#sewage-lifting-pump

Explore tagged Tumblr posts

Text

How does a sewage lift pump operate?

A sewage pump, also known as an ejector pump, collects sewage from your home and deposits it in a tank or basin. The pump works when the waste reaches a particular level, propelling it uphill to your home's main sewer line. Gravity then directs the sewage to the city line on the street or a septic tank.

0 notes

Photo

Top 10 Inventions of the Industrial Revolution

The British Industrial Revolution transformed life at work and at home for practically everyone. Noise, pollution, social upheaval, and repetitive jobs were the price to pay for labour-saving machines, cheap and comfortable transportation, more affordable consumer goods, better lighting and heating, and faster ways of communication.

Any shortlist of inventions is bound to be far from complete, but the following have been chosen not only for what they could do but also for how they permitted other inventions to become possible and how they transformed working life and everyday living for millions of people. The period under consideration is also important and here is taken as 1750 to 1860. With these criteria in mind, the top 10 inventions of the Industrial Revolution were:

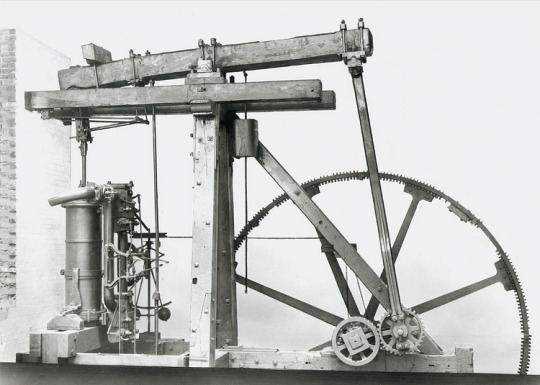

The Watt Steam Engine (1778)

The Power Loom (1785)

The Cotton Gin (1794)

Gas Street Lighting (1807)

The Electromagnet (1825)

The First Photograph (c. 1826)

Stephenson's Rocket (1829)

The Electrical Telegraph (1837)

The Steam Hammer (1839)

Mass Steel Production (1856)

The Watt Steam Engine

The steam engine, which harnessed power from the expansion of heated water, is often cited as the single most important invention of the Industrial Revolution, principally because so many other important subsequent inventions used it as their power source. The steam engine was born from the necessity to pump out flooded mine shafts and enable deeper mining. The first steam pump was invented by Thomas Savery (c. 1650-1715) in 1698. In 1712, Thomas Newcomen (1664-1729) perfected his more powerful steam pump to drain coal mines of water in Dudley in the Midlands.

To make the steam engine more useful for other purposes, it had to be made more efficient both in terms of fuel consumption and power. The Scottish instrument maker James Watt (1736-1819) and Matthew Boulton (1728-1809) kept tinkering with the workings of the steam engine until, in 1778, they had perfected a separate condenser to vastly increase the engine's efficiency. Power was also increased by the steam powering the piston down not just up (hence its name, a double-acting engine), increasing the 'horsepower', a term coined by Watt. The engine also had its power converted to a more versatile rotary motion using a flywheel. Using just one-quarter of the fuel of Newcomen's engine, Watt's engine was cheap enough to use almost anywhere. Steam engines kept on evolving, notably with the expansion steam engine, and they benefitted from ever-better tool machinery that could make stronger and better-fitting parts.

By 1800, Britain boasted over 2,500 steam engines, most of them used in mines, cotton mills, and manufacturing factories. 500 of these engines were made by the Watt and Boulton factory in Birmingham. Every walk of life was affected. Steam now powered fountains, threshing machines, sewage pumps, and printing presses. Essentially, any work that required pushing, pulling, lifting, or pressing could be made much more efficient using steam-powered machines. Steam engines were harnessed for trains and steamships, and, aptly, all these uses caused a boom in the coal mining industry, which had been the origin of the machine in the first place.

Continue reading...

33 notes

·

View notes

Text

Edinburgh women negotiate the gradients of the old town, bringing home their washing from the steamie

Bicep curls and thigh burning lunges, twists, lifts and muscle-aching stretches – it must have been the ultimate workout in the most unlikely of places.

These days we spend a small fortune on fitness classes and gym memberships. But in granny’s day, all you needed to shape up, was a few regular trips to the ‘steamie’.

Shoving a pram full of clothes and sheets to the wash house would have been one way to get the heart pumping – even before the back-breaking task of trying to lift sodden sheets and towels from the hot tub of soapy water into the cold one for a rinse.

Then feeding endless pairs of your man’s newly scrubbed dungarees through a hand mangle would probably have done more for keeping the bingo wings at bay than any number of Zumba classes.

The women who passed endless hours scrubbing and wringing, folding and hanging up also had the added benefit of the camaraderie of the wash house – a place where the banter could be as spicy as that of any male-dominated factory, the laughs just as raucous and the support network in times of need, vital.

Incredible as it sounds, Edinburgh’s wash houses were still operating in the early 1980s, nearly a century after concerns over the city’s terrible infant death toll, cholera and disease led to public health pioneers pushing for their construction.

The first wash house appeared 90 years earlier after it became clear that Edinburgh’s authorities had to step in to tackle a public health crisis.

Urban areas like the Old Town were so poor, they had no facilities for washing in the houses and a lot of places didn’t have running water,That led to diseases, in particular cholera, which spread through dirty clothing and beddinThe hope was that by providing public wash houses, they could start to sort out the terrible infant mortality.”

For many Old Town residents, wash day had involved a trip to the Nor Loch, to rinse out garments among the sewage and stench of slaughterhouse waste which flowed into the water. Others made do with public water fountains, dirty burns or whatever source of water they could find.

While Edinburgh’s authorities had the power from 1880 to begin construction of wash houses, there was a 12-year delay while efforts were made to find the right locations for the new facilities. Meanwhile in Glasgow, wash houses were already up and running.

Edinburgh’s first opened at St Gray’s Close in the Old Town in 1892 – and immediately locals were queuing out of the door in the hope of finally having clean clothing and bedding. Stockbridge wash house in Allan Street followed in 1903 and Simon Square at St Leonards in 1908.

Eventually there would be ten more built at locations across town: Greenside Lane, Lochrin at Tollcross, MacLeod Street serving Gorgie, Causewayside, Abbeymount at Abbeyhill, Adelphi Grove in Portobello, Bonnington Road/Great Junction Street in Leith, Henderson Row in Canonmills, Union Street and Murdoch Terrace, Dalry.

The wash houses were constructed along similar lines – a large central hall where the tubs were positioned, a heated chamber with drawers for clothes to be dried, office space and a coal-fired boiler room.

Remarkably given the era, most had a crèche.

The first one at St Gray’s Close didn’t and children were being scalded,So it was decided to create a crèche so women could get on with doing the washing while the children were looked after.

The work was sweat-�inducing, with heavy loads of bedding and clothes being plunged into hot tubs, rubbed with hard soap and then cleaned with a ‘wash dolly’ before being fed through a hand mangle. Soaking items were then hung in the drying area – often emerging within an hour, bone dry.

As washing machines became more compact and efficient, the wash houses fell into disuse and despite a lively political battle between Labour and Tory politicians over their future – and angry demonstrations by loyal users desperate to keep them alive – the last wash house closed in 1982.

Some became warehouses or car showrooms before being demolished. Today only three remain: at Adelphi Place in Portobello, now a community centre, MacLeod Street at Tynecastle which is expected to be earmarked for demolition and at Union Street, the base for Edinburgh Printmakers and where there are markings on the walls referring to the building’s previous use.

There was this feeling that they were part of the bad old others thought of them as being like a community centre and very much a women’s environment, run by women and for women. There seems to have been a great deal of sadness when they closed.

21 notes

·

View notes

Text

The Great Stink-

The Great Stink was an event in Central London during July and August 1858 in which the hot weather exacerbated the smell of untreated human waste and industrial effluent that was present on the banks of the River Thames. The problem had been mounting for some years, with an ageing and inadequate sewer system that emptied directly into the Thames. The miasma from the effluent was thought to transmit contagious diseases, and three outbreaks of cholera before the Great Stink were blamed on the ongoing problems with the river.

The smell, and fears of its possible effects, prompted action from the national and local administrators who had been considering possible solutions for the problem. The authorities accepted a proposal from the civil engineer Joseph Bazalgette to move the effluent eastwards along a series of interconnecting sewers that sloped towards outfalls beyond the metropolitan area. Work on high-, mid- and low-level systems for the new Northern and Southern Outfall Sewers started at the beginning of 1859 and lasted until 1875. To aid the drainage, pumping stations were placed to lift the sewage from lower levels into higher pipes. Two of the more ornate stations, Abbey Mills in Stratford and Crossness on the Erith Marshes, with architectural designs from the consultant engineer, Charles Driver, are listed for protection by English Heritage. Bazalgette's plan introduced the three embankments to London in which the sewers ran—the Victoria, Chelsea and Albert Embankments.

Bazalgette's work ensured that sewage was no longer dumped onto the shores of the Thames and brought an end to the cholera outbreaks; his actions are thought to have saved more lives than the efforts of any other Victorian official. His sewer system operates into the 21st century, servicing a city that has grown to a population of over eight million. The historian Peter Ackroyd argues that Bazalgette should be considered a hero of London.

Read more

20 notes

·

View notes

Text

|__LAB RUINS__|

“Crossing The River”

‼️TW Body Horror!

"Alright, here's the shortcut I was talking about."

The moment the giant metal doors swung open, Peppino recoiled at the stench of sewage-infused cheese, a scent he had hoped he would never have to smell again. A giant raging river of molten cheese separated the two halves of the room. Pizzahead seemed unphased and headed over to a storage bin and started digging around in it.

"Cheese slimes must've gotten into the sewage, absorbed all of the trash."

"Eugh..are you sure there's-a no other way there?"

"You'd rather take the long route? Run into more of those things? I mean look at ya, you're falling apart already!"

Peppino looked down at himself. His white tank top was now a dingy grey from the grime and dirt it was accumulating and he was starting to get sore from how many doors and walls he had been smashing into. His body hadn't really recovered from his last adventure before he started this journey and it was really starting to take a toll on him. Turns out to need to take care of yourself more when you're 45. Who knew?

"I guess you're-a right. We better not be swimming through this though."

"Don't worry, I put some emergency rafts somewhere in here."

As Pizzahead was still digging through the bins, Peppino's attention was drawn to a group of clones that entered the room on the other side of the river. Two clones of himself were dragging a feral-looking Pepperman clone towards the river.

The pepper hissed and gnashed it's teeth as it tried to escape, but the two other clones held it tight. As they got closer to the edge of the river, ripples started to form in the raging cheese and the waves started to get higher.

When they finally got to the edge, Peppino watched as a tendril of cheese flew out of the river and wrapped itself around the Pepperman like a lasso. The two clones to the side let go as it was pulled into the river in a flash, disappearing beneath the waves without a sound.

"Ah here we go! I knew I put one in here!"

Pizzahead pulled out an inflatable raft triumphantly and slammed it onto the ground. He grabbed a pump from the chest and started to inflate it

"Pizzahead...I...Um....I don't think-"

"Don't worry this raft is big enough for both of us. And it's heavy duty too! You wouldn't be able to sink it if you tried!"

He lifted the inflated raft and headed over to the edge of the platform to toss it in.

"PIZZAHEAD WAIT DON'T-"

The raft hit the surface of the cheese river with a wet plap. Pizzahead smiled and gestured towards it.

"After you!"

But before Peppino could take a step, the raft shot backwards out of the river towards Pizzahead and knocked him into the ground with a thud. It let out a squeal as it deflated and Peppino could see that something had ripped a massive hold in its side. He ran over to Pizzahead and lifted the plastic off of him while the river behind him started to bubble and churn.

They both watched in horror as a massive lump of cheese rose out of the river and towered over them. Two eyeholes opened up near the top of the mound and two milky white eyes tumbled out of them, loosely hanging on to the edges of the sockets. The creature opened its mouth and let out a mighty roar, rattling the sewage pipes and stirring up the waves around it.

As Peppino screamed in terror, Pizzahead noticed something floating on top of the creature's head. It was a cowboy. It was small, but immediately recognizable.

"I-is that....Vigilante? Or uh...'Riverlante'..I guess?"

The creature closed its massive maw and slowly nodded.

“Ydwoh..”

"Wow! What a..uh...mighty man of the law you've become! I bet you rule over these parts with an iron fist!"

Rivilante smirked for a moment, but then went back to scowling.

“Yrettalf tnow krow no em. Uoy deen ot yapeth eef ot ssorc.”

(Flattery wont work on me. You need to pay the fee to cross.)

“What did he say?”

Peppino whispered to Pizzahead.

“He wants us to pay a fee to cross.”

“But we’re-a both broke as hell!”

The two suddenly jumped as a ginormous cheesy hand slammed something onto the platform in front of them.

It was a messily drawn wanted poster depicting a nasty-looking little gang of toppin clones. There were doodles scattered around the paper showing the little creatures biting and terrorizing other clones. They definitely looked like bad news.

“Dnif meht. Gnirb meht ereh. Neht uoy nac ssorc.”

(Find them. Bring them here. Then you can cross.)

“Ohhh I see.”

Pizzahead turned to Peppino.

“We gotta hand over these hardened criminals to get through.

Peppino grabbed the poster from him and looked it over.

“I’ve collected toppins before. This shouldn’t-a be too hard. Let’s-a get a move on.”

The pair turned and headed back out the doors they came in from as Rivi slowly descended back into the raging waves.

(Finally done with this!! I also added the backwards translations to make this a bit easier to read lol)

#lab ruins au#pizza tower au#pizza tower art#pizza tower#vigilante#peppino spaghetti#pizzahead#tw body horror

19 notes

·

View notes

Text

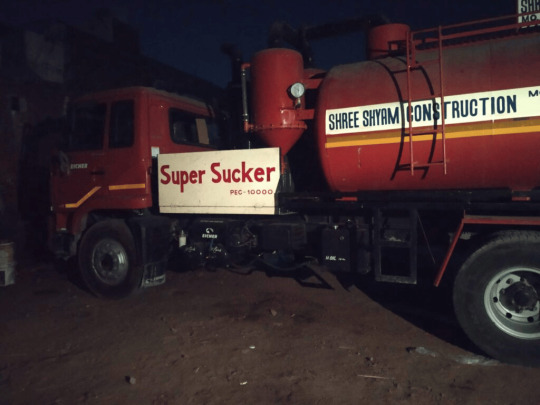

SUPER SUCKER MACHINE

The Super Sucker Machine is a heavy-duty industrial vacuum cleaner used to suck up large volumes of solids, liquids, and sludges from a variety of industrial settings. It is an extremely powerful and efficient machine that is used to clean up a range of substances, including oil spills, sewage, and hazardous waste. The machine is particularly useful in environments where traditional cleaning methods are not practical or effective.

The Super Sucker Machine is a self-contained unit that is mounted on a truck or trailer. It consists of a large vacuum pump, a high-pressure water pump, and a storage tank for the collected materials. The machine is typically operated by a crew of two or more people who are trained in the use of the equipment.

One of the key features of the Super Sucker Machine is its powerful vacuum pump. This pump is capable of creating a vacuum that is strong enough to lift heavy materials such as rocks and bricks. It is also capable of sucking up large volumes of liquids and sludges. The pump is driven by a powerful diesel engine that provides the necessary power to operate the machine.

SUPER SUCKER MACHINE

In addition to the vacuum pump, the Super Sucker Machine also has a high-pressure water pump. This pump is used to spray water onto surfaces to help loosen and remove stubborn materials such as grease and oil. The water pump is also used to clean up spills and to flush out pipes and tanks.

The collected materials are stored in a large tank on the Super Sucker Machine. The tank is designed to hold large volumes of solids, liquids, and sludges. Once the tank is full, the crew can transport it to a disposal site where the materials can be safely disposed of or recycled.

The Super Sucker Machine is used in a variety of industries, including oil and gas, mining, and construction. In the oil and gas industry, the machine is used to clean up oil spills and to remove solids and sludges from storage tanks and pipelines. In the mining industry, the machine is used to clean up tailings ponds and to remove solids and sludges from mining operations. In the construction industry, the machine is used to clean up construction sites and to remove debris from demolition projects.

If you have any query please free to ask:

Supertechengineer

Contact No:09910715032, 09311309436

Email: [email protected]

Address: MORTA INDUSTRIAL AREA, MORTA GHAZIABAD, Ghaziabad, Uttar Pradesh, India.

18 notes

·

View notes

Text

Efficient Wastewater Management with Archimedes Screw Pumps

Find out the reliability and efficiency of wastewater screw pumps, known as Archimedes screw pumps, designed for smooth water movement in treatment plants and industrial applications. These pumps have been fitted with a spiral design that has been time-tested and proved efficient to lift and transport liquids with very minimal energy consumption. They are excellent for handling large volumes of wastewater and provide a low-maintenance solution that minimizes clogging and wear. Applications range from sewage treatment to irrigation; the Archimedes screw pump is available as a sustainable, cost-efficient fluid management. They are strength and efficiency designed, which makes it one of the most reliable water-handling solutions for those with environmentally friendly interests. Innovate your wastewater management today.

#wastewaterbiologicaltreatment#wastewaterscrewpump#wastewaterscreens#wastewaterclarification#wastewaterbarscreen#sludgescreeningsystem#fatoilandgreasescreening#wastewatertreatment#wastewaterclarifier#archimedesscrewpump

0 notes

Text

2BHK Flat for Sale at Newtown AA-2 |2mi from Biswa Bangla Sarani | Ready to Move | starting price Rs-52 Lakh

✦ CALL for more info - 9875369644 (Call Or WhatsApp)

★ PRICING FEATURES ★

___________________________________________

(F) -840 sqft - 2BHK - Rs- 51.68 Lakh

---------------------------------------------

(G) -970 sqft - 2BHK - Rs- 58.44 Lakh

___________________________________________

★ LOCATION - Newtown Action Area-2,Just Nearest Eco park gate-1 Metro. Newtown Metro - 3min, Eco Park - 2Min.Biswa Bangla Sarani 2 min.

★ PROJECT DETAILS ★

➤ G+4 Storied Building.

➤ Project Size :2 Buildings - 28 units.

➤ Basement Car Parking.

➤ Ground Floor Commercial Space.

➤ 2BHK - 840sqft & 970sqft.

➤ Available floor: 840sqft 2nd & 4th Floor,

970sqft 1st & 2nd Floor.

➤ All Leading Bank Loan Available Like SBI, BOB, LIC ETC.

➤ Possession - Ready to Move.

★★ Project Specifications ★★

★ Building Level ★

➤ Lobbies on all floors and staircase of the said Building.

➤ Lift machine room and lift well of the Said Building.

➤ Water reservoirs/tanks of the said Building.

➤ Water supply, pipeline in the Said Building (save those inside any Unit).

➤ Drainage and sewage pipeline in the Said Building (save those inside any Unit).

➤ Wiring, fittings and accessories for lighting of lobbies, staircase and other common portions of the Said Building.

➤ Space for Electricity meters.

➤ Lift and allied machinery in the building.

➤ Ultimate roof of the building will be treated as common space.

★ Complex Level ★

➤ Water Treatment Plant & 24 hour water supply arrangement.

➤ Water pump/s and motor/s.

➤ Central drainage and sewage pipeline and connection with Panchayet Authority.

➤ Wiring, fittings and accessories for lighting of common portions.

➤ Installations for receiving and distributing electricity from supply agency.

➤ Boundary walls and main gates.

➤ C.C.T.V., Water Treatment Plant & Generator Facility.

➤ Fire extinguisher & 24x7 Security Guards.

➤ Other such common areas, fittings and installations as may be specified by the developer to be common areas fittings and installations/equipments.

✔ STRUCTURE

Building designed with R.C.C. Frame structure which rest on individual column, design approved by the competent authority.

✔ EXTERNAL WALL

10" thick ash brick wall and plastered with cement mortar.

✔ INTERNAL WALL

3" thick brick wall and plastered with cement mortar.

✔ FLOORING

Flooring is of flat will be of Tiles. Flooring of car parking will be cement.

✔ BATH ROOM

Bath room fitted upto 5'-6" height with glazed tiles of standard brand.

✔ KITCHEN

Cooking platform and sink will be of Steel Sink with 2'-6" height standard tiles above the platform to protect the oil spot.

✔ TOILET

European type commode with standard P.V.C. ISI Cistem. All fittings are in standard type. One wash hand basin is in dining space.

• Common Toilet One two pin mixture bibcock.

One shower, one Tap.

• Attached Toilet One shower and two CP Bibcock.

✔ DOORS

Sal Wood Frame. All doors including Main Door & Other door palla of the flat of flash door.

✔ WINDOWS UPVC

Sliding. WATER SUPPLY Water supply around the clock is assured for which necessary 4" CRI Submartible pump/deep tube well will be installed.

✔ PLUMBING

Toilet concealed wiring with PVC Pipe (Supreme) all fittings are standard quality (Jaquar/Essco/Johnson/Cera).

✔ BALCONY

Upto 3'-0" height grill will be provided in the balcony.

✔ LIFT

Four persons capacity lift will be provided in each block of the building complex.

★ PRICING FEATURES ★

✦ PRICE - 5,200/- Per Sq. Ft. Rate.

✦ Car Parking - 5 Lakh.

✦ Amenities Cost 3 Lakh.

✦ Box Price - For 2BHK 840sqft Rs-51,68,000/- (all included),

and 2BHK 970sqft Rs-58,44,000/-(all included).

We are happy to help you find your DREAM HOME 🏡

✦ CALL for more info - 9875369644 (Call Or WhatsApp)

Thank you,

One Acre

#2bhk #2bhkflatsforsale #2BHKSALE #FlatInNewtown

0 notes

Text

Ejector Pumps in Denver: Essential Solutions for Efficient Waste Management by Blue Sky Plumbing and Heating

Managing wastewater effectively is crucial for any property in Denver, especially where gravity-based systems can’t move waste up and out to the main sewer lines. Ejector Pumps in Denver play a pivotal role in overcoming these challenges, allowing residential and commercial properties to manage sewage efficiently. When paired with high-quality services like those offered by Blue Sky Plumbing and Heating, homeowners and businesses can be assured that their ejector pump systems will operate smoothly and safely. Additionally, services such as Sewer Cleaning Service in Surrey, Heating & Plumbing Experts in Vancouver, and Drain Cleaning Service in Surrey offer vital insights and expertise applicable across cities.

Understanding Ejector Pumps: Why Are They Necessary?

Ejector pumps are designed to handle waste in basements or lower-level areas where gravity alone isn’t enough to move sewage to the main sewage line. They’re equipped to pump wastewater upwards, ensuring it reaches the main sewer or septic system effectively. These pumps are vital for homeowners in Denver who want to ensure that their sewage systems remain free of blockages, which could lead to costly repairs. For this reason, Blue Sky Plumbing and Heating recommends regular inspections and maintenance to keep ejector pumps functioning efficiently.

Key Benefits of Ejector Pumps in Denver

Investing in an ejector pump in Denver offers multiple advantages:

Effective Waste Management: Ejector pumps manage waste smoothly, preventing overflow and backups.

Prevention of Property Damage: Properly maintained ejector pumps prevent sewage from seeping into basements or other low-lying areas.

Reliability in Any Season: With Colorado’s varied climate, ejector pumps ensure consistent waste management regardless of temperature changes.

Improved Property Value: Having a high-quality ejector pump system, installed by a reputable company like Blue Sky Plumbing and Heating, can increase property value by providing a more comprehensive waste management solution.

How Blue Sky Plumbing and Heating Assists with Ejector Pumps in Denver

When it comes to selecting and installing ejector pumps, Blue Sky Plumbing and Heating is the go-to company in Denver. They specialize in determining the right pump model for each property based on its specific layout and waste management needs. Once the pump is installed, their experts provide ongoing maintenance and support to ensure the system runs smoothly. Their expertise isn’t limited to Denver, as they also bring valuable insights from services like Drain Cleaning Service in Surrey and Heating & Plumbing Experts in Vancouver.

Installation Process for Ejector Pumps in Denver

Assessment of Property Needs: A technician from Blue Sky Plumbing and Heating will evaluate the property to understand its waste management requirements, focusing on factors like basement layout and existing plumbing systems.

Choosing the Right Pump: The right ejector pump is selected based on the property’s demands and size. Factors such as the amount of waste produced and the height of the required lift are considered.

Professional Installation: Installing an ejector pump requires specialized knowledge to ensure safe and reliable performance. Blue Sky Plumbing and Heating has skilled technicians who handle this with precision.

Testing and Adjustments: After installation, the pump is rigorously tested to make sure it operates correctly, and adjustments are made as necessary.

Routine Maintenance and Sewer Cleaning: To keep the pump working efficiently, regular maintenance is recommended, along with the Sewer Cleaning Service in Surrey, which provides insights into effective waste management across locations.

Common Issues with Ejector Pumps and How to Prevent Them

Ejector pumps, while durable, can face issues without proper maintenance:

Clogs and Blockages: Non-biodegradable materials can clog ejector pumps. Avoid flushing items like wet wipes and cooking grease.

Pump Overload: If the pump is undersized, it may not handle the waste load effectively. Consulting with Heating & Plumbing Experts in Vancouver can help identify the best pump size.

Motor Wear and Tear: Like any mechanical system, ejector pumps can wear out over time. Regular checks by Blue Sky Plumbing and Heating help catch issues before they become severe.

Preventive measures, such as scheduled cleanings and inspections by experts in both Drain Cleaning Service in Surrey and Sewer Cleaning Service in Surrey, can extend the life of your ejector pump and improve its efficiency.

Maintenance Tips for Ejector Pumps in Denver

For homeowners wanting to extend the lifespan of their ejector pumps in Denver, here are essential tips:

Regular Inspections: Set up regular inspections with Blue Sky Plumbing and Heating to catch any signs of wear and tear.

Proper Use: Avoid flushing harmful materials, which can lead to blockages.

Prompt Repairs: Any signs of leaks or unusual noises should prompt an immediate call to a professional. Timely intervention is key to maintaining your system.

Why Choose Blue Sky Plumbing and Heating for Ejector Pump Services?

Selecting the right service provider for ejector pumps in Denver is crucial. Blue Sky Plumbing and Heating stands out for several reasons:

Expertise in Plumbing and Heating Systems: With years of experience, they bring unparalleled knowledge to each project.

Commitment to Quality Service: Blue Sky Plumbing and Heating is dedicated to customer satisfaction, offering top-tier service for every installation and repair.

Cross-Region Expertise: Their approach is informed by knowledge from services like Heating & Plumbing Experts in Vancouver and Drain Cleaning Service in Surrey, ensuring a comprehensive understanding of plumbing systems.

Conclusion

In Denver, effective waste management systems are essential, especially in areas where gravity cannot drive waste flow. An ejector pump plays a pivotal role in keeping homes and businesses free from sewage backups and water damage. With professional services from Blue Sky Plumbing and Heating, properties in Denver can enjoy the benefits of a properly installed and maintained ejector pump system. From initial installation to ongoing maintenance, Blue Sky Plumbing and Heating offers the expertise needed to ensure your system runs efficiently.

Moreover, they bring in techniques from Sewer Cleaning Service in Surrey, Heating & Plumbing Experts in Vancouver, and Drain Cleaning Service in Surrey to create a holistic approach to waste and water management in Denver. By selecting Blue Sky Plumbing and Heating for your ejector pump in Denver needs, you are investing in both the functionality and longevity of your home’s plumbing system.

#drain services#drain sewer#sewer and drain services#professional sewer cleaning#commercial plumbing#drain cleaning#plumbing#plumbing services#heating and plumbing services#heating service#ejector pumps

0 notes

Text

Advances in Submersible Screw Pump Technology: Key Developments and Applications

The submersible screw pump has evolved significantly over the past few decades, driven by advancements in technology and increasing demand for reliable, efficient fluid-handling solutions. This article explores the latest developments in submersible screw pump technology, highlighting their key benefits and diverse applications across various industries.

Submersible screw pumps are designed to operate underwater or submerged within a fluid, making them particularly useful in applications where space constraints and fluid conditions pose challenges. Unlike traditional pumps, which may require extensive infrastructure for installation, the submersible screw pump can be placed directly within the fluid, simplifying both installation and maintenance processes.

Recent advancements in submersible screw pump technology have focused on enhancing efficiency, durability, and versatility. One notable development is the improvement in materials used in the construction of these pumps. Modern submersible screw pumps now incorporate advanced alloys and coatings that offer predominant resistance to corrosion and abrasion. This enhancement significantly extends the operational life of the pump and reduces the frequency of maintenance required.

Another key development in submersible screw pump technology is the integration of smart monitoring systems. These systems provide real-time data on the pump's performance, including flow rates, pressure levels, and energy consumption. By leveraging this data, operators can optimize the performance of the submersible screw pump, ensuring that it operates efficiently and reliably. Additionally, these smart systems can alert operators to potential issues before they become major problems, less downtime and maintenance costs.

The design of the submersible screw pump has also seen significant advancements. Modern pumps are designed with improved hydrodynamics, which enhances their ability to handle a wide range of fluids, including those with high viscosities or containing solids. This versatility makes the submersible screw pump suitable for various applications, from handling sewage and wastewater to transferring thick slurries in industrial processes.

In the agricultural sector, submersible screw pumps have become indispensable for irrigation and drainage systems. Their ability to operate efficiently in challenging conditions, such as muddy or debris-laden environments, makes them ideal for agricultural applications. The ability to handle varying flow rates and deliver consistent performance under different conditions ensures that irrigation systems remain effective and reliable.

In the oil and gas industry, the submersible screw pump plays a crucial role in the extraction and transportation of crude oil and natural gas. The pump's design allows it to operate in deep wells and harsh environments, where other types of pumps might struggle. Advances in submersible screw pump technology have enhanced their efficiency in handling high-pressure and high-temperature fluids, making them an essential component in modern oil and gas operations.

Municipal water treatment facilities also benefit from the advancements in submersible screw pump technology. These pumps are used for lifting and transferring wastewater, ensuring that treatment processes run smoothly. Enhanced durability and efficiency features in modern submersible screw pumps reduce the need for frequent maintenance and ensure that the pumps can handle the varying flow rates and pressures encountered in wastewater treatment.

Additionally, the mining industry has adopted submersible screw pumps for dewatering operations. The ability of these pumps to handle abrasive and corrosive fluids is particularly valuable in mining environments, where the conditions can be bad. Advances in materials and design have made submersible screw pumps more robust and reliable, ensuring that they can perform consistently even in challenging conditions.

As industries continue to push the boundaries of efficiency and performance, the submersible screw pump will undoubtedly play a vital role. Ongoing research and development efforts are likely to yield further improvements in pump technology, addressing emerging challenges and expanding the range of applications. The integration of advanced materials, smart monitoring systems, and innovative design features will continue to drive the evolution of the submersible screw pump, making it an even more valuable tool for fluid handling across various sectors.

In conclusion, the advancements in submersible screw pump technology have significantly enhanced the performance, efficiency, and versatility of these essential fluid-handling devices. From agricultural irrigation to municipal water treatment and industrial processes, the submersible screw pump has proven to be an invaluable asset. As technology continues to evolve, we can expect further innovations that will enhance the capabilities of the submersible screw pump, ensuring its continued relevance and effectiveness in meeting the diverse needs of modern industries.

0 notes

Text

Working Principle of a Sewage Lifting Pump - SFA Pumps

A sewage pump is a device that transports liquid and solid sewage from one location to another. Sewage is typically pushed from a sewage basin to a sewage system or a septic tank, where it may contain soft sediments up to 2 inches in diameter. At the bottom of the sewage basin, a submersible sewage pump is installed.

For more information click: https://www.sfapumps.in/en/15-installing-a-lift-station

0 notes

Text

Sewage & Treatment Pumps: Essential Solutions for Wastewater Management

Efficient and reliable wastewater management is critical for maintaining public health and environmental standards. Sewage and treatment pumps are vital components in this process, ensuring the smooth and effective handling of wastewater from residential, commercial, and industrial sources. In this blog, we will explore the features, benefits, and applications of sewage and treatment pumps, with a focus on the high-quality solutions provided by Raah International.

Understanding Sewage & Treatment Pumps

Sewage and treatment pumps are designed to transport wastewater, sewage, and sludge through the various stages of wastewater treatment processes. These pumps are built to handle solids, abrasives, and corrosive substances commonly found in wastewater, ensuring efficient and uninterrupted operation.

Key Features of Sewage & Treatment Pumps

Robust Construction:

Made from durable materials such as cast iron and stainless steel to withstand harsh wastewater environments.

Solids Handling Capability:

Equipped with features like large passageways and non-clog impellers to handle solids and debris without clogging.

Corrosion Resistance:

Constructed with materials that resist corrosion and wear, ensuring long-term durability and performance.

High Efficiency:

Designed to operate efficiently, reducing energy consumption and operational costs.

Easy Maintenance:

Built for easy access and maintenance, minimizing downtime and ensuring continuous operation.

Types of Sewage & Treatment Pumps

Submersible Sewage Pumps:

Features: Fully submersible, designed to operate while submerged in wastewater.

Applications: Used in sewage lift stations, sump pits, and wastewater treatment plants.

Centrifugal Sewage Pumps:

Features: Utilize a rotating impeller to move wastewater.

Applications: Commonly used in municipal and industrial wastewater treatment facilities.

Positive Displacement Sewage Pumps:

Features: Move wastewater by trapping a fixed amount and forcing it through the discharge pipe.

Applications: Ideal for handling high-viscosity sludge and slurry.

Grinder Pumps:

Features: Equipped with cutting mechanisms to grind solids into smaller particles.

Applications: Used in residential and commercial sewage systems to prevent clogs and blockages.

Screw Pumps:

Features: Use a helical screw mechanism to move wastewater.

Applications: Suitable for low-flow, high-head applications in wastewater treatment.

Benefits of Using Sewage & Treatment Pumps

Reliable Performance:

Engineered to handle challenging wastewater conditions, ensuring consistent and reliable operation.

Efficient Wastewater Management:

Designed to move large volumes of wastewater quickly and efficiently, reducing the risk of overflows and backups.

Cost-Effective:

High efficiency and low maintenance requirements lead to cost savings in operation and upkeep.

Environmental Protection:

Ensure proper wastewater treatment and disposal, protecting public health and the environment.

Versatility:

Capable of handling various types of wastewater, including residential, commercial, and industrial sources.

Applications of Sewage & Treatment Pumps

Municipal Wastewater Treatment:

Essential for transporting sewage from residential and commercial areas to treatment facilities.

Industrial Wastewater Treatment:

Used in industries to handle and treat wastewater generated from manufacturing processes.

Residential Sewage Systems:

Employed in home sewage systems to move wastewater to municipal sewage lines or septic tanks.

Commercial Buildings:

Utilized in commercial properties to manage wastewater from bathrooms, kitchens, and other facilities.

Agricultural Waste Management:

Used in agriculture to handle and treat wastewater from livestock and farming operations.

Raah International’s Sewage & Treatment Pump Solutions

Raah International offers a comprehensive range of sewage and treatment pumps designed to meet the diverse needs of various wastewater management applications. Their products are characterized by:

Advanced Technology: Incorporating the latest innovations to ensure superior performance, precision, and durability.

Robust Construction: Engineered for long-lasting reliability in demanding environments.

Custom Solutions: Providing tailored pump solutions to meet specific operational requirements and industry standards.

For more detailed information on Raah International’s sewage and treatment pump offerings and to explore a range of products tailored to your specific needs, visit Sewage & Treatment Pump page.

0 notes

Text

Discover the DAB FEKA VS 550 Automatic Sewage Pump, designed for lifting non-aggressive sewage and grey water with solids up to 50mm. This durable submersible pump features a waterproof motor, overcurrent protection, and 10m power cable. Ideal for fixed or portable installations. Contact us for reliable water management solutions.

#DAB FEKA VS 550#automatic sewage pump#submersible pump#sewage and grey water pump#water management solutions#centrifugal pump#non-aggressive sewage pump#UK sewage pumps#motor protection class F#vertical installation pump#Packaged Pumping Stations Ltd

0 notes

Text

Lift Station Pump

Understanding Lift Station Pumps: An Essential Component in Wastewater Management

Introduction: In the intricate web of urban infrastructure, there lies a critical but often overlooked component: lift station pumps. These unsung heroes play a crucial role in managing wastewater in both residential and commercial settings. Despite their significance, many are unfamiliar with the inner workings and importance of lift station pumps. In this article, we'll delve into the world of lift station pumps, exploring their functions, types, maintenance requirements, and the pivotal role they play in modern sewage systems.

Body:

Understanding Lift Stations

Lift stations, also known as pumping stations, are key elements in wastewater management systems, particularly in areas with varying elevations. These stations facilitate the transportation of sewage from lower to higher elevations, where gravity alone cannot accomplish the task efficiently. Lift stations typically consist of pumps, control systems, piping, and various sensors to monitor flow rates and system health.

Functionality of Lift Station Pumps

At the heart of every lift station lies the pump, the workhorse responsible for lifting sewage against gravity. These pumps come in different types, including centrifugal, submersible, and vacuum-assisted, each tailored to specific applications and station requirements. Centrifugal pumps, for instance, use rotating impellers to impart kinetic energy to the sewage, propelling it upward through the piping system.

Types of Lift Station Pumps

Centrifugal Pumps: Widely used in lift stations, these pumps are efficient and versatile, capable of handling various types of wastewater with minimal clogging.

Submersible Pumps: Designed to operate submerged in the sewage, submersible pumps are compact and require less maintenance compared to their counterparts.

Vacuum-Assisted Pumps: Ideal for scenarios where the lift required exceeds the capabilities of traditional pumps, vacuum-assisted pumps utilize differential pressure to move sewage effectively.

Importance in Wastewater Management

Lift station pumps are indispensable in ensuring the smooth flow of sewage through the collection and treatment process. By overcoming elevation differences, they enable the efficient transport of wastewater to treatment plants, preventing backups and overflows that can result in environmental contamination and public health hazards.

Maintenance Requirements

Like any mechanical system, lift station pumps require regular maintenance to operate optimally and prolong their lifespan. Maintenance tasks may include inspecting pump components, checking for leaks, cleaning debris from intake screens, and testing pump performance. Routine maintenance not only reduces the risk of costly breakdowns but also ensures compliance with regulatory standards for wastewater management.

Challenges and Considerations

Despite their critical role, lift station pumps are susceptible to various challenges, including clogging, corrosion, and power outages. Proper design, sizing, and installation are crucial considerations to mitigate these challenges and optimize pump performance. Additionally, implementing preventive measures such as backup power systems and alarm systems can help minimize disruptions and ensure uninterrupted operation.

Future Trends and Innovations

As technology continues to advance, so do innovations in lift station pumps and wastewater management systems. Emerging trends include the integration of smart sensors for real-time monitoring, the use of predictive analytics to anticipate maintenance needs, and the adoption of energy-efficient pump designs to reduce operating costs and environmental impact. Conclusion: In the grand scheme of urban infrastructure, lift station pumps may seem like minor players. However, their significance in wastewater management cannot be overstated. From facilitating the transportation of sewage to preventing environmental contamination, lift station pumps play a pivotal role in ensuring the health and well-being of communities. As we continue to innovate and improve our sewage systems, let us not overlook the humble lift station pump, an essential component in the quest for cleaner and more sustainable urban environments.

1 note

·

View note

Text

Are you Looking for Self Priming Pump Manufacturer?

If you are Looking for Self Priming Pump. Creative Engineers are the leading Self Priming Pump manufacturer and supplier in Ahmedabad, India.

We supply Self Priming Pump, Self Priming centrifugal pump, self-priming cum centrifugal pumps & cum centrifugal type mud pump in Ahmedabad, Vadodara, Vapi, Gandhinagar, Surat, Rajkot, Halol, Nagpur, Mumbai, Bangalore, Hyderabad, Pune, Pimpri Chinchwad. South Africa, Dubai, Nepal, SriLanka.

What is working of Self Priming pump?

Self Priming Pump is a category of pump designed to eliminate the need for manual priming for industrial solutions. Self-priming centrifugal pumps work by using a rotating impeller to create a low-pressure zone at the center of the pump, which causes fluid to be drawn into the pump through the inlet.

Applications

This unique feature of self-priming pump makes a particularly useful when dealing with suction lifts. Self-priming pumps are used in various industrial and commercial facilities, Pumping water, fuels, clear or gray water, raw sewage, industrial wastewater, and more.

For more details Click here: https://www.sspumpsindia.com/self-priming-centrifugal-pump/12

0 notes

Text

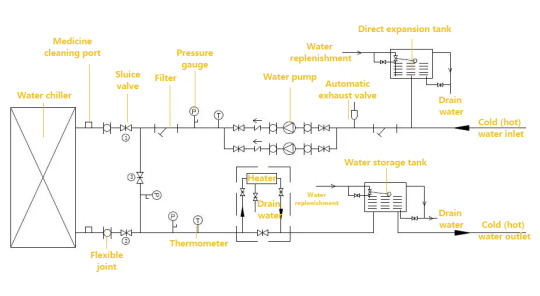

Installation content of air cooling modular cooling and hot water unit

The installation contents of air cooling modular cooling and hot water unit are divided into: host installation, fan coil installation, air duct installation, auxiliary equipment installation, water pipe construction, power distribution and communication, etc.

Host installation

Host installation location

The main engine is fixed with bolts, and there are shock cushion, cement pier, and drainage ditch below the unit. To sum up, the installation position of the host has the following requirements: installation foundation, fixed with bolts, shock absorption measures, and drainage channel. The host installation also considers the distance from the surrounding objects, and the distance is too close will affect the heat exchange. The general requirement is good ventilation and adequate maintenance space. The specification requires that the distance is not less than 3 meters from the roof, not less than 2 meters from the objects before and after, and not less than 1 meter between the units.

Host leak check

The equilibrium pressure of the system is generally close to the corresponding saturation pressure at the ambient temperature. After the unit is in place, the leakage inspection should be conducted step by step. The method is to observe the pressure gauge on the unit or measure the balance pressure of the system with the composite pressure gauge, which is required to be close to the corresponding saturation pressure at the ambient temperature.

Installation of fan coil

Installation mode of fan coil unit:

Air duct and room air outlet should be added soft connection, both vibration reduction and easy to install. Add 50~200mm soft connection between the air outlet and the air duct and heat preservation. Air duct shall be installed horizontally with diameter or long side size less than or equal to 400mm, spacing shall not be more than 4m; greater than 400mm, not more than 3m. The air duct shall be installed vertically, and the spacing shall not be greater than 4m, and a single straight pipe shall have at least two fixed points.

Auxiliary equipment installation

Main engine water inlet and water outlet:

Install soft connection, pressure gauge, thermometer and butterfly valve at the inlet and outlet of the main engine.

water pump:

The installation of the pump is relatively complex, the main purpose is to ensure the normal operation of the pump and facilitate maintenance. Many parts are installed in front and back, forming standard components, including manual stop valve, Y type filter, soft joint, pressure gauge, check valve, etc.

expansion cistern:

Expansion water tank is an important device to make the water system able to adapt to the volume expansion caused by the change of water temperature, stabilize the water pressure, and make the water system work stably. It is composed of water supply pipe, expansion pipe, overflow pipe, sewage pipe, and anti-freezing circulation pipe. The micro-pressure difference between the expansion tube and the circulation tube is used to form the water microcirculation to achieve the purpose of antifreezing.

Water pipe construction

In order to connect the main engine, the fan coil pipe and the auxiliary equipment, the water pipe construction should be carried out. This work mainly includes: lifting, bracket installation, pipe connection, pipe pressure test, pipe cleaning, drainage pipe installation and water testing, pipe insulation and protection.

distribution and communication

The power line specifications of air cooling module cooling and hot water unit are selected according to the requirements of the manual, and an electrical box needs to be specially made to install the AC contactor for auxiliary electric heating and water pump. The power supply of each module is independently controlled to facilitate unit management and maintenance.

0 notes