#role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors.

Explore tagged Tumblr posts

Text

#“”��Empowering effectiveness with Perennial Turbo Engine#Rubber processing oil manufacturers in Ahmedabad the special liquid used#automobiles and industrial types of applications to control#equipment temperature and control overheating Industrial Oil Industrial oil plays a pivotal#role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors.#expectations and maintain your engine’s Effectiveness#and at peak performance.“”“”Read More --“”/:https://perennialturbo.com/services/rubber-processing-oil-manufacturers-in-ahmedabad///“#Rubber processing oil manufacturers in Ahmedabad

0 notes

Text

Introduction to Refcon Engineering Works

Refcon Engineering Works boasts a rich legacy of delivering top-notch air filtration products and services. With years of experience and expertise, the company has earned a reputation for reliability, efficiency, and customer satisfaction.

Importance of Air Filters

Air filters play a pivotal role in removing airborne particles, contaminants, and pollutants from the air. They ensure cleaner and healthier indoor air quality, contributing to the well-being of occupants and the longevity of equipment.

Types of Air Filters Offered: Refcon Engineering Works offers a comprehensive range of air filters tailored to meet specific industry requirements. These include:

HEPA Filters: High-Efficiency Particulate Air (HEPA) filters are renowned for their exceptional filtration efficiency, capable of capturing even the smallest particles with high precision.

Pleated Filters: Pleated filters are designed to maximize surface area, allowing for increased particle capture and prolonged filter life.

Panel Filters: Panel filters are versatile filters suitable for various applications, offering reliable performance and ease of installation.

Manufacturing Process of Air Filters: Refcon Engineering Works employs advanced manufacturing processes to ensure the highest quality standards for its air filters. This includes meticulous material selection, precise fabrication techniques, and stringent quality control measures.

Applications of Air Filters: Air filters manufactured by Refcon Engineering Works find extensive applications across diverse industries, including:

HVAC Systems: Air filters are integral to HVAC systems, ensuring efficient air circulation and maintaining optimal indoor air quality.

Industrial Processes: In industrial settings, air filters play a crucial role in safeguarding equipment and processes from contamination, thereby enhancing productivity and product quality.

Automotive Sector: Air filters are essential components of automotive engines, preventing dust and debris from entering critical engine parts and ensuring smooth operation.

Benefits of Using Air Filters: The utilization of high-quality air filters offers several benefits, including:

Improved Air Quality: Air filters effectively remove pollutants and allergens from the air, leading to cleaner and healthier indoor environments.

Enhanced Equipment Performance: By preventing the accumulation of dust and debris, air filters help prolong the lifespan and improve the performance of HVAC systems and machinery.

Health Benefits: Clean indoor air, facilitated by efficient air filtration, promotes better respiratory health and reduces the risk of airborne illnesses.

Refcon Engineering Works’ Commitment to Quality

Refcon Engineering Works prioritizes quality in every aspect of its operations, from product design and manufacturing to customer service. The company adheres to stringent quality control measures to ensure the reliability and durability of its air filtration products.

Customer Satisfaction and Testimonials

Refcon Engineering Works takes pride in its commitment to customer satisfaction. Positive testimonials from satisfied clients attest to the company’s dedication to delivering superior products and exceptional service.

Sustainability Initiatives

As part of its corporate responsibility, Refcon Engineering Works is dedicated to implementing sustainable practices in its manufacturing processes, minimizing environmental impact, and promoting a greener future.

Global Reach and Presence

With a strong global presence, Refcon Engineering Works serves clients across various industries worldwide, providing tailored air filtration solutions to meet diverse needs and requirements.

After-Sales Support and Services

Refcon Engineering Works offers comprehensive after-sales support and services, including installation assistance, maintenance programs, and technical support, ensuring optimal performance and longevity of its air filtration systems.

Competitive Advantage

The company’s commitment to innovation, quality, and customer satisfaction gives it a competitive edge in the air filtration industry, making it a preferred choice for businesses seeking reliable filtration solutions.

Industry Recognition and Awards

Refcon Engineering Works has garnered recognition and accolades for its contributions to the air filtration industry, further solidifying its reputation as a market leader.

Conclusion

In conclusion, Refcon Engineering Works stands as a trusted name in the field of air filtration, offering high-quality products, innovative solutions, and unmatched customer service. With a focus on quality, reliability, and sustainability, the company continues to exceed customer expectations and set industry standards.

FAQs

1. Are air filters suitable for residential use? Yes, air filters are commonly used in residential HVAC systems to improve indoor air quality and protect equipment.

2. How often should air filters be replaced? The frequency of air filter replacement depends on various factors, including usage, environment, and the type of filter. It is recommended to follow manufacturer guidelines for optimal performance.

3. Can air filters help reduce allergies and asthma symptoms? Yes, high-quality air filters can effectively capture airborne allergens and pollutants, thus reducing allergy and asthma symptoms for occupants.

4. Do air filters contribute to energy savings? Yes, by maintaining clean air circulation and preventing equipment inefficiencies, air filters can contribute to energy savings and lower utility costs.

5. Are custom air filtration solutions available? Yes, Refcon Engineering Works offers customized air filtration solutions tailored to specific industry requirements and applications.

Contact us right away if you want to learn more about our wide range of Air Filter products. Call us at +91–9810388086 or send an email to [email protected], we are India’s largest Air Filter Manufacturers and Suppliers.

#air filter#Air Filter Manufacture#Air Filter Supplier#Air Filter Manufacturers in India#Air Filter Suppliers in India

1 note

·

View note

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

Comprehensive Guide to Land Freight Services in Dubai

Dubai is a global logistics hub strategically located at the crossroads of Europe, Asia, and Africa. While the city is renowned for its sea and air freight capabilities, land freight services play an equally crucial role in maintaining its position as a trade epicenter. This article explores the ins and outs of land freight services in Dubai, highlighting its infrastructure, advantages, and practical applications.

1. The Backbone of Dubai’s Logistics Network

Land freight services in Dubai are powered by an extensive road network that connects the UAE to neighboring countries like Saudi Arabia, Oman, and beyond. The Emirate's well-maintained highways and state-of-the-art border facilities streamline the movement of goods across the GCC (Gulf Cooperation Council) region.

Key Infrastructure:

Sheikh Zayed Road: The primary artery connecting Dubai to other Emirates.

E611 (Emirates Road): Offers alternative routes for heavy freight traffic, reducing congestion.

Al Ghuwaifat Border Post: Ensures smooth cross-border operations to Saudi Arabia.

2. Advantages of Land Freight Services

Dubai’s land freight industry offers unique benefits tailored to both domestic and international businesses:

Cost-Effectiveness: Land freight services are generally more affordable compared to air freight, making them ideal for bulk shipments.

Flexibility: With multiple transport modes like trucks and trailers, companies can customize their solutions based on cargo size and type.

Fast Turnaround for Regional Deliveries: Land freight ensures quicker transit for destinations within the GCC.

3. Types of Goods Transported

From perishable goods to industrial equipment, land freight services in Dubai handle a diverse range of cargo:

FMCG (Fast-Moving Consumer Goods): Transported quickly due to high demand.

Construction Materials: Essential for the UAE's booming construction industry.

Automobiles and Machinery: Leveraging specialized trailers and equipment for safety.

4. Challenges and Solutions

While land freight offers immense potential, it also comes with challenges such as:

Border Delays: Due to stringent customs procedures.

Weather Conditions: Sandstorms can temporarily disrupt transit schedules.

Solutions:

Partnering with experienced logistics providers ensures compliance and contingency planning.

Advanced GPS systems and route optimization reduce delays and increase efficiency.

Conclusion

Land freight services form the backbone of Dubai’s thriving logistics sector. With its robust infrastructure, strategic location, and seamless connectivity, Dubai continues to be a leader in land freight services across the GCC and beyond.

0 notes

Text

Best Foundry in India: The Secret to Superior Metal Castings

India has emerged as a global leader in the production of high-quality metal casting components. With cutting-edge technology, skilled workers, and a focus on precision, the best foundry in India have set the benchmarks in this sector. From motor castings to intricate parts such as gearbox spares, casting for pumps, and three-wheeler parts, foundries in India offer excellence in various sectors. This article explores why India is a hub for high-quality metal foundries. It also emphasizes the critical role that significant foundries play in shaping the industry.

The Role of the Best Foundry in India in Metal Casting Excellence

Metal casting is a unique process that involves shaping molten metal into a desired shape using a mold.The best foundry in India is famous for combining traditional techniques with modern advancements to produce high-quality cast parts. Foundries in India serve various sectors, including automotive, agriculture and construction. They produce parts that meet strict quality standards. With a robust infrastructure, These foundries have positioned themselves as leaders in the global market. The secret lies in being able to balance innovation with the cost-benefit ratio. Guaranteed durability and superior performance at the same time.

What Makes the Best Foundry in India Stand Out?

Expertise in Diverse Metal Castings

Foundries in India specialize in manufacturing a wide range of products, including motor-casting three-wheeler parts casting, gearbox spares casting, and pump castings. Each casting requires precise engineering, attention to detail, and compliance with international standards. The best casting employs qualified engineers who design the mold and ensure that the metallurgical properties of the final product are perfect.

Advanced Technology and Automation

Integrating advanced technologies such as 3D modeling and automation. It is a trademark of top foundry manufacturers in India. These technologies improve accuracy and reduce errors. This makes parts foundries in India more reliable for customers across the world. Automating processes also helps improve efficiency. Guaranteed on-time delivery without compromising on quality.

Motor Casting: Precision and Performance Redefined

Motor casting is one of the flagship of the best foundries in India. The process involves creating complex components such as engine housings and supports, which are an essential part of machines and vehicles. Foundries in India have excelled in producing motor casting components with thermal conductivity properties. Mechanical strength and excellent corrosion resistance. Utilizing superior materials and advanced techniques, These casting parts meet the needs of various industries. Including automotive and heavy engineering

Applications of Motor Casting

Automotive Industry: Used in engine components and electric motors.

Industrial Equipment: Essential for pumps and machinery.

Renewable Energy: Found in wind turbine generators and other energy-efficient systems.

Three-Wheeler Parts Casting: Driving Efficiency and Durability

Three wheelers are the backbone of India's transport sector. Three wheeler components require exceptional durability and precision. The best foundries in India play an essential role in manufacturing three-wheeler parts casting, including engine components, suspension parts, and chassis components. These castings are known for their durability. Lightweight features and savings

Why Indian Foundries Excel in Three-Wheeler Parts Casting

Cost Advantage: Competitive pricing without compromising quality.

Custom Solutions: Tailored designs to meet client specifications.

Eco-Friendly Practices: Use of sustainable materials and energy-efficient processes.

Gearbox Spares Casting: Ensuring Smooth Operations

Gearboxes are essential for transmitting power in machines and vehicles, making gearbox spares casting an important process. Foundries in India specialize in manufacturing gearboxes, shafts, and other prominent parts, which are highly resistant to adhesion and wear. The precision involved in casting these components guarantees perfect functionality, reducing the risk of mechanical failure.

Features of Gearbox Spares Casting

Dimensional Accuracy: Ensures perfect fitting in assemblies.

Durability: Withstands high stress and operational loads.

Versatility: Compatible with various machinery and automotive applications.

Pump Casting: Reliable Solutions for Fluid Management

Pump casting involves creating components for pumps used in industries such as agriculture, water management, and oil and gas. India's top foundry manufacturer specializes in manufacturing pump housings, impellers and volutes that provide superior corrosion resistance and mechanical strength. This meticulous process ensures that the components Can withstand high pressure and harsh environments.

Benefits of Pump Casting from the Best Foundry in India

Extended Lifespan: Resistant to wear and tear.

Energy Efficiency: Improves the overall efficiency of the pump.

Custom Designs: Tailored to meet industry-specific requirements.

Top Foundry Manufacturers: Leaders in Innovation

Foundries in India are globally recognized for their innovation and excellence. Top foundry manufacturers invest heavily in research and development to stay ahead of the competition. By combining advanced materials, Optimizing production techniques and maintaining strict quality control. They guarantee that their products are unrivaled.

Key Practices of Top Foundry Manufacturers

Sustainability: Adoption of green technologies.

Quality Assurance: Compliance with ISO and other international standards.

Client-Centric Approach: Focus on delivering tailored solutions.

How to Identify the Best Foundry in India

Selecting the right foundry is crucial for ensuring the success of your projects. Here are some factors to consider:

Experience: Look for a foundry with a proven track record in producing high-quality castings.

Certifications: Ensure the foundry complies with global quality standards.

Technology: Advanced facilities and automated processes are essential.

Customer Reviews: Positive feedback from clients is a strong indicator of reliability.

The Future of Metal Casting in India

The foundry industry in India is growing rapidly. With increased investment in infrastructure and technology, the best foundry in India will need to expand their capabilities. Emerging trends such as additive manufacturing and IA-based quality control are expected to revolutionize the sector and make it more efficient and sustainable.

Conclusion:

In summary, the best foundry in India is a beacon of quality, innovation, and reliability in the foundry industry. Whether you are looking for motor castings, three-wheeler parts casting, gearbox spares casting or pump castings, Indian foundries deliver unmatched solutions tailored to your needs. With a commitment to excellence and sustainability, these foundries are not just manufacturers but also partners in success.

By selecting the best foundry in India. You are guaranteed superior performance, savings and lasting results. Partner with your trusted foundry today to experience the difference in quality and skill.

Sigma Malleable proudly stands as the best foundry in India, delivering unmatched quality and innovation in metal casting. With expertise in manufacturing critical components such as motor castings, three-wheeler parts casting, gearbox spares casting, and pump castings, Sigma Malleable caters to industries including automotive, agriculture, and heavy machinery.

Our state-of-the-art facilities, advanced technology, and commitment to excellence ensure precision and durability in every product. Trusted by clients nationwide, Sigma Malleable combines superior craftsmanship with cost-effective solutions, making it a leader among top foundry manufacturers in India. Contact Sigma Malleable for superior metal casting solutions tailored to your needs.

#Best Foundry in India#Top Foundry Manufacturers#Motor Casting#three wheeler parts casting#Gearbox Spares casting#Pump Casting

0 notes

Text

In a world where voltage fluctuations are common and can disrupt essential operations, voltage stabilizers are crucial to ensuring a stable and consistent power supply. Businesses, industries, and homes in Oman often face challenges related to power instability, which can harm sensitive equipment, reduce efficiency, and even lead to costly repairs. Kiyumi, a leading voltage stabilizer supplier in Oman, provides reliable solutions to protect your equipment from these fluctuations and ensure continuous, stable power.

The Role of Voltage Stabilizers in Power Protection

Voltage stabilizers are devices that regulate the power supply and correct voltage fluctuations automatically. When there’s a sudden dip (low voltage) or surge (high voltage) in the supply, stabilizers adjust the output to the desired level, protecting your devices and appliances. They are particularly essential for equipment like:

Medical Devices: Hospitals and clinics rely on sensitive equipment that requires steady voltage for accurate diagnostics and patient care.

Manufacturing and Industrial Equipment: Many industries use machinery that can be damaged by unstable power, leading to production delays.

IT and Data Centers: Servers, storage units, and network devices require constant voltage to avoid data loss or corruption.

Home Appliances: Air conditioners, refrigerators, and TVs can suffer wear and tear from voltage fluctuations, shortening their lifespan.

Why Choose Kiyumi for Voltage Stabilizers in Oman?

Kiyumi has established itself as a trusted name in Oman, known for high-quality voltage stabilizers that cater to diverse applications. Here’s why businesses and households choose Kiyumi for their power protection needs:

Wide Range of Voltage Stabilizers Kiyumi offers an extensive selection of voltage stabilizers designed for different types of equipment, from small household appliances to industrial machines. Their range includes automatic stabilizers, servo-controlled stabilizers, and digital stabilizers, allowing customers to choose the best solution for their unique requirements.

High-Quality and Durable Products Kiyumi provides voltage stabilizers that are designed to withstand Oman’s unique climate and power challenges. Manufactured with high-quality materials and advanced technology, these stabilizers are built to last and operate efficiently even in demanding environments.

Expert Consultation and Custom Solutions Understanding that every application has unique power requirements, Kiyumi’s team offers expert guidance to help clients select the best stabilizer. They also provide custom solutions tailored to specific needs, ensuring that clients receive optimal protection for their equipment.

Efficient After-Sales Support Kiyumi’s commitment to customer satisfaction extends beyond sales. Their responsive after-sales service includes maintenance, repairs, and technical support to ensure your stabilizers continue to perform effectively over time.

Energy-Efficient Designs Kiyumi’s voltage stabilizers are designed with energy efficiency in mind, helping clients save on electricity costs while ensuring stable power. By using energy-efficient stabilizers, clients can enjoy long-term savings while reducing their carbon footprint.

How Kiyumi’s Voltage Stabilizers Benefit Various Sectors in Oman

Kiyumi’s voltage stabilizers cater to a wide range of applications, benefiting multiple sectors across Oman:

Healthcare Facilities: Voltage fluctuations can compromise the accuracy of medical devices. Kiyumi’s stabilizers protect equipment in hospitals, clinics, and laboratories, ensuring reliable performance.

Industrial and Manufacturing Plants: Fluctuations in voltage can halt production and damage machinery. Kiyumi’s high-capacity stabilizers are ideal for maintaining steady voltage in factories and manufacturing units, minimizing downtime and repair costs.

Retail and Hospitality: In Oman’s retail and hospitality sectors, stable power is essential for smooth business operations. Kiyumi’s stabilizers protect equipment like POS systems, HVAC units, and lighting, helping businesses avoid disruptions.

IT and Data Centers: For data centers that handle vast amounts of information, a voltage stabilizer is essential to prevent data loss or hardware damage. Kiyumi’s stabilizers ensure continuous and stable power, supporting reliable data management.

Choosing the Right Voltage Stabilizer with Kiyumi’s Expertise

When it comes to selecting the ideal voltage stabilizer, Kiyumi’s knowledgeable team is here to help. They evaluate factors such as:

Load Capacity: The stabilizer should match or exceed the power requirements of the connected devices.

Voltage Range: Depending on the severity of voltage fluctuations, the stabilizer’s input range can be chosen to match the power variations in the specific area.

Type of Stabilizer: Servo-controlled stabilizers are ideal for heavy-duty applications, while automatic digital stabilizers are perfect for smaller, sensitive devices.

The Kiyumi Advantage in Voltage Stabilizers

Choosing Kiyumi for voltage stabilizers in Oman means choosing quality, reliability, and peace of mind. Kiyumi’s solutions are designed to:

0 notes

Text

Reliable Kirloskar Gensets | High-Quality Gensets for All Power Needs

Understanding the Importance of Gensets in Modern Power Solutions

In today’s world, reliable power is essential across various sectors, from industries and hospitals to residential complexes and remote sites. Gensets, or generator sets, play a crucial role in providing backup power when there are outages or where grid access is limited. Among the various brands available, Kirloskar Gensets stand out for their durability, efficiency, and exceptional performance. When it comes to Diesel Gensets, Kirloskar has established a reputation for reliability, offering both high-performance and cost-effective power solutions that meet diverse requirements.

Why Choose Diesel Gensets?

Diesel Gensets have long been a popular choice for their fuel efficiency and durability. Unlike gasoline-powered generators, Diesel Gensets tend to consume less fuel while offering more robust performance, especially over extended periods. The construction of Diesel Gensets typically allows them to withstand more wear and tear, making them a preferred choice for industrial applications where heavy-duty power is needed. Kirloskar Diesel Gensets, in particular, are known for their superior engineering, ensuring long-lasting performance even in challenging conditions. With a Kirloskar Genset, you can expect both reliability and efficiency, reducing the long-term operational costs associated with power generation.

Key Features of Kirloskar Gensets

Kirloskar Gensets are engineered with innovative features to meet the evolving needs of power users. A Kirloskar Diesel Genset comes with a robust engine, designed to deliver consistent power while maintaining fuel efficiency. Many users choose Kirloskar Gensets because of their low operational noise, making them suitable for both commercial and residential applications. Additionally, these Gensets are built with advanced safety features, including automatic shut-off systems that activate during overloads or low fuel situations. This means that Kirloskar Gensets not only provide reliable power but also ensure safe operation under various conditions.

Applications of Gensets in Different Industries

Gensets are versatile power solutions used across multiple industries. In the healthcare sector, Diesel Gensets are critical for powering essential equipment and maintaining uninterrupted service in the event of a power failure. Kirloskar Gensets, with their reliable performance, are often the first choice for hospitals and medical facilities. Similarly, in the manufacturing and construction sectors, Gensets provide power for heavy machinery, ensuring smooth operations even in remote locations. Kirloskar Diesel Gensets are frequently deployed in these settings due to their durability and ability to handle high-power outputs, offering a dependable power source for challenging industrial applications.

Environmental Considerations of Diesel Gensets

One of the advantages of modern Diesel Gensets is their improved environmental profile. Advances in engineering have made Kirloskar Gensets more fuel-efficient, which helps in reducing carbon emissions. Additionally, many Kirloskar Diesel Gensets are equipped with emission control technologies, making them compliant with international environmental standards. This focus on sustainability makes Kirloskar Diesel Gensets a responsible choice for companies looking to reduce their carbon footprint while maintaining reliable power. By choosing a fuel-efficient genset, users not only benefit from lower operational costs but also contribute to a cleaner environment.

Maintaining Your Kirloskar Genset for Longevity

Proper maintenance is essential to ensure the longevity and optimal performance of Gensets. Regular checks on fuel levels, oil changes, and timely servicing are crucial for any Diesel Genset, including Kirloskar models. Kirloskar Gensets come with user-friendly maintenance guidelines, helping users keep their units in peak condition. Regular maintenance minimizes the chances of unexpected breakdowns, ensuring that your Genset is ready to provide backup power when you need it most. For those who rely on Gensets for critical operations, adhering to a maintenance schedule is key to preserving the reliability and efficiency of their power solution.

Choosing the Right Kirloskar Genset for Your Needs

Selecting the right genset depends on your specific power requirements. Kirloskar Gensets come in a wide range of sizes and configurations to meet varying needs, from small residential units to large industrial Diesel Gensets. Understanding your power requirements can help you choose a Genset with the appropriate capacity, ensuring that you have a reliable power supply during outages. Consulting with experts can also be beneficial in identifying the best Kirloskar Diesel Genset model based on your specific needs, whether it’s for emergency backup, remote locations, or continuous operation in high-demand environments.

Conclusion: The Reliability of Kirloskar Diesel Gensets

In summary, Gensets are essential in today’s world, where continuous power is crucial for business continuity, safety, and convenience. Kirloskar Gensets, particularly their Diesel Gensets, have proven to be highly reliable, efficient, and well-suited for various applications. Whether you need a backup power source for your home or a robust solution for an industrial site, Kirloskar Gensets offer versatile and dependable options. Investing in a quality genset like those from Kirloskar ensures that you’re prepared for power interruptions and that your operations continue smoothly, regardless of external conditions.

Related Searches

Gensets , Kirloskar Gensets , Diesel Genset, Kirloskar Generator

0 notes

Text

Hiwin Linear Motion Products: Transforming Industrial Efficiency

In today’s fast-paced industrial landscape, companies across various sectors are constantly seeking innovative solutions to improve efficiency, precision, and performance. A critical component in achieving these objectives is the use of advanced linear motion products that facilitate smooth, reliable movement in machines and equipment. One of the industry leaders in this domain is Hiwin, known globally for its comprehensive range of linear motion products that meet the high demands of modern machinery. As an authorized dealer, Jai Krishna Bearing House offers a broad selection of Hiwin’s products to its clients across India, backed by expertise, transparent business policies, and a commitment to exceptional service.

This article explores the Advantanges of Hiwin linear motion products, the role of Jai Krishna Bearing House as a key provider in India, and how these solutions are revolutionizing various industrial applications.

1. Overview of Hiwin Linear Motion Products

Hiwin offers a wide range of linear motion products, including linear guideways, ball screws, linear motors, and positioning systems, designed to ensure precision, durability, and efficiency. These products are ideal for various industries, from automotive manufacturing and medical equipment to automation and aerospace. Each product is crafted to meet the demanding requirements of high-speed operations, heavy loads, and harsh industrial environments.

Some popular Hiwin products include:

Linear Guideways: Designed for smooth, accurate linear movements, these are essential in systems requiring high precision and stability.

Ball Screws: Known for converting rotational motion to linear motion with exceptional accuracy, ball screws offer high efficiency and minimal backlash.

Linear Actuators: These facilitate motion control with precision, perfect for applications in automation and robotics.

Positioning Systems: Highly accurate systems that aid in assembly, inspection, and quality control processes, helping industries maintain high standards.

Each product is backed by Hiwin’s commitment to innovation and reliability, ensuring they provide long-lasting performance even in rigorous operational environments.

2. Importance of Hiwin Linear Motion Products in Industrial Applications

Hiwin linear motion products are invaluable in many industrial applications due to their capability to optimize efficiency, increase machine life, and minimize maintenance costs. Here are some of the key benefits:

a) Enhanced Efficiency and Productivity

Linear motion products allow for faster, smoother, and more precise movement, reducing machine downtime and enhancing overall productivity. Industries such as electronics, automotive, and packaging rely heavily on this technology to streamline operations, resulting in higher output and more efficient use of resources.

b) Cost savings and reduced maintenance

Hiwin products are designed to require minimal maintenance, resulting in reduced operational costs over time. High durability and robust construction also mean fewer replacements and repairs, which contributes to long-term savings for industrial enterprises.

c) Precision and accuracy

With industries increasingly leaning towards automation and robotics, precision has become a non-negotiable factor. Hiwin’s linear motion solutions enable machines to operate with extreme accuracy, which is critical in industries like pharmaceuticals, where even minor deviations can have significant repercussions.

d) Versatile Applications

Hiwin’s products cater to diverse applications, from industrial manufacturing to medical equipment and laboratory automation. This versatility makes Hiwin an ideal choice for companies seeking a reliable solution across multiple functions and applications.

3. Jai Krishna Bearing House: Authorized Dealer of Hiwin in India

Jai Krishna Bearing House is proud to be an authorized dealer of Hiwin linear motion products in India, serving a wide range of industries across the country. As a trusted name in the bearing industry, Jai Krishna Bearing House combines its expertise with Hiwin’s innovative technology to offer top-notch solutions tailored to the specific needs of Indian industries.

a) Comprehensive Product Range

As an authorized dealer, Jai Krishna Bearing House provides a comprehensive selection of Hiwin products, including linear guideways, ball screws, actuators, and positioning systems. This extensive range ensures that clients can find precisely the right product for their specific needs.

b) Spacious Warehouse Facilities

To ensure the safe storage and quick distribution of bearings, Jai Krishna Bearing House boasts a spacious warehouse where products are stored under optimal conditions. This setup enables the company to efficiently handle large volumes of orders, ensuring clients receive their products in perfect condition and on time.

c) Transparent business policies

Jai Krishna Bearing House has established a reputation for transparency and integrity in all business dealings. Clients appreciate this approach, which fosters trust and long-term relationships. The company’s dedication to clear communication and ethical practices has enabled it to build a strong client base both within India and internationally.

d) Extensive Client Base and Support

Jai Krishna Bearing House’s transparent policies and dedication to quality have helped the company build a loyal client base across various industries. With a strong presence in India and export relationships worldwide, Jai Krishna Bearing House is well-equipped to meet the growing demand for Hiwin linear motion products.

4. Key Industries Benefiting from Hiwin Products through Jai Krishna Bearing House

Jai Krishna Bearing House supplies Hiwin products to a wide range of industries, each benefiting uniquely from Hiwin’s state-of-the-art solutions:

Automotive: Hiwin’s precision products are crucial for manufacturing parts and assemblies in the automotive industry, where accuracy and durability are essential.

Packaging: Linear motion systems streamline processes in the packaging sector, enabling faster, more efficient packing and sorting.

Electronics: Precision and speed are critical in the electronics industry, where Hiwin’s products enhance manufacturing efficiency.

Medical and Laboratory: Linear motion products are indispensable in medical equipment, ensuring high accuracy in diagnostic devices and laboratory automation.

5. Why Choose Jai Krishna Bearing House for Hiwin Linear Motion Products?

As a reliable partner for industrial solutions, Jai Krishna Bearing House stands out for several reasons:

Authorized Dealership: Being an authorized Hiwin dealer in India ensures clients receive genuine products with full warranty and support.

Dedicated Support: Jai Krishna Bearing House provides technical assistance and guidance, helping clients choose the right products and offering after-sales support.

Client-centric approach: The company prioritizes client satisfaction through transparent business policies, clear communication, and a focus on long-term relationships.

Conclusion

Hiwin linear motion products are transforming industrial processes by offering advanced technology for precise, efficient, and reliable motion control. Jai Krishna Bearing House, with its vast expertise and commitment to excellence, is at the forefront of delivering these innovative solutions to industries across India.

For industries seeking to enhance their machinery’s performance and operational efficiency, partnering with Jai Krishna Bearing House for Hiwin products is a decision that promises quality, reliability, and lasting benefits.Contact for Hiwin linear motion products.

#best hiwin linear motion#hiwin linear products#hiwin linear guide distributors#hiwin ball screws#hiwin dealers in delhi#hiwin dealers in delhi ncr#hiwin linear bearing distributors#hiwin bearings suppliers

0 notes

Text

Exploring Precision Engineering With Deep Hole Drilling Machine By Widma

In the world of precision engineering, machinery plays a crucial role in ensuring accuracy, efficiency and quality. From aerospace and automotive to heavy industries, the demand for advanced machines that deliver high-precision results continues to grow. Among the key players in this sector are deep-hole drilling machine manufacturers, tool-grinding machine producers and those specialising in fine boring machines. One company that stands out for its expertise and innovation in this space is Widma, known for its state-of-the-art manufacturing solutions.

Deep Hole Drilling Machines: Precision at Its Best

Deep hole drilling is a specialised process used to create holes that are significantly deeper than their diameter. This process requires advanced machinery capable of maintaining high accuracy while dealing with the challenges of heat, lubrication and chip removal. Deep hole drilling machine manufacturers focus on producing equipment that can handle these tasks efficiently, often used in sectors like oil and gas, automotive and aerospace.

Widma, a leader in this industry, designs and manufactures cutting-edge deep-hole drilling machines that meet the exacting standards of modern engineering. Their machines ensure minimal deviation, high surface finish and excellent bore accuracy, making them a go-to choice for industries that require deep, precise drilling. The machines are equipped with advanced cooling and chip removal systems, ensuring smooth operation even in challenging environments.

Tool Grinding Machines: Enhancing Performance

Tool grinding machines are essential for maintaining the sharpness and precision of cutting tools. In industries where metal cutting is integral, the accuracy of the tool directly affects the final product's quality. Grinding machines are used to sharpen, reshape and refurbish tools, ensuring they perform at their peak efficiency.

Widma’s range of tool-grinding machines is designed to enhance the performance of cutting tools, whether for milling, drilling, or turning applications. With a focus on precision, their machines offer customisable settings for different tool types and materials, making them versatile across various industries. By investing in high-quality tool grinding machines, manufacturers can extend the life of their tools and ensure consistent performance.

Fine Boring Machines: Ensuring Perfect Bores

A fine boring machine is crucial when high-precision finishing of boreholes is required, particularly in automotive and aerospace applications. These machines are designed to achieve tight tolerances, improve surface finish and ensure the dimensional accuracy of boreholes. Fine boring is an essential process in engine manufacturing, gearboxes and hydraulic components where exact specifications are non-negotiable.

Widma offers highly advanced fine boring machines that ensure superior accuracy, surface finish and repeatability. These machines are equipped with modern control systems and precision tools, allowing operators to achieve the desired bore quality with ease. Widma’s fine boring machines are designed to handle both small and large-scale production, making them versatile across various industrial applications.

Conclusion

In the field of precision engineering, high-quality machinery is the backbone of efficient and accurate production. Deep hole drilling machine manufacturers, tool grinding machine producers and fine boring machine specialists like Widma are at the forefront of this technological revolution. Widma’s dedication to innovation and precision has made it a trusted name in the industry, offering advanced solutions that cater to the needs of diverse sectors. Whether it's deep hole drilling, tool grinding, or fine boring, Widma provides machines that ensure exceptional results, making it a preferred choice for manufacturers around the world.

0 notes

Text

"Empowering effectiveness with Perennial Turbo Engine,Rubber processing oil manufacturers in Ahmedabad the special liquid used in the cooling systems of machinery,automobiles and industrial types of applications to control equipment temperature and control overheating Industrial Oil Industrial oil plays a pivotal role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors. expectations and maintain your engine’s Effectiveness, and at peak performance.""Read More --"/:https://perennialturbo.com/services/rubber-processing-oil-manufacturers-in-ahmedabad///

#“”“Empowering effectiveness with Perennial Turbo Engine#Rubber processing oil manufacturers in Ahmedabad the special liquid used#automobiles and industrial types of applications to control#equipment temperature and control overheating Industrial Oil Industrial oil plays a pivotal#role in the smooth and efficient operation of machinery and equipment across diverse industrial sectors.#expectations and maintain your engine’s Effectiveness#and at peak performance.“”“”Read More --“”/:https://perennialturbo.com/services/rubber-processing-oil-manufacturers-in-ahmedabad///“#Rubber processing oil manufacturers in Ahmedabad

0 notes

Text

Examining Round Bars' Function in Manufacturing and Machinery

Rajkrupa Metal Industries is a highly ranked Round Bars Manufacturers in India. We have made a reputation for ourselves as one of the top companies in the Round Bars sector. Rajkrupa Metal Industries aims to be a top Round Bar manufacturer because of its highly skilled technical and commercial workforce. Let's delve into the diverse roles round bars play in machinery and manufacturing processes.

1. Shafts and Axles

Round bars serve as the backbone for shafts and axles in machinery. Their cylindrical shape allows for uniform distribution of stress and torque, making them ideal for transmitting rotational motion. From automotive driveshafts to industrial conveyor systems, round bars provide the structural integrity necessary to support heavy loads and maintain smooth operation.

2. Pins and Dowels

In manufacturing, round bars are commonly used as pins and dowels to align and secure components in place. Whether joining machine parts, assembling furniture, or constructing intricate mechanisms, round bars offer precise tolerances and reliable fastening solutions. Their cylindrical design facilitates easy insertion and removal, ensuring efficient assembly and disassembly processes.

3. Tooling and Fixtures

Round bars serve as foundational elements in tooling and fixtures for machining operations. They provide stable support and precise positioning for workpieces during milling, drilling, and turning processes. By incorporating round bars into jigs and fixtures, manufacturers can enhance productivity, maintain accuracy, and streamline production workflows.

4. Actuators and Linkages

In robotics and automation, round bars function as actuators and linkages to translate mechanical motion into desired actions. Whether controlling robotic arms, operating valves, or regulating machinery, round bars facilitate smooth and controlled movement across a range of applications. Their versatility allows engineers to design intricate motion control systems that optimise efficiency and performance.

5. Guide Rods and Linear Bearings

Round bars serve as guide rods and shafts in linear motion systems, providing support and guidance for sliding components such as bearings and bushings. By minimising friction and reducing wear, round bars enable smooth and precise linear motion in CNC machines, 3D printers, and industrial robots. Their high-strength construction ensures long-term reliability and accuracy in dynamic motion applications.

6. Structural Frameworks

Round bars play a vital role in constructing structural frameworks for machinery and equipment. Whether reinforcing frames, bracing structures, or supporting heavy loads, round bars provide the strength and stability necessary to withstand rigorous operating conditions. Their adaptability allows engineers to design robust frameworks that optimise space, minimise weight, and maximise durability.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India. We have made a reputation for ourselves as one of the leading manufacturers of Aluminium Bronze Round Bar. Rajkrupa Metal Industries has made a conscious effort to establish itself as a premier global producer and merchant.

Website: rajkrupametal.com

Source: Round Bars Manufacturer in India

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar

0 notes

Text

Best Construction Company in Dibrugarh

When it comes to quality construction in Dibrugarh, one name that stands out among the rest is Kohinoor Construction. Known for its commitment to excellence, Kohinoor Construction has been leading the industry with high-end construction services across various sectors. Whether it’s commercial buildings, infrastructure projects, or industrial developments, Kohinoor Construction ensures that each project is delivered with the highest standards, cutting-edge technology, and unmatched craftsmanship.

Why Choose Kohinoor Construction?

Choosing the right construction company is one of the most critical decisions in ensuring the success of any building project. Here’s why Kohinoor Construction should be your top choice in Dibrugarh:

1. Expertise and Experience

With years of experience in the construction industry, Kohinoor Construction has developed a strong reputation for handling a variety of projects. From large-scale commercial structures to small industrial units, the team’s expertise ensures timely completion while maintaining top-notch quality.

2. Timely Project Completion

A significant concern for many clients is the completion time of their projects. Kohinoor Construction guarantees efficient planning and execution, ensuring projects are completed on or ahead of schedule without compromising quality. This dedication to timelines reduces unnecessary delays and extra costs.

3. Use of Advanced Technology

Modern construction is heavily reliant on cutting-edge technology. Kohinoor Construction incorporates advanced machinery and equipment to boost productivity and ensure precision. From foundation laying to structural frameworks, the use of technology aids in delivering projects that meet international standards.

4. Sustainable and Eco-Friendly Practices

Environmental sustainability is at the forefront of construction practices today. Kohinoor Construction ensures that all their projects are carried out with minimal environmental impact. By integrating eco-friendly materials and waste management solutions, the company contributes positively to Dibrugarh’s environmental efforts.

5. Skilled Workforce

The strength of any construction company lies in the skills of its workforce. Kohinoor Construction employs highly trained engineers, skilled laborers, and project managers who work cohesively to ensure each project’s success. Their attention to detail ensures that each aspect of construction is handled with expertise.

Kohinoor Construction Services

Understanding the wide variety of needs in the construction sector, Kohinoor Construction offers a range of services that cater to diverse project types. Let’s dive into the specific construction services provided:

1. Commercial Construction

Kohinoor Construction specializes in creating commercial buildings that are not only aesthetically pleasing but also functionally efficient. Whether it’s retail spaces, office buildings, or shopping complexes, each commercial project is designed to provide maximum utility to clients while ensuring safety and compliance with local regulations.

2. Industrial Construction

Industrial facilities require specific planning and execution to accommodate large-scale operations. Kohinoor Construction understands these unique needs and delivers robust industrial structures such as warehouses, factories, and production units. The company ensures that each facility is built to withstand heavy use and integrates all the necessary utilities for smooth operations.

3. Infrastructure Development

Dibrugarh is rapidly growing, and infrastructure development plays a crucial role in its expansion. Kohinoor Construction takes pride in contributing to the city’s growth by constructing roads, bridges, and public facilities. These projects demand precision and durability, and the company excels in providing long-lasting infrastructure solutions.

4. Turnkey Construction Solutions

For clients who prefer a one-stop solution, Kohinoor Construction offers turnkey projects. These projects are managed from concept to completion, ensuring seamless coordination at every stage. Turnkey solutions reduce client stress by providing full accountability, from design to the final construction phase.

5. Renovation and Remodeling

Renovation is as important as new construction, and Kohinoor Construction excels in remodeling and refurbishing old structures. Whether it’s commercial spaces or industrial facilities, the company brings new life to old buildings, ensuring they meet modern standards while preserving structural integrity.

6. Pre-Construction Services

Planning is the key to a successful construction project. Kohinoor Construction offers pre-construction services, including feasibility studies, budgeting, and scheduling. By assessing the project beforehand, the company identifies potential risks and challenges, ensuring that projects proceed smoothly and efficiently.

Safety at Kohinoor Construction

One of the core values of Kohinoor Construction is its commitment to safety. Construction is a high-risk industry, and Kohinoor Construction adheres to strict safety protocols to ensure the well-being of its workers and clients.

1. Strict Safety Standards

Kohinoor Construction has implemented a comprehensive safety management system across all of its sites. This system ensures that all workers are equipped with the necessary protective gear, and all machinery is regularly inspected and maintained to avoid accidents.

2. Training and Development

To further enhance safety, Kohinoor Construction conducts regular training sessions for its employees. These sessions focus on the latest safety techniques, first aid procedures, and equipment handling. Continuous learning helps prevent accidents and ensures that every worker is well-prepared for any on-site situation.

3. Emergency Response

Accidents can occur at any construction site, but Kohinoor Construction is prepared for emergencies. Every site is equipped with emergency response teams and first aid kits, ensuring that any incidents are swiftly and efficiently handled.

Building Trust with Clients

Trust is the foundation of any successful project. Over the years, Kohinoor Construction has built a strong relationship with its clients by delivering quality work on time and within budget. Here’s how they ensure client satisfaction:

1. Transparent Communication

One of the key factors that sets Kohinoor Construction apart is its focus on transparent communication. Clients are kept informed at every stage of the project. From initial consultations to project handover, Kohinoor Construction maintains a clear line of communication, addressing any concerns immediately.

2. On-Time Delivery

Kohinoor Construction is known for its on-time delivery. Each project is carefully scheduled, with progress monitored closely to avoid delays. This ensures that clients can move forward with their plans without any setbacks.

3. Budget Control

Staying within the budget is crucial for any project. Kohinoor Construction takes meticulous care to plan expenses, ensuring that there are no cost overruns. The company provides clients with detailed financial reports and keeps them informed of any changes to prevent surprises at the end of the project.

Client Testimonials

Here are a few testimonials from clients who have experienced the exceptional work of Kohinoor Construction:

1. “We chose Kohinoor Construction for our industrial warehouse, and they delivered exactly what we needed. The project was completed ahead of schedule, and their attention to detail was outstanding.” – Mr. Arun Sharma, Dibrugarh

2. “Kohinoor Construction handled the renovation of our office building, and the result was beyond our expectations. Their team was professional and responsive throughout the project.” – Ms. Renu Dutta, Dibrugarh

The Future of Construction in Dibrugarh

As Dibrugarh continues to grow, the need for reliable construction companies becomes more essential. Kohinoor Construction is at the forefront of this growth, contributing to the city’s expansion through high-quality construction services. The company is committed to enhancing Dibrugarh’s skyline with sustainable, durable, and aesthetically pleasing structures.

Kohinoor Construction’s mission is to build not just structures, but trust, relationships, and a better future for Dibrugarh. As the city evolves, Kohinoor Construction will continue to deliver excellence, ensuring that each project, big or small, meets the highest standards.

Kohinoor Construction stands as the beacon of trust and reliability in Dibrugarh’s construction landscape. If you are planning a construction project in the region, don’t hesitate to reach out to Kohinoor Construction for a consultation. Let’s build the future of Dibrugarh, together.

0 notes

Text

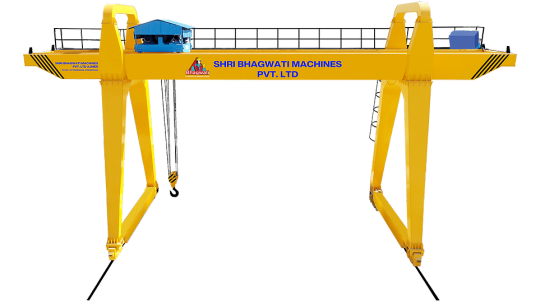

Understanding Cranes: A Comprehensive Guide for All Types of Cranes

Cranes are essential machinery in various industries, particularly in manufacturing and construction. They play a critical role in lifting, transporting, and arranging heavy objects and machinery. This guide will explore how cranes work, the different types available, and their specific applications, focusing on manufacturers of all types of cranes, including the cranes exclusively manufactured by Shri Bhagwati Machines Pvt. Ltd.

How Do Cranes Work?

Cranes operate on fundamental principles that allow them to lift heavy loads with ease. Here’s a breakdown of the basic operational principles:

1. Mechanical Advantage

Cranes utilize mechanical components such as levers and pulleys to gain a mechanical advantage. This reduces the amount of effort required to lift heavy objects, making it easier for operators to manage large loads.

2. Distribution of Loads

Cranes are designed to distribute weight evenly across their structure. This distribution minimizes structural stress and enhances stability during lifting operations. Key components such as the base, boom, and counterweights work together to maintain balance.

3. Control Systems

Modern cranes are equipped with sophisticated control systems that allow operators to maneuver loads precisely. These systems may include levers, joysticks, or remote controls, enabling smooth operation even in complex environments.

Types of Cranes and Their Purposes

1. Overhead & Gantry Cranes

Shri Bhagwati Machines Pvt. Ltd. is a prominent manufacturer of Electric Overhead Traveling (EOT) cranes, known for their exceptional quality and reliability. EOT cranes are essential in various industrial applications, providing efficient solutions for lifting and transporting heavy loads with ease. Designed to operate on a fixed track, these cranes feature a robust construction that ensures stability and safety during operation. The EOT cranes manufactured by Shri Bhagwati Machines are equipped with advanced control systems, allowing for precise maneuverability and enhanced operational efficiency. Their design maximizes workspace utilization, making them ideal for factories, warehouses, and construction sites. With a commitment to excellence,SBMPL has established itself as a trusted name in the crane industry, delivering high-performance EOT cranes tailored to meet the diverse needs of clients across various sectors.

Visit : https://bhagwatimachines.com/eot-cranes.html

2. Wall Mounted Cranes

SBMPL specializes in manufacturing high-quality wall-mounted cranes, designed to optimize space and enhance efficiency in various industrial settings. These cranes are ideal for environments where floor space is limited, as they utilize overhead areas effectively, allowing for the lifting and moving of loads without occupying valuable ground space.

Visit : https://bhagwatimachines.com/wall-cranes.html

3. JIB Cranes

We are a leading manufacturer of high-quality jib cranes, designed to enhance efficiency and productivity in various industrial applications. Jib cranes are versatile lifting solutions that feature a horizontal arm (jib) mounted on a vertical mast, allowing for flexible load handling within a defined radius.

4. Gantry/Goliath Cranes

We manufacturer high-quality gantry and goliath cranes, designed to meet the diverse needs of various industries. These cranes are essential for lifting and transporting heavy loads, making them invaluable in manufacturing, construction, and logistics.

Visit : https://bhagwatimachines.com/gantry-cranes.html

4. Semi Gantry Cranes

We are a prominent manufacturer of semi-gantry cranes, designed to provide efficient lifting solutions in various industrial applications. These cranes are characterized by their unique design, featuring one leg that runs on a track while the other is fixed to a wall or column. This configuration allows for greater flexibility in confined spaces where traditional gantry cranes may not fit.

Visit : https://bhagwatimachines.com/semi-gantry-cranes.html

5. Additional Crane Types

Mobile Cranes: These cranes offer mobility on job sites and can be driven on highways.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Rough Terrain Cranes: Designed for off-road use with enhanced stability on uneven surfaces.

Crawler Cranes: Feature tracks for mobility and can lift extremely heavy loads.

Floating Cranes: Used in maritime applications for loading and unloading cargo from ships.

Operational Procedures for Planning and Setup

Preoperative Planning: Engineers and operators assess the site, calculate load weights, and plan the lifting procedure to ensure efficiency and safety.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Lifting Procedure: Operators use control systems to raise the load while counterweights help maintain balance

Weight Shifting: Once lifted, the operator carefully moves the load horizontally using the boom or gantry system while ensuring precise synchronization to avoid obstructions.

Positioning: The operator gently lowers the load into place, often guided by signals from ground crew members to ensure accuracy.

Frequently Asked Questions regarding types of manufacturing and construction cranes

How do cranes work? Cranes used in manufacturing and construction are essential for lifting, transporting, and arranging large objects and machinery.

What is the Basic Crane Operation Principles Mechanical Advantage ? Cranes have an edge when lifting large objects because they use mechanical components like hydraulic cylinders, levers, and pulleys. This lowers the amount of work required to move objects.

How cranes helps in Distribution of Loads ? Cranes disperse weight uniformly, reducing structural stress and guaranteeing stability. To balance loads, the base, boom, and counterweights cooperate.

What are System Of Control in Cranes ? Control systems installed on cranes enable operators to precisely move loads. Levers, joysticks and occasionally remote controllers that are manipulated by hand fall under this category.

What are Overhead Cranes ? These tracks-based cranes are commonly observed in production facilities and have the ability to lift and transport objects within a predetermined region. They are very handy when transferring large items between warehouses or assembly lines.

What are wall-mounted Cranes ? ? Wall-mounted cranes serve a specific and valuable purpose in the manufacturing and construction industries. Here’s a detailed overview of their functions and benefits: Wall-mounted cranes allow for lifting and moving loads in areas where floor space is limited. They utilize overhead space, leaving the floor clear for other activities.Their installation against walls helps free up valuable floor space, making them ideal for smaller workshops or factories.

What are JIB Cranes ? Jib cranes are adaptable lifting tools that are frequently utilized in a variety of sectors, such as building, manufacturing, and warehousing. Jib cranes can raise and move big loads both horizontally and vertically, which makes them appropriate for a variety of tasks, including handling commodities and moving industrial parts.

What are the Operating Procedures for Planning and Setup in Manufacturing and Construction ? Engineers and operators arrange the lifting procedure, calculate load weights, and evaluate the site before starting up. Efficiency and safety are guaranteed by a proper setup.

0 notes

Text

Light Diesel Oil in Gujarat

Light Diesel Oil in Gujarat (LDO) is a vital fuel product, widely used in various industries for its efficiency and cost-effectiveness. Gujarat, known for its thriving industrial sector, relies heavily on fuels like LDO to power machinery, vehicles, and equipment. Gujarat, being one of India’s most industrially developed states, has a diverse range of industries including textile, chemicals, pharmaceuticals, and construction. These sectors require a consistent and efficient fuel supply to ensure smooth operations. KSGR Group is one of the prominent names in the fuel supply industry, known for providing high-quality Light Diesel Oil across Gujarat. It ensures that all batches of LDO meet industry standards, providing clients with fuel that guarantees efficient performance and low emissions. One of the major concerns for industries is the uninterrupted supply of fuel. KSGR Group has a robust distribution network that ensures timely delivery of Light Diesel Oil, no matter where the client is located in Gujarat. Understanding that different industries have unique requirements, It offers tailored solutions to meet specific fuel needs, ensuring maximum efficiency and cost savings for clients. KSGR Group provides high-quality LDO at competitive rates, making it an economical choice for industries looking to optimize their operational costs. While Light Diesel Oil is efficient and cost-effective, it is essential to consider its environmental impact. KSGR Group is committed to promoting sustainable practices by offering LDO that meets stringent environmental standards. This ensures lower emissions and reduced carbon footprint, helping industries align with green energy goals.

Choosing the right fuel supplier can make a significant difference in an industry’s operational efficiency. Here’s why industries in Gujarat prefer KSGR Group for their Light Diesel Oil needs:

Reliability: KSGR Group has built a reputation for being a reliable supplier, ensuring that clients never have to face fuel shortages.

Expertise: With deep industry knowledge, KSGR Group understands the needs of various sectors, offering solutions that perfectly align with client requirements.

Sustainability: The company’s focus on providing high-quality, low-emission LDO reflects its commitment to sustainability and responsible energy use.

Light Diesel Oil plays a crucial role in powering the industrial sector in Gujarat. Its versatility, efficiency, and cost-effectiveness make it an ideal choice for various applications. For businesses in Gujarat looking for a dependable Light Diesel Oil supplier, KSGR Group stands out with its quality products, excellent service, and customer-centric approach. With a focus on sustainability and competitive pricing, KSGR Group continues to be a preferred choice for industries across the state.

0 notes

Text

The Role of Heavy Equipment Companies in UAE's Construction and Industrial Growth

The UAE has witnessed tremendous growth in the last few decades, becoming a hub for construction, real estate, and industrial projects. From towering skyscrapers in Dubai to sprawling infrastructure developments across the region, none of these projects would be possible without the support of heavy equipment companies in UAE. These companies provide the machinery and equipment needed to build, maintain, and expand the nation’s rapidly developing landscape. Among these leaders in the sector, AAQ stands out for its exceptional services, cutting-edge equipment, and industry expertise.

Understanding the Importance of Heavy Equipment in the UAE

The UAE is synonymous with rapid development and growth, which heavily relies on the construction and industrial sectors. Large-scale projects such as road networks, bridges, ports, airports, and residential complexes require specialized heavy machinery. From excavators and bulldozers to cranes and loaders, heavy equipment companies in UAE supply the essential tools that enable these ambitious projects to take shape.

Without access to the latest heavy equipment, contractors and developers would find it challenging to meet the high standards expected in the UAE. Precision, safety, and efficiency are critical in every project, and the role of heavy equipment companies in UAE in meeting these requirements cannot be overstated. AAQ has positioned itself as a go-to partner for these industries, offering advanced machinery and services that contribute to the region's economic development.

Key Services Offered by Heavy Equipment Companies in UAE

Equipment Rental and Leasing Many contractors and developers in the UAE prefer renting or leasing equipment rather than purchasing new machines. Renting offers the flexibility to choose specific machinery for short-term projects without the commitment of long-term ownership. AAQ provides an extensive fleet of heavy machinery for rent, including cranes, bulldozers, excavators, and forklifts, giving businesses the flexibility to tackle a range of projects.

Sales of New and Used Equipment For businesses that prefer to own their machinery, heavy equipment companies in UAE like AAQ offer a wide selection of new and used equipment for sale. Whether you're looking for the latest model with cutting-edge technology or a reliable used machine that fits your budget, AAQ ensures that you have access to the best options.

Maintenance and Repair Services Keeping heavy equipment in top condition is crucial for the smooth execution of projects. Heavy equipment companies in UAE, such as AAQ, provide maintenance and repair services that minimize downtime and extend the lifespan of machines. Regular servicing ensures that all equipment operates efficiently and meets safety standards, which is essential in the fast-paced construction industry.

Consultation and Custom Solutions Every project is unique, and one-size-fits-all solutions rarely apply in construction and industrial projects. AAQ offers expert consultation services, helping businesses select the right equipment based on their specific project needs. Whether it’s a massive infrastructure development or a more specialized industrial task, AAQ provides custom solutions that ensure optimal performance and cost efficiency.

Why Choose Heavy Equipment Companies in UAE Like AAQ?

Diverse Range of Machinery One of the key advantages of working with leading heavy equipment companies in UAE is the variety of machinery available. AAQ takes pride in offering an extensive selection of top-quality equipment to suit different project requirements. From earth-moving equipment to industrial forklifts, businesses can find all the tools they need in one place, making AAQ a preferred choice for contractors and developers in the UAE.

High-Quality Standards The UAE has set global benchmarks for quality and safety in its construction and industrial sectors. In response to these demands, heavy equipment companies in UAE must provide high-quality, reliable machinery. AAQ ensures that all its equipment meets the stringent safety and quality standards required in the region, giving clients peace of mind as they work on their projects.

Timely Support and Logistics Timely delivery of heavy equipment can make or break a project. AAQ is known for its reliable logistics services, ensuring that machinery is delivered on time and ready for use. This efficiency is essential in a fast-paced market like the UAE, where delays can lead to significant cost overruns. With AAQ, you can count on seamless delivery, set-up, and ongoing support for your machinery needs.

Sustainable Practices As the world increasingly focuses on sustainability, heavy equipment companies in UAE have begun adopting eco-friendly practices. AAQ is committed to offering environmentally responsible solutions, providing fuel-efficient machines and maintaining rigorous standards to minimize emissions. These practices not only contribute to a greener environment but also help businesses meet regulatory standards related to sustainability.

The Future of Heavy Equipment in the UAE

As the UAE continues to grow and evolve, the demand for heavy machinery will only increase. From upcoming megaprojects like Expo City and Dubai Creek Harbour to new industrial zones and commercial developments, there will be a need for specialized heavy equipment that can handle the scale and complexity of these projects. Heavy equipment companies in UAE, particularly AAQ, will play an essential role in enabling the successful completion of these ventures.

In addition, technological advancements such as automation, AI, and IoT are set to revolutionize the way heavy machinery is used in the UAE. AAQ is at the forefront of this transformation, continually investing in the latest technologies to provide innovative solutions for their clients. This future-forward approach ensures that businesses partnering with AAQ remain competitive and can tackle the most demanding projects with ease.

Conclusion

The significance of heavy equipment companies in UAE cannot be understated when it comes to supporting the country’s infrastructure and industrial growth. Companies like AAQ offer a comprehensive range of services that include equipment rental, sales, maintenance, and consultation, ensuring that businesses have access to top-quality machinery for their projects.

Whether you are a contractor working on a residential development or a company overseeing a large-scale industrial project, partnering with a trusted name like AAQ guarantees that you will have the right tools to get the job done. As the UAE continues to develop and expand, heavy equipment companies in UAE will remain pivotal in shaping the future of the region.

For reliable, high-quality heavy equipment solutions, look no further than AAQ, your trusted partner in the UAE’s construction and industrial landscape.

0 notes

Text

Machine Handles Manufacturer and Wholesalers in Bangalore - Dirak India

Machine handles play a crucial role in enhancing the functionality and safety of industrial equipment, tools, and enclosures. As a leading manufacturer and wholesaler of machine handles in Bangalore, Dirak India is committed to delivering high-quality products that meet the diverse needs of industries such as manufacturing, automotive, and electronics. Our machine handles are designed to provide a strong grip, ease of use, and long-lasting durability, making them essential for various industrial applications.

The Importance of Quality Machine Handles

Machine handles are critical components in various machinery and enclosures, offering users a convenient and secure way to open, close, or operate equipment. The right machine handle ensures ease of operation, safety, and precision in industrial environments.

Key benefits of high-quality machine handles include:

Ergonomics: Properly designed handles reduce operator fatigue, ensuring comfort during repetitive tasks.

Durability: High-quality materials like stainless steel or engineering plastics ensure machine handles can withstand harsh environments, temperature fluctuations, and constant use.

Safety: Secure and stable grips reduce the risk of accidents and improve the overall safety of operations.

Dirak India: Leading Manufacturer of Machine Handles in Bangalore

At Dirak India, we pride ourselves on being a trusted manufacturer and supplier of machine handles, offering a wide range of products designed to meet the specific requirements of various industries. We use top-grade materials to ensure that our handles are strong, durable, and capable of withstanding tough industrial conditions.