#rotary vane vacuum pump

Explore tagged Tumblr posts

Text

Rotary Vane Vacuum Pump

Falcon Vacuum Pumps & Systems offers high-performance rotary vane vacuum pumps designed for efficient and reliable operation across various industrial sectors. Our pumps are built with advanced technology to provide consistent vacuum levels, low maintenance, and long-lasting durability. Ideal for applications requiring precision, Falcon’s rotary vane pumps deliver unmatched reliability and performance.

0 notes

Text

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Rotary Vane Vacuum pump#Vacuum Furnace

0 notes

Text

The role of Lubricated Rotary Vane Vacuum Pump in medical applications

High efficient rotary vane vacuum pumps are dependable air-cooled, ideal for small facilities, easy installation and flexible equipment layout.

0 notes

Text

Rotary Vane Vacuum Pump

Rotary Vane Vacuum Pump is used for creating a vacuum in various applications,The pump operates by using rotating vanes (blades) that slide in and out of slots in a rotor, As the rotor turns the vanes create chambers of varying volumes, allowing the pump to draw in and compress gases or vapors, ultimately creating a vacuum.The cycle repeats as the rotor continues to rotate, creating a continuous vacuum.Efficient air cooling system.Pumping Speed=1050L/min; Ultimate Pressure=50-pa; Oil Capacity=2l; Rotating Speed=1400-rpm;for more visit Labtron.us

0 notes

Text

How does a rotary vane vacuum pump work?

Oil sealed rotary vane vacuum pump working principle

A rotary vane vacuum pump (referred to as a rotary vane pump) is an oil-sealed mechanical vacuum pump. Its working pressure range is 101325~1.33×10-2 (Pa), which belongs to the low vacuum pump. It can be used alone or as a backing pump for other high vacuum pumps or ultra-high vacuum pumps. It has been widely used in production and scientific research departments such as metallurgy, machinery, military industry, electronics, chemical industry, light industry, petroleum, and medicine.

The rotary vane pump can pump out the dry gas in the sealed container, and if it is equipped with a gas ballast device, it can also pump out a certain amount of condensable gas. But it is not suitable for pumping gas with high oxygen content, corrosive to metal, and chemical reactions to pump oil and dust particles.

The rotary vane pump is one of the most basic vacuum-obtaining equipment in vacuum technology. Rotary vane pumps are mostly small and medium-sized pumps. There are two types of rotary vane pumps: single-stage and two-stage. The so-called two-stage is to connect two single-stage pumps in a series structure. Generally, it is made into two stages to obtain a higher vacuum degree. The relationship between the pumping speed and the inlet pressure of the rotary vane pump is stipulated as follows: when the inlet pressure is 1333Pa, 1.33Pa, and 1.33×10-1 (Pa), the pumping speed value shall not be lower than 95%, 50% and 20%of the nominal pumping speed of the pump.

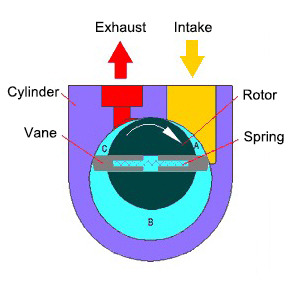

The rotary vane pump is mainly composed of the pump body, rotor, rotary vane, end cover, spring, and so on. A rotor is eccentrically installed in the cavity of the rotary vane pump, the outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small gap between the two), and two rotary vanes with springs are installed in the rotor slot. When rotating, relying on the centrifugal force and the tension of the spring to keep the top of the rotary vane in contact with the inner wall of the pump chamber, the rotation of the rotor drives the rotary vane to slide along the inner wall of the pump chamber.

The two rotating vanes divide the crescent-shaped space surrounded by the rotor, the pump chamber, and the two end covers into three parts A, B, and C, as shown in the figure. When the rotor rotates in the direction of the arrow, the volume of space A communicating with the suction port increases gradually, and it is in the process of suction. And the volume of space C communicating with the exhaust port is gradually reduced, just in the process of exhausting. The volume of space B in the middle is also gradually decreasing, which is in the process of compression. Since the volume of space A gradually increases (that is, expands), the gas pressure decreases, and the external gas pressure at the inlet of the pump is higher than the pressure in space A, so the gas is inhaled.

When space A is isolated from the suction port, it turns to the position of space B, the gas starts to be compressed, the volume gradually decreases, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas passes through the oil layer in the tank and is discharged into the atmosphere. The purpose of continuous pumping is achieved by the continuous operation of the pump.

One stage rotary vane vacuum pump working principle

The single-stage rotary vane pump has only one working chamber, and the pump is mainly composed of a stator, a rotary vane, and a rotor. The rotor is installed eccentrically in the pump chamber, and two rotating vanes are installed in the rotor groove, which is close to the cylinder wall due to the elastic force of the spring (there is also a centrifugal force of the rotating vanes after rotation). The rotor and vanes divide the stator cavity into suction and discharge.

When the rotor rotates in the stator cavity, the volume on the side of the air inlet is gradually expanded periodically to inhale the gas, while the volume on the side of the exhaust port is gradually reduced to compress the inhaled gas and discharge it from the exhaust valve.

The vent valve is immersed in oil to prevent atmospheric air from entering the pump. The vacuum pump oil enters the pump chamber through the oil hole and the exhaust valve so that all the moving surfaces in the pump chamber are covered with oil, forming a seal between the suction chamber and the exhaust chamber.

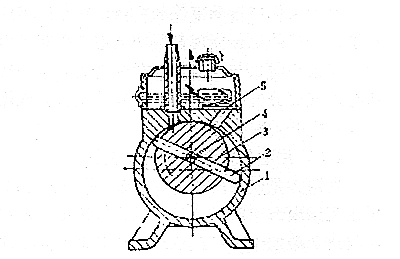

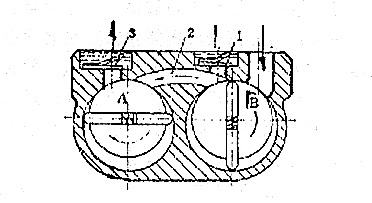

Two stage rotary vane vacuum pump working principle

In order to improve the ultimate vacuum of the pump, in addition to improving the machining accuracy of the pump body, rotor, and rotary vane, and minimizing the assembly gap and harmful space, the most effective way is to connect two single-stage pumps in series to form a two-stage pump.

The pump consists of two working chambers. The two chambers are connected in series and rotate in the same direction at the same speed. A chamber is the front stage of B chamber. A is the low vacuum stage and B is the high vacuum stage. The pumped gas enters the front stage through the high vacuum stage (B ), and is discharged out of the pump through the exhaust valve. The front stage (A) is the same as the single-stage pump, oil enters the pump chamber at any time, while the high vacuum stage (B) only has a small amount of oil when it starts to work, and no oil enters the pump chamber after working for a period of time. When the pump starts to work and the pressure of the inhaled gas is relatively high (such as starting to pump air from atmospheric pressure), the gas is compressed through the B chamber, and the pressure increases sharply, and a part of the compressed gas is directly discharged from the auxiliary exhaust valve (1) , and the other part is discharged through the front stage.

When the pump works for a period of time, when the pressure of the gas inhaled by the B chamber is low, even though it is compressed by the B chamber, the pressure cannot reach above one atmospheric pressure, and the auxiliary exhaust valve 1 cannot be discharged, and all the inhaled gas will enter The front-stage A room is discharged through the exhaust valve 3 through the continuous compression of the A room.

After the pump works for a period of time since the pressure of the high-vacuum stage air intake is greatly reduced, the outlet pressure is also very small, so the pressure difference between the inlet and outlet of the B chamber is also small, and the amount of compressed gas returned is correspondingly reduced; at the same time, the latter stage The oil molecules that are easy to evaporate in the pump are continuously sucked away by the front-stage A chamber, and the partial pressure of the oil vapor is reduced. Therefore, the oil pollution of the two-stage pump is smaller than that of the single-stage pump, and the ultimate vacuum degree will be greatly improved.

1 Stage vs. 2 Stage Rotary Vane Vacuum Pump

1 stage rotary vane pump consists of a single rotor with multiple vanes that rotates within a cylindrical chamber. As the rotor spins, centrifugal force pushes the vanes against the chamber wall, creating a seal and forming variable-volume chambers. The pumping action occurs through the expansion and compression of gas in these chambers, resulting in the generation of a vacuum.

Simplicity: 1-stage pumps have a straightforward design with fewer moving parts, making them compact, lightweight, and easy to operate and maintain.

Cost-Effective: These pumps are typically more affordable compared to 2-stage pumps, making them a cost-effective option for applications that do not require extremely low vacuum levels.

Suitable for Low to Medium Vacuum: 1-stage pumps are ideal for applications that require vacuum levels within the range of approximately 100 to 1,000 mbar (millibar).

Efficient for Low Gas Loads: They perform well when handling low gas loads, making them suitable for applications where gas flow rates are not excessive.

In a 2 stage rotary vane pump, the pumping process is divided into two sequential stages, each with its own set of vanes. The first stage, known as the high-vacuum stage, operates similarly to a 1 stage pump, creating an initial level of vacuum. The gas discharged from the first stage then flows into the second stage, where further compression occurs, resulting in even lower vacuum levels.

Higher Vacuum Levels: 2 stage pumps are capable of achieving significantly higher vacuum levels compared to 1 stage pumps. They can reach vacuum levels as low as 0.1 mbar or even lower.

Improved Gas Handling: These pumps are effective in handling higher gas loads and can efficiently evacuate larger volumes of gas.

Enhanced Backstreaming Resistance: The two-stage configuration provides better resistance to backstreaming, preventing oil or contaminants from reaching the vacuum chamber or system.

Suitable for High Vacuum Applications: 2 stage pumps are well-suited for applications requiring high vacuum levels, such as analytical instruments, vacuum coating, and semiconductor manufacturing.

#rotary vane vacuum pump#two stage rotary vane vacuum pump#rotary vane vacuum pump working principle

0 notes

Text

Why Eject System is India’s Go-To Manufacturer for Vacuum Pumps and Chillers

Efficiency, reliability, and innovation are the hallmarks of high-quality industrial equipment. Eject System, a leading name in the industry, specializes in offering cutting-edge vacuum pumps and chillers that enhance operational performance across diverse industrial applications. With a commitment to quality and customer satisfaction, Eject System delivers robust, efficient, and tailor-made solutions to suit the exact needs of its clients.

What sets Eject System apart is their dedication to precision engineering and the use of advanced technology. Every product is crafted to ensure durability and high performance, catering to industries that demand consistent and reliable results. Their expertise and customer-focused approach allow businesses to maximize efficiency and minimize downtime, ensuring smooth operations.

Trusted Liquid Ring Vacuum Pumps by Eject System for Demanding Applications

Recognized as a trusted industrial vacuum pump manufacturer, Eject System provides unparalleled solutions built for demanding environments. Their focus on innovation and high standards has cemented their position as one of the reliable rotary vane vacuum pump manufacturers in India, paving the way for performance-driven systems.

Eject System further strengthens its portfolio as one of the reputed liquid ring vacuum pump suppliers, delivering durable and efficient pumps for various industrial requirements. Additionally, their reputation as premier water chiller manufacturers in India underscores their commitment to excellence, offering energy-efficient cooling systems designed to meet the needs of modern industries.

Choosing Eject System means aligning with a partner that prioritizes your success. With a wide range of high-quality products, superior customer support, and a legacy of excellence, Eject System is the logical choice for businesses seeking reliable and innovative industrial solutions. Trust Eject System to empower your industry with precision and efficiency.

#water chiller manufacturers in India#liquid ring vacuum pump suppliers#rotary vane vacuum pump manufacturers in India#industrial vacuum pump manufacturer

0 notes

Text

Rotary Vane Vacuum Pumps and Single-Stage Rotary Vane Pumps are integral components used in various industries for creating a vacuum environment. These pumps are designed to remove air or gases from a sealed space, creating either a low or medium vacuum.

0 notes

Text

Reliable Rotary Vane Vacuum Pumps for Industrial Use

Get reliable performance and cost-effective solutions for your vacuum needs. Vacuum Pumps offers the best Rotary Vane Vacuum Pumps for industrial applications.

#industrial vacuum pumps#vacuum pumps#industrial equipment supplier#vacuum pumps australia#vacuum pumps suppliers#rotary vane vacuum pumps

0 notes

Text

#Rotary Vane Vacuum Pumps Market#Rotary Vane Vacuum Pumps Size#Rotary Vane Vacuum Pumps Growth#Rotary Vane Vacuum Pumps Trend#Rotary Vane Vacuum Pumps segment#Rotary Vane Vacuum Pumps Opportunity#Rotary Vane Vacuum Pumps Analysis 2024#Rotary Vane Vacuum Pumps Forecast

0 notes

Text

Rotary Vane Vacuum Pump

Falcon Vacuum Pumps & Systems is a trusted name in providing high-performance rotary vane vacuum pumps at very low price in the market. Designed for durability and efficiency, these pumps are perfect for various industrial applications. They ensure consistent, reliable vacuum generation, making them ideal for laboratories, manufacturing units, and more. Experience precision and quality with Falcon’s innovative vacuum solutions.

0 notes

Text

Exploring Advanced Vacuum and Helium Leak Detection Solutions

In industries ranging from manufacturing to research, vacuum systems play a pivotal role in ensuring operational efficiency and product quality. Among the various technologies available, rotary vane vacuum pumps, dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems have become essential tools. Let’s dive into the functionalities and applications of these systems to better understand their impact.

Rotary Vane Vacuum Pump: Reliable Performance in a Compact Design

The rotary vane vacuum pump is one of the most commonly used types of vacuum pumps. Its compact design, reliability, and versatility make it suitable for various applications. The pump operates by using vanes that rotate inside a cylindrical chamber, creating a vacuum by displacing air or other gases.

Applications:

Medical and Laboratory Equipment: Rotary vane vacuum pumps are used in medical applications such as vacuum-assisted wound closure systems and laboratory vacuum systems.

Packaging Industry: These pumps are integral to vacuum packaging machines, ensuring products remain fresh by eliminating air from packaging.

HVAC Systems: In heating, ventilation, and air conditioning systems, rotary vane pumps help in refrigerant recovery and evacuation processes.

Key benefits of rotary vane vacuum pumps include their durability, low noise operation, and ease of maintenance.

Dry Vacuum Pump: Oil-Free Efficiency for Sensitive Processes

Unlike rotary vane pumps, dry vacuum pump operate without the use of oil or any other sealing liquid. This makes them ideal for processes where contamination must be avoided.

Advantages of Dry Vacuum Pumps:

Clean Operation: With no oil involved, these pumps prevent contamination of the pumped gases or the environment.

Energy Efficiency: Many dry vacuum pumps are designed to consume less energy, reducing operational costs.

Low Maintenance: Without oil changes or sealing fluid replacement, maintenance requirements are minimal.

Common Applications:

Pharmaceutical Industry: Dry vacuum pumps are used in tablet coating and other sensitive pharmaceutical processes.

Semiconductor Manufacturing: These pumps play a critical role in processes like chemical vapor deposition and etching, where cleanliness is paramount.

Food Processing: Dry vacuum pumps are used in freeze-drying and vacuum cooling applications.

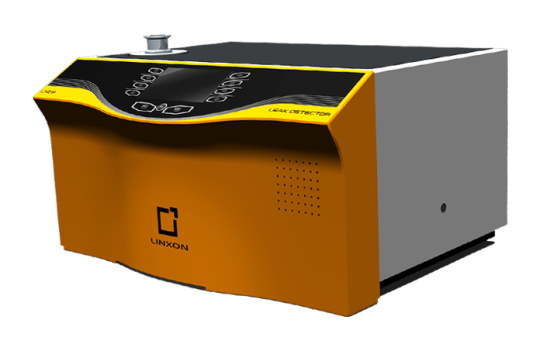

Helium Leak Detector: Precision in Leak Detection

Helium leak detector are essential tools for identifying and quantifying leaks in sealed systems. Helium is an ideal tracer gas due to its small molecular size and inert properties, making it capable of detecting even the tiniest leaks.

Working Principle:

A helium leak detector typically consists of a mass spectrometer that senses the presence of helium within a system. When helium is introduced into the system under test, the detector identifies any escaping helium, pinpointing leaks with high accuracy.

Key Applications:

Automotive Industry: Helium leak detectors are used to ensure the integrity of fuel systems, air conditioning systems, and exhaust systems.

Aerospace Sector: Ensuring leak-tight components in critical aerospace systems, such as fuel tanks and propulsion systems.

Medical Devices: Used in testing the hermeticity of medical implants and diagnostic equipment.

The precision and reliability of helium leak detectors make them indispensable for maintaining safety and quality standards.

Helium Leak Testing Machine: Comprehensive Leak Testing Solutions

A helium leak testing machine is a complete system that incorporates a helium leak detector, pumping systems, and control units to automate the leak testing process. These machines are tailored to meet the specific requirements of various industries.

Features and Benefits:

Automation: Automated testing reduces human error and increases throughput.

Customizability: Machines can be designed for specific applications, such as testing automotive radiators, batteries, or high-pressure vessels.

High Sensitivity: These systems can detect leaks at the micro-level, ensuring the highest standards of quality control.

Industrial Applications:

Energy Sector: Used for testing high-pressure gas cylinders and pipelines.

Electronics Manufacturing: Ensures the integrity of sealed electronic components such as sensors and displays.

Vacuum Technology: Essential in testing vacuum chambers and components for scientific and industrial applications.

Helium Recovery System: Sustainability in Leak Detection

As the demand for helium increases and its availability decreases, helium recovery system have become a critical component of modern leak detection setups. These systems capture and recycle helium, reducing operational costs and environmental impact.

How Helium Recovery Systems Work:

Capture: Helium used in the testing process is captured from the test environment.

Purification: The captured helium is purified to remove contaminants.

Storage: The purified helium is stored for reuse in subsequent tests.

Advantages:

Cost Savings: Reducing the need for new helium purchases can significantly cut costs.

Environmental Benefits: Minimizing helium waste supports sustainable operations.

Enhanced Efficiency: Continuously recycled helium ensures a steady supply for testing operations.

Applications:

Manufacturing Plants: Ideal for large-scale operations where helium usage is high.

Research Facilities: Ensures a sustainable supply of helium for experiments and testing.

Aerospace Industry: Critical for testing and maintaining expensive and sensitive components.

The Future of Vacuum and Leak Detection Technologies

With advancements in technology, vacuum systems and helium leak detection solutions are evolving to meet the growing demands of precision, efficiency, and sustainability. Integration with IoT and smart systems enables real-time monitoring and diagnostics, reducing downtime and increasing productivity. Moreover, the push toward eco-friendly solutions is driving the adoption of oil-free and helium recovery systems.

Final Thoughts:

Whether it’s a rotary vane vacuum pump ensuring efficient vacuum creation, a dry vacuum pump delivering oil-free operation, or a helium leak detector safeguarding the integrity of critical systems, these technologies are indispensable. Helium leak testing machines and helium recovery systems further enhance efficiency and sustainability, making them vital in today’s industrial landscape.

By understanding and implementing these advanced systems, industries can achieve higher standards of quality, safety, and environmental responsibility.

#Rotary Vane Vacuum pump#Dry Vacuum Pump#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System

0 notes

Text

Why Tekman Vacuum Pumps Are Ideal for Heavy-Duty Industrial Applications

When it comes to heavy-duty industrial applications, reliable and high-performance equipment is crucial. Tekman, one of the leading manufacturers of industrial vacuum pumps in India, stands out for its advanced technology and durable solutions. Tekman’s vacuum pumps are specifically designed to meet the demands of various industrial sectors, ensuring maximum efficiency, reliability, and cost-effectiveness. In this article, we will explore why Tekman vacuum pumps are the ideal choice for heavy-duty industrial applications.

High Efficiency and Performance

The great efficiency of Tekman vacuum pumps is one of the main factors that makes them perfect for demanding industrial applications. These pumps are designed to withstand the most taxing duties and continue to operate at their best for extended periods. The rotary vane vacuum pumps from Tekman are well-known for their capacity to function in harsh environments and at high pressures, which makes them ideal for sectors like manufacturing, chemical processing, and the automotive industry.

Advanced Technology for Precision

Modern technology is used by Tekman to create their vacuum pumps. Accurate and reliable performance is made possible by the use of sophisticated features like automated control systems. For applications where accuracy is crucial, such as helium leak testing devices and helium recovery systems, Tekman's vacuum pumps are perfect. Tekman's pumps are a great choice for these systems since they need to be extremely accurate to detect leaks and recover helium effectively.

Durability in Harsh Environments

Equipment used in heavy-duty industrial applications is frequently subjected to corrosive materials, high temperatures, and continuous operation. Tekman vacuum pumps are designed to endure these demanding circumstances. Their vacuum furnaces, for example, are made to function dependably in hot conditions. Tekman's pumps, whether used for material processing or heat treatment, provide enduring durability that enables businesses to minimize downtime and preserve seamless operations.

Versatility across Industries

Industrial vacuum pumps from Tekman are very adaptable and can be used for a variety of industrial applications. Tekman offers solutions that satisfy particular needs, ranging from vacuum furnaces used in the metallurgy sector to helium leak detectors used in the aerospace industry. Because of their versatility, Tekman vacuum pumps are a preferred option for a wide range of industries. These applications include vacuum impregnation, drying, and coating.

Energy Efficiency for Cost Savings

Energy efficiency is a crucial component in cutting operating costs in the cutthroat industrial environment of today. Industries can reduce their energy usage by using Tekman vacuum pumps, which are developed with energy efficiency in mind. For heavy-duty applications, where continuous pump running might result in high energy costs, this is especially crucial. Energy-efficient pumps from Tekman, such as their rotary vane vacuum pumps, are designed to use less energy while still providing excellent performance, which eventually saves organizations a significant amount of money.

Seamless Integration with Other Systems

Tekman vacuum pumps are made to easily interface with other industrial systems; they are not merely stand-alone devices. When dealing with intricate machinery such as helium recovery systems and helium leak testing devices, this integration is very crucial. With these solutions, Tekman's pumps function well, guaranteeing little interference and seamless operations. Many companies use Tekman because of its ability to integrate with other equipment, which improves the overall performance of industrial operations.

Customization Options for Specific Needs

When it comes to vacuum pump performance, many industries have different needs. Tekman provides a variety of pumps designed for particular industrial applications since it recognizes the need for customization. Tekman makes sure that its products satisfy the exact requirements of every business, whether that means creating pumps with specific specifications or modifying the vacuum levels. For instance, Tekman's pumps may be tailored to precisely match the requirements of helium recovery systems, guaranteeing efficient helium capture and little waste.

Maintenance and Support for Longevity

The upkeep and support services provided by industrial equipment are crucial to its success. By offering outstanding after-sales support, Tekman makes sure that their vacuum pumps keep operating at their peak efficiency. Even in heavy-duty applications, Tekman pumps have a longer lifespan thanks to routine maintenance and timely support services. Industries can guarantee that their equipment stays in optimal condition with Tekman's assistance, increasing uptime and total output.

Cost-Effectiveness Without Compromising Quality

Cost-effectiveness cannot be disregarded when selecting an industrial vacuum pump, even though performance and efficiency are important considerations. Tekman provides premium vacuum pumps at affordable costs, which makes them an economical choice for demanding industrial uses. Through the provision of long-lasting performance, energy savings, and minimal maintenance expenses, Tekman guarantees that its vacuum pumps offer exceptional performance for the money. In the market for industrial vacuum pumps, Tekman is a popular brand due to its price and quality balance.

Tekman’s Contribution to Environmental Sustainability

Tekman is a major player in the field of environmental sustainability, which is becoming a more significant consideration for industries. Their helium recovery systems and helium leak testing machine greatly aid in the reduction of helium waste, which is an essential resource for numerous industrial uses. By recovering and reusing helium, Tekman's pumps reduce their negative effects on the environment and encourage sustainability. Industries may achieve their environmental objectives while retaining good performance by investing in Tekman's vacuum pumps.

Reliable Performance for Heavy-Duty Applications

The vacuum pumps from Tekman are designed to function dependably even under the most demanding industrial circumstances. Tekman pumps provide reliable performance under all conditions, including high temperatures, demanding jobs, and continuous operation. Their vacuum furnaces work especially well in fields like metallurgy and heat treatment that need high temperatures to process materials. Because of Tekman's dedication to dependability, its vacuum pumps will continue to satisfy industrial sectors' demands for many years to come.

Simplifying Complex Processes with Tekman Pumps

Advanced equipment is necessary for complex processes in industries like manufacturing, automotive, and aerospace. Tekman's vacuum pumps make these procedures easier by offering dependable and effective solutions. Their pumps are made to tackle complex jobs like detecting helium leaks, which is essential for maintaining the integrity of aeronautical parts. Tekman's pumps are a great option for companies with demanding applications because of their capacity to streamline intricate procedures while upholding high performance requirements.

Enhancing Industrial Automation with Tekman

Tekman's vacuum pumps are essential to improving industrial automation as companies continue to adopt automation. The seamless functioning of automated systems is facilitated by the dependability and effectiveness of Tekman pumps. Industries may increase overall operational efficiency, decrease downtime, and boost output by incorporating Tekman pumps into automated production lines. An integral part of the contemporary automated industrial ecosystem is Tekman's pumps.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Rotary Vane Vacuum pump#Vacuum Furnace

0 notes

Text

Benefits of Oil less Rotary Vane Vacuum Pump

The benefits of oil-less rotary vane vacuum pump are low maintenance , Simple filter change and No lubrication fluids are required, safe and reliable to use and also environmental friendly no waste oil disposal issues its is easy installation process.

0 notes

Text

Unveiling the Power of Rotary Vane Vacuum Pumps

Introduction

Welcome to our comprehensive guide on rotary vane vacuum pump. In this article, we delve into the intricacies of these remarkable devices, exploring their functionality, applications, advantages, and key features. Whether you’re a seasoned professional in the field of vacuum technology or someone seeking to expand their knowledge, you’ll find valuable insights within these pages.

Understanding Rotary Vane Vacuum Pumps

Rotary vane vacuum pumps are mechanical devices designed to create a vacuum within a closed system by removing air or gas molecules. They operate on the principle of positive displacement, utilizing rotating vanes or blades to compress and exhaust air. This process results in the generation of a vacuum, making these pumps indispensable in a wide range of industrial, scientific, and commercial applications.

Applications

Industrial Applications

In the industrial sector, rotary vane vacuum pumps play a crucial role in various processes, including:

Vacuum Packaging: Ensuring product freshness and extending shelf life.

Material Handling: Facilitating the transportation of materials in manufacturing environments.

Chemical Processing: Handling corrosive gases and vapors safely and efficiently.

Medical Equipment: Powering devices such as vacuum ovens and freeze dryers.

Scientific and Research Applications

In scientific laboratories and research facilities, rotary vane vacuum pumps are utilized for:

Analytical Instrumentation: Supporting instruments like mass spectrometers and electron microscopes.

Vacuum Deposition: Creating thin films of materials for semiconductor and optical applications.

Space Simulation: Mimicking outer space conditions for testing aerospace components.

Commercial Applications

Beyond industrial and scientific realms, rotary vane vacuum pumps find application in various commercial sectors, including:

HVAC Systems: Assisting in the evacuation and maintenance of air conditioning and refrigeration systems.

Printing and Paper Handling: Enabling the removal of air from paper feed systems in printing presses.

Waste Management: Supporting processes such as vacuum sewage systems and waste oil recovery.

Advantages of Rotary Vane Vacuum Pumps

Efficient Operation

Rotary vane vacuum pumps offer high efficiency, providing reliable vacuum generation with minimal energy consumption. Their robust design ensures long-term performance and durability, making them a cost-effective solution for diverse applications.

Versatility

One of the key advantages of rotary vane vacuum pumps is their versatility. They can handle a wide range of gases and vapors, making them suitable for diverse process requirements. Additionally, they are available in various sizes and configurations to meet specific application needs.

Low Maintenance Requirements

Thanks to their simple design and fewer moving parts, rotary vane vacuum pumps require minimal maintenance. Routine tasks such as lubrication and filter replacement contribute to extended service life and operational reliability.

Key Features

Vane Configuration

The design of the vanes in a rotary vane vacuum pump significantly impacts its performance. Factors such as vane material, length, and arrangement influence parameters such as vacuum level, flow rate, and ultimate pressure.

Sealing Mechanism

Effective sealing is critical for maintaining vacuum integrity and preventing air leakage. Rotary vane vacuum pumps employ various sealing mechanisms, including oil-sealed and dry-running options, each offering distinct advantages based on application requirements.

Cooling Systems

To prevent overheating and ensure continuous operation, rotary vane vacuum pumps incorporate efficient cooling systems. These may include air-cooled or water-cooled configurations, designed to dissipate heat and maintain optimal operating temperatures.

Conclusion

In conclusion, rotary vane vacuum pumps represent a versatile and efficient solution for vacuum generation across a wide range of applications. With their robust design, high performance, and minimal maintenance requirements, they continue to play a vital role in industries ranging from manufacturing and research to healthcare and commercial sectors.

Read More : https://www.becker-international.com/in/1788/rotary-vane-vacuum-pumps-oil-lubricated.htm

0 notes