#six sigma green belt training

Explore tagged Tumblr posts

Text

What Is Six Sigma? Definition, Methodology, and Belts – A Guide by MindCypress

Six Sigma is a data-driven methodology aimed at improving the quality of processes by reducing defects and minimizing variability. Originating from the manufacturing industry, it has expanded into various sectors, including healthcare, finance, and IT, to optimize performance and ensure consistent results. MindCypress offers comprehensive training programs to help individuals and organizations master Six Sigma techniques and implement them effectively.

Understanding Six Sigma

Six Sigma is a statistical approach for the improvement of process quality, and its defect reduction aim is to be at or below 3.4 defects per million opportunities in achieving near-perfect quality. It employs the use of the DMAIC methodology- Define, Measure, Analyze, Improve, Control-which ensures a structured and scientific method for process identification:

Define: Identify the problem, project goals, and customer requirements.

Measure: Collect data to establish current process performance and set benchmarks.

Analyze: Identify the root cause of defects and process inefficiencies.

Improve: Develop solutions and implement process changes to eliminate defects.

Control: Monitor the new process to ensure continued improvements.

How to Get Certified: Six Sigma

Mastering the methodology would require Six Sigma certification. MindCypress has different training programs for all levels and meets the diversified career goals of its clients. Six Sigma certifications, like martial arts, have "belts" which are divided into increasing levels of expertise.

White Belt: Introduction to Six Sigma fundamentals, suitable for newcomers who want to learn the basics.

Yellow Belt: Involves supporting project teams, focusing on data collection, and understanding process improvements.

Green Belt: More advanced level, involving leading projects and analyzing data. Six Sigma Green Belt training by MindCypress equips individuals with practical skills for problem-solving and project management.

Black Belt: Focuses on leading project teams, conducting in-depth statistical analysis, and driving change within an organization.

Master Black Belt: Represents the highest level of expertise, involving mentoring Black Belts and advising on strategy.

The Council for Six Sigma Certification is the most credible accrediting organization which certifies many training organizations against its standards of certification to assure industry conformation. Therefore, the design of the Six Sigma program by MindCypress ensured that they followed the certification standards of CSSC. This ensures that it remains a best recognized and respected form of certification possible.

Conclusion

This method has been a powerful change tool for businesses. Such methodologies as DMAIC assist an organization in significantly raising the quality, reducing cost, and increasing customer satisfaction. MindCypress delivers total Six Sigma certification. For both beginners and practitioners, our training and material will equip you to take a significant step forward.

Embrace the power of Six Sigma with MindCypress and start your journey toward operational excellence today.

Resource: https://www.mindcypress.com/blogs/quality-management/what-is-six-sigma-definition-methodology-and-belts-a-guide-by-mindcypress

0 notes

Text

Lean Six Sigma Green Belt Training

Lean Six Sigma Green Belt Training

One way to improve the quality of service of an organization is by implementing professionals who are Six Sigma Green Belt certified. Tremendous benefits in the form of Strategic, people development, financial, customer, and competitive benefit are achieved through Six Sigma Green Belt Certification Training. It provides a deep understanding of Defining, Measuring, Analyzing, Improving, and Controlling (DMAIC) methodology. Six Sigma Green Belt Classes also helps in understanding the various analysis tools. Six Sigma Green Belt Examination will be conducted after the training is completed on day three. On clearing the exam, participants can procure the “Certified Six Sigma Green Belt” Certificate within few working days.

#six sigma training#six sigma course#lean six sigma green belt training#six sigma green belt certification#six sigma green belt training

0 notes

Text

Lean Six Sigma Green Belt Training and Certification

#Lean Six Sigma#Green Belt Certification#Process Improvement#DMAIC#Lean Principles#Operational Excellence#Continuous Improvement#Waste Reduction#Efficiency#Statistical Analysis#Project Leadership#Professional Development#Quality Management#Six Sigma Training.

1 note

·

View note

Text

Mastering Process Excellence: Advanced Lean Six Sigma Black Belt Training and Certification

In today’s competitive business environment, mastering process excellence is crucial. The Lean Six Sigma Black Belt Training and Certification program offers professionals an unparalleled opportunity to learn advanced tools and methodologies for significant process improvement and operational excellence. The program covers key Six Sigma principles and methodologies like DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify). Additionally, it integrates Industry 4.0 technologies such as IoT, AI, and big data analytics, enhancing traditional Six Sigma approaches to drive efficiency and innovation. Participants gain expertise in advanced data analysis with tools like Minitab, as well as root cause analysis techniques and value stream mapping, enabling them to identify and implement effective process improvements.

The program also emphasizes practical applications and real-world scenarios, drawing on case studies from successful companies like ABB and General Electric to illustrate the global adoption and evolution of Six Sigma. By blending traditional Six Sigma principles with modern technologies, the Lean Six Sigma Black Belt Training prepares professionals to lead complex projects, manage teams, and drive significant improvements. Whether involved in operations, manufacturing, services, or operational excellence (Opex), this program provides the comprehensive toolkit needed to achieve superior business results and maintain a competitive edge.

For more information, visit:

0 notes

Video

youtube

¿Qué es Six sigma? | Six sigma explicado en 8 minutos | Pasos para aplic...

0 notes

Text

Hub 0851-0826-6666, Six Sigma Green Belt: Solusi Manufacturing di Banyuwangi

Hub 0851-0826-6666, Di era globalisasi ini, persaingan industri manufaktur semakin ketat. Untuk mempertahankan dan meningkatkan daya saing, perusahaan perlu mengadopsi metode yang efisien dan efektif dalam manajemen operasionalnya. Salah satu pendekatan yang telah terbukti efektif adalah Six Sigma Green Belt. Program ini menawarkan solusi bagi perusahaan untuk meningkatkan kualitas dan efisiensi produksi.

Pentingnya Six Sigma Green Belt di Banyuwangi

Banyuwangi, sebagai salah satu pusat industri di Indonesia, memiliki potensi besar untuk berkembang melalui implementasi Pelatihan Six Sigma Green Belt for Manufacturing di Banyuwangi. Program pelatihan ini dirancang untuk membantu perusahaan mengidentifikasi dan mengeliminasi cacat dalam proses produksi, mengurangi variabilitas, dan meningkatkan konsistensi produk.

Mengapa Harus Mengikuti Pelatihan Six Sigma Green Belt?

Gabung pelatihan Six Sigma Green Belt untuk manufacturing di Banyuwangi. Efisiensi dan kualitas! Dalam pelatihan ini, peserta akan mempelajari berbagai teknik dan alat yang digunakan dalam Six Sigma, seperti DMAIC (Define, Measure, Analyze, Improve, Control). Teknik ini sangat efektif untuk meningkatkan proses produksi dan mengurangi biaya operasional. Selain itu, peserta juga akan mendapatkan sertifikasi yang diakui secara internasional, yang akan meningkatkan kredibilitas mereka di dunia kerja.

Implementasi Lean Six Sigma di Industri Logistik

Selain di sektor manufaktur, metode Lean Six Sigma di Industri Logistik juga semakin populer. Industri logistik di Banyuwangi memerlukan pendekatan yang efektif untuk mengurangi waktu pengiriman, mengoptimalkan rute, dan mengurangi biaya operasional. Melalui pusat pelatihan lean six sigma, perusahaan logistik dapat mempelajari cara-cara untuk meningkatkan efisiensi dan produktivitas mereka.

Strategi Lean Six Sigma

Lean Six Sigma menggabungkan prinsip-prinsip Lean Manufacturing yang fokus pada pengurangan limbah dengan metode Six Sigma yang fokus pada peningkatan kualitas. Kombinasi ini menciptakan pendekatan holistik untuk manajemen operasional yang mampu mengatasi berbagai tantangan yang dihadapi oleh industri logistik.

Manfaat Sertifikasi Lean Six Sigma Bagi Karier

Sertifikasi Lean Six Sigma memberikan banyak manfaat bagi individu yang ingin meningkatkan karier mereka. Manfaat Sertifikasi Lean Six Sigma Bagi Karier antara lain adalah peningkatan kompetensi profesional, peningkatan peluang kerja, dan potensi kenaikan gaji. Sertifikasi ini menunjukkan bahwa individu memiliki kemampuan untuk memimpin proyek perbaikan proses yang kompleks dan memiliki pemahaman yang mendalam tentang teknik manajemen kualitas.

Meningkatkan Kompetensi Profesional

Dengan mengikuti pelatihan dan mendapatkan sertifikasi, individu akan memiliki pengetahuan dan keterampilan yang dibutuhkan untuk mengidentifikasi masalah, menganalisis data, dan menerapkan solusi yang efektif. Hal ini akan meningkatkan kompetensi profesional mereka dan membuat mereka lebih berharga bagi perusahaan.

Pelatihan Manajemen Bisnis Lean Transactional Processes

Pelatihan Manajemen Bisnis Lean Transactional Processes adalah salah satu program yang dapat membantu perusahaan meningkatkan efisiensi dalam proses bisnis yang bersifat transaksional. Proses ini mencakup berbagai aktivitas administratif seperti pengelolaan pesanan, pelayanan pelanggan, dan manajemen keuangan.

Efisiensi Proses Transaksional

Dalam pelatihan ini, peserta akan mempelajari cara-cara untuk mengidentifikasi dan mengurangi pemborosan dalam proses transaksional, meningkatkan kecepatan dan akurasi, serta mengoptimalkan penggunaan sumber daya. Hasilnya, perusahaan akan dapat memberikan layanan yang lebih baik kepada pelanggan dan meningkatkan profitabilitas.

Studi Kasus: Penerapan Six Sigma Green Belt di Banyuwangi

Salah satu contoh sukses penerapan Six Sigma Green Belt di Banyuwangi adalah sebuah perusahaan manufaktur yang berhasil mengurangi tingkat cacat produk mereka sebesar 30% dalam waktu enam bulan. Dengan mengidentifikasi penyebab utama dari cacat dan menerapkan solusi yang tepat, perusahaan ini tidak hanya meningkatkan kualitas produknya, tetapi juga mengurangi biaya produksi dan meningkatkan kepuasan pelanggan.

Langkah-langkah Implementasi Six Sigma Green Belt

Implementasi Six Sigma Green Belt melibatkan serangkaian langkah sistematis yang dirancang untuk meningkatkan kualitas dan efisiensi dalam proses produksi. Berikut adalah penjelasan rinci dari setiap langkah dalam metodologi DMAIC (Define, Measure, Analyze, Improve, Control):

1. Define (Mendefinisikan)

Langkah pertama dalam Six Sigma adalah mendefinisikan masalah yang akan diselesaikan. Pada tahap ini, tim proyek perlu melakukan beberapa kegiatan penting:

Identifikasi Masalah: Mengidentifikasi masalah utama yang dihadapi dalam proses produksi atau operasi. Masalah ini harus didefinisikan secara jelas dan spesifik.

Penentuan Tujuan: Menetapkan tujuan yang ingin dicapai dengan proyek perbaikan ini. Tujuan harus SMART (Specific, Measurable, Achievable, Relevant, Time-bound).

Pembentukan Tim Proyek: Membentuk tim yang akan bertanggung jawab atas pelaksanaan proyek. Tim ini biasanya terdiri dari individu yang memiliki keahlian yang relevan dengan masalah yang akan dipecahkan.

Pembuatan Charter Proyek: Mengembangkan charter proyek yang merinci masalah, tujuan, ruang lingkup, batasan, dan anggota tim. Charter ini berfungsi sebagai panduan resmi untuk proyek.

2. Measure (Mengukur)

Langkah kedua adalah mengukur kinerja saat ini dan mengumpulkan data yang relevan untuk memahami sejauh mana masalahnya:

Identifikasi Metrik Kunci: Menentukan metrik kunci yang akan digunakan untuk mengukur kinerja proses. Metrik ini harus relevan dengan masalah yang diidentifikasi.

Pengumpulan Data: Mengumpulkan data yang diperlukan untuk memahami kinerja saat ini. Data ini bisa berupa data historis atau data yang dikumpulkan selama proses berjalan.

Validasi Data: Memastikan bahwa data yang dikumpulkan akurat dan dapat diandalkan. Data yang tidak valid dapat menyebabkan kesimpulan yang salah.

Analisis Baseline: Menggunakan data yang dikumpulkan untuk menentukan baseline kinerja saat ini. Baseline ini akan digunakan sebagai titik acuan untuk mengukur perbaikan.

3. Analyze (Menganalisis)

Tahap ketiga adalah menganalisis data untuk mengidentifikasi akar penyebab masalah:

Analisis Penyebab Utama: Menggunakan alat analisis seperti diagram sebab-akibat (fishbone diagram), analisis Pareto, dan 5 Whys untuk mengidentifikasi akar penyebab masalah.

Analisis Data: Menggunakan teknik statistik untuk menganalisis data dan mengidentifikasi tren atau pola yang menunjukkan penyebab masalah.

Hipotesis Penyebab: Mengembangkan hipotesis tentang penyebab utama masalah berdasarkan analisis data.

Validasi Hipotesis: Menguji hipotesis yang dikembangkan untuk memastikan bahwa mereka benar-benar merupakan penyebab utama masalah.

4. Improve (Memperbaiki)

Langkah keempat adalah mengembangkan dan menerapkan solusi untuk memperbaiki proses:

Pengembangan Solusi: Mengembangkan solusi yang mungkin untuk mengatasi akar penyebab masalah. Solusi ini harus didasarkan pada analisis yang telah dilakukan.

Pemilihan Solusi: Mengevaluasi solusi yang mungkin dan memilih yang terbaik berdasarkan kriteria seperti efektivitas, biaya, dan implementasi.

Perencanaan Implementasi: Mengembangkan rencana implementasi yang rinci, termasuk langkah-langkah yang diperlukan, sumber daya yang dibutuhkan, dan jadwal waktu.

Pelaksanaan Solusi: Menerapkan solusi yang dipilih dalam proses nyata. Ini mungkin melibatkan perubahan pada prosedur operasional, pelatihan karyawan, atau pembelian peralatan baru.

Pengujian dan Verifikasi: Menguji solusi yang diterapkan untuk memastikan bahwa mereka menghasilkan perbaikan yang diinginkan. Jika diperlukan, melakukan penyesuaian untuk mengoptimalkan hasil.

5. Control (Mengontrol)

Langkah terakhir adalah mengontrol proses untuk memastikan bahwa perbaikan yang dilakukan dapat dipertahankan dalam jangka panjang:

Pengembangan Rencana Kontrol: Mengembangkan rencana kontrol yang merinci langkah-langkah untuk memonitor dan mempertahankan perbaikan. Rencana ini harus mencakup metrik kinerja yang akan dipantau dan frekuensi pemantauan.

Pelatihan dan Dokumentasi: Melatih karyawan tentang perubahan yang telah dilakukan dan memastikan bahwa semua perubahan didokumentasikan dengan baik. Dokumentasi ini akan menjadi referensi bagi karyawan di masa mendatang.

Pemantauan Berkelanjutan: Memantau kinerja proses secara terus-menerus untuk memastikan bahwa perbaikan dipertahankan. Ini bisa dilakukan melalui audit berkala dan analisis data rutin.

Tindakan Korektif: Jika kinerja mulai menurun atau masalah baru muncul, mengambil tindakan korektif yang diperlukan untuk mengembalikan proses ke kondisi yang diinginkan.

Kesimpulan

Dalam menghadapi tantangan industri yang semakin kompleks, penerapan Six Sigma Green Belt di Banyuwangi menjadi solusi yang sangat relevan. Dengan mengikuti Pelatihan Six Sigma Green Belt for Manufacturing di Banyuwangi, perusahaan dapat meningkatkan efisiensi dan kualitas produksi mereka. Selain itu, metode Lean Six Sigma di Industri Logistik juga membantu perusahaan logistik mengoptimalkan operasional mereka. Sertifikasi Lean Six Sigma tidak hanya bermanfaat bagi perusahaan, tetapi juga bagi individu yang ingin meningkatkan karier mereka. Oleh karena itu, gabung pelatihan Six Sigma Green Belt untuk manufacturing di Banyuwangi. Efisiensi dan kualitas! adalah langkah yang tepat untuk masa depan yang lebih baik.

Dengan dukungan dari pusat pelatihan lean six sigma yang berkualitas, pelatihan ini dapat diakses oleh lebih banyak profesional dan perusahaan di Banyuwangi, membawa dampak positif yang signifikan bagi pertumbuhan ekonomi dan industri di wilayah ini. Melalui Pelatihan Manajemen Bisnis Lean Transactional Processes, perusahaan juga dapat mengoptimalkan berbagai proses administratif mereka, meningkatkan efisiensi, dan akhirnya, profitabilitas.

FAQ :

1. Apa itu Six Sigma Green Belt?

Six Sigma Green Belt adalah tingkat sertifikasi dalam metodologi Six Sigma yang berfokus pada peningkatan kualitas dan efisiensi proses produksi. Peserta dengan sertifikasi ini memiliki pengetahuan mendalam tentang teknik-teknik Six Sigma dan mampu memimpin proyek-proyek perbaikan dalam organisasi.

2. Mengapa penting untuk mengikuti Pelatihan Six Sigma Green Belt for Manufacturing di Banyuwangi?

Pelatihan Six Sigma Green Belt membantu perusahaan di Banyuwangi untuk mengidentifikasi dan mengeliminasi cacat dalam proses produksi, mengurangi variabilitas, dan meningkatkan konsistensi produk. Gabung pelatihan Six Sigma Green Belt untuk manufacturing di Banyuwangi. Efisiensi dan kualitas!

3. Apa yang akan dipelajari dalam pelatihan ini?

Peserta akan mempelajari teknik dan alat-alat Six Sigma seperti DMAIC (Define, Measure, Analyze, Improve, Control), serta metode statistik dan manajemen proyek yang digunakan untuk meningkatkan proses produksi dan mengurangi biaya operasional.

4. Apa saja Manfaat Sertifikasi Lean Six Sigma Bagi Karier?

Manfaat Sertifikasi Lean Six Sigma bagi karier antara lain peningkatan kompetensi profesional, peningkatan peluang kerja, dan potensi kenaikan gaji. Sertifikasi ini membuktikan kemampuan individu dalam memimpin proyek perbaikan proses yang kompleks dan pemahaman mendalam tentang teknik manajemen kualitas.

6. Apa saja langkah-langkah implementasi Six Sigma Green Belt?

Langkah-langkah implementasi Six Sigma Green Belt meliputi:

Define (Mendefinisikan): Mengidentifikasi masalah, menetapkan tujuan, membentuk tim proyek, dan membuat charter proyek.

Measure (Mengukur): Mengidentifikasi metrik kunci, mengumpulkan dan memvalidasi data, serta menentukan baseline kinerja.

Analyze (Menganalisis): Menggunakan alat analisis untuk mengidentifikasi akar penyebab masalah, mengembangkan dan memvalidasi hipotesis.

Improve (Memperbaiki): Mengembangkan, memilih, dan menerapkan solusi, serta menguji dan memverifikasi hasil.

Control (Mengontrol): Mengembangkan rencana kontrol, melatih karyawan, mendokumentasikan perubahan, dan memantau kinerja secara berkelanjutan.

7. Apa itu pusat pelatihan lean six sigma?

Pusat pelatihan lean six sigma adalah institusi atau organisasi yang menawarkan pelatihan dan sertifikasi Lean Six Sigma. Mereka menyediakan kursus dan pelatihan yang membantu perusahaan dan individu meningkatkan efisiensi dan kualitas operasional mereka.

8. Bagaimana Six Sigma Green Belt membantu meningkatkan kualitas produk?

Six Sigma Green Belt membantu meningkatkan kualitas produk dengan mengidentifikasi dan mengeliminasi cacat dalam proses produksi, mengurangi variabilitas, dan memastikan konsistensi produk. Metodologi ini menggunakan data dan analisis statistik untuk mengembangkan solusi yang efektif.

9. Apa perbedaan antara Six Sigma dan Lean Six Sigma?

Six Sigma fokus pada pengurangan variabilitas dan peningkatan kualitas menggunakan alat-alat statistik. Lean Six Sigma menggabungkan prinsip-prinsip Lean Manufacturing, yang fokus pada pengurangan limbah dan peningkatan efisiensi, dengan metode Six Sigma.

#Six Sigma Green Belt: Solusi Manufacturing di Banyuwangi#Six Sigma Green Belt#lean six sigma#Pelatihan Lean Six sigma#Training Six Sigma#Training Lean Six Sigma#Kursus Lean Six Sigma

0 notes

Text

Mastering Process Improvement: Six Sigma Green Belt Certification in UAE

The UAE's business landscape is fierce, and staying ahead requires constant innovation and efficiency.. Organizations are constantly seeking ways to streamline their operations, enhance efficiency, and deliver superior quality products or services. One powerful methodology that has gained widespread recognition for its ability to drive process improvement and reduce defects is Six Sigma. Among the various certification levels offered, the Six Sigma Green Belt certification is an excellent starting point for professionals looking to embark on their journey towards process excellence. In the United Arab Emirates, the demand for Six Sigma professionals has been steadily increasing as companies strive to stay ahead of the curve and maintain a competitive edge. Obtaining a Six Sigma Green Belt certification in the UAE not only equips individuals with valuable skills but also opens doors to exciting career opportunities in various industries.

What is Six Six Sigma Green Belt Certification?

The Six Sigma Green Belt certification is a globally recognized credential that validates an individual's proficiency in applying Six Sigma methodologies and tools to improve processes and enhance overall organizational performance. Green Belts are trained to identify and eliminate waste, reduce variability, and optimize processes within their respective areas of operation. By pursuing a Six Sigma Green Belt certification in the UAE, professionals gain a comprehensive understanding of the DMAIC (Define, Measure, Analyze, Improve, Control) problem-solving approach, as well as statistical analysis techniques and lean principles. This knowledge empowers them to effectively analyze data, identify root causes of issues, and implement sustainable solutions that drive continuous improvement.

Benefits of Six Sigma Green Belt Certification in the UAE

Competitive Advantage: In the UAE's dynamic business environment, organizations that embrace Six Sigma principles gain a significant competitive advantage. Green Belt certified professionals contribute to streamlining processes, reducing costs, and enhancing customer satisfaction, ultimately driving business growth and profitability.

Career Advancement: Obtaining a Six Sigma Green Belt certification in the UAE demonstrates an individual's commitment to professional development and process excellence. This credential is highly valued by employers across various sectors, including healthcare, manufacturing, finance, and government, opening up opportunities for career advancement and increased earning potential.

Practical Application: The Six Sigma Green Belt training focuses on providing hands-on experience with various tools and techniques, enabling participants to apply their knowledge immediately in their respective workplaces. This practical approach ensures that the skills acquired are directly transferable and valuable to organizations.

Continuous Improvement Culture: By enrolling in a Six Sigma Green Belt certification program in the UAE, professionals become catalysts for fostering a culture of continuous improvement within their organizations. They gain the ability to identify opportunities for improvement, implement data-driven solutions, and contribute to the overall success of their companies.

Six Sigma Green Belt Certification: Applications Across Industries The Six Sigma Green Belt certification empowers professionals across various industries to streamline processes, minimize defects, and drive significant improvements. Here's a glimpse of how Six Sigma Green Belts contribute in specific sectors:

Manufacturing:

Reduced production errors and rework:

Optimized inventory management:

Improved supply chain efficiency:

Healthcare:

Enhanced patient care:

Reduced healthcare costs:

Improved hospital resource allocation:

Finance and Banking:

Minimized financial errors: Improved customer service:

Reduced fraud risk:

Across Industries

Factories: Produce more with fewer errors, saving time and money.

Hospitals: Improve patient care by streamlining processes and reducing wait times.

Banks: Minimize errors and fraud, keeping your finances secure.

Tech Companies: Build software faster and fix bugs quicker.

Customer Service: Resolve customer issues efficiently, boosting satisfaction.

Construction: Deliver projects on time and within budget by minimizing errors.

Education: Optimize learning methods for better student outcomes.

Government Agencies: Streamline public services and improve efficiency.

Marketing & Sales: Increase campaign effectiveness and boost conversions.

Logistics & Transportation: Optimize delivery routes and reduce delays.

Six Sigma Green Belt is a superpower for anyone who wants to be a problem-solver and get ahead. Don't wait - enroll today and unlock your full potential!

Limited-Time Offer: Six Sigma Green Belt Certification

In recognition of the growing demand for Six Sigma professionals in the UAE, IMC Institute is offering an exclusive discount on its Six Sigma Green Belt certification program. This limited-time offer provides an excellent opportunity for individuals and organizations to invest in upskilling their workforce and gaining a competitive edge in the market.

Why Choose IMC Institute for Six Sigma Green Belt Certification in UAE?

IMC Institute is a leading provider of Six Sigma training in the UAE, offering a comprehensive Six Sigma Green Belt certification program.

Certification:

On successful completion of the course and course requisites, the candidate will receive Internationally recognized Six Sigma Green Belt Certification.

Here's what sets them apart:

Experienced Instructors: Learn from qualified and experienced instructors who are Six Sigma practitioners themselves. They bring real-world expertise to the classroom, ensuring you receive practical and relevant training.

Interactive Training: IMC Institute utilizes a blend of interactive learning methods like lectures, case studies, group discussions, and hands-on exercises. This engaging approach ensures effective knowledge transfer and skill development.

Exam Preparation Support: Benefit from dedicated exam preparation resources and guidance to help you confidently approach the Six Sigma Green Belt certification exam.

Flexible Learning Options: Choose from classroom, online, or blended learning options to suit your learning style and schedule.

Summary:

The Six Sigma Green Belt certification in the UAE offers numerous benefits, including a competitive advantage, career advancement opportunities, practical application of skills, and the ability to cultivate a culture of continuous improvement within organizations. By pursuing this certification, professionals gain a comprehensive understanding of the DMAIC problem-solving approach, statistical analysis techniques, and lean principles, enabling them to effectively analyze data, identify root causes of issues, and implement sustainable solutions. With IMC Institute offering an exclusive discount on its Six Sigma Green Belt certification program, this limited-time opportunity provides an excellent chance for individuals and organizations to invest in upskilling their workforce and gaining a competitive edge in the market. Don't miss out on this chance to master process improvement and unlock your full potential – enroll today and embark on a journey towards excellence, efficiency, and success.

#six sigma certification#six sigma course#six sigma training#six sigma black belt#supply chain#professional certification#six sigma green belt certification#certification#development#marketing

0 notes

Text

How Useful Is Six Sigma Certification in a Customer Support Role?

Over the years, the customer support field has evolved from merely resolving problems. It has become a promise of client pleasure, optimizing the effectiveness of service and bringing procedures in sync. Aspirants of this field gain vast benefits by obtaining their Six Sigma Certification from reputed platforms or institutes.

The Benefits of Six Sigma in Customer Support

The main goal of Six Sigma goals is to identify inefficiencies and hurdles in different processes. Customer support can streamline complaint resolution, lower wait times, and enhance procedures to provide a quicker service.

Data-Driven Decision Making

Six Sigma values measurements and statistics in order to keep a track on performance. It is also a great tool used for making defensible judgements. This method is beneficial for managers and agents in customer support in terms of measuring crucial performance metrics. These include average response time, satisfaction and happiness of a customer, first-call resolution and more, using real-time data.

Quality Control

Having a Six Sigma Green Belt training can help customer support professionals in ensuring consistent and optimum quality service. They will learn to adhere to the DMAIC framework. Following this framework prevents errors, good consistency and an overall upgrade in customer experience.

Cost Efficiency

Professionals can also effectively reduce relatively significant costs with the help of Six Sigma Green Belt training. Their training will include various means of eliminating unnecessary steps in the customer support process. When the processes are efficient, there is less need for rework. It will in turn mean that one doesn’t have to spend the resources in order to resolve repeated issues. In the end, it is a win-win situation for the business as well as the customer.

Key Skills Gained from Six Sigma Certification

Customer support professionals can gain fundamental skills by enrolling in a Six Sigma Certification Online Training. These include:

Problem-solving techniques that help address common issues of the customers

Enhanced collaborations with better communication and teamwork across various departments

An approach that is customer-centric and allows process improvements that are in alignment with the customers’ needs.

Conclusion

A Six Sigma certification can add great value to professionals working in customer support. With the online training, aspirants learn to enhance the efficiency of a process and make data-driven decisions. It is the onset of promising top quality of service. Professionals use structured methodologies and data-focused approaches to transform customer support teams into efficient, customer-centric units.

Sounds compelling? You too can advance your career in customer service with a top-notch Six Sigma Green Belt Certificate training. Enroll at MindCypress and become proficient in process improvement and formulating customer-centric solutions.

Resource: https://www.mindcypress.com/blogs/quality-management/how-useful-is-six-sigma-certification-in-a-customer-support-role

0 notes

Text

Six Sigma's Customer Value Delivery

In today's fiercely competitive business landscape, delivering consistent value to customers is paramount for sustained success. Companies across industries are constantly seeking methodologies to streamline processes, reduce defects, and enhance overall efficiency to meet customer demands effectively. One such methodology that has gained widespread recognition for its effectiveness is Six Sigma. Let's delve into how Six Sigma, through its structured approach and rigorous methodologies, delivers tangible value to customers.

Understanding Six Sigma

Before we delve into the value it brings to customers, let's briefly understand what Six Sigma entails. At its core, Six Sigma is a data-driven methodology aimed at improving processes by systematically eliminating defects and minimizing variations. It relies on statistical analysis and precise measurement to identify and eliminate the root causes of problems, ultimately leading to enhanced quality and efficiency. Obtaining a Six Sigma certification signifies proficiency in implementing and managing these methodologies, demonstrating expertise in process improvement.

Enhancing Product and Service Quality

One of the primary ways Six Sigma delivers value to customers is by significantly enhancing the quality of products and services. By meticulously analyzing processes and identifying areas of improvement, organizations can reduce defects and errors, leading to products that meet or exceed customer expectations consistently. Whether it's manufacturing defects, service errors, or process inefficiencies, Six Sigma provides a structured approach to identify and rectify issues, resulting in higher-quality deliverables.

Customers today have increasingly high standards, and they expect nothing short of excellence from the products and services they invest in. A company that has undergone a Six Sigma course is better equipped to deliver on these expectations, ensuring that each product or service meets rigorous quality standards. This not only enhances customer satisfaction but also fosters loyalty and positive word-of-mouth, further strengthening the company's reputation in the market.

Read this article: Why Six Sigma Certification in India?

Driving Continuous Improvement

Six Sigma is not just a one-time initiative; it's a philosophy centered around continuous improvement. Organizations that embrace Six Sigma are committed to constantly analyzing their processes, identifying areas for optimization, and implementing necessary changes. This relentless pursuit of perfection ensures that customers continually receive enhanced value from the products and services they patronize.

A key aspect of Six Sigma is its focus on data-driven decision-making. By collecting and analyzing data at every stage of the process, organizations gain valuable insights into their operations. This allows them to make informed decisions aimed at improving efficiency, reducing waste, and ultimately delivering greater value to customers. Whether it's shortening lead times, optimizing supply chains, or streamlining customer service processes, Six Sigma empowers organizations to make targeted improvements that directly benefit customers.

What is Quality

youtube

Empowering Employees for Success

Another crucial aspect of Six Sigma's value proposition lies in its emphasis on employee training and development. A well-executed Six Sigma training course equips employees with the tools, techniques, and mindset needed to drive process improvements effectively. By involving employees at all levels of the organization in Six Sigma initiatives, companies foster a culture of accountability, collaboration, and continuous learning.

Empowered employees are better equipped to identify inefficiencies and propose innovative solutions that directly impact customer satisfaction. Whether it's frontline staff identifying bottlenecks in customer service processes or manufacturing personnel optimizing production workflows, every employee plays a vital role in delivering value to customers. Six Sigma training provides employees with the skills and confidence to take ownership of improvement initiatives, ultimately leading to a more responsive and customer-centric organization.

In conclusion, Six Sigma is much more than just a quality improvement methodology; it's a strategic approach to delivering maximum value to customers. By systematically eliminating defects, driving continuous improvement, and empowering employees, organizations that embrace Six Sigma create a culture of excellence that resonates with customers. Whether it's through higher-quality products, streamlined processes, or exceptional service, the principles of Six Sigma enable companies to meet and exceed customer expectations consistently. As competition intensifies and customer demands evolve, investing in Six Sigma institute remains a wise decision for any organization committed to delivering unparalleled value to its customers.

What is Six Sigma

youtube

Six Sigma Green Belt Introduction

youtube

Six Sigma Black Belt Training Introduction

youtube

#six sigma green belt#six sigma course#six sigma training#six sigma certification#six sigma green belt certification#six sigma black belt#quality manager#quality management#Youtube

0 notes

Text

Sat-Gun-Sang Meet (172th Virtual Webinar) Topic - "Introduction to six sigma" Date - Saturday, 16th March-2024 Time - 11:00am to 12:30pm (IST) 9:30am to 11:00am (GST) Speaker : Dr. Richa Dayaramani (Principal & Professor(PQA)) Registration Link : https://lnkd.in/ewWadfzQ Join Zoom Meeting : https://us06web.zoom.us/j/81547548073… Meeting ID: 815 4754 8073 Passcode: 577368

0 notes

Text

#six sigma black belt#six sigma green belt certification#six sigma certification#six sigma course#six sigma training

0 notes

Text

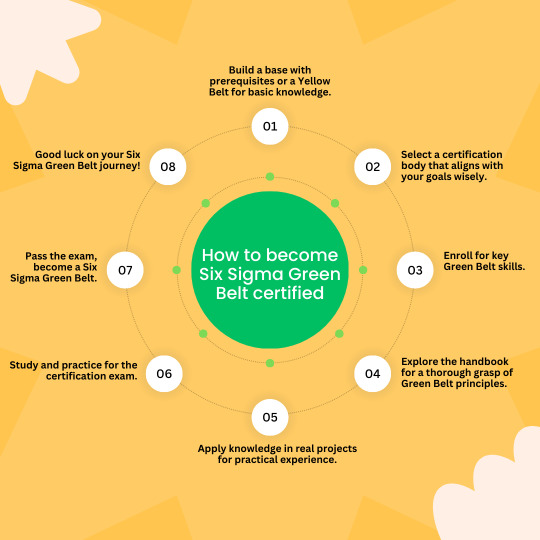

Join the journey to become a Six Sigma Green Belt certified professional! Our guide includes step-by-step instructions, training tips, and resources to help you pass the certification. Advance your career in quality management and recognize the value of continuous improvement.

#Six Sigma Green Belt#Certification#Quality Management#Professional Development#Career Advancement#Process Improvement#Training Program#Exam Preparation

0 notes

Text

8D Problem Solving Vs Lean Six Sigma

Both 8D Problem Solving and Lean Six Sigma are structured methodologies for addressing organizational challenges.

· 8D Problem Solving is a team-oriented approach that focuses on identifying and correcting the root cause of a problem. It’s ideal for complex issues in safety-critical industries like automotive and aerospace.

· Lean Six Sigma is a data-driven approach that combines Lean’s focus on efficiency with Six Sigma’s data-driven quality control. It’s suitable for various sectors like healthcare, finance, and manufacturing.

The blog also explores how these methodologies can be integrated for a more well-rounded approach.

· 8D’s root cause analysis can strengthen Lean Six Sigma projects.

· Lean Six Sigma’s data analysis and process optimization tools can enhance 8D.

The future involves using digital tools to improve problem identification and analysis in both methodologies.

The choice between 8D and Lean Six Sigma depends on your specific needs. But combining elements of both can be very effective.

Click here for more info : https://www.contiprove.com/8d-problem-solving-vs-lean-six-sigma/

0 notes

Text

Six Sigma Green Belt Training Course | Six Sigma Green Belt

You’ll learn how to plan and construct experiments in the Six Sigma Green Belt Training Course. Register Now.

0 notes

Text

Supply Chain Management Certification in UAE

Navigating the dynamic business landscape, supply chain management has emerged as a critical factor in driving organizational success. The UAE, a global trade and logistics hub, provides immense opportunities for professionals seeking to advance their careers in supply chain management. This blog post explores the significance of Supply Chain Management certification in the UAE, highlighting the benefits it offers and guiding aspiring professionals towards the best certification programs available.

Understanding Supply Chain Management:

Supply chain management encompasses the planning, organizing, and controlling of activities involved in the flow of goods and services from the point of origin to the end consumer. It involves various functions such as procurement, inventory management, warehousing, transportation, distribution, and customer service. Effective Supply chain management ensures the timely and efficient delivery of products while minimizing costs and maximizing customer satisfaction.

Importance of Supply Chain Management Certification in the UAE:

The UAE's strategic location and its role as a regional trade gateway make it an ideal destination for professionals seeking to excel in Supply chain management. With the country's rapidly growing economy and ambitious development plans, there is a strong demand for skilled supply chain professionals. Earning a Supply Chain Management certification in the UAE opens up a world of opportunities for career advancement, higher earning potential, and recognition as an industry expert.

Benefits of Supply Chain Management Certification:

Enhanced Knowledge and Skills:

Certification programs provide comprehensive training in the latest supply chain management practices, tools, and techniques. Professionals gain a deeper understanding of supply chain dynamics, enabling them to make informed decisions and optimize their operations.

Improved Job Prospects:

Supply chain management is a valuable credential that sets professionals apart from their peers. It demonstrates a commitment to professional development and proficiency in the field, making candidates more attractive to potential employers.

Higher Earning Potential:

Certified supply chain professionals are often compensated more than their non-certified counterparts. The specialized knowledge and skills they possess are highly sought after in the job market, leading to increased earning opportunities.

Global Recognition and Mobility:

A globally recognized Supply chain management certification opens up doors for professionals to work in multinational organizations and pursue international career opportunities. It enhances their credibility and employability across different countries.

Continuous Professional Development:

Supply Chain Management certification programs encourage professionals to stay updated with industry trends and advancements. This continuous learning ensures that they remain relevant and competitive in the rapidly evolving supply chain landscape.

How to Choose the Best Supply Chain Management Certification Program in the UAE Accreditation and Recognition:

Opt for programs at IMC Institute accredited by esteemed organizations like CPD London further underscores the quality and credibility of our certification programs.

Curriculum Relevance:

Evaluate the curriculum of IMC Institute's programs to ensure they encompass the latest trends, practices, and tools in supply chain management. Our commitment is to align with industry standards and best practices, providing a cutting-edge education.

Faculty Expertise:

Consider the qualifications and experience of IMC Institute's instructors, ensuring they are industry experts with a proven track record in supply chain management. Our faculty is dedicated to imparting practical knowledge and insights gained from real-world success.

Flexibility and Accessibility:

Choose IMC Institute for its programs that offer flexible delivery options, including online learning, catering to the schedules of busy professionals. Our commitment extends to providing convenient timings for classes.

Networking Opportunities:

IMC Institute's certification programs offer invaluable networking opportunities with industry professionals, mentors, and potential employers. We recognize the importance of networking for career advancement and staying abreast of the latest developments in the field.

Summary:

Investing in a Supply Chain Management certification at IMC Institute is a strategic move for career growth. With the UAE's thriving economy and our institute's affiliation with CPD London, certified professionals unlock numerous opportunities for growth, higher earnings, and international recognition. By choosing IMC Institute and its comprehensive certification programs, professionals enhance their knowledge, skills, and earning potential, contributing to the success of supply chains in the UAE and globally.

#six sigma certification#professional certification#agency#development#six sigma course#six sigma training#six sigma black belt#six sigma green belt certification

0 notes

Text

Lean Six Sigma Green Belt Certification Training Tips

Obtaining certification in Lean Six Sigma Green Belt Training is an important accomplishment for individuals who want to improve their quality management and process improvement abilities. This accreditation not only attests to your experience but also provides you with useful resources and techniques to promote excellence and efficiency in businesses.

Here is a thorough how-to guide and training guide to assist you get certified as a Lean Six Sigma Green Belt:

Understanding Lean Six Sigma Green Belt Classes Certification

Lean Six Sigma integrates concepts from Six Sigma that aim to significantly minimize defects and variation. It also includes concepts from Lean manufacturing that help reduce waste and enhance the flow. A Lean Six Sigma Green Belt Training certificate validates one’s expertise in Lean Six Sigma methods process improvements.

Benefits of Lean Six Sigma Green Belt Training Certification

Career Advancement: Increases opportunities for professional advancement by showcasing expertise in project management and process improvement.

Organizational Impact: Makes it possible for you to significantly raise customer satisfaction, efficiency, and quality.

Enhanced Skills: Fosters the development of leadership, problem-solving, and statistical analytic skills.

Training Tips for Lean Six Sigma Green Belt Course Certification

Choose a Reputable Training Provider: Choose a training provider who has received accreditation from reputable organizations like the International Association for Six Sigma Certification (IASSC) or the American Society for Quality (ASQ). Make that the course material complies with the Body of Knowledge for Lean Six Sigma Green Belts.

Understand the DMAIC Methodology: DMAIC (Define, Measure, Analyze, Improve, Control) approach sets the foundation for Lean Six Sigma. Learn about each step and the resources available for process optimization and problem-solving.

Gain Practical Experience: Use case studies in training or actual projects within your company to implement Lean Six Sigma principles. Gaining practical experience improves comprehension and gets you ready to carry out a project.

Master Statistical Tools: Gain expertise in statistical analysis software for data analysis and interpretation, such as Excel or Minitab. It is essential to comprehend statistical principles in order to make well-informed decisions while improving processes.

Prepare for the Certification Exam: Use study aids, practice tests, and suggested texts to approach your studies methodically. To reinforce learning, concentrate on comprehending important ideas, working through example problems, and going over case studies.

Collaborate and Network: During training, interact with instructors and classmates to share ideas, talk through problems, and obtain new perspectives. Support and more educational possibilities can be obtained through networking.

Stay Updated and Practice Continuous Learning: The concepts of Lean Six Sigma are subject to change, so keep up with new techniques, industry developments, and best practices. Attend conferences, webinars, and workshops to keep learning new things and developing your talents.

Conclusion

A thorough understanding of process improvement techniques, real-world application, and dedication are required for the Lean Six Sigma Green Belt course certification. Through efficient process improvement projects, you may significantly contribute to corporate performance and effectively navigate the certification route by selecting the correct training, mastering important concepts, obtaining practical experience, and maintaining a commitment to lifelong learning.

Resource: https://www.mindcypress.com/blogs/quality-management/lean-six-sigma-green-belt-certification-training-tips

0 notes