#resin floor coatings uk

Explore tagged Tumblr posts

Text

Lazercote Ltd

When selecting a flooring type for newly built or renovated flooring, you would surely look for a flooring solution that is durable, long-lasting, and easy to clean. You want something that will withstand heavy foot traffic and resist chemicals and moisture. You also want a floor that is easy to maintain and won't require frequent repairs. With that, you can always consider the resin flooring solutions offered by Lazercote—a leading provider of resin flooring solutions for commercial properties in the West Midlands and throughout the UK. Having been in the business for over 35 years, we are confident that we provide high-quality, cost-effective, and durable industrial resin flooring solutions for all our clients. We also work closely with leading manufacturers to ensure that we only use up-to-date technologies, so our clients receive the best possible service. If you are interested in learning more about our services or would like a free quote, don't hesitate to get in touch with us today at 01299 556943 or [email protected]. We will be more than happy to answer any questions and help you choose the right resin flooring for your commercial property.

#resin flooring#industrial resin flooring#resin floor coatings uk#epoxy resin flooring#polyurethane coatings

1 note

·

View note

Text

Powder Coatings Market - Forecast(2024 - 2030)

Powder Coatings Market Overview

The Powder Coatings Market size is forecasted to reach US$18.2 billion by 2027 after growing at a CAGR of 6.1% during the forecast period 2022-2027. Powder coating is a dry finishing process in which free-flowing, thermoplastic or thermoset powder material is applied to a surface, melted and then allowed to dry and harden into a protective coating. Powder coating based on thermoplastic polymers is derived from polyolefins, polyvinyl chloride, polyvinyl fluoride, polyester and so on whereas thermoset-based powder coatings are derived from epoxy, polyester, acrylic, polyurethanes and so on. Powder coating imparts a high-quality, durable finish, that allows for improved efficiency and is eco-friendly. Powder coatings are based on polymer resin systems. The environmental advantages offered by powder coatings compared to liquid coating methods drives the powder coatings market. The pandemic resulted in shortages of raw materials and supply chain disruptions. According to Echemi, a chemical industry B2B website, there were shortages of neopentyl glycol that is used in many of the resins for powder coatings and triglycidyl isocyanurate which is a curing agent used in polyester powder coatings. This resulted in price hikes of over 60% in the Powder Coatings industry.

Powder Coatings Market Report Coverage

The “Powder Coatings Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments of the Powder Coatings industry.

By Resin Type: Thermoset (Epoxy, Polyester, Acrylic, Fluoropolymer, Polyurethanes and Others) and Thermoplastic (Polyamide, Polyolefin, Polyethylene, Polyvinyl Chloride, Polypropylene and Others).

By Coating Method: Fluidized Spray, Electrostatic Fluidized Bed, Electrostatic Spray and Others.

By Substrate: Metal (Steel, Aluminum and Others) and Non-Metal (Plastic, Wood, Ceramics, Glass and Others).

By End-Use Industry: Automotive [Two-wheelers (Scooters and Bikes) and Three/Four-wheelers (Passenger Cars, Heavy Commercial Vehicles and Light Commercial Vehicles)], Construction (Outdoor Construction and Indoor Construction), Appliances (Refrigerator, Water Coolers, Vending Machines, Washing Machines, Air Conditioners/Coolers, Electrical Fans, Kitchen Blenders/Mixers, Vacuum Cleaners, Water Heaters, Ovens & Chimneys, LPG Cylinders and Others), Electrical & Electronics (Transformers, Generators, ATM Machines, Industrial/Commercial Systems, Electrical Motor Stators/Rotors, Electric Meters & Connectors, Computer Room Floor System and Others), General Industrial (Industrial Carts & Power Tools, Storage & Racking, Escalators & Elevators, Lockers, Walls & Fittings, Water Pumps, Steel Drums, Pipes & Rebars and Others), Furniture (Outdoor Metal Furniture, Beds & Chairs, Benches and Others), Medical, Transportation & Equipment (Railways, Industrial Transportation, Construction Equipment, Agricultural Equipment, Marine, Aerospace) and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Denmark, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World (the Middle East and Africa)

Request Sample

Key Takeaways

The Asia-Pacific region dominates the powder coatings market on account of the increasing construction activities and the recovering automotive industry. According to Invest India, the construction industry in India is expected to reach $1.4 trillion by 2025.

There are two types of powder coatings, thermoplastic and thermoset. Thermoplastic powders are commonly derived from polyolefins, polyvinyl chloride and polyvinyl fluoride while thermosetting powders are derived from acrylic, epoxy and polyester resins.

Thermoplastic powder coating melts and flows when heat is applied but continues to have the same chemical composition once it cools and solidifies. On the other hand, thermoset powder coatings will not melt when heated after curing.

The major opportunity for this market is developing thin-film coatings.

A detailed analysis of strengths, weaknesses, opportunities and threats will be provided in the powder coatings market report.

Powder Coatings Market Segment Analysis – by Resin Type

The thermoset segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 7.2% during the forecast period of 2022-2027. In the powder coating process, as the powder heats and melts it flows around the surface of the object and undergoes a chemical change called cross-linking which forms a hard and durable coating. Thermosetting coatings do not re-melt when they are cooled after heat is re-applied. In its powdered state, thermoset material tends to have a much lower molecular weight than other coating materials, usually requiring less heat to melt, making it more energy efficient. Thermoset powders are commonly derived from epoxy, acrylic, polyester and polyurethane groups. The most frequently employed are epoxy and polyester-based resins. Epoxy resin-based thermoset powders form a tough impact-resistant coating that has excellent corrosion resistance, so they are used for internal applications. Polyester-based coatings have the added advantage of being highly UV resistant, making them an ideal choice for outdoor applications. Thus, the thermoset segment is anticipated to dominate the powder coatings market.

Inquiry Before Buying

Powder Coatings Market Segment Analysis – by Application

The construction segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 8.3% during the forecast period of 2022-2027. Powder coating can be used for metal components such as door frames, railings, window frames, fencing, shelters, storefronts, façade or other areas of buildings. According to WSP, around 25% of the overall construction cost is the façade, with the metal contributing a major part of the cost. Powder coating can prevent corrosion and minimize re-coating as it imparts a long-lasting coating. The powder coat is more resistant to scratching, fading, erosion or other types of damage that can ruin the aesthetic appeal of a building The latest trend in the construction industry is low-emitting products and sustainable buildings. According to the U.S. Green Building Council (USGBC), 1,105 projects have been certified with LEED certification for green buildings in the U.S. in 2021. Powder coatings are solvent and VOC-free and produce less waste than other coating methods, making them a clear choice for green buildings. Thus, the construction industry is expected to dominate the market.

Powder Coatings Market Segment Analysis – by Geography

The Asia-Pacific region held the dominant Powder Coatings Market share up to 60% in 2021 owing to the rising consumption of powder coatings from the automotive, construction and appliances sector. The construction activities in the region rebounded after the initial lockdown in 2020. The government of India has made several investments in construction and infrastructure to aid in development. As per a report by the Indian Construction Equipment Manufacturers Association (ICEMA), the construction equipment industry recorded a 47% growth in the second quarter of FY2021-22. According to a news report in Reuters, in FY22-23, US$529.7 billion will be invested to further drive economic growth across the country. China’s construction sector is expanding rapidly. according to the National Bureau of Statistics, China’s construction output is estimated to be worth approximately US$4.3 trillion in 2021. China plans to invest US$1.43 trillion in key construction projects as part of its 14th five-year plan. As per the National Development and Reform Commission (NDRC), the Shanghai plans call for a total investment of US$38.7 billion over the next three years. The Japanese construction industry is expected to boom as the World Expo will be hosted in Osaka, Japan in 2025. Therefore, this region is set to dominate the Powder Coatings market.

Schedule a Call

Powder Coatings Market Drivers

Environmental Advantages of Using Powder Coatings

Powder coating is the green process of choice for finishing operations. It produces less waste than other finishing processes such as liquid coating. The use of powder coating aids in eliminating waste because, after application, the powder coating overspray can be reclaimed and reused. These types of reclamation practices keep overhead costs low while minimizing environmental impacts. Solvents contain volatile organic compounds (VOCs) which are detrimental to the environment. In liquid coatings, the average VOC content is between 3.5 to 5.5 pounds per gallon, which is approximately one-third to one-half of each gallon of the liquid coating being emitted into the environment during the application process. Since powder coating lines do not require the use of solvents, they do not emit VOCs and can operate with reduced energy, faster curing and lower temperatures. This makes powder coatings highly attractive from an environmental perspective. Innovations in the powder coatings industry strive to make it even better. For instance, in early 2020, Sherwin-Williams General Industrial Coatings division launched the Powdura ECO line made from a resin that uses pre-consumer recycled polyethylene terephthalate (rPET). Thus, the environmental advantages offered by using powder coatings drive the market.

Growing Usage of Powder Coatings in Electric Vehicles

The growth of electric vehicles (EVs) can be attributed to increasing oil prices and growing awareness regarding climate change. According to the International Energy Agency (IEA), in 2021, sales of electric cars (including fully electric and plug-in hybrids) doubled to a new record of 6.6 million. Sales kept rising in 2022 as well, with 2 million electric cars sold worldwide in Q1 2022, up almost 75% compared to Q1 2021. To keep EV motors and batteries operating efficiently, it’s important to maintain an optimum temperature range. Sometimes EV motors can generate operating temperatures that may exceed 200°C. Powder coatings are used to insulate battery boxes and isolate thermal activity. To take advantage of the growing EV market, powder coating manufacturers are launching products that cater to EVs. For instance, in January 2022, Arkema announced high-voltage coating solutions for electric vehicles. The two new polyamide 11 powder coating grades with UL certification were introduced for use in electric vehicle battery systems and other applications. Thus, the growing usage of powder coatings for EVs drives the market.

Powder Coatings Market Challenge

High Initial Investment

The major restraint in the Powder Coatings market is the high initial investment required to set up the powder coating equipment. Liquid coating applications only require a spray gun and a spray area. Comparatively, a powder coating workshop needs a spray gun, spray booth and curing oven. The addition of the curing oven adds significantly to the initial start-up costs for powder coating. The size of the curing oven purchased needs to take into account the maximum part size that can effectively be handled. Larger, thicker and heavier parts require a larger and more powerful oven, which further adds to the overall equipment costs. While metals can be powder coated using electrostatic spray deposition, non-metals require a fluidized bed powder coating application. The need for a fluidized bed also increases the overall equipment costs for the establishment of a complete powder coating facility. This can prove to be a challenge for the powder coatings market.

Buy Now

Powder Coatings Industry Outlook

Product launches, acquisitions and R&D activities are key strategies adopted by players in the Powder Coatings market. The top 10 companies in the Powder Coatings Market are:

PPG Industries

AkzoNobel Powder Coatings

BASF SE

Axalta Coating Systems

The Sherwin Williams Company

Jotun

Valspar Corporation

Nippon Paint Holdings Co. Ltd.

Kansai Nerolac Paints Limited

Tiger Coatings

Recent Developments

In June 2022, Polychem launched a new powder coating collection called the Effects Collection. The collection features powder special effects, such as speckles, translucents, metallics, sparkle translucent, veins, patina effects, river textures, fine textures and dramatic illusion colors, available in a variety of colors.

In May 2022, AkzoNobel Powder Coatings launched a comprehensive range of ready-to-ship powder coatings ranges specifically for the North American market. The range comprises approximately 500 unique powder coatings, with a broad variety of premium quality colors, textures and finishes.

In February 2022, PPG announced that it has entered into an agreement to acquire the powder coatings business of Arsonsisi, an industrial coatings company based in Milan, Italy. The acquisition will enable PPG to expand its powder coatings offering in the Europe, Middle East and Africa (EMEA) region.

#Powder Coatings Market#Powder Coatings Market Share#Powder Coatings Market Size#Powder Coatings Market Forecast#Powder Coatings Market Report#Powder Coatings Market Growth

0 notes

Text

Exploring the Booming Waterborne Polyurethane Market

Overview and Scope Waterborne polyurethane refers to a polyurethane polymer resin that can be dispersed in water. It has good adherence to numerous surfaces, including glass and polymeric fibres, and can be formed into coatings and adhesives.

Sizing and Forecast The waterborne polyurethane market size has grown strongly in recent years. It will grow from $5.07 billion in 2023 to $5.41 billion in 2024 at a compound annual growth rate (CAGR) of 6.6%. The growth in the historic period can be attributed to government investments in research and development, environmental regulations, market demand shift, advancements in formulation, industry adoption..

The waterborne polyurethane market size is expected to see strong growth in the next few years. It will grow to $6.98 billion in 2028 at a compound annual growth rate (CAGR) of 6.6%. The growth in the forecast period can be attributed to consumer preferences for eco-friendly products, collaboration with industries, customization, impact of covid-19 pandemic, supply chain restrictions, manpower & equipment shortage.. Major trends in the forecast period include brand reputation and consumer awareness, energy efficiency, market penetration strategies, global economic trends, focus on health & safety..

To access more details regarding this report, visit the link: https://www.thebusinessresearchcompany.com/report/waterborne-polyurethane-global-market-report

Segmentation & Regional Insights The waterborne polyurethane market covered in this report is segmented –

1) By Type: Polyurethane Emulsion, Polyurethane Dispersion, Polyurethane Aqueous Solution 2) By Application: Coating, Sealant, Adhesive, Elastomer 3) By End-use industry: Building and construction, Automotive and transportation, Bedding and furniture, Electronics, Other End Users

Asia-Pacific was the largest region in the waterborne polyurethane market share in 2023. The regions covered in the waterborne polyurethane market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report: https://www.thebusinessresearchcompany.com/sample.aspx?id=8316&type=smp

Major Driver Impacting Market Growth The growth of the construction industry is expected to propel the growth of the waterborne polyurethane market going forward. The construction sector is involved in building infrastructure such as houses, buildings, bridges, and so on. Waterborne polyurethane coatings are used for both floor and wall coatings in various newly constructed buildings as a protective layer for abrasion resistance, weathering resistance, and chemical resistance, thereby increasing the demand for the waterborne polyurethane market. For instance, according to data by The Construction Index, a UK-based publisher of construction sector information, construction output increased by 1.7% in volume terms in March 2022 in comparison with February data in the UK. The rise in repair and maintenance (3.0%) and new work (1.0%) activity drove the increase in monthly construction production in March 2022. Therefore, the growth of the construction industry is driving demand for the waterborne polyurethane market.

Key Industry Players Major companies operating in the waterborne polyurethane market report are Covestro AG, Koninklijke DSM NV, BASF SE, Allnex Belgium SA, Dow Inc., H.B. Fuller Company, Wanhua Chemical Group Co. Ltd., SNP Inc., Kamsons Chemicals Pvt. Ltd., Axalta Coating Systems Ltd., The Sherwin-Williams Company, Perstorp AB, C.L Hauthaway & Son Corporation, Lamberti S.p.A., Sun Polymers International Inc., R. STAHL GmbH, Chemtura Corporation, Lanxess AG, Lubrizol Corporation, Bayer MaterialScience AG, PPG Industries Inc., Capital Resin Corporation, Walter Wurdack Inc., Palmer Holland Inc., SIWO US Inc., Brilliant Group Inc., Aditya Birla Chemicals Ltd., Hauthaway Corporation, Henkel AG & Co. KGaA, Huntsman Corporation, Nippon Polyurethane Industry Co. Ltd.

The waterborne polyurethane market report table of contents includes: 1. Executive Summary 2. Market Characteristics 3. Market Trends And Strategies 4. Impact Of COVID-19 5. Market Size And Growth 6. Segmentation 7. Regional And Country Analysis . . . 27. Competitive Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Melamine Market : A Look at the Industry's Growth Drivers and Challenges

The global melamine market size is expected to reach USD 2,578.4 million by 2030 according to a new study by Polaris Market Research. The report “Melamine Market Share, Size, Trends, Industry Analysis Report By Type; By Application; By End-Use (Construction, Automotive, Chemical, Textiles, Others); By Region, Segment Forecast, 2022 - 2030” gives a detailed insight into current market dynamics and provides analysis on future market growth.

Melamine is a natural chemical that is frequently mixed with formaldehyde to generate this resin, a synthesized material that is fire and heat-resistant. Increasing the application of products for flooring, whiteboards, flame retardant materials, tableware, and industrial filters is expected to boost the product demand over the forecast period.

Furthermore, a rise in investments in research & development, as well as a growth in need from developing markets, are expected to generate lucrative possibilities for the industry throughout the projection period. The construction end-use segment is expected to hold the largest industry share over the forecast period due to increasing global construction activities. Increasing demand for construction applications including laminates, wood adhesives, surface coatings, concrete plasticizers, molding compounds, and others are expected to fuel the segment growth.

Have Questions? Request a sample report by clicking the link below: https://www.polarismarketresearch.com/industry-analysis/melamine-market/request-for-sample

Asia Pacific is expected to dominate the global industry over the forecast period due to increasing construction activities, growth in the automobile sector, along increasing disposable income of people. The demand in Europe is expected to increase over the forecast period due to the increasing demand for decorative wood panels along with the growth in the automotive industry in Germany.

Key players of the market include BASF SE, Allnex Belgium S.A., Borealis AG, Chemiplastica SP, Grupa Azoty Zaklady Azotowe Pulawy S.A. (ZAP), Cornerstone Chemical Company, Henan Zhongyuan Dahua Group Co Ltd., Haohua Junhua Group Co., Ltd., Methanol Holdings (Trinidad) Limited, Mitsui Chemicals Inc, Nissan Chemical Industries. Ltd., Mevion Medical Systems, Sichuan Golden Elephant Chemical Co, Sichuan Chemical Holdings Co. Ltd., and Xinji Jiuyuan Chemical Co. Ltd.

Polaris Market Research has segmented the melamine market report on the basis of type, application, end-use, and region:

Melamine, Type Outlook (Volume - Kiloton, Revenue – USD Million, 2018 - 2030)

Melamine Resin

Melamine Foam

Melamine, Application Outlook (Volume - Kiloton, Revenue - USD Million, 2018 - 2030)

Laminates

Wood Adhesives

Molding Compounds

Paints & Coatings

Others

Melamine, Application Outlook (Volume - Kiloton, Revenue - USD Million, 2018 - 2030)

Construction

Automotive

Chemical

Textile

Others

Melamine, Regional Outlook (Volume - Kiloton, Revenue - USD Million, 2018 - 2030)

North America

S

Canada

Europe

Germany

UK

Italy

France

Spain

Austria

Netherlands

Asia Pacific

China

Japan

India

Indonesia

Malaysia

South Korea

Latin America

Brazil

Argentina

Mexico

Middle East & Africa

Israel

Saudi Arabia

South Africa

UAE

Purchase the Report for Key Insights:@ https://www.polarismarketresearch.com/industry-analysis/melamine-market

About Us:

Polaris Market Research is a worldwide market research and consulting organization. We give unmatched nature of offering to our customers present all around the globe across industry verticals. Polaris Market Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We at Polaris are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures, present globally.

Contact Us:

Polaris Market Research

Email: [email protected]

Phone: +1-929-297-9727

0 notes

Text

Epoxy Resin Flooring

We are one of the leading indoor flooring coating companies in the United Kingdom and specialise in epoxy resin floors. Our floor coatings provide many benefits and are used across various industries. As an epoxy resin floors leader, we have worked with various clients across the UK and continue to provide high-quality services at competitive prices. If you are interested in learning more about specially designed epoxy floor coating and our work, please contact us today. We can explain the process of installing an epoxy resin flooring system and the costs involved.

Website: https://epoxyresinflooring.uk/

Address : Epoxy Resin Flooring, The Industrial Coatings Department, 82 Mallard Crescent, Poynton, Cheshire, SK12 1HT

Phone Number: 0177 239 3069

1 note

·

View note

Text

Epoxy Flooring

We are a leading provider of epoxy resin flooring coatings and work with clients across the UK to install this. There are many benefits that epoxy flooring can provide and our contractors work to install these coatings in key locations across the country. Resin floors like this are designed to be hard wearing and can offer additional benefits such as slip or chemical resistance. Our team is fully accredited in the installation of epoxy resin flooring and will find the best solution suitable for your needs. We aim to offer a cost effective exposy resin floor and will work on site with our clients until the project is completed for the highest standards of work. If you are interested in epoxy resin floors, please contact the team today.

Website: https://epoxy-flooring.uk

Address : Epoxy Flooring, The Resin Coatings Suite, 7 Lord Street, Liverpool, Merseyside, L2 1TS

Phone Number: 0151 380 0419

Business Hours: 9:00AM - 5:00 PM

1 note

·

View note

Text

Official Presentation Rhino Industrial Flooring

Rhino Industrial Flooring, we are one of the UK’s leading Epoxy flooring contractors specialising in industrial flooring, coating, and lining systems. Moreover, we have successfully installed high-performance flooring throughout the UK since 1998. Our highly skilled tradespeople average more than 20 years of experience in fitting 1000s of square miles of resinous flooring, which ranks us as one of the best in the industry.

Unit 28 Warren Workshops,Wrexham,Clywed,LL12 0PD

07865287813

#factory flooring#flooring warehouses#food grade flooring#industrial floor coating#industrial flooring.

0 notes

Text

Chemical Resistant Coatings Market to Witness Excellent Revenue Growth Owing to Rapid Increase in Demand

Latest released the research study on Global Chemical Resistant Coatings Market, offers a detailed overview of the factors influencing the global business scope. Chemical Resistant Coatings Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Chemical Resistant Coatings The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are BASF SE (Germany), Metal Coatings Corp (United States), ITW Polymers Sealants (United States), The Jotun Group (Norway), PPG Industries Inc. (United States), Sika AG (Switzerland), The Sherwin-Williams Company (United States), VersaFlex Incorporated (United States), Wacker Chemie AG (Germany), The Protech Group (Australia)

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/88333-global-chemical-resistant-coatings-market

Chemical Resistant Coatings Market Definition:

Chemical resistant coatings are employed in different industries like construction, waste product treatment, organic compound, etc. There are other forms of chemical resistant coatings resins that are employed in the coating to avoid the corrosion of the structures and metals. chemical resistant coating and paint extremely corrosive chemical environments and industries to shield metal, wood, etc. For some purpose, the majority of coatings can get disclosed to chemicals and acids, whether clean-up product, spills, or fumes. This coating plays a considerable role in protection against harmful acids, oils, solvents, and even clean-up solutions which may simply result in erosion on floors.

Market Trend:

Product Development with Additional Benefits like Heat Resistance and Water Resistance

Market Drivers:

Rising Applications in Construction and Infrastructure for Layering, Varnishing, or Flooring Applications

Market Opportunities:

Increasing Applications of Chemical Resistant Coating in Automobile Sector

Rising Demand for the Chemical Resistant Coating in Wastewater Treatment Plants and Sewer for Better Efficiency

The Global Chemical Resistant Coatings Market segments and Market Data Break Down are illuminated below:

by Type (Solvent-borne, Water-borne, Others), Form (Liquid, Granules, Powder), Industry Verticals (Chemical, Oil and Gas, Marine, Construction and Infrastructural), Product (Epoxy, Polyester, Fluoropolymers, Polyurethane, Other Resins)

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc.

Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/88333-global-chemical-resistant-coatings-market

Strategic Points Covered in Table of Content of Global Chemical Resistant Coatings Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Chemical Resistant Coatings market

Chapter 2: Exclusive Summary – the basic information of the Chemical Resistant Coatings Market.

Chapter 3: Displayingthe Market Dynamics- Drivers, Trends and Challenges of the Chemical Resistant Coatings

Chapter 4: Presenting the Chemical Resistant Coatings Market Factor Analysis Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying market size by Type, End User and Region 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Chemical Resistant Coatings market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by manufacturers with revenue share and sales by key countries (2021-2026).

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source

Finally, Chemical Resistant Coatings Market is a valuable source of guidance for individuals and companies in decision framework.

Data Sources & Methodology The primary sources involves the industry experts from the Global Chemical Resistant Coatings Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects.

In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age.

For Early Buyers | Get Up to 20% Discount on This Premium Report: https://www.advancemarketanalytics.com/request-discount/88333-global-chemical-resistant-coatings-market

What benefits does AMA research study is going to provide?

Latest industry influencing trends and development scenario

Open up New Markets

To Seize powerful market opportunities

Key decision in planning and to further expand market share

Identify Key Business Segments, Market proposition & Gap Analysis

Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837

0 notes

Video

youtube

Microcement PRO Installation Guide

As distributors of Microcement Pro - Clever Shield provide full support for installers with a full 10-year product guarantee directly from the manufacturers.

Epoxy Microcement is a decorative two-component mortar based on epoxy resins in aqueous dispersion. Due to its seamless, waterproof, hardwearing and beautiful decorative properties, Epoxy Microcement is becoming incredibly popular amongst residential and business owners across the UK.

One of the best features of Epoxy Microcement is that it doesn’t need joints, making cleaning and maintenance extremely easy. Epoxy Microcement offers a wide range of possibilities and finishes, where the limitations are applied only by you. Stamp your room with a unique and personal character, thanks to the our different textures (thick, medium or fine), the great variety of colours and the different finishes (matte, satin or gloss) available. With the final surface built up over 4-6 layers (yet only 2-3mm thick!), Epoxy Microcement can be used on floors, walls, stairs, large commercial floors, wet rooms, showers, patios and even swimming pools! Our handcrafted application makes the result of each project amazingly unique and special; unrepeatable as no two surfaces will ever be the same.

10 Years manufacturers warranty. Uses It can be applied to any hard surface, both indoors and out including (but not limited to): Existing floors Plastered walls and ceilings Bathrooms and kitchens Countertops Bathtubs Furniture Doors Stairwells and steps The following kits are available with individual components available via our sales order-line 01268 472385 Epoxy Microcement System Traditional Microcement System For further information and pricing on Microcement Pro please visit our website or call our customer services team.

CLEVER SHIELD - UK DISTRIBUTORS FOR MICROCEMENT PRO

Discount rates are available for larger projects on all coatings. T: 0800 7022176 E: [email protected] W: clevershieldcoatings.co.uk #microcement #microcementrepair #microcementkitchen #microcementbathroom #microcementshop #coatingsolutions #microcementwalls #microcementfloor #microcementstairs

0 notes

Link

1 note

·

View note

Text

0 notes

Text

Wiki Garden Gnome

Wiki Garden Gnome Article <3 Thanks Wiki

Garden gnome

Garden gnomes (German: Gartenzwerge, lit. 'garden dwarfs') are lawn ornament figurines of small humanoid creatures known as gnomes. Traditionally, the figurines depict male dwarfs wearing red pointy hats. Typically, gnomes stand between one and two feet (30 and 60 cm). A recent[when?] trend has introduced miniature gnomes of only a few inches in height. Originating as a decoration for the wealthy in Europe, garden gnomes are now prevalent in gardens and lawns throughout the western world, among all social classes, and often regarded as kitsch.

Gnomes

History

In ancient Rome, small stone statues depicting the Greco-Roman fertility god Priapus, also the protector of floors, were frequently placed in Roman gardens. Gnomes as magical creatures were first described during the Renaissance period by Swiss alchemist Paracelsus as "diminutive figures two spans in height who did not like to mix with humans". During this period, stone "grotesques", which were typically garishly painted, 1-metre-tall (3.3 ft) figurines, were commonly placed in the gardens of the wealthy. Among the figures depicted were gobbi (Italian for hunchbacks). In particular, Jacques Callot produced 21 versions of gobbi, which he engraved and printed in 1616.

Pre-twentieth century

By the late 1700s, gnome-like statues made of wood or porcelain called "gnomes" became popular household decorations. The area surrounding town of Brienz in Switzerland was known for their production of wooden house dwarfs. In Germany, these garden figurines became conflated with their traditional stories and superstitions about the "little folk" or dwarfs that they believed helped around the mines and on the farm. The Dresden company Baehr and Maresch had small ceramic statues of dwarfs or "little folk" in stock as early as 1841, and although the claim has been contested, some credit Baehr and Maresch with the first garden dwarfs (German: Gartenzwerge)

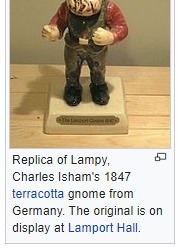

Within less than 10 years, statues of dwarfs had spread from the provinces of Saxony and Thuringia across Germany to France and, in 1847, Sir Charles Isham, brought 21 terracotta gnomes manufactured in Germany by Philip Griebel back to Britain where they were called "gnomes" in English and placed in the gardens of Isham's home, Lamport Hall in Northamptonshire. Nicknamed "Lampy", the only gnome of the original batch to survive is on display at Lamport Hall and insured for GB£1 million.

The manufacture of gnomes spread across Germany, with numerous other large and small manufacturers coming in and out of the business, each having its own particular style of design. From around 1860 onwards, many statues were made in Gräfenroda, a town in Thuringia known for its ceramics.

Garden gnomes spread to other countries in Europe in the 1840s and became particularly popular in France and Britain The term "garden gnome" may originate from the term "Gnomen-Figuren" (miniature figurines), used in the original German catalogues.

Twentieth century

Garden gnomes were further popularized when Sir Frank Crisp, the owner of the second largest collection of garden gnomes in the UK opened his Friar Park, Henley-on-Thames estate to the public at least once a week from 1910-1919. It was here where garden enthusiasts and visitors from around the world perhaps saw garden gnomes for the first time.

The reputation of German gnomes declined after World War I, but they became popular again in the 1930s following Disney's animated film Snow White and the Seven Dwarfs, when more working-class people were able to purchase them. Tom Major-Ball (father of former British prime minister John Major) was the most notable producer at that time with his company Major's Garden Ornaments.World War II and the years following were also hard on the industry, and most producers gave it up then.

Garden gnomes saw a resurgence in popularity again in the 1970s with the creation of more humorous types of gnomes. In the 1990s travelling gnome and garden gnome pranks became popular and made national news at times, where people steal a garden gnome from an unknowing person's lawn and then send the owner photos of the gnome as a practical joke before returning it.

Twenty-first century

Philip Griebel's descendants are still producing garden gnomes in Germany. As of 2008, there were an estimated 25 million garden gnomes in Germany.

Types of garden gnomes

Garden gnomes are typically male, often bearded, usually wear red phrygian caps and often have pipes. They are often shown pursuing leisurely pastimes such as fishing or napping.

Gnomes may be made from terracotta clay slip (runny clay) poured into molds. This is allowed to set up and the excess emptied from the centre, leaving a clay shell. The gnome is removed from the mold when firm, allowed to dry and then fired in a kiln until hard. Once cooled, the gnome is painted. More modern gnomes are made from resins and similar materials.

Today, many different variations of garden gnomes exist, including humorous ones ranging from the lighthearted biker or barbecuing gnome, to the more dark, such as one stabbed in the back or wearing an executioner's hood.

In popular culture and politics

Gnomes have become controversial in serious gardening circles in the UK, and were for a time banned from the prestigious Chelsea Flower Show, as the organisers claimed that they detract from the garden designs.Gnome enthusiasts accused the organisers of snobbery, as garden gnomes are popular in the gardens of working class and suburban households. The ban was lifted during 2013 to mark the show's centenary.

In the Italian movie The Monster (1994), the main character Loris, played by Roberto Benigni, is rightfully accused of stealing the garden gnome Bashful.

A subplot in the 2001 French movie Amélie revolves around a "travelling" garden gnome.

A two-foot-tall (60 cm) garden gnome with a long, white beard, red conical hat and blue coat is the central figure in Travelocity's Roaming Gnome advertising campaign which was launched in January 2004.

Gnomeo and Juliet is a 2011 British-American CGI film that is inspired by the tragedy of Romeo and Juliet featuring garden gnomes as the characters. In 2018, its sequel, Sherlock Gnomes, was released.

The Social Democratic Party of Austria (SPÖ) used garden gnomes, which they called "Coolmen", in their campaign for the 2014 regional elections in Vorarlberg. It was intended as an ironic pun since the SPÖ historically performed poorly in elections in this part of Austria and considered itself to be a political "dwarf". The campaign placed 20,000 Coolmen holding small posters with short slogans along highly frequented roads. The party made a police report after 400 of them went missing, drawing attention from the international media.

The 2010 video game Fable III includes a side mission where a collection of garden gnomes are given magical properties, which the player character must collect throughout the world.

Garden gnomes feature as the driving motivator of Old Man Henderson, whose exploits derailed a Call of Cthulhu variant tabletop roleplaying game, described on the website 1d4chan in 2010. The character Henderson's sole motivation was to "rescue" roughly $40,000 worth of garden gnomes from a local cult, not realizing that he'd given them to charity before the game's starting session.

A 2005 episode of King of the Hill titled "Yard, She Blows!" revolves around Bobby breaking Peggy's newly acquired, and very rare, garden gnome. Hank, hating the gnome, attempts to use the event to eliminate it from the front lawn.

https://en.wikipedia.org/wiki/Garden_gnome

Thanks again Wiki! <3

3 notes

·

View notes

Text

Milestone Flooring

https://www.milestoneflooring.co.uk/

Welcome to Milestone Industrial Flooring. We are one of the UK’s leading installers of industrial and commercial resin flooring, coatings and screeds.

1 note

·

View note

Text

Different Types of Flooring?

LINOLEUM This kind of material for flooring Luton has greatly improved its performance and design in recent times, so it deserves to be reviewed. Its main component is flaxseed oil mixed with other materials such as ground stone, and at the same time, biodegradable UK components. RUBBER Natural rubber is another long-lasting material in Watford Flooring but has made notable improvements over time. Among its main characteristics are its resistance and durability, its waterproofness and resistance to water and its easy maintenance and cleaning. VINYL FLOORS Unlike rubber and linoleum, vinyl or PVC floorings are synthetic. They are also non-slip, very resistant to moisture and wear in general and their maintenance and cleaning are simple. VINYL WITH REINFORCED GLASS FIBRE Some of the new Milton Keynes flooring feature high quality vinyl coatings, that give a textile appearance and, at the same time, provide durability and easy cleaning. CERAMIC FLOORS New technologies of ceramic production have made its reproduction possible, so that it recovers its spirit of geometries and organic or floral designs, but with improved characteristics with kitchen services. VINYL TILES The vinyl tiles allow diverse designs, such as is seen in ceramics. They are vinyl pieces of St Albans Flooring, resistant to moisture, which are placed in a fast, easy and simple manner. EPOXY RESIN FLOORS These are very suitable to renovate the your Flooring Bedford without removing the existing one and with a cost far below other options. It is self-leveling and formed by a thermosetting polymer that hardens when mixed with a catalyst agent. NEW TEXTILE FLOORS This new textile technology is made up of fabrics that incorporate, for example, a three-dimensional effect, which are 100% waterproof or even washable textileDunstable Flooring. They provide warmth and comfort, isolate noise and slow down the reverberation of the ambient sound, creating more pleasant environments.

2 notes

·

View notes

Text

Tips for Choosing the Best Resin Flooring Service Providers

You should as an individual ensure that you work hard toward procuring a house which matches your preference since this will go a long way in giving a sense of self-fulfillment. You might have a preference of a particular type of a structure for your dream hence the ball in your coat when it comes to achieving this. You can in some instances have a special liking to a certain type of a floor for your property and this will suit your taste when you have it. There are times when you might be looking forward to having a resin floor, and hence it will be for you to look for the right contractor. In the current times, it will dawn on you that there are specific resin flooring contractors providers who are available and such ought to be your primary target.

It will be necessary to scan the environment exhaustively as this is a great way to expose you to the different resin flooring service providers who you can engage. The tips which you use carry much weight to the accuracy of your selection. This article is suitable as it will expound more on the elements which ought to be in your mind when choosing the perfect resin flooring firm. At first, aim at going for the company which will have a team of highly qualified workers.

Target a contractor who will have the ability to use the best skills when it comes to fixing the floor accordingly since this will be impactful to the lifespan. Consider going for the resin flooring experts who are in the forefront when using advanced methodologies. Many are the times when such a contractor will take less time to make the whole flooring work complete. In the other hand, the flooring work will exhibit a high level of quality.

Select the resin flooring service providers who are long-serving with respect to the rendering of services. For the durability of the floor to be achieved, you need to know the best ways to handle it, and in that case, an experienced contractor will be in the position to giving you the insight. It is a good thing for you to do some background research on the flooring company of target as this will expose you to the length of service delivery. To get more tips on how to choose the best flooring, go to https://en.wikipedia.org/wiki/Flooring.

Finally, many are the times when you will work with a budget hence a competent epoxy resin flooring uk contractor is the one who will help you work by it. Doing a comparison of the different contractors will help you identify the one who will save you a lot of money.

1 note

·

View note

Text

Milestone Holdings Group

Leading specialist installers of resin flooring, coatings and screeds in the UK. Need some expert advice? Call us on 01977 269049

1 note

·

View note