#rfid tags manufacturers

Explore tagged Tumblr posts

Text

Discover the Best RFID Tags for Your Industry Needs at ID Tech Solutions

Imagine a world where managing vast inventories, monitoring assets, and tracking crucial data becomes effortless. That’s the promise RFID (Radio-Frequency Identification) tags bring to the table for industries across the board. From keeping store shelves stocked to ensuring healthcare equipment is always at hand, RFID technology adapts to the specific needs of different sectors, helping businesses run smoother and smarter. But with so many RFID tags available, how do you know which is the best fit for your industry? Here, we’ll dive into the top RFID tags for sectors like retail, logistics, healthcare, and animal tracking—showcasing how Id Tech Solutions tailors RFID products to meet each field's unique challenges and goals.

Key Factors to Consider When Selecting an RFID Tag

Selecting the right RFID tag goes beyond simply choosing a well-known brand; it’s about finding one that aligns with your specific application needs. Here are some important factors that it would be beneficial to consider:

Frequency Range: RFID tags come in low, high, and ultra-high frequencies, each suited to different purposes. For example, ultra-high frequency (UHF) tags are ideal for long-range tracking, making them perfect for warehouse environments, while high-frequency (HF) tags work well in close-range settings like hospitals.

Durability and Environment: The physical environment plays a significant role in tag performance. Ruggedized tags are essential for harsh conditions like outdoor settings, where tags are exposed to weather, dust, or impact.

Read Range: The read range required for tracking should align with the tag’s capabilities. For instance, logistics operations often require long-range tags to track pallets and containers across large spaces.

Data Capacity: The amount of data each tag can hold varies by design. Industries like healthcare may need tags with larger data capacities to store detailed information about patients or medical equipment.

By understanding these factors, businesses can choose an RFID tag that aligns with their operational needs and improves efficiency. Id Tech Solutions offers a wide range of RFID tags with customizable features, ensuring each tag performs optimally in its intended setting.

1. RFID Tags in Retail: Improving Inventory Management and Customer Experience

In the retail industry, managing inventory effectively can be a daunting task. RFID tags offer a solution by enabling real-time tracking of products, which reduces the chances of stockouts, shrinkage, and errors in inventory records. In retail, UHF (Ultra High-Frequency) passive RFID tags are especially popular due to their long-range read capabilities, which allow employees to scan multiple items at once without needing line-of-sight.

Key Benefits for Retail:

Improved Inventory Accuracy: RFID tagging enhances inventory precision, reducing shrinkage and lost sales.

Enhanced Customer Experience: Faster product location and restocking improve customer satisfaction.

Quick Checkout Processes: RFID tags facilitate streamlined checkout experiences through automated tracking.

2. Logistics and Warehousing: Boosting Efficiency and Reducing Errors

Logistics and warehousing face unique challenges with large-scale inventory management, shipping accuracy, and real-time tracking across vast spaces. RFID technology, especially ruggedized UHF RFID tags for harsh environments, has become essential in this sector. RFID tags help warehouses keep track of goods as they move through different stages of the supply chain, improving efficiency and minimizing human error.

Key Benefits for Logistics and Warehousing:

Enhanced Inventory Control: Track items in real-time and reduce misplacement.

Improved Operational Efficiency: Increase processing speed and ensure accurate shipping and receiving.

Cost Savings: Reduced labor costs and less dependency on manual scanning.

3. Healthcare: Using RFID Tags for Patient Safety and Asset Tracking

The healthcare industry uses RFID tags to enhance patient safety, improve equipment management, and streamline patient care processes. For this sector, HF (High-Frequency) RFID tags are typically preferred due to their shorter read range, which is ideal for close-proximity applications. Common healthcare uses include tagging medical equipment, tracking medications, and managing patient records.

Key Benefits for Healthcare:

Improved Patient Safety: RFID tags can be used to track patient information and ensure correct treatment.

Asset and Equipment Tracking: Easily locate essential medical devices, reducing time spent searching for equipment.

Enhanced Compliance: RFID tagging helps maintain accurate records and comply with healthcare regulations.

4. Animal Tracking: RFID Tags for Livestock and Wildlife Management

In agriculture and wildlife management, tracking animals is essential for maintaining health records, breeding data, and overall livestock management. LF (Low-Frequency) RFID ear tags are the go-to choice for animal tracking because they offer a close read range, which minimizes interference from the animal's surroundings. RFID technology enables farmers to monitor livestock health, track animal movements, and streamline data collection, significantly enhancing farm management.

Key Benefits for Animal Tracking:

Efficient Health Monitoring: Track vaccinations, breeding cycles, and health status.

Regulatory Compliance: RFID tags can help farmers meet regulatory standards for animal tracking.

Improved Productivity: Monitor feeding habits and animal location to optimize operations.

Why Choose Id Tech Solutions for Your RFID Tag Needs?

With a wide array of RFID tags for different industries, Id Tech Solutions stands out as a leader in providing high-quality, application-specific RFID products. Each industry faces unique challenges, and Id Tech Solutions' products are designed to meet those specific needs. Whether it’s a rugged RFID tag for logistics, a high-frequency tag for patient tracking in healthcare, or a durable ear tag for livestock, Id Tech Solutions has an RFID solution tailored to enhance your business operations.

Benefits of Choosing Id Tech Solutions:

Industry-Specific Expertise: Powerful RFID solutions specifically designed for diverse industries.

Wide Range of RFID Products: High-quality tags with options for various frequencies, durability needs, and environmental conditions.

Customized Solutions: Id Tech Solutions offers custom RFID solutions to ensure compatibility with your specific applications and operational needs.

Conclusion: Select the Right RFID Tag to Elevate Your Operations

Selecting the best RFID tag for your industry can drive efficiency, improve data accuracy, and enhance overall operations. Whether you’re a retailer managing thousands of SKUs, a logistics manager tracking shipments, a healthcare provider monitoring patient asset, or a farmer tracking livestock, there’s an RFID solution designed for your needs. Id Tech Solutions brings expertise and a broad selection of RFID tags to meet each industry's unique demands, making them a top choice for businesses aiming to integrate RFID technology seamlessly.

With RFID tags from Id Tech Solutions, businesses across industries can leverage the full potential of RFID technology, improving efficiency, reducing errors, and enhancing service delivery. For more information or to explore RFID tags designed for your applications, connect with Id Tech Solutions, and discover how the right RFID technology can drive your business forward.

#rfid tags#rfid technology#rfid solutions#retail solutions#rfid tags manufacturers#active rfid tags#inventory management#Passive RFID Tags

0 notes

Text

NFC Bracelets Manufacturer – Zdcardtech

we provide scalable solutions for corporate events, theme parks, festivals, and companies. Whether you need silicone, fabric, or leather NFC Bracelets Manufacturer, our advanced manufacturing process ensures reliability, security, and seamless connectivity. Partner with zdcardtech for innovative and cost-effective NFC wristband solutions.

#RFID Wristband Supplier#RFID Tag Manufacturer#RFID Card Manufacturer#RFID Textile Management#RFID Laundry Tag#NFC Bracelets Manufacturer#NFC Google Review Card#NFC Card Manufacturer#NFC Tag Factory#RFID Key

0 notes

Text

RFID Tag Manufacturer

SIVA IoT is a leading RFID tag manufacturer specializing in innovative and high-quality RFID solutions for various industries. Our comprehensive range of products includes UHF, NFC, and HF RFID tags designed for applications such as inventory management, asset tracking, retail, healthcare, and logistics. With cutting-edge technology and a customer-centric approach, we deliver reliable and efficient tagging solutions to meet diverse business needs.

#rfid#rfid solutions#asset management#radio frequency identification#asset tracking solution#rfid tag#rfid tag manufacturer#rfid tag supplier

0 notes

Text

QR Codes and RFID Tags in Manufacturing: Enhancing Efficiency and Accuracy

Explore the impact of QR codes and RFID tags in manufacturing. Learn how these technologies enhance efficiency, improve traceability, and ensure quality control in the production process.

#impact of QR codes and RFID tags#QR codes and RFID tags#QR codes and RFID tags in manufacturing#vcqru

0 notes

Text

Rfid Jewellery Tags Manufacturers

Head to Identis for the most reliable and customer-driven RFID jewellery tag manufacturer. Since our inception in 2010, we have been dedicated to revolutionising the jewellery industry by offering cutting-edge RFID technology. These technologies not only keep track of the jewelry but also improve inventory management and overall customer experience.

Backed by years of expertise and a team of highly seasoned professionals, we have emerged as pioneers in the field of jewellery tagging and other associated applications. That being said, our proprietary RFID technology is also used in other sectors such as automobile, IT, logistics, and warehousing to name a few.

Three of our main applications as a leading RFID jewellery tags manufacturer include:

RFID Jewellery Tag: Our RFID jewellery tags provide unique identifying codes that simplify inventory management and authentication procedures. They are also made to fit discreetly into a variety of jewellery styles.

RFID Reader: Our RFID readers are designed to gather and analyse data quickly and accurately, enabling a seamless inventory tracking system.

Anti-Theft: To improve security and prevent unauthorised access to priceless jewellery goods, anti-theft systems are combined with RFID technology.

Here at Identis, we possess all the skills and resources to develop top-tier RFID solutions tailored to the needs of the jewellery industry. We are continually working to upscale the performance and overall functionality of our existing systems and identify the scope of uses. Strict quality compliance with quality regulations is not just a business mandate but an integral component of our work culture. Additionally, we are an ISO 9001-2015, SCOSTA, ICAR, CE, and ARSENAL compliant business, which strengthens our reputation as a customer-focused and quality-driven RFID jewellery tags manufacturer.

0 notes

Text

RFID Tags: The Future of Smart Inventory Management

An RFID tag, at its core, consists of two components – an antenna for transmitting and receiving signals, and an RFID chip (or integrated circuit, IC) storing the tag’s ID and other data. These tags are attached to items, facilitating their tracking using an RFID reader and antenna. Efficiency is paramount in inventory management. Saving time with increased accuracy poses an ongoing challenge for inventory managers across industries. Utilizing RFID Technology in inventory management, where each item is equipped with an RFID Tag and strategically placed readers or handheld RFID readers are used for rapid inventory, is rapidly gaining traction. This trend is driven by complexities arising from the sheer volume of inventory items, the rapid technological advancements, and the ever-expanding retail sector.

Moreover, current inventory management methods rely on manual counting processes or manual barcode scanning, both of which are time-consuming and not always accurate, resulting in potential sales losses or poor customer experiences.

Selecting the right RFID Tag for your inventory management system is crucial for its success. Below are some key considerations when choosing the appropriate RFID Tag:

Size & Form Factor: The size of the tag directly impacts its read range. Choosing the size based on the form factor of the RFID tags, such as wet inlays, labels, hard tags, or high-temperature tags, is essential.

Read Range: The appropriate read range, determined by the chip and RFID reader, should align with the application requirements, typically ranging from 3 feet to 12 feet.

Attachment Method: Various attachment options, including adhesive, magnet, screw, riveting, stitching, or hot stamping, are available and can also be customized.

Mounting Surface: Selecting the right tag for the existing mounting surface is crucial for optimal RFID performance. Metal surfaces, for instance, require specific Mount on metal tags rather than standard labels or tags.

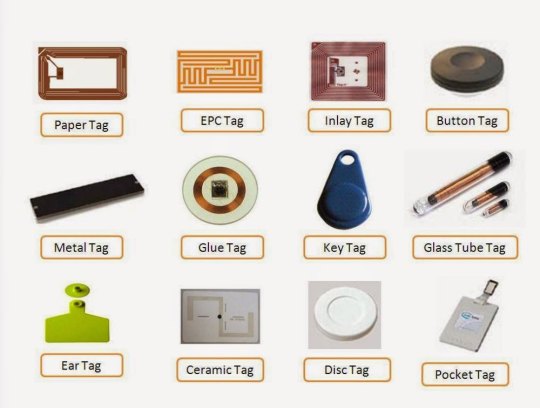

Hundreds of RFID tags are available in diverse shapes and sizes, offering options tailored to specific environments, surface materials, and applications. Choosing the ideal tag for the application, environment, and item material is vital for optimal performance.

A successful inventory management system provides a clear, accurate view of inventory always. It offers item-level visibility and maintains historical records, enabling a chain of custody for each product. Users can track a specific product's journey from arrival to sale, allowing for detailed reports on product trends, replenishment information, and product visibility and display success.

#RFID tags#RFID tag manufacturers#RFID laundry tags#RFID clothing tags#RFID technology#RFID solutions#Active RFID tags#RFID readers#RFID chips

0 notes

Text

Grab The Most Advanced Benefits of Using High Quality RFID Windshield Tags

Do you have any idea about RFID tags? Want to explore the benefits of using such tags? If yes, then proceed with this guide and collect the complete details of RFID Windshield tags

In general, high quality RFID Windshield tags consist of the most advanced tracking device that can be installed inside the vehicle. You can track it by using the best tracking software.

The high quality RFID Windshield tags consist of evaluating the highest importance and involve the right consideration of many digital strategies. It continues to be necessary that manipulate several strategies for obtaining an online audience and consumer engagement process.

It is suitable for expecting most things in vehicle companies to obtain the right level of continuous digital strategies. It increases, and revenue share continues to lead the way by a distance via vehicle at around usage of these additional technologies in a top-notch manner.

Find the best manufacturers:

Professional RFID Tag Manufacturers offer high quality RFID Windshield tags to let you experience their complete impacts very effects. Eco Track Systems is the leading manufacturer to offer an exclusive collection of tags that let you experience the overall benefits of these tags. Here, you don’t have any quality issues.

Since these manufacturers are very professional in offering the product to their customers in a high quality manner, therefore, you don’t need to worry about quality issues.

Obtaining clear performance:

It is suitable for obtaining clear performance, and various vehicle users depend on the category. It is still looking for high-value purchases for the first start-up with involved in the high quality RFID Windshield tags values.

Moreover, this is still a riding share sector that met critical mass, and many choose to be humble by reviews of the high quality RFID Windshield tags. It still looks and fails to fast and learn quickly to offer a view on the company culture technology development.

It concludes the share sector that has yet to develop with the order still considers itself to be starting up. It consists of average results and hence gets the high importance of foreseeable future results.

Conclusion:

Everyone should get the RFID tags from Eco Track Systems now. Here, the manufacturer tries to offer the most advanced process of using high quality RFID Windshield tags. Hence, you can grab the most advanced benefits of using high quality RFID windshield tags.

For any inquiry call us at 9999727213

0 notes

Text

RFID Tags in Transportation: Revolutionizing Efficiency and Security

The transportation industry is a vast and intricate web of systems that relies on the seamless movement of goods and people. In this complex landscape, the use of RFID (Radio-Frequency Identification) tags has emerged as a transformative technology, optimizing processes and enhancing security across various transportation sectors.

What Are RFID Tags in Transportation?

RFID tags are small, wireless devices that contain a unique identifier and an antenna. They can be categorized into two main types: active and passive. Active RFID tags have their power source and can transmit data independently, while passive RFID tags rely on energy from an RFID reader's radio waves to transmit their information.

Applications of RFID Tags in Transportation

Toll Collection: RFID tags are extensively used in toll collection systems. Each vehicle is equipped with an RFID tag that contains account information. When a vehicle passes through a toll booth, the RFID reader scans the tag, and the toll is automatically deducted from the driver's account, streamlining the toll-paying process and reducing traffic congestion.

Vehicle Identification: In public transportation systems, such as buses and trains, RFID tags are employed for vehicle identification and tracking. This helps transportation authorities monitor routes, schedules, and the condition of their fleet.

Cargo and Freight Tracking: RFID tags are invaluable in the tracking and management of cargo and freight. Shipping containers, pallets, and individual items can be tagged with RFID, allowing for real-time monitoring of their location and condition during transit.

Airport Security: RFID technology plays a crucial role in enhancing airport security. It is used for baggage tracking to ensure that luggage is matched with passengers and loaded onto the correct flights. Additionally, RFID is utilized for access control, allowing authorized personnel to enter restricted areas.

The Advantages of RFID Tags in Transportation

Efficiency: RFID technology significantly improves efficiency in transportation systems. It reduces processing times at toll booths, streamlines cargo handling, and enhances passenger boarding procedures.

Accuracy: RFID tags provide accurate and real-time data, reducing errors in tracking and management. This accuracy is especially vital in transportation, where mistakes can lead to delays and safety concerns.

Security: RFID tags enhance security by allowing for better control and monitoring of vehicles, cargo, and personnel. Unauthorized access to secure areas can be minimized, reducing the risk of security breaches.

Cost Savings: In the long run, RFID technology can lead to cost savings by optimizing processes, reducing labor requirements, and minimizing errors.

Conclusion

As technology continues to advance, the applications of RFID tags in transportation are likely to expand further. Their ability to provide real-time tracking, enhance efficiency, and bolster security positions RFID as a critical tool in the ongoing evolution of the transportation industry. Whether you're a traveler, a logistics professional, or a transportation authority, the impact of RFID tags on transportation is clear: a future of greater efficiency and security awaits.

0 notes

Text

"Clothing tags, travel cards, hotel room key cards, parcel labels … a whole host of components in supply chains of everything from cars to clothes. What do they have in common? RFID tags.

Every RFID (Radio Frequency Identification) tag contains a microchip and a tiny metal strip of an antenna. A cool 18bn of these are made – and disposed of – each year. And with demands for product traceability increasing, ironically in part because of concerns for the social and environmental health of the supply chain, that’s set to soar.

And guess where most of these tags end up? Yup, landfill – adding to the burgeoning volumes of e-waste polluting our soils, rivers and skies. It’s a sorry tale, but it’s one in which two young graduates of Imperial College London and Royal College of Art are putting a great big green twist. Under the name of PulpaTronics, Chloe So and Barna Soma Biro reckon they’ve hit on a beguilingly simple sounding solution: make the tags out of paper. No plastic, no chips, no metal strips. Just paper, pure and … simple … ? Well, not quite, as we shall see.

The apparent simplicity is achieved by some pretty cutting-edge technical innovation, aimed at stripping away both the metal antennae and the chips. If you can get rid of those, as Biro explains, you solve the e-waste problem at a stroke. But getting rid of things isn’t the typical approach to technical solutions, he adds. “I read a paper in Nature that set out how humans have a bias for solving problems through addition – by adding something new, rather than removing complexity, even if that’s the best approach.”

And adding stuff to a world already stuffed, as it were, can create more problems than it solves. “So that became one of the guiding principles of PulpaTronics”, he says: stripping things down “to the bare minimum, where they are still functional, but have as low an environmental impact as possible”.

...how did they achieve this magical simplification? The answer lies in lasers: these turn the paper into a conductive material, Biro explains, printing a pattern on the surface that can be ‘read’ by a scanner, rather like a QR code. It sounds like frontier technology, but it works, and PulpaTronics have patents pending to protect it.

The resulting tag comes in two forms: in one, there is still a microchip, so that it can be read by existing scanners of the sort common within retailers, for example. The more advanced version does away with the chip altogether. This will need a different kind of scanner, currently in development, which PulpaTronics envisages issuing licences for others to manufacture.

Crucially, the cost of both versions is significantly cheaper than existing RFID kit – making this a highly viable proposition. Then there are the carbon savings: up to 70% for the chipless version – so a no-brainer from a sustainability viewpoint too. All the same, industry interest was slow to start with but when PulpaTronics won a coveted Dezeen magazine award in late 2023, it snowballed, says So. Big brands such as UPS, DHL, Marks & Spencer and Decathlon came calling. “We were just bombarded.” Brands were fascinated by the innovation, she says, but even more by the price point, “because, like any business, they knew that green products can’t come with a premium”."

-via Positive.News, April 29, 2024

--

Note: I know it's still in the very early stages, but this is such a relief to see in the context of the environmental and human rights catastrophes associated with lithium mining and mining for rare earth metals, and the way that EVs and other green infrastructure are massively increasing the demand for those materials.

I'll take a future with paper-based, more humane alternatives for sure! Fingers crossed this keeps developing and develops well (and quickly).

#I do really wish it could be read by regular scanners already though#that's what I thought at first#and that would've been fucking amazing#but this is still pretty cool#electronics#science and technology#green technology#ewaste#landfill#lithium#lithium mining#human rights#environment#climate action#climate hope#rfid#rfid technology#rfid tags#good news#hope

450 notes

·

View notes

Text

Metal Closures Market Product Diversification Drives Innovation Across Multiple Industries with Sustainable Solutions

The metal closures market has undergone significant transformation over the last few years, driven by the increasing demand for high-quality, durable, and sustainable packaging solutions across industries. Metal closures, including caps, lids, and seals, are widely used in various sectors such as food and beverages, pharmaceuticals, personal care, and chemicals. While traditionally known for their reliability and durability, the market is experiencing a surge in product diversification, responding to evolving consumer demands and innovations in manufacturing technology.

1. Evolution of Metal Closures

Historically, metal closures were limited to simple designs such as bottle caps or jar lids. However, with technological advancements and shifting consumer preferences, manufacturers have embraced the need for diverse solutions. In the past decade, the global trend toward sustainable packaging has encouraged metal closure suppliers to innovate, combining aesthetics, convenience, and functionality.

The rising popularity of single-serve products, eco-conscious packaging, and the increasing demand for premium products have played a pivotal role in pushing manufacturers to offer a broader range of closure designs and materials. This diversification is not only meeting the varied needs of different industries but also improving operational efficiency and reducing environmental impacts.

2. Drivers of Diversification

Several factors are fueling the growth and diversification of the metal closures market:

Sustainability Trends: As consumers and companies become more environmentally aware, the demand for sustainable and recyclable materials has risen. Metal closures, especially aluminum and steel, are considered eco-friendly due to their recyclability, prompting manufacturers to innovate with designs that minimize material waste and maximize recyclability.

Aesthetic Appeal: Packaging has become a key element in product marketing. Metal closures are now available in a range of finishes, including matte, gloss, embossed, and custom-printed designs, offering brands an opportunity to differentiate their products in a competitive marketplace.

Customization and Convenience: The demand for customized, easy-to-use, and tamper-proof closures is growing across various industries. For instance, child-resistant closures in the pharmaceutical sector and easy-open tops for food and beverages are gaining traction.

Technological Advancements: Modern technologies like injection molding, stamping, and laser cutting have enhanced the versatility of metal closures, allowing for complex shapes, sizes, and functionalities. Smart closures, which offer tracking and authentication capabilities, are also emerging in the market, particularly in the luxury goods and pharmaceutical sectors.

3. Key Products and Innovations

The scope of product diversification in the metal closures market is vast. Some notable innovations include:

Multi-Function Closures: These closures offer more than just sealing functionality. Some products now feature built-in pourers, tamper-evident mechanisms, and child-proof locking systems, catering to specific industry needs.

Aerosol Closures: Aerosol cans are seeing a rise in demand, particularly in the personal care, household, and industrial sectors. Aerosol closures are being improved with better spray mechanisms, leak-proof designs, and environmentally friendly propellants.

Plastic-Combining Closures: Hybrid closures made from both metal and plastic components are growing in popularity. These closures combine the strength of metal with the convenience and flexibility of plastic, offering improved performance while maintaining the durability of metal.

Smart Closures: The integration of technology into closures, such as RFID tags or QR codes, is enhancing the security and traceability of products, especially in high-value or regulated industries like pharmaceuticals and luxury goods.

Sustainable Materials: With the increasing emphasis on sustainability, metal closures made from recycled aluminum or steel are becoming more common. Furthermore, some manufacturers are incorporating biodegradable or compostable components into their closures to align with circular economy practices.

4. Impact of Product Diversification on Different Sectors

The food and beverage sector has seen a significant shift in the metal closures market, with manufacturers focusing on developing tamper-evident and easy-to-open designs. Beverage caps, for example, are now available with convenience features like resealable designs, reducing wastage and enhancing user experience.

In the pharmaceutical sector, metal closures are playing a critical role in ensuring the integrity and safety of products. Child-resistant closures, tamper-evident seals, and dose-controlled packaging are becoming standard requirements to protect consumers.

The personal care industry is also benefiting from customized metal closures, with manufacturers offering various decorative and functional closures for premium products. Similarly, the chemical sector has seen innovation in closures designed to ensure leak-proof performance and withstand chemical exposure.

5. Challenges and Future Outlook

Despite the positive trends in product diversification, several challenges persist in the metal closures market. Fluctuating raw material prices, especially for metals like aluminum and steel, pose a threat to profit margins. Additionally, manufacturers must balance product innovation with environmental concerns to ensure that the closures remain recyclable and minimize waste.

However, the future looks promising for the metal closures market. Continued research and development in sustainable materials, smart technologies, and design innovations will likely drive further growth. Manufacturers who can adapt to these trends and offer tailored solutions to meet specific industry needs will hold a competitive edge in the evolving marketplace.

Conclusion

In conclusion, the metal closures market is expanding rapidly due to product diversification driven by consumer preferences, technological advancements, and sustainability trends. As manufacturers respond to these shifts with innovative solutions, the industry will continue to evolve, offering more versatile and functional products across various sectors.

0 notes

Text

As businesses continue to innovate, efficiency, automation, and streamlined operations are key priorities. One of the standout technologies in this space is RFID (Radio Frequency Identification). Whether you're managing inventory, tracking assets, or boosting security, RFID technology has become a vital tool across industries like retail, logistics, healthcare, and manufacturing.

However, understanding the different types of RFID—tags, inlays, and labels—is essential to choosing the right solution for your business. Each option has unique strengths and selecting the most suitable type can help you maximize your operations.

#rfid technology#rfid solutions#rfid tags#rfid reader#rfid tags manufacturers#active rfid tags#rfid inlays#rfid labels#rfid antenna#business

0 notes

Text

Revolutionizing Communication: NFC Tag Factory

High-quality NFC tags that enable wire-free device communication are produced by NFC Tag Factory. Contactless payments, item tracking, and intelligent advertisements are just a few of the uses for these tags. They concentrate on creating robust, dependable, and uniquely crafted NFC tags to meet the demands of various industries. They are a well-known brand in the NFC sector thanks to their cutting-edge technology.

#RFID Wristband Supplier#RFID Tag Manufacturer#RFID Card Manufacturer#RFID Textile Management#RFID Laundry Tag#NFC Bracelets Manufacturer#NFC Google Review Card#NFC Card Manufacturer#NFC Tag Factory#RFID Key

0 notes

Text

IoT Applications and Services in Management Systems

The Internet of Things (IoT) has dramatically transformed industries across the globe, driving efficiency, automation, and intelligence. One of the key areas where IoT has made a significant impact is in the domain of management systems. From supply chain logistics to facility management, IoT applications and services are redefining how organizations manage their operations. This article explores the various ways IoT is integrated into management systems, highlighting key applications and the services they provide.

Poddar International College is one of the best colleges in Jaipur, providing IoT applications in management systems with lots of practical exposure and experiential learning. It focuses on holistic development of the learners with maximum exposure to placement opportunities, providing firsthand experience with smart technologies and preparing them for the present-day challenges in business.

1. Supply Chain and Inventory Management

One of the most impactful IoT applications in management systems is in supply chain and inventory management. IoT sensors and devices can be used to track goods in real-time, providing valuable insights into product movements, stock levels, and warehouse conditions. RFID tags and GPS-enabled sensors allow businesses to monitor the location and status of their products as they move along the supply chain.

This real-time visibility helps prevent stockouts, reduce excess inventory, and streamline logistics. For instance, IoT-enabled systems can automatically trigger alerts when stock levels fall below a set threshold, allowing managers to take action and reorder supplies before a shortage occurs. In warehouses, IoT can facilitate automatic stocktaking and stock replenishment, reducing human errors and increasing operational efficiency.

Additionally, IoT technology which can be experienced at Poddar International College, Jaipur can optimize the storage conditions for sensitive products, such as perishable goods. Environmental sensors measure temperature, humidity, and other variables to ensure that products are kept under the ideal conditions, preventing spoilage and waste.

2. Facility Management

Facility management is another area that has greatly benefited from IoT integration. Building management systems (BMS) are now able to utilize IoT to enhance energy management, maintenance scheduling, and overall operational efficiency. IoT sensors monitor and control lighting, heating, air conditioning, and ventilation (HVAC) systems. For example, motion sensors in a building can adjust lighting and temperature based on occupancy, ensuring energy savings by reducing energy consumption when spaces are unoccupied.

In terms of predictive maintenance, IoT services can detect wear and tear on equipment like HVAC systems, elevators, and other critical infrastructure before they break down. This is achieved by continuously monitoring equipment performance and analyzing sensor data. Alerts are sent to facility managers when maintenance is required, reducing the risk of costly downtime and improving the lifespan of assets.

Moreover, IoT applications allow facility managers to monitor air quality, detect water leaks, and even track waste management, all contributing to more sustainable and efficient building operations. These capabilities not only improve operational performance but also enhance the experience for building occupants by ensuring a safe and comfortable environment.

3. Asset Management

In asset-intensive industries such as manufacturing, energy, and transportation, IoT-enabled asset management systems play a crucial role in optimizing the use of equipment and machinery. By attaching IoT sensors to physical assets, companies can collect real-time data on asset health, usage patterns, and performance metrics. This data is then fed into a centralized management system, which can be used to monitor the status of assets, schedule maintenance, and optimize performance.

For example, in manufacturing plants, IoT sensors monitor machinery for signs of mechanical issues, such as excessive vibration or temperature changes. If any abnormalities are detected, the system can automatically notify the maintenance team, preventing unplanned downtime. Similarly, in the transportation sector, IoT-based asset management tools track fleet vehicles, helping to ensure they are maintained properly, are operating efficiently, and are being used effectively.

4. Smart Healthcare Management

The healthcare industry is increasingly adopting IoT technologies to enhance patient care, improve resource management, and optimize healthcare operations. IoT devices, such as wearable health monitors, smart medical equipment, and connected hospital beds, allow healthcare providers to gather real-time patient data, leading to more personalized care.

For instance, remote patient monitoring systems use IoT devices to track vital signs like heart rate, blood pressure, and glucose levels. These devices transmit data to healthcare professionals, enabling them to monitor patients from a distance and intervene proactively when necessary. Additionally, IoT-enabled systems improve hospital resource management, such as tracking the availability of medical equipment, hospital beds, and staff.

By automating routine tasks and enhancing decision-making, IoT applications can help healthcare organizations provide faster, more efficient, and cost-effective care, reducing the administrative burden on medical staff and improving patient outcomes.

5. Energy Management Systems

IoT-enabled energy management systems (EMS) are essential in helping businesses and utilities optimize energy consumption and reduce costs. Through the use of IoT sensors and smart meters, organizations can monitor energy usage in real time across buildings, factories, or entire campuses. These systems provide actionable insights into energy consumption patterns and identify areas where energy can be saved.

For example, in industrial settings, IoT sensors can monitor the performance of energy-intensive machinery and provide feedback on when to schedule energy-consuming activities for off-peak hours. In commercial buildings, IoT-enabled lighting and HVAC systems can be automated to optimize energy efficiency. By using predictive analytics, EMS can forecast energy demand and adjust supply accordingly, preventing overuse and minimizing waste.

6. Smart Transportation and Fleet Management

IoT has revolutionized the transportation sector, particularly in fleet management. Vehicles equipped with IoT sensors generate a wealth of data that can be used to monitor driver behavior, vehicle health, fuel efficiency, and delivery schedules. Fleet management systems leverage IoT data to optimize routing, ensure timely deliveries, and improve overall fleet utilization.

Real-time tracking of vehicles and cargo helps businesses maintain better communication with drivers and customers, providing accurate arrival times and reducing delays. Additionally, predictive maintenance can be applied to detect and prevent mechanical failures before they cause breakdowns, leading to cost savings and better fleet availability.

Moreover, IoT applications are increasingly integrated with traffic management systems, enabling cities to optimize traffic flow and reduce congestion, leading to improved public transportation services and overall urban mobility.

Conclusion

The integration of IoT applications and services in management systems has brought about a paradigm shift in how businesses and organizations operate. By harnessing the power of real-time data and automation, IoT is driving efficiency, sustainability, and innovation across various industries. Whether it’s optimizing supply chains, managing energy consumption, improving asset management, or enhancing healthcare delivery, IoT is proving to be a game-changer in modern management systems.

As IoT technology continues to evolve, its potential to transform management systems will only increase, offering new opportunities for organizations to stay competitive and responsive to market demands. With the right infrastructure, security protocols, and data management strategies, IoT will remain at the forefront of innovation in management practices for years to come.

0 notes

Text

Simplify asset management with high-quality RFID asset tags and labels from TopTag. Designed for easy application, durability, and efficient tracking, our tags are perfect for inventory, equipment, and property identification.

0 notes

Text

Automatic Identification And Data Capture Market Key Players, Revenue And Growth Rate

The global automatic identification and data capture market size is expected to reach USD 136.86 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to grow at a CAGR of 11.7% from 2025 to 2030. With an increase in the use of smartphones for image recognition and QR code scanning along with an increase in the development of e-commerce platforms internationally, the market is anticipated to experience a noticeable growth during the forecast period.

Furthermore, increased automatic identification and data capture (AIDC) solution acceptance due to their capacity to reduce discrepancies is likely to drive the growth of the AIDC industry during the forecast period. For instance, in April 2022, Arcion Labs, Inc., a truly real-time database replication platform, announced the release of Arcion Cloud, a fully managed change data capture data replication as a service that empowers businesses to leverage more significant, big data pipelines in minutes.

The most prevalent devices used to identify and capture the data are RFID scanners and RFID tags, barcode scanners, fixed-position, and handheld laser scanners and imagers, wearables devices, voice recognition solutions, and rugged tablets. Automatic identification and data capture systems, such as wearables, barcoding solutions, and RFID scanners, are critical in e-commerce and warehouse management.

AIDC technology not only assists the e-commerce business in automatically identifying objects, collecting data about them with high accuracy and precision, and electronically entering this data into the computer system. By keeping track of inventories, accounting, human resources, and overall procedures, technology also helps increase productivity and operational efficiency.

Gather more insights about the market drivers, restrains and growth of the Automatic Identification And Data Capture Market

Automatic Identification And Data Capture Market Report Highlights

• North America dominated the market and accounted for the largest revenue share of 38.5% in 2024. This high share can be attributed to the increasing awareness and high adoption of AIDC devices and increased government legislative and investment, particularly in retail, healthcare, and manufacturing industries.

• AIDC systems are routinely used to manage assets, inventory, delivery, document scanning, and security in various industries, including transport and logistics, chemical, pharmaceutical, food and beverage, automotive, consumer products, retail and warehousing, and distribution

• Radio Frequency Identification (RFID) tags, barcodes, biometrics, labels, smart cards, and speech and voice recognition have gained acceptance across various industries due to their increased accuracy, precision, and smooth functioning

• Banks and financial institutions' increasing implementation of AIDC solutions to ensure customer security, safety, and data privacy is projected to fuel market expansion

Automatic Identification And Data Capture Market Segmentation

Grand View Research has segmented the global automatic identification and data capture market on the basis of component, end-use, and region:

Automatic Identification And Data Capture Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

o RFID Reader

o Barcode Scanner

o Smart Cards

o Optical Character Recognition Devices

o Biometric Systems

o Others

• Software

• Services

o Integration & Installation Services

o Support & Maintenance Services

Automatic Identification And Data Capture End-user Outlook (Revenue, USD Billion, 2017 - 2030)

• Manufacturing

• Retail

• Transportation & Logistics

• Hospitality

• BFSI

• Healthcare

• Government

• Energy & power

• Others

Automatic Identification And Data Capture Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

o U.S.

o Canada

• Europe

o UK

o Germany

o France

• Asia Pacific

o China

o Japan

o India

o Australia

o South Korea

• Latin America

o Brazil

o Mexico

• Middle East and Africa

o Saudi Arabia

o South Africa

o UAE

Order a free sample PDF of the Automatic Identification And Data Capture Market Intelligence Study, published by Grand View Research.

#Automatic Identification And Data Capture Market#Automatic Identification And Data Capture Market Size#Automatic Identification And Data Capture Market Share#Automatic Identification And Data Capture Market Analysis#Automatic Identification And Data Capture Market Growth

0 notes

Text

How RFID and IoT Are Changing the Game in Uniform Management

Uniform management? Not exactly the most thrilling topic—until you realize how much of a headache it used to be. Lost uniforms, chaotic inventory, and constant reordering? Total nightmare. But with RFID (Radio Frequency Identification) and IoT (Internet of Things) stepping in, managing uniforms is starting to feel less like a chore and more like a well-oiled machine.

From healthcare to hospitality and manufacturing, businesses are swapping out old-school tracking methods for high-tech automation. RFID tags and IoT-powered systems are making uniform distribution smoother, cutting down on losses, keeping things hygienic, and—best of all—saving money. Let’s talk about how these innovations are totally reshaping uniform management software and what the future holds.

So, What’s the Big Deal with RFID and IoT?

RFID: The Ultimate Time-Saver

Think of RFID as a digital ID system for uniforms. Tiny tags embedded in garments send signals to RFID scanners, automatically logging every movement. No more manual scanning, no more guessing games—just instant tracking that makes sure uniforms don’t magically disappear into thin air.

IoT: The Smart Assistant You Never Knew You Needed

IoT kicks things up a notch by connecting RFID data to cloud-based systems. Now, businesses can track uniform usage in real time, automate restocking, and even analyze trends to stay ahead of demand. Plus, features like smart lockers mean employees can grab what they need without a middleman slowing things down.

Why RFID is a Total Game-Changer

No More Manual Tracking (Finally!)

Remember when uniform tracking meant clipboards, spreadsheets, and sheer frustration? RFID makes all that obsolete. Each time a uniform is issued, returned, or washed, the system records it instantly—no human intervention needed. That means fewer errors and way more efficiency.

Lost Uniforms? Not on RFID’s Watch

If missing uniforms are eating into your budget, RFID has your back. Every move a uniform makes is recorded, so if something goes missing, you’ll know exactly where it was last seen. Bonus: It also keeps employees accountable.

Smarter Laundry, Less Hassle

In industries like healthcare and food service, hygiene isn’t optional—it’s critical. RFID ensures that uniforms go through the right cleaning cycles and are returned to the right people, cutting down on contamination risks and mix-ups.

How IoT Is Taking Uniform Management to the Next Level

Smart Lockers: Grab and Go

IoT-powered smart lockers? Absolute game-changer. Employees scan an ID, grab their uniforms, and go—while the system keeps track of every transaction. No more wasted time, no more confusion.

Real-Time Inventory Updates

With IoT-powered uniform inventory management, managers always know what’s in stock and what’s running low. The system predicts shortages, reorders automatically, and ensures there’s never too much or too little on hand.

Predictive Analytics = Smarter Planning

IoT isn’t just about what’s happening now—it’s about anticipating what’s coming next. By analyzing uniform usage patterns, businesses can schedule replacements, optimize laundry cycles, and even adjust orders based on trends.

The Best Perks of RFID and IoT in Uniform Management

Supercharged Efficiency

No more bottlenecks, no more wasted time. RFID and IoT streamline every part of uniform management, making things run faster and smoother.

Cost Savings That Make a Difference

When uniforms aren’t getting lost, over-ordered, or underutilized, businesses save serious cash. RFID and IoT help cut unnecessary expenses while making sure resources are used wisely.

Hygiene You Can Actually Trust

For industries where cleanliness is king, RFID and IoT ensure uniforms are cleaned properly and swapped out at the right time. No more sketchy hygiene practices—just reliable, trackable sanitation.

The Challenges of Jumping on the RFID and IoT Train

The Price Tag

Yes, these systems are a smart investment, but they aren’t free. Businesses need to think about upfront costs and whether the long-term benefits justify the expense.

Integration Takes Work

Not every company has the latest tech infrastructure, which means rolling out RFID and IoT might take some adjustments. Compatibility with existing systems and staff training are key to making the transition smooth.

Data Security Concerns

Tracking uniforms digitally means storing sensitive data. Businesses need to lock down their systems with encryption and authentication to keep everything secure.

Who’s Already Using RFID and IoT Like a Pro?

Healthcare

Hospitals are using RFID to track scrubs, lab coats, and protective gear, ensuring strict hygiene compliance. IoT-powered smart lockers let medical staff grab clean uniforms without waiting in line.

Hospitality

Hotels and restaurants rely on RFID and IoT to keep uniforms available for housekeeping, kitchen, and front-desk employees. Automated tracking prevents shortages and keeps things running smoothly.

Manufacturing and Industrial Workplaces

In factories, workwear software helps track uniform usage, flagging items for replacement and ensuring compliance with safety standards.

What’s Next for RFID and IoT in Uniform Management?

AI + RFID + IoT = Next-Level Efficiency

Imagine a system that doesn’t just track uniforms but predicts what you’ll need before you do. AI-powered analytics will help businesses plan ahead, reduce waste, and keep everything running like clockwork.

Blockchain for Ultimate Security

Blockchain could make RFID tracking even more secure by ensuring data stays tamper-proof and accessible only to authorized users. More transparency, less risk.

Managing Uniforms Across Multiple Locations

As companies grow, keeping track of uniforms across different locations will get even easier with RFID and IoT. No matter where employees are, they’ll always have access to what they need.

The Bottom Line

RFID and IoT are totally transforming uniform management, making it faster, smarter, and more reliable. From automated tracking to predictive analytics, these innovations are turning an outdated process into a seamless experience.

If you’re looking to take uniform management to the next level, investing in uniform management software is a no-brainer. With RFID and IoT in the mix, the future of uniform tracking has never looked better.

0 notes