#silica sand processing plant

Explore tagged Tumblr posts

Text

Silica Sand Washing Plant

CFlo's Silica Sand Washing and Processing Plant ensures optimised silica sand specification, reduced plant footprint and minimal environmental impact. For more information please browse the website : https://cfloworld.com/solutions/process-equipment/micrograder/ .

0 notes

Text

Silica sand

CFlo's Silica Sand Washing and Processing Plant ensures optimised silica sand specification, reduced plant footprint, and minimal environmental impact. For more information please visit us : https://cfloworld.com/micrograder.html .

0 notes

Text

Examples of sand from Earth magic Recycling

We sell all the way from less than an ounce to a ton, in five sizes from silica powder to chunks that are maybe 1/4 inch thick. It comes out of the machine used to process completely save and tumbled.

Most common sizes are 8oz 3lb and 10lb for every day use. It can be added to house plants as ground cover or mixed with soil for aeration. You can also use it for crafts as a natural glitter substitute (it is messy tho). As someone recommended it can be used in aquariums but it does need to be washed before adding animals. In the second size we over it's comparable to beach sand so could be good for reptiles or burrowing animals so long as they do not eat sand..

In larger quantities it can be used as mulch or ground cover. A couple sandbags (50lbs each) could be put to use as ground fill for patios or walkways. Here locally it's going to the city as trail sand soon.

Please take a look at our website and see if recycled sand is for you.

and this is our instagram

102 notes

·

View notes

Text

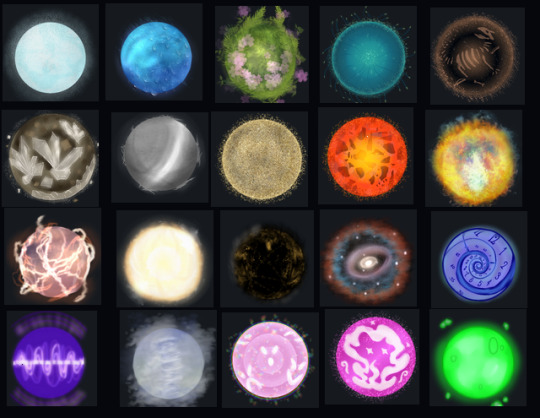

Explaining my 20 Ghost Cores

Important to know; Core type is not a limiter of what they can learn to accomplish. As an Ice Core type can use Fire Core-type attacks and the like, It's just going to be harder for them to learn and do. 1 Ice Core - Literal ice, snow, blizzards, and cooling. 2 Water Core - Literal water, ocean/freshwater, rain to tsunami. 3 Earth Core - Literal dirt and things that grow in it, like plants and their properties, herbal healing. 4 Air Core - Wind in all forms, from a light breeze to hurricanes and tornados, propelled flight. 5 Fire Core - Literal fire, embers to wildfires, fire whirls, and heating. 6 Electric Core - Everything from static to thunderstorms. It can control electronics with electrical impulses impacting the item's software. 7 Light Core - Physical light, think hard light, positive things like good luck and good Intent. 8 Dark Core - Physical darkness, negative things like bad luck, but also evil Intent. 9 Ecto Core - Death energy, newly dead matter, bones, intangibility, and Invisibility. (*The Normal Type of Ghosts*) 10 Sound Core - Controls sound and vibrations, radio waves, and also the vibration caused by sound. For example, you can feel things shaking because of the intense sound. 11 Metal Core - Has dominion over literal metals and the power to manipulate anything containing metals, like iron, in one’s bloodstream. Can control technology but only the hardware. 12 Emotion Core - It has its domain over the emotional spectrum, anything from love to hate. It also covers psychic elements and dreams. 13 Rock Core - Covers rocks but also crystals and their properties, crystal healing, and landslides. 14 Ground Core - Domain over underground things like oil and other fossilized materials. But also earthquakes. 15 Lava Core - Has dominion over the literal lava and other chemical processes that affect the world around us. Explosions are under this domain as well. 16 Sand Core - Coves Sand, sandstorms, and the like, but also coves things made of sand like glass, concrete, and silica. 17 Nature Core - The domain is biological things, like animals, bio-healing, and life energy. 18 Magic Core - Destruction. Creation. Illusion, Distortion, Hypnosis. Mystical and Unknown energies. Shape manipulation. 19 Space Core - It has dominion over gravitational forces, both contracting and expanding. Magnetic forces fall under this domain. Things in physical space that are moving, Telekinesis. 20 Time Core - Future vision, time manipulation, and time travel. Portals as they send you to a different spot in time, you otherwise would have to move through time to get to. So, this is what I landed on, even 20, as that made the most sense to me, and I decided to write them down so you can see my thinking.

25 notes

·

View notes

Text

I'm curious: If you had to give Batfamily a power over 1 element out of the 20 element thing I've made up, who would you pick for what element and why? Though an extra challenge is to give them one each, as I got 20, there should be enough for the main batfam and more. Here is the list of elements and their domains; Ice - Literal ice, snow, blizzards, and cooling. Water - Literal water, ocean/freshwater, rain to tsunami. Earth - Literal dirt and things that grow in it, like plants and their properties, herbal healing. Nature - The domain is biological things, like animals, bio-healing, and life energy. Ground - Domain over underground things like oil and other fossilized materials. But also earthquakes. Rock- Covers rocks but also crystals and their properties, crystal healing, and landslides. Metal - Has dominion over literal metals and the power to manipulate anything containing metals, like iron, in one’s bloodstream. Can control technology but only the hardware. Sand Coves Sand, sandstorms, and the like, but also coves things made of sand like glass, concrete, and silica. Lava- Has dominion over the literal lava and other chemical processes that affect the world around us. Explosions are under this domain as well. Fire - Literal fire, embers to wildfires, fire whirls, and heating. Electric - Everything from static to thunderstorms. It can control electronics with electrical impulses impacting the item's software. Light - Physical light, think hard light, positive things like good luck and good Intent. Dark- Physical darkness, negative things like bad luck, but also evil Intent. Space - It has dominion over gravitational forces, both contracting and expanding. Magnetic forces fall under this domain. Things in physical space that are moving, Telekinesis. Time- Future vision, time manipulation, and time travel. Portals as they send you to a different spot in time, you otherwise would have to move though time to get to. Sound - Controls sound and vibrations, radio waves, and also the vibration caused by sound. For example, you can feel things shaking because of the intense sound. Air - Wind in all forms, from a light breeze to hurricanes and tornados, propelled flight. Emotion- It has its domain over the emotional spectrum, anything from love to hate. It also covers psychic elements and dreams. Magic- Destruction. Creation. Illusion, Distortion, Hypnosis. Mystical and Unknown energies. Shape manipulation. Ecto - Death energy, newly dead matter, bones, intangibility, and Invisibility. Image A tiny image ref. My DA has the full-resolution ones individually. This is just to help you visualize

I hope you all have fun with it. There is no right or wrong answer; there are just alternative options.

6 notes

·

View notes

Text

Latin America Silica Sand Market Outlook and Forecast 2025-2032

Silica sand, also known as industrial sand, is a high-purity form of quartz sand that undergoes processing to meet specific industrial and manufacturing requirements. It consists primarily of silicon dioxide (SiO₂), with purity levels exceeding 95% in most commercial applications. The sand is categorized based on its grain size, impurity levels, and intended use.

Silica sand is a crucial raw material in industries such as glass manufacturing, construction, foundry applications, hydraulic fracturing (oil & gas), filtration, and ceramics. The demand for silica sand in Latin America has increased significantly due to the expansion of construction activities, growth in the glass industry, and rising industrialization across major economies such as Brazil and Mexico.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

Market Size

The Latin America Silica Sand Market was valued at US$ 845 million in 2024 and is expected to reach US$ 1.12 billion by 2030, growing at a CAGR of 4.8% during the forecast period from 2024 to 2030.

Key Market Trends and Statistics:

Historical Growth: The market has grown steadily over the past decade due to increasing demand in construction, glass production, and foundry applications.

Projected Demand: The demand for high-purity silica sand is projected to rise with the expansion of the solar panel manufacturing sector, which requires ultra-clear glass made from superior-grade silica sand.

Production Growth: Leading silica sand producers in Latin America, including Brazil, Mexico, and Chile, are investing in advanced mining technologies to enhance production efficiency.

End-Use Distribution:

Glass Manufacturing: 35%

Construction: 28%

Foundry Applications: 22%

Oil & Gas (Hydraulic Fracturing): 15%

Quality Segmentation:

High-grade (>99% SiO₂): 42%

Medium-grade (98-99% SiO₂): 35%

Standard-grade (<98% SiO₂): 23%

Market Dynamics

Drivers

Rising Demand for Glass Manufacturing

The expansion of automotive, construction, and solar energy industries has driven the demand for high-quality silica sand for glass production.

Latin America's glass manufacturing industry is expected to grow at a CAGR of 5.2% through 2030.

Infrastructure Development & Urbanization

Countries like Brazil, Mexico, and Argentina are witnessing rapid urbanization, leading to increased demand for cement, concrete, and silica-based construction materials.

Growing Oil & Gas Exploration

The hydraulic fracturing (fracking) industry in Argentina and Mexico is fueling demand for proppant-grade silica sand.

Restraints

Environmental Regulations & Mining Restrictions

Strict regulations on sand mining activities due to environmental concerns may limit production capabilities.

Governments are enforcing sustainable mining practices to protect natural water bodies and ecosystems.

High Transportation Costs

Transporting bulk silica sand across long distances increases logistics costs, impacting profitability.

Opportunities

Sustainable Mining Practices

Companies investing in eco-friendly mining technologies and water-efficient processing methods have a competitive advantage.

Expansion of High-Purity Silica Market

Electronic-grade silica sand used in semiconductors and solar panels is gaining traction.

Challenges

Supply Chain Disruptions

Geopolitical tensions and trade policies can disrupt the export and import of silica sand.

Fluctuations in Raw Material Prices

Variability in the cost of extraction, processing, and transportation impacts overall pricing.

Regional Analysis

Brazil

Largest producer of silica sand in the region.

Major players are investing in new silica mines and advanced processing plants.

Growing construction and solar energy sector fueling silica demand.

Mexico

Strong export market for silica sand, particularly to the United States.

Increased usage in glass and filtration industries.

Chile

Foundry industry and ceramic manufacturing are the key drivers of silica sand consumption.

Government incentives to boost mining activities.

Other Countries

Argentina, Colombia, Peru, and Venezuela contribute to the market with localized mining operations and niche industry applications.

Competitor Analysis

Major Players in the Latin America Silica Sand Market

Sibelco – Leading supplier with a strong presence in Brazil and Mexico.

Canteras Industriales – Focuses on high-purity silica sand production.

Arena Silícea Dorada – Key supplier in Argentina.

Emisiles C.A – Specialized in foundry-grade silica sand.

Saint-Gobain – Major player in the glass and construction sector.

Industrias Extractivas de México, S.A. de C.V. – Large-scale mining operations in Mexico.

Mineração Jundu Ltda – Major silica sand producer in Brazil.

Grupo Arenas y Gravas Silicas – Key regional player in filtration-grade silica sand.

Arena Sílice de Veracruz – Mexican supplier with a strong export market.

Market Segmentation (by Application)

1. Construction

Used in concrete, cement, and road construction.

2. Glass Manufacturing

High-purity silica sand is essential for flat glass, container glass, and specialty glass.

3. Filtration

Used in water treatment plants for removing contaminants.

4. Foundry

Foundry-grade silica sand is used for molding and core-making in metal casting.

5. Ceramics & Refractories

Essential for tiles, sanitaryware, and high-temperature-resistant materials.

Market Segmentation (by Type)

Less than 40 mesh – Used in construction applications.

40-70 mesh – Preferred for glass manufacturing and filtration.

More than 70 mesh – Used in high-purity applications like semiconductors.

Key Company Profiles

Sibelco

Canteras Industriales

Arena Silícea Dorada

Emisiles C.A

Saint-Gobain

Industrias Extractivas de México, S.A. de C.V.

Mineração Jundu Ltda

Grupo Arenas y Gravas Silicas

Arena Sílice de Veracruz

Geographic Segmentation

Brazil

Mexico

Argentina

Chile

Colombia

Peru

Venezuela

FAQ

What is the current market size of the Latin America Silica Sand Market?

➣ The market was valued at US$ 845 million in 2024 and is expected to grow to US$ 1.12 billion by 2030 at a CAGR of 4.8%.

Which are the key companies operating in the Latin America Silica Sand Market?

➣ Major companies include Sibelco, Saint-Gobain, Mineração Jundu Ltda, and Industrias Extractivas de México.

What are the key growth drivers in the Latin America Silica Sand Market?

➣ The main growth drivers are increased demand from the glass industry, urbanization, and rising hydraulic fracturing activities.

Which regions dominate the Latin America Silica Sand Market?

➣ Brazil, Mexico, and Chile are the top producers.

What are the emerging trends in the Latin America Silica Sand Market?

Eco-friendly mining practices

Expansion in high-purity silica for semiconductors

Increased use in renewable energy applications

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Silica Sand revenues in Latin America market, 2019-2024 (Estimated), ($ millions)

Key companies Silica Sand revenues share in Latin America market, 2023 (%)

Key companies Silica Sand sales in Latin America market, 2019-2024 (Estimated),

Key companies Silica Sand sales share in Latin America market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Latin America and country-wise market of Silica Sand

It describes present situation, historical background and future forecast

Comprehensive data showing Silica Sand capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Silica Sand manufacturers

Silica Sand forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

0 notes

Text

https://github.com/Sona75310/DevBase/blob/main/North America Silica Sand Processing Plant Equipment Market Drivers And Trends.md

0 notes

Text

How to Implement AFM in Water Treatment

Activated Filter Media (AFM) is a groundbreaking technology in water treatment that is gaining recognition for its ability to improve filtration efficiency while reducing operational costs. Implementing AFM in water treatment systems can significantly enhance the quality of treated water and make the process more cost-effective. This article explores the steps involved in implementing AFM in water treatment facilities

1. Understanding AFM Technology

Activated Filter Media (AFM) is a specialized filtration material made of high-purity silica, designed to replace traditional sand filters in water treatment plants. It provides better filtration by removing particles, microorganisms, and contaminants from water. AFM is known for its superior performance, including higher filtration rates and longer filter life, compared to conventional sand media.

2. Assessing the Water Treatment Requirements

Before implementing AFM, it's essential to assess the water treatment facility’s specific needs. Understanding the water’s source, the types of contaminants present, and the desired water quality is crucial in determining how AFM can be best utilized. A comprehensive analysis will help identify the most suitable AFM configuration for the system.

3. Designing the Filtration System

Once the water treatment requirements are assessed, the next step is to design the filtration system. AFM can be used as a replacement for sand in existing filter beds or incorporated into new filtration designs. The design should include key factors such as the required flow rates, filter dimensions, and the type of AFM to be used. The design should also consider the integration of AFM with other treatment processes like chemical dosing, disinfection, and post-treatment filtration.

4. Installing AFM in Existing Systems

If you are retrofitting an existing water treatment plant, the installation process typically involves replacing the existing filter media with AFM. This process may require adjustments to the filter structure to accommodate AFM’s unique characteristics. The installation should be carried out by professionals who are experienced with water filtration systems to ensure proper setup and functionality.

For new installations, AFM can be integrated into the design from the start, ensuring a seamless and efficient water treatment process.

5. Operational Considerations

After installation, it’s important to adjust operational procedures for optimal AFM performance. AFM filters require regular maintenance to ensure they function efficiently. This includes periodic backwashing to remove accumulated contaminants and prevent clogging. The backwashing process is generally more efficient with AFM than with traditional sand filters, helping to reduce water wastage and downtime.

Operators should also monitor the performance of AFM filters to ensure they are consistently meeting the desired water quality standards. This may involve regular testing of treated water to ensure contaminants are being effectively removed.

6. Cost Optimization with AFM

One of the key advantages of using AFM is its ability to optimize operational costs. AFM’s higher filtration efficiency and extended lifespan mean that water treatment facilities can reduce the frequency of media replacement and maintenance costs. Moreover, AFM can operate at higher filtration rates, reducing the overall energy consumption of the system.

Advanced Cost Optimization in Drinking Water Treatment with Activated Filter Media (AFM) by SVS Aqua

The integration of AFM in water treatment systems not only improves water quality but also offers significant savings in operational costs. The advanced cost optimization achieved with AFM technology makes it an attractive option for water treatment plants looking to improve efficiency while reducing overall expenses.

7. Benefits of AFM Implementation

Implementing AFM in water treatment systems brings several benefits:

Enhanced Filtration Efficiency: AFM provides a higher level of filtration, removing finer particles and improving the overall quality of treated water.

Longer Filter Life: AFM filters last longer than traditional sand filters, reducing the need for frequent media replacement.

Cost Reduction: The efficiency and durability of AFM contribute to lower operational costs, including savings on maintenance, energy, and media replacement.

Environmental Sustainability: AFM reduces the environmental impact of water treatment by optimizing resource usage and minimizing waste.

8. Conclusion

Implementing AFM in water treatment systems is a smart and cost-effective choice for enhancing filtration performance and reducing operational costs. By understanding the technology, designing an appropriate system, and maintaining the filters properly, water treatment facilities can maximize the benefits of AFM. With its superior filtration capabilities and cost optimization potential, AFM is paving the way for more efficient and sustainable water treatment practices.

The use of AFM in water treatment facilities offers not only technical advantages but also financial and environmental benefits, making it a valuable investment for modern water treatment plants.

#sewage waste water treatment#waste water treatment#sewage treatment#industrial waste water treatment

0 notes

Text

Potassium Silicate Prices: Trend | Pricing | News | Price | Database

Potassium Silicate Prices is a versatile compound widely used across various industries, including agriculture, construction, and industrial manufacturing. The pricing dynamics of potassium silicate are influenced by several factors, including raw material costs, production methods, regional demand, and macroeconomic conditions. Over recent years, the market has seen notable fluctuations in potassium silicate prices, driven by shifts in supply chain logistics and evolving end-user applications. Manufacturers rely heavily on the availability of key raw materials such as potassium carbonate and silica sand, both of which are subject to global trade trends and natural resource availability. Any disruption in the supply of these inputs directly impacts production costs, thereby influencing the price of potassium silicate.

Demand from the agricultural sector is a significant driver of potassium silicate prices, as it is widely utilized in fertilizers and crop protection solutions. Farmers and agricultural companies value potassium silicate for its role in enhancing plant resilience against pests and environmental stress. This consistent demand has provided a stable growth trajectory for the market, but seasonal variations in agricultural activities and climate conditions often contribute to short-term price volatility. Additionally, potassium silicate is a preferred choice in the construction industry for its ability to improve the durability and longevity of cement and concrete structures. The expansion of urbanization and infrastructure projects globally has created sustained demand for this compound, adding upward pressure on prices in regions experiencing robust construction activity.

Get Real time Prices for Potassium Silicate: https://www.chemanalyst.com/Pricing-data/potassium-silicate-1305

Another major factor influencing potassium silicate prices is the energy cost associated with its production. The manufacturing process is energy-intensive, requiring high temperatures for the chemical reactions to occur. Rising energy prices, particularly in regions heavily reliant on fossil fuels, have increased production costs, pushing prices higher for end-users. Conversely, advancements in production technologies aimed at improving energy efficiency have helped to moderate these costs to some extent. Innovations such as recycling waste heat and optimizing reactor designs are enabling manufacturers to produce potassium silicate more sustainably, which could potentially stabilize or even reduce prices in the long term.

Regional disparities in potassium silicate pricing are also a critical consideration. In regions with abundant natural resources and established manufacturing infrastructure, such as North America and parts of Asia, production costs are relatively lower, resulting in more competitive pricing. Conversely, regions dependent on imports face higher prices due to shipping costs, import duties, and currency fluctuations. These variations highlight the importance of strategic sourcing and supply chain management in maintaining price competitiveness. The global potassium silicate market is further influenced by trade policies and regulations, as import-export restrictions and tariffs can disrupt market dynamics and lead to price disparities between regions.

Environmental regulations are playing an increasingly important role in shaping potassium silicate prices. With growing global emphasis on sustainability and reducing carbon emissions, manufacturers are under pressure to adopt eco-friendly production processes. Compliance with stricter environmental standards often involves additional costs, which can be reflected in the final price of potassium silicate. On the other hand, this shift toward greener practices has opened new market opportunities for potassium silicate as an environmentally friendly alternative in various applications. For example, its non-toxic nature and biodegradability make it an attractive choice in the formulation of eco-friendly detergents and cleaning agents.

The competitive landscape of the potassium silicate market also impacts pricing. The market is characterized by the presence of both large multinational companies and smaller regional players, each vying for market share. Larger companies benefit from economies of scale and can often offer competitive prices, while smaller players may focus on niche markets and specialized applications. Price competition among these manufacturers can drive innovation but may also lead to price wars in some cases, temporarily lowering market prices. Strategic collaborations and partnerships are becoming increasingly common as companies aim to expand their market reach and mitigate risks associated with price volatility.

Future trends in potassium silicate pricing are expected to be influenced by advancements in technology and the exploration of alternative raw materials. Research into bio-based materials and renewable energy sources for production could lead to significant cost savings, benefiting both manufacturers and end-users. Additionally, the growing demand for high-performance materials in emerging industries, such as electronics and advanced ceramics, could further drive the development of innovative potassium silicate products. As these trends unfold, market participants will need to balance cost considerations with the need to meet evolving customer requirements and regulatory standards.

In conclusion, the potassium silicate market is shaped by a complex interplay of factors, including raw material availability, energy costs, regional demand, environmental regulations, and geopolitical influences. Understanding these dynamics is crucial for stakeholders to navigate the challenges and opportunities in this market effectively. While short-term price fluctuations are likely to continue, long-term prospects for potassium silicate remain promising, driven by its diverse applications and the ongoing pursuit of sustainable production practices. As the market evolves, strategic investments in technology and supply chain resilience will be key to maintaining competitive pricing and ensuring a stable supply of this essential compound.

Get Real time Prices for Potassium Silicate: https://www.chemanalyst.com/Pricing-data/potassium-silicate-1305

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Potassium Silicate#Potassium Silicate Price#Potassium Silicate Prices#Potassium Silicate Pricing#Potassium Silicate News#Potassium Silicate Price Monitor

0 notes

Text

Manufacturer of Quartz Grains in India

Manufacturer of Quartz Grains in India

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications. Click for more information Quartz Silica Powder Manufacturers in India

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced. Click now for more update Quartz Silica Grains Manufacturers

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-Northen region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar - soda and potash feldspar, quartz. Click now Quartz Silica Grains

Our roots trace back to a founding team of IIT and NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs.

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click for more information Quartz Silica Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future.

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability. Click now Quartz Silica Powder Manufacturers

Potash Feldspar

A feldspar is typically referred to as 'potash' if there is significantly more potassium than sodium (typically there will be 2-5% Na2O). If the amounts are closer to equal they are termed potash-soda feldspars (or vice versa). Read more Manufacturer of Quartz Grains in India

The main vitrifying agent in ceramic body is feldspar. The majority of white ware bodies contains good proportions of feldspar. It acts as flux in the ceramic industry, the flux is defined as that portion of the body which develops glass phase and this is provided by fledspar. The amount of flux in a ceramic body should be only in such a proporation as to develop the desired amount od vitrification. if excess of flux is added, the fired body becomes very glassy and consequently brittle. Click now for more information Quartz Powder Manufacturers & Suppliers in India

Potassium feldspar melts at around 1200C (higher than soda feldspar) producing a more a viscous melt than does sodium feldspar. It can also produce a crystalline phase (leucite) that contributes to opacity. Thus, in industry, potash feldspars are often used more for matte glazes while soda feldspar is used for glossy glazes.

0 notes

Text

Glass sand

One of the most common applications for silica sand is in glass production – we manufacture the full range of equipment required on a glass sand processing plant and the modular nature of our equipment ensures maximum process efficiency, minimal footprint, and rapid deployment, while minimizing environmental impact. For more information please click here : https://cfloworld.com/solutions/industries-we-serve/purification-of-silica-sand-for-solar-panels-glass/ .

0 notes

Text

Silica Sand Washing Plant

Tailored for industrial sand applications like frac sand, foundry sand, and more - Micrograder, our modular silica sand washing plant ensures optimized specifications and minimal environmental impact. From efficient feed point management to superior abrasion resistance, our technology delivers high-quality sand products while maximizing water recycling and minimizing footprint. For more information please browse the website : https://cfloworld.com/solutions/process-equipment/micrograder/ .

0 notes

Text

0 notes

Text

Cost Analysis: Establishing a Sodium Silicate Plant

sodium silicate plant silicate plant involves a comprehensive cost analysis to ensure profitability and sustainability. Sodium silicate, commonly known as water glass, is used in various industries, including construction, detergents, and agriculture. This article outlines the key components of cost analysis for setting up a sodium silicate plant.

Market Research and Feasibility Study

Before initiating a sodium silicate plant, conducting thorough market research is essential. This research helps in understanding the demand for sodium silicate in various sectors. A feasibility study should evaluate the potential market size, competition, and pricing strategies. This step ensures that the investment is viable and aligns with market needs.

Location and Infrastructure Costs

The location of the plant significantly impacts overall costs. Factors such as proximity to raw materials, transportation facilities, and labor availability should be considered. Infrastructure costs include land acquisition, construction of the plant, and installation of machinery. A well-chosen location can reduce logistics costs and enhance operational efficiency.

Raw Material Costs

Sodium silicate is produced from silica sand and sodium carbonate. The cost of these raw materials fluctuates based on market conditions. Establishing reliable suppliers and negotiating favorable contracts can help manage raw material costs. Additionally, considering alternative sources or substitutes may provide cost advantages.

Labor Costs

Labor costs are a significant component of the overall expenses in establishing a sodium silicate plant. This includes wages, benefits, and training for employees. Hiring skilled labor is crucial for efficient operations. It is advisable to conduct a labor market analysis to determine the availability and cost of skilled workers in the chosen location.

Equipment and Machinery Costs

Investing in the right equipment and machinery is vital for the production of sodium silicate. The costs associated with purchasing, installing, and maintaining machinery can be substantial. It is essential to evaluate different suppliers and consider both initial costs and long-term operational efficiency. Proper maintenance of equipment can also reduce unexpected costs.

Utilities and Operational Costs

Utilities such as water, electricity, and gas are necessary for the operation of a sodium silicate plant. Estimating these costs accurately is crucial for financial planning. Additionally, operational costs include maintenance, transportation, and administrative expenses. Implementing energy-efficient practices can help in reducing utility costs over time.

Regulatory Compliance Costs

Establishing a sodium silicate plant requires compliance with various environmental and safety regulations. Costs associated with obtaining permits, conducting environmental impact assessments, and implementing safety measures should be factored into the overall budget. Non-compliance can lead to fines and operational disruptions, making this an essential aspect of cost analysis.

Marketing and Distribution Costs

Once the sodium silicate is produced, marketing and distribution costs come into play. Developing a marketing strategy to promote the product and establishing distribution channels are critical for reaching customers. These costs can vary based on the target market and distribution methods chosen.

Financial Projections and Funding

Creating financial projections is essential for understanding the potential profitability of the sodium silicate plant. This includes estimating revenues, expenses, and break-even points. Securing funding through loans, investors, or grants may be necessary to cover initial setup costs. A solid business plan can attract potential investors and facilitate funding.

Risk Assessment and Contingency Planning

Risk assessment is a crucial part of the cost analysis process. Identifying potential risks, such as market fluctuations, supply chain disruptions, and regulatory changes, allows for better preparation. Developing contingency plans can mitigate the impact of these risks on the plant's operations and finances.

Conclusion

In conclusion, establishing a sodium silicate plant requires a thorough cost analysis encompassing various factors. From market research to regulatory compliance, each component plays a vital role in ensuring the plant's success. By carefully evaluating these costs and planning accordingly, investors can establish a profitable and sustainable sodium silicate production facility.

0 notes

Text

Establishing a Plant to Produce Fiber Cement Boards

As the construction industry embraces sustainability and innovation, fiber cement boards have emerged as a leading building material that combines durability, versatility, and eco-friendliness. Establishing a dedicated plant to produce fiber cement boards represents a significant opportunity to meet the growing demand for high-quality building materials. This article explores the importance of fiber cement boards, the manufacturing process, and the advantages of setting up a production facility.

Understanding Fiber Cement Boards

Fiber cement boards are composite building materials made from a mixture of cement, cellulose fibers, and sand. This combination results in a robust, non-combustible material that is resistant to moisture, pests, and rot. Fiber cement boards can be used in a variety of applications, including exterior cladding, roofing, and interior wall panels, making them a versatile choice for builders and architects.

The Manufacturing Process

The production of fiber cement boards involves several essential steps:

Raw Material PreparationThe process begins with sourcing high-quality raw materials. Cement, cellulose fibers (often sourced from recycled paper), and silica sand are combined to create the core mixture for the boards.

MixingThe raw materials are carefully mixed in precise ratios to ensure uniformity. The mixing process may involve the addition of water and other additives to enhance specific properties, such as flexibility or durability.

FormingOnce mixed, the slurry is poured into molds to form boards of desired sizes and thicknesses. This step can be adjusted based on market requirements, allowing for customization in product offerings.

PressingThe formed boards are then subjected to high pressure to remove excess moisture and compact the mixture. This step is crucial for achieving the desired density and strength of the final product.

CuringAfter pressing, the boards undergo a curing process, where they are allowed to dry and harden. This can be done naturally or in controlled environments to accelerate the curing time.

FinishingOnce cured, the boards are trimmed and sanded to achieve a smooth surface. They may also undergo additional treatments, such as painting or coating, to enhance their aesthetic appeal and performance.

Quality ControlRigorous quality control measures are implemented throughout the manufacturing process to ensure that the boards meet industry standards for strength, durability, and safety.

Advantages of Fiber Cement Boards

DurabilityFiber cement boards are highly resistant to weathering, rot, and pests, making them ideal for both residential and commercial applications.

Fire ResistanceBeing made primarily from cement, fiber cement boards are non-combustible and provide excellent fire resistance. This feature enhances safety in building construction and can potentially lower insurance costs.

Moisture ResistanceFiber cement boards resist moisture absorption, preventing issues such as mold and mildew. This property is especially beneficial in humid climates or areas prone to heavy rainfall.

SustainabilityWith a significant portion of their composition coming from recycled materials, fiber cement boards are an eco-friendly choice. Their production process can also be optimized to minimize waste and energy consumption.

Aesthetic FlexibilityFiber cement boards can be manufactured in various colors, textures, and finishes, allowing for design versatility. They can mimic the appearance of wood, stone, or other materials, making them suitable for a wide range of architectural styles.

Low MaintenanceUnlike traditional materials, fiber cement boards require minimal maintenance. Their durability and resistance to environmental factors mean they do not need regular painting or sealing, saving time and resources.

The Business Opportunity

Establishing a plant to produce fiber cement boards offers significant business potential. The global demand for sustainable building materials is on the rise, driven by increased awareness of environmental issues and a shift toward greener construction practices. A dedicated production facility can cater to this demand, providing builders and contractors with high-quality, reliable products.

Additionally, the growing trend of urbanization and infrastructure development in emerging markets creates further opportunities for fiber cement boards. By positioning the plant strategically and leveraging local resources, manufacturers can capitalize on these trends while contributing to sustainable building practices.

Conclusion

The establishment of a plant to produce fiber cement boards represents a forward-thinking investment in the future of construction materials. With their numerous advantages—durability, fire resistance, moisture resistance, and sustainability—fiber cement boards are poised to become a cornerstone of modern building practices. As the industry evolves, this innovative material will play a crucial role in meeting the challenges of sustainable construction, making it an ideal choice for both manufacturers and builders alike.

0 notes

Text

https://github.com/Sona75310/DevBase/blob/main/North America Silica Sand Processing Plant Equipment Market Drivers And Trends.md

0 notes