#predictive maintenance systems

Explore tagged Tumblr posts

Text

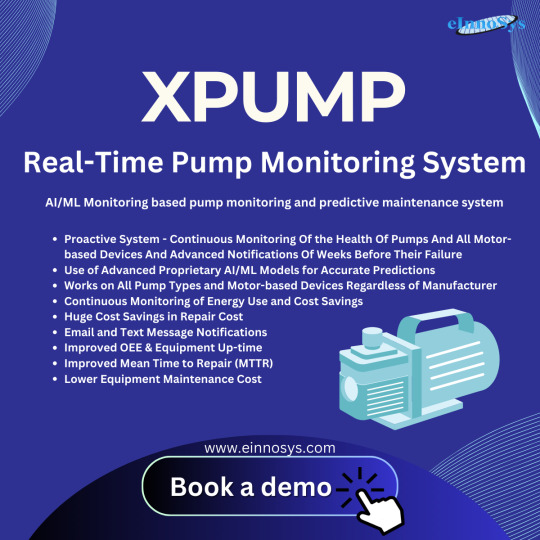

XPump is a cutting-edge, AI/ML-based solution designed for real-time monitoring and predictive maintenance of pumps. It continuously tracks critical parameters like vibration, temperature, and voltage, providing early warnings to prevent failures and optimize performance. XPump integrates seamlessly with your existing systems, enhancing operational efficiency and reducing downtime and maintenance costs.

#Real Time Pump Monitoring System#predictive maintenance software#predictive maintenance for pumps#best predictive maintenance software#predictive maintenance systems#predictive maintenance applications#predictive maintenance pumps#predictive maintenance software cost

0 notes

Text

Predictive Maintenance: Strategies for Enhancing Asset Performance and Reducing Costs

Meticulous Research®, a globally recognized market research firm, has recently released a comprehensive report titled “Predictive Maintenance Market by Offering (Software, Hardware), Deployment Mode, Organization Size, Technology (IoT, AI & ML), Application (Oil Analysis, Temperature Monitoring), End-use Industry, and Geography - Global Forecast to 2031.” This extensive study highlights the promising trajectory of the predictive maintenance market, which is expected to reach $79.1 billion by 2031, reflecting a remarkable compound annual growth rate (CAGR) of 30.9% from 2024 to 2031.

Download Sample Report Here @ https://www.meticulousresearch.com/download-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Factors Driving Market Growth

The surge in the predictive maintenance market can be attributed to several pivotal factors, including the urgent need to reduce maintenance costs and enhance asset performance. The increasing complexity of infrastructure systems has necessitated the widespread adoption of predictive maintenance solutions. Despite the favorable outlook, the market grapples with significant challenges, particularly related to data privacy and security concerns. These issues pose potential barriers to growth, as organizations must navigate the complexities of compliance and consumer trust.

Another critical aspect of the market is the burgeoning demand for predictive maintenance solutions in healthcare devices and navigation systems. This trend presents valuable growth opportunities for companies operating within this sector. However, a notable challenge remains: the scarcity of skilled professionals capable of managing advanced predictive maintenance technologies. As organizations strive to adopt these sophisticated solutions, the lack of expertise may hinder their progress. Furthermore, emerging trends, such as the integration of digital twins and augmented reality (AR), are reshaping the market, introducing both innovative possibilities and operational challenges.

Market Segmentation Overview

The predictive maintenance market is meticulously segmented to provide a nuanced understanding of its various components. The key segments include:

Offering: Software, hardware, and services

Deployment Mode: Cloud-based and on-premise solutions

Organization Size: Large enterprises versus small and medium-sized enterprises (SMEs)

Technology: IoT, AI, machine learning, cloud connectivity, advanced analytics, and digital twins

Application: Vibration analysis, oil analysis, temperature monitoring, and other applications

End-use Industry: Manufacturing, healthcare, automotive, aerospace, and other sectors

Geography: North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa

This segmentation framework allows for a comprehensive analysis of market dynamics and growth drivers across various categories.

Discover More About Market Segmentation And Geographic Forecasts By Accessing The Full [PDF] Sample Research Report – https://www.meticulousresearch.com/request-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Offering: Software, Hardware, and Services

The segmentation of the predictive maintenance market by offering includes software, hardware, and services. In 2024, the software segment is projected to capture a substantial market share, exceeding 81% of total revenue. This dominance is driven by the increasing necessity for organizations to reduce maintenance costs. Moreover, predictive maintenance software plays a vital role in ensuring compliance by providing essential documentation of maintenance activities and adherence to maintenance schedules.

Conversely, the services segment is expected to witness the highest CAGR during the forecast period. This growth can be attributed to the increasing adoption of predictive maintenance services that analyze equipment data to identify potential issues. As organizations seek to minimize overall maintenance costs, the integration of IoT, AI, and machine learning technologies enables real-time monitoring and proactive maintenance.

Deployment Mode: Cloud-Based vs. On-Premise

The predictive maintenance market is also categorized based on deployment modes, distinguishing between cloud-based and on-premise solutions. In 2024, cloud-based deployments are anticipated to hold a significant market share, exceeding 58%. This trend is largely attributed to the growing preference for cloud solutions that offer flexibility, scalability, and the capability to analyze large volumes of data in real-time. Furthermore, cloud platforms often incorporate advanced analytics features, including machine learning and predictive modeling, enhancing their appeal to organizations seeking comprehensive maintenance solutions.

The cloud-based segment is also expected to register the highest CAGR throughout the forecast period, as more businesses recognize the strategic advantages of cloud technology in predictive maintenance.

Organization Size: Large Enterprises vs. SMEs

Another important segmentation criterion is organization size, which differentiates between large enterprises and small and medium-sized enterprises (SMEs). In 2024, large enterprises are projected to account for the larger market share, exceeding 74%. This dominance is primarily driven by the growing adoption of predictive maintenance as a strategy to mitigate costly unplanned downtime and repairs. Large enterprises leverage predictive maintenance to monitor equipment health, identify performance degradation, and take proactive measures to maintain optimal operating conditions.

In contrast, the small and medium-sized enterprise segment is expected to exhibit the highest CAGR during the forecast period. This growth is fueled by the increasing adoption of predictive maintenance solutions that automate monitoring and analysis of equipment health, thereby alleviating the burden on maintenance personnel. Additionally, predictive maintenance enables SMEs to meet regulatory requirements and enhance operational efficiency, further contributing to the segment's expansion.

Technology: IoT, AI, and Machine Learning

The predictive maintenance market is also segmented by technology, encompassing IoT, AI, machine learning, cloud connectivity, and advanced analytics. In 2024, the IoT segment is anticipated to dominate the market, capturing the largest share. This trend is driven by the widespread adoption of IoT-based predictive maintenance solutions, which facilitate the prediction of equipment failures and improve technician efficiency by providing real-time information on equipment performance.

However, the AI and machine learning segment is expected to achieve the highest CAGR during the forecast period. The growing integration of AI and ML in predictive maintenance contributes to real-time analytics, energy savings, and reduced environmental impact for industrial operations. By leveraging AI and ML algorithms to analyze vast amounts of data from sensors and equipment logs, organizations can identify patterns and trends that drive proactive maintenance strategies.

Have specific research needs? Request a customized research report- https://www.meticulousresearch.com/request-sample-report/cp_id=5936?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=29-10-24

Application: Vibration Analysis and Temperature Monitoring

The applications segment of the predictive maintenance market is categorized into various key areas, including vibration analysis, oil analysis, temperature monitoring, and more. In 2024, the temperature monitoring segment is projected to account for a substantial market share, exceeding 26%. This trend is driven by the increasing adoption of predictive maintenance practices aimed at anticipating equipment failures and facilitating timely notifications for maintenance personnel.

Conversely, the vibration analysis segment is expected to exhibit the highest CAGR during the forecast period. The growing emphasis on predictive maintenance for vibration analysis allows organizations to detect, measure, and analyze vibrations in rotating machinery parts, thus controlling downtime and enhancing product quality.

End-Use Industry: Manufacturing and Healthcare

The predictive maintenance market is further segmented by end-use industry, including manufacturing, healthcare, automotive, and other sectors. In 2024, the manufacturing segment is expected to dominate the market, accounting for over 30% of total revenue. This dominance is attributed to the increasing adoption of predictive maintenance strategies aimed at minimizing costs associated with unscheduled downtime, as well as the growing implementation of Industry 4.0 principles within the manufacturing landscape.

Conversely, the healthcare segment is anticipated to register the highest CAGR during the forecast period. This growth is primarily driven by the expanding utilization of IoT and telematics within healthcare facilities, as well as the increasing reliance on predictive maintenance to gather data on critical medical equipment parameters such as temperature and pressure. Predictive maintenance enables healthcare facility managers to schedule maintenance efficiently, ensuring the continuous operation of vital medical equipment.

Geographic Analysis: North America and Asia-Pacific

From a geographical perspective, the predictive maintenance market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. In 2024, North America is projected to maintain its position as the market leader, accounting for over 33% of the overall share. This significant presence can be attributed to the rising demand for predictive maintenance solutions in the healthcare sector, coupled with the growing need to reduce equipment failure, maintenance costs, and downtime.

Conversely, the Asia-Pacific region is expected to exhibit the highest CAGR of over 32% during the forecast period. This growth is fueled by the rapid expansion of SMEs, increasing industrialization, and government initiatives aimed at enhancing operational efficiency. The emergence of Industry 4.0 in key countries, including China, India, and Japan, further propels the demand for predictive maintenance solutions.

Key Players in the Predictive Maintenance Market

The competitive landscape of the predictive maintenance market features several key players who are actively driving innovation and shaping the industry. These prominent organizations include:

International Business Machines Corporation (IBM) (U.S.)

ABB Ltd (Switzerland)

Hitachi, Ltd. (Japan)

Siemens AG (Germany)

Amazon Web Services, Inc. (a subsidiary of Amazon.com, Inc.) (U.S.)

Google LLC (a subsidiary of Alphabet Inc.) (U.S.)

Microsoft Corporation (U.S.)

Emerson Electric Co. (U.S.)

Oracle Corporation (U.S.)

Splunk Inc. (a subsidiary of Cisco Systems, Inc.) (U.S.)

Axiomtek Co., Ltd. (Taiwan)

Presage Insights Pvt Ltd (India)

XMPro Inc. (U.S.)

Faclon Labs Private Limited (India)

SenseGrow Inc. (U.S.)

These key players leverage their technological prowess, extensive industry experience, and innovative approaches to develop state-of-the-art predictive maintenance solutions tailored to meet the evolving needs of their clients.

Conclusion

The predictive maintenance market is on a promising growth trajectory, propelled by advancements in technology and the increasing demand for operational efficiency across various sectors. While challenges related to data privacy and workforce skills persist, the opportunities for expansion, particularly in emerging markets and industries, are substantial. With ongoing integration of advanced technologies such as IoT, AI, and machine learning, the predictive maintenance market is set to evolve, offering innovative solutions that address the diverse needs of businesses globally.

This landscape presents an opportunity for stakeholders to invest in predictive maintenance strategies that not only reduce operational costs but also drive sustainable growth and enhanced competitiveness in an increasingly dynamic market. As organizations continue to embrace the digital transformation journey, the role of predictive maintenance will become increasingly critical in ensuring asset reliability, performance, and longevity.

Read Full Report :- https://www.meticulousresearch.com/product/predictive-maintenance-market-5936

Contact Us: Meticulous Research® Email- [email protected] Contact Sales- +1-646-781-8004 Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

#Predictive Maintenance Market#Vibration Analysis#Oil Analysis#Acoustics Monitoring#Motor Circuit Analysis#Temperature Monitoring#Manufacturing#Oil & Gas#AI and Machine Learning#IoT#Data Acquisition Systems#Sensors

0 notes

Text

Video Autogenerated by Faceless.Video

Micro AI is revolutionizing the way we interact with technology.

Micro AI is transforming our interaction with technology by providing lightweight, hyper-efficient models tailored for Edge devices such as smartwatches, IoT sensors, drones, and home appliances. This cutting-edge innovation facilitates real-time data processing and decision-making directly on the device, eliminating reliance on constant cloud connectivity. Imagine your smartwatch instantly analyzing health data or your smart home system making immediate adjustments based on real-time inputs—all thanks to micro AI. One of the key benefits of micro AI lies in its low latency and local processing capabilities. In industrial automation, it can monitor machinery in real time to predict failures before they occur. For smart homes, it enhances convenience and security by allowing appliances to learn from user behavior while optimizing energy consumption. In healthcare, wearable devices equipped with micro AI can provide critical monitoring of vital signs and alert medical professionals during emergencies—ensuring timely interventions that could save lives.

#microai #EdgeComputing

#neturbiz#micro AI#AI technology#Edge devices#SmartWatches#IoT sensors#drones#home appliances#real-time data#local processing#low latency#industrial automation#smart homes#healthcare technology#productivity enhancement#energy efficiency#wearable devices#health monitoring#smart thermostat#security systems#user behavior#machine monitoring#predictive maintenance#autonomous appliances#emergency alerts#continuous monitoring#technology revolution#intelligent systems#operational costs#data processing

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

ngl I really thought it was more widely casually understood that fascism is a permanent threat in liberalism and/because it's part and parcel of it, and that this uh. wasn't a defense of the former or particularly damning critique of the latter. but the bird site sure keeps braining themselves on this in new and different ways

#'perfect incorruptible political system not yet discovered by humankind WEEP AND WAIL AND GNASH TEETH' like what#almost as if highly functional systems still require careful maintenance lest they go completely fucking haywire in predictable ways#and it's not actually a threat to cop to that. what#anyway what actually prompts this is the slap fighting about the 'scifi is fascist' claim#(a particularly trivial and dumb version of the same old same old but hey)#obviously stupid in many ways obviously you can also imagine the kinda true point that's been bastardized#NOT useful or interesting at that degree of abstraction on either side of the argument and yet!#shockingly things can be irrevocably related to other things and yet not be the same thing!!!#gasp gasp corruption and vileness#but what do you MEAN that taking an idea to its utmost extremes isn't the clearly correct way to use it!!#how dare you express the hope that people or systems that are capable of being corrupted nevertheless not become so!#the mere possibility of corruption is as damning as it occurring! and once occurred there's no point wishing to undo it!#VILENESS AND WEAKNESS!#to gripe about another discourse thread lol

1 note

·

View note

Text

The Impact of AI and Automation on the Trucking Industry

Photo by Ricky Esquivel on Pexels.com So, we’ve all heard about the buzz around AI and automation in the trucking industry, right? It’s pretty fascinating stuff. I know it sounds all high-tech and futuristic, but it’s really changing the game for truckers in ways that are super practical and beneficial. First off, there’s predictive maintenance. Imagine you’re on the road, hauling a load, and…

View On WordPress

#AI and truck safety#AI driving systems#AI for truck maintenance#AI for truckers#AI in logistics#AI in transportation#AI in trucking#AI route planning#AI transportation management#AI truck efficiency#AI truck technology#AI trucking solutions#automated load matching#automated trucking#automation in trucking#autonomous driving trucks#autonomous trucks#business#cash flow management#digital freight platforms#driver assistance systems for trucks#Freight#freight industry#Freight Revenue Consultants#logistics#predictive maintenance for trucks#route optimization for truckers#small carriers#Transportation#truck automation benefits

0 notes

Text

Say goodbye to manual errors! Keep your production floor running smoothly with iDataOps and digitalize your machine data!

#machine monitoring software#predictive machine maintenance#preventive maintenance#asset maintenance management#machine monitoring system

0 notes

Text

Manufacturing Software (MES) for Metal Fabrication, Millwork and Furniture

Empower your metal fabrication, millwork and furniture production with our advanced MES software. Increase efficiency, increase accuracy, and maintain control to increase quality, reduce costs, and streamline operations, creating a competitive edge in your industry.

#MES#manufacturing execution systems#benefits of mes software#inventory management system#purchase order management#predictive maintenance managements

0 notes

Text

RAILSoft: Maintenance and Railway Safety

RAILSoft: A Comprehensive Software Solution for Railway Companies – Maintenance and Railway Safety Petrosoft.pl’s RAILSoft is a comprehensive software solution designed specifically for the railway industry. With its robust suite of modules and functionalities, RAILSoft offers a complete solution for all types of railway companies, addressing every aspect of railway operations from infrastructure…

View On WordPress

#digitalisation#Petrosoft.pl#Predictive Maintenance#Rail Data Management#Rail Operations#Rail Software Systems#Supplier News

0 notes

Text

Why Are Industries Using IoT to Enhance Predictive Maintenance?

If you're looking to minimize your machinery's downtime, explore this blog to learn the advantages and practical applications that IoT Predictive Maintenance can offer your business.

0 notes

Text

Revolutionizing Industrial Efficiency: AI/ML-Based Pump & Motor Health Monitoring and Predictive Maintenance

In today’s fast-paced industrial landscape, minimizing downtime and optimizing operational efficiency are crucial for maintaining a competitive edge. Pumps and motors are essential components in numerous industries, and their failure can lead to significant operational disruptions and financial losses. Traditional maintenance approaches, often based on reactive or scheduled maintenance, are no longer sufficient. The solution lies in leveraging advanced technologies: AI and Machine Learning (ML) for predictive maintenance. The Power of Predictive Maintenance

Predictive maintenance uses AI and ML algorithms to analyze data from pumps and motors, predicting potential failures weeks in advance. This proactive approach allows maintenance teams to address issues before they escalate into costly downtime or catastrophic failures.

Key Benefits of AI/ML-Based Health Monitoring

AI/ML algorithms can detect anomalies in pump and motor performance far earlier than human operators or traditional monitoring systems. By identifying subtle changes in vibration, temperature, or sound patterns, these systems can predict failures weeks before they occur, providing ample time for corrective action.

Reduced Downtime and Maintenance Costs

By predicting and preventing failures, companies can significantly reduce unplanned downtime and the associated costs. Maintenance can be scheduled at optimal times, avoiding the need for emergency repairs and minimizing production disruptions.

Extended Equipment Lifespan

Regular, condition-based maintenance helps keep pumps and motors running at peak efficiency, extending their operational lifespan. This reduces the frequency of equipment replacements and lowers capital expenditure.

Improved Safety and Reliability

Predictive maintenance ensures that equipment is always in good working condition, enhancing the overall safety of operations. Reliable equipment also means fewer interruptions and more consistent production output.

How AI/ML-Based Systems Work

AI/ML-based health monitoring systems use a combination of sensors, data analytics, and machine learning models to continuously monitor the condition of pumps and motors.

Data Collection

Sensors attached to pumps and motors collect real-time data on various parameters, including vibration, temperature, pressure, and electrical currents.

Data Processing and Analysis

The collected data is processed and analyzed using advanced ML algorithms. These algorithms learn the normal operating conditions and identify patterns that indicate potential issues.

Anomaly Detection

When the system detects anomalies that deviate from the learned normal patterns, it flags them for further analysis. These anomalies can indicate early signs of wear and tear, misalignment, or other potential failures.

Predictive Modeling

Based on historical data and identified anomalies, predictive models forecast the remaining useful life of the equipment and predict the likelihood of future failures. This allows maintenance teams to prioritize and schedule interventions proactively.

Actionable Insights

The system provides actionable insights and recommendations to maintenance teams, enabling them to address issues before they lead to failure. This could include instructions for specific repairs, adjustments, or replacements.

Applications Across Industries

AI/ML-based health monitoring and predictive maintenance systems are versatile and can be applied across various industries, including:

Manufacturing

Ensuring continuous operation of critical machinery, reducing production downtime, and optimizing maintenance schedules.

Oil and Gas

Monitoring pumps and motors in harsh environments, predicting failures, and preventing costly shutdowns.

Water and Wastewater Management

Ensuring the reliability of pumps and motors in treatment plants, preventing service interruptions, and reducing maintenance costs.

HVAC Systems

Monitoring the health of motors and pumps in heating, ventilation, and air conditioning systems, improving efficiency and reducing energy consumption.

The Future of Industrial Maintenance

As AI and ML technologies continue to evolve, the capabilities of predictive maintenance systems will only improve. Future advancements may include more sophisticated anomaly detection algorithms, better integration with other industrial systems, and enhanced user interfaces that provide more intuitive insights and recommendations.

Call to Action

Implementing an AI/ML-based health monitoring and predictive maintenance system is not just a technological upgrade; it's a strategic investment in your business's future. By adopting these advanced solutions, you can ensure the longevity and reliability of your pumps and motors, reduce maintenance costs, and maintain continuous, efficient operations.

Don't wait for unexpected failures to disrupt your operations. Embrace the future of maintenance today and see the difference predictive maintenance can make for your business. Contact us to learn more about how our AI/ML-based pump and motor health monitoring systems can transform your maintenance strategy and drive your business towards greater efficiency and reliability.

#AI/ML-Based Health Monitoring#predictive maintenance system#Predictive Maintenance#Motor Health Monitoring#predictive modeling#Manufacturing#Industrial Maintenance#motor health monitoring systems#AI/ML-based pump and motor health monitoring systems

0 notes

Text

According to a recent report by Meticulous Research®, the predictive maintenance market is expected to reach $79.1 billion by 2031, growing at a compound annual growth rate (CAGR) of 30.9% from 2024 to 2031. This rapid expansion is driven by the increasing need to reduce maintenance costs, enhance asset performance, and the rising adoption of predictive maintenance in complex infrastructure systems. The integration of predictive maintenance into healthcare devices and navigation systems presents new growth opportunities, although challenges like data privacy concerns and the shortage of skilled workers hinder market growth. Key market trends include the use of digital twins and augmented reality (AR), with the market being segmented by offering (software, hardware, services), deployment mode (cloud-based and on-premise), organization size, technology (IoT, AI, cloud connectivity, and advanced analytics), application (vibration analysis, oil analysis, temperature monitoring), and end-use industry (manufacturing, energy, automotive, healthcare, and others). The report also evaluates regional and country-level market dynamics and competitors.

#Predictive Maintenance Market#Vibration Analysis#Oil Analysis#Acoustics Monitoring#Motor Circuit Analysis#Temperature Monitoring#Manufacturing#Oil & Gas#AI and Machine Learning#IoT#Data Acquisition Systems#Sensors

0 notes

Text

Industrial Overload Relays Market Industry Analysis Outlook by 2032

Market Overview:

Intrinsic safety modules are crucial components used in hazardous environments to ensure the safe operation of electronic equipment. These modules are designed to limit electrical energy and prevent the generation of sparks or excessive heat that could ignite flammable gases, vapors, or dust present in the surrounding atmosphere. By employing intrinsic safety modules, industries can reduce the risk of explosions and fires in potentially explosive atmospheres.

Intrinsic safety is a widely adopted protection technique in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, chemicals, and others where flammable substances are present. These modules are typically used with sensors, transmitters, and other electronic devices that need to operate in hazardous locations.

The Global Intrinsic Safety Modules Market size is projected to grow from $2.7 billion in 2021 to a billion by 2028, at a CAGR of 7% 2023-2031.

Industrial Overload Relays: Overview Industrial overload relays are electrical devices used to protect motors and other electrical equipment from damage due to overcurrent conditions. They are an essential component of motor control systems in industrial settings. These relays monitor the current flowing through a motor and can trip the circuit if the current exceeds a predefined threshold, thus preventing overheating and potential damage.

Industry Analysis and Trends:

Industrial Automation: The increasing adoption of industrial automation across various sectors has driven the demand for overload relays. Automation requires efficient motor protection to ensure smooth operation and prevent downtime.

Energy Efficiency: There is a growing emphasis on energy efficiency and reducing operational costs. Modern overload relays often come with features that enable energy monitoring and optimization.

Smart Technologies: The integration of smart technologies, such as IoT and connectivity, into industrial equipment has led to the development of smart overload relays. These relays can provide real-time data, remote monitoring, and predictive maintenance insights.

Safety Regulations: Stringent safety regulations and standards in industrial environments have led to the increased adoption of protective devices like overload relays. Compliance with these regulations is crucial for safe operations.

Miniaturization and Integration: The trend toward miniaturization and integration has led to the development of compact and multifunctional overload relay solutions, saving space and enhancing functionality.

Customization and Flexibility: Industries often have specific requirements for their motor protection needs. Manufacturers are focusing on offering customizable overload relay solutions to cater to various applications.

Global Industrial Growth: As industries continue to grow worldwide, the demand for machinery and equipment, including motors and overload relays, also increases.

Demand and Scope:

The demand for industrial overload relays is closely tied to the overall industrial growth, especially in sectors like manufacturing, oil and gas, utilities, mining, and more. As these industries expand, the need for reliable motor protection solutions becomes more critical. Moreover, the increasing adoption of automation and the integration of advanced technologies further contribute to the demand for modern overload relays.

The scope of the industrial overload relays market extends across various industries and applications, including conveyor systems, pumps, fans, compressors, HVAC systems, and more. As technologies evolve, the scope of overload relays may expand to include smarter and more advanced features, addressing emerging challenges in motor protection and predictive maintenance.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/intrinsic-safety-modules-market/13068/

Market Segmentations:

Global Intrinsic Safety Modules Market: By Company • Eaton • Rockwell Automation • Schneider Electric • Siemens • ABB • Pepperl+ Fuchs • OMEGA • Rotork • IMI Sensors • Extronics Global Intrinsic Safety Modules Market: By Type • Zener Barriers • Isolator Barriers • Converter Barriers Global Intrinsic Safety Modules Market: By Application • Oil and Gas • Mining • Power • Chemicals and Petrochemicals Global Intrinsic Safety Modules Market: Regional Analysis The regional analysis of the global Intrinsic Safety Modules market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Intrinsic Safety Modules market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Intrinsic Safety Modules in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Intrinsic Safety Modules in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: The Asia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Intrinsic Safety Modules in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Intrinsic Safety Modules in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Click Here, To Purchase Premium Report: https://stringentdatalytics.com/purchase/intrinsic-safety-modules-market/13068/?license=single

Reasons to Purchase Intrinsic Safety Modules Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Industrial Overload Relays#Motor Protection#Overcurrent Protection#Industrial Automation#Energy Efficiency#Smart Technologies#IoT Integration#Predictive Maintenance#Safety Regulations#Miniaturization#Customizable Solutions#Global Industrial Growth#Manufacturing#Oil and Gas#Utilities#Mining#Conveyor Systems#Pumps#Fans#Compressors#HVAC Systems#Market Trends#Demand Analysis#Industry Insights#Industrial Equipment#Motor Control#Electrical Protection.

0 notes

Text

Energy Management System: Dynamic Solutions by Zenatix

Zenatix's Energy Management System is a dynamic solution that optimizes energy consumption, boosts efficiency, and reduces costs. With advanced analytics and intelligent controls, it empowers businesses to make data-driven decisions, mitigate waste, and achieve sustainability goals effortlessly. Maximize your energy potential with Zenatix and unlock unparalleled efficiency in every aspect of your operations.

#energy management system#energy management solution#energy analytics#building automation systems companies#building automation system#building management system#IOT BMS#IoT Gateway#predictive maintenance#Energy Monitoring System#remote asset management#remote monitoring iot#smart building

0 notes

Text

Predictive Maintenance Management: Revolutionizing Maintenance Practices for Optimal Efficiency

1. Understanding Predictive Maintenance Management

Predictive Maintenance Management is an advanced approach to maintenance that leverages data and analytics to predict and prevent equipment failures. Unlike traditional reactive or preventive maintenance practices, Predictive Maintenance Management relies on real-time equipment monitoring, data analysis, and machine learning algorithms to detect early signs of equipment deterioration and potential failures.

By continuously monitoring equipment performance, collecting data on various parameters such as temperature, vibration, pressure, and operating conditions, organizations can detect anomalies and patterns that indicate potential issues. With the help of advanced analytics, organizations can predict when a failure is likely to occur and take proactive measures to address the issue before it leads to costly breakdowns or unplanned downtime.

2. Key Components of Predictive Maintenance Management

Predictive Maintenance Management consists of several key components that work together to ensure effective equipment monitoring and failure prediction. These components include:

Condition Monitoring:Condition monitoring involves the use of various sensors, devices, and data collection methods to continuously monitor the condition and performance of equipment. This may include monitoring parameters such as temperature, vibration, oil analysis, acoustic emissions, and more. The collected data is then analyzed to identify deviations from normal operating conditions.

Data Analytics and Machine Learning:Data analytics and machine learning techniques are applied to the collected data to identify patterns, correlations, and anomalies that may indicate potential equipment failures. Machine learning algorithms can learn from historical data to predict failure probabilities and generate proactive maintenance recommendations.

3. Benefits of Predictive Maintenance Management

Implementing Predictive Maintenance Management offers numerous benefits to organizations across industries. Firstly, it enables organizations to minimize unplanned downtime by predicting and preventing equipment failures before they occur. By addressing issues proactively, organizations can schedule maintenance activities during planned downtime, resulting in significant cost savings and uninterrupted operations.

Predictive Maintenance Management also helps organizations optimize maintenance schedules and reduce overall maintenance costs. Instead of relying on fixed maintenance intervals, which may lead to unnecessary maintenance activities, organizations can perform maintenance tasks when data indicates a potential need. This eliminates unnecessary maintenance, reduces spare part inventory costs, and maximizes the lifespan of equipment.

Another key benefit is improved equipment reliability and performance. By continuously monitoring equipment condition and addressing issues in their early stages, organizations can ensure that equipment operates at peak performance levels, reducing the risk of breakdowns and improving overall productivity.

4. Implementation Strategies for Predictive Maintenance Management

Implementing Predictive Maintenance Management requires a strategic approach. Organizations should start by assessing their existing maintenance practices and identifying critical equipment that would benefit from predictive maintenance strategies. This includes evaluating equipment history, failure patterns, and available data sources.

Data collection is a crucial aspect of Predictive Maintenance Management. Organizations need to implement the necessary sensors, devices, and data collection methods to gather relevant equipment performance data. This may involve retrofitting existing equipment with sensors or investing in new equipment with built-in monitoring capabilities.

Once the data collection infrastructure is in place, organizations need to establish a robust data management and analysis system. This includes storing and organizing data in a centralized database, applying appropriate data analytics techniques, and developing machine learning models to predict failure probabilities.

5. Overcoming Challenges in Predictive Maintenance Management

Implementing Ppm System may come with certain challenges. Organizations need to ensure that data collection processes are accurate, reliable, and secure. They must also invest in the necessary technology infrastructure and skilled personnel to handle data analysis and interpretation.

Additionally, organizations need to carefully balance maintenance costs and equipment performance. While Predictive Maintenance Management can significantly reduce maintenance costs, organizations must also consider the cost of implementing and maintaining the necessary infrastructure and systems.

6. Embracing the Power of Predictive Maintenance Management

Predictive Maintenance Management has emerged as a game-changer in the maintenance field, offering organizations the ability to optimize equipment performance, reduce downtime, and minimize maintenance costs. By leveraging real-time data, advanced analytics, and machine learning algorithms, organizations can transition from reactive or preventive maintenance to a proactive and data-driven approach.

Embracing the power of Predictive Maintenance Management requires a commitment to data collection, analysis, and continuous improvement. By implementing Predictive Maintenance Management, organizations can revolutionize their maintenance practices, enhance equipment reliability, and achieve optimal efficiency in their operations.

In conclusion, Predictive Maintenance Management is reshaping maintenance practices by leveraging data and analytics to predict and prevent equipment failures. The ability to proactively address issues, reduce downtime, and optimize maintenance schedules has become a competitive advantage for organizations across industries. Embrace the power of Predictive Maintenance Management and revolutionize your maintenance strategies for optimal efficiency, reduced costs, and improved equipment performance.

Source URL: https://terotam.wordpress.com/2023/06/23/predictive-maintenance-management-revolutionizing-maintenance-practices-for-optimal-efficiency/

1 note

·

View note

Text

18+ FTM!LOGAN H. X M!READER | AFAB TERMS USED

There’s no doubt that LOGAN HOWLETT is a certified brat. If you think work is the only thing that gives you stress on a daily, you’re nothing but wrong. He likes to act out; suggestively bending over in front of you, standing too near, roaming his hands needily—all of it. He’s similar to a feisty cat, one that demands high maintenance.

He should’ve predicted it. Should’ve known your restraint would crumble the second he retorted a bit too bitchy, too offensive.

You have LOGAN sitting on your lap, both of you facing the mirror, devoting to memory at how his pretty hole continued to drool arousal as it’s stretched open on your cock. His thighs are quivering, one hand of his clinging onto your nape, and yet he won’t take the fucking hint. “This all ye’got for me?” He grinds his hips down to envelop you in deeper with a tongue-twisted gasp.

His sloppy walls are gripping you tightly, wetly squeezing around your equally leaky length. His clit aches, yearning for the attention he’s dumbly convinced he’s entitled to receive. He reaches for it, meeting your gaze through the mirror. Oh fuck, that heated look he catches - that you gave him, makes his entrance weep of pre.

You slap LOGAN’S hand away, gifting your ears with his objecting whine. “R-really, yer gonna deny me? You ain’t even doing shit.” He’s about to expand on his complaint, tell you how cruel of a man you are, until he’s met with two of your fingers pulling the hood of his nub back. Your other hand pries his thigh wider, the pad of your middle digit directly applying pressure on his clit. He cries out, his attention beginning to fade away from the lewd scene painted on glass as his thighs attempt to lock around your hand.

You don’t give him the time to process anything. Your wrist rocks, roughly sliding your finger up and down. You feel him clench around your length, and you have to remind yourself that you have to resist the urge to pound the attitude out of his system.

“Mfnnnngh! It’s too much!” LOGAN wails, getting wetter and wetter. Slick graces his inner legs, a climax building low within his belly. He leans forward, a fruitless intention on running, really. “Gonna make you cum on my cock first,” you dismiss, pressing down on the glans before rubbing circles. You twitch inside, and he thinks his heightened senses are both a blessing and a curse.

“and then I’ll fuck you.” Continuing on, your pace increased. Wetness pooled on your finger, the sight making you impossibly harder. The intoxicating pull of submission encompasses LOGAN HOWLETT as he listens to you talk. It has him regretting his behavior towards you, a whimper passing through his lips. His mouth falls agape with a silent scream, suddenly creaming on your fat cock because it’s the only ‘sorry’ he’s willing to give you.

#진 cigarettes.#— azrael.worksᵎᵎ#marvel#marvel x male reader#marvel x reader#wolverine#james logan howlett#logan howlett#james howlett#top male reader#wolverine x male reader#wolverine x reader#wolverine x you#logan howlett x male reader#logan howlett x reader#logan howlett x you#james howlett x reader#wolverine smut#ftm!logan howlett#ftm logan howlett#afab logan howlett#afab!logan howlett#logan howlett smut#james howlett smut#bottom logan howlett#bottom character#marvel smut#top!reader#male!reader#top reader

1K notes

·

View notes