#pu conveyor belts

Explore tagged Tumblr posts

Text

PVC / PU Conveyor Belts Distributor in Mumbai

PU Conveyor Belt Manufacturers, Importer, Distributor in India, available in multiple sizes, hardness levels, and finishes. These belts ensure durability, flexibility, and efficient material handling across industries.

2 notes

·

View notes

Text

Durable, Efficient PVC Conveyor Belts by Arrowcon Conveyors Unlimited

Why Choose Arrowcon Conveyors Unlimited?

With years of expertise in the conveyor industry, Arrowcon Conveyors Unlimited is committed to providing high-quality PVC conveyor belts tailored to meet industry standards. Our belts are manufactured in our Noida-based facility using the latest technology to ensure durability and efficiency.

1. Custom Solutions – We offer customized belt sizes, textures, and coatings to match your specific needs.

2. High-Quality Standards – Our PVC conveyor belts undergo strict quality checks to ensure reliability.

3. Competitive Pricing – Get the best quality at affordable prices.

4. Expert Support – Our team of experts is always ready to assist you with the right conveyor belt solutions.

Maintenance Tips for PVC Conveyor Belts

To increase the lifespan and efficiency of PVC conveyor belts, follow these maintenance tips:

1. Regular Cleaning – Clean the belts regularly to avoid debris, dust, and food particles.

2. Proper Tensioning – Avoid applying too much tension to prevent early wear.

3. Check for Wear & Tear – Always check the belt to make sure it is not broken anywhere.

4. Lubricate Moving Parts – Ensure smooth operation with appropriate lubrication.

5. Use the Right Belt for the Application – Use suitable belts for every task.

How to choose the Right PVC Conveyor Belt?

Choosing the right PVC conveyor belt depends on factors such as:

1. Load Capacity – The loading capacity of PVC conveyor belt is high enough to handle the industry operations.

2. Operating Environment – Consider temperature, humidity, and chemical exposure.

3. Surface Texture – Always select the smooth or patterned belts on the basis of application needs.

4. Industry Requirements – Ensure compliance with safety and hygiene standards.

5. Belt Thickness & Strength – Choose the belt according to the load and the industry operations.

Applications of PVC Conveyor Belts

At Arrowcon Conveyors Unlimited, we supply PVC conveyor belts for various industries, including:

1. Food Industry – Used for transporting bakery products, dairy items, and packaged foods.

2. Pharmaceuticals – Ensures safe handling of tablets, capsules, and medical equipment.

3. Logistics & Warehousing – Ideal for parcel sorting, packaging, and distribution centers.

4. Retail & Supermarkets – Commonly found at checkout counters for automated stock handling.

5. Manufacturing Units – Used in assembly lines, material handling, and quality control processes.

Types of PVC Conveyor Belts

There are many types of PVC conveyor belts on the basis of industry and application:

1. General Purpose PVC Belts – Used in packaging, warehousing, and assembly lines.

2. Food-Grade PVC Belts – Designed for food processing with hygienic coatings.

3. Flame-Retardant PVC Belts – Best for industries where fire resistance is crucial.

4. Oil & Grease Resistant PVC Belts – Used in industries that deal oily or greasy materials.

5. High-Strength PVC Belts – For heavy-duty applications requiring extra durability.

Get in Touch!

If you are looking for reliable PVC conveyor belts, Arrowcon Conveyors Unlimited is your trusted partner. Contact us today for expert advice and the best conveyor solutions for your business.

#PVC Conveyor Belts#PU Conveyor Belts#conveyor belt manufacturers in india#conveyor belts india#conveyor belt manufacturer in india#conveyor belt suppliers#conveyor belt manufacturer#conveyor belt supplier in india#pvc conveyor belt manufacturers in india#conveyor belt in india#conveyor belt company in india

0 notes

Text

PVC Conveyor Belts: A Cost-Effective Solution for Material Handling

Polyvinyl chloride (PVC) conveyor belts are a popular choice for material handling applications due to their affordability, versatility, and durability. This blog explores the benefits of PVC conveyor belts and their widespread use in various industries.

What Are PVC Conveyor Belts?

PVC conveyor belts are made from polyvinyl chloride, a synthetic plastic polymer known for its strength and flexibility. These belts are designed to handle a wide range of materials and are commonly used in manufacturing, logistics, and other industries.

Key Benefits of PVC Conveyor Belts

Affordability: PVC conveyor belts are cost-effective compared to other types of belts, making them an attractive option for businesses looking to reduce expenses without compromising on quality.

Versatility: These belts are highly versatile and can be used in a variety of applications, from light to medium-duty tasks. They are available in different thicknesses, colours, and surface textures to suit specific needs.

Chemical Resistance: PVC belts are resistant to a wide range of chemicals, including oils and greases, making them suitable for environments where exposure to such substances is common.

Durability: Despite being affordable, PVC belts are durable and can withstand the rigours of everyday use. They are resistant to abrasion and wear, ensuring a long service life.

Ease of Maintenance: PVC belts are easy to clean and maintain, which is crucial for maintaining efficiency and hygiene in various applications.

Applications of PVC Conveyor Belts

PVC conveyor belts are used in a multitude of industries due to their versatility and cost-effectiveness:

Manufacturing: In manufacturing plants, PVC belts are used to transport raw materials and finished products efficiently through production lines.

Logistics and Warehousing: PVC belts streamline the movement of packages and goods in warehouses and distribution centers, enhancing operational efficiency.

Food Processing: Although not as hygienic as PU belts, PVC belts are used in certain food processing applications where hygiene requirements are less stringent.

Packaging: PVC belts are ideal for packaging lines, where they help in the efficient handling and movement of products.

Maintenance Tips for PVC Conveyor Belts

To ensure the longevity and optimal performance of PVC conveyor belts, regular maintenance is essential. Here are some tips:

Routine Cleaning: Keep the belts clean to prevent the buildup of materials that could cause slippage or damage.

Regular Inspections: Inspect the belts regularly for signs of wear, damage, or misalignment and address any issues promptly.

Proper Tensioning: Ensure that the belts are correctly tensioned to prevent slippage and ensure smooth operation.

Lubrication: Keep pulleys and rollers well-lubricated to reduce friction and extend the life of the belts.

Conclusion

PVC conveyor belts offer a cost-effective and versatile solution for material handling applications across various industries. Their affordability, durability, and ease of maintenance make them an excellent choice for businesses looking to enhance operational efficiency. Companies can achieve reliable and efficient material handling by understanding the benefits and applications of PVC conveyor belts and maintaining them properly.

0 notes

Text

Unveiling the Role of a PVC Conveyor Belt in Ensuring Food Safety and Efficiency

You might not think about it often, but conveyor belts play a crucial role in our everyday lives, especially in industries that rely on efficient material handling and automation. One of the most versatile and widely used types of conveyor belts is made from PVC. This PVC Conveyor Belt plays a pivotal role in ensuring the smooth flow of food items through various stages of production and…

View On WordPress

0 notes

Text

Are you ready to revolutionize your industrial processes? Look no further than the cutting-edge PVC & PU Conveyor Belts from Conveyor's Joint! Our innovative Steel-Tire Conveyor Belt promises to redefine efficiency and reliability in the world of material handling.

0 notes

Text

1 note

·

View note

Text

Conveyor belt Manufacturers - Dynamic industries

As leading importer & distributor of various conveyor belts, timing belts, transmission belt, pu conveyor belts, pvc conveyor belt, silicon coated conveyor belts, teflon coated conveyor belt etc, we have created a broad understanding of the industry to be able to offer our customers advanced solutions to their belting needs. To do so, we have created a network through outside sources as well as in-house infrastructure which focuses at every level to provide a fast, accurate response to requirements with quality as the driving factor.

#conveyor belt manufacturers in india#conveyor belts india#transmission belt manufacturers in india#conveyor belt manufacturer in india#conveyor belt suppliers#conveyor belt manufacturer#conveyor belt supplier in india#pvc conveyor belt manufacturers in india#pu conveyor belt manufacturers in india#conveyor belt in india#conveyor belt company in india

1 note

·

View note

Text

The Phoenix Industry is one of the best manufacturers of PVC and PU conveyor belts in India. We have managed to develop our position as the best PVC and PU conveyor belt manufacturers through heavy contributions and commitments for many years. As a prime manufacturer and supplier of PVC and PU conveyor belts, we offer innovative services for various industrial purposes.

0 notes

Text

Basic Types of Conveyor Belts and Their Applications

Conveyor belts are indispensable in various industries, serving as a crucial element in the seamless transportation of goods and materials. These dynamic systems come in a variety of types including Cleated Belt Conveyors, each designed to cater to specific applications based on the nature of the materials being transported and the operational requirements. In this blog, we will explore the basic…

View On WordPress

#PU Conveyor Belt#Pu Timing Belt#PU Timing Belt Suppliers#Treadmill Belt#Treadmill Belt Manufacturers#Treadmill Belt Suppliers

0 notes

Text

Memories

Chapter 6: Collisions

Chris Redfield x Reader. Anotherrrrr chapterrrrr. I'm going to try and focus on this series and Aftermath.

Enjoy my lovelies!!

Lanshiang, China – on the hunt

The streets blurred past as the three of you sprinted through the ruined city, dodging debris, gunfire, and the occasional explosion. The rain had turned into a light drizzle, misting the air and making the pavement slick beneath your boots.

Chris was leading, jaw clenched, his expression locked into something dangerously close to rage.

Not the reckless, half-drunk fury from before.

No, this was something colder, sharper.

And it was aimed at you.

“Chris, slow down” you called, but he ignored you.

Piers caught up beside him, breathless. “Captain, we need a plan-“

Chris abruptly stopped, turning so fast you almost ran into his back.

“No more plans.” His voice was low, but it carried over the distant gunfire. “No more running, no more bullshit. I want the truth.”

Piers exhaled, rubbing his temple. “Chris-“

Chris’s head snapped towards him. “Don’t. Don’t act like you don’t know what I’m talking about.” He pointed between the two of you, blue eyes burning. “Both of you. You’ve been keeping something from me this entire time.”

Your stomach dropped.

“Chris, it’s not the time.”

“Then when, huh?” he snapped. “After Ada slips away again? After we lose more people? After I lose my mind? When are you two finally gonna let me in on what the hell is going on?”

Piers pressed his lips together but didn’t answer.

Chris let out a bitter laugh, shaking his head. “Figures.” He turned, motioning forward. “Let’s go.”

You hesitated.

Chris was pissed. Not just at Ada anymore. Not just at himself.

At you.

And the worst part?

You didn’t know how to fix it.

But right now, Ada Wong was still out there. And Chris wasn’t going to stop until she was in his sights.

So you followed.

Warehouse District – the chase begins

The facility was massive, an old shipping warehouse turned battle zone. You barely had time to register the size before you spotted her.

Ada Wong, slipping through a side entrance, her movements effortlessly smooth despite the chaos around her.

Chris didn’t even think. “There!”

The three of you took off after her, sprinting down the metal walkways as gunfire rang out in the distance.

Ada glanced back once, locking eyes with Chris. Then she smirked, a ghost of a smile.

And disappeared inside.

Chris growled. “Not this time.”

You followed him inside the warehouse, the air thick with dust and the hum of machinery. Ada’s silhouette flickered ahead, weaving between towering cargo containers, always just out of reach.

You jumped over a conveyor belt, boots slamming onto the grated platform gaining on her.

Chris was right on her tail.. “ADA! STOP!”

She didn’t

She slid under a rusted pipe, vaulting up onto a stack of crates. Chris climbed after her, faster, more aggressive, like he was hunting.

Like he wasn’t going to let her slip away this time.

You could hear the barely restrained fury in his voice. “I’m not losing you again, Wong!”

Ada glanced back over her shoulder, Then-“

BOOM

An explosion ripped through the warehouse as a fuel barrel ignited behind you. The force threw you off balance, knocking you hard against a container.

You barely had time to recover before you heard it, the struggle.

Chris had caught her.

Ada was pinned against the railing on the upper catwalk, Chris’s forearm pressing against her throat.

He was breathing hard, eyes wild with something between fury and desperation.

Ada didn’t even look worried.

She smiled. “You’re starting to remember aren’t you?”

Chris’s grip tightened. “You killed my men.”

Ada tilted her head. “Did I?”

Chris’s hands shook. His memory wasn’t fully back. Not yet. But Ada knew things. And it was eating him alive.

You stepped forward. “Chris-“

Then someone tackled him.

You barely had the time to react as the two fighting figures hit the ground hard.

Chris grunted, rolling onto his back, throwing a punch.

The other guy blocked it, flipping him over and pinning him down.

And the, the moment froze.

Both men locked eyes.

Recognition flickered.

A breathless pause.

Then,

Leon: “Chris?”

Chris: “Leon?”

Silence.

The rain pattered against the metal roof. Ada above them, expression unreadable.

Chris shoved Leon off him, rolling to his feet, gun raised. “She’s not getting away this time.”

Leon stood slowly, gun raised right back at Chris. “You’re not taking her.”

Chris’s jaw tightened. “She killed my men!”

Leon’s expression hardened. “And I lost 70,000 people!, including the president!. Ada didn’t do this. Simmons did, the national security advisor.”

The air was thick with tension.

Chris didn’t lower his gun.

Neither did Leon,

Piers shifted beside you, ready to step in. you could feel the moment on the edge of snapping.

Then, Ada moved.

A hiss of smoke.

A click of a device.

Before anyone could react, the world disappeared in a cloud of smoke.

You coughed, eyes burning. “Shit!”

Chris cursed, waving the smoke away. “Where is she?!”

Leon grimaced. “Gone.”

Chris turned on him, pissed. “You let her escape!”

Leon squared his shoulders. “No. you did.”

Chris exhaled sharply, running a hand down his face. He was still angry. Still frustrated. But the weight of Leon’s words settled into him.

Piers stepped in. “So, what now?”

Leon exhaled. “We bot want the same thing here, Chris.” He lowered his gun slightly. “You handle Ada. Don’t kill her. I’ll go after Simmons.”

Chris held his gaze for a long moment.

Then, reluctantly, he lowered his weapon.

“…Fine.”

Leon gave a small nod, then turned, disappearing into the shadows with the brown haired woman he was with.

The smoke still lingered in the air, leaving behind the scent of burned metal and fading chances.

Chris finally turned back to you and Piers. His jaw was still tight. His hands still shaking.

But his voice?

Steady.

Resolved.

“Let’s move.”

#chris redfield#resident evil#chris redfield x reader#chris redfield resident evil#chris redfield x you#resident evil 6#chris redfield imagine#daddy chris redfield#re6#re6 chris#resident evil chris#resident evil 5#resident evil fanfiction#chris redfield fic#re5#re1999#re1 remake#re1 chris#resident evil remake#re5 chris#re6 piers#re8 chris redfield#re8 village#re8#resident evil village#vendetta chris#re vendetta#resident evil vendetta#re6 leon

9 notes

·

View notes

Text

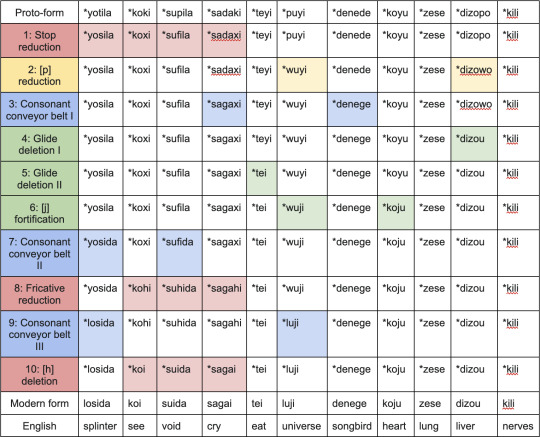

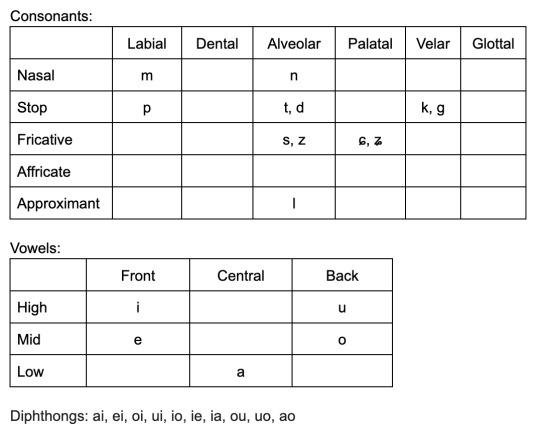

Conlang Year Days 31–33

At long last and after an uphill battle, I have a finalized list of ten sound changes (several of which are actually groups of similar processes affecting different but similar sounds) in order. There's a chance—though not a good one—that I might prod at a couple changes (specifically those in the glide-deleting vein) in the coming days, but what I have right now is solid enough.

Ten sounds like a lot given I've never tried anything similar to this before, but nearly all the sound changes I implemented fall under one of three different multi-step processes, so I'm really just doing four things that all need to be a little spread out. The processes in question:

Stop reduction. For the purposes of creating a few diphthongs, voiceless stops sometimes reduce, very slowly, to nothing at all.

All glides must die. We hardly knew ye. (You may recall that the original phonology only had one glide, [j]. We'll get to that.)

The Consonant Conveyor Belt. An only slightly shaky series of sounds shifting to fill gaps left by those behind them. I must have had something against [g] at the start of the year that I don't have now, and I wanted it back.

Bonus—clean up the ugly sounds. I find [pu] to be an unattractive syllable. That's not the only thing this one gets rid of, but it's most of it.

Complete and lengthy detail under the cut.

Day 31

All three days kind of bled into one another—especially the first two—but day 31 was the one where we were supposed to have a full list of sound changes, if not necessarily an ordered one. I ended up making a few edits yesterday and today, so here's the most current list of sound changes:

Voiceless stops [p] [t] and [k] reduce to [f] [s] and [x] respectively in contexts [a_i], [u_i] and [o_i].

[p] becomes [w] before [u], and before [o] in unstressed syllables.

[d] becomes [g] before [a] and [o], and before [e] in unstressed syllables.

[owo] and [owu] become [ou]. [uwo] and [uwu] become [uo]. [awo] becomes [ao]. [eje] becomes [ei].

[j] vanishes in contexts [a_i], [e_i], and [o_i], as well as [i_o], [i_e], and [i_a]

[j] becomes [ʑ] before high vowels and after [i].

[l] fortifies to [d] before [a] and [o].

[f] and [x] reduce to [h] everywhere they occur.

Glides fortify to [l] anywhere they persist.

[h] is deleted universally where possible. Where not possible, it changes to [ɕ].

If you're looking closely, you might notice a few things:

Why [ɕ] and [ʑ] rather than [ʃ] and [ʒ]? Couple reasons. First, unashamedly, they're fun to say, even if they're not quite sounds I'm all too familiar with in the wild (and I can't distinguish between the two when listening too well...). They're also not sounds I've used in a conlang before—Yvelse has [ ʃ], and I think a couple projects I've left by the wayside did as well. The... interesting conlang idea I mentioned a while back has all four of these, but that's just a concept right now, so it doesn't count. Second, it just made a bit more sense for the sound created in step 10 to be palatal, and I was not about to have two similar sounds in two different places of articulation, one voiceless and one voiced, when I could just put them together. Also, this way the final form of the language uses all the same places of articulation as the original did!

Some of these steps look like they're going to end up tripping over themselves, Strix—unless you want triphthongs or something. Yes. Yes they do (look like that) and yes they do (interfere with themselves). We'll get to that. Incidentally, this is the same force behind that last little bit in step 10.

What do you mean by "where not possible?" Diphthongs are allowed—the set of diphthongs created by these changes is the same as the set of allowable diphthongs—but more than two vowels in a row is forbidden. That little clause is there to stop that from happening if something weird happens between steps 1 and 10.

Hey, you never said anything about where stress goes, but now you're referencing it! I did not! In the proto-forms, primary stress falls as close to the antepenultimate syllable as it can, and secondary stresses radiate out from there, every other syllable. When a word has two syllables, stress lands on the first syllable. I'm ignoring secondary stress when I talk about stress-based sound changes.

Day 32

This was the day where we were supposed to start testing out the changes—though I did a lot of that the day before. I've got a color-coded table where I test a few of the proto-forms I already created—but first, the rules, and some of these are pretty important. For one thing, we can say goodbye to IPA now—at least for the finalized forms of words. Any rules that were only added today (as in, during the "break things" phase) will be in bold.

[j] is represented by y, [ʑ] by j, and [ɕ] by c

Stress-based changes look only to primary stress

Diphthongs shift stress to themselves as soon as they occur (not as though that changes anything, but as a note)

Vowels within diphthongs do not count as single vowels for deletion purposes. They may be considered as single vowels for fortification purposes (the only other context-dependent change that occurs after formation of diphthongs).

If a single step affects multiple parts of a word, work from beginning to end.

And the final phonology:

Day 33

Today's goal was to make a few new forms to "test" sound changes. Of course, "test" as used here means "do your best to break." As such, you'll notice that most of the new forms have three syllables to fit in as many bumps as possible, and the final versions are very diphthong-heavy—every diphthong that wasn't represented in the original chart gets to show up here.

They also tend to hit up several different sound changes. *mijena is maybe the only root that's still pretty similar at the end to the beginning, as opposed to the initial table, where several roots go through only one sound change or none at all.

In my doc, the roots still use IPA as I've been doing for the previous days. Here, I've switched fully to the same romanization system as in the table above, for ease of reading.

*miyena: Companion animal ⇒ miena *yupuki: Friend ⇒ juoci (This is where that [ɕ] clause comes from.) *tiyola: Bone ⇒ tioda *sodeye: Limbless creature (why not?) ⇒ sogei *kiyapo: Fire ⇒ kijao (Here's where that weirdly specific diphthong rule comes from) *zapiyo: Time machine (obviously this is a basic root) ⇒ zacio *lokiye: Tooth ⇒ docie *dayi: Grain (mass) ⇒ gai *yupo: Sun ⇒ juo *yayiyo : Moon ⇒ laijo (And this is why you have to work from start to finish in step 5. This one was fun.) *nopula: Sky ⇒ nouda *siyapo: Hair or analogue (as it's possible for an intelligent species to have feathers or somesuch instead of fur) ⇒ sialo

4 notes

·

View notes

Text

Best PU Conveyor Belt Manufacturers in India

Arrowcon Conveyors Unlimited is the ideal name among all the top conveyor belt manufacturers in India, so if you are looking for the best PU Conveyor Belts, we are the best choice. Our conveyor belts are designed in a manner that will be suitable for various types of industries. They are also known for their durability, efficiency, and versatility.

Why Choose Arrowcon Conveyor Belts?

As the best PU conveyor belt manufacturer in India, we provide:

Best Quality: Our belts are made from the best materials.

Customization: PU Conveyor Belts are available in different sizes, colors, and designs.

Competitive Pricing: Get the best rates in the market.

Quick Delivery: Fast and trusted delivery across India.

Excellent Customer Support: A dedicated team to assist with your requirements.

Why Choose PU Conveyor Belts?

PU conveyor belts are widely used for their excellent properties, such as:

Durability: They are long-lasting and very efficient.

Hygiene: PU Conveyor Belts are known for their hygiene in case of food and pharmaceutical industries

Flexibility: They are used in curved and inclined conveyors because of their flexibility.

Low Maintenance: They are easy to clean and maintain.

Chemical Resistance: They are useful in those industries that deal with oils and chemicals.

Applications of PU Conveyor Belts

Our PU conveyor belts are used in various industries like:

Food Processing: It maintains hygiene and safety in food production.

Pharmaceutical: It is best for transporting medical products.

Automobile: Used for assembling and transporting vehicle parts.

Packaging: Helps in smooth and efficient packaging processes.

Textile: Supports fabric transportation and processing.

Contact Us

Looking for ideal PU conveyor belt manufacturers in India? Arrowcon Conveyors Unlimited is your go-to destination. Contact us today for high-quality conveyor belts that meet your business needs.

#PU Conveyor Belts#Conveyor Belt Importer#conveyor belt manufacturers in india#conveyor belts india#conveyor belt manufacturer in india#conveyor belt suppliers#conveyor belt manufacturer#conveyor belt supplier in india#pu conveyor belt manufacturers in india#conveyor belt in india#conveyor belt company in india#Premium PU Conveyor Belts#Premium PU Conveyor Belts Manufacturer

0 notes

Text

Understanding the Versatility of Conveyor Belts

Conveyor belts are the backbone of various industries, facilitating the efficient movement of materials and products. From manufacturing to food processing, these belts are essential for streamlined operations. This blog explores the versatility of conveyor belts and their impact on modern industry.

What Are Conveyor Belts?

Conveyor belts are continuous belts used to transport materials from one place to another. They are typically made of flexible materials that move over pulleys and rollers. The primary purpose of conveyor belts is to simplify the transport of goods, reducing manual labor and increasing efficiency.

Types of Conveyor Belts

PU Conveyor Belts: Polyurethane (PU) conveyor belts are known for their durability and flexibility. They are resistant to wear, chemicals, and high temperatures, making them ideal for food processing, packaging, and pharmaceutical industries.

PVC Conveyor Belts: PVC conveyor belts are popular due to their affordability and versatility. They are resistant to chemicals and oils, making them suitable for various applications, including manufacturing and logistics.

Silicon Conveyor Belts: Silicon conveyor belts are used in high-temperature environments and applications requiring a non-stick surface. They are commonly used in the baking and textile industries.

Applications Across Industries

Manufacturing: Conveyor belts are integral to manufacturing processes, moving raw materials, and finished products efficiently through production lines.

Food Processing: In food processing, conveyor belts are used to transport ingredients, raw food, and finished products while maintaining hygiene standards.

Logistics and Warehousing: Conveyor belts streamline the sorting and distribution of packages, enhancing the efficiency of warehouses and distribution centers.

Mining and Quarrying: Heavy-duty conveyor belts are used to transport bulk materials such as ore, coal, and gravel over long distances.

Benefits of Using Conveyor Belts

Efficiency: Conveyor belts significantly reduce the time and effort required to move materials, leading to faster production cycles and increased output.

Cost-Effectiveness: By automating material transport, conveyor belts reduce the need for manual labor, lowering operational costs.

Safety: Conveyor belts enhance workplace safety by reducing the risk of accidents associated with manual material handling.

Versatility: With various types available, conveyor belts can be customized to meet the specific needs of different industries.

Maintenance and Care

To ensure the longevity and optimal performance of conveyor belts, regular maintenance is essential. Here are some tips:

Routine Inspections: Regularly inspect the belts for signs of wear, damage, or misalignment and address any issues promptly.

Cleaning: Keep the belts clean to prevent the buildup of materials that could cause slippage or damage.

Lubrication: Ensure that the pulleys and rollers are properly lubricated to reduce friction and wear.

Replacement: Replace worn or damaged belts to prevent breakdowns and maintain efficiency.

Conclusion

Conveyor belts are indispensable in modern industry, providing a reliable and efficient means of transporting materials. Their versatility, efficiency, and cost-effectiveness make them essential components in various applications. By understanding the different types of conveyor belts and maintaining them properly, businesses can optimize their operations and achieve greater productivity.

#Hygiene Conveyor Belt#Conveyor Belt#pu conveyor belts#pu belts#pvc conveyor belt#silicon conveyor belt

0 notes

Text

Durable PU Timing Belts for Industrial Use

We trust TP Industry as one of the leading manufacturers of PU timing belts in India. We sell these belts with the guarantee of being strong, reliable, and durable in order to render great services in production using the very best quality polyurethane raw material. Belts for machines offer smooth power transfer with low noise and an ability for extreme durability. From small workshops to greater industrial units, these belts find application in most industries. While working for many decades and with a customer-oriented strategy made it easy for TP Industry to provide reliable quality.

PU Timing Belts Distinguished From Others?

PU (polyurethane) timing belts have the edge over the normal rubber-ones with respect to strength, flexibility, and longevity. Most time, being loaded by heavy weights and speeds with working conditions being harsh, these belts hardly engage in any sort of abrasion. Being very resistant to oil, dust, and chemicals make PU timing belts a very popular one for a lot of industries to choose from.

Why TP Industry is the Best Choice?

We at TP Industry are committed to quality and customer satisfaction. We make belts with great care and inspect them at every level so that they are of the best standards of the industry. If you need belts for light duty or heavy-duty applications, we have solutions designed for you based on your requirements. Our rates are competitive, our delivery is prompt, and our personnel are always ready to help.

Uses of PU Timing Belts across Different Industries

PU timing belts are used in all types of machines including conveyors, printers, food processing machines, packaging machinery, and textile machines. They are most suitable to be used in industries that need timing and control because they travel with precision and smoothness. Because they are non-poisonous and safe, they are also the best application to utilize for medical and food processing machines.

Choose TP Industry for Service and Quality

Whatever you need—high-performance PU timing belts with extended lifespan, TP Industry is here for you. We are one of the leading PU timing belt makers in India with a promise of quality, service, and satisfaction. Contact us now for bulk purchases, tailored belts, or technical support—our machines are ready to serve you.

visit- https://www.tpindustrialbelts.com/pu-timing-belt/ Address- Sector-10, Noida 201301, UP

0 notes

Text

Exploring the Advantages of PVC and PU Conveyor Belts in Industrial Applications

Conveyor belts are the backbone of countless industries, enabling efficient material handling and streamlined production processes. Among the various types available, PVC (Polyvinyl Chloride) and PU (Polyurethane) conveyor belts have gained significant popularity due to their exceptional performance and versatility. In this blog post, we will delve into the advantages of PVC and PU conveyor belts, exploring their unique characteristics and highlighting their suitability for different industrial applications.

PVC Conveyor Belts: PVC conveyor belts are known for their durability, flexibility, and cost-effectiveness. Here are some key advantages:

a) Excellent Chemical Resistance: PVC belts exhibit high resistance to a wide range of chemicals, making them suitable for industries such as chemical processing, food and beverage, and pharmaceuticals.

b) Strong Impact and Tear Resistance: PVC belts can withstand heavy loads and resist impact and tearing, making them ideal for applications involving heavy-duty materials or rough handling.

c) Easy to Clean and Maintain: PVC belts have a smooth surface that is easy to clean, ensuring hygienic operations. They are also resistant to moisture and mold, making them suitable for industries with strict sanitation requirements, such as food processing and packaging.

d) Versatility in Applications: PVC conveyor belts can be customized to meet specific application needs. They are available in various surface patterns, including smooth, rough-top, and cleated, allowing for efficient transportation of different types of materials.

PU Conveyor Belts: PU conveyor belts offer a balance of flexibility, strength, and resistance. Let's explore their advantages:

a) Superior Flexibility: PU belts are highly flexible and can withstand bending and twisting without compromising their structural integrity. This characteristic makes them ideal for applications requiring conveyors with curves or inclines.

b) High Abrasion Resistance: PU belts excel in applications where materials with sharp edges or rough surfaces need to be conveyed. Their excellent resistance to abrasion ensures prolonged belt life and reduces maintenance costs.

c) Low Noise Operation: PU belts generate less noise during operation compared to other conveyor belt materials. This feature is particularly beneficial in industries where noise reduction is a priority, such as airports, distribution centers, and packaging facilities.

d) Good Resistance to Oils and Greases: PU belts exhibit resistance to oils, greases, and other lubricants, making them suitable for applications in automotive manufacturing, bottling plants, and other industries where oily substances are present.

Choosing the Right Belt for Your Application: Selecting between PVC and PU conveyor belts depends on the specific requirements of your industry and application. Factors to consider include the type of material being conveyed, operating conditions (e.g., temperature, moisture), load capacity, and regulatory compliance.

PVC and PU conveyor belts offer unique advantages and are widely used in industrial applications for efficient material handling. PVC belts provide durability, chemical resistance, and easy maintenance, while PU belts offer flexibility, abrasion resistance, and low noise operation. Understanding the specific needs of your industry and application will help you make an informed choice between PVC and PU conveyor belts, ensuring optimal performance, enhanced productivity, and reliable material transportation throughout your operations.

0 notes

Text

Top PU Conveyor Belt Manufacturer – Quality You Can Trust

Are you looking for a reliable PU conveyor belt manufacturer? We provide strong, long-lasting belts that are ideal for a range of applications. Obtain specialized solutions, timely delivery, and affordable costs.

1 note

·

View note