#six sigma methodology

Explore tagged Tumblr posts

Text

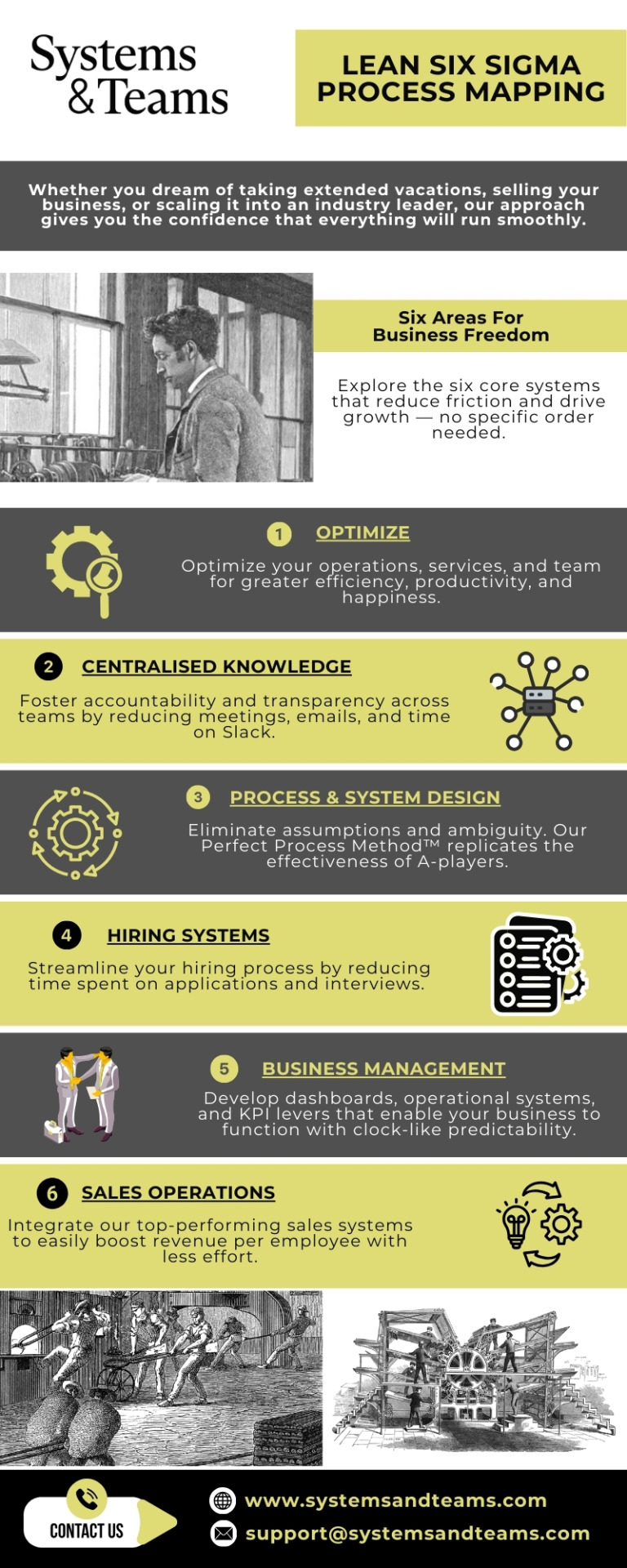

Business Process Mapping - Systems And Teams

Systems and Teams specialises in making businesses more efficient by removing the friction caused by unstructured operations. Our systems-first approach ensures that businesses can scale by creating error-free processes that team members can follow without extensive training. Our solutions are designed to allow business owners to focus on growth while the business runs itself.

#Business Process Mapping#Lean Methodology#Lean Thinking#Business Processes#Small Business Systems#Six Sigma Methodology#Six Sigma Process Mapping#Business Systems#Business Process Solutions

0 notes

Text

Looking for Six Sigma consulting? MechMinds enhances your business efficiency and reduces defects. Achieve operational excellence with us.

0 notes

Text

Understanding Six Sigma: A Path to Process Perfection

Six Sigma is a data-driven methodology focused on improving business processes by reducing defects and variability. Originating from Motorola in the 1980s, it aims for near-perfection, targeting only 3.4 defects per million opportunities. Six Sigma uses DMAIC (Define, Measure, Analyze, Improve, Control) for existing processes and DMADV (Define, Measure, Analyze, Design, Verify) for new ones. It…

View On WordPress

#100 word article#a short article#a short article on six sigma#Business Efficiency#Operational Excellence#Process Improvement#Quality Management#Six Sigma#six sigma methodology#what is six sigma

0 notes

Text

Six Sigma DMAIC

The Six Sigma quality improvement methodology uses a problem-solving technique called DMAIC. It stands for Measure, Analyze, Improve, and Control. Here is a quick summary of each stage of the DMAIC process: Define: This stage defines the project’s scope and problem precisely. Ensuring that everyone participating in the project has a clear grasp of the issue and what needs to be done is the goal…

View On WordPress

#Analyze#Continuous improvement#Control#Data-driven decision making#Define#DMAIC process#Improve#Measure#Performance metrics#Process Improvement#Process optimization#Quality improvement#Root Cause analysis#Six Sigma methodology#statistical analysis

0 notes

Note

Check in because I notice the polls are uploaded a lot- doth has the Button slept?

I want to thank you so much for your concern. Buttons hasn't slept much in the last few days, but that has been stressing over something I can't control. Buttons has decided 2025 is the year of personal growth, though.

Buttons earned her Six Sigma White Belt and it was free (Six Sigma is a methodology that utilizes statistical tools and concepts to identify variations or defects in a process.)

I may pay to get my Yellow Belt, but I won't go any farther than that unless my employer pays for it.

39 notes

·

View notes

Text

Mastering Lean Six Sigma Green Belt Your Path to Operational Excellence

Introduction to Lean Six Sigma Green Belt

Lean Six Sigma Green Belt training is a powerful and valuable program that equips professionals with the skills to improve processes, enhance quality, and drive operational excellence. This training is crucial for those aiming to advance their careers in process improvement and quality management

Why Choose Lean Six Sigma Green Belt?

Understanding the importance of Lean Six Sigma Green Belt certification is the first step toward recognizing its value. This certification demonstrates a professional’s ability to lead small-scale improvement projects, analyze and solve quality problems, and contribute to the overall efficiency of an organization

Core Concepts and Methodologies

Lean Six Sigma Green Belt training covers essential concepts such as DMAIC (Define, Measure, Analyze, Improve, Control), value stream mapping, root cause analysis, and statistical process control. These methodologies help professionals identify inefficiencies and implement effective solutions

Real-World Applications

The real-world applications of Lean Six Sigma are vast and varied. Green Belt professionals work across industries such as manufacturing, healthcare, finance, and IT, using their skills to streamline processes, reduce waste, and improve customer satisfaction

Benefits of Certification

Obtaining a Lean Six Sigma Green Belt certification not only enhances your skill set but also increases your marketability. Certified professionals often experience career advancement opportunities, higher salaries, and a greater ability to contribute to their organizations’ success

Conclusion

Your Journey to Excellence

Embarking on Lean Six Sigma Green Belt training is a strategic move for any professional seeking to excel in their career. By mastering these techniques, you position yourself as a valuable asset capable of driving significant improvements and achieving operational excellence

2 notes

·

View notes

Text

Demystifying the Different Types of Agile Certifications

A Beginner's Guide

Are you new to the world of Agile methodologies and wondering what all the talk about certifications is? Look no further, as this beginner's guide will break down the different types of Agile certifications and help you understand the benefits and differences between each. From Scrum and Kanban to SAF e and PMI-ACP, we will demystify the jargon and give you a clear understanding of how each certification can enhance your career and benefit your organization. Whether you're a project

Breaking Down the Different Types of Agile Certifications

Agile certifications are becoming increasingly popular in the business world as more and more companies are adopting agile methodologies With so many different types of certifications available, it can be overwhelming trying to decide which one is right for you or your team In this comprehensive guide, we will break down the different types of agile certifications and help you understand their benefits and requirements.

Firstly, let's define what agile training certification actually means Agile training refers to a specific type of education that teaches individuals about various agile practices, principles, and frameworks By obtaining an agile certification, professionals can demonstrate their knowledge and expertise in these areas.

There are several different types of agile certifications available depending on the specific methodology or framework being used The most common ones include Scrum Master Certification (SMC, Certified Scrum Product Owner (CSPO, Agile Certified Practitioner (ACP, Lean Six Sigma Green Belt (LSSGB and Professional Scrum Master )

Each certification has its own unique set of requirements such as attending a certain number of hours in training sessions or passing an exam with a minimum score It is important to carefully research each certification before deciding which one best fits your needs and goals.

The benefits of obtaining an agile certification are numerous First and foremost, it demonstrates to employers that you have a solid understanding of the principles behind agility and possess valuable skills that can contribute to successful project execution It also sets you apart from other candidates when applying for jobs or promotions within your company.

Additionally, getting certified shows commitment to continuous learning and improvement in your career field which is highly valued by employers Having an official recognition from a reputable organization also adds credibility to your resume which can lead to higher salary potential.

In conclusion, there are many factors to consider when choosing the right type of agile certification for yourself or your team members including cost, time commitment required for completing the program, specific skill-set needs within your industry etc. It is important to carefully research and understand each certification before making a decision The benefits of being certified can greatly impact your career growth and open up new opportunities With this comprehensive guide, we hope you have gained a better understanding of the different types of agile certifications available and can make an informed decision in your pursuit towards becoming an expert in agile methodologies

2 notes

·

View notes

Text

Shrngga Global Solutions (About Us)

We work with Organizations and Stakeholders to build scalable result driven solutions for the black holes in system, process and the value-chain. We ensure that our client keep focus on their business and we focus on the solutions for them.

Much more than consultants, we allies on our clients digital journey.

We believe in transformative power of Consulting & Training solutions to elevate excellence in System, Operations, Process, Business & People.

SGS innovation solutions approach and methodologies go beyond traditional analytic consulting approaches. Our innovation solutions will help our client discover the unknown – and identify and leverage opportunities and markets that don’t yet exist.

SGS support organizations/Business & Stakeholder to anchorage capabilities and virtues that they already have to drive Organic Growth i.e. more sales per customer , more revenues per customer, or more customers for the same products . This focus enables us to bring deep expertise, experience, judgment, and pattern recognition to growth problems.

We at Shrngga Global Solutions are committed to provide leading edge Business Consulting and Training Services in Business Excellence, Process Excellence, Operation Excellence, Digitization enhancement and Strategy Execution with the usage of Lean Six Sigma, Lean Management, Robotics Process Automation, Project Management and Business Analysis & analytics.

Our Training Services comprises of Lean Six Sigma Green Belt, Black Belt, Master Black Belt, Business Process Modelling, Theory of Constraints, Robotics Process Automation, Business Analysis, Business Analytics, Project Management (Prince 2), ITIL, ISO 9000, ISO 27000, ISO 31000.

www.shrnggaglobalsolutions.com

www.linkedin.com/in/kapil-mohan-sharma-43512434

#service#learning#finance#sigma#lean six sigma#statistics#economics#excel#digitalmarketing#digital#business#startup#entrepreneur#consulting#training#course#coaching#digital transformation#transformation#freelance

12 notes

·

View notes

Text

Six Sigma and Lean Six Sigma: Concepts, Methodology, and Benefits.

In the pursuit of operational excellence and continuous improvement, organizations have turned to methodologies such as Six Sigma and Lean Six Sigma. Six Sigma is a data-driven approach that aims to eliminate defects and reduce process variations, while Lean focuses on waste reduction and process optimization. Together, these methodologies form Lean Six Sigma, a powerful framework that combines the principles of statistical analysis, problem-solving, waste elimination, and continuous improvement. Lean Six Sigma has become a cornerstone for organizations seeking to enhance efficiency, quality, and customer satisfaction. By integrating these methodologies, businesses can streamline processes, drive cost savings, and gain a competitive advantage in today's competitive marketplace.

What is Six Sigma?

Six Sigma is a data-driven, structured approach for process improvement that originated at Motorola in the 1980s. It gained widespread recognition after General Electric (GE) successfully implemented the methodology, leading to significant cost savings and improved customer satisfaction. At its core, Six Sigma aims to achieve process efficiency and effectiveness by minimizing process variation and aligning outcomes with customer expectations.

The term "Six Sigma" refers to a statistical concept that measures process performance. It represents a level of quality where the number of defects is extremely low, allowing for only 3.4 defects per million opportunities. This stringent quality standard reflects a commitment to excellence and sets the bar for organizations aiming to deliver superior products and services consistently.

Six Sigma is not limited to manufacturing industries; its principles and techniques have been successfully applied in service organizations, healthcare, finance, and many other sectors. It provides a structured framework that empowers organizations to drive process improvement, increase customer satisfaction, reduce costs, and achieve operational excellence.

History and Evolution of Six Sigma

Six Sigma is a methodology for process improvement that has become widely recognized as a standard for quality management across many industries. It was first developed in the 1980s by Bill Smith, a senior engineer at Motorola, who was tasked with finding a way to reduce defects in their production processes.

The development of Six Sigma was influenced by several other quality management initiatives that came before it, including Total Quality Management (TQM) and Statistical Process Control (SPC). These initiatives emphasized the importance of process improvement and data-driven decision-making, which are also core principles of Six Sigma.

Motorola implemented Six Sigma in the late 1980s and early 1990s, and the results were impressive. They reported a reduction in defects of more than 99% and a cost savings of over $16 billion. As a result, other companies began to take notice of Six Sigma and its potential for improving business processes and reducing costs.

In the 1990s, Six Sigma gained widespread popularity, particularly in the manufacturing sector. General Electric (GE) was one of the early adopters of Six Sigma, and they made it a core part of their business strategy. Under the leadership of CEO Jack Welch, GE reported cost savings of over $10 billion as a result of Six Sigma.

Since then, Six Sigma has continued to evolve and expand beyond the manufacturing sector. It has been adopted by many other industries, including healthcare, finance, and service industries.

Understanding the DMAIC Process in Six Sigma

DMAIC is an acronym that stands for Define, Measure, Analyze, Improve, and Control. It represents the five phases of Six Sigma Methodology and typically makes up the process:

Define: In this phase, the project team defines the problem they are trying to solve and identifies the goals and objectives of the project. They also identify the key stakeholders like current and future customers and develop a project charter that outlines the scope and timeline of the project.

Measure: In this phase, the team collects data on the process they are trying to improve. They use this data to create a baseline measurement of the process and identify areas of variation that need to be addressed. Mapping of various processes, capability analysis and Pareto chart can be prepared to analyze the frequency of problems or its causes.

Analyze: In this phase, the team analyzes the data to identify the root cause of the problem to identify the errors. They use statistical tools and techniques like FMEA and Multi vari chart to identify patterns and trends in the data and develop hypotheses about the root cause of the problem.

Improve: In this phase, the team develops and implements solutions to address the root cause of the problem. They use data to test and refine their solutions, and they implement controls like Design of experiments (DOE) to solve problems from complex processes or systems where there are many factors influencing the outcome and where it is impossible to isolate one factor or variable from the others and Kaizen event to introduce rapid change by focusing on a narrow project and using the ideas and motivation of the people who do the work to ensure that the improvements are sustained over time.

Control: In this phase, the team monitors the process to ensure that the improvements are sustained. They also develop a control plan for ongoing monitoring and measurement (through various processes like – SPC for monitoring process behavior, 5S to create visual controls for workplace and Poka yoke for error proofing or immediately detect errors) to ensure that the process continues to meet the desired quality standards.

By following this structured approach, Six Sigma can help businesses improve their processes and reduce defects, which can lead to increased customer satisfaction, improved efficiency, and reduced costs.

Key Benefits and Advantages of Implementing Six Sigma

One of the key benefits of Six Sigma is that it provides a common language and methodology for process improvement across different departments and functions within an organization. This can help to break down silos and improve communication and collaboration across the organization. So in process improvement it offers several benefits like:

Increased efficiency and productivity which leads to cost saving and improved competitiveness.

Reduced defects: Cost saving by avoiding the costs associated with rework, scrap, and warranty claims.

Data-driven decision-making

Improved collaboration across different departments and functions within an organization.

Continuous improvement

Standardization

Competitive advantage

So overall, by focusing on process improvement and data-driven decision-making, Six Sigma can help businesses achieve significant improvements in efficiency, quality, and customer satisfaction.

What is Lean Six Sigma?

While Six Sigma focuses on reducing defects and process variations, Lean Manufacturing aims to eliminate waste and enhance efficiency. By combining the principles of Lean and Six Sigma, organizations can achieve a powerful methodology known as Lean Six Sigma.

Lean principles, derived from the Toyota Production System, emphasize the identification and elimination of waste in all its forms. Waste, or "muda" in Japanese, can take several forms, including overproduction, excess inventory, defects, waiting time, unnecessary transportation, over-processing, and unused employee skills. Lean Six Sigma utilizes various tools and techniques to identify and eliminate these wasteful activities, streamlining processes and reducing costs.

The integration of Lean and Six Sigma creates a synergistic effect, enabling organizations to optimize their processes and achieve sustainable improvements. Lean focuses on improving flow and minimizing non-value-added activities, while Six Sigma provides the statistical analysis and problem-solving capabilities to drive quality improvements.

Key concepts of Lean Six Sigma

Value: Lean Six Sigma revolves around delivering value to the customer. Value is defined as any action or process that directly contributes to meeting customer requirements and is something that customers are willing to pay for. The goal is to maximize value while minimizing waste.

Waste (Muda): Waste refers to any activity, process, or resource that does not add value to the customer. Lean Six Sigma identifies eight types of waste: overproduction, waiting, unnecessary transportation, excess inventory, over-processing, defects, unused employee creativity, and motion. Eliminating waste is a fundamental principle of Lean Six Sigma.

Flow: Flow refers to the smooth and uninterrupted movement of products, services, or information through a process or value stream. Lean Six Sigma aims to eliminate obstacles, delays, and disruptions in flow to improve overall process efficiency and reduce lead times.

Pull: The concept of pull focuses on producing or providing products or services based on actual customer demand rather than pushing them into the system based on forecasts or assumptions. Pull systems help reduce overproduction, minimize inventory, and enable a more responsive production process.

Standardization: Standardization involves creating consistent and repeatable processes, procedures, and work instructions. It ensures that best practices are established and followed consistently across the organization, reducing variations and improving quality.

Continuous Improvement: Continuous improvement is at the heart of Lean Six Sigma. It emphasizes the ongoing pursuit of small, incremental improvements in processes, products, and services. Through the use of tools like PDCA (Plan, Do, Check, Act) or DMAIC (Define, Measure, Analyze, Improve, Control), organizations can systematically identify and implement improvements.

Variation: Variation refers to the differences or deviations that occur in processes, outputs, or outcomes. Lean Six Sigma aims to reduce variation to achieve consistent and predictable results. Statistical tools and techniques are used to measure, analyze, and control process variations.

Root Cause Analysis: Identifying the root causes of problems or defects is crucial in Lean Six Sigma. By digging deep into the underlying causes, organizations can address the core issues and prevent their recurrence. Tools such as fishbone diagrams, 5 Whys, and cause-and-effect analysis are commonly used for root cause analysis.

Data-Driven Decision Making: Lean Six Sigma emphasizes making decisions based on objective data and analysis rather than relying on assumptions or opinions. Statistical analysis and data collection techniques are employed to measure process performance, identify trends, and make informed decisions for process improvement.

Teamwork and Employee Engagement: Lean Six Sigma recognizes the importance of involving employees at all levels in process improvement efforts. Cross-functional teams are often formed to work collaboratively, share knowledge, and generate innovative solutions. Employee engagement and empowerment foster a culture of continuous improvement and create a sense of ownership.

These concepts form the foundation of Lean Six Sigma and guide organizations in their pursuit of operational excellence, waste reduction, and quality improvement.

Future and Innovation in Six Sigma and Lean Six Sigma

Six Sigma and Lean Six Sigma has come a long way since its inception in the 1980s. Originally developed by Motorola, it has now become a widely accepted methodology for improving business processes across different industries. While the basic principles of Six Sigma remain the same, there are numerous future trends and innovations that can shape the future of Six Sigma like;

Integration with Artificial Intelligence (AI) and Machine Learning (ML)

Focus on Customer Experience

Emphasis on Sustainability: Organizations can use Six Sigma and Lean Six Sigma to identify and reduce their environmental impact, minimize waste, and improve their carbon footprint. This can not only benefit the environment but also help organizations reduce costs and improve their reputation.

Application in the service industry: The future of Six Sigma and Lean Six Sigma lies in its ability to adapt to the unique needs of different industries and help them achieve their specific goals.

Integration with Agile: Agile are popular approaches for project management and process improvement. Six Sigma can be integrated with these methodologies to create a hybrid approach that combines the best of both worlds.

Lean Six Sigma combines the power of Six Sigma and Lean methodologies to create a comprehensive approach for organizations to drive efficiency, reduce waste, and improve quality. Six Sigma focuses on data-driven decision making and problem-solving to reduce process variations and defects, while Lean aims to eliminate waste and streamline processes. By integrating these two methodologies, Lean Six Sigma enables organizations to achieve remarkable results in terms of operational excellence, cost reduction, and customer satisfaction. It provides a structured framework for continuous improvement, empowers employees to contribute to process optimization, and fosters a culture of excellence and innovation. With Lean Six Sigma, organizations can maximize their potential, achieve sustainable improvements, and gain a competitive edge in today's dynamic business environment.

#iso certification consultants#iso certification#iso training#iso consultancy#iso certificate online

3 notes

·

View notes

Text

🔰 Stakeholder management poses various challenges, including identifying and prioritizing stakeholders, effectively engaging them, and resolving conflicts.

Lean Six Sigma Green Belt methodology offers valuable solutions. By applying the Define phase, stakeholders can be clearly defined and their expectations identified, ensuring focused efforts. Engaging stakeholders is enhanced through the Measure phase, utilizing tools like surveys and interviews to gather feedback and involve them in decision-making. The Analyze phase enables understanding of conflicts and their root causes, aiding in the development of targeted solutions. The Improve phase facilitates implementing stakeholder-centric improvements and monitoring their impact.

Finally, the Control phase establishes mechanisms to sustain stakeholder satisfaction. Lean Six Sigma Green Belt techniques enable structured stakeholder management, fostering collaboration, addressing conflicts, and ultimately delivering improved outcomes.

➡️ "Unlock your potential with a Green Belt course. Gain in-demand skills, drive process improvements, and boost career prospects. Enroll now and transform your future!"

lean6sigmaacademy #leansixsigma #leansixsigmagreenbelt #greenbelt #stakeholdermanagement

2 notes

·

View notes

Text

Six Sigma Process Mapping - Systems And Teams

#Six Sigma Methodology#Six Sigma Process Mapping#Small Business Systems#Business Processes#Lean Thinking#Lean Methodology#Business Process Management System#Business Process Operations#Succession Planning#Business Process Management#Business Process Mapping Consultants

1 note

·

View note

Text

Lean, 5S, and Six Sigma 1/2

Lean, 5S, and Six Sigma are three methodologies that organizations can use to improve their operations and processes. Each of these approaches focuses on reducing waste, increasing efficiency, and improving quality, but they use different tools and techniques to achieve these goals.

Let's take a closer look at each methodology: 1. Lean: Lean is a philosophy that aims to eliminate waste and create value for customers. It originated in manufacturing, but it can be applied to any industry. The primary goal of Lean is to create a process that is as efficient as possible by identifying and eliminating anything that does not add value to the final product or service. Lean relies on continuous improvement and encourages employees at all levels to identify opportunities for improvement.

The second part is coming soon

2 notes

·

View notes

Text

➡️ Complete Tutorial of 5S Methodology Explained with Examples

#lean six sigma #excellence #tutorial #kaizen #iso9001 #leansixsigma #tutorials #leanmanufacturing #5s #oee #industrialengineering #pokayoke #7qctools #histogram #tpm #iatf16949 #g8d #iatf #qms #vsmstudy #flowchart #histograms #smartgoal #DMAIC #5Why #BlackBelt #GreenBelt #YellowBelt

2 notes

·

View notes

Text

What is the best industry to start a six sigma career?

Six Sigma methodology can be applied to a wide range of industries, including manufacturing, healthcare, finance, and service industries, among others. Therefore, there is no specific industry in which to start a Six Sigma career.

The choice of industry will depend on your personal interests, career goals, and the opportunities available in your area. For example, if you are interested in manufacturing, you may want to pursue a Six Sigma career in that industry, while if you are interested in healthcare, you may want to focus on applying Six Sigma principles to improve patient care and reduce medical errors.

That being said, some industries may have a higher demand for Six Sigma professionals than others. For example, the manufacturing industry has traditionally been a major user of the Six Sigma methodology, as it helps to reduce defects and improve productivity. However, other industries, such as healthcare and finance, are increasingly recognizing the benefits of Six Sigma and are starting to adopt it in their operations.

In general, the best way to start a Six Sigma career is to gain a solid understanding of the methodology, its tools, and its applications, and then look for opportunities to apply that knowledge in your chosen industry. You can gain this knowledge through training programs and certification courses, as well as through practical experience working on Six Sigma projects.

#six sigma type#six sigma course#six sigma certification cost#six sigma certification#six isgma#business#growing a business#popular#entrepreneur#startup

2 notes

·

View notes

Text

Personal framework for running a global engineering team

Five months in being Director of Engineering for a fintech startup, overseeing a small team that spans south Asia and North America, I'm building a global engineering culture that produces a high-quality technology product. Greatest challenge I've ever faced. What is helping me?

1. Being a systems thinker.

As a child my uncle would go to a used computer store, Weird Stuff, in Silicon Valley and bring home junk. I would take apart and rebuild computers. At the same time, on weekends, I would help mom look after our garden filled with abundant fruit trees.

Looking after a garden helped me practice managing micro-ecologies. I played a lot of video games growing up, notably SimCity, Civilization, and SimEarth. It was fun to explore different ways of managing complex systems (cities, nations, planet).

2. Understanding culture via ethnic studies.

I became interested in understanding my Vietnamese heritage while entering college. I became involved in Vietnamese student organizing at the school, regional, and continental level, especially organizing conferences.

I took a course in Native American Studies and Asian American Studies to help compare. What was important was to have a statistical and anecdotal view of culture. Traits can manifest by many, or by few who still see themselves part of the group.

Also important was tweaking or implementing new cultural practices. A big focus during my time as a student organizer—credit which goes to my peers—was building social cohesion among people in different geographies via group activities, e.g. scavenger hunt, trò chơi lớn.

Sometimes it failed. Other times it succeeded. Either way, a lesson learned: utilize one's upbringing, or design a way to introduce people into a new practice. Which segues into...

3. Practice marketing and product development.

I practiced asking/answering: What do people do? Is there something (a product) that exists to fulfill their needs? How can it be improved? I practiced via student community organizing, and continued having joined many tech startups.

At every startup company, we created a tech product (I developed my software engineering skills), and had to test and validate its viability. And in the context of a startup, I learned product development processes such as Agile methodology.

Culture is a product too, e.g. instituting a mentorship program, or Vietnamese New Year festival. They're not software, but it benefits from asking the same questions. Can't just do things just cuz it's always been done that way. Why do it? Otherwise people flock to alternatives.

4. Study leadership.

One way to approach it is learning the levels of leadership. The first person you lead is yourself. And then you learn to lead peers/groups, then organizations, then communities, societies, etc.

For each level one had to learn different skills. Level 1 (self) you learn self-awareness and self-love. Level 2 (peers) you learn empathy, chit chat, paired activities (hanging out; dates). Level 3 (group) you learn things like conflict resolution mediation.

Learning and practice never ends. Just because I practiced how to do it with peers my age, as time goes on, you just end up practicing with people of different backgrounds: age, origin, beliefs, life circumstances, disabilities, etc.

5. Learning and applying industrialization.

So it's one thing to learn how to create products. It's another matter to make it accessible at scale. I'll watch videos on how things are built such as how Coca-Cola Company makes soda. Or how McDonald's churn out burgers quickly.

It helps to be a systems thinker, to really identify where things get slow. When I played SimCity, I loved identifying and clearing out traffic bottlenecks. It also helps to understand lifecycles (thanks high school biology), because a lot of problems come down to timing issues.

Now... I don't have a formal training in industrial processes like Six Sigma or Toyota Production System. But it's definitely something I'm interested in. Why? Because I like to model after good practices that already exist. Which segues into...

6. Leverage partnerships and external inspirations.

An important lesson I learned while organizing in the Vietnamese nonprofit community is: if you can't do it yourself, partner with someone who can. Build their work into your flow. Or model their process.

I worked with nonprofits, so I only had shoestring budgets or volunteer hours to work with. My mentees created youth development programs by inviting staff of other nonprofits to participate. DIY is cool, but if it's not an option, collaborate.

Or if limited resources, introduce an abbreviated form. Set a goal for each team member to learn and apply one new thing each month to steer the team towards a framework. Sometimes it's about introducing terminology, because words shape our reality and the way we do things.

Sorry this is so long; really this is a brain dump. I need it because I needed to create my own personal framework for how I am running the engineering team.

5 notes

·

View notes

Text

Discover how Lean and Six Sigma methodologies can drive long-term cost savings, eliminate waste, and strengthen your market position. Learn strategies to optimize processes and boost efficiency for sustained growth and success in a competitive market.

0 notes