#rice husk ash India

Explore tagged Tumblr posts

Text

Soda Feldspar Powder Manufacturers

Soda Feldspar Powder Manufacturers

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications.

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced.

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-North region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar, quartz, rice husk ash powders, and more. Soda Potash Feldspar

Our roots trace back to a founding team of IIT/NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs. Click for more information Soda Feldspar Powder

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click now for more update Potash Feldspar Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future. Click now Soda Feldspar Powder Manufacturers

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability.

0 notes

Text

U.S. Mortar and Admixtures In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

Concrete Admixtures Construction Chemicals Market Overview:

Global Concrete Admixtures Construction Chemicals Market revenue is expected to reach $16,324 million by 2023, from $11,027 million in 2016, with a CAGR of 5.7% from 2017 to 2023. Cement is used as a binding material in construction. Concrete admixtures are ingredients that are added to the concrete before or during blending for high workability, high strength, durability, watertight, wear resistant, and high finish. Various types of admixtures used in concrete are fly ash, silica fume, rice husk ash, superplasticizers, normal plasticizers, waterproofing agents, air-entraining agents, water-reducing agents, retarding agents, hydration-control agents, accelerating agents, anti-corrosion agents, coloring agents, and others. Three types of admixtures prevalent in the market are ligno-based, sulfonated naphthalene formaldehyde (SNF) & sulfonated melamine formaldehyde (SMF) based and polycarboxylate ether (PCE) based. Ligno-based admixtures were the first-generation admixtures with lower performance as compared to SNF & SMF- and PCE-based admixtures. The global concrete admixtures construction chemicals market is segmented based on type, application, and geography. Based on type, the market is bifurcated into mineral and chemical admixtures. Based on application, itis classified into residential, commercial, infrastructure, and repair structures. Geographically, itis categorized into North America, Europe, Asia-Pacific, and LAMEA.

Asia Pacific is anticipated to grow at significant rate from 2017 to 2023. Emerging countries, such as China and India, offer lucrative opportunities to market players, due to the growing urbanization and industrialization. Thus, significantly large population base, rise in construction activities and increase in disposable income are expected to drive the growth of the market in this region.

Top Investment Pocket

Residential complexes and buildings are in high demand in response to the perennial urbanization globally. Construction firms initiate comparatively larger number of residential projects with high-grade construction materials to provide improved structural integrity and sustainability. Residential segment is the most lucrative market in the concrete admixtures construction chemicals market and is expected, to grow at the significant CAGR during the forecast period. Infrastructure segment is the second accretive market in global concrete admixtures construction chemical market.

Segment Review

Chemical admixtures segment accounted for the largest share in concretes admixtures construction chemical market, owing to its high strength, excellent workability, high performance, and durability. It is expected to grow at a high CARG during 2017 to 2023.

LAMEA Review

The emergence of new markets in the LAMEA region has boosted construction schemes and elevated the living conditions of the population. The rise in urbanization and increase in living standards of people in Brazil is responsible for the growth in residential structures. As per the Brazilian Institute of Geography and Statistics, in 2012, the construction industry in Brazil accounted for about $109 billion. Further, growth in the construction industry is expected to drive the concrete admixture market in Brazil.

Some of the key players operating in the global concrete admixtures construction chemicals market are BASF SE, Arkema SA, Ashland Inc., Fosroc International Limited, Mapie S.p.A, Pidilite Industries, RPM International Inc., Sika AG, The Dow Chemical Company, and W.R. Grace & Company.

Other key concrete admixtures construction chemicals market players (not profiled in this report) in the value chain include CEMEX S.A.B de C.V., Conmix Ltd., CICO Technologies Ltd., and Chryso S.A.S.

Full Report With TOC:-https://www.alliedmarketresearch.com/concrete-admixtures-construction-chemical-market

0 notes

Text

What is heat insulation compound and how it works?

Heat insulation compound is a special chemical formulation which is made for decreasing the transfer of heat of massive extent, heat insulation compound is an insulation compound with sole heart absorbing properties which insulate against heat moving during soldering, welding, brazing or any other heat treatment.

The heat absorption properties shelter closely soldered parts, thin gauge metal, valve GASKETING and all other contents which could be harmed during installation and repair work. Heat insulation compound is used to protect plastic drain pipes in core proximity to metal pipes soldered or replaced. Heat insulation prevents distortion to plastic rubber, light gauge metals and plastic components and painted surfaces while brazing, welding or soldering.

This non-hazardous material might be formed around or on the surface of metal onto surfaces which may be damaged by heat flame during soldering or welding. It’s simply eliminated by wiping with running water or wet rags.

Clean surface to which heat insulation is to be applied, removing every dirt and grease. Apply a thick layer of Heat Sink totally surrounding the part to be soldered or welded.

Press tightly to eliminate air pockets and voids. Once the repair is done, eliminate heat insulation compound with running water or damp rag. This should leave no marks or stain and contains no toxic materials and is risk-free to the skin. Heat insulation compound is nonflammable and provides off no toxic fumes when exposed to heat.

Heat insulation compound is used in automotive, welding, plumbing, HVAC/R and shipyard industries, as-well-as other specialized industries. Heat insulation compound will:

· Protect against distortion of welded stainless

· Protect painted wiring, surfaces, tubing (rubber and plastic)

· Protect surrounding shells from flame

· Prevent surface staining of welded stainless

· Prevent harm to valves in close proximity to weld spot

· Prevent spatter from adhering to surrounding shells

· Prevent damage to adjoining valves and washers during sweating and soldering

· Protect surrounding surfaces from flame and heat

· Protect pipe insulation from flame and heat damage

· Protect valve gaskets all through plumbing repairs and many more.

· Protect cable from flame and heat during plumbing and welding repairs,

Use heat insulation compound where there’s a potential danger for Heat, solder in unwanted spots. Heat insulation compound is a heat absorbing paste that stops surface heat from adjoining spots. Protect again harm reasoned by excessive heat from soldering, welding, and all other heat-related treatment.

1 note

·

View note

Text

Precipitated Silica and Its Uses

According to Wikipedia.org, “Precipitated silica is an amorphous form of silica (silicon dioxide, SiO2); it is a white, powdery material. Precipitated silica is produced by precipitation from a solution containing silicate salts.”

Many companies these days produce precipitated silica by making an alkaline silicate solution and mineral acid react with each other. During the process, they add sulphuric acid and sodium silicate solutions to the solution concurrently. The chemical process terminates with production of a material which is powdery in texture, non-toxic in nature, and white in color.

The chemically balanced nature and superior properties of precipitated silica makes it useful for a variety of industries. Businesses from various industries use precipitated silica to product a variety of products. Hence, the usage and application of precipitated silica varies from across industry vectors.

Understanding Diversified Role of Precipitated Silica across Industries

Food and Medicines Industries

Unlike other components, precipitated silica does not accumulate in the body of human being. This property of precipitated silica makes it useful for food and medical industries. Many enterprises these days use precipitated silica as a core component for powdered soups, instant coffee and creamers to make the product flow more seamlessly.

Toothpaste Industry

Many businesses use precipitated silica as a core component for producing toothpastes and similar oral care products. They leverage precipitated silica as a thickening, cleaning and polishing agent to protect and clean teeth more effectively.

Rubber Industry

The rubber industry has been using precipitated silica since a long time. While producing rubber, enterprises use precipitated silica as a thickening agent and to boost bonding strength. They add precipitated silica to the liquid mixture to thicken the mixture, improve heat resistance and enhance control flow. Hence, precipitated silica helps companies to produce footwear, tires, gas pipes and conveyor belts which are more durable and tear-resistant.

Detergent and Plastic Industries

The properties of precipitated silica help businesses to produce plastic and detergent of higher quality. Like paint industry, plastic and detergent industry also use the chemical as a thickening and flattening agent. They even leverage the properties of the chemical to produce more durable plastic products.

Paint Industry

Precipitated silica is used widely by enterprises as a component for producing ink and paint. The ink and paint industries leverage precipitated silica as a thickening and flatting agent. The properties of precipitated silica further help these businesses to produce paint, adhesive, sealants and inks which are both high-performing and durable.

On the whole, precipitated silica is used by enterprises from various sectors to produce a variety of products. Its non-toxic nature and superior properties further make precipitated silica useful for various industries. The diversified role of precipitated silica can be determined from the consistent growth of the worldwide precipitated silica market.

According to a market research report released by Research and Research, “The precipitated silica market is set to escalate at a CAGR of 4.46% during the period 2017-2021. The precipitated silica is broadly divided into several applications such as electronics, automotive, personal care, food, agriculture, adhesives and sealants and others.”

#Precipitated silica manufacturers in india#Precipitated silica manufacturers in gujarat#Precipitated silica manufacturers#Precipitated silica from rice husk ash#Precipitated Calcium Carbonate manufacturers in india#Precipitated Calcium Carbonate manufacturers in gujarat#Precipitated Calcium Carbonate manufacturers#Highly dispersible silica manufacturers in india#Highly dispersible silica manufacturers in gujarat#Highly dispersible silica manufacturers#Highly dispersible silica from rice husk ash

1 note

·

View note

Text

https://www.databridgemarketresearch.com/reports/global-rice-husk-ash-market

#rice husk ash market#rice husk ash silica manufacturer in india#mesoporous silica market#Rice Husk Ash#precipitated silica from rice husk ash#rice husk definition#ashmarket

0 notes

Text

Improved Paddy Straw as Ruminant Feed: A Review-Juniper Publishers

Abstract

Paddy straw is a major agro-residue fed to ruminants in India. Feeding only rice straw does not provide enough nutrients to the ruminants even for maintenance due to the low nutritive value of this highly lignified material containing high concentration of anti-nutrition factors like lignin, silicates and oxalates. Despite the improvements of crop residues through various processing methods such as physical and chemical, the efficient utilization to desirable extent is still awaited. So utilization of paddy straw in association with concept of complete feed along with biological agents is need of the hour to maximize advantage from given feeds in animal production systems.

Introduction

In tropical zones of the world, ruminants depend on grazing on natural pastures usually during summer months when these pastures have abundant biomass or these animals are fed with cut grass and crop residues. Most of these areas face seasonal periods in which there is decrease in availability of herbages in these pasture. There is also reduction in the content of digestible energy and crude protein. In these areas rice straw is abundantly available from paddy cultivation and farmers offer rice straw as the main roughage source to their animals. This is particularly the case in developing Asian countries such as Thailand, Vietnam, Indonesia and India [1]. Approximately 80% of the world's rice is grown by small scale farmers in many developing countries including South East Asia (Table 1) and it is common to use rice straw for animal feeding. As per reports of Devendra [2] that of the total rice straw production, 30-40% is utilized for animal feeding in South East Asia, including China and Mongolia, as rice straw being the principal crop residue fed to more than 90% of the ruminant livestock in this area [3]. Rice straw becomes especially important during periods when other feeds are deficient. In general, the maximum intake of rice straw by ruminants is about 1.0 to 1.2kg per 100kg live weight [2]. As per Saritha et al. [4], the major agro-residues in terms of volumes generated in India (in million metric tons, MMT) were rice straw (112.00), rice husk (22.40), wheat straw (109.90), sugarcane tops (97.80) and bagasse (101.30).

Chemical composition of paddy straw and constraints in feeding to ruminants

The chemical composition of paddy straw varies between varieties and growing seasons, with higher nitrogen and cellulose contents in early season rice compared to others [5]. Paddy straw contains 25-45% cellulose, 25-30% hemi- cellulose and 10-15% lignin with low nitrogen, vitamins, minerals and high quantities of silica which hinder the nutrient availability to rumen microbes and eventually limits the necessary nutrient uptake for a satisfactory performance of the animals [6,7]. Presence of anti-nutritional factors like silicates and oxalates in rice straw with low nutritive value, poor palatability and limited ruminal degradation render paddy straw as non-maintenance type of fodder, so cannot support nutrient requirement of the animals when fed alone [6,8].

Compiled from Prasad et al. [39], Singh & Oosting [52], Shen et al. [49], Van Soest [59], Wanapat et al. [62], Ganai & Teli [19], Akinfemi & Ogunwole [4], Hossain et al. [22], Gomma et al. [21], Hussein et al. [23], Sheikh et al. [48].

The chemical and mineral compositions of rice straw, cited by different workers, are illustrated in Table 2. Rice straw consists predominantly of cell walls, comprised of cellulose, hemi cellulose, and lignin. To break down these components cellulase, hemi cellulase and ligninase are required [9]. In ruminants cellulase and hemicellulase are produced by rumen microorganisms however, lignin cannot be broken down in the rumen due to the lack of ligninase. Lignin, however, has important effects on livestock production through effects on degradability and feed intake. Theoretically, lignin located between the cellulose micro fibrils is regarded as the most abundant natural aromatic organic polymer that plays a role in resisting compressing forces, providing protection against consumption by insects and mammals, and also inhibiting the rate and degree of microbial degradation [10]. Silica, one element of the rice cell walls, can be present in high concentrations ranging from 5% to 15%, depending on the rice variety [11] and the availability of this mineral in the soil [12]. Silica reduces palatability and the degradability of rice straw in the rumen due to its direct action in preventing colonization by ruminal microorganisms [12,13]. The role of silica on the quality of rice straw was also reviewed by Van Soest [8], in an attempt to put into perspective the problems of silicon metabolism. Besides cell wall polymers, rumen organisms need other nutrients for growth and metabolism.

Since rice straw does not contain enough sugars, amino acids and minerals for efficient microbial growth, feeding ruminants with only rice straw, without any supplementation of other required nutrient sources, will result in poor performance of the animals [14]. The combination of low intake, low degradability, low nitrogen content and an unbalanced mineral composition means that rice straw alone may not even meet the animal's maintenance needs. Poor degradability is caused by a series of factors [9]. The fiber is very difficult to degrade, which is partly an intrinsic characteristic of the straw fiber (higher lignin and silca content). The degradation of the straw fiber is also complicated by the poor functioning of the rumen due to the unbalanced availability of nutrients, the low protein content, the lack of easily available energy and the low content of essential minerals such as phosphorus and sulphur. Hence, due to the low degradability and the poor rate of degradation, animals will tend to consume less. The generally accepted theory of feed intake regulation for poor quality roughages is that the capacity of the rumen to process the feed is the major factor determining voluntary feed intake [15,16]. The rumen processing capacity is characterized by rumen fill, the rate of degradation of potentially degradable matter and the rate of passage out of the rumen. Devendra [2] summarized that the main determinants of intake and degradability of rice straw depend on their morphological characteristics, such as the proportion of the different plant parts (leaves and stems), their chemical composition and the distribution of the different chemical components in the tissues, their relative amounts of cell contents and cell walls and the physical and chemical nature of the cell walls. These factors influence the chewing behavior of animals and the extent of fragmentation in the reticulo-rumen. As per Theander & Aman [17], rice straw contains a relatively high proportion of leaf (60%), compared to other cereal straws such as barley (35%), oats (43%) and wheat (20-41%). Vadiveloo [18] reported that leaves of rice straw contain less NDF than the stems, but more ash and acid-insoluble ash, resulting in a lower in vitro dry matter digestibility (IVDMD) of the leaves (50-51%) compared to the stems (61%). In goats, Phang & Vadiveloo [19] observed an in vivo dry matter digestibility of 56.2% for rice leaf and 68.5% for the stem. However, treatment with a 4% urea solution for 21d increased the IVDMD of the leaf fraction more than that of the stem fraction [18]. Since rice straw consists of approximately 60% leaves [20], which are less degradable than stems, improving the feed value of rice straw should focus on improving the degradability of the leaves.

Possible strategies to improve rice straw utilization in ruminants

Feeding only rice straw does not provide enough nutrients to the ruminants even for maintenance due to the low nutritive value of this highly lignified material. Basically, the key to improving the use of crop residues for ruminants is to overcome their inherent barriers to rumen microbial fermentation. In the case of rice straw, the important factors that restrict bacterial degradation in the rumen are its high levels of lignification and silicification, and its low contents of nitrogen, vitamins and minerals [21]. The high level of lignification and silicification, the slow and limited ruminal degradation of the carbohydrates and the low content of nitrogen are the main deficiencies of rice straw, affecting its value as feed for ruminants [8]. To improve the feeding value of rice straw, it can be treated with different means and methods and other required nutrients can be supplemented in the ration of the animal. Strategies to improve the utilization of rice straw are summarized.

Physical and chemical treatment

Extensive work has been done to improve nutritive value of crop residues by chemical and physical treatments. In physical treatment crop residues can be ground, soaked, pelleted or chopped to reduce particle size or can be treated with steam or X-rays or pressure cooked. Many of these treatments are not practical for use on small-scale farms, as they require machines or industrial processing. This makes these treatments in many cases economically unprofitable for farmers as the benefits may be too low or even negative [9] By treating rice straw with urea or calcium hydroxide or by supplementing rice straw with protein, the intake, degradability and milk yield can be enhanced as compared to feeding untreated rice straw alone [22,23]. In past years, several studies have been reported on the physical and chemical characterization and utilization of rice straw as ruminant feed [5,17,24]. In addition, numerous methods of physical, chemical and biological treatments have been investigated, including supplementation with other feed stuffs or components in order to improve the utilization of rice straw by ruminants [25-30]. The most commonly used alkaline agents are sodium hydroxide (NaOH), ammonia (NH3) and urea. Chemical treatments appear to be the most practical for use at farmers level, the chemicals are relatively cheap and the procedures to use them are relatively simple. However, safety precautions are needed for their use as these chemicals themselves are not harmless. Warly et al. [31] showed in a field trial that a ration of rice straw supplemented with soybean meal increased both degradability and intake. Because of the poor quality of untreated rice straw, supplementation easily can increase milk production, as shown for supplementation with cottonseed meal with an urea molasses- multi-nutrient block [28,32,33] and urea molasses treatment [34].

Rice straw is usually fed untreated without supplements in spite of the fact that many methods for improved utilization of rice straw have been developed and recommended. There are several reasons for farmers not to adopt the already developed methods for improved utilization of straw, such as physical, socio-economic conditions and practical reasons [2].

Biological Methods

Despite the improvements of crop residues through various processing methods such as physical and chemical, the efficient utilization to desirable extent is still awaited. Hence, it is the need of the hour to utilize these crop residues available in appreciable quantum locally in association with concept of complete feed technology and use of biological agents (feed additives) to maximize advantage from given feeds in animal production systems. Biological treatment is a much favorable option and is believed to be more eco-friendly and safer than the use of chemicals. Various methods of biological treatment/ fortification of paddy straw to enhance its utilization in animals include treatment with white rot fungi, ensilage with agro-industrial byproducts like apple pomace or fortification with proteins, greens or enzymes [35-38]. Although the use of white rot fungi causes significant loss of dry matter and organic matter [21,39] besides needs much more technical know and sometimes beomes impracticable at farmers level. The ensiling of straw with fruit pommace or poultry excreta or rumen liquor does not need sophisticated infrastructure with such facilities available at farmers level, but the advantage of these methods lies in fact of improving digestibility of nutrients, gain in body weight and overall performance of animals. Despite being safe and environmental friendly these biological agents have potent effect on digestibility of fodder by manipulating rumen environment. Gado et al. [40] reported decrease in the total phenolics, saponins and aqueous fraction with higher average daily gain, TDN and digestibility coefficients for DM, OM, CP, CF, NDF and ADF in Ossimi male lambs fed paddy straw ensiled orange pulp treated with exogenous enzymes diet than control. In other study Gado et al. [40] suggested a strong potential in improving digestibility and degradation of NDF and ADF of rice straw pre-treated with exogenous enzymes. Karunanandaa et al. [26,41] also reported enhanced IVDMD in both leaves and stems of rice straw by incubation with white-rot fungi (Pleurotus sajor-caju) for 30 days. However, entire rice straw (leaf and stem) treated with Cyathus stercoreus had the highest IVDMD compared to the other fungi. This improved digestibility of biologically treated straw is result of improvement in chemical composition as Akinfemi & Ogunwole [4] evaluated chemical composition and in vitro digestibility of rice straw treated with Pleurotus ostreatus, Pleurotus pulmonarius and Pleurotus tuber-regium found significant increase in the crude protein and significant decrease in crude fibre, cellulose, neutral detergent fibre, acid detergent fibre and acid detergent lignin of fungal treated rice straw than control. Fungal treated rice straw showed higher values of minerals (Ca and Mg), gas volume, metabolisable energy, organic matter digestibility and short chain fatty acid were also higher in fungal treated straw than control. White rot fungi efficiently degraded the lignin and enhanced the in vitro digestibility of paddy straw [4]

In another study Ganai & Teli [21] reported increase in CP, DCP and TDN content and nitrogen balance in Corriedale sheep fed paddy straw treated white rot fungi (Pleurotus ulmarius). Similarly Abdel-Azim et al. [42] reported that treating rice straw and corn stalks with Trichoderma viride, improved feeding value resulting in higher intake, N balance and growth rate in cross-bred lambs. The author also reported that DM consumption of fungal treated paddy straw was significantly higher than untreated straw. Bassiouni et al. [43] studied the effect of fibrolytic enzymes supplementation on In Situ degradability of DM, CP and CF of different rations consisted of concentrate feed mixture + berseem hay, dried sugar beet tops, corn silage, rice straw or wheat straw in different ratios 60:40or 40:60 incubated in canulated multiparous Friesian cows. Rations contained rice straw showed the lowest (P<0.05) values of in situ DM, CP and CF disappearance. In support of these findings Khattab et al. [37] studied chemical composition, nutritive value, in vitro digestibility and scanning electron microscopy (SEM) of rice straw (RS) and Pleurotus ostreatus spent rice straw (SRS) and reported higher protein, amino acids (mg/100g) content, in vitro dry matter disappearance (IVDMD) and in vitro organic matter disappearance (IVOMD) for SRS compared to RS while, DM, OM, NFE, CF, NDF, ADF, ADL, hemicellulose and cellulose were less for SRS than for RS. Pothiraj et al. [44] reported that fibrolytic enzymes of A. nigersuch as cellulase, p-glucosidase and xylanase had reduced the lignocellulose compound of the rice straw (Figure 1).

Some studies, using fibrolytic enzymes alone could not significantly increase the degradability of rice straw because the ability of these enzymes to break down the esterified bonds within lignin-carbohydrate complexes may be limited. However, when using in combination with other pre-treatments they could increase degradability and in vitro fermentation characteristics, as shown by Eun et al. [51] treated rice straw with xylanase or cellulase in combination with ammonia, Hussein et al. [52] treated rice straw with urea and commercial effective microorganisms, Liu & 0rskov [29] treated rice straw with cellulase in combination with steam pre-treatment, Wang et al. [46] treated rice straw with multi-enzymes (xylanase, β-glucanase, carboxymethyl cellulase and amylase) in combination with NaOH, found that the use of combinations of fibrolytic enzyme with these pre-treatments is expected to have a synergistic effect on the nutritive improvement of rice straw. evaluated use of rumen liquor, chicken manure and commercial probiotic to improve nutritional value of rice straw and reported that crude protein level of rice straw fermented with chicken manure was the highest followed by that of rumen liquor treatment and significantly different from those of commercial probiotic and control treatments. Crude fiber level of rice straw fermented with manure showed the lowest level but not significantly different from rumen liquor and commercial probiotics. These values were significantly lower than control. While assessing the effect of incorporation of wheat straw-rice straw (WS-RS in 50:50 ratio) or Pleurotus florida harvested spent WS-spent RS (50:50) in kids, Kaur et al. [47] observed a higher DM intake (0.80 vs. 0.65kgd-1), digestibility of majority of nutrients (except cellulose which was depressed), N-retention (5.36 vs. 4.87g), apparent biological value (63.08 vs. 53.43%) and daily live weight gain were comparable in both the groups. Apart from enzymatic treatment [37] reported the microbial application of rice straw degraded the lignocellulosic contents, thus improving the rumen DM degradability which would affect the weight gain of animal. By degrading the lignocellulosic contents of rice straw, more nutrients are made available for ruminal microflora, which in turn will sustain the longevity of the microbes.

More importantly, harmful microorganisms such as toxin-producing fungi that contaminate the rice straw could be suppressed by application of microbials on the feedstuff, proving its ability to restrain the growth of the harmful toxin- producing fungi. Gomaa [48] verified the potential benefits of supplementing rice straw with exogenous anaerobic bacterial enzymes (ZAD) and orange pulp for Ossimi sheep found significant (P<0.05) decreases in %CF, %NDF; while %CP, %ADF and %ADL values increased for rations containing either ZAD, orange pulp or both. Rams fed rations containing either ZAD, orange pulp or both significantly increased (P<0.05) ruminal ammonia-N, total volatile fatty acids plasma total protein with low level of gas production post feeding values. Similarly Salehpor et al. [49] evaluated the effect of rice straw processing by Lactobacillus, multi enzymes and calcium hydroxide on the digestibility and nutritional value. Each of three processing operation, reduce the amount of ADF, cellulose and hemicelluloses in the straw. The same trend also has been in the NDF and bacterial processing has the lowest and enzymatic, chemical and control straw have the greatest amount of NDF, respectively. The amount of gas production rate in the bacterial methods was more than the other methods and with increasing incubation time, shows upward trend. Addition of lignocellulolytic enzymes and bacterial lignocellulolytic on rice straw resulted in significant improvement of all the fermentation products (volatile fatty acid, acetate, propionate, butyrate, and ammonia) between control and treatment groups. Lignocellulolytic enzymes @ 5% of dry matter dose rate resulted in optimal products of volatile fatty acid and ammonia [50].

Similarly Samsudin et al. [51] found improved nutritive values of rice straw fed to goats when treated with Aspergillus niger, fungal and effective microbes (EM). No significant (P>0.05) difference was observed on the chemical composition of rice straw treated with A. niger except the CP content increased significantly (P<0.01) when compared with untreated rice straw. However, when the fungal-treated rice straw was inoculated with EM, significant (P<0.01) improvement was observed in DMD, CP, OM, NDF, ADF and cellulose content of the rice straw compared with control. In other study Elmoghazy et al. [53] evaluated effect of sheep diets containing lignolytic microbiological treated (Bacillus licheniformis, Ruminococcus albus, Aspergillus oryzae, Rhizopus nigricans & Saccharomyces cerevisiae) rice straw on blood parameters and nitrogen balance. Results exhibited that the microbiological treatments significantly decreased the DM and CF while CP was significantly increased. Regarding nitrogen balance, haemato- biochemical and serum enzymes (aspartate transaminase and alanine transaminase) were not affected with microbiological treatment. The use of combinations of fibrolytic enzyme with these pre-treatments is expected to have a synergistic effect on the nutritive improvement of rice straw. Especially, the use of lignin-degrading enzymes, originating from fungi, seems a promising development. Although, application of enzymes has proven to increase the feed value of poor quality feedstuffs, its use by smallholder farmers is, for the time being, economically unattractive. However, it becomes a promising technology when used at commercial level [54-65].

Conclusion

Rice straw being the principle agro-residues in terms of volumes generated in India, is poor in nutritive value with high level of lignification and silicification. So feeding of rice straw to livestock does not provide enough nutrients even for maintenance. Rice straw is usually fed untreated without supplements in spite of the fact that many methods for improved utilization of rice straw have been developed and recommended such as physical, chemical and biological treatments. Among these methods, biological treatment is a much favorable option and is believed to be more environmental friendly and safer.

To read more articles in JOJ Sciences

Please Click on: https://juniperpublishers.com/jojs/index.php

For more Open Access Journals in Juniper Publishers

Click on: https://juniperpublishers.com/journals.php

1 note

·

View note

Text

6 THINGS TO CONSIDER WHILE CHOOSING THE MATERIALS FOR THE PROJECT

AA good design is achievable only with quality materials and hence materials are the solution to a good functioning building. The quality of construction is majorly dependent on the materials utilized. The building materials you pick will define the overall durability, endurance, and character of the building. Thus, one should be cautious and particular while deciding building materials. The most beneficial means to decide materials that suit your requirements is by analyzing the stability, maintenance, aesthetics, and cost of each material.

There is a broad array of construction materials available and it can be challenging to decide the best possibilities for our various needs as the selection of construction material needs taking note of various factors.

Here are the 6 Things to Consider

1. Cost

When looking for various construction materials, one will realize that the rate varies extensively. As a rule of thumb, it is not always desirable to look for the most affordable products. One needs to take into account the lifespan or utility of the products. The cost of material is one crucial factor while choosing materials for construction as eventually, it will safeguard your building.

2. Climate

Another significant aspect of the selection of materials is the climate. Determinants like the average extent of heat or cold during the year, rain or snowfall, amount of daylight, needed ventilation are some points to consider. The construction material should respond to the climate and context. When climate appears in the picture, the characteristics of materials also evolve and help respond to the climate.

Also, Check Out: Product Design Companies in Bangalore.

3. Durability

Some materials serve longer and are more repellent to corrosion, moisture, and other environmental conditions. By determining the most suitable material for climate, we ensure that they are long-lasting. It is essential to consult experts when choosing building materials that respond to climatic conditions. It is hence desirable to get materials that demand as limited maintenance and replacement as likely so they can last through the actual life of the building and become profitable for the user.

They will help us to determine materials that are most suitable as per our requirements. The materials should be capable of adapting to the weather and climatic conditions. Some materials degenerate quickly, especially in a humid setting. Materials selected must have the durability and strength required for the specific area and condition of use.

Also, Check Out: Packaging Design Company India.

4. Availability

It is always advisable to acquire easily available materials. The availability of building materials also determines the cost and time for installation. Certain materials are locally available and are challenging to transport. Not only the shipping costs become expensive but it also postpones the work. On the other hand, if the material is locally obtainable, it minimizes the shipping cost. It’s also a time saver and work can be completed smoothly.

Also, Check Out: Top Industrial Designers in India.

5. Sustainability

With the evolution of the construction industry, the requirement for building materials is growing and is also accountable for the surge in carbon footprint, i.e. use of cement raises the carbon emission. Hence using eco-friendly and sustainable construction materials like earth, bamboo, fly ash, metakaolin, silica fume, rice husk ash, etc are beneficial rather than the use of cement or concrete. Locally found materials also reduce the transportation hassle and thus reduce the emissions.

Also, Check out: Design Studios in Bangalore.

6. Maintenance

The most suitable materials are those that are effortless or easy to maintain and manage. Maintenance will aid to preserve the building looking good and new for a long time.

Also, Check Out: Graphic Design Studios in Bangalore.

0 notes

Text

Rice Husk Ash Market Capacity and Application Forecast 2022-2028

Rice husk ash is the remaining by-product after combustion is done. In the context of China-US trade war and COVID-19 epidemic, it will have a big influence on this market. Rice Husk Ash Report by Material, Application, and Geography – Global Forecast to 2025 is a professional and comprehensive research report on the world’s major regional market conditions, focusing on the main regions (North America, Europe and Asia-Pacific) and the main countries (United States, Germany, United Kingdom, Japan, South Korea and China).

Get Sample Report @ https://martresearch.com/contact/request-sample/6/16307

In this report, the global Rice Husk Ash market is valued at USD XX million in 2022 and is projected to reach USD XX million by the end of 2028, growing at a CAGR of XX% during the period 2022 to 2028.

The report firstly introduced the Rice Husk Ash basics: definitions, classifications, applications and market overview; product specifications; manufacturing processes; cost structures, raw materials and so on. Then it analyzed the world’s main region market conditions, including the product price, profit, capacity, production, supply, demand and market growth rate and forecast etc. In the end, the report introduced new project SWOT analysis, investment feasibility analysis, and investment return analysis.

Get Enquiry Report @ https://martresearch.com/contact/enquiry/6/16307

The major players profiled in this report include:

l Yihai Kerry Investments

l Usher Agro

l Guru Metachem

l Agrilectric Power

l Rescon (India)

l Deelert

l Jasoriya Rice Mill

……

Get Discount Report @ https://martresearch.com/contact/discount/6/16307

The end users/applications and product categories analysis:

On the basis of product, this report displays the sales volume, revenue (Million USD), product price, market share and growth rate of each type, primarily split into-

Silica Content between 85-89%;

Silica Content between 90-94%;

Silica Content between 80-84%;

Silica Content More Than or Equal to 95%

……

On the basis on the end users/applications, this report focuses on the status and outlook for major applications/end users, sales volume, market share and growth rate of Rice Husk Ash for each application, including-

Building & Construction

Silica

Steel Industry

Ceramics & Refractory

Rubber

……

Contact Us:-

+1-857-300-1122

0 notes

Text

Fluidized bed combustion in solid fuel boilers

In order to generate steam, one of the first steps in the process is combustion. In order to produce steam and prevent greenhouse gas emissions from unburned fuels, solid fuel boilers ignite a variety of fuels. For efficient fuel combustion in solid fuel boilers, a process known as fluidized bed combustion is used. Using a calculated ratio of fuel to air, the fluidization technique facilitates combustion. To put it simply, a fluidized bed is a bed of solid particles that has been subjected to pressured fluid (gas or liquid) in such a way that the solid particles behave as a fluid under the right circumstances. The standard grate fuel fire system in India is hampered by the poor quality, low calorific value, and high ash content of the coal that is most readily accessible. Fuels including coal, rice husk, bagasse, agro waste, etc., burn cleanly and efficiently using fluidized bed combustion, and the process has several advantages over more conventional fire methods. Fluidized bed combustion's guiding principle When a gas or air is equally dispersed and transported upward over a bed of tiny solid particles, such as sand, combustion occurs. To begin with, while the particles' velocities are low, they don't interact with one another. The bed becomes fluidized when the particles reach a critical velocity at which they are suspended in the air stream. Fluidization is very sensitive to particle size and air velocity. The average velocity of a solid object moves more slowly than that of a gas. The slip velocity is defined as the speed at which one velocity is lower than the other. For optimal heat transmission, slip velocities must be maximised by the studded bed coils manufacturer. When sand particles in a fluidized condition are heated to the combustion temperature of coal while the coal is delivered steadily into the bed, it results in quick burning of coal and uniform temperature of the bed. Combustion in the fluidized bed happens at temperatures of 8400C to 9500C. It takes time, turbulent air, and high temperatures to start a fire. Limestone is used in the FBC's particle bed to reduce the release of sulphur dioxide and nitrogen oxide. Fluidized-bed combustion circulation When using the CFBC method, crushed fuel between 6 mm and 12 mm in size and limestone is introduced into the combustor. The bottom of the furnace comprises air distribution nozzles that provide upward-flowing air in which the particles are suspended. Between 840 and 900 degrees Celsius, fluidizing velocities vary from 3.7 to 9 metres per second, and combustion occurs at these temperatures. Without internal steam-generating tubes, the CFBC relies on heat exchangers on the outside. Particle circulation results in enough heat transfer and residence time for carbon and limestone usage & Economizer coil boiler Manufacturer. Greater area, fuel particle, and sorbent residence time are provided by CFBC for effective combustion and SO2 management in bigger process facilities. It is more cost-effective than AFBC and a good solution for medium to large boiler capacity burning low-grade fuel that needs control on sulphur emission.http://www.modernboilers.com/

0 notes

Text

Green Concrete - An Eco Friendly Concrete Substitute

One of the major issues in the 21st century is the increase in pollution. And the concrete manufacturing industry is seen as a major contributor to releasing toxic fumes into the air.

However, shutting down concrete industries doesn’t seem like a viable solution. What we need is an advanced type of concrete which does less damage to the environment. And this led to the manufacturing of green concrete.

In this blog, we will talk in-depth about green concrete.

What is green concrete?

Green concrete as the name suggests is eco-friendly concrete substitute, it is a sustainable form of concrete that does not harm the environment.

The term “green” in green concrete stands for the eco-friendly and waste material that is used in its manufacturing, the term “green” has nothing to do with the color of the concrete.

One of its components from which it is made up of is waste material. It reduces the waste and reduces the manufacturing cost of the concrete.

Hence, green concrete is a form of concrete that is eco-friendly and sustainable.

The scope of green concrete is growing rapidly in India as new projects are constructed to minimize harm to the environment.

Materials used in green concrete

Green concrete has waste material as one of its components. One or other type of waste material is used to replace the original components of the concrete.

Materials used in green concrete are :-

Industrial Waste

The byproducts of industries like fly ash, red mud, silica fumes, etc are used in the manufacturing of green concrete.

Also Read : Composition of High Strength Concrete

Agriculture Waste

The waste products of agriculture industries like rice husk ash, sugarcane bagasse ash, coconut husk ash, etc are utilized in the manufacturing of green concrete.

Recycled Aggregates

The aggregates that are generated from demolished concrete structures are also used as a component in the manufacturing of green concrete.

Substitutes of Sand

The original sand component is replaced with substitute sand. Substitutes like waste glass, sawdust, and manufactured sand replace the original sand component in the green concrete.

These were the components used in the manufacturing of green concrete.

Uses of green concrete

Green concrete is used in the manufacturing of green concrete buildings, these are eco-friendly buildings that are made to minimize the damage to the environment.

Other uses of green concrete are :-

Green concrete is used to decrease the demand for conventional concrete so that the industry can meet the huge demand for concrete.

Green concrete is used to reduce the emission of CO2 gas which is produced while manufacturing traditional concrete.

Green concrete recycles the waste material and this helps in minimizing the non-biodegradable waste.

Advantages and disadvantages of green concrete

Here are some advantages and disadvantages of green concrete.

Advantages of green concrete

Reduces the emission of CO2

Green concrete has good thermal and acid resistance

It is economic as compared to traditional cement

Green concrete provides better workability than conventional cement

Environment-friendly

Disadvantages of green concrete

It has less split tensile strength

It has high water absorption

A detailed analysis of green concrete is a must to understand its properties

Final Verdict

Buildings are touching the sky and so is the demand for concrete and green concrete acts as a good eco-friendly concrete substitute for traditional concrete and helps in tackling that high demand.

Therefore, green concrete is a great option with some hiccups.

0 notes

Text

Potash Feldspar Powder

Potash Feldspar Powder

Quartz Silica powder is a versatile material used across various industries for its unique properties In the glass industry, it serves a key ingredient, providing clarity and strength. In metal casting, quartz sand is combined with other substances to create durable molds. Additionally, it plays a crucial role in ceramics, abrasives, fillers, water filtration, and even in some personal care products, showcasing its wide-ranging applications.

Iota Metaflux is manufacturing and exporting Quartz powder in different grades for various Industrial uses. Iota metaflux is manufacturing Grade A quartz powder with high brightness of around 98% and high whiteness of 95% plus with confirmation of product quality through Rasin test in all the lots produced.

Iota Metaflux is also manufacturing Grade B and Grade Super Quartz powder for industries like paint Industry, Cement Industry, ceremic industry, coating Industry etc. We specilize in manufacturing quartz powder as per the clients specifications. Our Quartz powder is widely used in cement Industries for concrete slab manufacturing.

Welcome to Iota Metaflux, a thriving mineral manufacturing and supplying company established in 2010. Nestled in the heart of the Rajasthan-North region in India, our mines and processing plants yield an abundant supply of high-grade materials, specializing in feldspar, quartz, rice husk ash powders, and more. Soda Potash Feldspar

Our roots trace back to a founding team of IIT/NIT alumni with over two decades of industry experience. Comprising experts in Metallurgy and Material Science, Chemistry, Ceramic Engineering, and Chemical and Process Engineering, our professionals bring a wealth of knowledge to the table. At Iota Metaflux, we pride ourselves on our unique approach to understanding the science behind minerals, fostering high-level customer interaction to meet specific industrial needs. Click for more information Soda Feldspar Powder

We are committed to offering our clients top-notch, competitively priced raw materials with consistent and timely supplies. Our goal is to emerge as an industry leader, leveraging our unparalleled knowledge and expertise. From our in-house processing technology to the dedicated efforts of our R&D teams, we prioritize precision and maintain stringent quality standards. Click now for more update Potash Feldspar Powder

At Iota Metaflux, we operate under three core principles:

Top Quality: Our commitment to delivering products of the highest caliber sets us apart. We adhere to rigorous quality control measures to ensure our materials meet the most demanding industry standards.

Customer-Friendly: We understand the unique requirements of our clients and engage in meaningful interactions to tailor our offerings accordingly. Your satisfaction is our priority, and we strive to foster long-lasting partnerships.

Reduced Environmental Impact: We are dedicated to sustainability. By adopting eco-friendly practices and minimizing our environmental footprint, we contribute to a greener future. Click now Soda Feldspar Powder Manufacturers

As technology evolves, so do we. By staying at the forefront of industry advancements, we guarantee that our clients receive the best products available. Explore our site to discover how Iota Metaflux can provide you with quality, innovation, and reliability.

0 notes

Photo

Our tundish Covering Compound is an insulating powder having good expandability in the Tundish . Tundish Covering Compound is used in ladles tominimize heat loss from the liquid steel.

#rice husk ash seller#rice husk ash manufacturer#rice husk ash suppliers#rice husk ash India#rice husk ash

0 notes

Text

JBES Journal by INNSPUB | January Issue 2022

Journal Name: Journal of Biodiversity and Environmental Sciences | JBES

Content of The Issue

Anthropogenic noise reduces bird species richness and diversity along a Rur-urban gradient: A case study from a city in central India during nationwide lockdown amid COVID-19

By: Garima Tiwari and Fergus Mark Anthony

J. Bio. Env. Sci. 20(1), 1-9.

Assessing the suitability of fly ash and rice husk ash from Misamis Oriental, Philippines in producing bricks for pedestrian and light traffic applications

By: Liezl M Jabile, Jeffrey Ken B Balangao, Consorcio S Namoco Jr, Dave Raphael A Dumanat, John Paul M Relacion

J. Bio. Env. Sci. 20(1), 10-23.

Discrimination of bee populations in Côte d’Ivoire by geometrical morphometry

By: Assielou Brou Aubin, Adja Nahoule Armand, Abo Kouabenan, Wandan Eboua Narcisse

J. Bio. Env. Sci. 20(1), 24-31.

Distribution and eco-toxicological risk characteristics of polycyclic aromatic hydrocarbons in water from Changdang Lake, China

By: Javid Hussain, Ittehad Hussain, Raana Fahim, Jawad Ali, Zhang yunyun, Sadia Hassan Sherani

J. Bio. Env. Sci. 20(1), 32-42.

Ethnobotany of Oyster nut (Telfairia pedata) in Northern Tanzania

By: Philipina F. Shayo, Anna C. Treydte, Ernest R. Mbega

J. Bio. Env. Sci. 20(1), 43-52.

Invisible waste: Understanding the political culture of solid and liquid waste management in towns of Tanzania

By: Francis Moyo, Hans C Komakech

J. Bio. Env. Sci. 20(1), 53-61.

Organizations environmental awareness and attitude

By: Mary Jane J. Bulusan

J. Bio. Env. Sci. 20(1), 62-76.

A checklist of traditional and wild edible phyto-resources sold in the local markets of Kokrajhar, Assam

By: Bhisma Narayan Swargiari, Rubul Buragohain, Smriti Rekha Sonowal

J. Bio. Env. Sci. 20(1), 77-84.

Distribution, diversity and roles of insects in mulberry plantation

By: Elizabeth P Obra

J. Bio. Env. Sci. 20(1), 85-92

Geospatial analysis of soil erosion rates using RUSLE and GIS model in Bong-bong Subwatershed Pangantucan Bukidnon

By: Dr. Ricardo G. Villar, Neli Jean L. Remotigue

J. Bio. Env. Sci. 20(1), 93-104.

Get the full issue by following the link Archive for | JBES |- January, 2022

Call for Papers 2022 | INNSPUB Journals

INNSPUB Journals invites all respected researchers to submit their research papers, review papers, short communication, etc. in the different fields of Natural Sciences and Life Sciences including Biology, Biodiversity, Environmental Science, Agronomy, Agricultural Research, Ecology, Zoology, Botany, Mineralogy, Oceanology, Oceanography, Hydrology, Plant Sciences, Animal Sciences, Fisheries, Genetics, Biochemistry, Plant Physiology, Biotechnology, Molecular Biology, Microbiology, Pathology, Cell Biology, Aquatic Biology, and Agricultural Sciences.

1 note

·

View note

Text

Rice Husk Ash Market by Product, Types, Procedure, Application, End-user Global Forecast to 2029

Industry Analysis

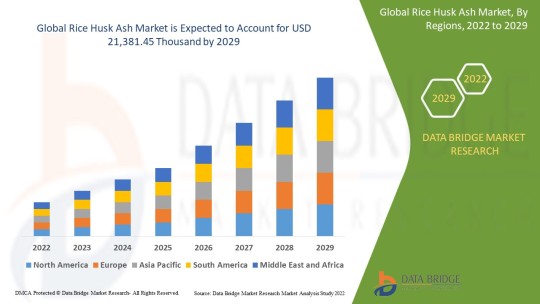

The global rice husk ash market is expected to gain significant growth in the forecast period of 2022 to 2029. Data Bridge Market Research analyses that the market is growing with a CAGR of 4.9% in the forecast period of 2022 to 2029 and is expected to reach USD 21,381.45 thousand by 2029. The major factor driving the growth of the global rice husk ash market is extensive product scope in the construction industry due to high silica content.

Data Bridge market report covers an array of aspects of the market analysis which today’s businesses call for. This market document also defines a chapter on the global market and allied companies with their profiles, which provides important data pertaining to their insights in terms of finances, product portfolios, investment plans, and marketing and business strategies. This market research report is generated with a nice blend of industry insight, talent solutions, practical solutions and use of technology to advance user experience. An outstanding Data Bridge market report puts light on many aspects related to Agriculture and Animal Feed industry and market.

Market Insights and Scope

Rice Husk Ash Market report helps the manufacturer in finding out the effectiveness of the existing channels of distribution, advertising programs, or media, selling methods and the best way of distributing the goods to the eventual consumers. Taking up such market research report is all the time beneficial for any company whether it is a small scale or large scale, for marketing of products or services. It makes effortless for Agriculture and Animal Feed industry to visualize what is already available in the market, what market anticipates, the competitive environment, and what should be done to surpass the competitor.

Industry Segmentation

The global rice husk ash market is categorized based on form, silicon content, and downstream application. The growth amongst these segments will help you analyze major industry growth segments and provide the users with a valuable market overview and market insights to make strategic decisions to identify core market applications.

Form

Granule/ Nodules

Pallets

Flake

Powder

Silicon Content

80-84%

85-89%

90-94%,

More Than 95%

Downstream Application

Concrete Mixes

Roofing Shingles

Building Blocks

Refractory Bricks

Metal Sheets

Insulators

Water Proofing Chemicals

Pesticides

Get a Free Sample of The Report: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-rice-husk-ash-market

Market Country Level Analysis

The global rice husk ash market is further segmented into

North America, South America, Asia-Pacific, Europe, the Middle East and Africa. North America is segmented into U.S., Canada, and Mexico, Germany, U.K., Italy, France, Spain, Russia, Switzerland, Turkey, Belgium, Netherlands, Luxemburg, and the Rest of Europe, Japan, China, South Korea, India, Singapore, Thailand, Indonesia, Malaysia, Philippines, Australia & New Zealand, and Rest of Asia-Pacific, South Africa, Egypt, Saudi Arabia, United Arab Emirates, Israel, and the Rest of Middle East and Africa.

Get full access to the report: https://www.databridgemarketresearch.com/reports/global-rice-husk-ash-market

Industry Share Analysis

Some of the prominent participants operating in the global rice husk ashmarket are

Astrra Chemicals, Global Recycling, K V Metachem, Brisil, The Agrilectric Companies, Rice Husk Ash (Thailand), Guru Corporation, JASORIYA RICE MILL, and PIONEER Carbon, among others.

An influential Rice Husk Ash Market research report displays an absolute outline of the market that considers various aspects such as product definition, customary vendor landscape, and market segmentation. Currently, businesses are relying on the diverse segments covered in the market research report to a great extent which gives them better insights to drive the business on the right track. The competitive analysis brings into light a clear insight about the market share analysis and actions of the key industry players. With this info, businesses can successfully make decisions about business strategies to accomplish maximum return on investment (ROI).

Get TOC Details: https://www.databridgemarketresearch.com/toc/?dbmr=global-rice-husk-ash-market

Browse Related Reports@

Global 1, 4-Cyclohexanedimethanol Dibenzoate Market

Global Plant Hydrocolloids Market

U.S. Tahini Market

Asia-Pacific Hydroxyl-Terminated Polybutadiene (HTPB) market

West Africa Shisha Tobacco Market

Global Orthostatic Hypotension Drugs Market

Europe Customer Journey Analytics Market

About Us: Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact: Data Bridge Market Research Tel: +1-888-387-2818 Email: [email protected]

#Rice Husk Ash Market-by Product-Types-Procedure-Application-End User-Global-Forecast to-2029#Rice Husk Ash Market-Global Opportunity-Analysis and-Industry-regional#Rice Husk Ash Market-Growth-Competition-Scenario-Outlook#Rice Husk Ash Market-Insights-Country-Share-Competitors-Research-Study#Rice Husk Ash Market-Demands-Size-Share-Top Trends-Report-to-2029#Rice Husk Ash Market Value-Segmentation-CAGR rate-Future Trends#Rice Husk Ash Market-drivers-advantages-restraints-challenges#Rice Husk Ash Market-Leading Brands-Business-Agriculture and Animal Feed#Rice Husk Ash Market-Growing Popularity-Traffic-DBMR

0 notes

Text

The report "Zeolites Market by Type (Natural, Synthetic), Function (Ion-Exchange, Catalyst, Molecular Sieve), Synthetic Zeolites Application (Detergents, Absorbent, Catalysts), Natural Zeolites Application, and Region - Global Forecast to 2026" The global zeolites market size is estimated to be USD 12.1 billion in 2021 and is projected to reach USD 14.1 billion by 2026, at a CAGR of 3.1% between 2021 and 2026, owing to an increase in demand of zeolites in detergent industry.

Growing demand for synthetic zeolites in detergent industry is aiding to the growth of this segment. Synthetic zeolites are synthesized in laboratories using raw materials containing silica and alumina as the main constituents. Other raw materials used to synthesize zeolites include clay, fly ash, rice husk ash, and natural zeolites, amongst others.

The Asia Pacific dominated the global zeolites market in 2020. It is majorly due to the increase in demand for zeolites from major countries such as China, Japan, and India. China is the largest market for zeolites market in Asia Pacific. Surging demand for transportation fuels is driving the market for refinery catalysts in the Asia Pacific region.

The key market players include Albemarle Corporation (US), BASF SE (Germany), Honeywell International Inc. (US), Clariant (Switzerland), W.R. Grace & Co. (US), TOSOH Corporation (Japan), Union Showa KK, (Japan), Zeochem AG (Switzerland), KNT Group (Russia), Arkema (France), Zeolyst International (US), Huiying Chemical Industry(Xiamen) Co., Ltd. (China), Chemiewerk Bad Köstritz GmbH (Germany), NALCO India (India), and PQ (US). These players have adopted product launches, agreements, expansions, collaborations, acquisitions, divestments, and partnerships as their growth strategies.

#Zeolites Market#COVID 19 impact on Zeolites Market#MarketsandMarkets#Global Zeolites Market#detergent industry#Zeolites industry#global zeolites market size#demand for synthetic zeolites#demand for adsorbents#synthetic zeolites#Natural Zeolites#Asia Pacific zeolites market#zeolites market size#zeolites market share#zeolites Market Forecast#zeolites market growth#zeolites market manufactures

0 notes