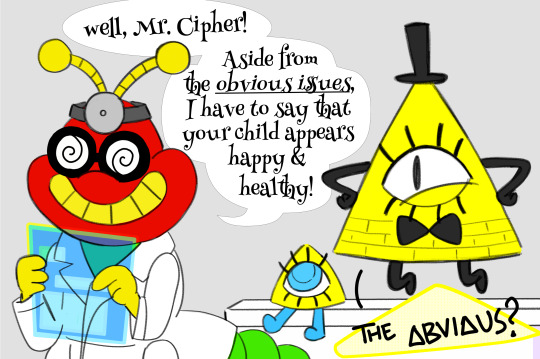

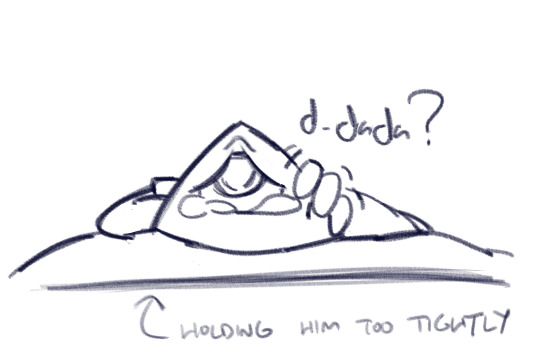

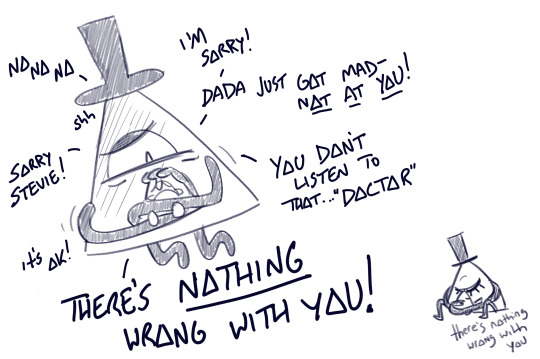

#pyramid steve is a perfect little angle

Explore tagged Tumblr posts

Text

pediatricians are hard to find.

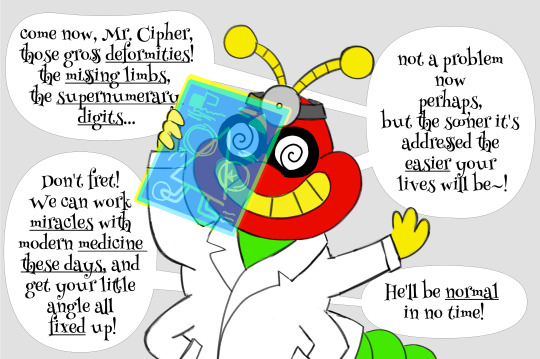

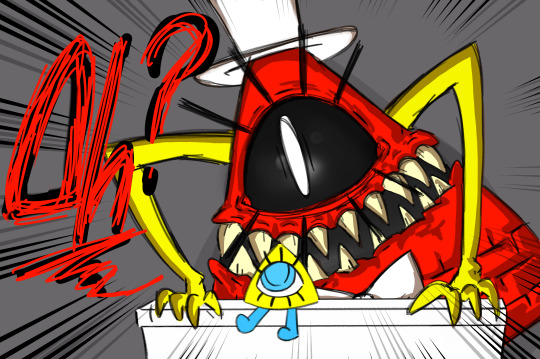

you aren't broken and other important things a triangle needs to hear

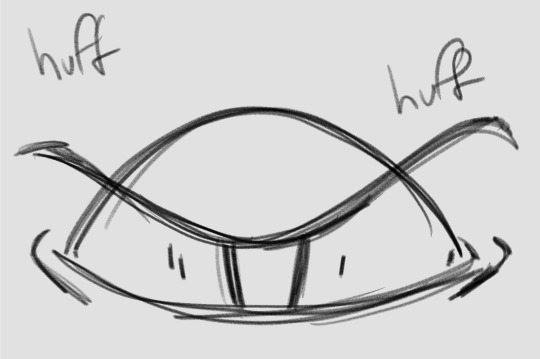

#gravity falls#book of bill#non euclidean geometry au#bill cipher#pyramid steve#billford#parent au#rip doc mc buggins#you won't be missed#ableism#pyramid steve is too young to really understand what's going on here which is Good#ford would be here for the checkup but bill simply has more inter-dimensional contacts on his side#also far far FAR more medical trauma to work with#not that ford doesn't#but i think his problems were always rooted in more SOCIAL problems#while bill got the fun cocktail of childhood bullying AND medical abuse AND parents couldn't/wouldn't help him#he should not be a parent#he IS trying#he is trying so hard#he will not share these worries of course#why worry ford? bill's a GOD clearly he's got this#...bill is deep down terrified he ALREADY screwed up pyramid steve#he probably had more to do with him existing as the power half of the couple-#anything wrong IS probably his fault-#he doesn't know what he's doing! did?! how does his own body even work let alone-#whatif-what if he put him together wrong. what if whatifwhatif#thoughts he will never EVER say outloud#pyramid steve is a perfect little angle#anyone who says otherwise is dead wrong#my art

656 notes

·

View notes

Text

CNC Shop Tour | 5th Axis: PHENOMENAL Workholding Solutions & Embracing Social Media Community!

I love this yeah robot arms testing awesome folks we really want to make an open-source it's also cool to see America become more efficient everyone loves the a word automation but you know really how do you do it what do you buy do you actually buy this do you put up the light curtain you go to the Cova you load vices do you load raw material what are the consequences I love this yeah robot arms testing I've only been here for like 00 minutes and they've already brought up Raspberry Pi and automation and sensors it's awesome folks we are here at 0th axis in San Diego yep San Diego California I'm here with Matt how's it going guy and Chris and we're gonna get to see automation robots and some pretty awesome machine tools let's let's take a tour you have this entrepreneurial story of being a manufacturer that then ended up moving into workholding yeah correct we started as a chop shop and now about one third of our business is still contract ok factory up then 0/0 of it now approximately is the wore clothing product line and that's all here yeah yup and you are you are this is your story you started it Steve my business partner myself started 0th axis about 00 years ago ok and yeah Dave all this by ourselves so you did you call it thick that 0th axis then we had a consulting company and so for the first few months it was run under that name but yeah very early on we named it fifth axis our first machine that we ordered was a haas VF 0 TR about five axes and I'll try to envision like you know pops oh yeah a never yes that was our very first that was what started that happening was we saw you know haas came out with a five axis machine that somebody could sort of afford yes you know what was a legacy where you they were you know you would find a five axis of General Electric and there were a million dollars right and so Hoss really kind of tipped that scale that's kind of what caught us you know started we saw five axis machine running away oh my gosh look at the capabilities and all the things this is gonna be the future we got to get into this yeah and so that and that was like 0000 000 for I got in its I cannot emphasize this enough folks the folks that have followed our story we've been doing this for 00 years now it has been completely rejuvenating to have a 0 access machine now this the way you think the way you use cam the way you run presses reliability fixturing probing and just not having to set up soft jobs multiple parts picking up coordinate systems like I only say this because it wasn't until I I knew it but until you do it that's when you clicks yeah and then our guys you know they get more and more partial okay come on we can do this on a three axis you know no all 0b else for those but they all want to use some real high-end machines yeah everybody wants to drive the Ferrari to worry yeah right and we're like you know the price on the racetrack right now drive your Toyota truck to work yeah awesome good sweet so what's going on here so right now we're running trucks that go in our small bikes okay 00 parts at a time on a little pyramid okay that's actually rock lock Fiona teams between different parts but early does a lot of our precision tooling okay okay okay chairs trucks what's the material these are forty one forty and they're heat treated to around 0000 Wroclaw semi-hard yeah yeah oh that's awesome and do you tap or thread Millville DC Fresno okay control yeah matter got it actually Brian yeah got it yeah we're just cruising around so when we switch to a different part number we do a couple other tears that real standard ones yeah so this one around eight parts of the key on this one three at a time yeah and so you know we've got a nice family of hard to get on here and it's all like Urmi yeah okay so it's a standard herm la platter but then you put the rock lock on it yeah and so right now you've got the quad or what do you call that the four-sided yeah I would have to read oh yeah right but you just you just it's just like our rock hug you just do two screws or something and then you can pop yeah yeah so that's a standard rock lock Beach yeah yeah awesome the Harmony has laser tool measurement Pro being a lot of nice bells and whistles yeah but you know and then it's a very stable precision machine yeah great for doing you know plus or minus 0/0 00th tooling like we're doing here yeah d what year it is the sinks older a man that has been reliably ok we can look at the planer yeah yeah it's like an oh 000 something an old I mean 0000 survived chaotic then you went did you go for a Haas vf0 TR to this that quickly um so the Hurley we've got in like oh seven okay yeah it's not that long so pretty quickly yeah we got a contract to do I'm not these parts put some bladed parts on it and found limitations after that speed of the hosta specially back in yeah and then also the software we were using master cam yeah especially back then yeah not really capable and so that's when we switched to hypermile and got the normally this is like what you want her foots so hsk 00 machine are you sir these are hsk 00s ago in the small microns oh okay got it the hardly run sixty three okay pretty beefy machinist so these that's pretty cool right now they're probing the blank yeah so this is kind of you guys intermix job chop work with work holding products yeah and then some machines are more dedicated for the work holding like the Harmelin really does all work holding you know this machine will do a mix yeah and then we'll see some other machines that are like dedicated to all work whole damn and this one that looked like how to built-in automation from the addition this one has a 0 palette yep that's the system 0r ok so it's got the robot on there there's just automatically and ramadhan awesome sweet the wax is really hard on the machines and messy riza we only run brutal really so if you're familiar with wax in a surfboard no oh hi oh okay so you rub it on there and it continues to build up oh so you rub wax on your like linear bearings on it and flavor comes off it like kind of adds like little by little and so next thing you know your linear bearing just grenades you're like oh there goes $00,000 she's like scrape it or clean it or so we only run two parts and then we'll stop back and clean the machine that makes her wax isn't getting packed into places it shouldn't be I always think of like the machinist wax as being like the learning like using material great tool it's easy on the cutting tool setup you know but yeah and you're doing production and you got lots of it it gets in nooks and crannies yeah and the machines are really built to deal with metal chips true not not something that actually kind of melts yeah spend more time probing than we do machining you guys turn the bikes yeah we do yeah we turn them on hostel room lanes just go sir because it's open and it's so easy to clean again and got all this wax okay you put all that wax in like an enclosed turning centre and like you know the tool room is so much easier to clean and maintain here's a lotta machine another micron Sekou there is another micron this one is running the medium size of ice trucks to parts at a time okay similar to the small one we're running four parts at a time Laser tool management yep oh that was a factor these strike me is one of those parts that actually could be done on a fourth axis the Red Mill so we so this is interesting is this the other micron was supported on the far side is this one also or is it only supported on the backside all the microns except for our five hundreds or cantilever bike they are cantilever okay yeah got it yeah so we could look at the 000 IU's it's a smaller one yeah and it's similar but Chandler we've got three of those oh that's awesome look at that motion that's insane holy cow is that a linear machine you know no this is a ball screw but it is oh my god the other two are linear I was gonna ask if you run panic or Seema's or it's a tall hide behind all of our high-end machines are high tonight I would say that probably the Siemens at this point is that equally is good okay you know in the past high mine was absolutely the best five axis control period now you know all the controls are so fast that you're not seeing Layton sees and things like that and so we just stick with i-00 so it's standard right you know we like the hind line we are those a workload apartment no that's a job shop boring and so we're getting four parts per cycle and then these machines have a 00 pallet automation system oh yeah baby pallet is 00 parts on a load all right right you feel the thing I don't know how many we have Oh quite a few oh my god yeah looking at 00 so they've got 00 going so on these you'll do an OP 0 to do a stock press this one has a dovetail PF yeah uh-huh yeah you can see the stock here there's a bunch of it here ok and then it's got the two locating pins you need to well they're running to dovetail fixture so yeah got it okay right this pyramid allows you to do one two or three okay on there you can see this one still has a leaner or got it so this one has still has the third fixture on there yeah that's the perfect like I totally get it now that I actually had a machine like when you think about the angle it's mean tell that and presented to the spindle yeah and how your ARB is this is important awesome so we have two of the grove chief 000s and then they have the +00 tool magazine which gives us a hundred and forty ish tools these are amazing machine real stable real reliable yeah after years of messing with it we finally got a combination of the right work you know you're gonna have the customers are gonna have the volume and then you gotta have the automation everything dialed in we've been running 00 hours 00/0 so we'll run with nobody here maybe something they'll check in all through the weekend come in Monday morning and the thing's full of finished parts also shop owners dream right yeah I know it really is that's awesome a lot more work than that everybody wants to make it out to but yeah oh these are these are celled together on all right so we have two identical groves and grow a robot that feeds both look at that oh so you're making the base right now on the base yeah so that's making them rock lock faces yeah Coco Hall so we designed the whole robot enclosure so that we can actually move this over and access one machine and then the robot can still operate the second to feed Steve and one of our engineers designed and implemented the whole thing with all the double safety interlocks yeah all the ocean stuff and developed it so that an operator can access you can do setup so you can work on the machine doesn't interfere with the robot the unwanted production on the other machine our first attempt at this when somebody would work on one machine shut the whole cell down and then they'd go to lunch and forget to hit the bottom and now the other machines sitting there for like two hours and they're like you know so so we kind of designed the fencing and the safety interlock system so that we would always keep going you don't have that pressure of sweeping the party and quicker you can get rid of it tonight oh ho look at that it's doing a simultaneous tamper something yeah probably Bieber yeah that's awesome that's it uh-huh yeah cuz if you look yeah there's a C on inside here where these features cross over yeah so he can come in five axis and Bieber that cross it with a lollipop and I think the saw like it's got to look perfect you can't have like oh the deeper guys slipped and there's a scratch on it we can't sell that those end up in this scrap bin so the more t-bar we can do on the machine the less I can touch less risk of any like imperfections you can see were burned in a little bit of cycle time but you know it's worth it so that one finished before this one the robot did a gripper team to grab the gripper for this whole pallet got it so this system can load two different sized College oh my got a loop puts it back yeah how many did it how many did that hold six not one holds four rows so 00 so we got sixty in there kind of reminds me of like the Hermit HS flex where you've got the ability to change and effectors tools work holding pallets to and washdown that's a lot of weight yeah yeah the Aurora system can hold I don't know three hundred pounds or Athene that's one of the differences with the robotic arm to be able to lift a reasonable amount of weight the robotic arms become just massive it was this stressful to build out and think about it was a lot of work yeah you know we 0d models everything and you don't do it wrong right I mean you can't know because you know if you're off I mean the robots programmable but if you're off by too much then you gotta like bring a rigor back in to move yeah the Groves I just mean like we don't want to buy the wrong mix of pallets or the wrong style robot yeah and then you add a third machine did a lot of research before we pick the Eroica awesome oh so that's literally how he's now gonna load the next part yeah that's awesome yeah so that's the five axis i0 active internal deburring and other facts these are our newest addition we've got two of the micron 000 these the ones that are like brand-new brand-new yeah been here a month and a half baby and polish yeah and this is your riser yeah this is a like a 00 millimeter like a 0 inch riser thereafter yeah yeah and then these are that right angle was yeah we were at Autodesk event and they had their VF to setup with one of these uh-huh well it was weird it was on the left side yeah that's really cool you do there's got a billet yep yeah no bottom material removal yeah fair amount uh-huh not that finishes huh only one Senate part one strap that's pretty impressive yeah I wish I could say that about all our jobs over that your workflow you'll do the one run it through a QC oh yeah yeah so we so we run a first article something like this it's precision tooling full CMM program okay you know expect the whole thing and then they'll do on these they'll do in processor like almost every part just Chuck and then they have go/no-go gauging Deltron X things like that so every single part alive key features and they're probably sort of business standpoint are you guys trying to do just in time or light in the story are you really socking up you know it's interesting because you have you know these guys don't work in the team chops come up with these buzzwords like just in time and the reality is that a machine shop the amount of work it is to get that first article dialed in to get all the stars lined up and all the schools and the links and all the cutters comped and everything going and then and then wait for QC and and so a day and a half later you're like okay everything's perfect do you want to make one you got to do some some fat sighs - you know amortize all that fat assignment you know and they can dream in their little ivory towers that bent like somehow there's a magic where you you know recipe where you can just put a block of metal in there and push the button and make it hard Slayer in the real world we know that's not it it just doesn't work that way so when these have to get anodized or plated lady they are yeah so we try and pick batch sizes that you know aren't too massive because you don't want to sit on a ton of inventory but if they're too small you're just killing yourself with you know set up at you know somebody had this so somebody had to create all the paperwork yeah right somebody's got to write a purchase order and we've got minimum lot sizes when we anodized them yeah you know so there's all these things where GI key having it all set up where oh we got an order for one make one I find it hard to imagine a scenario or that like really makes sense when you buy the raw material for this do you have it come up so of a soft cut or are you processing that weight we've got in building three we have material storage and a balcony so we've got a really big automatic Amata okay saw like you know the super sweet yeah yeah we could pop down there pretty cool holy now oh that's that the job job job yeah so this is a project that we've been working on automating which we'll see over here on these with things you ought you enjoy what you do this is awesome yeah oh my god yeah that's cool well we just being able to have a mix of it like not that it would be boring to just make vices but like it's fun to have that you know you live and breathe what yeah well and then you've seen already all these applications where we're using our vices and in my opinion that keeps us honest and keeps our new products are like you know that's it and like all the little bugs are worked out and you know we see our competitors like they see us do something they go oh we got to make one of those but they never use it and they miss like key little features you know so I think as much as I honestly hate job shop work it's what makes us that's what makes our products like real yes yeah it's not like they're like some guy says oh I think you should view this it's like this is what we're doing and we fine-tune it to the point where we feel like we want to share it with the rest of world so so this is one larger fan of robot this feeding to robos yeah so cataract yeah and so here we're using a smaller tube CERN oh you can you put an HRT on there just to load the partes to load the part of you that's amazing oh my gosh so just have a manual indexer yeah the old-school hose right excerpt yeah oh my god can you can you rotate it so for folks that don't know this is actually kind of how gene Haas got started with building he was a 0c indexer and to this day ha still sells these for larger machines for manual machines where you want that indexing 0th axis feature I never thought about just practical well so our engineers of course they're like oh yeah I can design and build a rotary and I'm like well we got to get this thing going and we've got one of these and one of those on the shelf so let's use what we got now and two years from now when you get your design done right then we can't have anymore switch it out you know but for now we got to make parts so and the robot will load it under there as well yes yes yeah the robot oh right yeah - jelly has four positions the two machines the whole sort of storage throughout the loading station awesome so we're going to interface this with our HMI or human machine interface okay will control this it has to be at a certain a angle right for the gripper right I say yeah so that's at least new right now it's manual so yeah it's it's uh yeah it knows yeah it released it also this is the new yeah so we've got that under loading station then also in the machines so this is these machines are still limited to the like fourteen tools though or whatever they twenty tools okay twenty twenty fourth twenty four thousand rpm the pundits okay sure I know that's not what lights out machinery listen I'm not so embarrassed now because I'm looking for the switch that says light they asked my guy how to turn the lights on obviously you hit the memory buddy hey don't get me started on panic holy yeah really fast and then but I see what you mean you can see chips I mean maybe it's okay but well then if you look in the back the chips will build up and so you constantly you know every hour or so holy cow that was a faster DDR is so quick oh my god yes what you miss it that is the panic no Kenny the panic TBR fourth access yeah we got to get this on camera on another index this was insane that's cool we can do that later today oh so it's almost done so it's gonna so he's loading up okay there's our soft jaws yeah yeah oh so yeah that's our double station yeah 00 000 it's like a three by six inch version of the vise yep and then those are some custom soft eyes that we built off one runs on a dovetail okay uh on a little bit bigger tombstone and then we're also gonna be able to robot load that we went after off to first got it because the that's a bit more of our bottleneck so oh okay yeah in addition to doing this because we think it's cool unfortunately also have to pay the bills thing is this you're gonna keep this or is this gonna end up being kind of sold to a customer oh this is so this is a production job shop job that's for us but it the concept I could see we've actually already started talking about the potential to need another setup like this and then we really want to make an open-source yeah you know for other people that copy it you know if it works good you know obviously we've got a little motivation there because we'd like to sell you some by sitter but it's also cool to see America become more efficient yep you know and looks like what we were talking about earlier I think there's this kind of question of like everyone loves the a word automation but you know really how do you do it what do you buy do you actually buy this you put up the light curtain you go to the Cova if you load vices do you load raw material what are the consequences right it's interesting to see people go through that workflow so with this setup because we're loading tombstones so we can easily switch to this part so right so we could run that robotic li then you don't have to reprogram the robot yeah I know and so if other part numbers that's why we're looking at like oh can we justify another one of these and yeah that's a VF to like let's a BF to YT that with the roller cam HR tees RC yeah plays a stir yeah it's also uh huh look at that so here we've got twelve of our small vices and we're running we can look at the density if you ever use the double basses so we get two parts per vice off one yeah and then here we get that's the soft jaw soft jaws aren't you a lift soft chalk yep and we get one part per vice here so we get listen yeah these two go into there yeah they play poker so we can eat finished parts first cycle with awesome yeah and it's literally just I mean a great machine yeah but looks more common job shot machine right way yeah yeah so you know we hear people oh no like that's really cool but man the price of it you know but if if we can run twice as efficient we could ship another thousand dollars a day this thing will pay for itself in like a couple weeks so I think a lot in America especially people are sort of like short-sighted when it comes to investing in Chile like we're talking about earlier in Europe they're way more willing to invest in you know two hundred thousand dollar robot for their five hundred thousand dollar machine even if they're a little job shop and they're looking 00 years into the future where in America it seems like a lot of people are like oh what's it going to do for me tomorrow you know like when I put myself in the shoes of a shop owner you know one of the things because there's I have this is my friends aren't going or the friends I had that are doing it or doing it on the yacht so than a harmless yeah whoo cool my friends is actually putting a hundred grand into automating a hot vertical right I want to see how they succeed so I can write right over there footsteps for sure I'll be very interesting to see more that's amazing how steady they are even when multi axes are moved we missed the spin cycle they added a high-speed spin to like kind of yeah can you imagine that's scary to think of that go in a spin we added it to me and we miss it but they hunted it to the end of the program to kind of spin dry the this setup is pretty cool okay we should actually make them tear it down and set it back up no because we want to show how easy oh okay Tony tear this thing down and set it back up so we can some time doing it so you saw how easy it is he's gonna run a set of parts I wonder where that they have a map of the rock lock positions can you ask him I thought there they're not a couple amount here so he standardized the position to the rock lock place and then we have what you see in the machine is 0d model yep right he doesn't you know where everything is in CAD cam right amazing yeah and so that's a VF 0 that's a VF 0 right so this is really cool they're showing how they're handling internal versatile production without true automation like a robot or a neuro system but where they can switch jobs switch setups really quickly so they've got exactly the same rock lock base that we've got on our UMC it's just the flat version to fit on three axis and switching between one vice to the dimmer by system is what you would expect but what's pretty cool is how they handle this from a programming standpoint was back in the office where they've got the guy program it they've got a master sheet the reference is each one of the offsets fin axis actually wrote a script to handle how they push tooling names and ensure the names match the numbers is it absolute genius then you're good to go you don't have to worry about touching off parts again or loading the right program or tearing down and re setting up bases really cool how are you doing tool setting we set that all our tools off the table the machine okay a lot of people go off top apart yeah but if you take a cut on your part now where's the top of your putter doesn't you know so for us having a reference it always it you know repeats now if you want to go like preset or whatever then you're setting or if you sit the tool center yeah now you're setting like cage down so it's upside down but on the Haas simple 0x of stuff or axis we just use the table we run it awesome 00 minutes or so no no running out we need the parts we'll come back by in a little bit and then I know we can switch over to a different job and then we get also yeah that's what we want to do a switch switch the first plate over I've run some dovetails and then switch back and show how easy it is to go from one to another and then right back again yeah so Jeff one of our programmers could show us into the 0d of all this stuff which would be cool oh you got a couple of the m00 TVs these are awesome seems real precision we order them with the extra precision package they get another decimal place we order them with a the real high-end Renishaw pro yep so probing some more precision yeah Oh 00 00 yeah I've done it on the model but I know it's the extra precision one and on so this would you know cool we're doing awesome by spaces no kidding right so the answer there's your well does your key so I better to run oh that's sick yeah that's a pH horn cutter yep yeah that's really cool yeah tool Center huh on the run around it quick release so you can put that thing away if you using it because yeah we estimate we figure Renishaw makes all their money off selling that $0 part for a thousand bucks every time you break part so it's nice to be able to put it away yeah look at that this is cool this is a 0r palette for little work on actually the micron 000 we saw down there and then the two new ones also yeah and so we're building our own 0r pallets so that we can do really cool custom stuff so it's hard to tell here we can show you a 0d model of it so this will be all one integrated unit and it'll be a three-sided pyramid with rock lock build and an integral though integral that's awesome so now vertical one it you know you look at the micro and go oh bitch and it comes with a robot this is great and there you go 0 0 0 0 0 0 0 well I got a 00 minute part so what's that behind you yeah you know so now with something like this we can run you know three times that part down and get you you know maybe closer to a full ship yeah really it's nice if a robot can run a whole ship that's nice one of the guys run first second shift third shifts impossible if you're gonna have your second shift guys load the thing up and come into the morning and you're still cutting chips as you know that's value so so that's what this stuff project is yeah there's a probe right there that we were talking about I'm not sure yeah he's a 0000 I was locked in a lock oh no 000 okay damn sweet yeah the fancy one by one we're doing precision tooling you know I mean you need it I mean we're making Palace yeah I've got it ought to be right I saw a big grinder back there yeah yeah we could go by [Applause] we have to surface trainers running into more that we are about to bring online to increase our capacity holy cow yeah so he's actually grinding some of the first article parts for those three are pallets we looked at so these guys are sixty Rockwell 000c okay yeah no steaming steel they make knives and pulling out of it right so these have been machine heat treated yep now they get precision ground and then they'll get assembled into the pallet that you saw over on on the Akuma yep and then those will get loaded in the machine and then all the angles in the five axis stuff gets machine in place that's perfect great thanks so much it yeah it's a three Okamoto huh yeah we've got a fourth one as well so we've got the to run T and then the two other ones are going to be hopefully running here within the next month or so we just got another unit across the street so the kinda number them in order of when we got them so this is building one he's in building to building threes next door where we do sawing material storage building pours down below and then building live is back across the street we're fifty five sixty thousand feet total what's the UH what's this for so because the you know rock expose steel rust who are constantly brushing or rolling on Russ inhibitor sure and then we're like four miles from the ocean which is awesome because we're not air-conditioned yeah so the ocean keeps the temperature stable but you do get you know more humidity and a touch of salt in the air so it's a constant battle to fight rust beyond there you know it's amazing how cool it is for me xenical for you yeah yeah yeah being that close to the ocean there's a big difference yeah cool but the humidity set when you're cutting you know working with a lot of Steel to battle no way medium so why re diem these are the these are the keys for the three are palettes so these have been machined heat treated surface ground on both sides and then the what the angle wedge is that like lock and position it we wire cut on them on the EDM you could like do some side grind operation but site grinding is a little funky yeah and the EDM is so precision and just every sinew bashed him up in in big quantity he's running one two three four five at a time got it Oh 00 at a time sorry okay there we go so this rooms climate control and then we can split tents yeah and then it's like the cool thing about Edie and even though it's slow like the tool never wears out there yeah the first part is it identical for the last part so when you're building precision cooling it's he can set it up walk away make 00 perfect identical parts versus you know out there you'd be like Mike and everyone and then everybody knows how hard it is to measure an angle yeah a small team or it's like a nightmare you know where's the where's the corner you know so with this we actually cut two flats which you can easily measure with a micrometer and because it's all the same tool path then that ensures that the taper so perfect paintings are of God so it's a trick to allow for super easy inspection yeah of something that normally would be pretty tough to even bring it in there and put it on the vision and the vision system when you're trying to split tints you know where is the eggs yeah and and the small needles can be tough yeah the flats about halfway down the part turning yep we've got a nice Maxim awesome Akuma Oh spacing that sweet nice machine let's are our biggest slave yeah so we do like small to medium sized parts so some of the bigger rock lock bases and pyramids leaking up to almost 00 inches on here but that's about the Mac size work with you here winter it's over ladies let's just go these are the pulse yeah so we designed the mechanism to be really free floating on the rock lock so this part of it doesn't need to be very precision because the locks will adjust in mine and then also end up with because they can adjust you'll end up with real equal pressure on all yeah all four pole studs so it makes a little easier to manufacture then we only got to do you can see the two shiny surfaces we found those are of everything that's there so you know he's got a couple ten tolerance on there and we do those after he treat on the spinner okay so this is a German super precision are turning small heart turning later not very popular in America about a pretty big brand in Europe yeah cool let's got that special anti a backlash bearings and the extra you know decimal place on the controller and yeah now there's a hilarious yeah there's your picture yeah oh look at the we got a chocolate bar feet on the big one yeah that one has a bar fever yeah so your buddy is ready for us okay this is they call it the phone booth yeah a little tiny bugs are yeah so here were using we call this a pin vise we actually started selling these and nobody could wrap their head around that it's a vise and it works really good so we took it out of the catalog but we still use them eternity analysis but we don't really offer them for sale anymore yeah so it's like a small double station soft machinable bytes yeah so here we get you know half an outline to pull the whole thing off right yeah we did have a pneumatic on here and then no see which eats that plate yes that way yeah yeah look a NASA one you ever do that okay yeah so so the cool thing about these is they're late yeah so you know you've got a plate with three vices and the plate and you know we do 00 pounds or something that's how you keep it so that's one of the places you know you get value in it's compact so you know a lot of parts small density lightweight so if you have a robot that can't lift very much you know that's nice or an operator you know so a guy can pick this up and you're not going to have you know the guys I'm going to hurt his back and go out on workers comp yeah so they sold the pneumatic Chuck off of here and put it on the loading station over there it's funny how everybody else gets our stuff in our in-house shop is always fighting for scraps sure so you're gonna switch over to a different job so this is a actual situation that came up where we needed to run like I don't know 00 or so 00 they've got an 00 ducktail so we need to do yeah and so using ours and the guys come up with cool names for stuff right our to our write it off so funny all right so I got a yard okay so a programmer for this because there's only 00 parts we're only going to do one station so he's right now use it e0 e0 and e0 t okay looks like yeah and then that would be the same here yeah make it more inner inner but the dovetail program is easy because it's only a third for tool so you can actually leave it leave the tools and a couple machines around the shop and you know whatever you can squeeze it in you know the tools are already preset in the machine is the blue and that base of product of yours ya know yeah that comes we're actually having it like a kit where you get the rock off base yep and then the two blue basis and four vices come as a package even for like op 0 and stuff to go on a 0 axis like let's say it's the dovetail plus a couple of critical offs on the left side keep your density higher here yeah I like that with the heat treated parts will do a lot of that work well do some rough machining and do the dovetail then heat treat it yeah comes back from heat treat now you've got the dovetail on there and you can do all your precision put you know stuff like on the Harley one we saw is exactly that where they've got multiple dovetails on a little tree and yeah then you've moved that rough machining you know preheat treat and on to a less expensive machine yeah yeah I love that this program that is one right yeah up one side down the other yeah a big thank you and a shout out to fifth access for for the hospitality and for letting us come in film they're modern manufacturing isn't always easy and being in the San Diego area as they've grown they've had to separate out in the building so most of what you saw was their main production facility but we also spent some time in seeing how they store their inventory how they assemble do the QC and the vise alignment they even showed us one of the prototypes for their new soft draw style system on one of their smaller vices and I said I realized sure there's on camera and they said absolutely and I think that really says it all I think a lot of their success has come from how they've embraced modern manufacturing sharing and paying it forward and how they've embraced this social media community so hope you folks learn something hope you enjoy take care see

CNC Shop Tour | 5th Axis: PHENOMENAL Workholding Solutions & Embracing Social Media Community! nyc cnc via www.99istifada.com

0 notes