#ConditionBasedMaintenance

Explore tagged Tumblr posts

Text

Condition-Based Maintenance: How It Works & Why It Matters

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

0 notes

Text

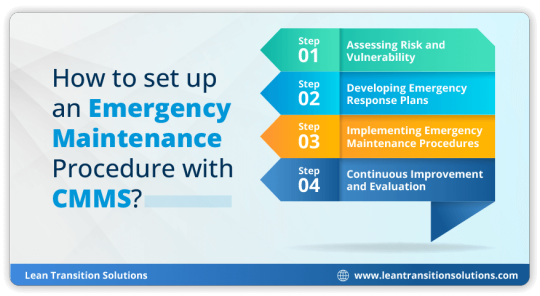

How to set up an Emergency Maintenance Procedure with CMMS?

Read More on the 4 Steps in emergency maintenance procedures help manufacturers with risk assessment setting response plans & implementing reliable maintenance strategies : https://cmmssoftware.leantransitionsolutions.com/emergency-maintenance

#preventivemaintenance#preventivemaintenanceprogram#preventivemaintenanceschedule#emergencymaintenance#preventivemaintenanceplan#preventativemaintenancesystems#maintenanceprogram#predictivemaintenance#plannedmaintenance#maintenancemanagement#preventivemaintenancechecklist#maintenancesoftwarefree#maintenancesoftware#emergencymaintenanceservice#conditionbasedmaintenance#freecmmssoftware#facilitymaintenance

0 notes

Text

RT Parcinc What are the benefits of #ConditionBasedMaintenance? Our own Kai Goebel explains in a recent Q&A with ManufTmrw. https://t.co/bkEJ72uvIk #AdvancedManufacturing #IIoT https://t.co/kTA1Toz8BK #Emp, Brian Ruiz, TheBrianRuiz #Xerox #Print #Printing #InkJet #Printer #Dig…

RT Parcinc What are the benefits of #ConditionBasedMaintenance? Our own Kai Goebel explains in a recent Q&A with ManufTmrw. https://t.co/bkEJ72uvIk #AdvancedManufacturing #IIoT pic.twitter.com/kTA1Toz8BK #Emp, Brian Ruiz, TheBrianRuiz #Xerox #Print #Printing #InkJet #Printer #Dig…

— Brian Ruiz (@TheBrianRuiz) August 29, 2019

via Twitter https://twitter.com/TheBrianRuiz August 29, 2019 at 09:17AM

0 notes

Text

Condition-Based Maintenance: How It Works & Why It Matters

Imagine if your car could tell you exactly when it needs an oil change rather than following a fixed schedule. Instead of guessing or changing the oil too early, you’d only do it when it’s actually necessary, saving time and money while keeping your engine in top shape. That’s the core idea behind Condition-Based Maintenance (CBM) in industries.

CBM is a smart maintenance strategy that monitors the real-time condition of machines and equipment. Instead of performing maintenance on a fixed schedule (like every three months), CBM uses sensors and data analysis to determine when maintenance is truly needed. This approach helps prevent unnecessary servicing while avoiding unexpected breakdowns.

➥ How Does Condition-Based Maintenance Work?

CBM relies on real-time monitoring and data-driven decision-making. Here’s a simple breakdown of how it works:

✅ 1. Sensors Collect Real-Time Data

Machines are equipped with sensors that track critical performance indicators such as:

Temperature – Helps detect overheating issues.

Vibration – Identifies misalignments or wear in rotating equipment.

Pressure Levels – Ensures pumps, compressors, and hydraulic systems are working properly.

Oil Quality – Measures contamination or degradation in lubricants.

✅ 2. Data Is Analyzed to Detect Problems

The collected sensor data is continuously monitored and compared to normal operating conditions. If the system detects unusual behavior, like excessive vibration or rising temperature, it signals a potential issue.

For example, if a motor starts vibrating abnormally, it could indicate a misalignment, loose parts, or an upcoming failure. Maintenance teams receive an alert, allowing them to inspect and fix the issue before the motor breaks down.

✅ 3. Maintenance Is Performed When Needed

Instead of following a fixed maintenance schedule (which can either be too frequent or too late), CBM ensures maintenance is done only when the data suggests it's necessary. This reduces unnecessary downtime and repair costs while keeping machines running efficiently.

Read in detail: https://www.knowledgewale.com/2025/03/condition-based-maintenance.html

#conditionbasedmaintenance#predictivemaintenance#industrialmaintenance#machinereliability#maintenanceoptimization#equipmentmonitoring#proactivemaintenance#cbmstrategy#maintenanceefficiency#preventivedowntime#reliabilityengineering#smartmaintenance#maintenancebestpractices#industrialautomation#assetmanagement

1 note

·

View note

Text

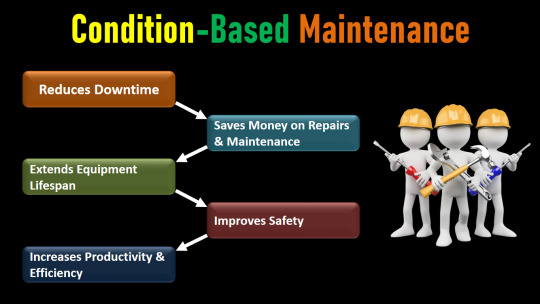

Benefits of implementing Condition-Based Maintenance

Condition-Based Maintenance utilises real-time sensor data for proactive equipment maintenance based on actual machine health and performance.

Read More: https://cmmssoftware.leantransitionsolutions.com/condition-based-maintenance

#CMMS#cmmssoftware#cmmssystem#conditionmonitoring#vibrationmonitoring#cbmmaintenance#conditionbasedmonitoring#conditionbasedmaintenance#vibrationmonitoringequipment#machinemonitoringsystem#vibrationmonitoringsystem#conditionmonitoringsystem#wirelessvibrationmonitoring#conditionmonitoringsensors#machineconditionmonitoring#titancmms#Lean#lts#Industry4.0#Leantransitionsolutions

0 notes

Text

#cmms#cmmssystem#MaintenancePlanning#PreventiveMaintenance#AssetManagement#MaintenanceStrategy#EquipmentMaintenance#CMMSSoftware#ReliabilityEngineering#WorkOrderManagement#MaintenanceScheduling#MaintenanceBestPractices#MaintenanceOptimization#ConditionBasedMaintenance#MaintenanceEfficiency#MaintenanceManagement#MaintenanceAutomation#FacilityManagement#PredictiveMaintenance#MaintenanceMetrics#MaintenanceAnalytics#lts#lean#leantransitionsolutions

1 note

·

View note