#processengineer

Explore tagged Tumblr posts

Text

To bring in the best brands across the world under one roof to provide the finest quality equipment matching client’s requirement which are also cost effective.

Making Mohnot Instruments a leading supplier in Test & Measurement industry keeping our client’s betterment in mind and making a priority to maintain our quality service all the way.

For best price of the product, do reach us on 𝐢𝐧𝐟𝐨@𝐦𝐨𝐡𝐧𝐨𝐭𝐢𝐧𝐬𝐭𝐫𝐮𝐦𝐞𝐧𝐭𝐬.𝐜𝐨𝐦

You can also reach us on +91-9821614731

#panelbuilders#panelessolares#processengineer#processindustry#electricaldistribution#mohnotinstruments#electricalcontractor#kyoritsu#insulationtester#insulation#measurement#megger#resistance#voltage#kew3552#measurementspeed#1kV#40GΩ#PI#DAR#india#testandmeasurement#instruments#brands#meters#supplier#b2bsales#businesstobusiness

1 note

·

View note

Text

Y Strainer Manufacturers in India

Speciality valve is top Y Strainer Manufacturers in India, A Y Strainer is the type of simple and efficient filter put in pipes to remove all forms of dirt, debris, or other particles from liquids, gases, or steam.

Description: 1.Body: Carbon Steel, CF8, CF8M, CF3M, Cast Iron, SS304, SS316 2.Nominal Diameter: DN25 to DN500 3.Nominal Pressure: Class150 to Class300 4.Inspection and Test: API 598 5.Size: ½” to 32” 6.Ends- Flanged, threaded, Buttweld, socket weld

Visit Us: https://www.specialityvalve.com/product-category/y-strainer/

#YStrainer#Strainer#PipeFitting#FluidFlow#WaterTreatment#IndustrialPiping#WaterFiltration#MechanicalEngineering#YStrainerFilter#PipingSystem#FiltrationTech#IndustrialEquipment#StrainerFilter#YShapeStrainer#FlowControl#PipeStrainer#FiltrationSystem#YStrainerInstallation#PipingSolutions#MaintenanceEngineering#FlowManagement#StrainerDesign#ProcessEngineering#FiltrationIndustry

0 notes

Text

💧 Understanding Industrial Pumps 💧 Discover the unique working principles of three essential pump types:

🔹 Screw Pumps: Perfect for high-viscosity fluids, providing a steady flow. 🔹 Rotor Pumps: Ideal for gentle handling of sensitive materials. 🔹 Gear Pumps: Excellent for high-pressure applications with precise flow rates.

Each pump type serves a specific purpose in industries like oil and gas, food processing, and wastewater treatment.

Explore more on our blog! : https://www.svblowers.in/blog?page=2

#IndustrialPumps#ScrewPumps#RotorPumps#GearPumps#FluidHandling#WastewaterTreatment#OilAndGas#FoodProcessing#PumpSolutions#Engineering#SVE Engineers#PumpingTechnology#ProcessEngineering#HighViscosityFluids#PrecisionPumps#GentleHandling

0 notes

Text

Essential Maintenance Practices for Optimal Performance of Float Steam Traps

Float steam traps��are critical components in steam systems, ensuring the efficient removal of condensate while preventing steam loss. To maintain their functionality and extend their lifespan, it’s essential to implement effective maintenance practices. Here, we’ll explore key strategies to ensure the optimal performance of float steam traps.

1. Regular Inspections

Routine inspections are the cornerstone of effective maintenance for float steam traps. Check the traps for signs of wear and tear, leaks, and corrosion. A visual examination can often reveal potential issues before they escalate. Pay attention to the trap’s connections, seals, and the float mechanism itself. Regular inspections help in identifying malfunctioning traps that could lead to energy loss and increased operational costs.

2. Monitor Performance Metrics

Keeping track of performance metrics is crucial. Monitor parameters such as discharge temperature, pressure, and condensate flow rates. Any significant deviations from normal operating conditions can indicate a problem with the steam trap. Implementing a monitoring system can help detect issues early and allow for timely intervention, ultimately preventing costly downtime.

3. Clean the System

Contaminants and debris can accumulate in steam systems, impacting the efficiency of float steam traps. Regularly cleaning the steam lines and traps helps to minimize the risk of blockages that can impede proper function. It’s advisable to use appropriate cleaning agents and techniques to avoid damaging the internal components of the traps. A clean system enhances performance and promotes longevity.

4. Test for Leaks

Leaks in steam traps can significantly impact energy efficiency and operating costs. Implement a schedule for testing float steam traps for leaks. This can be done through the use of ultrasonic leak detectors or by employing a simple soap solution to identify escaping steam. Early detection of leaks allows for prompt repairs, ensuring that the steam system operates efficiently.

5. Replace Worn Parts

Over time, components of float steam traps can wear out, affecting their performance. Be proactive in replacing worn parts, such as the float, seat, and seals. Keeping spare parts on hand can expedite repairs and minimize downtime. Regular replacement of these components not only maintains efficiency but also ensures that the trap functions correctly throughout its lifecycle.

6. Train Personnel

Ensuring that maintenance personnel are well-trained in the operation and maintenance of float steam traps is vital. Proper training equips staff with the knowledge to identify issues, perform maintenance tasks, and understand the importance of each component within the steam system. Ongoing training and awareness of the latest technologies and practices can significantly enhance overall system performance.

7. Document Maintenance Activities

Keeping detailed records of maintenance activities is essential for effective management of float steam traps. Documentation should include inspection dates, performance metrics, repairs, and replacements. This information can help identify patterns over time and inform future maintenance strategies. Having a historical log can also be beneficial when troubleshooting recurring issues.

Maintaining float steam traps is crucial for the efficient operation of steam systems. By implementing regular inspections, monitoring performance, cleaning the system, testing for leaks, replacing worn parts, training personnel, and documenting maintenance activities, you can ensure the optimal performance of these essential components. A proactive approach to maintenance not only enhances energy efficiency but also contributes to significant cost savings, ultimately improving the overall productivity of your operations. Investing in the maintenance of float steam traps will pay dividends in performance and reliability, making it a smart choice for any facility utilizing steam systems.

#FloatSteamTraps#SteamSystems#MaintenanceTips#EnergyEfficiency#IndustrialMaintenance#ProcessEngineering#SteamTrap

0 notes

Text

Knowledge Sharing Series#2

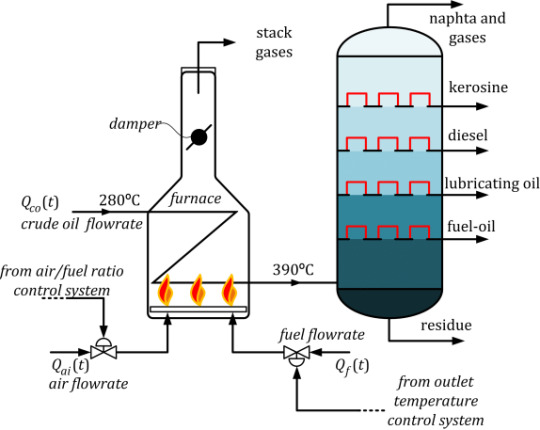

What is the Process that undergoes in Oil Preheating Furnace?

Crude Oil Entry: The desalted crude oil, which has already been heated and mixed with water to remove salt, enters the preheating furnace.

Heat Exchange: The furnace is typically designed with a series of tubes through which the crude oil flows. Hot flue gases, generated by burning fuel (such as natural gas or fuel oil), pass over these tubes, transferring heat to the crude oil.

Temperature Increase: As the crude oil flows through the tubes, it absorbs heat from the flue gases, gradually increasing in temperature.

Desired Temperature: The furnace is carefully controlled to ensure that the crude oil reaches the desired temperature, typically around 350°C to 360°C. This temperature is essential for effective vaporization of the lighter components in the crude oil.

Exit to Distillation Column: Once the crude oil has reached the target temperature, it exits the preheating furnace and enters the atmospheric distillation column, where the separation process begins.

#OilAndGas#Refinery#ChemicalEngineering#ProcessEngineering#Petrochemical#DownstreamProcessing#Distillation#UnitOperations#EnergyIndustry#Fuels#FossilFuels#PreheatingFurnace#CrudeOilPreheating#AtmosphericDistillation#DistillationColumn#HydrocarbonSeparation#RefiningProcess#OilAndGasEquipment#ProcessControl#HeatTransfer#Decontamination

0 notes

Text

Manufacturing Engineering Services - Vee Technologies

Vee Technologies’ manufacturing engineering services are powered by extensive industry experience and a team of highly skilled engineers. They improve manufacturing processes with our pragmatic approach and hands-on technical support. Explore More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing/manufacturing-engineering.htm

#ManufacturingEngineering#IndustrialEngineering#ProductionOptimization#SmartManufacturing#FactoryAutomation#EngineeringSolutions#ManufacturingInnovation#ProcessEngineering

0 notes

Text

Manufacturing Engineering Services - Vee Technologies

Vee Technologies’ manufacturing engineering services are powered by extensive industry experience and a team of highly skilled engineers. They improve manufacturing processes with our pragmatic approach and hands-on technical support.

Explore More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing/manufacturing-engineering.htm

#ManufacturingEngineering#IndustrialEngineering#ProductionOptimization#SmartManufacturing#FactoryAutomation#EngineeringSolutions#ManufacturingInnovation#ProcessEngineering#VeeTechnologies

0 notes

Text

The Role of Centrifugal Pumps in Pharmaceutical Production

0 notes

Text

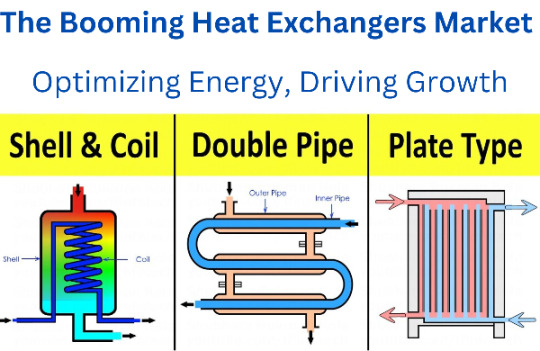

Heat Exchangers Market Landscape: Detailed Analysis of Size, Share, and Emerging Trends

The global heat exchangers market size is expected to reach USD 26.26 billion by 2030, registering at a CAGR of 5.4% from 2024 to 2030, according to a new report by Grand View Research, Inc. Rising demand from various industries, including chemical & petrochemical, and power generation, along with an increasing focus on improving efficiency standards is expected to drive the market.

Heat Exchangers Market Report Highlights

The demand for plate & frame heat exchangers is anticipated to witness growth at a CAGR of 6.1% from 2024 to 2030 on account of its simple & compact structure coupled with their ability to increase capacity easily by adding new plates to the system

The shell & tube segment led the market and accounted for 35.6% of the global revenue in 2023

Asia Pacific heat exchanger demand is likely to grow at a CAGR of 6.8% over the forecast period

The demand for heat exchangers in Saudi Arabia is expected to witness a CAGR of 4.5% owing to the presence of a robust oil & gas industry coupled with the growth in the manufacturing sector attributed to the government’s diversification efforts

For More Details or Sample Copy please visit link @: Heat Exchangers Market Report

The presence of favorable government regulations in the emerging economies of China, India, Brazil, and Mexico about setting up new manufacturing facilities is expected to spur the demand for heat exchangers in various industries. In addition, upcoming nuclear power projects, particularly in the Asia Pacific, are anticipated to drive market growth during the forecast period.

Technological advancements coupled with constant efforts and investments by major market participants in product innovation and research & development are expected to increase the market competitiveness over the coming years. The adoption of novel techniques of additive manufacturing in the production of heat exchangers is likely to complement industrial growth.

The COVID-19 pandemic has severely impacted several economies worldwide. Containment measures, including lockdowns imposed by various countries to curb the spread of COVID-19, have resulted in limiting the operations of manufacturing facilities, thereby negatively impacting the demand for heat exchangers in 2020.

#ThermalManagement#EngineeringSolutions#IndustrialHeating#CoolingSystems#EnergySystems#EcoFriendlyTech#PowerGeneration#ProcessEngineering#HeatTransfer#CleanEnergy#MechanicalEngineering#TechInnovation#EnvironmentalRegulations#HVAC#RenewableEnergy

0 notes

Text

Taknik Inc provide Process equipment

for order

Email Id [email protected]

Contact no-9510430147

#taknikinc#processengineering#processequipment#heat#exchanger#industries#chemicalindustry#bharuchcity#gujarat

0 notes

Text

Vacuum Emulsifying Mixer - VGA Automation

VGA Automation Vacuum Emulsifying Mixer is a specialized piece of industrial equipment designed to create fine emulsions, typically in the cosmetics, pharmaceuticals, food, and chemical industries. This type of mixer is used to blend different liquids, often immiscible ones, into a stable emulsion or to finely disperse solids into liquids under a vacuum. The vacuum environment reduces air bubbles, oxidation, and contamination, leading to higher-quality products.

#VGAAutomation#VGApackingmachine#VGA#vgaautomationmixer#vgaVacuumEmulsifyingMixer#VacuumEmulsifyingMixer#EmulsifyingMixer#IndustrialMixing#MixingTechnology#HighShearMixer#CosmeticManufacturing#PharmaceuticalManufacturing#FoodManufacturing#ChemicalMixing#Homogenization#ProcessEngineering#VacuumTechnology#vgaprocessingmachine#packingmachine#vgashearmixer

0 notes

Text

Serge Vessel – Level Control

S.R. Bhat (Technical Director, COMFIT)

Many times, a product produced in a process equipment is used as feed to another equipment. In these cases, it is necessary to make the feed flow to the second equipment steady, i.e. any variations in the feed should be very slow. This must be achieved even if the product out coming put of the first equipment is not steady. E.g. Naphtha coming out of the crude distillation unit of a refinery is unstable, i.e. it contains a lot of volatile components. These volatile constitute Liquefied Petroleum Gas (LPG), which is very valuable. This stream is fed to another distillation column called Naphtha Stabilizer. Purpose of the Naphtha Stabilizer are two. They are:

1. Recover the LPG, allowing minimum slippage of LPG to Naphtha.

2. Remove LPG from Naphtha with minimum slippage of Naphtha to LPG. To achieve this, a serge vessel is introduced in between the Crude Distillation Column and the Naphtha Stabilizer. Feed flow into the stabilizer is controlled by a control valve introduced between the serge tank and stabilizer. Process variable for this control loop is the liquid level in the serge tank. This level keeps varing around 50%. If this controller is well tuned, level will always mainted tightly near the 50 % mark. This would defeat the purpose of surge vessel by making the vessel outlet flow closely follow the badly varing inlet flow. On the other hand, by keeping the controller sluggish (i.e. making proportionality gain low), the surge tank serves its purpose. When the input flow to the serge vessel increses, sluggish level controller acts very slowly, resulting in the slow and steady increase of outlet flow from the vessel. This increses the level in the serge tank. On the other hand, when the inlet flow to the serge vessel reduces, exactly the reverse happens.

This is a strange case of attuned controller gives the desire result. This has been successfully done in the Naphtha Stabilizer of refinery, which resulted in substantial increase in of the production of the valuable LPG, but also improved its weathering.

#SergeVessel hashtag#LevelControl hashtag#ProcessEngineering hashtag#FeedFlowStabilization hashtag#NaphthaStabilizer hashtag#LPGRecovery hashtag#ControlSystem hashtag#ProcessOptimization hashtag#RefineryTechnology hashtag#SurgeTankSuccess hashtag#EfficientProduction hashtag#ProcessControl hashtag#SteadyFeedFlow hashtag#industrialengineering hashtag#comfit hashtag#valvemanufacturer hashtag#valves hashtag#valveindustry hashtag#valvefactory hashtag#india

0 notes

Link

Process Engineer-UAE, Apply Here!

0 notes

Text

Chemical Engineering

Chemical Engineering is a diverse field that merges principles of chemistry, physics, and mathematics to develop and optimize processes for producing, transforming, and efficiently using chemicals, materials, and energy. It plays a crucial role in industries like pharmaceuticals, energy, food, and environmental technology, focusing on innovation and sustainability to meet global needs.al Engineering

International Chemistry Scientist Awards

Website: chemistryscientists.org

Contact us: [email protected]

Nominate now: https://chemistryscientists.org/award-nomination/?ecategory=Awards&rcategory=Awardee

#sciencefather#researchawards#Professor,#Lecturer,#Scientist,#Scholar,#Researcher#ChemicalEngineering #ProcessEngineering #SustainableEnergy #Innovation #MaterialsScience #Chemistry #IndustrialProcess #PharmaceuticalEngineering #EnvironmentalTech #EnergyEfficiency

0 notes

Text

Major Equipment in Atmospheric Distillation Unit (ADU)

The Atmospheric Distillation Unit (ADU) is the primary processing unit in most oil refineries.

It separates crude oil into various fractions based on their boiling points. The following are the key pieces of equipment found in an ADU:

1. Crude Oil Preheat Furnace:

Purpose: Heats the crude oil to a temperature close to its boiling point before it enters the distillation column.

Type: Typically, a fired heater that uses fuel gas or oil to generate heat.

2. Atmospheric Distillation Column:

Purpose: Separates the heated crude oil into different fractions based on their boiling points.

Components:

Tray or Packing: Used to provide contact between the vapor and liquid phases.

Reboilers: Heat the bottoms product to generate vapor.

Condenser: Cools the vapor to condense it into liquid.

3. Fractionators:

Purpose: Further refine certain fractions (e.g., naphtha, kerosene) to meet specific product specifications.

4. Strippers:

Purpose: Remove lighter components from heavier fractions to improve product quality.

5. Heat Exchangers:

Purpose: Recover heat from the process to reduce energy consumption.

Types: Shell-and-tube, plate-and-frame, etc.

6. Pumps:

Purpose: Transfer fluids between different equipment.

7. Piping:

Purpose: Connects the various equipment in the unit.

8. Instrumentation and Controls:

Purpose: Monitor and control the process variables (temperature, pressure, flow rate, etc.).

#oilrefining #petroleum #ADU #crudeoil #fractionation #petroleumengineering #energy #fuels #petrochemicals #chemicalengineering #processengineering #Quora #Question #Answer #Discussion #KnowledgeSharing #Learn #Explore #OilRefining #Petroleum #ADU #Distillation #Engineering #ProcessEngineering #ChemicalEngineering #Energy #Fuel #Petrochemicals #Share #Follow #Like #Comment

#atmosphericdistillationunit#ADU#distillationunit#chemicalengineering#petroleumindustry#refiningprocess#industrialengineering#engineering#science#technology#fractionatingcolumn#reboiler#condenser#overheadcondenser#refluxdrum#pumparound#feedtray#strippingsection#enrichingsection#chemicalplant#oilrefinery#petroleumproducts#processcontrol#automation#engineeringstudent#engineeringlife#education#ADUcomponents#ADUprocess#majorpartsofADU

1 note

·

View note

Text

Manufacturing Engineering Services - Vee Technologies

Vee Technologies’ manufacturing engineering services are powered by extensive industry experience and a team of highly skilled engineers. They improve manufacturing processes with our pragmatic approach and hands-on technical support.

Explore More: https://www.veetechnologies.com/industries/engineering-services-and-solutions/product-engineering-manufacturing/manufacturing-engineering.htm

#ManufacturingEngineering#IndustrialEngineering#ProductionOptimization#SmartManufacturing#FactoryAutomation#EngineeringSolutions#ManufacturingInnovation#ProcessEngineering

0 notes