#silica quartz powder

Explore tagged Tumblr posts

Text

Quartz Powder - Nature's Gift to Industry

Conclude by recognizing quartz powder as nature's invaluable gift to the industry, offering unparalleled versatility, reliability, and performance across a spectrum of applications. Embrace the enduring legacy of quartz as a cornerstone of modern materials science and industrial innovation.

0 notes

Text

Quartz Silica Powder Manufacturers

Quartz Silica Powder Manufacturers

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications. Click for more information Quartz Silica Powder Manufacturers in India

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced. Click now for more update Quartz Silica Grains Manufacturers

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-Northen region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar - soda and potash feldspar, quartz. Click now Quartz Silica Grains

Our roots trace back to a founding team of IIT and NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs.

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click for more information Quartz Silica Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future.

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability. Click now Quartz Silica Powder Manufacturers

Potash Feldspar

A feldspar is typically referred to as 'potash' if there is significantly more potassium than sodium (typically there will be 2-5% Na2O). If the amounts are closer to equal they are termed potash-soda feldspars (or vice versa). Read more Manufacturer of Quartz Grains in India

The main vitrifying agent in ceramic body is feldspar. The majority of white ware bodies contains good proportions of feldspar. It acts as flux in the ceramic industry, the flux is defined as that portion of the body which develops glass phase and this is provided by fledspar. The amount of flux in a ceramic body should be only in such a proporation as to develop the desired amount od vitrification. if excess of flux is added, the fired body becomes very glassy and consequently brittle. Click now for more information Quartz Powder Manufacturers & Suppliers in India

Potassium feldspar melts at around 1200C (higher than soda feldspar) producing a more a viscous melt than does sodium feldspar. It can also produce a crystalline phase (leucite) that contributes to opacity. Thus, in industry, potash feldspars are often used more for matte glazes while soda feldspar is used for glossy glazes.

0 notes

Text

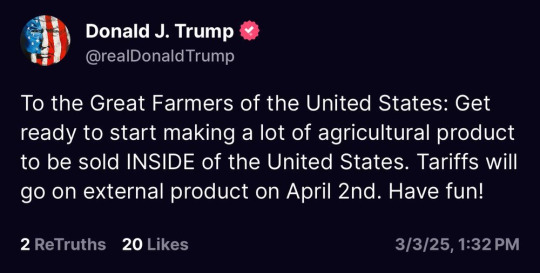

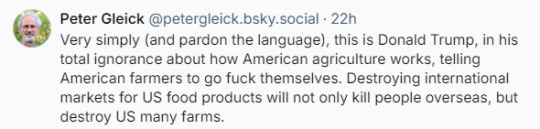

Donald fucked around, we get to find out

Via Narcity: "Starting Tuesday, Canada is slapping new counter-tariffs on U.S. products, targeting $30 billion worth of American goods. And that's just the beginning — Trudeau says an additional $125 billion in tariffs will roll out in the next three weeks if things don't de-escalate."

What follows is the full list of affected American products:

Food & drink

Poultry & eggs — chicken, turkey, goose, duck and their byproducts (fresh, frozen, preserved)

Dairy products — milk, cream, butter, ice cream, yogurt, cheese

Fruits & vegetables — tomatoes, beans, snap peas, citrus fruits, melons, peaches, nectarines, berries

Coffee & tea

Spices & flavourings — pepper, vanilla, dried spices (cinnamon, turmeric, curry, etc.)

Sauces & condiments — soy sauce, ketchup, mustard, mayonnaise, salad dressing, peanut and nut butters

Grains & baking essentials — wheat, rye, rice, barley, oats, flour, mixes and doughs

Oils & fats — canola, sunflower, safflower, palm, peanut and nut oils; margarine and butter substitutes

Sugars & sweeteners — honey, cane sugar, beet sugar, maple sugar and syrup, sugar syrups, molasses

Packaged foods — pasta, pizza, bread, cakes, biscuits, cereal-based foods, soup and broth, pickles, gum, candies, chocolate

Supplements — whey powder, casein, fish oil

Beverages & alcohol — orange juice, soda beer, wine, cider, spirits, liqueurs, coolers, bitters

Tobacco products

Raw & processed tobacco — unmanufactured tobacco, tobacco extracts, chewing tobacco, pipe tobacco

Cigarettes & cigars — cigars, cheroots, cigarillos and cigarettes

Nicotine products — vapes, e-cigarettes, nicotine patches and other smokeless tobacco products

Personal care products

Cosmetics & skincare — makeup, nail polish and manicure tools, hair care, deodorants, soaps and cleansers, razors, shaving products, bath products

Electronic tools — electric razors and clippers, hair dryers, curling irons, flatirons

Fragrances — perfumes, room deodorizers

Oral care — toothpaste, dental floss

Paper products — toilet paper, tissues, napkins

Home & office items

Kitchenware — paper and plastic tableware, storage containers, glassware, cutlery and utensils, kitchen knives, scissors

Furniture & home goods — metal, wooden and plastic furniture; chairs; mattresses and bedding; lighting; storage racks

Home textiles — carpets, rugs, blankets, bed linens, table and kitchen linens, curtains, cleaning cloths

Paper & books — stationery, notebooks, memo pads, binders, file folders, carbon sets, albums, printed materials

Office supplies — letter openers, pencil sharpeners

Artwork — paintings, drawings, pastels

Clothing & accessories

Clothing — shirts, pants, dresses, suits, underwear, hosiery, pyjamas, sweaters, activewear, swimwear, outerwear, baby clothes

Activity-specific attire — diving suits, ski suits, protective gear, life jackets, climbing harnesses, work belts, safety headgear, animal saddlery

Accessories — footwear, hats, gloves, scarves, belts, neckties, jewelry

Bags & luggage — handbags, wallets, suitcases, briefcases, backpacks

Electronics & appliances

Household appliances — refrigerators, freezers, dishwashers, washing machines and dryers, stoves, barbecues, fans, humidifiers, vacuum cleaners, fabric steamers

Countertop appliances & kitchen gadgets — blenders, food mixers, juicers, microwaves, grills, rice cookers, coffee makers, toasters

Gaming & entertainment — video game consoles, board games, card games

Vehicles & machinery

Motorcycles & recreational vehicles — motorbikes, sidecars, recreational boats, drones

Yard equipment — snowblowers, lawnmowers

Tools — saws, pliers, wrenches, spanners, hammers, drills, cutting tools, screwdrivers, staple guns, vices, lighters, pneumatic tools, padlocks

Rubber tires

Building materials

Silica & quartz sands

Plastic wall, floor & ceiling coverings

Window and door fixtures — window and door components and frames, shutters, blinds

Bathroom fixtures — plastic and ceramic baths, showers, sinks and wash basins, toilets, bidets, urinals

Plastic packaging

Wood products — planks, chips, veneer sheets, particle board, MDF, fibreboard, laminated wood, posts, beams, floor panels, wood pulp

Cardboard & paper — cartons, boxes, cases, paper bags

Textiles — tarps, tents, canopies, sails, woven fabric

Precious metals & gemstones — diamonds, silver, palladium

Weapons & ammunition

Firearms — pistols, revolvers, rifles, shotguns, air guns

Ammunition — bullets, cartridges, pellets

"Have fun!"

8 notes

·

View notes

Text

Calcium Carbonate

LimeStone Granules ( Feed )

LimeStone Lumps ( Calcite )

Silica Sand ( Glass )

Foundry Sand

Frac Sand ( Proppant Sand )

Silica Flour ( Quartz Powder )

Cullet ( Broken Glass )

Glass Powder ( Cullet Flour )

Rock Gypsum

Agriculture Gypsum

Gypsum Plaster ( POP - Plaster of Paris )

Poultry Meal

Rock Phosphate

Quick Lime

Hydrated Lime

Bentonite

Barite

#calcium carbonate#raw materials#foundry sand#silica sand#limestone#Cullet#Poultry_Meal#$Silica_Sand

2 notes

·

View notes

Text

U.S. Colloidal Silicon Dioxide Prices 2025, Trend, Graph, Chart and Forecast

Colloidal silicon dioxide is a crucial ingredient in multiple industries, including pharmaceuticals, food and beverage, cosmetics, and industrial applications. The market for this versatile compound has witnessed significant fluctuations in pricing due to various factors, including supply chain dynamics, raw material availability, demand trends, and geopolitical influences. Understanding the pricing trends of colloidal silicon dioxide requires a comprehensive analysis of these market dynamics and their impact on production costs and end-user pricing strategies.

One of the primary factors influencing the price of colloidal silicon dioxide is the cost of its raw materials, primarily silicon and other silica-based compounds. Silicon dioxide is derived from quartz sand or synthetic silica sources, and fluctuations in the price of these raw materials directly impact the production cost of colloidal silicon dioxide. Market volatility in the availability of high-purity silica and increased mining regulations have added pressure on manufacturers, leading to periodic price hikes. Additionally, energy costs play a crucial role, as the synthesis of colloidal silicon dioxide involves high-temperature processes that require significant energy consumption. Any surge in electricity or fuel prices directly translates into increased production costs, ultimately affecting the market price.

Get Real time Prices for Colloidal Silicon Dioxide: https://www.chemanalyst.com/Pricing-data/colloidal-silicon-dioxide-1246

Demand trends also play a pivotal role in determining colloidal silicon dioxide prices. The pharmaceutical industry is one of the largest consumers of this compound, as it is widely used as an excipient in tablet formulations to enhance flow properties and prevent caking. The growing pharmaceutical sector, driven by increased drug production and the rising prevalence of chronic diseases, has fueled steady demand for colloidal silicon dioxide, supporting price stability. Similarly, the food and beverage industry relies on colloidal silicon dioxide as an anti-caking agent in powdered foods, spices, and supplements. The increasing consumer preference for processed and packaged foods has further bolstered demand, contributing to price fluctuations based on supply and demand balance.

The cosmetics industry is another key sector impacting the market for colloidal silicon dioxide. Its applications in skincare and beauty products as a thickening, mattifying, and suspending agent have driven steady consumption. The rise of the global cosmetics market, particularly with the increasing demand for organic and high-performance beauty products, has influenced the pricing dynamics of colloidal silicon dioxide. The industrial sector also plays a role, as this compound is used in coatings, paints, adhesives, and other applications requiring enhanced stability and performance. The expansion of these industries in emerging economies has led to increased consumption, affecting price trends.

Regional market variations also contribute to price fluctuations. Asia-Pacific, particularly China and India, remains a major producer and consumer of colloidal silicon dioxide due to its large manufacturing base and availability of raw materials. The presence of numerous pharmaceutical and food processing industries in these regions has led to competitive pricing. However, environmental regulations and government policies on silica mining and chemical manufacturing have occasionally disrupted supply, causing price shifts. In contrast, North America and Europe experience relatively higher prices due to stringent regulatory frameworks, higher production costs, and quality control measures. The demand for high-purity grades in these regions further influences pricing, as premium-quality colloidal silicon dioxide commands a higher price in the market.

Another crucial aspect influencing price trends is technological advancements in production methods. Manufacturers are constantly investing in research and development to enhance production efficiency, reduce energy consumption, and develop high-purity colloidal silicon dioxide for specialized applications. These advancements often lead to cost optimization, allowing manufacturers to offer competitive pricing. Additionally, the trend towards sustainable and eco-friendly manufacturing processes has led to investments in alternative silica sources, such as biosilica derived from agricultural waste. While these innovations contribute to long-term price stability, the initial costs of adopting new technologies may temporarily affect market prices.

Market competition among key players also plays a vital role in pricing dynamics. Several multinational corporations, along with regional manufacturers, are actively engaged in the production and distribution of colloidal silicon dioxide. Companies such as Evonik Industries, Wacker Chemie, Cabot Corporation, and PPG Industries hold significant market shares and influence pricing strategies. The presence of multiple players fosters competitive pricing, while mergers, acquisitions, and strategic partnerships among companies impact supply chain efficiency and market stability.

Future price trends for colloidal silicon dioxide are expected to be shaped by several factors. The increasing demand from pharmaceutical and food industries, coupled with growing applications in advanced material sciences, is likely to sustain market growth. However, potential challenges such as raw material scarcity, environmental regulations, and geopolitical risks may lead to occasional price hikes. Additionally, the shift towards green chemistry and sustainable production methods will influence long-term pricing trends, as the industry adapts to new technologies and regulatory requirements.

Overall, the market for colloidal silicon dioxide remains dynamic, with multiple variables affecting its pricing structure. From raw material costs and energy expenses to supply chain disruptions and regional demand variations, numerous factors contribute to price fluctuations. Businesses involved in the procurement and use of colloidal silicon dioxide must stay informed about market trends and strategic developments to navigate potential price changes effectively. By leveraging technological advancements, optimizing supply chain efficiencies, and monitoring regulatory shifts, manufacturers and consumers can better adapt to the evolving pricing landscape of colloidal silicon dioxide.

Get Real time Prices for Colloidal Silicon Dioxide: https://www.chemanalyst.com/Pricing-data/colloidal-silicon-dioxide-1246

Our Blog:

Cement and Concrete Additives Prices: https://www.chemanalyst.com/Industry-data/cement-and-concrete-additives-6

Packaging Materials Prices: https://www.chemanalyst.com/Industry-data/packaging-materials-7

Personal Care Chemicals Prices: https://www.chemanalyst.com/Industry-data/personal-care-chemicals-8

Polar Solvents Prices: https://www.chemanalyst.com/Industry-data/polar-solvents-9

Surfactants Prices: https://www.chemanalyst.com/Industry-data/surfactants-10

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Colloidal Silicon Dioxide Pricing#Colloidal Silicon Dioxide News#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

What is Silica Sol Process of Investment Casting VS Water Glass Investment Casting and The Differences

Since our silica sol process is a type of lost wax method, and LE-TA has been focusing on silca sol investment casting, and a lot of our customers are confused with silica sol investment casting and water glass investment casting. In this article, we will explain in details of the two process and the differences between silica sol casting and water glass investment casting.

In simple terms, the lost wax method is to first use wax to replicate the object to be cast, then immerse it in a pool of sand/powder and wait for it to dry, so that the wax replica is covered with a layer of sand outer film, and the steps are repeated until the outer film is sufficient to support the casting process, then melt the wax in the mold and remove the mold. After that, the mold needs to be heated several times to enhance its hardness before it can be used for casting. This method has good accuracy, but due to the high price of sand/powder, and the need for multiple heating and complexity in production, the cost is quite expensive.

The surface roughness of the products cast by our factory's silica sol process can reach Ra3.2-6.4. Since the casting blank is almost formed, it can achieve the purpose of no mechanical processing or little processing, which reduces the cost and reduces the production time to a certain extent.

What is Water Glass Casting?

Water glass casting is also called sodium silicate casting. Its casting process is very similar to silica sol investment casting (that is the lost wax investment casting method). It is a technology that uses water glass as the binder for the shell to cast. The process provides a far superior surface finish and dimensional precision to that achieved through sand casting. And more complex shapes can be achieved. It is particularly suited to larger castings and is cheaper to produce. The raw materials are mainly steel and iron.

Water glass investment casting process

Silica sol investment casting(Lost wax casting)

What's the Difference of Water Glass Process and Silica Sol Process

Another commonly used lost wax casting method is the water glass process. Compared with the castings produced by the silica sol process, water glass has certain advantages in price, that is, it is cheaper.

Here is a brief analysis of the differences between the two processes. Different production processes lead to great differences in the final products. Products produced by silica sol process have higher dimensional accuracy and better surface roughness than those produced by water glass process. Because the back layer retains the water glass binder, the overall high temperature strength and creep resistance of its shell are lower than those of silica sol shell. Its mold baking temperature is limited to below 950℃. After 900℃, the deformation of the shell increases by 30%. The baking temperature of silica sol shell can reach 1000-1200℃, and the shell does not deform before 1000℃. Therefore, the water glass process cannot be compared with the silica sol process in terms of quality and product accuracy.

The Main Differences Between Silica Sol Investment Casting & Water Glass Casting

1. Molding Material: The water glass casting process uses water glass quartz sand as the molding material, which can stand temperature up to 1800 degrees, but it is more expensive than wet clay sand. The silica sol investment casting process uses silica sol zircon sand as the molding material, which can stand temperatures up to 2000 degrees. This molding material is very expensive.

2. Wax Temperature: Silica sol wax is middle temperature, water glass wax is low temperature( which can stand temperature up to 1800 degrees). while silica sol casting uses medium temperature wax which can stand temperatures up to 2000 degrees.

3. Casting material is different. Usually carbon steel apply to water glass casting, however silica sol investment casting can manufacture more materials including carbon steel, stainless steel, high temperature alloy, etc.

4. Casting Surface Quality and Defects Water glass castings have much better surface smoothness, fewer surface and inside casting defects.

The followings are some photos to show the surface quality of steel castings made by this process. Its surface finish roughness could reach Ra 12.5, the dimensional tolerance could be CT6-CT8: Silica sol investment castings have very good surface quality, are much smoother than water glass casting, have very few surfaces, and have inside defects. The followings are some photos to show the surface quality of steel castings made by this process. Its surface finish roughness could reach Ra 3.2-6.3, the dimensional tolerance could be CT4-CT6

5. Differences of Specifications on unit weight and wall thickness differences Silica sol Investment casting can make casting smaller than 10b, while water glass casting is more suitable for making larger parts. The following table could be a reference to tell their difference.

6. Casting prices The mold material costs have caused a very big difference in their casting prices. The water glass quartz sand is cheap, and silica sol zircon sand is very expensive. The investment casting process always costs higher than sand casting for the complexity and preparation needed.

7. Surface Finishing Surface finish is another big difference between silica sol investment casting and Water glass investment casting. Silica sol investment casting can create finished parts showing smooth surfaces and low tolerances under the work of pattern. After removing the sprue gate and shot blasting, the casting blank is the final part for delivery. The water glass casting has less smooth surface than silica sol investment casting. And due to the rough surface of finished cast parts made by water glass process, so additional cost and time will be required in secondary machining for removing the parting line and a more smooth surface.

The Core Advantages of Silica Sol Investment Casting

Finally, let's summarize the core advantages of silica sol casting: the casting surface is good and the dimensional accuracy is high, which saves a lot of surface treatment time and dimensional outsourcing processing. From the perspective of the finished product, it actually reduces the cost. The choice of process depends on the needs of the customer, but if you choose us, we will not let you down. Our experienced engineering team will guide you on your projects to choose the right process and materials for your project and track the status from project acceptance to completion. Please feel free to contact us if you have such needs.

0 notes

Text

Fused Silica Optics JGS1 JGS2 JGS3 Glass Plates Fused silica optical JGS1, JGS2, JGS3 glass plates are high-performance optical materials, widely used in photoelectricity, electronics, new energy, semiconductor, optical new technology and other fields. These glass plates are made of high purity quartz powder through high temperature fusion process and have excellent optical properties, chemical stability and thermal stability.

Luverre Quartz is a manufacturer focusing on producing various quartz plates, we can produce customized quartz plates in different sizes and shapes, such as square, round, oval and other special shaped designs according to customer's requirements. The processing includes cutting, bending, welding, etc., and there are different colors available, such as transparent quartz plates, opaque quartz plates, milky quartz plates and so on. https://www.luverrequartz.com/Quartz-Plate-pl3742109.html Welcome to inquire about ordering

#FusedSilicaglassplate#FusedSilicaplate#FusedSilicaplatemanufacturer#FusedSilicaglassplatemanufacturer#FusedSilicaplatesupplier#FusedSilicaglassplatesupplier#CustomFusedSilicaplate#CustomFusedSilicaglassplate#FusedSilicaplateprice#FusedSilicaglassplateprice#highpurityFusedSilicaplate#highpurityFusedSilicaglassplate#ultrafineFusedSilicaplate#ultrafineFusedSilicaglassplate#largeFusedSilicaplate#largeFusedSilicaglassplate#fusedsilicaglassplate#luverrequartz

0 notes

Text

Exploring the Versatility of Quartz Powder in Industry

Quartz powder, derived from the natural mineral quartz, has emerged as a cornerstone material across various industries. With its unique physical and chemical properties, it has become indispensable in applications ranging from construction to electronics. Quartz Powder Manufacturers around the globe are striving to meet the increasing demand for this versatile material, ensuring that industries continue to thrive with high-quality quartz powder.

Understanding Quartz Powder

Quartz is a silica-rich mineral that undergoes processing to produce fine quartz powder. The end product is known for its high purity, excellent hardness, and resistance to chemical reactions. These qualities make quartz powder a preferred choice in sectors such as:

Construction: Used in cement and concrete mixtures for improved durability and aesthetic appeal.

Electronics: Essential for producing semiconductors, solar panels, and optical devices due to its insulating properties.

Glass Manufacturing: Serves as a key raw material in the production of glass, contributing to its clarity and strength.

Paints and Coatings: Acts as a filler to enhance weather resistance and texture.

Ceramics: Adds strength and smoothness to ceramic tiles and sanitary ware.

With such diverse applications, the demand for quartz powder continues to soar, urging manufacturers to innovate and deliver products that meet industry standards.

Qualities of High-Grade Quartz Powder

For quartz powder manufacturers, quality is paramount. High-grade quartz powder possesses:

Purity: Contains minimal impurities, especially in silicon dioxide (SiO₂) content.

Granular Consistency: Fine, uniform particles that ensure seamless application.

Thermal Stability: Withstands high temperatures, making it ideal for industrial processes.

Chemical Resistance: Non-reactive to most chemicals, ensuring long-lasting performance.

Manufacturing Process of Quartz Powder

Quartz powder production involves a multi-step process:

Mining and Extraction: Raw quartz is mined from quarries and transported for processing.

Crushing and Grinding: Quartz is crushed into smaller pieces and ground to the desired powder consistency.

Screening and Sorting: Advanced machinery ensures that the powder meets specific size requirements.

Purification: Techniques such as magnetic separation and acid washing remove impurities to achieve high purity.

Packaging and Distribution: The final product is packed in moisture-resistant bags and transported to clients.

The process is energy-intensive and requires precision to maintain consistent quality.

The Role of Quartz Powder in Modern Industries

The adaptability of quartz powder has positioned it as a vital resource in modern industrial applications. For instance:

In the solar energy sector, quartz powder is used to manufacture photovoltaic cells, driving sustainable energy solutions.

In oil and gas exploration, it plays a crucial role in hydraulic fracturing, improving extraction efficiency.

Pharmaceutical and cosmetic industries utilize its non-toxic nature for formulating products that are safe and effective.

Such wide-ranging uses underline its importance in both traditional and emerging markets.

India’s Growing Market for Quartz Powder

India has emerged as a significant player in the global quartz powder market. With abundant natural resources and advanced manufacturing capabilities, the country has positioned itself as a hub for high-quality quartz powder. Indian manufacturers focus on:

Export Excellence: Supplying premium quartz powder to countries across Asia, Europe, and the Americas.

Sustainability: Implementing eco-friendly practices in mining and processing.

Customization: Catering to specific client needs by offering tailored grades of quartz powder.

One such prominent name in the Indian quartz powder manufacturing landscape is the Sudarshan Group. Known for its commitment to quality and innovation, the company has set benchmarks in delivering quartz powder that meets global standards.

Choosing the Right Quartz Powder Manufacturer

For businesses reliant on quartz powder, selecting the right manufacturer is crucial. Here are key factors to consider:

Reputation: Look for manufacturers with a proven track record of quality and reliability.

Certifications: Ensure compliance with industry certifications and environmental standards.

Supply Chain Efficiency: A robust logistics network ensures timely delivery of products.

Customer Support: Responsive service for addressing client requirements and concerns.

Conclusion

Quartz powder manufacturers are the backbone of industries that depend on this versatile material. With advancements in technology and increasing global demand, the future of quartz powder manufacturing is bright. Companies like the Sudarshan Group exemplify the industry's potential by consistently delivering quality products tailored to diverse needs.

By choosing the right quartz powder manufacturer, businesses can ensure the success of their projects while contributing to sustainable industrial growth. As quartz powder continues to shape industries, its significance in the global economy will only expand further.

0 notes

Text

Quartz Powder: A Versatile Material for Every Industry

One of the most common minerals on Earth is used to make quartz powder, which is now essential in many industrial processes. Its distinct physical and chemical characteristics make it an essential raw material for a variety of sectors, such as electronics, paints, glassmaking, ceramics, and building. Selecting a trustworthy Supplier of Quartz Powder for companies looking to purchase dependable, superior quartz powder.

The Increasing Significance of Quartz Powder

Crystals of quartz are crushed and ground into a fine powder to create quartz powder, sometimes referred to as silica powder. The material's exceptional hardness, thermal stability, and great purity make it valuable. It can be used in a number of high-performance applications thanks to these qualities:

Manufacturing of Glass: One of the main ingredients used to make glass is quartz powder. It is essential for creating high-quality glass products because of its high silica concentration, which guarantees clarity, strength, and resistance to thermal shock.

Tiles and Ceramics: Quartz powder is utilized in the ceramics sector to improve the robustness and longevity of goods. It also gives tiles their glossy appearance, which makes it a popular choice for contemporary interior design.

Construction Materials: Quartz powder adds durability and a clean finish to cement and concrete. Its use in engineered stones gives flooring and countertops a polished appearance.

Electronics: To create silicon wafers, which are essential parts of contemporary electronics, the semiconductor industry depends on the exceptional purity of quartz powder.

Quartz powder is used as a filler in paints and coatings to enhance their texture, toughness, and weather resistance.

What Makes a Perfect Supplier

In order to guarantee the quality and functionality of quartz powder in your industrial processes, choosing the correct supplier is essential. Here are some characteristics to search for in a supplier:

Consistency in Quality: Quartz powder's purity and particle size must adhere to industry norms. To satisfy certain application requirements, a trustworthy supplier should continuously deliver high-quality material.

Customization: Different industries require quartz powder in varying grades and specifications. A supplier that offers customized solutions based on individual needs adds significant value.

Sustainability: In the modern, environmentally conscious world, mining, processing, and packaging methods must be sustainable. Suppliers employing eco-friendly methods not only reduce environmental impact but also align with the growing emphasis on sustainability in industrial operations.

Timely Delivery: Because industries have strict deadlines, it is crucial that raw materials arrive on time. A dependable supplier ensures consistent supply chains without delays.

Choosing a Trusted Partner for Quartz Powder

India is a prominent hub for quartz powder production due to its abundant reserves and advanced processing facilities. Among the numerous suppliers, Pratibha Refractory Minerals has earned a reputation for excellence in the industry. With their commitment to quality, sustainability, and customer satisfaction, they cater to diverse industrial requirements while adhering to international standards.

Their state-of-the-art facilities and stringent quality control measures ensure the delivery of premium-grade quartz powder. Additionally, their focus on sustainable practices resonates with industries aiming for eco-friendly operations.

Applications in Emerging Industries

While traditional industries like glass and ceramics continue to drive demand for quartz powder, emerging sectors are also recognizing its potential. For instance:

Solar Energy: Quartz powder is a critical material in the production of photovoltaic cells, driving the growth of renewable energy.

3D Printing: Additive manufacturing technologies are increasingly incorporating quartz powder for creating intricate and durable components.

Conclusion

Quartz powder's versatility and indispensability across industries underline the importance of sourcing it from a trusted supplier. High-quality quartz powder not only enhances the performance of end products but also contributes to operational efficiency and innovation.

As businesses seek to achieve excellence, partnering with a reliable supplier like Pratibha Refractory Minerals ensures access to superior-quality materials, competitive pricing, and sustainable solutions. Whether for traditional applications or cutting-edge technologies, quartz powder remains a cornerstone for industrial success.

0 notes

Text

Additive Manufacturing Market, Industry Forecast, 2024–2030.

Additive Manufacturing Market Overview:

Sample Report :

Additionally, Increasing focus on metal additive manufacturing technologies. Researchers and companies have been actively working on expanding the range of metals and alloys available for AM. This includes not only traditional metals like titanium, aluminum, and stainless steel but also high-performance alloys for specialized applications. The development of new metal powders suitable for various AM processes has been a focus area. The integration of Additive Manufacturing with traditional manufacturing processes in companies were exploring hybrid manufacturing approaches that combine the strengths of additive and subtractive methods. This integration aimed to leverage the design flexibility of Additive Manufacturing and the efficiency of traditional methods to optimize production workflows. These factors impact the growth in Additive Manufacturing Market.

Market Snapshot:

Additive Manufacturing Market — Report Coverage:

The “Additive Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Additive Manufacturing Market.

AttributeSegment

By Type

● Materials

● Systems

● Services & Parts

By Material

● Plastics

○ Acrylonitrile Butadiene Styrene (ABS)

○ Polylactic Acid (PLA)

○ Polyethylene (PE)

▪ High-Density Polyethylene (HDPE)

▪ Low-Density Polyethylene (LDPE)

▪ Linear Low-Density Polyethylene (LLDPE)

▪ Others

○ Polycarbonate (PC)

○ Polypropylene (PP)

○ Polyethylene Terephthalate (PETE)

○ Nylon

○ Others

● Metals

○ Iron

○ Steel

○ Silver

○ Aluminum

○ Copper

○ Titanium

○ Gold

○ Zinc

○ Others

● Ceramics

○ Glass

○ Silica

○ Quartz

○ Others

● Others

By Technology

● Powder Bed Fusion

○ Direct Metal Laser Sintering (DMLS)

○ Selective Laser Sintering (SLS)

○ Selective Laser Melting (SLM)

○ Electron Beam Melting (EBM)

○ Others

● Binder Jetting

● Directed Energy Deposition

○ Laser Deposition Technology (LDT) excluding LCT

○ Laser Additive Manufacturing (LAM)

○ Laser Metal Deposition (LMD)

○ Laser Engineering Net Shape (LENS)

○ Laser Cladding Technology (LCT)

○ Electron Beam Additive Manufacturing (EBAM)

○ Wire Arc Additive Manufacturing (WAAM)

○ Laser Deposition Welding (LDW)

○ Others

● Material Extrusion

● Material Jetting

○ Drop On Demand (DOD)

○ Polyjet by Object

○ Others

● Vat Polymerization

○ Stereolithography (SLA)

○ Digital Light Processing (DLP)

○ Continuous Liquid Interface Production (CLIP)

○ Others

● Others

By End-Use Industry

● Industrial

● Aerospace

○ Commercial

○ Military

○ Others

● Consumer Goods

○ Furniture

○ Watches and Jewelry

○ Shoes and Soles

○ Others

● Oil & Gas

● Automotive

○ Passenger Cars

○ Light Commercial Vehicles (LCV)

○ Heavy Commercial Vehicles (HCV)

○ Others

● Medical & Healthcare

● Electrical & Electronics

○ Conductors

○ Resistors

○ Sensors

○ Semiconductors

○ Others

● Building and Construction

○ Residential

○ Commercial

○ Industrial

○ Infrastructure

The COVID-19 pandemic had a mixed impact on the Additive Manufacturing (AM) market. While disruptions in global supply chains initially posed challenges for material sourcing, the flexibility of AM processes proved beneficial in addressing urgent needs for medical equipment and components. The demand for 3D printing surged during the pandemic, with AM technologies being utilized for the rapid production of ventilator parts, face shields, and other critical supplies. The crisis highlighted the agility of AM in responding to unforeseen challenges and increased awareness of its potential across various industries.

Inquiry Before Buying :

The situation in Ukraine had indirect effects on the Additive Manufacturing (AM) market, primarily through broader geopolitical and economic repercussions. Disruptions in supply chains, especially for metals and other raw materials used in AM processes, were potential concerns. Additionally, uncertainties in global markets may have influenced investment decisions and R&D activities in the AM sector. However, the impact varied depending on the resilience of individual companies and their exposure to the geopolitical developments.

Key Takeaways:

North America Dominated the Market

Geographically, in the Additive Manufacturing market share, the North America region has held a dominant market share of 41% in 2023, Rising government investments and projects in the United States for additive manufacturing have also raised the growth of the market. For instance, to address the challenges in single laser melting (SLM), America Makes awarded GE Global $2.6 million to build an open-source, multi-laser production machine and AM platform. Additionally, in Canada, the rising partnership between research universities in the field of additive manufacturing is also influencing the growth of the market. U.S. is anticipated to lead the global additive manufacturing market with the largest installed base for 3d printer in the world. With such a dominant presence of the 3d printers in the country U.S. is likely to contribute more than one third in the revenue generated by additive manufacturing worldwide.

Metal is the Fastest Growing Segment

In the Additive Manufacturing Market forecast, the Metal segment is estimated to grow with a CAGR of 23.5% during the forecast period. Metals are a better option for 3D printing compared to plastics, as they have more industrial usage. Often the 3D metal printing shows itself to be unique as the new technologies can readily surpass what was offered by traditional processes. In AM of metals a powder feedstock or more rarely a wire is fully melted by the energy input of a laser or electron beam and transformed layer by layer into a solid part of nearly any geometry. The most popular processes for AM of metals are Laser Beam Melting (LBM), Electron Beam Melting (EBM) and Laser Metal. In a survey conducted across the globe, about 23% of the 3D printing materials used are metals. The 3D printing metals segment is also poised to grow as it has a competitive edge over other plastic materials used in 3D Printing. Metal 3D printing is too expensive, furthermore other companies, like Desktop Metal and Markforged, are developing approaches to manufacture affordable metal 3D printers.

Schedule A Call :

Aerospace to Hold Largest Market Share

According to the Additive Manufacturing Market analysis, the Aerospace segment is estimated to hold the largest market share of 34% in 2023, the aerospace and defense industry is a perfect example of how to use additive manufacturing (AM) (commonly referred to as 3D Printing) to produce components that are heavier and lighter than parts manufactured using conventional manufacturing methods. Additive manufacturing or 3D printing has applications in the aerospace industry such as engine compartments, cabin accessories, air ducts among others. NASA researchers are looking into how electroplated SLA parts perform in space. Engineers at NASA’s Goddard Space Flight Center designed brackets that were 3D printed on printers, electroplated, and sent to space aboard a summer 2022 SpaceX commercial resupply services (CRS-25) mission to the International Space Station (ISS). The results could inform how NASA and possibly other aerospace manufacturers may incorporate electroplating and additive manufacturing into potential future product plans.

Ease of Manufacturing Complex Design

he basic physical difference in how objects are made with the additive manufacturing process produces some major functional differences when compared with other traditional manufacturing processes. The most significant of these functional differences is the ability of additive manufacturing to produce complex geometries that would be difficult or impossible to achieve using conventional manufacturing methods. These intricate geometries are also stronger and lighter than their conventional counterparts. Additive manufacturing eliminates the additional costs normally associated with creating more complex objects. A highly complex component usually costs much more using conventional methods. This is primarily because conventional fabrication methods rely on the conversion of three-dimensional illustrations into two-dimensional drawings for fabrication, as well as the labor cost of assembling such components. However, regardless of the complexity of a component, the method in additive manufacturing is the same. Thus, no additional cost is incurred for manufacturing complex designs using additive manufacturing.

Buy Now :

Relatively Lower Production Cost for Rapid Manufacturing

The manufacturing companies experience various benefits while using additive manufacturing methods to produce objects. Since the complexity of the component has little or no impact on the manufacturing time and costs, additive manufacturing is ideal for low-cost production as well as small and (very) large series. Design changes can be implemented quickly at a low cost. Metal structures are made up of atom by atoms in additive manufacturing, as opposed to subtractive approaches like chemical etching. As a consequence, almost every piece of metal is utilized during the production process, with almost no waste of material and reducing material wastage. When using additive manufacturing, all of the extra features that are needed for the assembly, such as fasteners, brazing, or welding, can be omitted. Thus, additive manufacturing also reduces assembly costs.

Difficulty in Producing Large Single Parts

Even if additive manufacturing were to dramatically increase production speed and volume performance, it would still be unable to manufacture large single parts. This is yet another major challenge confronting additive manufacturing researchers as they pursue new applications for 3D printing technology. Arc-based wire feed metal AM was chosen as the best process to produce large metal parts. While metal powder bed printers are available commercially, they are not currently capable of producing large-scale metal parts. Therefore, arc-based wire feed technology provided the most cost-effective solution. The building envelope for current additive manufacturing technologies is limited, meaning even larger components that can be printed must still be assembled by mechanical joining or welding.

For More Details on This Report — Request for SampleKey Market Players:

duct/Service launches, approvals, patents and events, acquisitions, partnerships and collaborations are key strategies adopted by players in the Additive Manufacturing Market. The top 10 companies in this industry are listed below:

Proto Labs, Ltd.

3D Systems, Inc

Stratasys Ltd.

Desktop Metal

Autodesk, Inc.

Materialise NV

Markforged

Optomec, Inc.

Dassault Systemes

Titomic Limited

Geographies Covered

North America (U.S., Canada and Mexico), Europe (Germany, France, UK, Italy, Spain, Netherlands and Rest of Europe), Asia-Pacific (China, Japan, South Korea, India, Australia & New Zealand and Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia and Rest of South America), Rest of the World (Middle East and Africa).

Key Market Players

For more Automation and Instrumentation Market reports, please click here

0 notes

Text

Quartz Silica Powder Manufacturers in India

Quartz Silica Powder Manufacturers in India

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications. Click for more information Quartz Silica Powder Manufacturers in India

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced. Click now for more update Quartz Silica Grains Manufacturers

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-Northen region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar - soda and potash feldspar, quartz. Click now Quartz Silica Grains

Our roots trace back to a founding team of IIT and NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs.

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click for more information Quartz Silica Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future.

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability. Click now Quartz Silica Powder Manufacturers

Potash Feldspar

A feldspar is typically referred to as 'potash' if there is significantly more potassium than sodium (typically there will be 2-5% Na2O). If the amounts are closer to equal they are termed potash-soda feldspars (or vice versa). Read more Manufacturer of Quartz Grains in India

The main vitrifying agent in ceramic body is feldspar. The majority of white ware bodies contains good proportions of feldspar. It acts as flux in the ceramic industry, the flux is defined as that portion of the body which develops glass phase and this is provided by fledspar. The amount of flux in a ceramic body should be only in such a proporation as to develop the desired amount od vitrification. if excess of flux is added, the fired body becomes very glassy and consequently brittle. Click now for more information Quartz Powder Manufacturers & Suppliers in India

Potassium feldspar melts at around 1200C (higher than soda feldspar) producing a more a viscous melt than does sodium feldspar. It can also produce a crystalline phase (leucite) that contributes to opacity. Thus, in industry, potash feldspars are often used more for matte glazes while soda feldspar is used for glossy glazes.

0 notes

Text

Unlocking the Potential of Quartz Powder in Manufacturing

Quartz powder, a finely ground form of crystalline silica, is an essential industrial material used in various sectors such as glass manufacturing, electronics, ceramics, construction, and more. It is highly valued for its physical and chemical properties, including durability, high melting point, low electrical conductivity, and resistance to wear. Industries across the globe are reliant on high-quality Quartz Powder Manufacturers to create products ranging from everyday household items to advanced technological components.

When it comes to sourcing premium-grade quartz powder, Sudarshan Group has established itself as a leading manufacturer and supplier in the market. With decades of experience and a commitment to innovation, Sudarshan Group has become a name synonymous with quality and reliability in the mineral industry. In this article, we will explore the importance of quartz powder, its applications, and why Sudarshan Group stands out among quartz powder manufacturers.

What is Quartz Powder?

Quartz powder is derived from natural quartz, a mineral composed primarily of silicon dioxide (SiO2). It is abundant in the Earth’s crust and occurs in a variety of forms, including large crystals, sand, and finely ground powder. Quartz has exceptional hardness, chemical stability, and optical properties, making it ideal for use in multiple industrial applications.

The process of creating quartz powder typically involves mining quartz deposits, crushing the raw material, and then grinding it to the desired particle size. High-purity quartz powder, which has fewer impurities such as iron and other trace minerals, is often used in specialized applications, especially in electronics and high-tech industries.

Applications of Quartz Powder

Glass Manufacturing: One of the most well-known applications of quartz powder is in the glass industry. Quartz is a key ingredient in the production of glass, contributing to the material’s strength, transparency, and resistance to high temperatures. The silica content in quartz powder acts as a flux, lowering the melting point of the raw materials used in glassmaking. This allows for the production of various types of glass, including soda-lime glass, borosilicate glass, and specialty glass used in laboratory equipment and optics.

Ceramics: In the ceramics industry, quartz powder is used as a filler material to enhance the mechanical strength of the final product. It helps improve the thermal shock resistance and overall durability of ceramic items, making them suitable for use in high-temperature environments. The fine particle size of quartz powder also ensures a smooth surface finish for ceramics, contributing to their aesthetic appeal.

Construction: Quartz powder is widely used in the construction industry, particularly in the production of concrete and mortar. The addition of quartz powder improves the strength, durability, and weather resistance of these materials, making them ideal for building structures that need to withstand harsh environmental conditions. In addition, quartz is used in engineered stone products, such as countertops and flooring, which combine beauty with practicality.

Electronics: High-purity quartz powder plays a critical role in the electronics industry. It is used in the production of semiconductors, integrated circuits, and solar cells due to its excellent electrical insulation properties. Quartz also has piezoelectric properties, meaning it can generate an electrical charge when subjected to mechanical stress. This makes it an essential component in devices like oscillators, sensors, and watches.

Paints and Coatings: In the paints and coatings industry, quartz powder is used as a filler material to improve the durability, gloss, and resistance of paints. It helps create coatings that are resistant to chemicals, heat, and wear, making them suitable for use in harsh environments. Quartz powder also enhances the adhesion of paint to surfaces, ensuring a long-lasting finish.

Foundry and Refractory Applications: Quartz powder is used in foundries to create molds for casting metals. Its high melting point and resistance to thermal expansion make it ideal for producing molds that can withstand extreme temperatures. In refractory applications, quartz powder is used to create heat-resistant materials that are essential for lining furnaces, kilns, and other high-temperature processing equipment.

Leading the Way in Quartz Powder Manufacturing

As one of the foremost quartz powder manufacturers, Sudarshan Group has a proven track record of providing high-quality quartz products to clients across various industries. Established with a mission to supply premium-grade minerals, Sudarshan has become a trusted name in the field of industrial minerals, especially quartz powder.

Commitment to Quality

Sudarshan Group prides itself on delivering quartz powder that meets the highest standards of purity and consistency. The company uses state-of-the-art technology in its mining and processing operations to ensure that the final product is free from impurities and has the desired particle size distribution. This commitment to quality is what sets it apart from other manufacturers.

The company also adheres to strict quality control measures throughout the production process, ensuring that every batch of quartz powder meets the specifications required by its clients. Whether it’s for glass manufacturing, electronics, or construction, Sudarshan quartz powder is designed to meet the demanding requirements of various industries.

Conclusion

Quartz powder is a versatile and essential material in a wide range of industries, from glass manufacturing to electronics and construction. As demand for high-quality quartz products continues to grow, manufacturers like Sudarshan Group play a crucial role in meeting this need. With a commitment to quality, sustainability, and customer satisfaction, it has earned its reputation as a leading quartz powder manufacturer. Whether you’re in the market for quartz powder for industrial or technological applications, it is a trusted partner that can deliver the products and support you need.

0 notes

Text

The Dental Filling Guide from Milestone Dentistry: Materials, Techniques, and Aftercare Advice

Restorative dentistry depends critically on dental fillings to cure cavities and restore damaged teeth. Knowing the many kinds and materials used in dental fillings helps patients at Milestone Dentistry make wise selections for their oral health. This guide will help you sort through the many dental filling materials and provide aftercare advice to guarantee the lifetime of your fillings.

Types of Dental Fillings

Direct and indirect fillings are two general classification schemes for dental fillings.

Direct Fillings

Mercury combined with metals like copper, tin, and silver forms these silver-coloured fillings. Often utilised in molars where chewing pressures are highest, they are robust.

Popular for their aesthetic appeal, composite resin fillings—made from a resin basis combined with powdered glass or quartz—have They give the teeth a natural appearance by bonding right to it.

Made from a blend of silica glass powder and polyacrylic acid, these tooth-coloured fillings are glass ionomer. The fluoride they produce helps guard the tooth from further deterioration.

Indirect Fillings

Inlays and Onlays:

Inlays and onlays are dental lab-ade bonded to teeth with significant decay beyond conventional fillings, requiring a full crown if the decay is beyond what a conventional filling can handle.

Gold Fillings:

Gold fillings may endure for decades and are very strong. Made from gold combined with other metals like copper or silver, they are corrosion- and wear-resistant.

Porcelain Fillings:

Custom-made to fit your tooth, naturally appearing porcelain fillings for teeth are additionally exceptionally stain resistant.

Selecting Correct Dental Filling Materials

The location of the cavity, degree of tooth decay, your budget, and aesthetic tastes all affect the dental filling material you choose.

Durability:

Given their long-lasting character, amalgam or gold fillings are great options if your main concern is this.

Aesthetics:

Composite resin and porcelain fillings are perfect for a natural look as they colour your teeth exactly.

Cost:

Because of the materials and work needed, gold and porcelain fillings are usually more costly; while amalgam fillings are usually more reasonably priced.

Aftercare Advice Regarding Dental Fillings

Maintaining the integrity of your dental fillings and preventing further damage depends on appropriate treatment.

Keep up good oral hygiene.

Using fluoride toothpaste, brush your teeth a minimum of two times a day.

To clear food particles and plaque from between your teeth and around your fillings, floss every day.

Steer Clear of Sticky or Hard Foods

Steer clear of hard or sticky meals that can knock out or break a filling just after receiving one.

Control Sensitivity.

After a filling, one often feels rather sensitive. Usually, this passes a few days. Use a toothpaste designed for sensitive teeth and steer clear of particularly hot or cold meals if sensitivity lasts.

Regular Dental Check-ups

See Milestone Dentistry for routinely scheduled visits. Your dentist can make sure your dental fillings stay in excellent health and track their status.

Look for Signs of Trouble

See Milestone Dentistry right soon if you find any indicators of concern, including discomfort while biting down, the sensitivity that persists, or a loose filling.

Finally

Knowing the many kinds of dental fillings and the materials accessible will enable you to choose the ideal one for your oral condition. From choosing the correct filling to offering professional aftercare, our staff at Milestone Dentistry is ready to walk you through each phase of the procedure. Your dental fillings should last many years with appropriate care, therefore guaranteeing the health and beauty of your smile.

Call Milestone Dentistry now to arrange an appointment or for more information. With individualised treatment and the newest in dental technology, we are committed to helping you reach ideal oral health.

FAQs

1. For what purpose is a dental filling used?

A tooth affected by decay or small fractures may be restored in function and integrity by a dental filling. It preserves the tooth's form and helps stop further breakdown.

2. Usually, dental fillings last what duration?

The component utilised determines how long a dental filling will last. With careful care, gold or porcelain fillings may last 15-20 years or more; composite resin fillings usually last 5-7 years; and amalgam fillings can last 10-15 years.

3. Are dental fillings safe?

Dental fillings are safe really. Common materials utilised and well-evaluated for safety include composite resin, glass ionomer, gold, and porcelain. Though certain populations may be advised to avoid them, major health organisations also see amalgam fillings—which contain mercury—as safe.

4. During the tooth-filling process, what do I expect?

Your dentist will initially numb the vicinity of the impacted tooth during the operation. They will next clean the cavity, remove the decaying part of the tooth, and pack the selected material into it. Designed to fit your bite, the filling is polished for a flawless finish.

5. Following a dental filling, will I be in pain?

Following a filling, moderate sensitivity or pain is common, particularly when consuming hot or cold food. Usually, this sensitivity passes over a few days. Any pain may be controlled with over-the-counter meds.

6. Should I eat right after following a dental fill-in?

You may eat right immediately if you have a composite resin filling; however, to prevent biting your face or tongue, wait until the numbness from the anaesthesia passes off. Wait at least 24 hours before consuming hard or sticky foods for amalgam fillings.

7. How should I look after my dental fillings?

Twice a day brushing and daily flossing help you to have proper dental hygiene. Steer clear of biting on hard things and plan frequent dental visits to keep an eye on your fillings' health.

8. Should a dental filling need to be changed, what are the indicators?

See your dentist if you bite and feel discomfort; alter your sensitivity to cold; have a cracked or chipped filling; or find the filling to be loose. Regular visits allow one to identify these problems early on.

9. Is it possible for me to decide on the filling's material?

Indeed, your choices of filling material will depend on your tastes, financial situation, and particular dental needs. Your dentist will go over the choices with you and guide you towards a wise conclusion.

10. What happens if I fail to get a cavity filled?

Untreated, a cavity may widen and perhaps cause more severe dental decay, infection, or even tooth loss. A timely dental filling will maintain your oral health and help you avoid these problems.

0 notes

Text

Industrial Wastewater Treatment Plant Market Scope & Growth Projection till 2032

Industrial Wastewater Treatment Plant Market provides in-depth analysis of the market state of Industrial Wastewater Treatment Plant manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Industrial Wastewater Treatment Plant in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Industrial Wastewater Treatment Plant Market Report:

The report offers a comprehensive and broad perspective on the global Industrial Wastewater Treatment Plant Market.

The market statistics represented in different Industrial Wastewater Treatment Plant segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Industrial Wastewater Treatment Plant are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Industrial Wastewater Treatment Plant.

Major stakeholders, key companies Industrial Wastewater Treatment Plant, investment feasibility and new market entrants study is offered.

Development scope of Industrial Wastewater Treatment Plant in each market segment is covered in this report. The macro and micro-economic factors affecting the Industrial Wastewater Treatment Plant Market

Advancement is elaborated in this report. The upstream and downstream components of Industrial Wastewater Treatment Plant and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/industrial-wastewater-treatment-plant-market-100570

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Pulse Electromagnetic Field Therapy Devices MarketMarket

Liquid Sodium Silicate MarketMarket Share

Cold Chain Monitoring MarketMarket Growth Rate

Ships Ballast Water System MarketMarket Forecast

Global Touch Screen Controllers MarketMarket Size

Shipbuilding and Offshore Rig Fabrication and Repair MarketMarket Growth

Quartz Monitor Crystals MarketMarket Analysis

Marine Fleet Management Software MarketMarket Size

Global Software Development Tools MarketMarket Share

Global Automotive Remote Diagnostics MarketMarket Growth

Industrial Ethernet Cables MarketMarket

Energy Recovery Ventilation System MarketMarket Share

Machine Control System MarketMarket Growth Rate

Supply Chain Visibility Software MarketMarket Forecast

Global Wealthtech MarketMarket Size

Energy Storage Battery For Microgrids MarketMarket Growth

Online Tutoring MarketMarket Analysis

Flat Panel Satellite Antenna MarketMarket Size

Global Office Suites MarketMarket Share

Global RV Rental MarketMarket Growth

Electric Trucks MarketMarket

Digital Commerce Platform MarketMarket Share

Uhmwpe Sheet MarketMarket Growth Rate

Low Light Level Imaging Sensors MarketMarket Forecast

Global Small and Medium Business (SMB) Software MarketMarket Size

Anticoagulant Reversal Drug MarketMarket Growth

Crude Oil Desalter and Electrostatic Dehydrator MarketMarket Analysis

Optical Transceivers MarketMarket Size

Global Machinable Ceramic MarketMarket Share

Global Spherical Silica Powder MarketMarket Growth

Private Cloud Services MarketMarket

Quartzite MarketMarket Share

Dual Brightness Enhancement Film (DBEF) MarketMarket Growth Rate

Battery Free RFID Sensor MarketMarket Forecast

Global Integrated Revenue and Customer Management (IRCM) for CSPs Software MarketMarket Size

acs-self-climbing-formwork-marketMarket Growth

Eltrombopag Olamine API MarketMarket Analysis

Mascara Cream MarketMarket Size

Global X-Ray Irradiators MarketMarket Share

Global HER2 Antibody MarketMarket Growth

0 notes

Text

Top-Quality Soapstone Powder: Leading Manufacturers and Suppliers in India

Zillion Sawa Minerals Pvt. Ltd. stands out as a premier Soapstone Manufacturer in India, offering high-quality soapstone powder at competitive prices. As a leading Soapstone Supplier in India, our diverse range of products includes cosmetic-grade soapstone powder, body-grade soapstone powder, and industrial-grade soapstone powder, catering to various industry needs.

Why Choose Soapstone?

Soapstone, known for being one of the softest minerals, is a vital component in many everyday products. While all soapstone shares properties like softness, platy structure, water repellence, and chemical inertness, each type of soapstone is unique. Soapstone plays a crucial role in enhancing the quality of items such as magazines, automotive plastics, household paints, and floor tiles.

Our Expertise

We procure soapstone from the top soapstone powder manufacturers in India. Soapstone, or Mg3Si4010(OH)2, is a hydrated magnesium sheet silicate, known for being insoluble in water, mild acids, and alkalis. It is also non-explosive and non-flammable, with a strong affinity for organic compounds despite its low chemical reactivity.

Soapstone in Various Forms

Lumps Form: Found in the mountainous regions of India, soapstone is an excellent building material due to its durability, natural insulating properties, and acid resistance.

Powder Form: Pulverized soapstone powder serves multiple industrial purposes. It is used as a filler in rubber, textiles, plastics, linoleum, asbestos products, polishes, and soaps; as a loading agent in paper; as a carrier for insecticidal and pesticidal dust; and as a coating for calcium ammonium fertilizer. Additionally, soapstone powder acts as a lubricant to prevent ungalvanized rubber goods from sticking. Calcined steatite, known as ‘Lava,’ is used in low-loss ceramic materials for high-frequency insulation in electronic devices.

Applications in Cosmetics and Pharmaceuticals

In cosmetics, soapstone is utilized as a thickening agent, lubricant, and filler. It is also a popular filler in the paper industry and serves as a tablet binder in pharmaceuticals. Zillion Sawa Minerals offers some of the purest, most affordable soapstone available.

Product Variety and Quality

We provide a wide range of soapstone powders, including cosmetic, body, and industrial grades. Our soapstone, sourced from leading manufacturers, includes silicone-talc available in granules, powder, and flakes, suitable for various industries such as cosmetics, pharmaceuticals, and construction.

Your Trusted Supplier

As a renowned Soapstone Manufacturer in India and Soapstone Supplier in India, Zillion Sawa Minerals also supplies kaolin, quartz, and silica sand. We ensure safe and timely doorstep delivery of products through our dedicated logistic partners, providing a seamless experience from order placement to delivery.

Choose Zillion Sawa Minerals Pvt. Ltd. for top-quality soapstone powder and experience unparalleled service and reliability.

1 note

·

View note

Text

Examine the Top Powder Choices for Commercial Uses

It's critical to collaborate with suppliers who can provide consistent, superior products that are suited to the requirements of diverse industries when looking for trustworthy quartz powder manufacturers. Because of its exceptional physical qualities, including high hardness, low chemical reactivity, and durability, quartz powder—which is derived from the mineral quartz—is a material that finds extensive use. Consequently, quartz powder finds use in a wide range of industries, such as construction, electronics, glass manufacturing, and ceramics. Because of its many uses, quartz powder is an essential component of many industrial processes.

The naturally occurring mineral quartz is ground into fine particles to make quartz powder. Because these particles are available in a range of sizes, they can be used in a variety of applications. One of the most important ingredients in the ceramics industry is quartz powder, which is used to make porcelain and ceramics. Because of its high hardness, ceramic products are stronger and last longer. Quartz powder is a key ingredient in the glassmaking process that helps create transparent, premium glass. For glass products used in windows, containers, and other applications, it offers the strength, transparency, and smoothness that are necessary.

Concrete, mortar, and grout are all made with quartz powder in the construction sector. These materials are perfect for construction projects that call for strong, long-lasting solutions because of their high silica content, which increases their strength and durability. Additionally, quartz powder is used to enhance the final product's opacity, finish, and surface texture in paint and coating manufacturing. The powder is perfect for a variety of industrial coatings because of its inert nature, which prevents it from reacting chemically with other materials.

Manufacturers of quartz powder are required to make sure their product satisfies industry standards, which frequently entail stringent quality control procedures to ensure consistency and purity. The manufacturing process involves carefully selecting raw materials and using advanced grinding techniques to achieve the desired particle size. Additionally, some producers might provide specially made quartz powder solutions to satisfy particular requirements, like changing the particle size or adding surface treatments to improve functionality.

The consistency of product quality is one of the most crucial factors to consider when selecting a quartz powder manufacturer. Even small variations in quartz powder composition or particle size can affect the performance of the final product in various applications. For businesses that rely on quartz powder in high-performance industries, selecting a manufacturer with a track record of delivering high-quality, consistent products is essential to maintaining operational efficiency and ensuring the durability and quality of the end products.

Reliability in delivery is also crucial for companies that require bulk quantities of quartz powder. Supply delays can affect company operations and cause schedule disruptions for production. Businesses can therefore feel more at ease by working with a manufacturer who is renowned for prompt deliveries and first-rate customer support. Furthermore, maintaining low production costs and guaranteeing the overall profitability of operations depend heavily on competitive pricing.

One of the top brands in the production of quartz powder, Sudarshan Group is renowned for supplying top-notch quartz powder to businesses worldwide. The Sudarshan Group, which places a high priority on innovation and quality, uses cutting-edge facilities and technology to create quartz powder that is tailored to the individual needs of its clients. Their reputation as a reliable supplier for a range of industries, including glass manufacturing, construction, and ceramics, stems from their dedication to quality and customer satisfaction. Sudarshan Group provides products that guarantee the smooth and effective operation of your production processes, regardless of your need for bulk quantities or customised solutions.