Don't wanna be here? Send us removal request.

Text

3RP lobe pump is designed for the transportation of suspensions containing solid particles and corrosive and hygienic media. It is especially applicable for food, beverage, pharmaceutical, chemical, daily chemical, petroleum and other industries.

1 note

·

View note

Text

ZYB Series gear pump is available for conveying non-metallic impurities, heavy oil, diesel oil, coal tar and grain, chemicals, building materials, household chemicals and other impurities transport industry, less lubrication various media.

0 notes

Text

KCB Gear Oil Pump used to deliver non-corrosive lubricating oil or similar liquid without particles and fibers, such as crude oil, diesel oil, lubricating oils, animal oils and vegetable oils.

0 notes

Text

The machine is used for pumping impurities including heavy oil, diesel oil, coal tar and grain, oil, chemical, building materials and daily chemical products.

1 note

·

View note

Text

This pump can help you fill high-viscosity liquid medium, including honey, chocolate, cosmetics, etc. You can use it in the food and beverage, bio-pharmaceutical manufacturing and other hygienic processing industries due to the stainless steel materials for components.

0 notes

Text

Using a LPG transfer pump can help you handle liquefied petroleum gas, liquid ammonia, propylene, propane, ethylene oxide, methanol and various volatile liquids with similar nature or petroleum products. It is particularly suitable for LPG loading and unloading trucks, feeding workshops, cylinder filling and other workplaces.

0 notes

Text

What are the Advantages of Gear Pumps and What do I Need to be Aware of?

In general, a gear pump belongs to a positive displacement rotary pump with more than two internal gears. They work together to mechanically create vacuum pressure, which is intended to accelerate the flow of fluid through the pump. The gear pump is often used for the transportation of water, besides, this machine also can be utilized in many different industries, such as the chemical or petroleum industries. Meanwhile, the gear transfer pump is the ideal choice for conveying caustic and viscous fluids due to its exceptional qualities and smooth operation features. The following articles show the detailed advantages and precautions of gear pumps.

A gear oil pump is a device that has two gears of the same size meshing with one another inside a tightly fitting casing. It moves fluid mechanically to provide a smooth, pulse-free flow that is proportionate to the speed at which its gears rotate by repeatedly enclosing a set volume inside interlocking gears.

Low cost

The gear type pump is easier to move and lighter than a standard pump, which helps to somewhat reduce transportation expenses. In addition, the gear pump is not expensive due to its straightforward design and lower production costs. In a word, using the gear pump in your production line can effectively save costs and improve working efficiency.

Great Efficiency

By limiting energy usage and cutting operational expenses, electric gear pumps achieve great volumetric efficiency. Their effectiveness is especially useful in procedures where energy conservation is a top concern.

Non-Sensitive to Fluid Viscosity and Density

Changes in fluid density or viscosity do not significantly affect gear pumps. When a restrictor or strainer is positioned beside the discharge port, the gear pump will force the fluid to pass past them. The gear pump will continue to run continuously even if the filter is clogged or unclean until it hits the weakest component of the unit's mechanical limit. Consequently, the gear pump is less susceptible to oil contamination and is better suited for usage in the petrochemical sector.

Simple Operation & Maintenance

The gear pump with a simple and compact structure consists of the pump body, front and rear covers, and the two gears that make up the gear pump are all very small. As a result, the gear pump weighs less than conventional pumps, making it easy to daily transport and requiring less labor. In other words, this machine is also easier to use and more convenient when the task content is the same by its lightweight. In the same time, it is easier to fix when issues arise due to its straightforward construction and smaller number of parts.

Handling Precautions

Keeping Debris Out

① No ferromagnetic impurities and particles are allowed to enter the magnetic drive and bearings.

② In order to prolong the service life of the plain bearings, they should be flushed promptly after conveying media that crystallize or precipitate easily. This involves filling the pump chamber with fresh water after stopping the pump and draining it after one minute of operation.

③ Filter the media at the pump flow pipe's input while transferring materials that contain solid particles.

2. Avoid arid friction

① It is strictly forbidden to idle.

② The medium cannot be evacuated under any circumstances.

③ In order to keep the magnetic actuator from overheating and malfunctioning, the pump's continuous operation period must not exceed two minutes when the outlet valve is closed. With good outcomes, gear pumps are employed in critical and hazardous sections of several installations in ethylene plants and refineries.

3. Keep from demagnetizing

① It is impossible to create the magnetic torque too tiny.

②It must be used within the designated temperature range, and going above the recommended mean temperature is strictly forbidden. In order to detect temperature rise in the annulus area and to alert or shut down the pump when the temperature surpasses the limit, a platinum resistance temperature sensor can be mounted on the outside of the gear pump isolating sleeve.

0 notes

Text

What' s the main parts of the screw pump?

A screw pump is a positive displacement pump that moves water or other fluids along the axis of one or more screws. In order to pressurize the fluid and transport it into the system, the machine is equipped with two counter-rotating screw rotors inside the machine for operation. When the screw rotates, the gas is compressed inside the machine and at the same time it is moved towards the exhaust port. The design of a screw pump is a simple structure, including inlet and outlet ports, timing gear, pressure relief valve, bearing and drive shaft. Next, we will show you the detailed parts information of the screw pumps.

Inlet & Outlet Ports

A screw pumps have separate ports for its inlet and outlet. The water is drawn into the pump and released through the intake and output ports. The design of the output and inlet makes sure there is adequate liquid medium when the pump eventually stops. Therefore, even if the straws are empty or dry, the straws will not dry out quickly.

Timing Gear

To prevent metal-to-metal contact between the male and female rotor assemblies, the timing gear drives the driven screws. It creates a connection between the driven screws and the driver. When the drive screw is fitted with the optional timing gear, it transmits the rotation to the driven screw. If you need to switch off the pump for a short period of time, we also ensure that this connection does not occur.

Pressure Relief Valve

Screw compressor pumps belong to a type of positive displacement pump, and pressure is also generated when the outlet is closed. This means the pressure will be raised to cause serious issues, including breaking down internal pump parts and danger to the pump operator. For the purpose of protecting the pump, the operator, and any associated gear, all screw pumps are equipped with a relief valve. This valve returns excess pressure to the intake. In general, recirculating the exit fluid will help you reduce the extra pressure when you need it.

Bearing

The vertically mounted screw pump's top bearings experience axial and radial strains in addition to severe loads during pump operation. Consequently, there is little load on the lower bearings. The main purpose of the bottom bearing is to maintain the alignment of the pump's parts. Meanwhile, the water screw pumps, roller bearings, and slide bearings arranged in parallel have very little loads.

Drive Shaft

The pump components are connected to the drive motor by the driving shaft, and this connection is realized by employing a suitable flexible coupling set. This driving shaft plays an indispensable role in many types of pumps, which run from side to side to guarantee the driver screw's operation. Correct drive shaft alignment is therefore essential to maintaining the bearings and service life of the pump.

The high pressure screw pump with wide application has become the standard solution for industrial processes. Whether for oil and gas or ceramics and paints, progressive cavity pumps are the ideal choice.

0 notes

Text

Why are centrifugal pumps with wide application in industry?

Centrifugal pump plays a crucial role in the industrial operation of oil and gas, power production, water treatment, and other areas. At the same time, this series of pumps enjoys a good reputation for its high efficiency, reliability and wide range of applications. The following article will explain why electric centrifugal water pumpare widely used in industry.

Wide-Ranging Applications

The centrifugal pump with great versatility is adaptable for various industrial applications to convey a wide range of fluids including oil, water, chemicals and slurry. When you use this machine in your mining and beneficiation processes, it can effectively and quickly process corrosive and abrasive materials. The centrifugal pump is an ideal choice for the mining industry due to its specially designed to withstand slurry transport.

Reliable Operation

Generally speaking, the industrial sector often requires durable and continuous operation of equipement. We designed the centrifugal pumps for sale with robust construction and exceptional dependability that will effectively deal with harsh environments with temperature and high pressure. Compared with other series pumps, centrifugal pump has less maintenance time and steps due to its simple design and fewer moving parts. In other words, the use of centrifugal pumps will reduce downtime and save money in your industrial facilities for continuous production.

Increased Production Capacity

Self priming centrifugal pump made by Shenghui adopt energy-efficient design for the reduction of power consumption and operations costs in your industries. The development of technology has led to the development of high-pressure slurry pumps and vertical centrifugal pumps, effectively improving production efficiency. Using the centrifugal pump convey the liquid over long distances or to higher elevations while using less energy because the pumps have the design of higher operating pressure.

Productive Conveying

The capacity of high pressure centrifugal pump to transport fluids effectively is one of the major factors contributing to their widespread use in industrial environments. In order to provide a high flow rate, the pump converts into kinetic energy to operate by converting mechanical energy. Liquids may pass through a rotating impeller in centrifugal pumps thanks to their design, which produces centrifugal force. Therefore, the centrifugal pump is perfectly suitable for industrial applications where liquids must be moved continuously because it will handle enormous volumes of fluids, such as chemical manufacturing plants.

Industrial centrifugal pumps are indispensable role in industrial environments because of their working efficiency, wide application, smooth operation. You can use this machine for mining, water treatment, oil and gas, and various industries to transport a broad range of fluids.

As one of the professional manufacturers and producers in China, Shenghui company has been producing and developing pumps for more than ten years, with a professional research team and machines. Our company's success is based on specializing in the manufacture of high quality pumps, the implementation of innovative technology and the provision of excellent customer service. If you need centrifugal pumps for industrial use, we can provide you with reliable and professional centrifugal pumps according to your needs, please contact us immediately!

0 notes

Text

This machine is ideal for liquid water-filling production lines. You can already enjoy automated production without much human intervention, in other words, you only need one person to operate the whole filling machine.

0 notes

Text

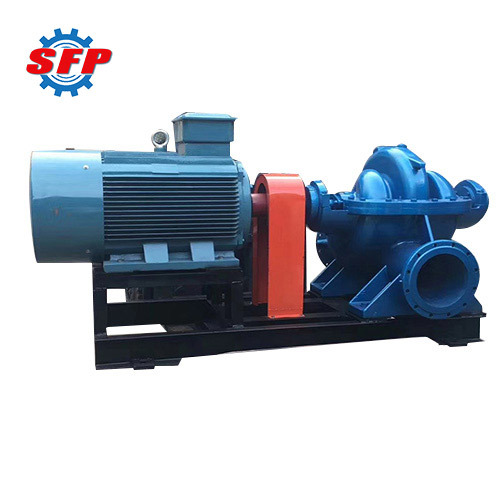

OEM ODM S/SH Single-Stage Double-Suction Centrifugal Pump has the advantages of beautiful appearance, compact structure, stable operation for improving working efficiency in your industry.

0 notes

Text

3RP Viscosity Liquid Filling Machine Lobe Pump is often used to transfer the corrosive and suspension high viscosity liquid in the food and beverage, bio-pharmaceutical manufacturing and other hygienic processing industries

0 notes

Text

2BV series water ring vacuum pumps allow to pumping the gases and steam, and its suction pressure can reach 33mbar (abs) (i.e. 97 % vacuum degree). You can use this machine in machinery, petrochemicals, pharmaceuticals, food, sugar, electronics, etc.

0 notes

Text

What is the NYP Series Internal Gear Pump?

NYP series internal gear pumps can be due to different fields such as petroleum, chemical, paint, grease, pharmaceutical, food and so on. In order to make this pump widely applicable to delivery a variety of different properties, viscosity of the media, so we use a special structure and high quality pump body materials. The seal of this NYP series internal gear pump adopts packing seal or mechanical seal in the pumps' seal. When you should handle the medium of high temperature, high viscosity and strong corrosion, this machine utilize the packing as seal. If the handling medium easy become crystal, We can design the heat preservation jacket in pump body and front cover in order to melt the medium with steam when working.

0 notes

Text

Since its establishment in 2010, ShengHui Pump Company has developed into one of the professional manufacturers and suppliers of pumps and related products. To make our pumps one of the most reliable and trustworthy pumps on the market, ShengHui utilizes the most durable components and advanced production techniques. As a reliable supplier to more than 3,000 customers from a wide range of industries, our company enjoys a strong reputation in markets around the world, and we have established friendly cooperative relationship relationships with some of the world's top 500 well-known companies. We hope to establish a long-term relationship with you and we promise to serve you with our warmest welcoming hand.

1 note

·

View note