With the goal and dedication of "integrity and trustworthiness, win-win cooperation",We provide customers with the highest quality products and best service, we warmly welcome all new and old customers visit our company!

For more information on pumps, please click here.

https://www.jishiyupump.com/

0 notes

Text

We are Specialize in Exporters and Suppliers of Slurry Pump Spare Parts, High Chrome Slurry Pump, High Chrome Investment Casting Manufacturers in India, Finland, USA, and Australia.

#Slurry Pump Spare Parts#High Chrome Slurry Pump#High Chrome Investment Casting Manufacturers in India

0 notes

Text

http://slengineer.in/slurry-pumps/#slurry-pumps-high-chrome

We are leading manufacturer, supplier and exporter of Slurry Pumps, Mining Slurry Pumps, Vertical Extended Shaft Slurry Pumps, Upto 5 M Column Height Chemical Slurry Pumps, Non-clog Slurry Pumps, Molten Metal Transfer Pumps, Centrifugal Chemical Process Pumps.

#Slurry pump#slurry pump manufacturer#slurry pump supplier#slurry pump exporter#slurry pump manufacturer in india#slurry pump in Ahmedabad#vertical extended shaft slurry pump#non-clog slurry pump#molten metal transfer pumps

1 note

·

View note

Link

shree laxmi engineers is manufacturers and suppliers of slurry pumps parts | spare and wear parts for slurry pumps | slurry pumps high chrome In India. We are also supplier and exporter in India.

#slurry pump high chrome#slurry pump high chrome in Ahmedabad#slurry pump high chrome manufacturer#slurry pump high chrome supplier#slurry pump high chrome in india

1 note

·

View note

Link

Shree Laxmi Engineers is a big professional high-tech industrial pump manufacturer engaged in researching and exporting slurry pump high chromes in india.we are provide the one of the best quality materials .

#slurry pumps high chrome#slurry pumps high chrome manufactures#slurry pumps high chrome manufactures in india#slurry pumps high chromes exports#slurry pumps high chrome exports in india#slurry pumps high chrome suppliers

0 notes

Link

Shree Laxmi Engineers is a big professional high-tech industrial pump manufacturer engaged in researching and exporting slurry pump high chromes in india.we are provide the one of the best quality materials .

#slurry pumps high chrome#slurry pumps high chrome manufactures#slurry pumps high chrome manufactures in india#slurry pumps high chromes exports#slurry pumps high chrome exports in india#slurry pumps high chrome suppliers#slurry pumps high chrome suppliers in india

0 notes

Link

shree laxmi engineers is manufacturers and suppliers of slurry pumps parts | spare and wear parts for slurry pumps | slurry pumps high chrome In India. We are also supplier and exporter in India.

#slurry pump parts and spares#slurry pump parts and spares manufacturer#slurry pump parts and spares in Ahmedabad#slurry pump parts and spares in india#slurry pump parts and spares supplier in all over india

1 note

·

View note

Text

Shree Laxmi engineers is manufacturers and suppliers of slurry pumps parts | spare and wear parts for slurry pumps | slurry pumps high chrome In India. We are also suppliers and exporters in India.

#SlurryPumpsParts#SlurryPumpSparePartsManufacturer#SlurryPumpsPartsSuppliers#SlurryPumpsPartsinIndia#SlurryPumpsPartsinGujarat#SlurryPumpsPartsManufacturer&suppliers

1 note

·

View note

Text

Sl Engineer are specialize in manufacturer of slurry pump spare parts, high chrome slurry pump, high chrome investment casting in india, We are also supplier of slurry pump spare parts in India, Get more info details in Ahmedabad.

#SlurryPumpSparePartsManufacturer#SlurryPumpSparePartsManufacturerinIndia#SlurryPumpSparePartsManufacturer&Exporter#SlurryPumpSparePartsManufacturerinGujarat#SlurryPumpsarts

1 note

·

View note

Text

oem shaft sleeve for slurry pumps

shree laxmi engineers is manufacturers and suppliers of slurry pumps parts | spare and wear parts for slurry pumps | slurry pumps high chrome In India. We are also supplier and exporter in India

URL

#oem shaft sleeve for slurry pumps#oem shaft sleeve for slurry pumps in india#oem shaft sleeve for slurry pumps in Gujarat#oem shaft sleeve for slurry pumps in ahmedabad

0 notes

Text

oem shaft sleeve for slurry pumps

shree laxmi engineers is manufacturers and suppliers of slurry pumps parts | spare and wear parts for slurry pumps | slurry pumps high chrome In India. We are also supplier and exporter in India

URL: http://slengineer.in/slurry-pumps/

#oem shaft sleeve for slurry pumps#oem shaft sleeve for slurry pumps in india#oem shaft sleeve for slurry pumps in Gujarat#oem shaft sleeve for slurry pumps manufacturers and suppliers

0 notes