#reliabilityengineering

Explore tagged Tumblr posts

Link

Discover how rigorous testing and quality assurance ensures the reliability of life-saving medical devices. Safeguarding health through innovation and precision!

Click to read more: https://bit.ly/3YrMY3d

#medicaldevice#lifesavingdevices#devicetesting#qualityassurance#healthcaresafety#medicaldevicestandards#reliabilityengineering#devicesafety#regulatorycompliance#medicaldeviceinnovation

2 notes

·

View notes

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#MaintenancePlanning#AssetManagement#ReliabilityEngineering#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization#OperationsManagement

1 note

·

View note

Text

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

Oil Condition Monitoring in Taif: Advanced Solutions by Bafco Reliability

Effective oil condition monitoring is crucial for maintaining industrial machinery and preventing unexpected failures. Bafco Reliability provides top-notch Oil Condition Monitoring in Taif, helping industries enhance equipment performance, reduce maintenance costs, and extend machinery lifespan.

Importance of Oil Condition Monitoring

Oil plays a critical role in lubricating and cooling machinery components. Contaminated or degraded oil can lead to equipment failures, increased friction, and reduced efficiency. Our expert Oil Condition Monitoring in Taif services ensure the optimal performance of industrial assets through comprehensive oil analysis and predictive maintenance.

Key Oil Condition Monitoring Services We Offer

1. Oil Sampling & Analysis

Detects contamination, oxidation, and wear particles to prevent potential failures.

2. Viscosity Testing

Ensures that oil maintains the proper consistency for smooth machinery operation.

3. Contamination Detection

Identifies water, dirt, and metal particles that can damage critical components.

4. Lubricant Quality Assessment

Monitors the chemical composition of oil to ensure it meets performance standards.

5. Real-Time Condition Monitoring

Utilizes advanced sensors and data analysis to provide continuous insights into oil health.

Industries Benefiting from Our Oil Condition Monitoring Services in Taif

- Oil & Gas Industry:

Prevents failures in drilling and refining equipment, ensuring operational safety.

- Power Plants:

Optimizes turbine and generator performance with real-time oil analysis.

- Manufacturing & Heavy Industries:

Reduces downtime and enhances productivity through predictive maintenance.

- Marine & Offshore Operations:

Protects engines and hydraulic systems from premature wear and breakdowns.

Why Choose Bafco Reliability?

Bafco Reliability is a leading provider of Oil Condition Monitoring in Taif, utilizing state-of-the-art technology and expert diagnostics to enhance industrial efficiency. Our monitoring solutions help businesses reduce maintenance costs, extend equipment life, and prevent unexpected failures.

Ensure optimal machinery performance with Bafco Reliability’s expert oil monitoring solutions.

Contact Bafco Reliability Today!

For more details on our Oil Condition Monitoring in Taif, get in touch with Bafco Reliability now!

#OilConditionMonitoringTaif#BafcoReliability#PredictiveMaintenance#LubricationManagement#IndustrialEfficiency#MachineryProtection#ReliabilityEngineering#EquipmentMaintenance#ConditionMonitoring#PreventiveMaintenance

0 notes

Text

Preventing Power System Failures: How Arteche Trip Circuit Supervision Relays Improve Protection

In the modern power industry, reliability and protection are essential to ensuring smooth operations. Electrical systems are intricate, and any failure can lead to significant losses, both operationally and financially. One critical aspect of these systems is the trip circuit, which plays a vital role in the safe disconnection of faulty components. The Arteche VDF-10 Trip Circuit Supervision Relay and other Arteche supervision relays are designed to ensure that trip circuits remain reliable and functional, preventing system failures and enhancing protection.

In this blog, we will explore how Arteche’s supervision relays help prevent power system failures, their essential role in maintaining safety, and why they are critical for the protection of modern electrical infrastructures.

Understanding Trip Circuits and Their Importance

In power systems, trip circuits are part of the protective relaying scheme. When a fault occurs, such as a short circuit or overload, the trip circuit activates the circuit breaker, which disconnects the faulty part from the system to prevent damage or failure. Essentially, trip circuits are the backbone of system protection, as they ensure that the system responds appropriately to any malfunction.

However, trip circuits can sometimes fail due to wiring issues, mechanical faults, or component deterioration. If a trip circuit fails, the breaker may not operate when required, leaving the system vulnerable to extensive damage. Therefore, monitoring and ensuring the health of trip circuits is critical, and this is where Arteche VDF-10 Trip Circuit Supervision Relays come into play.

What is the Arteche VDF-10 Trip Circuit Supervision Relay?

The Arteche VDF-10 Trip Circuit Supervision Relay is a specialized device designed to continuously monitor the integrity of trip circuits in electrical systems. It ensures that the trip circuit is always operational, providing real-time supervision and instant detection of any faults.

Some key features of the Arteche VDF-10 include:

Continuous Supervision: The VDF-10 continuously monitors the trip circuit, detecting wiring faults, open circuits, or component failures.

Instant Alerts: If any malfunction occurs in the trip circuit, the relay sends an immediate alarm to alert the maintenance team of the issue.

Compact Design: The VDF-10 is designed to fit into compact spaces within substations and other electrical environments.

Versatility: It can be used in a wide range of voltage systems, making it applicable across different power system configurations.

By using the Arteche Relay, operators can detect potential issues early, before they cause system failures, and take preventive measures to maintain uninterrupted operations.

How Arteche Trip Circuit Supervision Relays Improve Protection

Let’s dive deeper into how Arteche trip circuit supervision relays, such as the VDF-10, contribute to the protection and reliability of power systems:

1. Real-Time Monitoring for Early Fault Detection

One of the biggest challenges in power systems is identifying problems before they escalate into full-scale failures. The Arteche VDF-10 Trip Circuit Supervision Relay continuously monitors the trip circuit in real-time, ensuring that the circuit is always functional. It checks for open circuits, wiring failures, loose connections, and other issues that may compromise the trip circuit’s ability to operate.

This real-time monitoring provides early detection of faults, allowing maintenance teams to address the problem before it leads to a critical failure. By proactively identifying issues, the VDF-10 prevents costly outages and reduces the risk of equipment damage.

2. Enhanced System Reliability

The reliability of the trip circuit directly impacts the reliability of the entire electrical system. When a fault occurs in the power network, the trip circuit must operate swiftly to disconnect the faulty section and protect the rest of the system. A malfunctioning trip circuit could lead to a delay in the breaker operation, resulting in extensive damage and prolonged downtime.

The Arteche VDF-10 Trip Relay enhances system reliability by ensuring that the trip circuit is always in good working order. By providing constant supervision, it ensures that power systems can respond promptly to any fault, improving overall reliability and system uptime.

3. Prevention of Catastrophic Failures

In the absence of trip circuit supervision, undetected faults can accumulate over time, increasing the risk of catastrophic system failures. A simple wiring issue in the trip circuit could prevent the breaker from disconnecting a faulty part, leading to large-scale damage to transformers, generators, and other critical equipment.

Arteche’s trip circuit supervision relays, like the VDF-10, prevent such failures by offering continuous supervision and immediate alerts. By ensuring that the trip circuit functions as intended, Arteche supervision relays safeguard electrical equipment and prevent failures that could lead to costly repairs or replacements.

4. Reduction of Maintenance Downtime

In traditional power systems, maintenance teams often conduct periodic manual checks to ensure the integrity of trip circuits. However, this process is time-consuming and prone to human error. By using Arteche VDF-10 Trip Circuit Supervision Relays, operators can automate the supervision process and receive alerts in real-time when a fault occurs.

This real-time fault detection reduces the need for manual inspections and allows maintenance teams to focus on addressing actual issues rather than spending time on routine checks. As a result, the system experiences less maintenance downtime, improving operational efficiency.

5. Improved Safety for Operators and Equipment

Electrical systems can be hazardous, and faults that go undetected in trip circuits can pose serious safety risks to operators. Without proper trip circuit supervision, an operator might unknowingly engage with a faulty system, leading to injury or damage.

Arteche trip circuit supervision relays improve safety by ensuring that operators are informed of any issues in the trip circuit before they interact with the system. Immediate alerts and fault detection give operators the necessary information to act safely, preventing accidents and protecting both personnel and equipment.

Arteche Supervision Relays: A Broader Perspective

While the Arteche VDF-10 Trip Relay plays a specific role in monitoring trip circuits, Arteche also offers a wide range of supervision relays designed to enhance the protection and functionality of electrical systems. These relays are used to monitor critical parameters such as voltage, current, and circuit continuity, ensuring that power systems operate efficiently and safely.

Arteche’s supervision relays are known for their reliability, ease of use, and versatility. They can be integrated into various power system configurations, making them suitable for substations, power plants, industrial facilities, and other electrical infrastructures.

Conclusion

In today’s highly interconnected and complex power systems, ensuring the reliability and functionality of trip circuits is essential for preventing system failures. The Arteche VDF-10 Trip Circuit Supervision Relay and other Arteche supervision relays offer a proactive solution to monitoring and protecting trip circuits, ensuring that electrical systems can respond swiftly to faults and maintain uninterrupted operations.

By providing real-time monitoring, early fault detection, and enhanced protection, Arteche’s supervision relays improve the safety, reliability, and efficiency of power systems. For operators seeking to prevent catastrophic failures and enhance system reliability, the Arteche Trip Circuit Supervision Relay is an indispensable tool.

At Digital & Smart Grid Enterprises, we are committed to providing industry-leading supervision relay solutions, including the reliable Arteche VDF-10 Trip Relay. Our team of experts specializes in ensuring the safety and operational efficiency of your power systems through comprehensive testing, commissioning, and monitoring services. Whether it’s enhancing the reliability of your trip circuits or safeguarding your infrastructure against potential faults, we utilize advanced diagnostic tools to deliver precise and dependable results.

Contact us today at +917021624024 or email [email protected] to learn how we can help you protect and optimize your electrical systems.Click here to explore our Supervision Relay Services.

#powersystems#ElectricalEngineering#ReliabilityEngineering#CircuitProtection#TripCircuit#SupervisionRelay#Arteche#PowerGrid#ElectricalSafety#FaultDetection#SmartGrid#IndustrialAutomation#MaintenanceEfficiency#ElectricalInfrastructure#EnergyManagement

0 notes

Text

#siemens#switchgear#mediumvoltage#electricalengineering#powerdistribution#electricgrid#energymanagement#utilities#industrialautomation#energyefficiency#electricalsafety#smartgrid#powersystems#gridsolutions#highvoltage#substation#reliabilityengineering

1 note

·

View note

Text

#cmms#cmmssystem#MaintenancePlanning#PreventiveMaintenance#AssetManagement#MaintenanceStrategy#EquipmentMaintenance#CMMSSoftware#ReliabilityEngineering#WorkOrderManagement#MaintenanceScheduling#MaintenanceBestPractices#MaintenanceOptimization#ConditionBasedMaintenance#MaintenanceEfficiency#MaintenanceManagement#MaintenanceAutomation#FacilityManagement#PredictiveMaintenance#MaintenanceMetrics#MaintenanceAnalytics#lts#lean#leantransitionsolutions

1 note

·

View note

Text

⚡ Transformer Monitoring Systems = Smart Power — Market to double from $2.1B to $4.5B by 2034, growing at 7.9%.

Transformer Monitoring System is a vital part of modern power infrastructure, providing real-time insights into the health and performance of transformers. By continuously tracking key parameters such as temperature, oil levels, gas content, load, and insulation condition, these systems help prevent unexpected failures and extend the life of critical assets. With the integration of IoT, sensors, and AI-powered analytics, transformer monitoring systems offer predictive maintenance capabilities, enabling utilities to make informed decisions and reduce operational downtime.

To Request Sample Report : https://www.globalinsightservices.com/request-sample/?id=GIS22753 &utm_source=SnehaPatil&utm_medium=Article

These systems improve grid reliability, optimize asset performance, and enhance safety by identifying issues before they become major problems. In an era of growing energy demand, renewable integration, and smart grid development, transformer monitoring is essential for maintaining efficient and stable power delivery. From substations to industrial facilities, adopting smart transformer monitoring systems ensures cost-effective management, regulatory compliance, and improved service continuity. As digital transformation reshapes the energy sector, these systems are becoming indispensable tools for utilities looking to modernize their operations and future-proof their infrastructure.

#transformermonitoring #smartgrid #powergridtechnology #utilityinnovation #assetmanagement #conditionmonitoring #iotenergy #predictivemaintenance #energyefficiency #gridreliability #powersystems #transformerhealth #energymanagement #digitalgrid #electricutilities #gridautomation #transformertechnology #aiinutilities #smartinfrastructure #reliabilityengineering #energydigitalization #realtimemonitoring #industrialautomation #transmissionnetwork #substationautomation #remoteassetmonitoring #infrastructurehealth #electricalmaintenance #powerdistribution #gridmodernization #energystorage #renewableintegration #monitoringsolutions #electricalengineering #energysustainability #datadrivenutilities

Research Scope:

· Estimates and forecast the overall market size for the total market, across type, application, and region

· Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

· Identify factors influencing market growth and challenges, opportunities, drivers, and restraints

· Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

· Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

💫Achieving reliable, efficient pump performance goes beyond simple operation. Discover the power of #ActiveFlowBalancing—an advanced strategy to maximize system resilience, reduce wear, and prevent unexpected downtime. Ready to elevate your pump system’s sustainability?

💡Dive into this week’s #MrNoP advice and unlock new insights for optimizing #parallelpump operations.

#WaterSolutions #PumpEngineering #EnergyEfficiency #SustainableSystems #SaudiEngineering #IndustrialSolutions #PumpsandSystems #SaudiIndustry #ReliabilityEngineering #LinkedInTechnical #SmartPumping

💫لضمان استدامة وكفاءة أنظمة #المضخات_المتوازية نحتاج إلى ما هو أكثر من مجرد تشغيل قياسي.

👇🏻تعرف على تقنية Active Flow Balancing التي تضمن توزيع الأحمال بالتساوي على جميع المضخات مما يقلل من التآكل ويحمي النظام من الأعطال غير المتوقعة.

هل أنتم مستعدون لتحقيق أقصى استقرار وكفاءة في أنظمة المضخات؟ 💡تابعوا نصيحة هذا الأسبوع من Mr.#NOP

#حلول_المياه #توازن_التدفق #كفاءة_الطاقة #مضخات #الصناعة_السعودية #المضخات_والأنظمة #التحكم_الذكي

0 notes

Text

"Reliability Redefined: The Role of Static and Rotating Machinery"

Static and rotating equipment form the backbone of industrial facilities, encompassing a diverse range of machinery essential for various processes across industries such as oil and gas, power generation, petrochemicals, and manufacturing. Static equipment, including pressure vessels, heat exchangers, tanks, and pipelines, play a crucial role in storing, transferring, and processing fluids and gases under different conditions of pressure and temperature. These robust structures provide the foundation for safe and efficient operations, ensuring the integrity and reliability of process systems. On the other hand, rotating equipment, such as pumps, compressors, turbines, and motors, are responsible for generating mechanical energy, fluid movement, and power transmission. These dynamic components are vital for maintaining fluid flow, driving machinery, and generating electricity, making them indispensable in industrial processes. With the increasing demand for energy efficiency, reliability, and safety, the optimization and maintenance of static and rotating equipment have become paramount. Predictive maintenance techniques, condition monitoring systems, and digital twins are revolutionizing asset management practices, allowing for proactive identification of potential failures and performance optimization. Additionally, advancements in materials, design, and manufacturing techniques are enhancing the performance, durability, and sustainability of static and rotating equipment, contributing to operational excellence and environmental stewardship. As industries embrace digitalization and automation, static and rotating equipment remain at the forefront of innovation, driving efficiency, productivity, and competitiveness in the global market.

#StaticEquipment #RotatingEquipment #IndustrialProcesses #AssetManagement #PredictiveMaintenance #ConditionMonitoring #DigitalTwin #EnergyEfficiency #OperationalExcellence #EnvironmentalStewardship #SmartManufacturing #IndustrialAutomation #ProcessOptimization #ReliabilityEngineering #InnovationInIndustry

0 notes

Text

KZ Bearings play a crucial role in industrial blowers as they support rotating components, reduce friction, and enable smooth operation.

👉Email your inquiry – [email protected]

👉KZ Bearings – https://kgbearing.com/products/

👉Follow us for wide range of bearings at - https://linktr.ee/kgbearingindia

industrialblowers #industrialbearings #blowerbearings #industrialmachinery #engineeringsolutions #industrialequipment #manufacturingtechnology #industrialmaintenance #mechanicalengineering #industrialtechnology #bearingsolution #blowerperformance #MechanicalDesign #industrialengineering #heavydutybearings #rotatingequipment #industrialautomation #maintenancetips #reliabilityengineering #powertransmission #bearing #kgbearingindia #kzbrand #engineering #manufacturer #rolamentos #rodamientos #lager #rulman #cuscinetti #подшипник

0 notes

Text

#DevOpsJobs#DevOps#CloudJobs#SRE#CICD#AutomationJobs#CloudOperations#DigitalInfrastructure#ReliabilityEngineering#SREjobs#EngineeringJobs#hiring#engineering#cloud#jobsearch#cicd#career#jobs#recruiting#techtalent

2 notes

·

View notes

Text

🔧 Struggling with Maintenance Planning & Scheduling? 🔧

Inefficient maintenance planning can lead to unexpected breakdowns, high costs, and lost productivity. This comprehensive Maintenance Planning, Scheduling & Control course will equip you with the right strategies to increase efficiency, reduce downtime, and optimize resources.

What you’ll learn:

✅ Work Order & Preventive Maintenance – Reduce equipment failures & improve asset lifespan

✅ Scheduling & Resource Allocation – Plan major maintenance & shutdowns effectively

✅ Inventory & Cost Control – Reduce waste and optimize spare parts management

✅ Safety in Maintenance – Prevent workplace accidents & ensure compliance

✅ Performance Measurement – Use KPIs to track & improve maintenance effectiveness

📅 10-day training course covering real-world strategies!

🔗 Register Now

What’s your biggest challenge in maintenance planning? Let’s discuss in the comments! 👇

#Maintenance #AssetManagement #ReliabilityEngineering #MaintenancePlanning #OperationsManagement

#MaintenancePlanning #AssetManagement #ReliabilityEngineering #MaintenanceScheduling #PreventiveMaintenance #WorkOrderManagement #ResourceAllocation #InventoryControl #CostOptimization #SafetyInMaintenance #PerformanceMeasurement #KPITracking #OperationalEfficiency #DowntimeReduction #MaintenanceStrategy #FacilityManagement #WorkplaceSafety #MaintenanceOptimization #OperationsManagement

#Maintenance#AssetManagement#ReliabilityEngineering#MaintenancePlanning#OperationsManagement#MaintenanceScheduling#PreventiveMaintenance#WorkOrderManagement#ResourceAllocation#InventoryControl#CostOptimization#SafetyInMaintenance#PerformanceMeasurement#KPITracking#OperationalEfficiency#DowntimeReduction#MaintenanceStrategy#FacilityManagement#WorkplaceSafety#MaintenanceOptimization

0 notes

Text

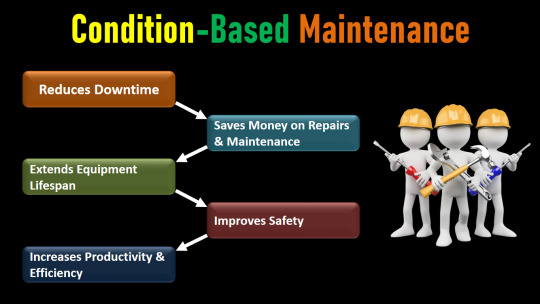

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

Condition Monitoring Technicians in Yanbu: Expert Reliability Solutions with Bafco

Effective condition monitoring is essential for ensuring the smooth operation of industrial machinery and reducing unexpected breakdowns. Bafco Reliability provides highly skilled Condition Monitoring Technicians in Yanbu to help industries maintain peak performance through advanced diagnostic techniques and predictive maintenance strategies.

The Role of Condition Monitoring Technicians

Our experienced Condition Monitoring Technicians in Yanbu specialize in detecting early signs of equipment failure, allowing for timely maintenance and repairs. This proactive approach prevents costly downtime and enhances overall operational efficiency.

Key Condition Monitoring Services We Offer

1. Vibration Analysis

Identifies misalignment, imbalance, and mechanical looseness to prevent machine failures.

2. Thermal Imaging

Detects overheating components to prevent electrical and mechanical failures.

3. Oil Analysis

Monitors lubricant quality and identifies potential wear and contamination issues.

4. Ultrasonic Testing

Detects air and gas leaks, electrical discharges, and mechanical anomalies before they lead to failures.

5. Motor & Gearbox Inspection

Ensures optimal performance and longevity of critical rotating equipment.

Industries Benefiting from Our Condition Monitoring Services in Yanbu

- Oil & Gas Industry:

Enhances safety and reliability of drilling, refining, and processing equipment.

- Power Plants:

Prevents sudden failures and increases energy efficiency.

- Manufacturing & Heavy Industries:

Reduces operational costs and improves machinery lifespan.

- Marine & Offshore Operations:

Minimizes maintenance issues for marine engines and offshore structures.

Why Choose Bafco Reliability?

Bafco Reliability is a leader in predictive maintenance, with a team of expert Condition Monitoring Technicians in Yanbu who use cutting-edge technology to optimize industrial machinery performance. Our approach minimizes downtime, improves safety, and maximizes asset reliability.

Keep your industrial equipment in peak condition with Bafco Reliability’s expert monitoring solutions.

Contact Bafco Reliability Today! For more details on our condition monitoring services in Yanbu, get in touch with Bafco Reliability now!

#ConditionMonitoringYanbu#BafcoReliability#PredictiveMaintenance#IndustrialEfficiency#VibrationAnalysis#ThermalImaging#UltrasonicTesting#ReliabilityEngineering#EquipmentMaintenance#PreventiveMaintenance

0 notes

Video

youtube

Introduction to MIL STD 810H Part 1

#mil standards#milstd810g#milstd810#milstd810h#environmentaltesting#reliability#reliabilityengineering#military#militarysystems#militaryhardware#tanks#rockets#vibrationtesting#temperaturetesting#thermaltesting#temperatureshock#thermalshock#thermal#physics

1 note

·

View note