#professional machined parts made in china

Explore tagged Tumblr posts

Note

Honestly, I love your thoughts on the MK games. Please feel free to talk about whatever part of MK you want with this ask, I will eat it

Ok so i will choose the topic of the lin kuei and its members. And what my take on it is.

Everybody knows they're a Chinese assassin group dated thousands of years old. Really secret, really professional, REALLY traditional. Of course, over the years certain traditions had to be adjusted to survive the new eras but the core traditions remain. These are:

Honor the lin kuei above all else.

Discipline is strength and life.

Do not allow outsiders to distract you from the lin kuei, the lin kuei are your brother's in arms. They are your family, respect them.

Be as strong as a glacier, swift as vapor, mysterious as smoke, and reliable as steel.

Oniro, the previous grandmaster we know to be a huge jerk, twisted these sacred tenets to manipulate the lin kuei. Oniro was cruel and greedy and quan chi hardly had to manipulate oniro to have the assassin group in his demonic little pockets.

Bi-han questioned the grandmaster only in secret, as well as few other members. But bi-han stayed a true lin kuei regardless of what the grandmaster put him through.

Kuai liang is the first one in lin kuei history to go against the grandmaster of the lin kuei, and not only live, but reform it to it's true glory. Kuai liang spent a lot of time studying his clan's history and philosophies, and discovered that oniro purposely hid the lin kuei's true purpose. Not just as deadly warriors for hire but to remain in the shadows to protect china and earthrealm.

Sektor's personality was easy to assimilate into the cyber lin kuei, but his soul is still strong to sometimes go against his programming in a way he deems unnecessary to the mission.

Cyrax's soul was strong enough to persist in the machine, but not enough to break the programming keeping his personality locked.

Smoke, on the other hand, is part demon. He could not only break the programming but due to the enhancements he did indeed grow powerful, but also unstable. He pretended to follow orders until the perfect moment he could get revenge on oniro, but kuai had the honors instead.

Frost i have different plans for. Frost has severe undiagnosed and untreated anger management issues, and perhaps other neurosis as well. Unlike canon, frost gave herself the cybernetic enhancements. It was an excruciatingly painful self inflicted surgery, but her will was strong. Although she is a cryomancer, her natural ki energy is actually fire. And a big mystery is that, is frost cursed? Who cursed her? Is her bloodline cursed? Why did she kill her mother, and seemingly tries to forget the event like it wounds her very soul? This confusion and conflict has made this poor woman extremely pissed off, and slightly depressed.

(Bonus ninja oc undercut)

Whisper was a struggling lin kuei member. Brought into the lin kuei as a "joke" by grandmaster oniro, since he's a bit of a traditionalist (aka sexist shithead). Whisper is mute and communicates with sign language, or in rare cases with pen and paper. Whisper proved herself to be so excellent, that she could earn the highest honor of the lin kuei, which is being associated with either ice, smoke, vapor, or steel. But oniro forbade a woman to have such status in the lin kuei.

Cue quan chi who receives whisper as a "gift" from oniro. Quan chi respects whisper as a warrior and offers her a position in his own clan, the brotherhood of shadow. Undead warriors to work in the shadows and collect information, or get rid of unwanted targets. Whisper becomes an eternal walking corpse of silence, she gains an ability to absorb sound itself and throw it back at her enemies. She is considered to be so deadly that even the likes of noob-saibot is cautious.

Of course in the story i have with her, despite her deadly reputation. Bo rai cho humiliates her, by sitting on her and farting until she passes out while bo rai cho is saving an infant katsumi. Not the greatest introduction but hey humility will happen to us all. Plus she unfortunately gets revenge by killing bo rai cho, but he comes back anyways so its ok

12 notes

·

View notes

Text

Perimeter Intrusion Detection Market is expected to reach USD 798.2 billion by 2034, rising at a 14.3% CAGR- FMI Study

The perimeter intrusion detection market is estimated to be worth US$ 210.2 billion in 2024 and is projected to be valued at US$ 798.2 billion in 2034. Between 2024 and 2034, the industry is expected to register a CAGR of 14.3%.

The market for perimeter intrusion detection systems, an essential part of physical security systems, is expanding rapidly due to growing security concerns in a number of industries, including critical infrastructure, government buildings, military installations, and commercial businesses.

Security measures such as perimeter intrusion detection systems (PIDS) are essential for preventing unwanted access to restricted areas and protecting persons, assets, and confidential data. The emergence of intelligent technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) has greatly improved perimeter intrusion detection systems’ capabilities, allowing for real-time threat analysis, detection, and reaction.

Innovative solutions that offer better precision, dependability, and scalability have been made possible by technological breakthroughs. Examples of these solutions include video surveillance systems, infrared motion detectors, radar-based sensors, and laser-based perimeter security systems.

When these systems are integrated with centralized platforms for command and control, perimeter security may be seamlessly monitored and managed throughout large-scale sites. Due to affordability, scalability, and flexibility, wireless and cloud-based perimeter intrusion detection systems are becoming increasingly popular.

Key Takeaways

From 2019 to 2023, the perimeter intrusion detection market expanded at a CAGR of 12.1%.

Based on the solution, the perimeter intrusion detection cameras segment is expected to account for a market share of 33.2% in 2024.

The demand for perimeter intrusion detection in Germany is predicted to grow at a CAGR of 9.70% through 2034.

In the United States, the perimeter intrusion detection industry is estimated to register a CAGR of 11.10% from 2024 to 2034.

China is projected to expand by a CAGR of 14.80% between 2024 and 2034.

The perimeter intrusion detection market in Australia is anticipated to record a CAGR of 17.80% during 2034.

“Increasing awareness about the importance of perimeter security in asset protection driving the perimeter intrusion detection market,” says an FMI analyst.

Competitive Landscape

To stay ahead of the curve and implement new technology, perimeter intusion detection market players make significant investments in R&D. This covers developments in AI-driven analytics, sensor technologies, and integration with existing security systems, including access control and video surveillance.

Heras – Heras offers customizable solutions tailored to customers’ specific requirements, ensuring scalability to accommodate future expansions or modifications. They focuses on integrating advanced sensor technologies such as radar, infrared, and microwave sensors into their perimeter intrusion detection systems.

Key Segments of Perimeter Intrusion Detection Industry Analysis

By Vertical:

Military & Defense

Government

Industrial

Critical Infrastructure

Commercial

Residential

Others

By Component:

Solutions

Microwave Sensors

Infrared Sensors

Fiber-Optic Sensors

Radar Sensors

Cameras

Optical Fiber

Software

Others

Services

Professional Perimeter Intrusion Detection Services

Managed Perimeter Intrusion Detection Services

By Type:

Barrier-Mounted Perimeter Intrusion Detection Systems

Ground-Based Perimeter Intrusion Detection Systems

Free-Standing Perimeter Intrusion Detection Systems

Rapidly Deployable Perimeter Intrusion Detection Systems

By Region:

North America

Latin America

Western Europe

Eastern Europe

South Asia and Pacific

East Asia

The Middle East and Africa

0 notes

Text

Cubic Boron Nitride (CBN) Wheels Market Industry Report | Analysis Report | 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Cubic Boron Nitride (CBN) Wheels Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Cubic Boron Nitride (CBN) Wheels Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Cubic Boron Nitride (CBN) Wheels Market?

The Cubic Boron Nitride (CBN) wheels market is expected to grow at a CAGR of 5.3% during the forecast period of 2024 to 2032.

What are Cubic Boron Nitride (CBN) Wheels?

Cubic boron nitride (CBN) wheels are advanced grinding tools made from cubic boron nitride, one of the hardest known materials, just behind diamond. These wheels are specifically designed for precision grinding and finishing of tough materials such as high-speed steel, tool steels, and superalloys. Renowned for their exceptional hardness, thermal stability, and resistance to wear, CBN wheels excel in high-speed machining and offer extended tool life. Their superior properties facilitate efficient material removal and high-quality surface finishes, making them essential in industries like aerospace, automotive, and manufacturing where precision and durability are paramount.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1932

What are the growth prospects and trends in the Cubic Boron Nitride (CBN) Wheels industry?

The cubic boron nitride (CBN) wheels market growth is driven by various factors and trends. The market for Cubic Boron Nitride (CBN) wheels is expanding due to the growing need for high-performance grinding tools in sectors such as aerospace, automotive, and manufacturing. CBN wheels are highly sought after for their exceptional hardness, thermal stability, and long-lasting durability, making them ideal for precision grinding of hard materials like tool steels and superalloys. As industries demand greater efficiency, extended tool life, and superior surface finishes, the use of CBN wheels is increasing. The market is also benefiting from technological advancements and the broader application of CBN wheels in high-speed machining, driving investment in these advanced tools to meet rigorous production and quality demands. Hence, all these factors contribute to cubic boron nitride (CBN) wheels market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Resin CBN Wheels

Metal CBN Wheels

Ceramic CBN Wheels

Electroplated CBN Wheels

By Application:

Automotive Parts

Metal Grinding

Industrial

Others

Market Segmentation By Region:

North America

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Saint-Gobain Abrasives Inc.

ILJIN Diamond Co., Ltd.

Noritake Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Ehwa Diamond Industrial Co., Ltd.

Diametal AG

Tokyo Diamond Tools Mfg. Co., Ltd.

Zhengzhou Hongtuo Superabrasive Products Co., Ltd.

Sandvik AB

Engis Corporation

Karnasch Professional Tools GmbH

Nanjing Sanchao Advanced Materials Co., Ltd.

SuperAbrasives, Inc.

View Full Report: https://www.reportsandinsights.com/report/Cubic Boron Nitride (CBN) Wheels-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Cubic Boron Nitride (CBN) Wheels Market share#Cubic Boron Nitride (CBN) Wheels Market size#Cubic Boron Nitride (CBN) Wheels Market trends

0 notes

Text

Information about laser engraver suppliers

Here is the information about laser engraver suppliers:

Linxuan Laser is a top industrial laser marking and engraving machine manufacturer in China with over 18 years of experience in the laser industry. They offer customizable laser marking and engraving solutions, as well as a variety of automated laser marking accessories. Linxuan Laser specializes in providing leading laser marking solutions for direct part and product marking at affordable prices.

Made-in-China.com provides a directory of manufacturers and suppliers, including companies like Zhejiang Holy Laser Technology Co., Ltd. and Shanghai Yuehua Laser Technology Co., Ltd. These companies offer a range of laser engraving machines, laser marking machines, and laser cutting machines.

Algo Technologies Co., Ltd. is an innovative technology company focused on commercial laser engraving machines, founded by Justin Tan, a renowned expert in the laser engraver industry. They are dedicated to offering innovative laser engraving machine solutions and have a strong professional team.

Hibo Laser is a high-tech enterprise specializing in the application of laser technology, customization, sales, and service of laser equipment. They offer a variety of laser equipment, including laser engraving machines, laser cutting machines, and laser marking machines.

BOGONG® is a CNC machine manufacturer that also provides laser engraving and laser welding machines among other equipment.

laser engraver suppliers offer a wide range of laser engraving machines and services, suitable for engraving and cutting a variety of materials such as metal, wood, plastic, acrylic, and more. You can contact laser engraver suppliers based on your specific needs and budget for further inquiries.

0 notes

Text

The Introduction

Pig breeding is an important part of China's agriculture, but the problem of handling a large amount of pig manure has become increasingly prominent. If not handled properly, pig manure not only causes environmental pollution, but may also pose a health threat to farm staff. Fortunately, through scientific treatment methods, pig manure can be converted into valuable organic fertilizer, which not only solves the pollution problem, but also realizes the recycling of resources. This article will describe in detail how pig manure is converted into organic fertilizer and the machinery and equipment required.

Feasibility of converting pig manure into organic fertilizer

Pig manure is a waste rich in organic matter, which can be converted into high-quality organic fertilizers after proper treatment. Pig manure contains a large amount of nitrogen, phosphorus, potassium and other nutrients, which are essential for plant growth. In addition, pig manure also contains a rich microbial community, which can decompose organic matter and produce heat and carbon dioxide during fermentation, achieving the effect of disinfection and sterilization. Therefore, it is completely feasible to convert pig manure into organic fertilizer.

Method of converting pig manure into organic fertilizer

Composting Method:

The pig manure was mixed evenly with organic materials such as straw and rice husk in a certain proportion.

Stacked in a ventilated, dry place for aerobic fermentation.

Turn the pile regularly to facilitate oxygen entry and heat release, speeding up the fermentation process.

After a period of time (usually a few months), pig manure will be converted into decomposed organic fertilizer.

Digester method:

Pig manure was mixed with water and put into a digester for anaerobic fermentation. In this process, microorganisms decompose organic matter to produce biogas and biogas residue.

Biogas can be used for electricity generation or domestic gas, while biogas residue can be used as organic fertilizer.

Biological fermentation method:

Use professional microbial agents to accelerate the fermentation process of pig manure.

After the bacteria agent and pig manure were mixed evenly, sealed fermentation was carried out. This method can shorten the fermentation time and improve the quality of organic fertilizer.

Required machinery and equipment

In order to efficiently convert pig manure into organic fertilizer, a series of professional machinery and equipment need to be used. Here are some of the main equipment introductions:

Fermentation and stacking machine:

It is used to turn the pile regularly to ensure sufficient oxygen inside the pig manure pile and promote the fermentation process.

There are trough type and crawler type (Windrow Compost Turning Machine) and other types, can be selected according to the site and demand.

Organic Fertilizer Crusher:

The large debris and stones in the fermented organic fertilizer are crushed to improve the quality of the fertilizer.

Rotary Screening Machine:

The crushed organic fertilizer was screened to remove impurities and ensure the purity of the fertilizer.

Double Shafts Paddles Mixer:

The organic fertilizer after screening and crushing is stirred and mixed to ensure stable product quality.

At the same time, it can be used to add other fertilizers and trace elements, and produce special fertilizer or compound fertilizer.

Disc Granulator:

The evenly mixed materials were pelleted to make granular organic fertilizer.

Rotary Dryer Machine:

The finished particles are dried to remove excess water and increase the strength of the particles for easy storage and transportation.

Rotary Cooler Machine:

The dried particles were cooled to prevent clumping.

Rotary Screening Machine:

The cooled particles were graded and screened to select qualified finished products.

Enveloping machine:

The qualified particles were coated to increase their brightness and roundness.

Packing machine:

The encapsulated organic fertilizer particles are bagged for easy storage and sale.

Conveying machine:

It is used for conveying materials between different processes to improve production efficiency.

Conclusion

The conversion of pig manure from pig farms into organic fertilizer not only solves the problem of environmental pollution, but also realizes the recycling of resources. By using scientific treatment methods and professional machinery and equipment, high quality organic fertilizer can be produced efficiently. This will not only help improve soil quality and plant growth, but also bring additional economic benefits to the farm. Therefore, pig farms should actively promote the production and application of pig manure organic fertilizer.

1 note

·

View note

Text

Russian Air Freight Service Typically Takes 3-5 Days; Hongmingda China Freight Forwarder Delivers in Just 2 Days

On May 11, 2023, my long-time Russian air freight client contacted me. He urgently needed a batch of coupling parts and required Hongmingda China Freight Forwarder’s Russian Air Freight Service again. However, his supplier's factory machine had broken down, delaying the delivery. He was extremely anxious as his factory was about to halt production, and these parts were crucial for its operation. A shutdown would result in enormous losses. Normally, our Russian Air Freight Service takes at least 3-5 days from pickup to airport delivery. This time, he needed a faster service that could deliver in just 2 days.

Understanding the urgency, I immediately arranged a solution using MU Airlines, offering a direct flight from Shanghai to Moscow SVO Airport to meet his time-sensitive requirements. He quickly chose this logistics plan and expressed his relief, thanking Hongmingda China Freight Forwarder for our professional service.

Huawei, Costco, SF Express, and nearly 20 other industry giants, along with over a hundred enterprises, have consistently used Hongmingda China Freight Forwarder. For over 20 years, Hongmingda China Freight Forwarder has maintained a 99% on-time rate, barring natural disasters and other uncontrollable events.

While communicating with the Russian client, I also contacted the supplier to determine the earliest pickup time. Once the Russian air freight client confirmed his satisfaction with the plan, I meticulously calculated the pickup and transport timings and coordinated the air freight flight schedule, immediately booking the earliest flight available. Timing in logistics is critical, especially from pickup to departure, and a single error could mean missing the flight, resulting in full cargo loss fees. Ensuring smooth operations requires exceptional timing, professional expertise, flexibility, coordination, and risk management abilities—qualities that set Hongmingda China Freight Forwarder apart from many competitors.

After calculating the costs, the supplier acknowledged that Hongmingda's prices and services were well-matched. Although not the cheapest, he understood the value of quality service, having learned from previous bad experiences with cheaper options.

During the shipment process, I pre-arranged the procedures and anticipated potential risks, mitigating them in advance. Consequently, the transportation was smooth, and the cargo cleared customs on the third day after departure, allowing the client to collect it promptly.

Upon delivery, I informed the supplier, who praised the speed and quality of Hongmingda China Freight Forwarder's service.

I explained to him that we always tailor our solutions to meet our clients' needs. Hongmingda China Freight Forwarder’s extensive experience enables us to quickly match clients with the most suitable transportation methods, providing peace of mind. This instance with the Russian Air Freight Service is a prime example.

Moreover, our professional operations and customer service teams ensure swift arrangements post-order, enhancing the client experience. This shipment's high-quality service left a lasting impression on the supplier.

There are always various prices in the market, but cheaper options can be found if you search. However, can you trust your cargo with an unprotected forwarder? Many small forwarders operate out of tiny offices and take any cargo, often disappearing when issues arise. Hongmingda China Freight Forwarder uses a self-developed ERP system to manage inventory, sharing interfaces and data with clients—an offering rare in the domestic market. Hongmingda owns its logistics fleet and operates from an 1800 square meter Grade A office in a Shenzhen commercial district, one of the few in the industry.

Several clients have suffered from such unreliable services before finding us. After one successful cooperation, our service quality made us their most trusted china freight forwarder, turning them into long-term clients of Hongmingda Logistics.

As a china freight forwarder with over 20 years of experience, Hongmingda Logistics prioritizes our clients' needs. If you have international transportation requirements, please contact us at [email protected]. You will be pleasantly surprised.

0 notes

Text

Why are centrifugal pumps with wide application in industry?

Centrifugal pump plays a crucial role in the industrial operation of oil and gas, power production, water treatment, and other areas. At the same time, this series of pumps enjoys a good reputation for its high efficiency, reliability and wide range of applications. The following article will explain why electric centrifugal water pumpare widely used in industry.

Wide-Ranging Applications

The centrifugal pump with great versatility is adaptable for various industrial applications to convey a wide range of fluids including oil, water, chemicals and slurry. When you use this machine in your mining and beneficiation processes, it can effectively and quickly process corrosive and abrasive materials. The centrifugal pump is an ideal choice for the mining industry due to its specially designed to withstand slurry transport.

Reliable Operation

Generally speaking, the industrial sector often requires durable and continuous operation of equipement. We designed the centrifugal pumps for sale with robust construction and exceptional dependability that will effectively deal with harsh environments with temperature and high pressure. Compared with other series pumps, centrifugal pump has less maintenance time and steps due to its simple design and fewer moving parts. In other words, the use of centrifugal pumps will reduce downtime and save money in your industrial facilities for continuous production.

Increased Production Capacity

Self priming centrifugal pump made by Shenghui adopt energy-efficient design for the reduction of power consumption and operations costs in your industries. The development of technology has led to the development of high-pressure slurry pumps and vertical centrifugal pumps, effectively improving production efficiency. Using the centrifugal pump convey the liquid over long distances or to higher elevations while using less energy because the pumps have the design of higher operating pressure.

Productive Conveying

The capacity of high pressure centrifugal pump to transport fluids effectively is one of the major factors contributing to their widespread use in industrial environments. In order to provide a high flow rate, the pump converts into kinetic energy to operate by converting mechanical energy. Liquids may pass through a rotating impeller in centrifugal pumps thanks to their design, which produces centrifugal force. Therefore, the centrifugal pump is perfectly suitable for industrial applications where liquids must be moved continuously because it will handle enormous volumes of fluids, such as chemical manufacturing plants.

Industrial centrifugal pumps are indispensable role in industrial environments because of their working efficiency, wide application, smooth operation. You can use this machine for mining, water treatment, oil and gas, and various industries to transport a broad range of fluids.

As one of the professional manufacturers and producers in China, Shenghui company has been producing and developing pumps for more than ten years, with a professional research team and machines. Our company's success is based on specializing in the manufacture of high quality pumps, the implementation of innovative technology and the provision of excellent customer service. If you need centrifugal pumps for industrial use, we can provide you with reliable and professional centrifugal pumps according to your needs, please contact us immediately!

0 notes

Text

Our paper straw single packaging machine is designed for environmental protection. Using advanced automation technology, each paper straw can be individually packaged quickly and accurately to ensure its hygiene and safety. Whether it's a restaurant, cafe or fast food restaurant, it can easily handle heavy use needs. Choose our pindividual straw packing machine to make every use full of environmental awareness and let us protect our earth together.

How Does Our Individual Straw Ping Machine Work?

Adopted with PLC controller; the main motor is equipped with variable frequency speed regulation; touch screen man-machine interface. Easy for parameters setting & operating.

The cutting section of our straw manufacturing machine adopted with numerical multi-blades cutting system. Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficient.

The single straw packing machine's body and main spare parts are made of stainless steel instead of painting. Ensure the hygiene and environmental protection of the products.

What to Expect from Our Paper Straw-Making Machines?

Embrace eco-friendliness with confidence by choosing our advanced individual straw packing machine from Chuangfeng. Here's what you can expect:

Cutting-Edge Technology: Our single straw packing machines incorporate state-of-the-art technology, ensuring the production of top-quality paper straws that are sturdy and durable.

Environmentally Conscious Production: Start your journey towards environmental conservation with small, yet impactful steps. Our paper straw packing machine craft paper straws, providing a sustainable alternative to traditional plastic straws.

High-Quality Output: Experience the excellence of Chuangfeng's machinery through the production of high-quality, reliable paper straws. Enjoy your drinks guilt-free, knowing you're contributing to a greener planet.

Expertise in Manufacturing: As one of the most professional paper straw and paper tube machines suppliers in China, Chuangfeng brings years of experience and expertise to the table, ensuring reliable and efficient equipment.

Unique Advantages: Benefit from Chuangfeng's distinctive advantages in paper straw and tube equipment manufacturing, setting us apart from others in the industry.

Make a conscious choice for the environment—choose Chuangfeng's Paper Straw Making Machines and make sustainability a way of life.

0 notes

Text

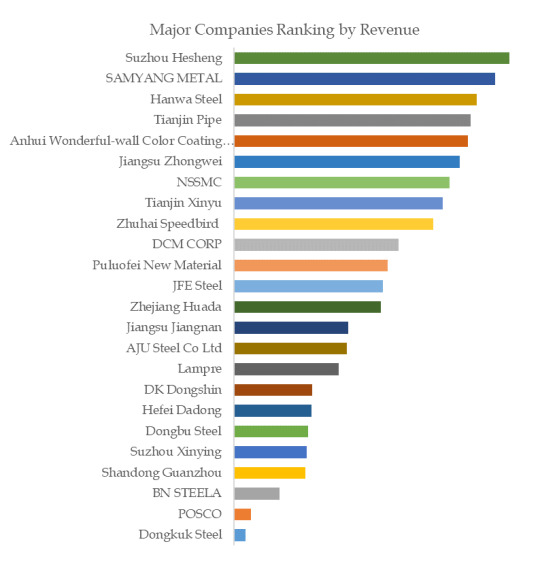

Global Top 27 Companies Accounted for 62% of total Household Appliances Color-Coated Sheet market (QYResearch, 2021)

Home appliance color-coated sheet is a pre-coated sheet, which is a pre-coated product made of metal coil as the base material and coated or laminated with various organic coatings or plastic films on the surface. The home appliance color-coated sheet series products are widely used and have bright colors. They not only have the strength of steel sheets and good formability, but also have good corrosion resistance and flexibility of paint films.

According to the new market research report “Global Household Appliances Color-Coated Sheet Market Report 2023-2029”, published by QYResearch, the global Household Appliances Color-Coated Sheet market size is projected to reach USD 3.88 billion by 2029, at a CAGR of 3.1% during the forecast period.

Figure. Global Household Appliances Color-Coated Sheet Market Size (US$ Million), 2018-2029

Above data is based on report from QYResearch: Global Household Appliances Color-Coated Sheet Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch..

Figure. Global Household Appliances Color-Coated Sheet Top 27 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

Above data is based on report from QYResearch: Global Household Appliances Color-Coated Sheet Market Report 2023-2029 (published in 2023). If you need the latest data, plaese contact QYResearch.

The global key manufacturers of Household Appliances Color-Coated Sheet include Shenzhen Huamei, Qingdao Hegang New Material Technology, Hebei Zhaojian Metal Product, Jiangyin Haimei, Yieh Phui (China), Suzhou Yangtze New Materials, Jiangsu Liba, Dingchuan Shengyu, Suzhou Hesheng, SAMYANG METAL, etc. In 2021, the global top 10 players had a share approximately 62.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

The Evolution of Eyebrow Shading

In the ever-evolving world of beauty, certain trends come and go, while others stand the test of time. One such trend that has transitioned into a timeless beauty staple is eyebrow shading. From its humble beginnings to its current status as a must-have beauty technique, eyebrow shading has undergone a remarkable evolution, becoming a transformative tool for enhancing natural beauty.

Eyebrow shading traces its roots back to ancient civilizations, where individuals used various techniques to darken and define their brows. In ancient Egypt, for example, both men and women darkened their eyebrows using a mixture of soot and animal fat. Similarly, in ancient China, eyebrow tattooing was practiced as a symbol of beauty and social status.

Fast forward to the 21st century, and eyebrow shading has experienced a renaissance, thanks in part to advancements in cosmetic tattooing techniques. One of the most popular methods of eyebrow shading today is microblading, a semi-permanent tattooing technique that involves using a handheld tool to create natural-looking hair strokes. Unlike traditional tattooing, microblading allows for precise control and customization, resulting in more realistic and flattering brows.

Another technique that has gained popularity in recent years is powder brows. This method involves using a machine to create a soft, powdered effect that mimics the look of filled-in brows. Powder brows are ideal for those seeking a more defined and polished appearance without the need for daily maintenance.

The rise of social media platforms like Instagram has also played a significant role in popularizing eyebrow shading. With influencers and celebrities showcasing their perfectly sculpted brows online, more and more people are turning to eyebrow shading as a means of achieving their desired look. Additionally, advancements in cosmetic technology have made eyebrow shading more accessible and affordable than ever before, allowing individuals to achieve professional-quality results without breaking the bank.

But perhaps the most compelling reason for the enduring popularity of eyebrow shading is its transformative power. Well-defined brows have the ability to frame the face, enhance the eyes, and create symmetry and balance. Whether you have sparse brows that need filling in or simply want to streamline your morning routine, eyebrow shading offers a practical and long-lasting solution.

In conclusion, eyebrow shading has evolved from a passing trend into a timeless beauty staple, thanks to its rich history, technological advancements, and transformative effects. Whether you prefer the precision of microblading or the softness of powder brows, there's no denying the impact that well-defined brows can have on your overall appearance. So why wait? Embrace the power of eyebrow shading and discover the confidence that comes with perfectly groomed brows.

0 notes

Text

Awareness, technology can help counter counterfeit products

The packaging industry has reached an alarming situation where on the one hand new technology facilitates an improved consumer experience and on the other, it enables counterfeiters to make near replicas of a product. The concerns have now reached a point where the active participation of the provider and the consumer attains much more significance, say industry stakeholders.

Packaging machine OEMs are experimenting with advanced technology to tackle this problem. With efficiency and quality assuming higher significance than ever before, the packaging industry is now focusing on scalable, high-performance automation solutions to deal with counterfeits.

Sudeep Goenka, director of Goldiee Group, a spice maker, said, “Awareness must be created among the consumers as well as the solution providers. The problem with counterfeit products is that it is possible to replicate packaging. Enhancement in traceability is a solution — QR codes, monograms, labels, and barcodes.”

https://packagingsouthasia.com/wp-content/uploads/2023/12/iStock-1440598169-300x200.jpg

The Hindu reported about counterfeit medicines of leading manufacturers such as Sun Pharmaceutical, Alkem, Cipla, Glenmark, GSK, Abbott, Novartis, Dr. Reddy’s and Aristo. The fake drugs that included Augmentin, Pan-D, Pantocid DSR, Urimax-D, Clavam were seized from unlicensed premises in Kolkata in August.

In June, five people were arrested for allegedly making and selling counterfeit dairy products of Amul. Police recovered materials that included ghee, butter, and packaging items from Noida Sector 70, media reports said.

Sanjay Gupta, vice-president of FMCG conglomerate DS Group, which has a presence in food and beverage, confectionery, hospitality, agri, luxury retail, etc, said reacting when counterfeit products are found is of little value.

“Industry professionals need to act beforehand to influence a better brand impact – safeguarding the trust of the consumer. A counterfeit department needs to be established in all segments of the industry. It has to be functional at every step, right from transit to when the product reaches the end consumer,” Gupta said.

An advanced ecosystem to prevent counterfeits is the need of the hour, said Sanket Randive, head of corporate quality assurance of leading multinational Marico. “A behavioral change needs to be implemented. The option of tracing the product by scanning a QR or a bar code has been there for ages. Being a consumer myself, I don’t scan the codes. If I purchase a pack of Surf, I am simply assured that I have a pack of Surf when needed. That would need to change. The profit margins dwindle due to counterfeits and delayed reaction adds to the waste of time and money.”

Counterfeit goods are made widely in Russia, North Korea, Taiwan, Bulgaria, and Turkey. Turkey is responsible for 3.3% of the world's counterfeit goods, according to the Organisation for Economic Co-operation and Development (OECD). Some counterfeits are allegedly produced in the same factory that produces the original, authentic product, using inferior materials.

A United States Senate Committee on Armed Services report regarding counterfeit electronic parts in the defense supply chain highlighted in an investigation in March 2011 that 1,800 cases of suspected counterfeit components were in use in over one million individual products". A 2012 report found that counterfeit parts came overwhelmingly from China.

According to Yogesh Kapur, executive vice-president of the holography business of Noida-based packaging giant Uflex, technology can be the answer.

The company, Kapur says, provides services and solutions by leveraging the best technology, in-house production, and an R&D division for each of UFlex’s processes. India is becoming a preferred supplier for global buyers of products, including anti-counterfeiting and brand-building solutions, he said.

“India is at the cusp of growth. From what we can see, a lot of global companies are trying to be a part of it. UFlex is well-positioned to tap this growing market with its country-wide footprint, by providing the latest technology for anti-counterfeiting, and brand recognition,” Kapur said in an interaction with Packaging South Asia.

“Global providers, when they come to India, are concerned about their IP because of counterfeiting. This is where UFlex holography anti-counterfeiting and branding solutions come in and ensure that their IP is protected and genuine products reach their (brand owners’) customers.”

In fact, traceability and authentication were the key focus of The Authentication Solutions Providers Association (ASPA) meeting in Delhi in July, where members and all stakeholders gathered to gain first-hand collaborative knowledge of anti-counterfeiting and traceability technologies, solutions, and systems.

0 notes

Text

A Dive into the Revolutionary CNC Technology in Manufacturing

Unleashing the Future: A Dive into the Revolutionary CNC Technology in Manufacturing

In the fast-evolving landscape of manufacturing, the gears of innovation never cease to turn. As we propel into the digital future,

the realm of CNC machining stands at the forefront of this technological revolution. How is the latest CNC technology reshaping

the manufacturing landscape? What groundbreaking features does it bring to the table? Let's embark on a journey through the

corridors of innovation to uncover the answers.

Digital Future: Exploring the Innovation of Our Latest CNC Technology in Manufacturing

In the heart of China, where precision meets prowess, CNC MACHINING at REGO takes center stage. With five production lines

humming in harmony and a dedicated team of 55 professionals, our commitment to delivering top-tier products resonates in

every meticulously crafted piece. But what sets us apart in this era of digital transformation?

Customization is the linchpin of our prowess. In a world where one size rarely fits all, our CNC machining capabilities extend

beyond the ordinary. We pride ourselves on tailoring solutions to the specific needs of our clients. Whether it's CNC machining,

injection molding, die casting mold, or 3D printing, REGO is not just a supplier; we are architects of precision.

The Technological Tapestry Unraveled

Now, let's delve into the core of our innovation. The latest CNC technology we employ seamlessly integrates with various

manufacturing processes, empowering industries ranging from aerospace to electronics. With precision at its zenith, this

technology has become the heartbeat of the manufacturing floor.

Our clients, a discerning executive in Canada, symbolizes our typical client. At 43, he understands the critical balance between

quality and cost. like many others, values the craftsmanship that comes with products made in China. His priority is not just a

transaction; it's a relationship built on trust and personalized service.

In a world where efficiency is a currency, REGO's CNC technology thrives. Our clients, have encountered the pain points of inefficiency,

delays, and the haunting specter of fraudulent certifications with other suppliers. At REGO, we understand these challenges,

and our commitment to quality control, certification, logistics, and transparent payment methods aims to alleviate these concerns.

Navigating the Digital Wave

As we ride the digital wave, accessibility and affordability have become the cornerstones of CNC machining. Small businesses

and individuals, not just industry giants, now harness the power of CNC machines for prototypes, custom parts, and personal projects.

The democratization of CNC technology transcends expertise levels, bringing manufacturing capabilities to anyone with a vision.

In the digital era, our online presence is as robust as our manufacturing lines. Platforms like Alibaba and Google serve as windows

to our world, showcasing not just products but a commitment to excellence. These platforms bridge the geographical gap,

connecting us with clients, who seek quality irrespective of borders.

Conclusion: A Glimpse into Tomorrow's Manufacturing Landscape

As we navigate the digital future, the innovation in CNC technology at REGO is not just about precision engineering; it's about forging

lasting partnerships. Our commitment to quality, customization, and transparency positions us as more than suppliers. We are enablers

of dreams, architects of progress, and custodians of trust in the evolving saga of manufacturing. Join us as we continue to redefine what's

possible in the relentless pursuit of excellence.

0 notes

Text

AI in BFSI: Redefining Customer Experience and Risk Management

Artificial intelligence (AI) is illustrated by machines rather than natural intelligence displayed by humans. Intelligence in machines is programmed to think like humans and mimic their actions. In addition, machines are designed to rationalize and function like human mind, such as learning, planning, identifying patterns, problem solving, and decision making to achieve a specific goal. Therefore, it has become an essential part of technology in the BFSI industry. In financial institutions and other major finance industries, AI has become a core adaption and is expected to change the overall scenario of service offerings.

The AI in BFSI Market study by Allied Market Research includes an overview of business trends, competitor analysis, and a future market and technical analysis forecast. In addition, the study gave an illustration of the global value and key regional trends in terms of Earthquake InsurMark size, share and growth opportunities. All information about the global market has been carefully analyzed and verified by industry professionals after being gathered from very reliable sources.

Download PDF Sample Copy: https://www.alliedmarketresearch.com/request-sample/2791

A comprehensive and detailed method that combined primary and secondary research was used to thoroughly investigate the global E-Banking Market. While secondary research gave a broad overview of the products and services, primary research involved a thorough examination of many factors that influence the market. A process of searching is done using a variety of sources, such as press releases, professional journals, and government websites, to gain insights into the industry. This approach has made it possible to acquire a clear, extensive understanding of the global E-Banking Market

Analysis of Key Players:

The market is fragmented, with many large and medium-scale vendors controlling minority shares. Vendors actively engage in product development by making significant investments in R&D initiatives. Through a variety of growth strategies, including alliances, partnerships, mergers, and acquisitions, they are increasing their Shop Insurance Marketshare.

Purchase this Report@ https://www.alliedmarketresearch.com/artificial-intelligence-in-BFSI-market/purchase-options

Major players operating in the AI in BFSI Market: industry include Oracle Corporation, Baidu, Inc., Palantir Technologies Inc., Inbenta Technologies Inc., Microsoft Corporation, salesforce.com, inc., Intel Corporation, International Business Machines Corporation, SAP SE, Alphabet Inc.

By Offering

Hardware

Software

Services

By Solution

Chatbots

Fraud Detection & Prevention

Anti-Money Laundering

Customer Relationship Management

Data Analytics & Prediction

Others

By Technology

Deep Learning

Querying Method

Natural Language Processing

Context Aware Processing

By Region

North America (U.S, Canada, and Mexico),

Europe (UK, Italy, Germany, France, Spain, Netherlands, Switzerland, and the Rest of Europe),

Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, Thailand, and Rest of Asia-Pacific),

LAMEA (Latin America, Middle East, and Africa).

The expert team at Allied Market Research continuously analyzes the market environment by making precise predictions about the necessary driving and restraining factors. On these factors, the stakeholders can base their business plans.

Key Benefits for Stakeholders:

This report offers a quantitative examination of the market segments, estimations, recent trends, and dynamics of the AI in BFSI Market: analysis from 2023 to 2032 to specify the key competitive advantages.

An in-depth analysis of Market segmentation helps in determining current market opportunities.

Porter's five forces analysis places a strong emphasis on consumers' and vendors' capacity to develop their supplier-buyer networks and come to profitable business decisions.

The report examines regional and global market segmentation, LAMEA Travel Insurance MarkeTrends, leading players, market growth strategies, and application areas.

Market participants' positioning encourages comparative analysis and provides a clear understanding of the player's current position.

The major countries in each region are mapped based on their revenue contribution to the global market.

The report provides in-depth details of the business tactics used by the major market participants in AI in BFSI Market: growth.

Customization Before Buying, Visit @ https://www.alliedmarketresearch.com/request-for-customization/2791

Key Questions Answered in the Research Report-

What are the market sizes and rates of growth for the various market segments in the global and regional market?

What are the key benefits of the AI in BFSI Market: report?

What are the driving factors, restraints, and opportunities in the global Market?

Which region has the largest share of the global Market?

Who are the key players in the global Market?

Top Trending Reports:

1) Budgeting Software Market: https://www.alliedmarketresearch.com/budgeting-software-market-A11766

2) Digital Mortgage Software Market: https://www.alliedmarketresearch.com/digital-mortgage-software-market-A12740

3) Premium Finance Market: https://amarketplaceresearch.com/2023/09/13/premium-finance-market-paving-the-way-for-financial-flexibility-in-insurance/

About Us:

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Wilmington, Delaware. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports Insights" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Allied Market Research CEO Pawan Kumar is instrumental in inspiring and encouraging everyone associated with the company to maintain high quality of data and help clients in every way possible to achieve success. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

1209 Orange Street, Corporation Trust Center, Wilmington, New Castle, Delaware 19801 USA.

Int'l: +1-503-894-6022 Toll Free: +1-800-792-5285

UK: +44-845-528-1300

India (Pune): +91-20-66346060 Fax: +1-800-792-5285 [email protected]

0 notes

Text

The World of Metal Fittings Manufacturers for Crafting Excellence

Metal fittings from Metal fittings manufacturer are essential in our daily lives, from the hinges on your front door to the delicate parts within your electronics. Metal fittings manufacture is a fascinating and vibrant business that stands behind these essential components. This blog will dig into the world of metal fittings producers, examining their function, the kinds of fittings they create, and the value of high standards of workmanship in this industry.

The Function of Metal Fittings Producers

The craftsmen of the manufacturing and building industries are the producers of metal fittings. They are in charge of creating a broad variety of metal parts that are used as supports, fasteners, and connections in a variety of applications. Metal fittings producers are essential in the construction of skyscrapers, the assembly of furniture, and the design of complex machinery.

Design and prototyping: To produce working prototypes and establish appropriate solutions that satisfy particular project needs, manufacturers collaborate closely with engineers and designers. They need to take into account things like the choice of materials, load-bearing capability, durability, and aesthetics.

Manufacturing and quality control: After the designs are complete, the makers of metal fittings put up manufacturing procedures to produce the fittings in large quantities. Quality control is crucial since even a small flaw may have a big impact on the industries they service.

Customization: Metal fittings manufacturer China frequently provide customization services, enabling customers to make fittings to suit their particular requirements. In fields where one-size-fits-all solutions fall short, this flexibility is essential.

The Importance of High-Grade Craftsmanship

At the core of the manufacture of metal fittings is quality craftsmanship. Here is why it's important:

Durability: Well-made fittings are long-lasting, which lowers maintenance costs and downtime across a range of sectors.

Efficiency: The total efficiency of machines and structures is influenced by the precision with which fittings are developed and produced. They lessen wear, friction, and energy use.

Aesthetics: Metal fittings are frequently evident in consumer goods and interior design and add to the aesthetics of the final product. Fittings of high-quality craftsmanship from professional metal manufacturers are guaranteed to be both aesthetically pleasing and useful.

NEXT: Common aluminum alloy grades and usages

#Metal fittings manufacturer#Metal fittings manufacturer China#Professional Metal Manufacturer#Metal Manufacturer China

1 note

·

View note

Text

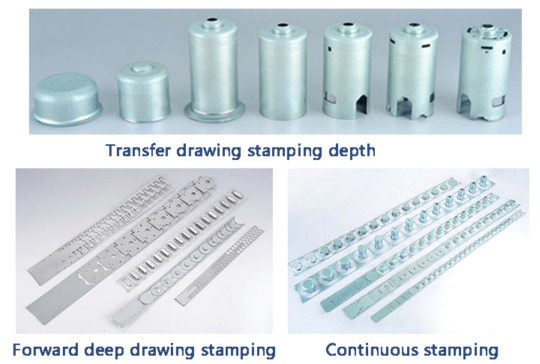

The structured shape, size, precision, materials, and technical requirements of bending parts must be conformed to the requirements of the bending process. Various shapes such as the U-shaped bending and V-shaped bending, cap-shaped parts, arc-shaped parts, etc can be made through the bending process. Orienson can provide solutions with a reasonable process, high precision, and low manufacturing cost according to customer requirements, we always commit to reducing the production cost, improving quality, and improving product yield, welcome your consultation.

Types of Custom Metal Bending Stamping Parts

2mm Thickness SPCC Metal Stamping with High Quality Precision2mm Thickness SPCC Metal Stamping with High Quality Precision

2mm Thickness SPCC Metal Stamping with High Quality Precision

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

0.6mm Thickness OEM H65 Copper Metal Stamping Bending Parts

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

1.5mm Thickness Steel Stamping Bending Parts1.5mm Thickness Steel Stamping Bending Parts

1.5mm Thickness Steel Stamping Bending Parts

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components

0.8mm Thickness OEM Copper Alloy Punch Forming Bending Components

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings, and other surface treatment.

0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory

0.65mm Thickness H65 Copper Metal Parts for Electrical Accessory

Material:0.1mm-5mm Copper Alloy(C10100/C11000 /C22000/C26000/C26800/C36000/C7025/C51000/C17200) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

0.46mm Thickness Custom Steel Bending Part0.46mm Thickness Custom Steel Bending Part

0.46mm Thickness Custom Steel Bending Part

Material:0.2mm-5mm Steel(SPCC-SD/SPCC-SB/DC01/SPCE/1075/DT4E) Processing services:CNC machining, metal stamping molding, metal plating, heat treatment, passivation, grinding, radium carvings and other surface treatment.

What is Metal Bending?

Metal bending is a manufacturing process that involves deforming a metal workpiece to create a specific shape or angle. The process is used to produce a wide range of metal products, including brackets, frames, enclosures, and other components.

Metal bending can be performed using a variety of techniques, including press braking, roll bending, and tube bending. Press braking involves pressing a metal sheet or plate between a punch and die to create a bend. Roll bending uses a set of rollers to gradually bend a metal workpiece into a specific shape. Tube bending involves bending a metal tube using a mandrel and a set of rollers.

Metal bending is often used in conjunction with other manufacturing processes, such as metal stamping, welding, and machining, to produce complex metal parts with high precision and accuracy. It is a versatile process that can be used with a wide range of metals, including steel, aluminum, copper, and brass.

At Orienson, we specialize in custom metal bending services and can provide you with the right solution for your specific application requirements. Our team of experts works closely with customers to understand their needs and develop customized solutions that meet their exact specifications. We use the latest equipment and techniques to ensure that every metal bending part we produce meets the highest standards of quality and durability.

Bending Parts Design

For the shape of simple bending stamping parts, such as V-shaped, U-shaped, L-shaped, Z-shaped, etc., we can adopt bending once-forming. For bending parts with complex shapes, it is generally necessary to adopt multiple bending forming.

As deformation will affect the shape accuracy of multi-angle bending parts, we generally bend the outer angle first and then bend the inner angle. The first bending should be set aside some reliable positioning for the next bending to ensure the first bending shape would be not destroyed by the next bending.

The work blank of bending parts with asymmetric structure is prone to deviation during the bending process, we should try to adopt the technique by curving in pairs and then cutting apart.

Bending times and working arrangements of bending parts must be considered comprehensively according to the complexity of workpiece shape, material performance, precision requirements, and the size of the production batch. Reasonable bending process can reduce bending times, simplify die structure, improve workpiece quality and productivity.

Application Of Bending Parts

Bending is the most common processing method in the stamping industry. Its metal stamping parts are widely used in the automobile industry, electronic and electrical industry, communication fiber industry, the energy development industry, and so on. Orienson has 20 years of industry experience in stamping, adhering to the manufacturing spirit of stamping craftsmen, In strict accordance with TS16949 standards to develop new product development, quality control, lean production management, and TPM management related production management process. We commit to meeting our customers' requirements with the best quality, welcome customers who need stamping parts to consult more details.

Application Of Bending Parts

What is the Common Defects and Technological Countermeasures of Bending Parts

What is the Common Defects and Technological Countermeasures of Bending Parts

Bending is a common process in stamping parts. In view of bending defects, Orienson adopts corresponding effective process measures through process control and prevention to improve the quality of the workpiece.

1. The size of the pressing parts after bending is not up to standard or the shape of the deviation.

2. The product surface quality is poor. The poor surface quality of bending parts is mainly: scratch, strain, concave and so on.

3. The bending crack, the crack is one of the most common problems of stamping bending part.

0 notes