#processcontrols

Text

Fluke Temperature Calibration: Precision Instruments for Accurate Temperature Measurement

Ensure precise and reliable temperature measurement with Fluke Temperature Calibration instruments. Trusted by professionals across various industries, Fluke Calibration tools offer superior accuracy and consistency, making them ideal for critical applications such as process control, laboratory testing, and industrial maintenance. With advanced technology and user-friendly features, Fluke’s temperature calibration solutions help you maintain high standards of performance and compliance.

0 notes

Text

Discover how industrial embedded systems are transforming the world of industrial automation in our latest blog, "Industrial Embedded Systems: The Backbone of Modern Industrial Automation." Learn how these powerful solutions are driving efficiency, reliability, and innovation across various applications.

🔍 Highlights:

🔧 Robust Performance: Engineered for high performance and durability.

🌐 Real-Time Processing: Ensures timely and accurate responses.

🛠️ Customization: Tailored to meet specific industrial needs.

📊 Connectivity: Extensive options for seamless integration.

Dive into how SolidRun’s cutting-edge embedded systems are shaping the future of industrial automation. Read the full article here and explore the potential of these advanced solutions for your projects!

#IndustrialEmbeddedSystems#Automation#TechInnovation#SolidRun#EmbeddedComputing#Manufacturing#ProcessControl#RealTimeProcessing#CustomSolutions

0 notes

Text

"Unlocking Efficiency and Precision: The Power of Control Integration Services"

Control Integration Services: Elevating Efficiency and Precision in System Management

In the ever-evolving landscape of modern business, the integration of control systems is becoming increasingly essential. To stay competitive and optimize operations, organizations need effective Control Integration Services (CIS). These services unify various control systems, enhancing operational efficiency, accuracy, and management precision. Let’s explore how Control Integration Services can transform your business operations.

What Are Control Integration Services?

Control Integration Services focus on integrating diverse control systems into a single, cohesive framework. Whether it's industrial automation, building management, or IT infrastructure, CIS ensure that various systems—such as process control systems, building management systems (BMS), and IT management tools—work together seamlessly. The primary objective is to create an integrated platform that enhances system communication, streamlines operations, and provides comprehensive real-time data.

Key Benefits of Control Integration Services

Increased Operational Efficiency: Integrating control systems into one unified platform simplifies operations, reduces duplication of efforts, and minimizes manual interventions. This leads to significant cost savings and more efficient use of resources, ultimately boosting productivity.

Enhanced Accuracy and Precision: With real-time data and analytics from integrated systems, organizations can make more informed decisions. This improves the precision of operations and reduces errors, leading to better overall performance.

Centralized Monitoring and Management: Control Integration Services provide a centralized interface for monitoring and managing all integrated systems. This centralization facilitates easier oversight and quicker issue resolution, enhancing operational control.

Scalability and Flexibility: Integrated control systems offer scalability and adaptability to changing business needs. Whether expanding operations or upgrading technology, CIS allow for the seamless integration of new systems and technologies.

Improved Security: A unified approach to system integration enhances security by providing a consolidated view of system activities and access controls. This helps in identifying and mitigating potential security threats more effectively.

Core Components of Control Integration Services

System Assessment and Planning: Successful integration begins with a detailed assessment of existing systems. This involves evaluating current control technologies, identifying integration gaps, and developing a strategic integration plan.

Integration Architecture Design: Designing an effective integration architecture involves selecting appropriate technologies and protocols for seamless communication between systems. This includes defining data exchange methods and system interactions.

Implementation and Configuration: The implementation phase involves setting up the integration framework, configuring various systems, and ensuring that all components work together as intended. Careful coordination and thorough testing are essential to ensure successful integration.

Testing and Validation: Comprehensive testing is critical to validate the integration and ensure it meets performance and reliability standards. This includes functional testing, performance assessment, and user acceptance testing.

Ongoing Support and Maintenance: Post-implementation support is crucial for addressing any issues and ensuring the continued smooth operation of integrated systems. Regular maintenance and updates are necessary to keep the system efficient and up-to-date.

Real-World Applications

Industrial Automation: In manufacturing, Control Integration Services streamline operations by integrating process control systems, safety systems, and enterprise resource planning (ERP) systems. This integration enhances production efficiency and minimizes downtime.

Building Management Systems (BMS): For commercial buildings, integrating HVAC, lighting, and security systems into a single BMS platform improves energy efficiency and operational control. This results in better resource management and reduced operational costs.

IT and Data Centers: In IT environments, Control Integration Services help manage data center operations, including server monitoring, network management, and security. Integrated systems ensure efficient, reliable, and secure IT infrastructure.

Conclusion

Control Integration Services are pivotal for organizations aiming to enhance efficiency and precision in their operations. By integrating various control systems into a unified framework, businesses can achieve greater accuracy, improved operational control, and centralized management. Whether in industrial settings, building management, or IT infrastructure, CIS offer substantial benefits that drive operational success and support growth.

As technology progresses, the need for effective system integration will only increase. Investing in Control Integration Services today positions your organization for a more efficient, accurate, and secure future.

#ControlIntegrationServices#SystemIntegration#OperationalEfficiency#IndustrialAutomation#BuildingManagementSystems#ITInfrastructure#ProcessControl#RealTimeData#SystemOptimization#IntegrationArchitecture#TechIntegration#CentralizedManagement#DataCenterManagement#ScalableSolutions#PrecisionEngineering#BusinessEfficiency#SecurityIntegration#AutomationSolutions#TechnologyTrends#SmartBuildingTechnology

0 notes

Text

0 notes

Text

#FlowSensors#IndustrialAutomation#SensorTechnology#AutomationEngineering#FluidMeasurement#ProcessControl#FluidFlow#IndustrialSensors

0 notes

Text

Pneumatic Actuator Operated Ball Valve | Aira SS Screwed Valve

Discover reliable pneumatic actuator operation with Aira's SS screwed ball valve. Ensure precise control and durability. Order now!

#PneumaticActuator#BallValve#IndustrialValves#SSValve#ValveAutomation#EngineeringSolutions#IndustrialAutomation#FluidControl#ProcessControl

0 notes

Text

PLC Automation Panels Compared: OEM vs. Custom Solutions

In the realm of industrial automation, Programmable Logic Controllers (PLCs) serve as the backbone, orchestrating the intricate dance of machinery, processes, and data. However, when it comes to implementing PLC systems, businesses are often faced with a crucial decision: should they opt for Original Equipment Manufacturer (OEM) panels or invest in custom solutions tailored to their specific needs? Let’s delve into the nuances of each option to uncover which best suits your industrial automation requirements.

OEM Panels:

Pros:

1. Standardization: OEM panels are pre-designed and manufactured to industry standards, ensuring compatibility with a wide range of applications.

2. Cost-Effectiveness: Mass production of OEM panels often translates to lower costs per unit, making them a more budget-friendly option for businesses with standardized automation needs.

3. Ease of Installation: With standardized designs and components, OEM panels typically offer straightforward installation processes, minimizing downtime during setup.

Cons:

1. Limited Customization: While OEM panels offer a plug-and-play solution, they lack the flexibility to accommodate unique requirements or specialized functionalities specific to your operations.

2. Scalability Challenges: As your automation needs evolve, OEM panels may struggle to scale alongside your business, potentially requiring costly upgrades or replacements in the future.

Custom Solutions:

Pros:

1. Tailored to Your Needs: Custom solutions are designed from the ground up to align precisely with your operational requirements, offering bespoke functionalities and features tailored to optimize efficiency and productivity.

2. Enhanced Compatibility: By integrating seamlessly with existing systems and processes, custom solutions mitigate compatibility issues and streamline data exchange across your automation ecosystem.

3. Scalability and Future-Proofing: Designed with scalability in mind, custom solutions can adapt and grow alongside your business, accommodating evolving needs and technological advancements without necessitating complete overhauls.

Cons:

1. Higher Initial Investment: Custom solutions often require a higher initial investment compared to off-the-shelf OEM panels due to the design and development processes involved.

2. Extended Lead Times: The bespoke nature of custom solutions means longer lead times for design, development, and manufacturing, potentially delaying implementation timelines.

Conclusion:

In the realm of PLC automation panels, the choice between OEM and custom solutions hinges on the unique requirements, priorities, and long-term objectives of your business. While OEM panels offer standardized functionality at a lower cost, they may fall short in accommodating specialized needs or future scalability. On the other hand, custom solutions provide unparalleled flexibility, scalability, and optimization tailored to your specific operational landscape, albeit at a higher initial investment. Ultimately, businesses must weigh the trade-offs between cost, customization, and long-term scalability to make an informed decision that aligns with their automation strategy and objectives. If you want more information on these type of topics so,

visit here👉https://www.pujacontrols.com/

#PLCautomation#AutomationPanels#OEMvsCustom#IndustrialAutomation#ManufacturingTech#CustomSolutions#PLCcomparison#FactoryAutomation#EngineeringSolutions#ProcessControl

0 notes

Text

Fabi Lok Measuring and Control Equipment LLC, a premier provider of cutting-edge measuring and control solutions has now joined TradersFind! They offer a range of top-notch products, including Wika Pressure Gauges, Calibration Services, Fluke Calibrator, and Biohall GlassWare. Their commitment to quality and precision ensures each product meets the highest industry standards, empowering businesses with the best-in-class instruments.

Click here to explore their superior-quality products and specialized services-

https://www.tradersfind.com/seller/fabi-lok-measuring-and-control-equipment-llc

#fabilokllc#measuringequipment#controlsolutions#industrialsupplies#qualityinstruments#precisiontools#wikapressuregauges#calibrationservices#flukecalibrator#biohallglassware#industrialautomation#processcontrol#engineeringtools#manufacturingsupplies#qualityassurance#precisionmeasuring#uaebusiness#uaemanufacturing#uaetrade#uaesuppliers#uaeindustry#uaebrands#tradersfind#b2bportal

1 note

·

View note

Text

VGA Automation Batching Weighing Dosing Machine is a type of equipment used in various industries for precise measurement and dispensing of materials in predetermined quantities. These machines are commonly used Pharmaceuticals, Food and Beverage, Chemical Industry, Cosmetics and Personal Care, Plastics and Polymers and Mining and Minerals.

#VGAAutomatio#VGApackingmachine#VGAautomationcandypackingmachine#VGA#BWDM#BatchingMachine#WeighingMachine#DosingMachine#PrecisionDosing#IndustrialAutomation#ManufacturingTech#ProcessControl#MaterialHandling#AccuracyMatters#BatchingWeighingDosingMachine#vgaautomationbatchweigher#vgaautomationdosingmachine#automaticweighbatchingmachine#batchfeeder#weighingbatchingsystem

1 note

·

View note

Text

Accurate Temperature Data Loggers for Reliable Monitoring and Recording

Ensure precise monitoring of temperature-sensitive environments with our advanced Temperature Data Loggers. Designed for reliability and ease of use, these loggers provide accurate data recording, essential for maintaining the integrity of your processes. Ideal for industries such as pharmaceuticals, food storage, and manufacturing, our Temperature Data Loggers offer peace of mind with consistent performance and compliance with industry standards.

0 notes

Text

Control valves are essential components in various industrial processes, regulating fluid flow by adjusting the aperture within a piping system. Comprising several key elements, control valves typically include a valve body housing the moving

0 notes

Text

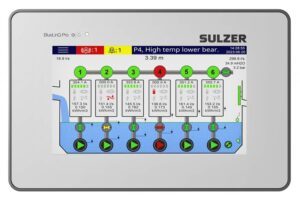

Sulzer launches next generation controller for optimized performance of wastewater pumping stations

Network pumping stations invariably encounter challenging conditions, and operators can face an uphill struggle to maintain reliability and low operating costs. BlueLinQ Pro, the latest addition to the Sulzer pump controller lineup, uses an intuitive, quick setup wizard for simplified configuration and uses experience-designed presets to solve complex operating scenarios.

Operators can interact seamlessly via the 7” touchscreen and use the integrated variable frequency drive (VFD) control to maximize pump efficiency and reduce energy costs. The new BlueLinQ Pro offers excellent scalability and is capable of controlling up to six assets including pumps, mixers and valves for the most effective operations.

Plug-and-play performance

The Sulzer BlueLinQ Pro offers advanced control features and a setup wizard that improve pump availability and reduce energy consumption - all within a small footprint that makes retrofitting easy. Built-in best efficiency point (BEP) and proportional integral derivative (PID) control logic functionality ensures that all pumps in the station operate as close to peak efficiency as possible. This reduces running costs and minimizes stress on the mechanical components.

Smart control functionality provides multiple features that optimize pump operations and minimize the need for interventions from the maintenance team. The ability to calculate in and outflows, measure the speed of level changes and vary pump start and stop points ensures each pumping station operates to its full potential. This includes the addition of mixers and valves, which can also be included in the control logic delivered by the BlueLinQ Pro.

Sulzer is setting a new standard for pumping station controllers. Simple module installation and configuration optimizes any retrofit by using multiple preset features to enhance performance. Round-the-clock remote monitoring and detailed analytics provide enhanced insights that support maintenance projects and minimize unnecessary call-outs.

Simplifying complex tasks

With so many very similar pumping stations in each network, the variety of controllers across sites can add unnecessary complexity for operators. The inherent flexibility of the BlueLinQ controller makes it ideal for many locations. Once the first station has been configured, all the settings can be easily transferred to others using the SD memory card facility, minimizing commissioning time.

To further enhance the benefits of the BlueLinQ Pro, modern communications protocols offer excellent connectivity and remote access possibilities to maximize the effectiveness of operators and technicians. Centralized monitoring and programing ensure valuable staff and resources are only dispatched when absolutely necessary.

In all, the features of this unique pump controller from Sulzer can support strategies to reduce operating costs, maximize reliability and optimize the productivity of the whole network.

www.sulzer.com

Ifat 24 Munich: Hall B1, Stand 321/420

Read the full article

0 notes

Text

Control Engineering Integrators

The Role of Control Engineering Integrators in Modern Automation Systems

In today's fast-paced industrial landscape, automation is the cornerstone of efficiency, precision, and productivity. At the heart of this transformation are control engineering integrators, the unsung heroes who bring complex systems to life. But what exactly is a control engineering integrator, and why are they crucial in the world of automation? Let's dive in and explore their pivotal role in shaping the future of industrial operations.

What is a Control Engineering Integrator?

Control engineering integrators are specialists who design, implement, and maintain control systems that manage industrial processes. Their work ensures that machinery, equipment, and systems operate smoothly and efficiently. They are experts in integrating various control technologies into cohesive systems that can handle complex operations with precision.

The Importance of Control Engineering Integrators

Customization and Optimization: Every industrial operation is unique, and control engineering integrators excel at tailoring solutions to meet specific needs. They analyze the requirements of a facility, design a control system that fits perfectly, and optimize it for peak performance. This customization helps businesses maximize their return on investment and enhance operational efficiency.

Seamless Integration: Modern industrial environments often use a mix of legacy and cutting-edge technologies. Integrators are adept at bringing these diverse systems together, ensuring that they communicate effectively and work in harmony. This integration is crucial for achieving seamless operations and reducing downtime.

Enhanced Reliability and Safety: Control systems are integral to maintaining safety and reliability in industrial processes. Integrators focus on designing robust systems that can handle unexpected conditions and prevent failures. Their expertise helps in mitigating risks and ensuring that safety standards are upheld.

Innovation and Adaptation: The field of control engineering is constantly evolving, with new technologies and methodologies emerging regularly. Integrators stay at the forefront of these developments, incorporating the latest innovations into their designs. This forward-thinking approach enables businesses to stay competitive and adapt to changing market demands.

Key Skills and Expertise of Control Engineering Integrators

Technical Proficiency: Integrators possess deep knowledge of various control systems, including PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, and DCS (Distributed Control Systems). Their technical expertise allows them to troubleshoot issues and ensure optimal performance.

Project Management: Successful integration projects require meticulous planning and execution. Integrators are skilled project managers who oversee every phase of the integration process, from initial design to final implementation. They coordinate with different teams, manage timelines, and ensure that project goals are met.

Problem-Solving Abilities: The integration process often involves overcoming unexpected challenges. Control engineering integrators are adept problem-solvers who can quickly identify issues, develop effective solutions, and implement them efficiently.

Communication Skills: Integrators must communicate effectively with clients, vendors, and team members. They need to translate complex technical concepts into understandable terms and ensure that all stakeholders are aligned with project objectives.

Future Trends in Control Engineering Integration

As industries continue to evolve, control engineering integrators are set to play an even more critical role. Here are some trends shaping the future of control engineering:

Increased Use of Artificial Intelligence (AI): AI is revolutionizing control systems by enabling predictive maintenance, optimizing processes, and enhancing decision-making. Integrators will need to incorporate AI technologies to keep pace with these advancements.

Expansion of IoT Integration: The Internet of Things (IoT) is becoming increasingly prevalent in industrial settings. Integrators will be tasked with incorporating IoT devices and platforms into control systems, enabling greater connectivity and data-driven insights.

Focus on Cybersecurity: As control systems become more interconnected, the risk of cyber threats increases. Ensuring robust cybersecurity measures will be a key responsibility for integrators, safeguarding systems against potential attacks.

Sustainability and Energy Efficiency: With growing emphasis on environmental sustainability, integrators will need to design control systems that optimize energy usage and reduce environmental impact. This includes integrating renewable energy sources and improving overall system efficiency.

Conclusion

Control engineering integrators are essential to the success of modern automation systems. Their expertise in designing, implementing, and maintaining control systems ensures that industrial processes run smoothly, efficiently, and safely. As technology continues to advance, their role will become even more critical, driving innovation and shaping the future of industrial automation. For businesses looking to stay ahead in a competitive landscape, partnering with skilled control engineering integrators is a strategic investment that can lead to substantial gains in efficiency and productivity.

#ControlEngineering#AutomationSystems#IndustrialAutomation#ControlSystems#EngineeringIntegrators#PLCIntegration#SCADA#DCS#IndustrialEfficiency#TechnologyIntegration#AutomationExperts#SystemOptimization#AIInEngineering#IoTIntegration#CybersecurityInAutomation#EnergyEfficiency#FutureOfAutomation#EngineeringSolutions#ProcessControl#IndustrialInnovation

0 notes

Text

Elevate industrial automation with #PLC and #SCADA solutions! 🏭✨ Discover how our cutting-edge technologies enhance efficiency and control in manufacturing processes.

Reach Us: 8807148869

PLC SCADA

#PLC#SCADA#AutomationTech#ControlSystems#PLCProgramming#IndustrialAutomation#SCADASystems#SmartFactory#Industry40#ProcessControl#PLCSCADA#AutomationEngineer#IoTinIndustry#SmartManufacturing#FactoryAutomation#PLCTechnology#DigitalTransformation#SCADAControl#AutomationSolutions#TechInnovation

0 notes

Text

Serge Vessel – Level Control

S.R. Bhat (Technical Director, COMFIT)

Many times, a product produced in a process equipment is used as feed to another equipment. In these cases, it is necessary to make the feed flow to the second equipment steady, i.e. any variations in the feed should be very slow. This must be achieved even if the product out coming put of the first equipment is not steady. E.g. Naphtha coming out of the crude distillation unit of a refinery is unstable, i.e. it contains a lot of volatile components. These volatile constitute Liquefied Petroleum Gas (LPG), which is very valuable. This stream is fed to another distillation column called Naphtha Stabilizer. Purpose of the Naphtha Stabilizer are two. They are:

1. Recover the LPG, allowing minimum slippage of LPG to Naphtha.

2. Remove LPG from Naphtha with minimum slippage of Naphtha to LPG. To achieve this, a serge vessel is introduced in between the Crude Distillation Column and the Naphtha Stabilizer. Feed flow into the stabilizer is controlled by a control valve introduced between the serge tank and stabilizer. Process variable for this control loop is the liquid level in the serge tank. This level keeps varing around 50%. If this controller is well tuned, level will always mainted tightly near the 50 % mark. This would defeat the purpose of surge vessel by making the vessel outlet flow closely follow the badly varing inlet flow. On the other hand, by keeping the controller sluggish (i.e. making proportionality gain low), the surge tank serves its purpose. When the input flow to the serge vessel increses, sluggish level controller acts very slowly, resulting in the slow and steady increase of outlet flow from the vessel. This increses the level in the serge tank. On the other hand, when the inlet flow to the serge vessel reduces, exactly the reverse happens.

This is a strange case of attuned controller gives the desire result. This has been successfully done in the Naphtha Stabilizer of refinery, which resulted in substantial increase in of the production of the valuable LPG, but also improved its weathering.

#SergeVessel hashtag#LevelControl hashtag#ProcessEngineering hashtag#FeedFlowStabilization hashtag#NaphthaStabilizer hashtag#LPGRecovery hashtag#ControlSystem hashtag#ProcessOptimization hashtag#RefineryTechnology hashtag#SurgeTankSuccess hashtag#EfficientProduction hashtag#ProcessControl hashtag#SteadyFeedFlow hashtag#industrialengineering hashtag#comfit hashtag#valvemanufacturer hashtag#valves hashtag#valveindustry hashtag#valvefactory hashtag#india

0 notes