#shear and punch machine

Explore tagged Tumblr posts

Text

Ironworker Machine at Best Price in India : Genuine Quality

Are you in need of reliable ironworker machines for your construction tasks? Look no further! Our Ironworker Machine Supplier offers top-quality equipment designed to streamline your metal punching and shearing needs.

Our QA32-8 Metal Punching and Shearing Machine is built to handle the toughest of tasks with precision and efficiency. With its shear and punch capabilities, it's the ideal solution for cutting and punching metal pieces for your construction projects.

#ironworker machine price#Ironworker Machine Supplier#Metal Punching and Shearing Machine#qa32 8 metal punching and shearing machine#shear and punch machine

0 notes

Text

Smith Structure |Efficient Manufacturing Facilities Engineering

Smith Structure is engineering company that specializes in designing & building efficient manufacturing facilities that are optimized for productivity & safety

#Plasma Cutting Machine#Deck Sheet Machine#PHI Welding Machine#Gantry Type H Beam Welding#Standing Seam Machine#CNC Shearing Machine#CNC Bending Machine#CNC Punching Machine#CNC Forming Machine#in#vadodara#Ahmedabad#Kutch#Delhi#Mumbai#Pune#Hyderabad#Indore#Surat#Vadodara#Chennai#gujarat#india

0 notes

Text

Labor advocates on Tuesday decried a business-backed bill introduced by Republican state lawmakers in Iowa that would roll back child labor laws so that teens as young as 14 could work in previously prohibited jobs including mining, logging, and animal slaughtering—a proposal one union president called dangerous and "just crazy."

Senate File 167, introduced by state Sen. Jason Schultz (R-6) would expand job options available to teens—including letting children as young as 14 work in freezers and meat coolers and loading and unloading light tools, under certain conditions.

Teens under 18 would still be generally barred from employment in fields including mining, logging, demolition, and meatpacking, and from operating potentially dangerous machinery and equipment including circular saws, guillotine shears, and punching machines.

However, the Des Moines Register reports the proposed law contains "an entirely new section" that "would allow the Iowa Workforce Development and state Department of Education heads to make exceptions to any of the prohibited jobs for teens 14-17 'participating in work-based learning or a school or employer-administered, work-related program.'"

The proposed bill—which comes amid an ongoing labor shortage in Iowa—also expands the hours teens may work, and shields businesses from liability if a minor employee is sickened, injured, or killed as a result of a company's negligence.

"This is just crazy," Charlie Wishman, president of the Iowa Federation of Labor, AFL-CIO, told the Des Moines Register. "A kid can still lose an arm in a work-based learning program."

Wishman said the bill will gut more than a century of child labor protections, many of which were enacted in an era when "children were hurt and killed" on the job.

"The idea of putting children into work activities that could be dangerous is something that is not only irresponsible but reprehensible," Wishman added.

Iowa state Sen. Claire Celsi (D-16) called the proposed legislation "another sign that the labor market in Iowa is in big trouble."

"Businesses are so desperate to hire warm bodies that they want politicians to bend child labor laws (and eliminate corporate liability)," she wrote on Twitter.

State Sen. Nate Boulton (D-20), an attorney specializing in labor law, described the bill as "offensive."

"Putting children at risk, and creating immunity for that risk, is not acceptable," he told Iowa Starting Line.

As in other states, child labor violations are not uncommon in Iowa, with immigrant minors particularly susceptible to exploitation.

"These efforts to roll back child labor laws overlap with the conservative changes to school curriculum," tweeted education podcaster and author Jennifer Berkshire. "The through line is an effort to teach kids that free enterprise rules and that the boss is king."

"Instead of raising the minimum wage and paying adults more or funding a social safety net, Iowa would rather bring back child labor," author Lyz Lenz tweeted.

#us politics#news#2023#iowa#child labor#child labor laws#conservatives#republicans#gop#gop policy#gop platform#labor shortage#Senate File 167#Jason Schultz#Des Moines Register#more perfect union#twitter#tweet#Charlie Wishman#Iowa Federation of Labor#Claire Celsi#Nate Boulton#Jennifer Berkshire#Lyz Lenz#Iowa Starting Line

72 notes

·

View notes

Text

Are you looking for DIN 2379 Steels for your Cold Work Steel projects?

Virat Special Steels is one of the most reputable Tool Steel & Die Steel and Mold Steel Suppliers in India.

DIN 2379 steel is Cold Work Steel with High Carbon High Chromium contents. Its very applicable for cold stamping or forming dies industries. DIN 2379 steel, also known as X153CrMoV12 material, is a high carbon chromium molybdenum vanadium cold-work tool steel.

Let’s dive into the details: Chemical Compositions:

Carbon ©: 1.45-1.60%

Silicon (Si): 0.10-0.60%

Manganese (Mn): 0.20-0.60%

Chromium (Cr): 11.0-13.0%

Molybdenum (Mo): 0.70-1.00%

Vanadium (V): 0.70-1.00%

Virat Special Steels is the leading Supplier & Stockiest of Din 2379 Steel. DIN 2379 steel is Cold Work Steel with High Carbon High Chromium contents. The Quality with high wear resistant and toughness properties due to Vanadium addition of 0.90% . Normally it supply condition is an Annealed and will offer hardness to reach 57-59 HRC.

It can be machinable in the annealed condition. DIN 2379 is the superior steels than D3 due to high alloys properties.

Applications: DIN 2379 tool steel applicable for cold stamping or forming dies, cold forming rolls, Chipper knives, Punches, slitters, shear blades, tools, tyre shredders, trimming, cutting Threading Dies, stamping tools Etc.

Learn more: https://www.viratsteels.com/din-2379.html

Learn from pdf: https://www.viratsteels.com/pdf/cold-steels/2379.pdf

Any queries feel free to contact us : Email us:[email protected] or call us:+91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#ToolSteel#SteelTrades#MetalIndustry#DIN2379#cold work steel

2 notes

·

View notes

Text

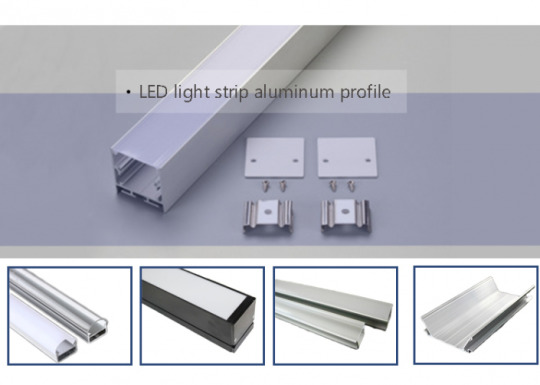

Exploring the Aluminum Profile Processing Intricacies

Aluminum profile is unique among components used in modern production because of their versatility and necessary nature. Applications for these extruded forms may be found in a wide range of sectors, including consumer products, electronics, automotive, and construction. A thorough grasp of material qualities, technical innovation, and precise engineering are all required in the exciting process of creating aluminum profiles.

Aluminum Profiles Significance

Because of their many benefits, aluminum profiles are the material of choice for a wide range of applications:

Lightweight

Power and Sturdiness

The corrosion free

Flexibility

The Procedure for Processing Aluminum Profiles

Design and Development of Die: Engineers develop the ideal profile form and proportions during the process's first design step. A unique die, or mold, is made after the design is complete in order to extrude the metal into the required shape.

Heating the billet: To prepare it for extrusion, aluminum billets, which are usually formed from primary or recycled aluminum, are heated to a particular temperature. In order to guarantee consistency and malleability, this preheating phase is critical.

Extrusion: Using mechanical or hydraulic pressure, the heated aluminum billet is pushed through a specifically made die. The metal takes on the shape of the profile as it goes through the die and emerges as a continuous length of extruded aluminum.

Quenching and Cooling: To maintain its shape and characteristics, the extruded aluminum profile is quickly cooled with either water or air. In order to achieve the appropriate mechanical characteristics and avoid distortion, this quenching procedure is essential.

Cutting and Finishing: Using precision saws or shears, the extruded aluminum profile is trimmed to the necessary lengths once it has cooled. The profile may also be modified by using additional machining techniques like punching, drilling, or milling to add holes or features. Lastly, surface treatments like powder coating or anodizing can be used to improve corrosion resistance and appearance.

Quality Control: Strict quality control procedures are followed during the whole Aluminum profile Process to guarantee that the final aluminum profiles have the required mechanical qualities, surface polish, and tolerances. To find any flaws or irregularities, this may entail visual inspections, mechanical testing, and dimensional inspections.

#Aluminum profile#Aluminum profile China#Aluminum profile Process#Aluminum profile Company#Aluminum profile Company China#Aluminum profile Manufacturer#Aluminum profile supplier

2 notes

·

View notes

Text

THE ULTIMATE GUIDE TO PRESSES, SHEARS, LASER CUTTERS AND PUNCHES

In the world of metal fabrication, several key machines play a vital role in shaping and cutting metal with precision and efficiency. This ultimate guide provides comprehensive knowledge and insights into the essential products of the industry: Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Whether you are a beginner or an experienced professional, this guide will equip you with the necessary information to understand, select, and optimize the use of these machines for your metalworking needs.

Press Brake:

1.What is a Press Brake?

A press brake is a key equipment used in the field of metal fabrication for bending and folding metal sheets. It utilizes pressure to bend the metal sheet into the desired shape. It is commonly used to create bent parts, enclosures, tubing, and other metal components.

A press brake consists of an upper die and a lower die, with the upper die fixed to the frame and the lower die movable through a hydraulic system or mechanical drive system. The metal sheet is placed between the two dies and then bent into the desired angle and shape by applying pressure.

Press brakes typically have the following features and capabilities:

(1)Bending capacity: Press brakes can achieve bends at different angles and radii to meet various workpiece requirements.

(2)Precision: High precision bending results can be achieved by adjusting the position of the upper and lower dies.

(3)Automation: Some modern press brakes are equipped with CNC systems, allowing for automated operation and programming.

(4)Versatility: Press brakes can be used for various bending tasks and different types of metal materials by changing different tools and dies.

(5)Safety: Press brakes are typically equipped with safety devices such as light curtains, protective covers, and emergency stop buttons to ensure operator safety.

Press brakes are widely used in industries such as automotive manufacturing, aerospace, construction, electronics, and more. They are essential equipment for achieving precise and efficient metal fabrication.

2.Types of Press Brakes

There are several types of press brakes commonly used in metal fabrication:

Mechanical Press Brake: Uses a mechanical flywheel and clutch system for bending.

Hydraulic Press Brake: Utilizes hydraulic cylinders for precise bending control.

Servo-Electric Press Brake: Uses electric servo motors for high precision bending.

Pneumatic Press Brake: Relies on compressed air for lighter applications.

CNC Press Brake: Equipped with computerized controls for automated and precise bending operations.

The choice of press brake depends on factors such as material type, thickness, bending requirements, and production volume.

3.Components and Working Principles

A press brake consists of several key components that work together to perform the bending operation. Here are the main components and their functions:

Frame: The frame provides structural support and stability to the press brake.

Bed: The bed is a flat surface where the material to be bent is placed.

Ram: The ram is the moving part of the press brake that applies force to the material for bending.

Die: The die is a tool that shapes the material by providing a specific bending angle.

Punch: The punch is another tool that presses against the material, working in conjunction with the die to bend it.

Backgauge : The backgauge is an adjustable device that positions the material accurately for consistent bending.

4.Key Features and Benefits

Material Placement: The operator places the metal sheet or plate on the bed of the press brake.

Tool Setup: The appropriate die and punch are selected and installed on the press brake.

Backgauge Adjustment: The backgauge is adjusted to position the material correctly for the desired bend.

Bending Process: The ram moves downward, applying force to the material, which is sandwiched between the punch and the die. This bending action creates the desired angle in the material.

Material Removal: Once the bending is complete, the operator removes the bent material from the press brake.

5.Applications and Industries

Press brakes are widely used in various industries for different applications, including:

Metal Fabrication: Press brakes are commonly used in metal fabrication shops to bend and shape metal sheets and plates for various products such as enclosures, brackets, frames, and panels.

Automotive Industry: Press brakes are used in the automotive industry for manufacturing components like chassis, brackets, and body panels.

Aerospace Industry: Press brakes are utilized in the aerospace industry for bending and forming metal parts used in aircraft structures and components.

Construction and Architecture: Press brakes are used in the construction and architectural sectors for bending metal components used in building structures, facades, and decorative elements.

Electronics and Appliances: Press brakes are employed in the manufacturing of electronic enclosures, appliance components, and consumer products.

Press Brake Tools:

1.Importance of Press Brake Tools

Press brake tools play a crucial role in the performance and efficiency of press brake machines. Here are some key points highlighting the importance of press brake tools:

(1) Precision Bending: Press brake tools are designed to provide precise and accurate bending angles. They ensure consistent results and help meet the required specifications for the final product. The quality and precision of the tools directly impact the overall quality of the bent parts.

(2) Versatility: Press brake tools come in various shapes, sizes, and configurations to accommodate different bending requirements. They can be customized or interchanged to achieve different bending angles, radii, or complex shapes. This versatility allows manufacturers to produce a wide range of products using the same machine.

(3) Durability and Longevity: Press brake tools are made from high-quality materials such as hardened steel or special alloys, which make them highly durable and resistant to wear and tear. Proper maintenance and regular tool inspections ensure their longevity, reducing the need for frequent replacements.

(4) Efficiency and Productivity: Well-designed press brake tools optimize the bending process, reducing setup time, and increasing productivity. They enable faster bending cycles, allowing manufacturers to produce more parts in less time. Efficient tooling also minimizes material waste and improves overall production efficiency.

(5) Cost Savings: Using the right press brake tools can lead to cost savings in multiple ways. Accurate bending reduces material waste, saving on raw material costs. Efficient tooling reduces setup time and increases machine productivity, maximizing the output per hour. Additionally, durable tools have a longer lifespan, reducing the frequency of replacements and maintenance costs.

(6) Safety: Press brake tools are designed with safety features in mind. They provide proper clamping and holding mechanisms to secure the material during bending, minimizing the risk of accidents. Additionally, using high-quality tools reduces the chances of tool failure or breakage, ensuring operator safety.

(7) In summary, press brake tools are vital for achieving precise and accurate bending results, improving productivity, reducing costs, and ensuring operator safety. Selecting the right tools and maintaining them properly is essential for the efficient operation of press brake machines.

2.Types of Press Brake Tools (including ARC Press Brake Tools)

There are several types of press brake tools available, each designed for specific bending applications. Here are some common types of press brake tools:

V-Die: V-dies are the most commonly used press brake tools. They consist of a bottom die with a V-shaped groove and a punch with a matching V-shaped tip. V-dies are versatile and can be used for a wide range of bending angles and materials.

(1) Bottoming Die: Bottoming dies, also known as flat dies, have a flat surface instead of a V-shaped groove. They are used for achieving sharp bends or bending thicker materials where a tighter radius is required.

(2) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep and offset bends. They are commonly used for bending channels, boxes, and other complex shapes.

(3) Hemming Tool: Hemming tools are used for creating hems or flanges on the edge of a sheet metal part. They consist of a punch and die set that folds the material over itself to create a secure edge.

(4) Radius Tool: Radius tools, also known as radius punches or radius dies, are used for creating curved bends with a specific radius. They are available in various sizes to accommodate different bending requirements.

(5) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different sizes on a single die. They allow for quick and easy tool changes without the need for separate dies for different bending angles.

(6) ARC Press Brake Tools: ARC press brake tools are specialized tools used for bending sheet metal into arc shapes. They are designed to create precise and consistent curved bends, commonly used in applications such as cylindrical parts, tubes, or curved profiles.

ARC press brake tools typically consist of a bottom die with a curved groove and a punch with a matching curved tip. They enable the accurate and repeatable bending of sheet metal into various arc shapes.

3.Material Selection and Coatings

When it comes to press brake tools, material selection and coatings play an important role in their performance and longevity. Here's a brief overview of material selection and coatings for press brake tools:

Material Selection:

(1) Tool Steel: Tool steel, such as D2 or A2, is commonly used for press brake tools due to its high hardness, wear resistance, and toughness.

(2) Carbide: Carbide inserts or tips are used for heavy-duty applications or when bending abrasive materials. Carbide provides excellent wear resistance but is more brittle than tool steel.

(3) High-Speed Steel (HSS): HSS is another option for press brake tools. It offers good toughness and wear resistance, but not as high as tool steel.

Coatings:

(4) Nitride Coating: Nitride coatings, such as TiN (Titanium Nitride) or TiCN (Titanium Carbonitride), improve the surface hardness and wear resistance of the tool. They are suitable for general-purpose bending applications.

(5) DLC Coating: DLC (Diamond-Like Carbon) coatings provide excellent hardness, low friction, and high wear resistance. They are ideal for bending stainless steel and other difficult-to-form materials.

(6) PVD Coating: Physical Vapor Deposition (PVD) coatings, like TiAlN (Titanium Aluminum Nitride), enhance the tool's performance by reducing friction and increasing wear resistance.

(7) Chrome Plating: Chrome plating is a common coating for press brake tools. It provides good corrosion resistance and reduces friction during bending operations.

The selection of material and coating depends on factors such as the type of material being bent, the bending application, and the desired tool life. It's important to choose the right combination of material and coating to ensure optimal performance and durability of the press brake tools.

4.Tooling Configurations and Considerations

When it comes to press brake tools, the tooling configurations and considerations are crucial for achieving accurate and efficient bending operations. Here are some important aspects to consider:

Tooling Configurations:

(1) V-Die: The V-die is the female tool that provides the desired bend shape. It comes in various widths and angles to accommodate different material thicknesses and bending requirements.

(2) Punch: The punch is the male tool that contacts the material and applies force to create the bend. It also comes in different shapes and sizes to achieve specific bend angles and radii.

(3) Multi-V Die: Multi-V dies have multiple V-shaped grooves of different widths and angles. They allow for bending different material thicknesses and angles without changing the die.

(4) Gooseneck Punch: Gooseneck punches have a curved shape that allows for deep or offset bends where space is limited.

(5) Hemming Tools: Hemming tools are used for creating hemmed edges or flanges on sheet metal.

Considerations:

(1) Material Thickness: The tooling configuration should be selected based on the material thickness being bent. Thicker materials may require larger tooling to accommodate the increased force and prevent tool damage.

(2) Material Type: Different materials have varying properties, such as hardness and ductility, which can affect the tooling selection. Harder materials may require tougher tooling materials or coatings.

(3) Bend Angle and Radius: The desired bend angle and radius dictate the selection of punch and die configurations. Sharp bends require smaller punch radii, while larger radii are needed for gentler bends.

(4) Tooling Alignment: Proper alignment between the punch and die is essential for achieving accurate and consistent bends. Misalignment can result in uneven bends or tool damage.

(5) Tooling Maintenance: Regular inspection and maintenance of the tooling are necessary to ensure optimal performance and longevity. This includes cleaning, lubrication, and replacement of worn-out components.

By considering the tooling configurations and these important factors, you can select the appropriate press brake tools for your specific bending requirements. This will help you achieve precise and efficient bending operations while prolonging the tooling life.

5.Tool Maintenance and Longevity

(1) Regular cleaning: Clean the press brake tools regularly to remove debris, dirt, and metal shavings. Use appropriate cleaning agents and tools to avoid damaging the tool surfaces. Ensure that the tools are completely dry before storing them.

(2) Lubrication: Apply lubrication to the press brake tools as recommended by the manufacturer. Lubrication helps reduce friction and wear, improving the tool's lifespan. Follow the manufacturer's guidelines for the type and frequency of lubrication.

(3) Inspection and repair: Regularly inspect the press brake tools for signs of wear, damage, or deformation. Check for any cracks, chips, or excessive wear on the cutting edges. If any issues are detected, promptly repair or replace the damaged parts to prevent further damage and ensure accurate bending results.

(4) Proper storage: Store the press brake tools in a clean and dry environment to prevent corrosion and damage. Use dedicated tool racks or boxes to keep the tools organized and protected. Avoid placing heavy objects on top of the tools to prevent deformation.

(5) Operator training: Proper training of operators is essential for tool maintenance and longevity. Educate operators on the correct usage techniques, operating limits, and safety precautions. Encourage operators to report any issues or abnormalities with the tools promptly.

By following these maintenance tips, you can extend the lifespan of your press brake tools and ensure consistent and accurate bending operations. Regular maintenance not only improves tool performance but also contributes to the overall safety and efficiency of the bending process.

6.Advanced Tooling Technologies and Innovations

Advanced tooling technologies and innovations have significantly improved the performance and capabilities of press brake tools. Here are some key advancements in press brake tooling:

(1) High-strength materials: Press brake tooling is now made from high-strength materials such as hardened steel alloys or carbide. These materials offer superior durability, wear resistance, and longer tool life compared to traditional tooling materials.

(2) Coatings and surface treatments: Advanced coatings and surface treatments, such as TiN (Titanium Nitride) or DLC (Diamond-Like Carbon), are applied to press brake tools to enhance their performance. These coatings reduce friction, improve wear resistance, and prevent material adhesion, resulting in improved bending quality and longer tool life.

(3) Precision tooling systems: Modern press brake tooling systems feature precision-ground tooling with tight tolerances. These systems ensure accurate and repeatable bending results, reducing setup times and increasing productivity.

(4) Quick-change tooling systems: Quick-change tooling systems allow for rapid tooling setup and changeovers. These systems utilize standardized tooling holders and clamping mechanisms, enabling operators to switch between different tooling setups quickly and efficiently.

(5) 3D modeling and simulation: Advanced software tools enable 3D modeling and simulation of bending processes. These tools help optimize tooling designs, simulate bending sequences, and detect potential collision or interference issues before actual production. This reduces setup time, minimizes errors, and improves overall efficiency.

(6) Custom tooling solutions: Tooling manufacturers now offer custom tooling solutions tailored to specific bending applications. These solutions include specialized tool profiles, custom tool coatings, and even tooling with integrated sensors for process monitoring and control.

These advancements in press brake tooling technologies have significantly improved productivity, accuracy, and tool life. By adopting these innovations, manufacturers can achieve higher efficiency, reduce downtime, and produce high-quality bent parts consistently.

Shearing Machine:

1.Understanding Shearing Machines

Shearing machines are industrial mechanical devices used for cutting metal sheets and other materials. They apply shearing force to cut the materials into desired shapes and sizes. Shearing machines are widely used in manufacturing and metalworking industries to produce various products and components.

The working principle of shearing machines involves placing the material on a shear table and applying force through cutting blades to cause the material to fracture. Shearing machines can perform operations such as straight cutting, curved cutting, and angle cutting. Depending on the specific requirements, shearing machines can have different cutting capacities and precision.

There are various types of shearing machines, including hydraulic shearing machines, mechanical shearing machines, and manual shearing machines. Hydraulic shearing machines use hydraulic systems to provide cutting force and offer high power and precision, making them suitable for large-scale and heavy-duty cutting tasks. Mechanical shearing machines use mechanical mechanisms to provide cutting force and are typically more compact and cost-effective, suitable for medium-sized cutting tasks. Manual shearing machines require manual operation and are suitable for small-scale and simple cutting work.

The cutting capacity of shearing machines depends on their maximum cutting thickness and cutting width. Larger shearing machines generally have higher cutting capacity and can handle thicker and wider materials. The cutting precision of shearing machines is influenced by factors such as blade sharpness, adjustment of blade clearance, rigidity of the frame, and material characteristics.

Safety considerations are important when operating shearing machines. Operators should receive proper training on the operation procedures and safety precautions of shearing machines. Additionally, appropriate personal protective equipment, such as safety goggles and gloves, should be worn. Regular inspection and maintenance of shearing machines are necessary to ensure their proper functioning and safe operation. Following the operation manual and manufacturer's recommendations is crucial to ensure the safety and effectiveness of operating shearing machines.

2.Hydraulic vs. Mechanical Shearing Machines

Hydraulic and mechanical shearing machines are two common types of shearing machines used in industrial applications. Here's a comparison between the two:

Power Source:

(1) Hydraulic Shearing Machines: These machines use a hydraulic system to generate the cutting force. The force is applied through hydraulic cylinders powered by a hydraulic pump. Hydraulic shearing machines offer high power and can handle heavy-duty cutting operations.

(2) Mechanical Shearing Machines: These machines use mechanical mechanisms, such as gears, levers, and flywheels, to generate the cutting force. The force is applied directly through the mechanical components. Mechanical shearing machines are generally more compact and cost-effective.

Power and Precision:

(1) Hydraulic Shearing Machines: Due to the hydraulic system, hydraulic shearing machines can provide high cutting power. They are capable of cutting thick and hard materials with precision. The hydraulic system allows for better control and adjustment of the cutting force, resulting in accurate and consistent cuts.

(2) Mechanical Shearing Machines: Mechanical shearing machines provide a lower cutting power compared to hydraulic ones. They are suitable for medium-duty cutting tasks. However, the cutting precision of mechanical shearing machines can be affected by factors such as mechanical wear and tear, which may require more frequent adjustments and maintenance.

Size and Space:

(3) Hydraulic Shearing Machines: Hydraulic shearing machines are generally larger and require more space due to the hydraulic system components, such as the hydraulic pump, cylinders, and hoses.

(4) Mechanical Shearing Machines: Mechanical shearing machines are more compact and take up less space. They are often preferred in smaller workshops or where space is limited.

Cost:

(1) Hydraulic Shearing Machines: Hydraulic shearing machines are typically more expensive due to the complexity and cost of the hydraulic system components.

(2) Mechanical Shearing Machines: Mechanical shearing machines are generally more affordable and cost-effective.

In summary, hydraulic shearing machines provide high power and precision, making them suitable for heavy-duty cutting operations. They are larger and more expensive. On the other hand, mechanical shearing machines are more compact, cost-effective, and suitable for medium-duty cutting tasks. The choice between hydraulic and mechanical shearing machines depends on the specific cutting requirements, available space, and budget considerations.

3.Components and Operation

Components of a Shearing Machine:

(1) Shear Table: This is the flat surface or bed on which the material to be cut is placed. It provides support and stability during the cutting process.

(2) Cutting Blades: These are the sharp blades that perform the actual cutting of the material. They are typically made of high-quality tool steel and are securely mounted on the machine. The blades can be straight, curved, or angled, depending on the desired cutting operation.

(3) Blade Clearance Adjustment: Shearing machines often have a mechanism for adjusting the clearance between the upper and lower blades. This adjustment allows for precise control of the cutting gap, ensuring clean and accurate cuts.

(4) Back Gauge: The back gauge is a movable stop or fence located behind the shear table. It helps in positioning the material accurately for repetitive cutting operations. The back gauge can be manually adjusted or controlled by a motorized system.

(5) Drive System: The drive system provides the power to move the cutting blades. In hydraulic shearing machines, the drive system consists of a hydraulic pump, cylinders, and valves. In mechanical shearing machines, it typically involves mechanical components such as gears, levers, and flywheels.

(6) Control Panel: The control panel houses the controls and switches for operating the shearing machine. It allows the operator to start and stop the machine, adjust settings, and monitor the cutting process.

Operation of a Shearing Machine:

(1) Material Preparation: The material to be cut is prepared by ensuring it is clean, straight, and properly aligned with the shear table. Any protective coatings or films on the material should be removed.

(2) Material Placement: The material is placed on the shear table, ensuring it is aligned with the back gauge if applicable. The operator should take care to position the material securely and avoid any obstructions that could interfere with the cutting process.

(3) Blade Clearance Adjustment: The blade clearance is set according to the thickness and type of material being cut. This adjustment ensures proper shearing without damaging the material or the blades. The manufacturer's guidelines or machine manual should be followed for the correct blade clearance settings.

(4) Cutting Operation: Once the material is properly positioned and the blade clearance is set, the operator initiates the cutting operation. In hydraulic shearing machines, the hydraulic pump is activated to provide the necessary cutting force. In mechanical shearing machines, the operator engages the drive system, which transfers power to the cutting blades.

(5) Monitoring and Control: During the cutting process, the operator monitors the operation to ensure smooth and accurate cutting. The control panel may provide indicators or displays for monitoring the cutting speed, blade position, and other parameters. Any abnormalities or issues should be addressed promptly.

(6) Material Removal and Repeat: After the cutting operation is complete, the cut pieces are removed from the shear table. The process can be repeated for subsequent cuts, adjusting the back gauge if necessary.

It's important to note that the specific operation of a shearing machine may vary depending on the machine model and manufacturer. Operators should always refer to the machine's manual and receive proper training before operating the shearing machine.

4.Cutting Capacity and Accuracy

Cutting Capacity and Accuracy are important considerations when using a shearing machine. Let's discuss each of them:

Cutting Capacity:

(1) Shearing machines have a specified cutting capacity, which refers to the maximum thickness and width of the material that can be effectively cut. The cutting capacity is determined by factors such as the power of the machine, the strength of the blades, and the rigidity of the shear table.

(2) It is crucial to choose a shearing machine with a cutting capacity that matches the requirements of the materials you will be working with. Attempting to cut materials beyond the machine's capacity can result in poor cutting quality, blade damage, or even machine malfunction.

Cutting Accuracy:

(1) Cutting accuracy refers to the ability of the shearing machine to make precise and consistent cuts. It is influenced by several factors, including the design and condition of the machine, the sharpness and alignment of the blades, and the control and monitoring systems.

(2) To achieve high cutting accuracy, it is important to maintain the shearing machine properly. Regular blade sharpening and replacement, as well as routine maintenance and calibration, can help ensure accurate cuts.

(3) The operator's skill and experience also play a significant role in achieving cutting accuracy. Proper material positioning, adjustment of blade clearance, and careful monitoring of the cutting process are essential for obtaining precise and clean cuts.

Factors Affecting Accuracy:

(1) Blade Condition: Dull or damaged blades can lead to uneven cuts and reduced accuracy. Regular inspection and maintenance of the blades are necessary to maintain cutting precision.

(2) Blade Clearance: Incorrect blade clearance can result in distorted or incomplete cuts. It is important to set the appropriate blade clearance for the material being cut.

(3) Material Alignment: Proper alignment of the material with the shear table and back gauge is crucial for accurate cuts. Misalignment can cause crooked or uneven cuts.

(4) Machine Rigidity: The rigidity of the shearing machine, including the shear table and frame, affects cutting accuracy. A sturdy and well-maintained machine provides better stability and reduces the chances of deflection during the cutting process.

It is recommended to follow the manufacturer's guidelines and recommendations for the specific shearing machine being used. Regular maintenance, blade inspection, and operator training are essential to ensure optimal cutting capacity and accuracy.

5.Safety Considerations

Safety considerations are of utmost importance when operating a shearing machine. Here are some key safety measures to keep in mind:

(1) Read and Follow the Manual: Familiarize yourself with the manufacturer's instructions and safety guidelines provided in the machine's manual. Understand the machine's features, controls, and potential hazards before operating it.

(2) Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles, gloves, and ear protection. Depending on the specific machine and the materials being cut, additional protective gear such as a face shield or apron may be required.

(3) Machine Inspection: Before starting the machine, inspect it for any signs of damage, loose parts, or malfunctioning components. Ensure that all safety guards and devices are in place and functioning correctly.

(4) Training and Competence: Only trained and authorized personnel should operate a shearing machine. Proper training should cover machine operation, safety procedures, emergency shutdown, and handling of materials.

(5) Material Handling: Use caution when handling materials, especially large or heavy ones. Use lifting equipment or assistance when necessary to avoid strain or injuries.

(6) Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button or switch. Be prepared to use it in case of any emergency or unsafe situation.

(7) Blade Safety: Never reach into the cutting area while the machine is in operation or attempt to adjust the blades without proper training. Always wait for the machine to come to a complete stop before making any adjustments or maintenance.

(8) Housekeeping: Maintain a clean and organized work area. Remove any debris, scraps, or obstructions that may interfere with the machine's operation or cause accidents.

(9) Lockout/Tagout: Follow proper lockout/tagout procedures when performing maintenance or repairs on the machine. This involves disconnecting the power source and ensuring that it cannot be re-energized accidentally.

(10) Regular Maintenance: Adhere to the recommended maintenance schedule for the shearing machine. This includes blade sharpening, lubrication, and inspection of mechanical and electrical components.

Remember, safety should always be the top priority when operating any machinery. If you have any concerns or encounter any issues with the shearing machine, stop the operation immediately and seek assistance from a qualified technician or supervisor.

Laser Cutting Machine:

1.Introduction to Laser Cutting:

Laser cutting is a highly precise and versatile method of cutting various materials using a high-powered laser beam. It has revolutionized the manufacturing industry by providing a faster, more accurate, and more efficient alternative to traditional cutting methods. Laser cutting machines are used in a wide range of industries, including automotive, aerospace, electronics, signage, and jewelry making.

2.Types of Laser Cutting Machines:

There are different types of laser cutting machines available, each with its own advantages and suitable applications. The most common types include CO2 lasers, fiber lasers, and neodymium lasers.

CO2 lasers are the most widely used type of laser cutting machine. They use a mixture of carbon dioxide, nitrogen, and helium as the laser medium. CO2 lasers are versatile and can cut a wide range of materials, including non-metallic materials such as plastics, wood, and fabrics, as well as metals.

Fiber lasers use optical fibers as the laser medium. They are highly efficient and are primarily used for cutting metals, including stainless steel, aluminum, and copper. Fiber lasers offer high beam quality, which results in faster cutting speeds and improved precision.

Neodymium lasers use neodymium-doped crystals (such as neodymium-doped yttrium aluminum garnet or Nd: YAG) as the laser medium. They are known for their high energy and are used for precision cutting and engraving. Neodymium lasers are commonly used in applications that require high power and fine detail, such as jewelry making and micro-machining.

3.Advantages and Limitations:

Laser cutting offers several advantages over traditional cutting methods. One of the key advantages is its high precision and accuracy. Laser cutting machines can achieve intricate and complex cuts with minimal distortion. They also provide excellent edge quality, eliminating the need for additional finishing processes.

Another advantage is the speed and efficiency of laser cutting. Laser cutting machines can cut at high speeds, resulting in faster production times and increased productivity. They can also cut multiple parts simultaneously, further improving efficiency.

Laser cutting is a non-contact cutting method, which means there is no physical contact between the cutting tool and the material. This reduces the risk of damage to the material and allows for cutting delicate or fragile materials.

However, laser cutting does have some limitations. The thickness capacity of a laser cutting machine depends on the power of the laser and the type of material being cut. Thicker materials may require multiple passes or a more powerful laser to achieve a clean cut. Additionally, laser cutting machines can be expensive to purchase and maintain, making them more suitable for high-volume production environments.

4.Material Compatibility and Thickness:

Laser cutting machines can cut a wide range of materials, including metals, plastics, wood, textiles, and more. The compatibility of a material with laser cutting depends on its ability to absorb the laser energy. Materials that are highly reflective, such as copper or aluminum, may require higher laser power for cutting.

The thickness of the material that can be cut depends on the power of the laser and the type of material. Laser cutting machines can typically cut thin materials with high precision. For example, a CO2 laser cutting machine can cut up to 25mm thick steel, while a fiber laser cutting machine can cut up to 30mm thick steel. However, the maximum thickness capacity may vary depending on the specific machine and laser power.

It is important to consider the material compatibility and thickness capacity of a laser cutting machine before selecting the appropriate machine for a specific application. Consulting with a laser cutting machine supplier or manufacturer can help determine the best machine for a particular material and thickness requirement.

Power Press:

1.Exploring Power Press Machines:

Power press machines, also known as press machines or stamping presses, are versatile machines used in metalworking for various operations such as punching, bending, forming, and blanking. They are commonly used in industries such as automotive, manufacturing, construction, and appliance production. Power press machines come in different sizes and configurations to accommodate different applications and production requirements.

Power press machines are designed to apply force to a workpiece using mechanical or hydraulic systems. They are capable of exerting high pressure to shape, cut, or form metal sheets or other materials. Power press machines can be categorized into mechanical and hydraulic types based on their power source and operation.

2.Mechanical vs. Hydraulic Power Press:

Mechanical power presses use mechanical force, typically generated by a flywheel and a crankshaft, to perform operations. They are known for their high speed and productivity. Mechanical power press machines have a mechanical clutch or brake system that controls the stroke and stopping motion of the ram. They are suitable for high-volume production environments where speed and precision are important.

Hydraulic power presses, on the other hand, use hydraulic systems to generate force. They utilize hydraulic cylinders to apply pressure to the ram and perform operations. Hydraulic power press machines offer more control and flexibility in terms of force adjustment and speed modulation. They are often used for operations that require precise force control or for applications that involve deep drawing or forming of materials.

The choice between a mechanical or hydraulic power press depends on the specific requirements of the application. Factors such as the type of operation, material thickness, production volume, and precision requirements should be considered when selecting the appropriate power press machine.

3.Components and Operation:

Power press machines consist of several key components that work together to perform various operations. These components include the frame, slide or ram, bolster, die, clutch or brake system, and control system.

The frame provides the structure and support for the machine. It is usually made of cast iron or steel to withstand the forces exerted during operation. The slide, also known as the ram, moves up and down to apply force to the material. It is guided by the frame and can be driven by a crankshaft or hydraulic cylinders.

The bolster is a flat surface on which the material is placed. It provides support to the workpiece during the operation. The die is a specially shaped tool that performs the desired operation, such as punching a hole or bending a metal sheet. The die is mounted on the bolster or the ram, depending on the type of operation.

The clutch or brake system controls the stroke and stopping motion of the ram. In mechanical power press machines, a mechanical clutch or brake is used to engage or disengage the flywheel, controlling the motion of the ram. In hydraulic power press machines, the hydraulic system controls the movement of the ram.

The control system of a power press machine can vary depending on the specific machine and its features. It can range from simple manual controls to advanced computer numerical control (CNC) systems. CNC systems offer precise control over the machine's operation, allowing for programmable and repeatable processes.

4.Punching, Bending, and Forming Capabilities:

Power press machines are capable of performing various operations, depending on the tooling and dies used. Some common operations include punching, bending, forming, blanking, coining, embossing, and deep drawing.

Punching is a process of creating holes or shapes in a material using a punch and die set. Bending is the process of deforming a material to form angles or curves. Forming involves shaping a material to create three-dimensional objects or complex geometries. Blanking is the process of cutting out a flat shape from a larger piece of material. Coining is a process that involves compressing a material to create a precise shape or pattern. Embossing is the process of creating raised or depressed

Conclusion:By delving into the comprehensive knowledge provided in this ultimate guide, you have gained a solid understanding of Press Brake, Press Brake Tools, Shearing Machine, Laser Cutting Machine, and Power Press. Armed with this knowledge, you can confidently select, operate, and optimize these machines to achieve precise and efficient metal fabrication results. Remember to prioritize safety, regular maintenance, and stay updated with the latest advancements in the industry to stay ahead in the ever-evolving world of metalworking.

https://www.mihating.com/

3 notes

·

View notes

Video

youtube

Iowa Republicans are proposing a new bill that would change Iowa's child labor law to allow teens to work more dangerous jobs. Ana Kasparian discusses on The Young Turks. Watch TYT LIVE on weekdays 6-8 pm ET. http://youtube.com/theyoungturks/live Read more HERE: https://www.commondreams.org/news/iowa-child-labor-laws "Labor advocates on Tuesday decried a business-backed bill introduced by Republican state lawmakers in Iowa that would roll back child labor laws so that teens as young as 14 could work in previously prohibited jobs including mining, logging, and animal slaughtering—a proposal one union president called dangerous and "just crazy." Senate File 167, introduced by state Sen. Jason Schultz (R-6) would expand job options available to teens—including letting children as young as 14 work in freezers and meat coolers and loading and unloading light tools, under certain conditions. Teens under 18 would still be generally barred from employment in fields including mining, logging, demolition, and meatpacking, and from operating potentially dangerous machinery and equipment including circular saws, guillotine shears, and punching machines." *** The largest online progressive news show in the world. Hosted by Cenk Uygur and Ana Kasparian. LIVE weekdays 6-8 pm ET. Help support our mission and get perks. Membership protects TYT's independence from corporate ownership and allows us to provide free live shows that speak truth to power for people around the world. See Perks: ▶ https://www.youtube.com/TheYoungTurks/join SUBSCRIBE on YOUTUBE: ☞ http://www.youtube.com/subscription_center?add_user=theyoungturks FACEBOOK: ☞ http://www.facebook.com/TheYoungTurks TWITTER: ☞ http://www.twitter.com/TheYoungTurks INSTAGRAM: ☞ http://www.instagram.com/TheYoungTurks TWITCH: ☞ http://www.twitch.com/tyt 👕 Merch: http://shoptyt.com ❤ Donate: http://www.tyt.com/go 🔗 Website: https://www.tyt.com 📱App: http://www.tyt.com/app 📬 Newsletters: https://www.tyt.com/newsletters/ If you want to watch more videos from TYT, consider subscribing to other channels in our network: The Watchlist https://www.youtube.com/watchlisttyt Indisputable with Dr. Rashad Richey https://www.youtube.com/indisputabletyt Unbossed with Nina Turner https://www.youtube.com/unbossedtyt The Damage Report ▶ https://www.youtube.com/thedamagereport TYT Sports ▶ https://www.youtube.com/tytsports The Conversation ▶ https://www.youtube.com/tytconversation Rebel HQ ▶ https://www.youtube.com/rebelhq TYT Investigates ▶ https://www.youtube.com/channel/UCwNJt9PYyN1uyw2XhNIQMMA #TYT #TheYoungTurks #BreakingNews 230208__TA01Iowa by The Young Turks

1 note

·

View note

Text

Happiness - Redux 5. Of Course Not

Sapphire forced herself up – and at the same time, Scisso Ring rose as well.

“Hurry up and jack off!” The referee urged.

“Shut up! I can keep going!” Sapphire yelled to the referee.

The large corrector to the side, in the same moment, sliced off Scisso Ring’s right arm clean off and with it, half of her shears fell.

Sapphire, in their physical and mental link...had her own right arm fall off and blood leaked forth. Less like the samurai film of old with blood spraying and more like like a thick, slow moving fountain of molasses flowing down.

The referee threw his hat down.

“That’s it! This is getting embarrassing! I’m stopping this right here!” He shouted. Less concerned now, more furious.

“We can still keep going!” Sapphire urged and had ripped off the bottom of her shirt to cover the bleeding. Her vision was blurring and she stumbled but her stubbornness fell on deaf ears, which may have even been her own as her hearing kept blinking in and out.

Cages descended down and captured the remaining Correctors on each side. The canyon sides, as well, were moved upward and taken out of sight, as if they were nothing more than stage props.

Turtle Dove watched the canyons move and the Correctors being hauled off in cages. While Sapphire was doing all in her power to remain conscious, it was Turtle Dove’s turn to protest.

“What?! You could just take away the dangers at any time before it gets too bad?!” He gestured to the Correctors being hauled off and the canyons being moved. “Why didn’t you do that for the boys before, then?! Why did you just let them die?!” He wanted to run up to the referee and punch him, but the referee held up one hand and placed the other hand on top horizontally, and Turtle Dove stopped.

“So, would you rather me let those Correctors come back down and finish the job?” The referee asked, devoid of emotion, yet suggesting whether the two lived or died was but a simple decision. The fans that run throughout Turtle Dove’s system he called a body worked in overdrive as if too much processing power was being used at once.

“That...that’s not what I’m saying at all, no…”

“Then I have some good news. Seeing as,” he looked toward Turtle Dove’s side of the arena. Throughout the exam, the referee paid close attention to Sapphire while paying Turtle Dove’s machinations no mind. A panel above displayed the kill count between Turtle Dove’s and Sapphire’s side. Sapphire had killed the most Correctors between the two. There were only two remaining on her side, while several would have overtaken him had the match not been stopped. But rather than mention that, the referee went in a different direction.

“Ahem. Seeing as all of your units survived, I consider your performance more in line with what we are looking for. In other words, welcome new commander Turtle Dove.

As if rage were a little ball and Sapphire caught it, she flared up.

“What the hell?! I killed more Correctors than he did! Since when is it a viable strategy to run from battle in the first place?!” She yelled with slurred words and gestured, the blood still seeping through her makeshift covering.

“It was a tactical retreat,” the referee corrected her. “He lost no units and the Correctors were starting to run low on energy. If the battle had concluded, they would have likely tried to run off to recuperate. Considering the Corrector side suffered more losses while suffering no loses on the commander side, while not a total victory, it’s closer to one than a loss.”

“That’s bullshit! I fought to the very end!”

“Yes, and that’s the problem: you were crippled in battle. In an actual battle, a commander knows when to jack on and when to jack off. Selkies can be remade. You cannot. There’s no place in the military for a crippled commander.”

All the anger in her dissipated and replaced with something far worse; that same feeling washed over Turtle Dove. She backed away. He stood in place.

“Come, Turtle Dove. You did well. Let me show you to the next stage of your journey,” the referee ushered Turtle Dove in a way that was meant to come off as friendly, but like everything else, it came off as a threat.

“What’s going to happen to her?” Turtle Dove voiced what Sapphire didn’t need to ask.

“What’s it to you?”

Turtle Dove’s heart skipped a beat.

“Where will she be going?”

“Not to worry, she’ll be sent home.”

“Didn’t she say her village was destroyed? Where is she supposed to go?”

“It doesn’t matter. Your place is with us. Unless you want to forfeit your right to be commander and spend some quality time with her?”

Turtle Dove shook his head.

“Of course not,” the referee smiled.

Rather than go through the double elevators that they came down from, the referee walked over to another platform and Turtle Dove followed close behind. Sapphire didn’t try to run toward them despite knowing what was to come: glass formed around Turtle Dove and the referee and the two descended further.

In the darkness of the tunnel, they traveled. The ride was silent, but Turtle Doves’ thoughts were anything but.

I should have done more for her. She deserves to be a commander more than I did. I was cowardly. She fought on.

“Why are we just leaving her there? She needs medical attention,” Turtle Dove tried to voice his concern once again. As usual, the referee was dismissive.

“She is of no concern to us.”

“Why save her only to leave her to die? Make it make sense!” Turtle Dove’s voice raised.

“Watch your tone, rookie. You may be a commander now, but you’re still on the lowest rung on the ladder. I can still strip you of your title for insubordination.”

That shut Turtle Dove up.

“Got nothing else to say? Good. This is cause for celebration, not consternation.”

It didn’t matter how much the referee tried to sugarcoat his ambivalence toward the lives of others, the sour taste of burnt almonds in Turtle Dove’s mouth would not leave. The rest of the ride down was silent until a bright underground facility revealed itself.

The door opened.

“Welcome,” the referee ushered Turtle Dove out, “to your new home.”

The walls were much shinier, much cleaner, and the brightness wasn’t so overpowering as to blind him. Each wall, metallic with a cerulean tint. From around the corner of the hallway stepped forth a familiar face with her teal and white uniform, that messy, walnut brown hair, and this time wearing glasses: Ms. Temerity.

“I heard the good news, commander,” she greeted Turtle Dove, then turned to the referee, “I can take it from here.”

Her voice made Turtle Dove shiver. It was airy, seductive.

“Ah, ha ha! Yes, I know he’ll be in good hands with you, overseer,” the referee chuckled and put on an act of friendliness.

The referee stepped back into the elevator and rode it up. Once it was out of sight, Turtle Dove, while still not at ease, breathed a sigh of relief for not having to be in that man’s presence any longer. However, there was another terrifying presence right next to him.

“You’re Turtle Dove?” She asked.

“Yes,” he said, his thoughts still elsewhere.

“You fought well. Let me give you the tour. Although for now, we may just meet a few other commanders and then head to your room for the night. I’m sure you’re exhausted.”

“You saw my performance?”

She nodded.

“It was a shame I couldn’t be there in person, but I tried to help in my own way.”

Turtle Dove froze. After a few second’s refresh, he asked:

“You were Temptress?” His voice echoed down the empty halls.

She gave him a pat on the back which was more like a shove, and he stumbled forward, almost fell onto the glazed, laminate floor.

“Oh dear,” she laughed, “please keep your voice down. You never know who might hear us. Come along, now.”

“You mean to tell me you’re a Selkie?” Turtle Dove asked with his voice hushed as the two walked down the hall, side by side. At multiple intervals, their hands brushed and Turtle Dove felt a brief rush of warmth.

“I am. You may call me Temperance. I just overrode your glove and replaced Fresh-Light. Of course, I have an appearance to maintain as overseer. Not many people know I’m a Selkie, after all.”

“So you pretend to be human?”

“I prefer the term ‘passing’. It’s rather easy to pass as human, don’t you think?”

“I wouldn’t know,” Turtle Dove crossed his arms together and looked away.

“You wouldn’t? By the way, how’s your shoulder?”

“Still sore.”

“It will pass. No matter how it felt at the time, I didn’t break any bones, and your frame is rather malleable. You’d be surprised.”

“I’ve been surprised all day,” Turtle Dove grumbled.

“Prepare to be surprised once more: I’m not just any Selkie, I’m your Selkie.”

“What?”

“The director of the Selkie program mandated that each commander is to be assigned one randomly selected SSR Selkie. I was selected to be yours. Consider me at your disposal for you to command.”

With those words, something sprung from Turtle Dove.

“Can you save Sapphire’s life?” He asked.

“Oh my. That’s a rather tall order. You are aware that you would be going against the military, yes? You never know when the director might be watching or listening.”

“But can you?”

“I’ll see what I can do. Now, may I show you to your room? We can continue the tour for tomorrow. If I’m going to be making such a huge risk, I’ll need some time to prep.”

“Fine by me.”

Temperance let slip an unnaturally narrow smile.

I’m going to enjoy this, she thought.

A navy blue sign plastered onto the wall with white lettering pointed two ways: ‘Dorms’ with an arrow pointing forward and ‘Elevator’ pointing back.

Temperance herself pointed to her left where another hallway led.

“Over there is where the locker room is. You’ll meet your fellow commanders there. There are training courses just past the locker rooms where you can work out and even enter mock battles to power up your Selkies. Past the dorms are the labs. Each commander is assigned one. Including you.”

He nodded.

They continued walking for a little while until they reached dorm room #187.

“Here we are,” she pulled out a blue, holographic key card from her pocket. She swiped it against the black panel on the door and the door slid open. She handed him the key card she used.

“This is yours. Don’t lose it. I have my own.”

She left after that. He didn’t know when he would return, but when he met the darkness of the dorm room, he smiled.

After a long, hot shower with unscented soap and unlabeled shampoo, provided by the military, he dried off with a thin, white tail and changed into generic black pants and black, spandex shirt. His clothes were currently being washed in the dorm’s washer.

Evening set. No sign of Temperance.

Less than a dorm, the room seemed bare with a bunk bed and thin sheets. Like a prison cell, with a few amenities.

He crawled into bed and rather than sleep on the plain white pillow provided, hugged it tight.

Temperance entered soon after and the glow from the light outside shone in.

“Did you save her?” He asked without looking toward his Selkie.

“Of course not,” she smiled. “That would have gone against the higher ups.”

Turtle Dove’s eyes started to well up as tears spilled forth and he hugged his pillow tighter, imagining it to be the large shark plushie he once had. As childish as it may have been, he missed it.

1 note

·

View note

Photo

【Enterprise News】Overseas customers visited CANWIN and praised the Transformer Core Machining Center. The transformer core machining center developed by CANWIN adopts Siemens system, which can support cutting modes such as two shear three punch, two shear four punch, two shear six punch, two shear eight punch, etc. According to the cutting width, it can be divided into 300 types, 450 types, 650 types, 850 types, 950 types, and can be customized into 1250 types. Combined with Keying's high-speed longitudinal cutting line, intelligent storage and vertical warehouse, and dozens of sets of machining centers, it is particularly suitable for standardized production of super enterprises in the future power field (annual production of 50000, 100000, and million iron cores). It can effectively solve the problems of previous horizontal cutting lines that only need to be cut without folding, requiring repeated transportation by transfer vehicles, troublesome pre positioning of truss mechanical stacking, low work efficiency, large equipment footprint, and requiring a lot of manpower.

0 notes

Photo

【Enterprise News】Overseas customers visited CANWIN and praised the Transformer Core Machining Center. The transformer core machining center developed by CANWIN adopts Siemens system, which can support cutting modes such as two shear three punch, two shear four punch, two shear six punch, two shear eight punch, etc. According to the cutting width, it can be divided into 300 types, 450 types, 650 types, 850 types, 950 types, and can be customized into 1250 types. Combined with Keying's high-speed longitudinal cutting line, intelligent storage and vertical warehouse, and dozens of sets of machining centers, it is particularly suitable for standardized production of super enterprises in the future power field (annual production of 50000, 100000, and million iron cores). It can effectively solve the problems of previous horizontal cutting lines that only need to be cut without folding, requiring repeated transportation by transfer vehicles, troublesome pre positioning of truss mechanical stacking, low work efficiency, large equipment footprint, and requiring a lot of manpower.

0 notes

Text

Custom Hand Tufted Carpets: Luxury Flooring Solutions Made From Carpet Companies in Dubai

When it comes to home décor, few elements have as much impact as flooring. It is the foundation of your design, influencing the overall atmosphere, style, and comfort of any space. One of the most luxurious and versatile options available today is custom hand tufted carpets. These bespoke pieces are not just functional but are also works of art, designed to reflect your unique taste while offering unmatched comfort and durability.

What Are Hand Tufted Carpets?

Hand tufted carpets are crafted using a manual tufting gun, allowing artisans to "punch" strands of yarn into a canvas that is stretched over a frame. Unlike machine-made carpets, which are produced in large quantities with set designs, hand tufted carpets allow for intricate patterns, textures, and customizations. This technique gives you the flexibility to choose every aspect of your carpet, from its size, shape, and colors to the type of yarn used and the complexity of the design.

The Luxury of Customization

What sets custom hand tufted carpets apart from other flooring options is the level of personalization they offer. With a custom carpet, you are in full control of the design process, ensuring that the final product perfectly complements your home’s décor and layout. Whether you prefer a bold geometric pattern, a delicate floral motif, or something entirely abstract, a skilled artisan can bring your vision to life, and carpet companies in Dubai provide exceptional design expertise to ensure that every detail meets your expectations.

1. Tailored to Your Space

One of the primary benefits of choosing a custom hand tufted carpet is that it can be tailored to the exact dimensions and shape of your room. Irregularly shaped spaces, open floor plans, or unique architectural features like pillars or fireplaces are no challenge when your carpet is made to order. This ensures that the carpet fits seamlessly into your space, enhancing its flow and aesthetic appeal.

2. Unlimited Design Possibilities

The beauty of custom carpets lies in their flexibility. You are not limited to standard colors, patterns, or textures. From earthy tones to vibrant hues, subtle textures to plush piles, and classic designs to modern interpretations, you can create something that is truly one-of-a-kind. Whether you want your carpet to blend into the background or serve as the focal point of a room, your options are only as limited as your imagination.

3. Material Selection

The choice of materials also plays a crucial role in the luxury of a hand tufted carpet. High-quality wool is a popular option due to its softness, durability, and natural stain resistance. However, you can also opt for other luxurious materials such as silk, bamboo silk, or a blend of fibers, depending on your aesthetic and practical preferences. The yarn selection influences not only the look but also the feel of your carpet, ensuring that it complements the overall ambiance of your space.

The Craftsmanship Behind Each Piece

While the design aspect of custom hand tufted carpets is certainly alluring, the craftsmanship behind each piece is equally impressive. These carpets are the result of hours of skilled labor by artisans who meticulously hand-tuft each section to bring the design to life. Once the tufting process is complete, the backing is applied, and the carpet is sheared to create an even surface, leaving behind a luxurious, handcrafted product that is both durable and visually stunning.

Why Choose Hand Tufted Carpets?

Hand tufted carpets are not just luxurious; they are also highly functional. Here are a few reasons why homeowners and interior designers alike love this flooring option:

Durability: Thanks to the sturdy construction, hand tufted carpets are incredibly durable and can withstand heavy foot traffic, making them ideal for both residential and commercial spaces.

Comfort: With a thick pile and soft texture, these carpets provide exceptional comfort underfoot, making them perfect for living rooms, bedrooms, and lounge areas.

Sound Insulation: Carpets are excellent for sound absorption, reducing noise and creating a more peaceful and serene environment in your home.

Versatility: Whether your home’s style is traditional, contemporary, or somewhere in between, hand tufted carpets can be designed to match your personal aesthetic.

Caring for Your Custom Hand Tufted Carpet

Although hand tufted carpets are durable, proper care is essential to maintain their beauty and longevity. Regular vacuuming helps to keep dust and dirt from settling into the fibers, and periodic professional cleaning can restore the carpet’s original luster. It’s also important to avoid excessive moisture, which can damage the backing and cause the fibers to weaken over time.

Conclusion

Custom hand tufted carpets are more than just floor coverings; they are a luxurious addition to your home that combines functionality, comfort, and personalized design. By investing in a custom carpet, you’re not just adding a piece of décor to your space—you’re creating a unique work of art tailored to your specific preferences. Whether you want to make a bold statement or subtly enhance the elegance of your interiors, carpet companies in Dubai offer the perfect solution for those seeking both style and quality in their flooring.

#carpetcompaniesindubai #customhandtuftedcarpets

0 notes

Text

Equipment Used in the Pharmaceutical Industry

The pharmaceutical industry relies on a vast range of specialized equipment to ensure that the production processes for medicines, vaccines, and other health products are safe, efficient, and compliant with regulatory standards. From raw material handling to the packaging of the final product, equipment plays a crucial role in ensuring quality and sterility. This article explores the essential equipment used in pharmaceutical manufacturing, highlighting the importance of each category and its application in the production process.

1. Mixing and Blending Equipment

Mixers and blenders are critical in combining raw materials and active pharmaceutical ingredients (APIs) into homogeneous mixtures. This equipment ensures that the components are evenly distributed, which is vital for dosage consistency in tablets, capsules, and other pharmaceutical forms. Different types of mixing equipment are used depending on the properties of the ingredients:

Ribbon Blenders: Used for dry powder mixing, commonly in tablet production.

High-Shear Mixers: Ideal for wet granulation processes where liquid binding agents are added to powders.

2. Granulation Equipment

Granulation is a key step in the production of tablets. This process converts fine powders into larger, free-flowing granules, making it easier to compress them into solid dosage forms. The two main types of granulation processes are wet granulation and dry granulation. Equipment used for this purpose includes:

Fluid Bed Granulators: Used in wet granulation to spray binder solutions onto powder particles.

Roller Compactors: Used in dry granulation, where powders are compacted between rollers to form granules without adding liquids.

3. Tableting and Encapsulation Machines

Tableting and encapsulation are the processes of converting granules into solid dosage forms. Specialized machines are required to compress powders into tablets or encapsulate them in capsules:

Tablet Presses: These machines compress powders or granules into tablets of uniform size and weight. Single-punch or rotary tablet presses are commonly used, depending on production scale.

Capsule Fillers: Capsule filling machines automatically fill empty gelatin or HPMC capsules with powders, granules, or liquid formulations, ensuring precise dosage in each capsule.

4. Coating Machines

Pharmaceutical tablets often require coatings for several reasons, such as improving taste, protecting the active ingredients, or controlling drug release. Coating machines apply a thin layer of polymer or sugar-based coating onto the tablet's surface. The most common equipment used for this purpose includes:

Pan Coaters: These machines rotate tablets in a pan while spraying the coating solution.

Fluidized Bed Coaters: Used for applying coatings to particles or small tablets by suspending them in an air stream while applying the coating material.

5. Sterilization Equipment

In pharmaceutical production, sterility is paramount, especially in the manufacturing of injectable drugs, vaccines, and other sterile products. Sterilization equipment ensures that any microbial contamination is eliminated. The common sterilization methods and equipment include:

Autoclaves: Use steam under pressure to sterilize equipment and pharmaceutical products. They are widely used for sterilizing surgical instruments, glassware, and some types of media.

Dry Heat Sterilizers: Ideal for sterilizing equipment that can withstand high temperatures but not moisture, such as glass bottles and metal equipment.

Gamma Irradiation: Used for sterilizing pharmaceutical products that are sensitive to heat or moisture.

6. Filtration Systems

Filtration is critical in ensuring that liquids and gases used in pharmaceutical manufacturing are free from particulates, bacteria, and other contaminants. Filtration systems are essential in the production of injectable drugs, vaccines, and sterile products:

Membrane Filters: Used to remove bacteria and particulates from liquid formulations. These filters are commonly used in the preparation of sterile solutions.

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are used in cleanrooms and HVAC systems to ensure the air is free from particulates and microorganisms.

7. Water Purification Systems

Water is a fundamental ingredient in the pharmaceutical industry, used in various forms, such as Purified Water (PW), Water for Injection (WFI), and Ultra-Pure Water (UPW). Water purification systems ensure that the water used in pharmaceutical production meets strict purity standards:

Reverse Osmosis (RO) Systems: Remove dissolved solids, bacteria, and organic impurities from water.

Electrodeionization (EDI) Systems: Used for the continuous production of ultra-pure water by removing ionic contaminants.

Water for Injection (WFI) Systems: Produce highly purified, sterile water used in the production of injectables and other sterile pharmaceutical products.

8. Packaging Equipment

Pharmaceutical packaging must ensure the product’s safety, integrity, and compliance with regulatory requirements. The packaging process also protects the product from contamination, tampering, and environmental factors. Common types of packaging equipment include:

Blister Packaging Machines: Used for packaging tablets and capsules in pre-formed cavities made of plastic or aluminum.

Bottle Filling Machines: Automatically fill liquid pharmaceuticals into bottles or vials, ensuring precise measurement and sealing.

Labeling Machines: Apply labels to pharmaceutical containers, ensuring that they contain the correct product information and batch details.

9. Quality Control Equipment

Pharmaceutical production requires stringent quality control to ensure that products meet regulatory standards. Quality control equipment is used for testing various attributes of the product, such as potency, purity, dissolution rate, and more:

HPLC (High-Performance Liquid Chromatography): Used to analyze the chemical composition of drugs and ensure that they contain the correct concentrations of active ingredients.

Dissolution Testers: Measure the rate at which tablets or capsules dissolve in liquids, ensuring that they meet specified release profiles.

Spectrophotometers: Analyze the absorbance of light in drug samples, helping to identify impurities or verify the concentration of active ingredients.

10. Cleanroom Equipment

Pharmaceutical manufacturing often takes place in cleanrooms, which are controlled environments designed to minimize contamination from airborne particles. Cleanroom equipment includes:

Air Showers: Used at the entrances to cleanrooms to blow off dust and contaminants from personnel before entering the sterile environment.