#slurry pumps high chrome

Explore tagged Tumblr posts

Text

We are Specialize in Exporters and Suppliers of Slurry Pump Spare Parts, High Chrome Slurry Pump, High Chrome Investment Casting Manufacturers in India, Finland, USA, and Australia.

#Slurry Pump Spare Parts#High Chrome Slurry Pump#High Chrome Investment Casting Manufacturers in India

0 notes

Text

The Future of Heavy Duty Slurry Pumps in India's Growing Infrastructure Projects

India's rapid urbanization and industrial expansion have positioned it as one of the fastest-growing economies in the world. Central to this growth is the nation's robust infrastructure development, which includes large-scale projects in sectors such as mining, construction, and power generation. These industries demand reliable and efficient equipment to handle the challenging conditions of material transportation, particularly in handling abrasive and corrosive slurries. Heavy duty slurry pumps in India have emerged as indispensable tools, driving efficiency and reliability in these sectors.

This article delves into the future of heavy duty slurry pumps in India’s growing infrastructure projects, focusing on the evolving market dynamics, technological advancements, and the role of slurry pumps dealers in India, with a special emphasis on slurry pump manufacturers in Coimbatore.

The Infrastructure Boom in India

India's infrastructure sector is set to receive significant investments over the next decade, with government initiatives like the National Infrastructure Pipeline (NIP) projecting an investment of over $1.5 trillion by 2025. The focus areas include transportation (highways, railways, ports), energy (renewable and conventional), water resources, and urban development. Each of these areas requires advanced machinery and equipment capable of operating in harsh environments, making heavy duty slurry pumps critical to the success of these projects.

In mining, for instance, the demand for efficient slurry transportation systems is paramount due to the nature of the extracted materials, which often include heavy metals, ores, and other abrasive substances. Similarly, in construction, slurry pumps are essential for dewatering, concrete mixing, and the removal of waste materials. Power plants, particularly thermal and hydroelectric facilities, also rely on slurry pumps for ash handling, coal slurry transportation, and water treatment processes.

Technological Advancements Shaping the Future

The future of heavy duty slurry pumps in India is being shaped by significant technological advancements. Manufacturers are focusing on enhancing the efficiency, durability, and environmental compatibility of their products to meet the evolving needs of infrastructure projects.

Material Innovations: One of the most critical areas of development is the use of advanced materials to improve the wear resistance and longevity of slurry pumps. Materials such as high-chrome alloys, elastomers, and ceramics are increasingly being used in pump components to withstand the abrasive nature of slurries. These materials not only extend the service life of the pumps but also reduce the frequency of maintenance, thereby lowering operational costs.

Energy Efficiency: With the growing emphasis on sustainability, energy-efficient slurry pumps are gaining traction in the market. Modern pumps are being designed with optimized hydraulics, reducing energy consumption while maintaining high performance. Variable frequency drives (VFDs) and advanced control systems are also being integrated to adjust pump speed and flow rates according to the specific requirements of the application, further enhancing energy efficiency.

Smart Pumping Solutions: The integration of IoT (Internet of Things) and AI (Artificial Intelligence) in slurry pumps is revolutionizing the industry. Smart pumps equipped with sensors and monitoring systems can provide real-time data on pump performance, predict maintenance needs, and even automatically adjust operating parameters to optimize efficiency. These advancements are particularly beneficial in large infrastructure projects, where downtime can lead to significant delays and cost overruns.

Environmental Considerations: Environmental regulations are becoming more stringent, prompting manufacturers to develop slurry pumps that minimize environmental impact. Innovations such as leak-proof designs, reduced noise levels, and the ability to handle environmentally hazardous materials safely are becoming standard features in new-generation slurry pumps. These advancements not only ensure compliance with regulations but also contribute to the sustainability of infrastructure projects.

The Role of Slurry Pumps Dealers in India

As the demand for heavy duty slurry pumps in India continues to grow, the role of slurry pumps dealers in India becomes increasingly important. These dealers serve as the critical link between manufacturers and end-users, ensuring that the right products are available for various applications. They provide essential services such as technical support, maintenance, and after-sales services, which are vital for the smooth operation of infrastructure projects.

Dealers also play a key role in educating customers about the latest technological advancements and helping them choose the most suitable products for their specific needs. By maintaining close relationships with both manufacturers and end-users, slurry pumps dealers in India are well-positioned to anticipate market trends and provide products that meet the evolving demands of the industry.

Coimbatore: A Hub for Slurry Pump Manufacturing

Coimbatore, often referred to as the "Manchester of South India," is a major industrial hub with a strong presence in the manufacturing of pumps and other engineering products. The city is home to several leading slurry pump manufacturers in Coimbatore, who have established a reputation for producing high-quality, durable pumps that cater to the needs of India's growing infrastructure sector.

Manufacturers in Coimbatore are known for their focus on innovation and quality. They are continuously investing in research and development to introduce new technologies and improve existing products. The presence of a skilled workforce, advanced manufacturing facilities, and a supportive business environment has further strengthened Coimbatore's position as a key player in the slurry pump industry.

These manufacturers are not only catering to the domestic market but are also expanding their reach to international markets, showcasing the capabilities of Indian engineering on a global stage. As infrastructure projects in India continue to expand, the demand for high-quality slurry pumps from Coimbatore is expected to rise, driving further growth and innovation in the sector.

Conclusion

The future of heavy duty slurry pumps in India’s growing infrastructure projects looks promising, driven by technological advancements, a strong manufacturing base, and the crucial role played by slurry pumps dealers in India. As the country continues to invest in infrastructure development, the demand for efficient, durable, and environmentally-friendly slurry pumps will only increase.

Manufacturers, particularly those based in Coimbatore, are well-positioned to meet this demand with their focus on innovation and quality. By embracing new technologies and materials, and by continuing to prioritize energy efficiency and environmental sustainability, these manufacturers will play a vital role in shaping the future of India’s infrastructure landscape.

In conclusion, heavy duty slurry pumps in India are set to play an increasingly important role in the nation’s infrastructure development, ensuring that projects are completed efficiently, sustainably, and cost-effectively. As the industry continues to evolve, the collaboration between manufacturers, dealers, and end-users will be key to driving growth and innovation in this critical sector.

0 notes

Text

Tobee® TG Gravel Sand Pump

Email:[email protected]

Mob/WhatsApp: +86 181 3207 9120

Tobee® TG Gravel Sand Pump is horizontal single-casing gravel pump with wide channel to transfer sands, slurries orgravels with big particle size. The wet parts sre made of Ni-hard and high-Chrome alloys to ensure long service life. It has superior performance tahn common pumps in dredging, sand mining, barde loading and mineral processing etc. With all the advantages of TG Gravel pump, TGH gravel pump has achieved extra high head for special working conditions.

#CycloneFeedslurrypump#highefficiencyslurrypump#solidwasteslurrypump#highflowslurrypump#submersiblepump#wearresistantrubberslurrypump#slurrypumpsparts#verticalslurrypumps#gravelpumps#missionpump

0 notes

Text

HH Slurry Pump

HH Slurry Pump

Superb performance in high head application; 2. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely; 3. Interchangeable anti-abrasive wet parts made of high-chrome alloys; 4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc; 5. The shaft seal uses the packing seal, expeller seal and mechanical seal.

PHH series were designed to produce high heads per stage at high pressures. commonly used for long distance transport lines, the PHH lines can often satisfy application duties with a single pump where others require multiple pumps.the range is capable of handling medium size particles and pumping at heads in excess of 90 meters per stage.

Typical Applications —

Tailings Delivery

Cyclone Feed

Diamond Concentrate

Slag Granulation

Bottom Boiler and Fly Ash

Mill Discharge

SELECTION CHART

CONSTRUCTION DRAWING

Outline and installation dimensions

0 notes

Text

Wear-Resistant Coatings for Submersible Pumps

Wear-Resistant Coatings are essential for enhancing the durability and performance of submersible pumps, particularly in applications where components are subject to abrasion, erosion, or other forms of mechanical wear. These coatings help extend the life of pump components by providing a protective layer that withstands the stresses of operation. Here’s a detailed overview of wear-resistant coatings, including their types, applications, benefits, and considerations:

1. Types of Wear-Resistant Coatings

a. Ceramic Coatings

Types: Includes thermal spray ceramics (e.g., alumina, zirconia) and ceramic liners.

Properties: Extremely hard and resistant to abrasion, high temperatures, and corrosive environments.

Applications: Often used on impellers, volutes, and other high-wear components in pumps handling abrasive materials.

b. Hard Chrome Plating

Types: Electroplated chromium coatings.

Properties: Provides a hard, smooth surface with excellent wear resistance and corrosion protection.

Applications: Commonly used on shafts, pistons, and other components subjected to high wear and friction.

c. Carbide Coatings

Types: Includes tungsten carbide and chromium carbide coatings.

Properties: Highly resistant to wear, corrosion, and high temperatures; often applied via thermal spray or weld overlay.

Applications: Suitable for components exposed to severe abrasive conditions, such as in mining and slurry pumping.

d. Polymer Coatings

Types: Includes polyurethane, epoxy, and PTFE-based coatings.

Properties: Provides good resistance to abrasion, chemicals, and wear; often used in less severe conditions compared to ceramics and carbides.

Applications: Used on internal surfaces of pumps and other components that require a smoother finish and moderate wear protection.

e. Composite Coatings

Types: Combines metal and ceramic particles to form a composite layer.

Properties: Offers a balance between toughness and hardness, providing enhanced wear resistance.

Applications: Applied to pump components subjected to both impact and abrasive wear.

2. Applications of Wear-Resistant Coatings

a. Abrasive Slurry Pumping

Need: Pumps handling slurries, sand, or other abrasive materials require coatings that resist erosion and wear.

Coatings Used: Ceramic, carbide, and hard chrome coatings are commonly applied to impellers, liners, and casings.

b. Mining and Quarrying

Need: Equipment used in mining operations is exposed to highly abrasive materials and harsh conditions.

Coatings Used: Tungsten carbide and chromium carbide coatings are used on components such as pumps and conveyors.

c. Water and Wastewater Treatment

Need: Pumps in wastewater treatment facilities may face wear from solid particles and corrosive elements.

Coatings Used: Polymer coatings, along with ceramic and hard chrome, are applied to components like impellers and volutes.

d. Chemical Processing

Need: Pumps handling aggressive chemicals need coatings that resist both abrasion and chemical attack.

Coatings Used: Polymer coatings and ceramic coatings are used for internal surfaces and components.

e. Oil and Gas Industry

Need: Equipment in the oil and gas sector faces abrasive and corrosive conditions.

Coatings Used: Carbide and hard chrome coatings are used to protect components like pumps and valves.

3. Benefits of Wear-Resistant Coatings

a. Extended Component Life

Benefit: Reduces wear and tear on pump components, leading to a longer service life.

Impact: Decreases the frequency of replacements and maintenance.

b. Improved Performance

Benefit: Maintains smooth operation and efficiency by reducing friction and wear.

Impact: Enhances overall pump performance and reduces energy consumption.

c. Enhanced Reliability

Benefit: Provides protection against mechanical failure due to wear and abrasion.

Impact: Increases the reliability of the pump system, reducing the risk of unexpected downtime.

d. Cost Efficiency

Benefit: Reduces maintenance and replacement costs over the long term.

Impact: Provides a cost-effective solution by extending the life of expensive components.

e. Corrosion and Erosion Resistance

Benefit: Many wear-resistant coatings also offer resistance to corrosion and erosion.

Impact: Provides additional protection in corrosive and erosive environments.

4. Considerations for Choosing Wear-Resistant Coatings

a. Type of Wear

What to Consider: Identify whether the wear is primarily abrasive, erosive, or due to friction.

Impact: Choose a coating that is specifically designed to address the type of wear.

b. Operating Conditions

What to Consider: Assess factors such as temperature, pressure, and exposure to chemicals.

Impact: Select coatings that can withstand the specific operating conditions of your pump.

c. Compatibility with Substrate

What to Consider: Ensure that the coating adheres well to the pump material and does not affect its structural integrity.

Impact: Proper adhesion and compatibility ensure the effectiveness and durability of the coating.

d. Application Method

What to Consider: Different coatings require different application methods, such as thermal spraying, electroplating, or brushing.

Impact: Choose a coating that can be applied effectively based on your equipment and operational constraints.

e. Cost vs. Benefit

What to Consider: Evaluate the cost of the coating relative to the expected benefits in terms of wear resistance and extended component life.

Impact: Ensure that the chosen coating offers good value for the investment.

5. Maintenance and Care

a. Regular Inspections

Action: Inspect coated components regularly for signs of wear, damage, or coating degradation.

Benefit: Early detection of issues allows for timely repairs or re-coating.

b. Proper Cleaning

Action: Clean coated surfaces as needed to remove debris and prevent buildup that could affect performance.

Benefit: Maintains the effectiveness of the coating and prevents premature wear.

c. Follow Manufacturer Guidelines

Action: Adhere to the manufacturer’s recommendations for the care and maintenance of coated components.

Benefit: Ensures the coating performs as intended and lasts as long as possible.

Wear-resistant coatings play a crucial role in enhancing the durability and performance of submersible pumps, particularly in demanding applications. By selecting the appropriate coating based on the type of wear, operating conditions, and other factors, you can significantly extend the life of pump components and improve overall efficiency. Regular maintenance and proper care further ensure that these coatings provide maximum protection and performance. For more info contact Submersible Pump Suppliers in UAE or call us at +971 4 2522966.

#Submersible Pumps#Submersible Pump Suppliers in UAE#Submersible Pump Suppliers in Dubai#Submersible Pump Suppliers

0 notes

Text

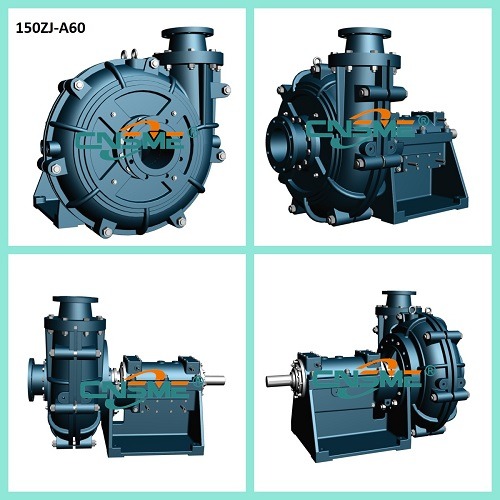

Pump Model: 150ZJ-A60

Flowrate: 135-550m3/hr;

Head: 14.7-63.5m;

Speed: 490-980rpm;

Lubrication: Thin Oil

Impeller: 5-Vane Closed Type with max.

Passage size: 48mm

ZJ series slurry pumps, totally designed and developed by Chinese local engineers, are high-head slurry pumps mainly used for filter press, coal washing, power plants, etc.

150ZJ is a 6-inch discharge-size slurry pump, with impellers varying from 420mm to 710mm.

Its wet-end spare parts are made of high chrome alloy ONLY, a kind of high abrasion and erosion-resistant white iron, similar to ASTM A532. There are no elastomer alternatives.

Applications:

Filter Press Loading, Power Plants, Mineral Processing, Flue Gas Desulphurization, Coal Washing, Metallurgy, etc.

www.cnsmepump.com www.slurrypump.co [email protected]

0 notes

Video

youtube

Tobee® Horizontal Bare Shaft Slurry Pump for Gold Mining Industry 14/12...

Email: [email protected] Web: www.tobeepump.com | www.slurrypumpsupply.com | www.tobee.store

#14x12 ST-AH Heavy Duty Slurry Pumps#14x12 Bare Shaft Slurry Pump with Electric Motor#China 14/12 AH Slurry Pump Manufacturer#14X12ST-AH High Pressure Slurry Pump#High Chrome AH Slurry Pump 14x12 AH

0 notes

Text

#Tobee® 2x1.5B-AH Centrifugal Mining Pumps Spare Parts#such as: Impeller B1127NA#Volute Liner B1110NA#Frame Plate Liner Insert B1041NA#Bearing Assembly B005M#etc. They can be made of wear resistant chrome alloy or rubber#and their designed for the handling highly abrasive#high density slurries.#E-mail: [email protected] | Web: www.tobeepump.com | Web: www.slurrypumpsupply.com | Web: www.tobee.cc | Web: www.hydroman.cn

0 notes

Video

youtube

Hydroman™ Hydraulic Excavating Head with Power Pack

Hydroman™ Hydraulic Submersible Slurry Pump Design Features: ▪ Submersible heavy duty agitator pump, hydraulic driven with variable RPM. ▪ All Pumps have standard high efficiency agitator to lift settled solids. ▪ High abrasion resistance with high chrome wear parts. ▪ Low rotation speed to reduce wear effect. ▪ Agitators, Head Cutter, Side Cutter, High pressure water jets ring, Cooling jacket, Excavators are available for options. ▪ Able to handle up to 70% solids by weight. ▪ Easy installation on the boom of hydraulic excavators.

Email: [email protected] Web: www.tobeepump.com | www.slurrypumpsupply.com | www.tobee.cc | www.tobee.store

#Power Pack Hydraulic Dredge Pump#Hydraulic Dredge Pump with Head Cutter#Hydraulic Submersible Dredge Pump#Hydraulic Excavator Dredge Pump#Submersible Dredging Pump

1 note

·

View note

Text

We have high chrome investment castingup upto 90 kg, shaft sleeve sl100, shaft sleeve sl150, shaft sleeve sl200, shaft sleeve sl250, shaft sleeve sl50, shaft sleeve sl750, slurry pump sl100, slurry pump sl250, slurry pump sl200, slurry pump spares job work, oem shaft sleeve for slurry pumps.

#slurry pumps high chrome#slurry pumps high chrome manufactures#slurry pumps high chrome manufactures in india#slurry pumps high chromes exports#slurry pumps high chrome exports in india#slurry pumps high chrome suppliers#slurry pumps high chrome suppliers in india

0 notes

Photo

Tobee® 14/12 AH Slurry Pumps are ready for shipping to an Iron Mine in Australia. The two 14/12 Slurry Pumps are made in A05A material with 27% chrome. The 14/12 AH Slurry Pump is the horizontal, cantilevered centrifugal slurry pump, with reasonable construction, reliable operation, long service life. It is widely used in transporting abrasive or / and corrosive slurry in mining, metallurgy, electric power, coal, chemicals, building, etc. Especially well accepted by coal / chrome washing plant, mineral processing plant, power plant etc. Features • Excellent performance High efficiency and low noise with powerful motor and reasonable airframe design. • Economical and practical Energy-saving design and reasonable price help you improve the quality of life. • Simple and convenient setup and assembly The new process design makes assembly easy and maintenance convenient. • Good seal performance Double seal arrangement provides positive seal of bearings against contamination. • Low maintenance The motor has long practical life, simple operation and convenient maintenance.

14/12 AH Slurry Pump Delivery Photos:

AH Slurry Pump Frame Type:

Support TypeABCDERFGST

Support Weight (kg)17244577.515422855510065461156

Max Power (kW)7.51530601203002606005601200

Seal Water Volume (l/s)0.150.250.350.550.70.70.71.21.21.6

14/12 AH Slurry Pump Application Range:

AluminaCopperOil Shale

WolframSugarTitanium

Water & Sewage TreatmentTinTobacco

CoalMineral SandsSilver

Chemical FertilizerMolybdenumSteel

CementLead & ZincSand & Gravel

Building ProductsIron OrePaper & Pulp

BauxiteGoldPotash

AsbestosElectric UtilitiesPhosphate

Contact the Tobee for slurry pumps price and availability via [email protected] or +86-18032034573

1 note

·

View note

Text

Tobee® 100 D-L Light Slurry Pump, Gold Recovery Pump

Email:[email protected] Mob/WhatsApp: +86 181 3207 9120

100D-L Light Slurry Pumps are higher efficient centrifugal slurry pumps, similar in design to the AH series slurry pumps. L series slurry pumps operate in high speed with small volumes to save floor area, the metal lined and rubber lined are interchangeable, Impeller adopts hyper chrome alloys or rubber etc. #CycloneFeedslurrypump#highefficiencyslurrypump#solidwasteslurrypump#highflowslurrypump#submersiblepump#wearresistantrubberslurrypump#slurrypumpsparts#verticalslurrypumps#gravelpumps#missionpump

0 notes

Text

PV Slurry Pump

1. Single casing structure with the advantages of light weight, small volume, easy installation; 2. Anti-abrasive wet parts made of high-chrome alloys; 3. Transmission shaft and suction pipe could be chosen according to liquid surface of the slurry pool; 4. Slurry pump agitator could be installed to improve transfer efficiency; 5. Able to run smoothly under various speeds.

PV sump pumps are vertical, centrifugal slurry pumps submerged in sump to work.They are designed for delivering abrasive,large particle and high density slurries.These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.Wet parts of type PV pump are made of abrasion-resistant metal. All parts of type PV(R) pump immersed in liquid are lined with rubber outer liner.They are suited to transport non-edge angle abrasive slurry.

Typical Applications —

● Sump drainage washdown

● Floor drainage

● Mill sumps

● Carbon transfer

● Monitoring

● Magnetite mixing

Construction of Vertical Sump Pump

Main Part With Numbers In The Drawing 1. Shaft 2. Dust Cover 3. Bearing 4.Bearing Gear Sleeve 5. Bearing Body 6. Bearing 7. Bracket 8. Filter Net 9. Rear Guard Plate 10. Impeller 11. Pump Body 12. Lower Filter 13. Spit Tube 14. Split Spout Flange 15. Bearing Gland

Contruction Drawing

Shijiazhuang Pansto Pump Industry Co., Ltd.

Web site:https://www.sumpslurrypump.com/

Movil:+86-19333581599

WhatsApp:+86-19333581599

Email:[email protected]

Skype:[email protected]

Twitter:https://twitter.com/panstopump

Pinterest:https://www.pinterest.co.uk/roseysu/

Address:Shijiazhuang Equipment Manufacturing Base, Hebei Province, China

Whatsapp code:

Wechat code:

0 notes

Text

Dredging Equipment and Consulting

Dredging Equipment and Consulting

youtube

Full line of heavy-duty dredging equipment for mining and environmental projects. High slurry high chrome pumps, dewatering, and dredge consulting pumpandslurry.com

With twenty years of experience in manufacturing equipment for the dredging and mining industry we deploy, consult, and set up projects with an equipment package to handle any big project. We have built industry relationships to get projects from ideas to completion for all types of stakeholders including companies, individuals, and municipalities. Explore our slurry transport and dredging equipment below and reach out to see about getting your project started.

#dredging equipment

1 note

·

View note

Link

End suction pumps are one of the main common types of centrifugal pumps. Cost-effective and reliable, they are suitable for a variety of pumping applications. They’re nearly always single stage pumps, meaning they need only one impeller. Available in an exceedingly big selection of sizes, construction materials, and styles, they will be accustomed to pump a range of fluids from ambient-temperature water to high-pressure and high- temperature viscous oils, abrasive slurries, and corrosive chemicals. Betting on the top pumping application, they will be constructed from plastic, standard iron, hardened iron, chrome steel, or more exotic alloys. End suction pumps are found across the spread of commercial facilities and water treatment and processing plants. They’re also commonly used for fire fighting and protection systems, HVAC systems, and pressure boosting large-scale plumbing systems for giant buildings like office buildings, shopping malls, and stadiums. Working of end-suction pumps Centrifugal pumps in general work by forcing the pumping fluid through one or more rapidly rotating impellers, thereby increasing the fluid’s velocity and pressure. End suction pumps usually contain just one impeller and a volute type casing. Volute casings have an offset impeller, which creates a curved funnel with the area increasing towards the pump outlet or discharge. This helps to increase the fluid pressure towards the outlet. The pumped fluid enters the impeller at its rotating axis or the eye of the impeller. The

rotation of the impeller then accelerates the liquid. It flows radially outward into the volute casing, where the high velocity is converted to high pressure through a diffusion process. An alternating current electric motor usually drives them. However, direct current motor driven ones are available and pump driven by air motors, hydraulic motors, steam turbines, and diesel and petrol engines. Applications & Services: ● Circulating Water System ● Power plants ● WTP & STP ● Fire Fighting ● HVAC ● Irrigation / Sprinkler service ● General Services

Types of End Suction Pumps

End suction pumps are useful in many types of residential, commercial, and industrial applications. Since they are so common and available from so many pump suppliers, they are often offered at very attractive prices. Standard water pumps are often close coupled and made of traditional iron or various plastics for a low cost. For more heavy-duty industrial applications, the pumps are usually mounted on a bedplate with a coupling separating the pump and motor. These are often supplied in stainless steel or more exotic alloys or plastics for corrosion resistance or made of hardened iron for slurry applications in mining, dredging, and minerals processing. End suction pumps can be fitted with open impellers for chemical or food processing applications that contain solids or have closed impellers for relatively clean water and oil services. The pump shaft is sealed from the

environment with conventional packing, mechanical seals, or the pump may be a magnetic drive or canned motor pump type. The best manufacturer of end-suction pumps, the FLOW MORE PUMPS, based in Gurugram, provides the best pumps. If you are looking for high- quality end-suction pumps at reasonable prices, then visit flowmorepumps.com today!

1 note

·

View note

Text

AH slurry pump frame plate liner insert

AH slurry pump frame plate liner insert Material in high chrome, harness up to HRC62 Welcome to contact us for more information mail to [email protected] Or visit us for more products at www.librafluid.com

1 note

·

View note