#powder batching systems

Explore tagged Tumblr posts

Text

powder coat oven

A powder coat oven is a specialized heating device used to cure powder coating oven on metal surfaces, creating a durable, smooth, and protective finish for industrial and DIY applications.

#powder coat oven#powder coating oven#industrial curing oven#cerakote oven#best oven for powder coat#best oven for cerakote#batch curing oven#electric curing oven#composite curing oven#powder coat oven for sale#powder spray booth#spray booths#sandblasting cabinets#spray systems#blasting equipment#paint spray booths#powder coating near me#cerakote oven for sale#powder coat equipment#custom powder coat oven

0 notes

Text

[ID: A plate of light brown bumpy flatbread with blackened spots, surrounded by za'tar and green olives. End ID]

خبز طابون / Khobz taboon (Palestinian flatbread)

Khobz taboon ("taboon bread") is a soft, chewy Palestinian flatbread. It may be eaten with olive oil and za'tar, but it is best known as the base of مسخن (musakhkhan), where it is topped with spiced aromatics and perhaps chicken.

Khobz taboon gets its name from the vessel it is traditionally cooked in—an outdoor, shallow conical oven with an opening at the top and a clay or metal cover to trap heat. Taboons may also have an opening at the side through which the fire can be stoked, especially in the east of Palestine. These ovens were historically made from a mixture of local clay and hay, but have more recently also been constructed from clay treated to be sturdier, or from metal.

A taboon is used by packing flammable material, such as hay, fabric, animal dung, wood, and charcoal, around the outside of the oven and letting it burn overnight; the fire transfers thermal energy to the clay, and to the river stones, sand, glass, or flint stones (صوان, "ṣawwān") that form the base of the oven. The ash is then brushed away, and the flattened dough is placed on the stones or stuck to the walls of the oven to cook. The clay and stones will continue to release thermal energy and cook things throughout the day. The clay and ash give a distinctive flavor to anything cooked inside the taboon, making this method a source of nostalgia for many people who have transitioned to cooking in indoor ovens.

Khobz taboon was traditionally made with whole wheat flour. Most people today use a blend of around two parts white flour to one part whole wheat, or else all white flour; they may even add milk or milk powder to ensure a very soft dough. This recipe uses a blend of flours to combine the nutty flavor of whole wheat dough with the pliancy of white dough. It also begins with an optional pre-ferment to mimic the traditional Palestinian method of including a piece of dough from the previous day's bread into each new batch (like a pâte fermentée) giving a rich and slightly sour flavor to the final bread. It calls for the use of rocks to imitate the bottom of a taboon; the rocks give the khobz its distinctive dimpled texture, and ensure that no interior pocket forms in the bread.

In the years following 2007, the siege Israel had imposed on Gaza caused a shortage of cooking gas that led to a resurgence in the use of taboons. The ovens were used to bake bread and to grill sweet potatoes during the time of their winter harvest. Meanwhile, in the West Bank, Israeli military forces repeatedly destroyed taboon ovens and assaulted villagers who tried to defend them, as Israeli settlers from nearby villages complained about the smoke that the ovens produced. Some of these ovens had been used to bake bread for entire families of 40 or more people. Palestinians continue to build, use, and defend these ovens, despite the fact that Israeli law de facto forbids Palestinians in the West Bank to build anything.

Today, Israel is deliberately targeting and destroying bakeries in refugee camps that had been supplying bread to tens of thousands of people in Gaza, continuing a long campaign of starvation of the Palestinian people.

Support Palestinian resistance by calling Elbit System's (Israel's primary weapons manufacturer) landlord; and donating to Palestine Action's bail fund.

Equipment:

A large, shallow mixing bowl, like a Moroccan qus'a

A large (12"), shallow clay cooking vessel, such as the bottom of a Moroccan tajine (one that is rated for very high temperatures), or a large baking tray

Assorted smooth river rocks of varying sizes, from 1 to 3" in diameter.

Make sure that your rocks have been thoroughly cleaned, and that they do not contain any fissures, cracks, or veins that could contain water (this water, once heated in the oven, could cause the rocks to crack open). Instead of river rocks, I used lava rocks designed for use in a clay tanoor. You just need something to provide thermal mass and give a bumpy texture.

Ingredients:

Makes 3 large breads.

For the pre-ferment:

140g whole wheat flour

1/2 tsp active dry yeast

140g water

You may also use a pâte fermentée that you already have (just adjust the ratio of white to whole wheat flour added later accordingly), or a sourdough starter. The hydration of the starter doesn't matter, since you will be adding water by eye later.

For the bread:

330g bread flour or all-purpose flour

30g whole wheat flour

5g salt

Water

If you skipped the pâte fermentée step, add 170g (rather than 30g) of wheat flour at this stage, as well as 1/2 Tbsp of active dry yeast. I have not tested the recipe this way.

Instructions:

For the pâte fermentée:

1. Mix flour and yeast in a small mixing bowl. Add water and stir to combine. Cover and leave out at room temperature for a day, or in the refrigerator for up to three days. At the end of the rising time, it should be about one and a half times its original size.

For the bread:

This recipe makes a high hydration dough that will need techniques such as slapping and folding to knead effectively.

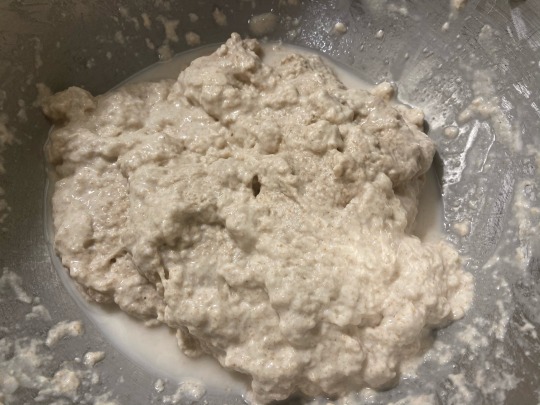

1. Mix flours and salt in a very large, shallow mixing bowl. Add your pâte fermentée and mix to combine.

2. Add water until the flour comes together into a soft, sticky dough and continue keading. Have a bowl of water on your workstation. Every time the dough starts to stick to your hands or the sides of the bowl, wet your hands and rinse down the side of the bowl with some water. This will gradually add water to the dough.

3. You will notice the dough growing smoother and laxer. At this point, start kneading by repeatedly folding the edges of the dough in towards the center. Do this by occasionally wetting your hands, then running a hand along the side of the bowl and under the edge of the dough to unstick it from the bowl; then fold. You will get stuck less often if you try to touch the dough as lightly and briefly as possible. Every few folds, dimple the surface of the dough all over with your fingertips. You will have been kneading for about 10 minutes at this point.

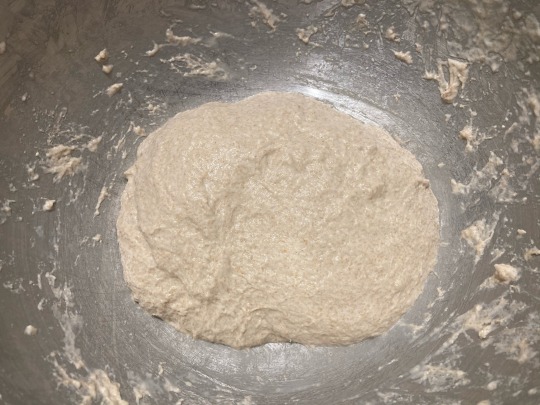

The dough should become more smooth and less bumpy—you will notice it holding its shape and becoming more stretchy as gluten forms. It should form into a ball when you fold the corners in and hold its shape for a minute, but then gradually expand to take the shape of the bowl. I added about 2 1/2 cups of water total (in dry conditions) during steps 2 and 3.

4. At this point, the dough is wet enough that the slap and fold method is the best way to knead. Wet your hands and again unstick the dough from the sides of the bowl. Hook your hands under the dough and quickly pull it all up into the air; fold the hanging bottom part of the dough under, and plop the dough back down, folding it on top of the part you plopped down earlier. Give the bowl a quarter turn and repeat. Do this continually for another few minutes.

5. When the dough is very smooth and lax, smear some olive oil on the sides of the bowl and under the dough, and pat some oil on top.

6. Cover the bowl and bulk ferment the dough at room temperature for 8 hours, or for 16-24 hours in the fridge. At the end of the rising time, you should see bubbles beginning to form on the surface of the dough.

To shape and bake:

1. Place a layer of rocks at the bottom of a clay cooking vessel or baking sheet. Put the sheet in the top third of the oven and preheat your oven to 550 °F (290 °C), or as hot as it will go.

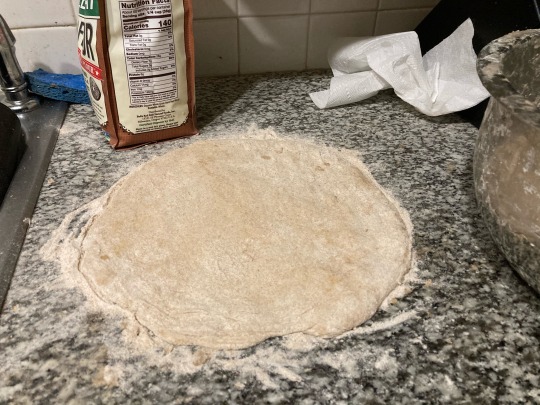

2. Meanwhile, fold the edges of the risen dough over into the middle a few more times with damp hands. Pinch off a large piece of dough (about the size of two fists), and fold the sides over into the middle to make a neat packet.

3. Drop the packet of dough onto a heavily floured surface, and flip to flour both sides. Pat the dough flat, then throw it back and forth between your hands, catching the edge each time as you spin it through the air, like a pizza crust, to stretch it into a circle about 1/4" (1/2cm) thick with a diameter of about 10" (25cm).

You may also stretch and pat the dough out on a flat surface.

4. Remove the tray from the oven. Flip the dough circle over the back of your hand to transfer it and lay it down over the hot rocks. Re-stretch it into a circle, if necessary.

5. Place the tray back in the oven and cook for 5-7 minutes, until the top of the bread has golden brown spots. Repeat with each piece of dough, leaving the rocks in the oven for a few minutes between each one to allow them to come back up to temperature.

6. (Optional): Hold each flatbread directly over a gas flame for a minute or two to blacken a few spots and mimic the flavor that a wood-fired oven would give to your khobz.

You may also use a method similar to the dhungar technique to smoke your bread. Place each piece of bread one at a time into a large vessel with a closely fitting lid, alongside a small bowl. Light a piece of wood on fire and drop it into the bowl; then cover the vessel with the lid as you allow the wood to smoke for a minute or two.

#note that I do not recommend this recipe to anyone who is not experienced with making bread#I'll have another Palestinian flatbread recipe up soon which will be more beginner-friendly#Palestinian#bread#khobz#flatbread

347 notes

·

View notes

Note

It’s Order 66. Every chip has activated and all of the clones are now against you. It’s the bad batch specifically that’s hunting you down. What is your survival plan?

I'm expected to survive this? (Anon's got more faith in me than I do.) Why are they after ME? I'm not a Jedi! Maybe they don't like that I haven't finished my long fic and have left them all hanging?

*Somewhat grown-uppy under the cut, but nothing too crazy.*

Well, after the initial freak out where I cut and dye my hair and skip town in a borrowed transport, I suppose I'll make my way to the corner booth of a space Waffle House to weigh my options over some rubbery cakes and surprisingly good caf. That's where my master plan will take shape on the back of a flimsi napkin.

The man in the floral shirt at the counter is sneezing, and it reminds me of all the links to sex pollen fics I see around here. I get out my datapad and start looking on the dark Holonet to see where I can procure a large quantity of the good stuff (aka the stuff that will turn anything with a pulse into a lustful mess).

Bingo! There's a guy in the Outer Rim who can get me a bunch of it on the condition that I don't open it around him. Fair enough. He leaves the alley while I unseal the canister. I don't even need to completely open it to know that the yellow-green powder is evil. Within seconds, I'm calling out for that sweaty old man with the skin condition like my ovaries will implode without him. He yells back to leave the money in the alley when I go, and I head back to my ship with the goods for an ice-cold shower and a shame spiral. Evil, evil stuff.

After that, I get my hands on a couple of willing medical droids and a crate of binders strong enough to hold a Dowutin on stims. If all goes well, I lure the Batch into a warehouse with pollen canisters in the ventilation system, push the button when they get close enough to ask why I'm wearing a particulate filtration mask, stun them while they're scrambling to get out of their armor, put binders on them just in case, and let my new metal besties take out those terrible chips.

And if things don't go well and the Batch end up capturing me—five hormonally compromised men, a bunch of binders, days in hyperspace on the way back to Imperial Coruscant—well, at least I go out with a bang. 😏

11 notes

·

View notes

Note

The path to the Hospital Wing seemed to stretch endlessly before him. The throbbing ache on the side of his head matched the pulse of each beat of his heart. Every step on the stone floors sent a jolt of pain, a hurtful reminder of the morning's misadventure in Herbology. His hand pressed against the spot where his ear should have been, the phantom pain still gnawing at him. The sharp bite of the Tentacula Vorax' teeth still echoed in his mind, the memory almost as painful as the wound it left behind.

It was a foolish mistake, Felix chastised himself. He should have been more careful, more gentle. Perhaps a kinder touch when pruning the plant might have spared him this torment. Professor Garlick had certainly thought so, lecturing him quite thoroughly before handing him two pieces of cloth - one to stem the bleeding, the other to transport the unfortunate remains of his ear.

The Ravenclaw shook his head, a motion he instantly regretted as dizziness washed over him. There was no time for a bad conscience, no room for self-recrimination. He needed to reach the Hospital Wing. He needed Als.

Als would know what to do. He always did.

Had he been feeling less queasy, he might have opted for the Floo Powder system. But the thought of spinning through the network of fireplaces only made his stomach churn further. So it had to be the long way - the very, very long way, with its many, many stairs.

A sigh escaped Felix as he leaned against the cool stone wall, allowing himself to take a small break. A few passing students glanced his way, their expressions a mix of curiosity and concern. With a forced smile, the Swede assured them that everything was fine. Or at least, it would be once he got to Alsius. He just hoped his friend wouldn’t be too annoyed with his clumsiness, but deep down, he knew he was in the best hands.

"Take a deep breath. In and out. You're almost there," he muttered to himself, trying to steady his breathing, the words a small comfort as he pushed off the wall. The stairs seemed never-ending, each one a cruel reminder of how much further he had to go.

"Just a little bit more..." The words were barely a whisper as he forced himself to keep moving. The trek was taking its toll, beads of sweat dotted Felix' forehead, and the sick feeling in his stomach grew worse with each step. The wound throbbed in time with his heartbeat, the cloth already soaked through with blood.

“Finally,” Felix breathed, both exhausted and relieved as the door to the Hospital Wing came into view. He paused at the door, peeking inside cautiously, his heart lifting slightly at the sight of the young healer, who was quietly tending to his duties. A weak smile tugged at Felix’s lips, a small flicker of relief and gratitude amidst the pain. Just seeing his friend was enough to make him feel safer.

Clearing his throat softly, Felix hesitated. He didn’t want to disturb Alsius if he was in the middle of something important, and the last thing he wanted was to wake any of the other patients. But the urgency of his situation couldn't be ignored.

“Als, um,” he began, his voice a little shaky, “how good are you at reattaching body parts?”

Two freshly corked phials in hand, Alsius crouched before the medicinal cupboard by the infirmary entrance. The beds were unusually vacant today, prompting the rest of the Hospital wing staff to indulge in an impromptu excursion around the grounds for some exercise. Since Professor Sharp had delivered fresh batches of healing potions earlier that afternoon, Alsius volunteered to stay and he took advantage of the rare quiet and solitude to steadily restock the ever-dwindling stores.

He ducked his head and tucked the last phials in with the others, the faint tinkling of glass against glass floating in the stillness as he ensured all labels were neatly aligned for easy readability in an emergency. After an unfortunate incident involving a nurse and a swarm of magimedical-grade leeches (not to mention the Coffee Bean Barrage), the use of Accio was indefinitely banned in the infirmary and the last thing any reasonable healer wished to do in time-sensitive situations was frantically rummage through wilfully neglected shelves. It was a personal pet hate of his, so he made a point of leaving the cupboard the way he always wished to find it.

Clean, tidy, and methodically organised.

The creak of the Hospital Wing door opening echoed that of the cupboard door closing. He hadn’t the chance to look up before he heard Felix’s voice, and the weak, nervous warble immediately drew his attention and concern.

“…reattaching body parts…”

Alsius turned and caught sight of Felix slumped against the doorway, his focus immediately pulled to his friend’s rapid breathing and sickly pallor. Despite the attempt to inject a certain nonchalance into his question, exhaustion etched Felix’s sweaty brow, his expression drawn painfully taut as he cradled a blood-soaked cloth against his head.

A sudden, leadened pit in Alsius’s stomach tipped the scales for haste. Fearing Felix would collapse to the floor, he rushed to the entrance and caught Felix’s weight against his side. He quickly ushered him to the nearest bed, and if the tall blond baulked at being unceremoniously laid out in such fumbling earnest, Alsius couldn’t hear it over the torrential roar of his racing thoughts.

“Sorry,” he whispered, somewhat amazed he had the presence of mind to apologise for such a brutish bedside manner. “With the bleeding, it’s better to lie down.”

Despite his relative youth, Alsius was generally cool and collected and not prone to dramatic mood swings, but when his gaze tracked the crimson rivulets steadily slipping down Felix’s wrist, something in him critically failed. He was no stranger to gruesome illness and injury, but Alsius was woefully unprepared for the visceral impact of seeing someone so dear to him in such a state.

As he stood and hovered over Felix, his chest tightened, heartbeat keeping time with the breakneck pace of all the grim possibilities reeling through his mind. Felix managed all the way here, he frantically reminded himself. It can’t be that serious. It was a paltry reassurance. He pinched his eyes shut against the unsettling swells in his emotions.

Set them aside. Heal. Reconcile the rest later. That was what his parents taught him in his early youth. That’s what Hogwarts more or less taught him in the infirmary. Yet his mind – his heart, still screamed: it’s Felix.

He turned and snapped the privacy curtains closed. Unnecessary considering they were alone, but the guise afforded him the barest moment to try to regain some semblance of composure.

The steadying breath he drew was audibly shaky.

After what felt like an age mustering his courage, Alsius returned to Felix’s side, lowering to sit at the edge of the bed. “Don’t worry, I’ll sort you out,” he murmured softly, though he was unsure if the reassurance for Felix’s benefit or his own.

He leaned forward to remove Felix’s hand and assess the damage, however just as his shaky fingertips brushed the back of Felix’s – he hesitated. He blinked and reached out again, only for his fingers to once again twitch away and curl defiantly into his palm.

There was more than a hint of frustration in Alsius’s sigh when he grudgingly compromised with himself. He rested his palm against the back of Felix’s hand as his gaze slowly surveyed the familiar topography of his friend’s face for all traces of primary and secondary injury. He murmured another apology when he lightly pressed his thumb into the side of Felix’s chin and carefully tilted his head to the side. Their hands remained protectively pressed over the wound, but Alsius still thoroughly searched the visible area for residual scorch damage from curses.

Any sort of evidence to restore the cool rationale upon which he so heavily relied.

A useless pursuit, like trying to capture vapour in his hands. The harder he focussed on ticking off a diagnostic checklist, the more each step dispersed into nothingness.

Alsius should just properly inspect the injury.

Alsius should just ask what happened.

It was the standard course of action no matter who found themselves in his care, but his faculties failed him. He shook his head against the internal contradictions: the spine-tingling fear and uncertainty, gut-wrenching anxiety, and the most alarming – the raw, hot sparks of anger that threatened his veins like flame at a fuse. At some point between his runaway thoughts and terrible excuse for a medical assessment, Alsius truly understood what Sebastian described feeling in the catacombs: cold, uncompromising protectiveness that overrode everything else. The ruthless sense of purpose that defied all rational thought was downright unnerving, and for someone as even-tempered as Alsius, its effect was so unsettling that he robbed him of his ability to function normally.

Nothing about it made sense, and it was maddening, but through the haze of it all there was one thing Alsius knew with unwavering certainty.

Felix would be fine because he would do absolutely everything in his power to ensure it.

Still, one question wrapped around his heart like a vice. It was the very first that crossed his mind in the emotional turmoil and the constant catalyst to whatever breakdown he actively tried to stave off.

It was an unrelenting, suffocating pressure that refused to be ignored. There was always the chance that it had been just an accident. Felix was unfortunately clumsy at times, but if this was maliciously inflicted on him…

Alsius didn’t need to know where or why, or what or how. He needed to know who.

And he would deal with that after.

Finally finding some sense of clarity once again, Alsius slowly exhaled into the heavy, ponderous silence as he gently tilted Felix’s face back to centre. When he finally spoke, the calm and even softness of his voice directly contradicted the steely intensity behind his eyes.

“Did someone do this to you?”

18 notes

·

View notes

Text

Happy Halloween!

“Sooooo… The three of us were planning on being aliens— urk… okay, fine, I roped them into doing this… Anyway. My interpreter at work randomly joked about us dressing up as the Little Green Men from the ‘Toy Story’ movies! And, well, here we are! Oh! But don’t use the claw to pick me up! I’ll stay where I am, thank you very much! Have a Happy Halloween, people of the internet!”

“Somehow I was roped into participating in a group costume. From time to time, silly costumes like these are cute, but it’s too damn hot to be in a full jumpsuit. Hah… as long as I have my lollies, I’ll do whatever my teammates want me to do.”

“…”

“… Shian…?”

“…”

What did you do with the rest of the lollies that were in your wagon just five minutes ago…?

“…”

“They were delicious.”

“Boo. I’m the cute-ugly little aliens from ‘Toy Story. At first, I’m when Anika brought up the idea of matching costumes, I wanted out. But then she convinced me to do it. Maybe it’s not so bad like this. Don’t I look cute? It’s gonna be… interesting to look at an LGM raiding arcades for claw machines. Let’s go, come spend Halloween with me at some of the best arcades here in Akiba.)

You received a treat from Pixel Syndicate!

✦ Solar System Batch: Many, many different sugar cookies that have been decorated to look like the different planets! These Halloween bikkies are pumpkin-flavored and they’re colored with black charcoal powder to make them as dark as the night sky!

#hypnosis mic#hypnosis mic oc#hypmic#hypmic oc#hypnosis mic arb#hypmic arb#akihabara division#pixel syndicate#anika kiyozaki#shian meizono#makina setsukura#halloween#halloween event 2024#hypmic halloween 2024#happy halloween

7 notes

·

View notes

Text

Home for the Holidays part 3

Part 2

thought this stopped at part two. wrong, here's part three. Caleb does some baking with his mom.

---

“Cream together the butter and Sugar until light and fluffy. Beat in the egg yolk and vanilla. Combine the flour and salt before adding to the creamed mixture alternately with the milk.”

Caleb rotated his shoulder, trying to get rid of the ache that was starting to form as he read off the directions from the book. His arms were starting to kill him.

To think the jocks at school had laughed at him saying baking was not a work out. Clearly they were the kind of people who thought buying premade cookie dough from the store and sticking them in the oven counted as baking. Caleb was sure that if he did this all year then he’d be able to shot-put a snorlax.

Currently Caleb had four different batches of cookies on the going, and he still had peppermint patties and almond bark he had to make.

He was half tempted to go and grab Fjord so that he could help with some of the mixing, just so his arms got a break.

But it would all be worth it to have some fresh baked goods for the holidays. And boy was it so much easier to bake in a real kitchen, rather than the small kitchenette that was in his and Fjord's dorm room.

At least here, if the smoke detector went off it didn't set off the sprinkler system for half the building.

Just as he leaned in to read once more from the book, he heard the door open behind him but he paid it no mind, thinking it was just his dad or uncle or one of their pokemon looking for a snack. “let's see, next we need to-”

“Hey Caleb!”

“Mom!” Caleb yelled, swinging around to face the door, almost dropping the bowl he was mixing.

“Hey, sorry, I didn't mean to scare you” She spoke softly, raising her hands in a calming motion. “Just come to see if you need any help, that's all.”

Within seconds, Caleb felt his eyes start to water and actively fought the urge to run over and embrace her…if only because he was covered in flour and he didn't want to get any on her.

Quickly he set down the bowl and spoon to quickly wipe his eyes, not wanting tears to get into the mix.

It was just really good to see her again, to see her the way he remembered her. But at the same time it stirred up a lot of thoughts and feelings that easily overwhelmed him.

A gentle hand suddenly took his face away from his face, and he looked up to see his mom standing there smiling at him. “You're getting flour all over your face.” she laughed, pulling his hands down to his sides before taking some paper towel. “Here let me.” she added as she started to carefully wipe the white powder away from his face.

and still more tears fell until his mother wiped those away too. Only for new ones to quickly replace them.

“Okay, now take a deep breath” his mother said, placing her hands on his shoulders, and Caleb did just that. “Now hold it…now let it out” they repeated the process several times until Caleb felt sure he wasn't going to burst into tears again. “Do you want me to get your phone?”

He thought about it for a second, before shaking his head. No, he didn't need the anxiety sticker on the back of his phone, right now.

“Okay, just let me know if you change your mind.” she smiled, giving his shoulders one last squeeze before standing up. “Now, do you need some help in here or do you want me to get out of your hair?”

“Don't go!” He winced as the words came far louder and more desperate than he meant them to. Taking another deep breath, he took a moment to think things through. “Yeah, I could use a hand, if you don't mind.”

“Wouldn't have asked if I minded”

Right. He quickly looked around and grabbed the bowl he had before, holding it out to his mom. “Could you finish mixing this for me? The moo moo milk hasn't quite blended into the dough yet, and I still have to melt the chocolate for it.”

“Sure. so I just keep stirring until it's all one thing?” She asked, taking the spoon from his hand and slowly stirring the ingredients.

“Yep! Just gotta keep stirring until it's all combined.” Caleb explained, pouring the chocolate melts in a bowl and popping them in the microwave. He needed that to be hot enough to melt but not scalding. “It needs to be a workable dough for the next part.”

“What are we making anyway?”

“They're called Icebox Pinwheel cookies.” Caleb answered, turning his back to his mom as he checked the Starchies in the oven, trying to hide the stupid smile on his face. He was actually baking cookies with his mom. “They’re one of the few cookies that both Dad and Uncle Emmet will eat.”

“OH the swirly ones! I always wondered how you made those. I’m normally at work with you Uncle and Dad when you bake em.”

Setting the Starchies aside on the cooling rack, Caleb quickly checked on how his mother was doing with the dough, grinning when he saw that it was done. “Okay, that’s enough. Now we need to slit it in half.”

He left his mom to divide the dough to get the chocolate. “Then we mix this into one half until it’s one uniform colour.”

“I can do that.”

As his mom worked the chocolate into one half of the dough, and Caleb started to set up for his next baking project, the two fell into easy conversation. Just simple ‘how’s school?’ ‘are you enjoying your classes?’ ‘have any good battles?’ ‘how was your trip to Hoenn?’ ‘what Pokemon did you catch?’ ‘Where are you guys planning to go next?’. Things that most mothers probably asked their kids everyday, and Caleb was enjoying every bit of it.

It had been really hard not having his mom in his life for the longest time, made only slightly harder by the fact that he had to keep her a secret. He couldn’t exactly tell the other kids at school that his mom was captain Zisu of the Galaxy team’s security corps and one of the founders of the Sinnoh league. Even if they did believe him there would be questions, and the last thing he wanted was the whole Hisui incident to be dragged back up. His dad had already been through enough.

It helped a bit in finding out that his Mom had been his dad’s Chandelure, knowing that she was always around to protect and comfort him. But at the same time it brought to light a horrible reality that his mom had in fact died, and not just that but died a long time ago. A hard truth to swallow, only helped by the fact that there was a ghostly ball of flames and metal he could hug tight.

But now he had his mom back, in the flesh, and it was probably only for a limited time, but Caleb planned to make the most of it.

“Mom,”

“Yes sweety?”

“What’s your favorite baked good?”

#submas#pokemon au#From Hisui to Unova#Ingo's Kids#Caleb (Oc)#Fjord (Oc)#captain zisu#chandelure#dojoshipping#pokemon fan fic

18 notes

·

View notes

Text

it never mattered who won the qsmp election. at the end of the day being “president” is only a fancy title for a puppet the federation will toy with as they choose. it’s not about whoever won being bad or unfit for the position its about actively working to dismantle the corrupt system that is oppressing you rather than working with them. in this case you cannot change the system from within when you are one individual against an entire group entity that is the federation. you cannot win. you cannot work alongside them in a way that matters. every action you take has to be a proposal, a proposition, a suggestion the federation then decides if approved. its a false sense of power on the island for the people to feel less puny when facing off against the federation. if anything this is a direct example of the federation toying with their food. the entire election was a massive setup from the moment a federation agent was planted in the running. it’s quite literally another tactic by the federation to make the islanders feel as if they’re making a difference. same as what they did with qcellbit simply on a larger scale. while the puzzles and anonymity was qcells bait the list of power and abilities for change was the candidates bait.

now some outside of roleplay and lore discussion. i think the only real powder is the ability to add a player. obviously, in a meta sense, i think it is wildly cool that the quackity and admin team are handing over that ability to another player. very lovely to see that level of trust and communication between players and admins. i feel like that is a really cool aspect of the qsmp

so in short thats just my take on everything qsmp election related:3 im excited to see whats to come and how any new batch of players will react to having a president they didn’t elect

52 notes

·

View notes

Note

for something to write about: do you (individually or collectively) have a favorite dish or cuisine?? if it’s something you make yourself, how did you learn to make it/do you have any strong memories of making it??

We have a few dishes we love. Collectively, we all love mashed potatoes. It’s a safe food of ours; our mom, when we were sick, would always get us one of those microwave mashed potato bowls, and we would put cheese and BBQ sauce in it to make what we called muddy mash. It was sooo delicious. We don’t usually do BBQ anymore since it’s so unpredictable (safe food = the same or nearly the same every time).

Since being with my partner (now spouse), we get homemade mashed potatoes anytime I’m sick. I love them so much; to me that’s so much effort, especially when things are so hard for us right now. But regardless, they still do it, because they love me just. That much.

In terms of individual parts, some of us gravitate to specific cuisine! Numb struggles a lot with the desire for raw meat, but Protector Instincts yell at him that it’s unsafe, so we found a lot of joy from sashimi and sushi for him. Octavian also loves Japanese food, with a major soft spot for ramen. Roy gravitates towards southern foods — because of course he does — and if we drink whiskey, he’s automatically out (even if we were unaware there was whiskey in the drink).

Debra likes all food, but she’s got a soft spot for deviled eggs and for popcorn. Extra butter obviously.

Lastly, we as a system actually love cooking. It can be stressful, yeah, but once we’re actually doing it, it’s incredibly satisfying to see a meal come together. I have a lot of good memories of cooking. A favorite dish of ours to make is this creamy spaghetti and beans dish. My parents used to call it Vendetta, which was some sort of inside joke involving V for Vendetta and the Simpsons? I couldn’t begin to explain it. I remember butterflies were involved?? Anyways.

We love the taste of it. It’s really filling, so one batch goes for awhile. When I think of my limited good memories of growing up, Vendetta is one of those memories. We found out later it’s a Rachel Ray recipe of all things, but we’ve made a few edits to the original recipe.

Here’s a quick recipe for those interested in trying it out (with the ONLY picture of it on my phone that I could find, good lord):

Creamy Spaghetti and Beans

Ingredients:

1 pound box of Spaghetti

4-6 cups of Vegetable Broth

Butter for Sautéing

At least a pound of mushrooms (I recommend mixing and matching for new flavors; if you can get your hands on some maitake, I highly suggest some of it. Paired with some oyster and some common white?? Delicious)

4 cloves of garlic, minced

1 mid onion, chopped

~1 cup of shredded carrot

1 can of cannellini beans

1 cup of white wine

1 cup of grated parm (have more for later)

As many seasonings as your little heart can carry

The only seasoning that is mandatory is lemon pepper

Instructions:

Add butter to a skillet. Let it melt, then add in the onion and garlic. Once the onion is translucent, add in the carrot. When cooked through, add in the mushrooms.

While the mushrooms sauté, add in some seasonings to the veggies. My go-to are usually red pepper flake, chili powder, lemon pepper, tumeric, rosemary, thyme, basil, and some powdered ginger. If I sees it, it goes in. Lemon pepper is a must, and you should use some later too.

Once the veggies are done, move them to a different bowl.

In the same pan, on a slightly lower heat, put the dry noodles in. Yes. Dry. Don’t boil em. Toss them in and let them burn a little — not a lot, but you want them to start browning. It should let off a nutty sort of smell. You may need more butter.

After about 3-4 minutes of toasting the noodles, add in a cup of white wine. BE CAREFUL OF STEAM BURNS. I have burnt myself numerous times because the wine steams horrendously. Let the noodles absorb the wine.

Add a cup of broth. Let the noodles absorb it. Then, add another cup. Let the noodles absorb it. Then, add another cup. Let the noodles absorb it. Magically, despite the noodles not boiling, they should now be soft and limp like a noodle should be. Incredible.

Add another cup of broth. When you do this, go ahead and now add in the veggies so they can get some good broth action.

At this point, you’ve got a choose your own adventure novel. My spouse loves saucy meals, so I do another cup of broth before tossing in the cup of parm, the can of cannellini (with about half the juice, which is disgusting but @circulars-singlet loves it), and another cup of broth if it’s not saucy enough — and some more parm if it needs to thicken. If you like it drier, you can add less broth, and drain the cannellini before putting the beans in.

Top with more parm and some lemon pepper. You should also use salt and pepper to your hearts content.

NOTES:

Mushrooms are easily replaced with bacon if you’d like that, and if you are vegetarian like Mush is, then tofu might be a good route to go — especially crumbled for the texture. But you do you boo.

The original recipe suggests doing this all at the same time, but I find that way too overwhelming. If you’d prefer to do it at the same time: start with the noodles at the same time as the onions, garlic, and carrots. Add the mushrooms at the same time as the first cup of broth. The mushrooms WILL absorb a LOT of broth, so be prepared to use closer to 6 cups.

My mother once put peas in? Feel free I guess.

If you can avoid whole wheat noodles, highly suggest you do. They taste… odd in this. They’re also thinner in my experience, and you really want a nood that can absorb nicely without being TOO thick. I haven’t tried this with a lot of other pasta types, though!

Recipes are just suggestions, you can change anything you want!!!

6 notes

·

View notes

Text

Patches

I'M MAKING PATCHES! HAH! YEAH! Anyway, I'm a bit excited presently because not only have I found a way to make E patches at home that give 200µg/day (each), it's actually very easy to do and relatively cheap (and should give similar yields if testosterone is used). Okay, so, because I love starch so much, it (again) is starch based (please note however, while corn starch may work, it is relatively low amylopectin, so it will likely work worse than potato starch or tapioca, so keep this in mind when you attempt). While I'm still working on refining the recipe, here's the gist of what I've gotten to work so far:

Make a powder of starch and estrogen with 2/3 – 3/4 teaspoon of starch per milligram of estrogen. When calculating how much estrogen you put in, estimate how many days you expect to keep the patch on in the same place (I would do no more than 3), take that number and multiply by 200µg (0.2mg) and then again by the number of patches you intend to make from that batch, and finally add 0.2 milligrams extra. So, 2 patches that I want to last me 2 days would simply be 2•2•0.2 which ends up with 0.8 milligrams, plus 0.2 getting us up to 1 milligram. Since it's really hard to weigh out that low of an amount, I recommend mixing a measurable amount of estradiol with your starch in either this ratio or simply a ratio that allows for easy serial dilutions into the concentration we want.

Mix glycerol (glycerine) with water in a 50/50 ratio such that the final volume is roughly equal (or slightly above) the volume of the dry mix you are using.

Take the desired amount of dry mix and mix it thoroughly with the appropriate amount of wet mix. Spread this evenly onto a 3.5x3.5cm piece of cloth (can be cut out of an old piece of clothing), put the cloth piece on top of a piece of paper that is just slightly larger, then put it in the microwave (paper side down) to heat for 10 seconds. It should come out quite hot and very sticky.

Once it cools down enough to put on your skin, you can do that, and that's it. You now have 1 or more patches that should stick to your skin for up to 4 days (likely only 3). And aren't watertight, so unless you want to cover it in cellophane/plastic wrap, you probably can't wear it in a shower, so be sure to clean yourself in other ways or make it with less estradiol so each patch/batch of patches lasts you one day and put it on immediately after you shower.

FYI, the dosing information for transdermal E (patches) is such that the µg/day is roughly equal to the amount of circulating E there is in your system in pg/mL (the normal unit for measuring E levels in a person). And to add to the complexity, the amount passing through the skin changes depending on where it is. You get the best yields where skin is thin and soft (more often than not), but worse elsewhere. Good locations include: under the arm (anywhere from armpit to end of your ribs but on that under arm space), your rear, your abdomen, the under side of your knee (though a lot of movement may decrease how well it sticks). Bad locations include: upper thigh, arms, and your shins or below. Be safe and happy transing that gender!

#diy hrt#hrt#estrogen#patches#transdermal#transfem#starch my beloved#good luck#another very good place in terms of amount that gets into your blood is genitalia but it seems really uncomfortable#so yeah#i hope this helps someone

16 notes

·

View notes

Video

Prostadine Prostate Supplement: A Game-Changer for Prostate Health

As we age, prostate health becomes increasingly crucial for men. The prostate is a gland located beneath the bladder, and its function is to produce and store semen. Unfortunately, the prostate is prone to various health conditions such as prostate enlargement, inflammation, and cancer. That's why it's essential to take proactive steps to maintain prostate health. One such way is by incorporating dietary supplements such as Prostadine into our daily routine.

What is Prostadine?

Prostadine is a natural dietary supplement made from nine potent ingredients, including Nori Yaki Extract Powder, Wakame Extract, Kelp Powder, Bladderwrack Powder, Saw Palmetto, Pomegranate Extract, Iodine, Shilajit, and Neem. Each ingredient is carefully selected for its unique properties and combined to create a powerful formula that supports prostate health.

How does Prostadine work?

Prostadine works by maintaining the function of the kidney and urinary tract, protecting against external toxins, and other potential threats that could harm these vital systems. It is produced in an FDA-approved facility under strict quality control guidelines, and each batch undergoes rigorous testing for purity and impurities. With over 160,000 satisfied customers and no significant side effects reported, Prostadine is one of the purest prostate supplements available in the market.

Benefits of Prostadine

Prostadine's benefits extend beyond prostate health. Its natural ingredients work together to promote overall well-being. The supplement supports kidney and urinary tract function, which is vital for maintaining healthy urinary habits. The ingredients also contain potent antioxidants that protect against external toxins and support the immune system.

How to use Prostadine?

To benefit from Prostadine, we recommend consuming a full dropper every morning. You can either consume it directly or mix it with your preferred beverage, such as tea, coffee, or juice. Make sure to shake the bottle well before use to ensure that the ingredients are thoroughly mixed.

Prostadine's 60-day guarantee policy

Each bottle of Prostadine comes with a 60-day money-back guarantee. If you are not satisfied with the outcomes, you can return the unused portion for a full refund, no questions asked. This policy shows Prostadine's commitment to customer satisfaction and confidence in its product's effectiveness.

Consulting with a physician

It's crucial to note that if you have a medical condition or are taking prescription medication, consulting with your doctor before taking Prostadine is crucial. While Prostadine is an all-natural supplement, it's always advisable to consult with a healthcare professional before starting any new supplement regimen.

Conclusion

Prostadine is an all-natural dietary supplement that supports prostate health, maintains kidney and urinary tract function, and safeguards against external threats. Its unique formula of nine potent ingredients, produced in an FDA-approved facility, makes it one of the purest prostate supplements available in the market. We highly recommend trying Prostadine, and with its 60-day guarantee policy, you have nothing to lose. Take control of your prostate health and try Prostadine today!

https://lookerstudio.google.com/reporting/c2af243d-12d4-4d09-8ac9-aa5e3f08cea2 https://www.reddit.com/user/shrillcomplete/comments/12ikqpf/prostadine_watch_this_prostadine_reviews/?utm_source=share&utm_medium=web2x&context=3 https://medium.com/@samuelschlossermeyerfb03/prostadine-prostate-supplement-the-ultimate-solution-for-prostate-health-e67810746208 https://us-prostadine.livejournal.com/326.html

2 notes

·

View notes

Text

So the previous poster had tags of "I couldn't give out any candy with peanut butter in it because of the outbreaks".

WHICH UNLOCKED MY SPECIAL INTEREST so here we goooo

Today, children, we're going to learn about something called The Peanut Corporation of America. See, in 2008, the PCA was the largest American provider of candied peanut butter, which is just peanut butter mixed with powdered sugar. That candied peanut butter is why your homemade Reese's or Nutter Butters taste a little different than the real thing. (And it's super easy to make, protip, you're welcome.) So that candied peanut butter has a ton of regulations to it, as it should, because peanut butter is prone to salmonella if not processed properly. And in 2008, this PCA corp sickened a bunch of people.

So what happened, it turned out, was the Food Safety Coordinator of the PCA, Mary Wilkerson, emailed her boss, Stewart Parnell, and said "Yo boss, we can't sell this batch of peanut butter. It's got hella salmonella in it." And that boss went "Mary, if you want to keep your job, you're going to sell it anyway. It's fine. People are resilient. And that recall is way too much money to lose, so sell it."

And then ~750 people got sick *and nine people died*.

Now, when this happened, it resulted in the then-largest food recall in the United States, involving 46 states, over 360 companies, and over 3,900 different products! Because this was a small but key ingredient in a ton of things! And because of regulations at the time, these people *went to fucking jail*.

Mary? Five years, because she was a foot soldier who nonetheless did not do her job well enough to stop this from happening. Stewart, the CEO? 30 years. His brother, the VP? 28 years. Yep, these two dudes are still in prison.

But what does that have to do with today?

Weakened regulations have allowed these two motherfuckers to almost-successfully file that they shouldn't have gone to jail *for killing nine and sickening 750* because "we only broke a regulation, it should be a fine". A fine. For getting hundreds sick and killing nine people. All because they failed to self-regulate properly. Mary WAS the self-regulator. That's what a Food Safety professional DOES. She went to jail for NOT seeing the fuckery going on and calling the FDA/USDA on them, because that WAS HER JOB. So weakening the self-regulations of the slaughterhouses is essentially giving us more Mary's of the world, but now they won't go to jail for not doing THEIR JOB.

The Human Face of the PCA Salmonella Outbreak | Food Safety News

These motherfuckers are ALSO trying to lobby to GET OUT OF JAIL EARLY because "weh, we're old, we're tired, but we're not sorry". Yeah? Tell that to the old, tired folks who FUCKING DIED eating your poison candy!

"B-B-But deliciousstrangeobject! They were old! They should have known not to eat anything that could hurt them if they were elderly and thus immunocompromised!"

Sure. Except they weren't eating raw oysters, which comes with that warning and is thus something that can sort-of be reasonably avoided. They were eating homemade things, like a peanutbutter cookie made from a grandchild. Or a PBJ sandwich. And also, peanut butter is a recognized healthy snack for immunocompromised folks because of the vitamin E that's supposed to help boost your immune system. And all of the peanut butter used was commercially packaged, which is assumed safe, *because of the regulations*.

What does all this have to do with Trump?

The above post mentioned the Boar's Head recall, a recall that is just as extensive as this one. 7 MILLION pounds of stuff have been recalled for listeria. That's wild! Two people, as of July, have died! And there's no call yet on if any of this is going to result in a change of regulation or not. I'm hoping that's because it's too soon to tell. But we don't yet know.

The weakening regulations are a problem because that implies that we believe that the honor system will stop something like this from happening again. But as we've seen time and again from problems like this, these corporations have lawyers specifically hired to find loopholes in laws like this to avoid jailtime. And the less regulations there are, the wider those loopholes get, and the easier these bastards can slip through. Mary was the honor system. She failed it. Others will, too.

Regulations are written in blood. They are formed because people had to die for them to be recognized as things that needed to be regulated. And easing those regulations is spitting on the graves of those who died because of greedy motherfuckers. And sure, maybe Boar's Head isn't full of greedy motherfuckers, and this was an oversight that turned deadly. Okay, that happens. But manslaughter is a criminal charge for a reason, it forces people to be careful or to face the consequences of their actions. And weakening regulations makes it so the consequences are just "bad press for a while".

Bad press doesn't prevent the dead.

TL;DR: Food Safety Important, Vote Kamala.

Headlines across eight years. Who you vote for really does matter. None of these headlines delve into the Boar's Head listeria outbreak because I can only post ten photos in one post. But the slaughter house self regulate headline? Yup, that's why.

59K notes

·

View notes

Text

Innovative Powder Coat and Systems Cooper Finishing

Cooper Finishing offers high quality surface finishing services, specializing in metal polishing, coating, and restoration for industrial applications.

#powder coat oven#powder coating oven#industrial curing oven#cerakote oven#best oven for powder coat#best oven for cerakote#batch curing oven#electric curing oven#composite curing oven#powder coat oven for sale#curing oven#powder spray booth#spray booths#sandblasting cabinets#spray systems#blasting equipment#paint spray booths#powder coating near me#cerakote oven for sale#powder coat equipment#custom powder coat oven

1 note

·

View note

Text

[ID: A bowl of a bright yellow stew topped with cilantro, mustard seed, chili, and curry leaf. End ID]

ಉಡುಪಿ ಸಾಂಬಾರ್ / Udupi sambar

A sambar is a lentil-and-vegetable stew distinguished by the use of a particular spice blend (Hindi: सांबर मसाला "sāmbār masālā," "sambar spice"; Kannada: ಸಾಂಬಾರ್ ಪುಡಿ "sāmbār puḍi," "sambar powder"). Sambars are a staple of South Indian and Sri Lankan cooking, sometimes made in households for multiple meals a week. The word "sambar" can be traced back to the Sanskrit सम्भार "sambhārá," "collection of things required for a particular purpose”; “spices."

The lentil used in sambar dishes is usually tur dal (split pigeon peas), though arhar dal, tuvur dal, or even blends containing masur or mung dal may be used, depending on the cook or the region. Vegetables also vary between combinations of okra, potato, ash gourd (petha), bottle gourd (doodhi / lauki), drumstick (saijan ki phalli), beetroot, tomato, carrot, pumpkin, brinjal, and pearl onions, among others. The sambar masala fries chilis, curry leaves, dal, and various spices including cumin, coriander, and fenugreek, then grinds them into a spicy, earthy, fragrant blend.

This recipe makes a sambar in the style of ಉಡುಪಿ (Udupi) cuisine—a subdivision of the cuisine of the ತುಳುವ (Tuluva) people localised in the Udupi District of Karnataka, a southeastern coastal state of India. (Tuluva cuisine is also commonly found in Dakshina Kannada, Karnataka, and Kasaragod, Kerala). In the Udupi region, sambar may be known as "ಕೊಡೆಲ್" "kodhel"; perhaps related to "ಕಡಲೆ" "kadhale" "Bengal gram"; or "ಹುಲಿ" "huḷi"; "tartness." Udupi huli has coconut oil and jaggery as its primary distinguishing features: the jaggery's deep sweetness and the earthy pungency of unrefined coconut oil combine with the spice of the chilis and the sour fruitiness of the tamarind to create a complex, flavorful, well-balanced dish.

Udupi huli may be further divided into a few major types. ಮಸಾಲೆ ಹುಳಿ ("masāla huḷi") contains shredded coconut and vegetables; ಬೋಳು ಹುಳಿ ("bolu huḷi") contains vegetables, but omits the coconut.

Hotel-style masala huli recipes typically add a lot of jaggery to produce a distinct sweetness; cut back on the amount of coconut included; and contain onion and garlic. The other main type of masala huli—“temple style”—is sattvic (from Sanskrit "सत्त्व" "sattva": "goodness," "essence," "existence"), which in this context means that onions and garlic are excluded.

A sattvic diet in Hinduism centres around the concept of maintaining sattva by eating only pure and mild (sattvic) foods, and omitting tamasic (“dark,” "inert," "destructive"; from Sanskrit तमस् "tamas") and rajasic ("exciting," "passionate," from Sanskrit रजस् "rajas") ones. The concepts of sattva, tamas, and rajas (the गुण "guṇa" system) are central to the construction of caste: the degree to which each person innately inherits each quality supposedly determines their possession of characteristics including honesty, intelligence, and goodness (sattva), stupidity and lack of creativity (tamas), and passion and pridefulness (rajas); the possession of these characteristics in turn determines their rightful place in a professional and social hierarchy. The association of certain foods with certain qualities thus links diet to caste: a distinction in diet is one of the methods by which those belonging to upper castes maintain and police caste boundaries.

This recipe makes enough pudi for one pot of sambar. Traditionally, sambar pudi is created fresh each time the dish is made, but many households make large batches and store them. In this case, omit the coconut; or, use dried coconut and store the masala in the refrigerator.

Recipe under the cut!

Patreon | Paypal | Venmo

Ingredients:

Serves 4-6.

For the sambar:

2 cups chopped vegetables

1 red onion, sliced*

1 cup (200g) yellow split pigeon peas / tur dal / ತೂರ್ ದಾಲ್ (ಹಳದಿ ಸ್ಪ್ಲಿಟ್ ಪಾರಿವಾಳದ ಬಟಾಣಿ)

4 cups (1 litre) water, or as needed

1/4 tsp ground turmeric / haldi / ಅರಿಶಿನ

2 tsp table salt

2 tsp jaggery / gur / ಬೆಲ್ಲ*

1/4 cup (60mL) tamarind pulp (from 1 Tbsp dried tamarind / imlie / ಹುಣಸೆಹಣ್ಣು)

2 tsp unrefined coconut oil / nariyal ka tel / ತೆಂಗಿನ ಎಣ್ಣೆ

Ingredient list format is English / Hindi (Latin transcription) / Kannada. The Hindi is provided for convenience while shopping.

Udupi sambar usually uses any of: gourd, brinjal (Indian eggplant), pumpkin, dumstick (saijan ki phalli), and okra. Pearl onion is not usually used in this region, but you can add whatever you want, according to taste.

*For a hotel-style sambar, include the onion; increase the jaggery to 2 Tbsp.

For the spice paste / sambar masala / ಸಾಂಬಾರ್ ಪುಡಿ ("sambar pudi"):

1/2 Tbsp split Bengal gram / chana dal / ಹಳದಿ ಸ್ಪ್ಲಿಟ್ ಗ್ರಾಂ

2 tsp split black gram / urad dal chilka / ಸ್ಪ್ಲಿಟ್ ಬ್ಲ್ಯಾಕ್ ಗ್ರಾಂ

2 tsp coriander seeds / dhaniya / ಕೊತ್ತಂಬರಿ ಬೀಜದ

1/2 tsp fenugreek seeds / methi / ಮೆಂತ್ಯ

1 tsp cumin seeds / jeera / ಜೀರಿಗೆ

1 tsp ground turmeric

5-6 curry leaves / kari pati / ಕರಿಬೇವು

3-4 Byadagi or other dried red chilis / byadagi mirch / ಬ್ಯಾಡಗಿ ಮೆಣಸಿನಕಾಯಿ

4 cloves garlic, skins on*

Large pinch asafoetida / hing / ಇಂಗು

1 cup (100g) fresh coconut (about one coconut)*

1/2 cup (120mL) water

While the ratio of ingredients in Udupi sambar pudi vary slightly, the ingredients themselves are almost always consistent.

*For a hotel-style sambar, include the garlic, and decrease the coconut in the sambar masala to 1/4 or 1/2 cup (25-50g).

The grams and pulses in this pudi have many different names. You can find them in a halal or South Asian grocery store; look on the bag for the Hindi names (since they have been transcribed into Latin, the spelling may vary from what you see here).

The urad dal you find may be husked, and thus yellow instead of black; these will work just as well.

For the tempering / tadka / ಹದಗೊಳಿಸುವ:

2 Tbsp unrefined coconut oil

2 red chilis

8 curry leaves

1 tsp brown mustard seeds / rai / ಸಾಸಿವೆ ಬೀಜಗಳು

Recipes from north Karnataka may add cumin and whole, unpeeled garlic cloves to the tempering.

Instructions:

For the sambar pudi:

1. Break open the coconut and remove and shread its flesh.

If using a whole dried coconut, break into the shell with the wrong side of a hammer and pry open. Break into a few smaller pieces and peel with a vegetable peeler until the skin is removed from the white flesh, wearing something to protect your hand. Soak in warm water for several minutes to soften, and then grate or food process.

2. Heat 2 Tbsp of coconut oil in a skillet on medium-low. Add asafoetida and fry for 30 seconds, until no longer raw-smelling. Add dal and fry, stirring often, for 30 seconds until golden brown; add coriander, mustard, fenugreek, and cumin seeds and fry until fragrant.

3. Add curry leaves and fry until wilted, then add garlic and dried chilis and fry another 30 seconds to a minute, until fragrant.

4. Add coconut and fry, stirring often, for another few minutes until a shade darker. Add turmeric and stir.

5. Grind all ingredients into a paste in a mortar and pestle, then mix in about 1/2 cup water to loosen (if using dried coconut, you may need more water).

Or, put all ingredients along with 1/2 cup water into a blender or food processor and process until a relatively smooth paste forms.

For the sambar:

1. Wash tur dal to remove excess starch. Simmer dal with 2 cups water, 1/4 tsp ground turmeric, and 1 tsp coconut oil for about 30 minutes until very tender. Mash until relatively smooth with a wooden spoon or bean masher, or process briefly with an immersion blender.

You may soak the dal in water after rinsing them to reduce the cooking time, but it is not necessary.

2. Meanwhile, make the tamarind paste. Soak 1 Tbsp tamarind dried pulp in 1/4 cup hot water for 20-30 minutes. Squeeze the tamarind into the water to extract the pulp. Discard the tamarind seeds and husk. Optionally, depending on your preferred texture, push the mixture through a metal sieve.

3. Prepare vegetables. Slice the onion; remove ends of okra and drumsticks and cut into 2-inch pieces; quarter tomatoes; quarter brinjal; peel pumpkin and cut into cubes; peel and cube potatoes.

4. If using onion, add a teaspoon of coconut oil to a large pot and fry until translucent.

5. In the same pot, boil vegetables in just enough water to cover, along with a pinch of salt, until they are beginning to soften.

Some recipes call for the vegetables to be boiled, and others call for them to be steamed. I prefer boiling, since it produces a nice savory broth.

6. Mix vegetables, dal, tamarind, jaggery, sambar pudi, and salt to taste and simmer 5-10 minutes to allow flavors to combine and vegetables to cook under tender. Add water as needed. Remove from heat and stir in cilantro. Taste and adjust salt.

The final sambar should be pourable, like a thick soup—Karnataka sambar is typically thinner in consistency than Tamil Nadu versions.

For the tadka:

1. Heat coconut oil in a small skillet on medium heat. Add tempering ingredients and fry, stirring often, until chilis and curry leaves are a couple shades darker and the mixture is fragrant.

2. Pour the oil and tempering ingredients into the sambar and stir in. If you like, retain some of the tadka as a garnish to serve.

3. Serve warm, in individual bowls, alongside long-grain white rice. To eat drumsticks, scoop the center out and eat it; the tough outer rind is left.

If you intend to save some sambar, it's a good idea to make just enough tadka for what you plan to eat that day, and then make fresh tadka to pour over the reheated leftovers.

112 notes

·

View notes

Text

Exporter of Flash Dryer in Sudan

Drytech Engineering Systems is a trusted Manufacturer and Exporter of Flash Dryer in Sudan.

We are located in Ahmedabad, Gujarat, India.

Drytech Engineering Systems specializes in delivering cutting-edge industrial drying solutions, with a focus on high-performance Flash Dryers.

We design, manufacture, and provide innovative drying technologies that efficiently meet the needs of a variety of industries worldwide.

Our Flash Dryers offer rapid, energy-efficient drying for powders, granules, and heat-sensitive materials.

We work closely with clients in industries like food processing, pharmaceuticals, chemicals, plastics, and agriculture to deliver customized solutions that improve productivity, product quality, and operational efficiency.

Why Choose Drytech Flash Dryers?

Efficiency: Our Flash Dryers offer quick drying times, reducing the overall processing time significantly.

Cost-Effective: Reduced energy consumption due to optimized design, saving operational costs.

Reliability: Built to last with high-quality components and robust construction, ensuring long-term performance.

Versatility: Suitable for a wide range of industries, including food, chemicals, and pharmaceuticals.

Technology: Cutting-edge technology for uniform drying, preventing clumping or degradation of sensitive materials.

Benefits of Using Flash Dryers:

Reduced Drying Time: Flash drying works rapidly, which increases production rates and reduces bottlenecks in manufacturing.

Improved Product Quality: By drying materials quickly, the Flash Dryer helps retain product quality, preventing over-drying or clumping.

Lower Energy Consumption: Our systems are designed to optimize energy usage, ensuring that you can achieve maximum output at lower operational costs.

Consistency and Uniformity: The drying process is uniform, ensuring consistent product quality across the entire batch.

Space Efficiency: Its compact design allows for integration into facilities with limited floor space.

FAQs:

Q1: What materials can be dried using a Flash Dryer? A1: Flash Dryers are versatile and can be used to dry powders, granules, crystalline materials, and even some heat-sensitive products across industries such as food, pharmaceuticals, and chemicals.

Q2: Are Flash Dryers energy-efficient? A2: Yes, Drytech Flash Dryers are designed to optimize energy consumption, reducing operational costs while maintaining high drying efficiency.

Q3: How easy is it to maintain a Flash Dryer? A3: Flash Dryers from Drytech are designed for easy maintenance, with simple-to-clean components and durable construction that ensures minimal downtime and long-lasting performance.

Drytech Engineering Systems is a Exporter of Flash Dryer in Sudan including locations Khartoum, Kassala, North Darfur, Sennar, Blue Nile, Northern, Red Sea, Al Qadarif, Gezira, North Kordofan, Gedaref, Lakes, Northern Bahr el Ghazal, Omdurman, River Nile, Juba.

Contact Us today for your flash dryer solutions!

#gujarat#india#ahmedabad#manufacturer#exporter#drytechengineeringsystems#supplier#Sudan#Khartoum#Kassala#North Darfur#Sennar#Blue Nile#Northern#Red Sea#Al Qadarif#Gezira#North Kordofan#Gedaref#Lakes#Northern Bahr el Ghazal#Omdurman#River Nile#Juba#Exporter of Flash Dryer in Sudan

0 notes

Text

Understanding High Shear Mixers: A Comprehensive Guide

High shear mixers are essential equipment in a variety of industries, including food processing, pharmaceuticals, cosmetics, and chemicals. They are designed to blend, emulsify, homogenize, or disperse products effectively, ensuring uniformity and high-quality results. In this article, we’ll delve into the details of high shear mixers, their working principles, applications, benefits, and factors to consider when choosing one for your needs.

What is a High Shear Mixer?

A high shear mixer is a device used to create a high-speed rotational force to mix, blend, or emulsify ingredients. These mixers work by subjecting materials to intense shear forces, breaking down particles and ensuring thorough mixing. The equipment typically consists of a rotor and stator assembly that works together to achieve desired consistency and quality in various applications.

How Does a High Shear Mixer Work?

High shear mixers operate on the principle of shear forces—a combination of velocity and pressure—created as the rotor moves rapidly within the stationary stator. Here’s a step-by-step breakdown of the process:

Ingredient Ingress: Ingredients are introduced into the mixer chamber.

Rotor-Stator Interaction: The rotor spins at high speeds, drawing materials into the stator. The small gap between the rotor and stator subjects the materials to intense shear forces.

Particle Reduction: Particles are broken down into smaller sizes, achieving a homogeneous mixture.

Continuous Circulation: The mixed material is continuously recirculated through the system until the desired texture, viscosity, or emulsification is achieved.

Key Features of High Shear Mixers

Adjustable Speeds: Allows customization based on the material and application requirements.

Compact Design: Modern high shear mixers are designed to be space-efficient while maintaining robust performance.

Versatility: Suitable for a range of applications, including blending liquids, dispersing powders, and creating emulsions.

Easy Maintenance: Built with durable materials and easy-to-clean components.

Applications of High Shear Mixers

High shear mixers are used in a variety of industries to achieve specific goals. Below are some common applications:

1. Food and Beverage Industry

Emulsification: Creating stable emulsions for salad dressings, sauces, and mayonnaise.

Homogenization: Ensuring smooth textures in dairy products like yogurt and cheese.

Blending: Mixing ingredients for beverages and nutritional supplements.

2. Pharmaceutical Industry

Suspensions: Creating fine particle suspensions for syrups and other liquid medications.

Emulsions: Stabilizing pharmaceutical emulsions for topical applications.

Active Ingredient Integration: Ensuring even distribution of active ingredients in tablets and capsules.

3. Cosmetic Industry

Creams and Lotions: Achieving smooth textures and stability in skincare products.

Color Dispersion: Ensuring uniformity in makeup products such as foundations and lipsticks.

Fragrance Integration: Incorporating fragrances evenly into formulations.

4. Chemical Industry

Polymer Blending: Mixing polymers for paints and coatings.

Adhesive Production: Ensuring uniformity in glue and adhesive formulations.

Oil and Water Emulsions: Stabilizing oil-water mixtures for industrial applications.

Benefits of Using High Shear Mixers

Efficiency: High shear mixers drastically reduce mixing times compared to traditional methods.

Consistency: Achieve uniform particle size and distribution in every batch.

Versatility: Adaptable to a variety of processes and industries.

Cost-Effectiveness: Saves energy and labor costs by delivering results quickly.

Improved Product Quality: Enhances texture, stability, and appearance of the final product.

Types of High Shear Mixers

1. Inline High Shear Mixers

Ideal for continuous production processes.

Ensures consistent mixing without batch-to-batch variation.

Suitable for emulsions, suspensions, and dispersions.

2. Batch High Shear Mixers

Perfect for small-scale or specific production runs.

Flexible and easy to operate.

Commonly used in research and development.

3. Multistage High Shear Mixers

Equipped with multiple rotor-stator stages for enhanced mixing.

Provides finer particle size reduction and improved homogenization.

Factors to Consider When Choosing a High Shear Mixer

Selecting the right high shear mixer depends on your specific needs. Here are some factors to keep in mind:

Material Properties: Consider the viscosity, density, and thermal sensitivity of the materials.

Capacity Requirements: Choose a mixer that matches your production volume.

Rotor-Stator Design: Different designs are suited for specific applications.

Power and Speed: Ensure the mixer has adjustable speed settings to handle diverse processes.

Ease of Maintenance: Look for equipment with minimal maintenance requirements and durable construction.

Cost: Balance the initial investment with long-term operational efficiency.

Maintenance and Care for High Shear Mixers

Proper maintenance is essential to maximize the lifespan and efficiency of your high shear mixer. Here are some tips:

Regular Cleaning: Prevent residue buildup by cleaning after every use.

Inspection: Check for wear and tear on the rotor-stator assembly and replace parts as needed.

Lubrication: Ensure moving parts are adequately lubricated to reduce friction.

Calibration: Periodically calibrate the equipment to maintain optimal performance.

Conclusion

High shear mixers are invaluable tools for industries requiring precision and consistency in their processes. From emulsifying delicate cosmetic creams to homogenizing pharmaceutical suspensions, these mixers ensure superior results every time. Understanding their working principles, applications, and benefits can help you make informed decisions when investing in this technology.

1 note

·

View note

Text

Optimize Your Tablet Production: Choosing the Right Ball Mill and Coating Machine

The pharmaceutical industry is a complex web of processes, a veritable maze of procedures and machinery, all working together to bring safe and effective medications to the market. Two key players in this intricate dance are the ball mill machine and the coating tablet machine. Choosing the right equipment can significantly optimize your tablet production, leading to higher efficiency, improved quality, and ultimately, greater success.

Why are Ball Mills and Coating Machines Crucial?

Ball mill machines are workhorses in the initial stages of tablet production. These powerful grinding machines use balls (typically made of steel or ceramic) to reduce particle size, ensuring a uniform and consistent powder blend for tablet pressing. This is critical for:

Content Uniformity: A consistent particle size ensures that the active pharmaceutical ingredient (API) is evenly distributed throughout the tablet, leading to accurate dosage and therapeutic efficacy.

Improved Bioavailability: Smaller particles dissolve more readily, leading to better absorption and faster onset of action.

Enhanced Stability: Reducing particle size can improve the stability of the drug formulation, extending its shelf life.

Coating tablet machines come into play after the tablets are pressed. These specialized machines apply a thin, uniform coating to the tablet's surface. This coating serves several important functions:

Taste Masking: Many APIs have unpleasant tastes. A coating can mask this, making the medication easier to swallow.

Protection: Coatings can protect the tablet from moisture, light, and oxygen, preserving its potency and stability.

Controlled Release: Specialized coatings can be used to control the rate at which the drug is released in the body, providing sustained therapeutic effects.

Brand Identity: Coatings can be colored and imprinted, enhancing the tablet's appearance and aiding in brand recognition.

Navigating the Maze: Choosing the Right Equipment

Selecting the optimal ball mill and coating machine for your specific needs can be daunting. Here's a breakdown of key factors to consider:

Ball Mill Machine:

Capacity: How much material do you need to process per batch? Consider your current and future production needs.

Grinding Media: The type, size, and material of the grinding media will impact the efficiency and effectiveness of the milling process.

Mill Speed and Design: Different mill designs and speeds are suited for different materials and desired particle sizes.

Maintenance and Cleaning: Ease of maintenance and cleaning is crucial for hygiene and efficient operation.

Coating Tablet Machine:

Coating Type: Do you need a standard film coating, a sugar coating, or a specialized functional coating?

Pan Design: Traditional pans or perforated pans offer different advantages in terms of efficiency and coating uniformity.

Spraying System: The spraying system should ensure even distribution of the coating solution and efficient drying.

Automation and Control: Automated systems with precise control over parameters like temperature, airflow, and spray rate can significantly improve consistency and reduce human error.

Beyond the Machine: Factors to Consider

While choosing the right equipment is essential, other factors can also impact your tablet production:

Raw Materials: The quality and characteristics of your raw materials will influence the milling and coating processes.

Formulation: The tablet formulation itself can impact how it behaves during milling and coating.

Process Optimization: Fine-tuning your processes, including milling time, coating parameters, and drying conditions, is essential for achieving optimal results.

Quality Control: Implementing robust quality control measures throughout the production process ensures consistent and high-quality tablets.

Escaping the Maze: Partnering with Experts

Navigating the maze of tablet production can be challenging. Partnering with experienced equipment manufacturers and technology providers can provide valuable guidance and support. They can help you:

Select the right equipment based on your specific needs and production goals.

Optimize your processes to achieve maximum efficiency and quality.

Troubleshoot any challenges you may encounter.

Stay up-to-date on the latest technologies and best practices.

By carefully considering these factors and seeking expert advice, you can optimize your tablet production, escape the all maze of inefficiencies, and deliver high-quality medications that meet the needs of patients and healthcare providers.

0 notes