#polymer testing laboratory

Explore tagged Tumblr posts

Text

How to Choose the Right Rubber Testing Laboratory in India?

Introduction

Choosing the right rubber testing laboratory in India is a critical decision for businesses involved in rubber manufacturing or related industries. With numerous options available, it's essential to make an informed choice to ensure accurate testing, compliance with standards, and ultimately, the quality and reliability of your products. In this guide, we'll explore key factors to consider when selecting a rubber testing laboratory in India.

Understand Your Testing Needs: Before beginning your search for a rubber testing laboratory, it's crucial to have a clear understanding of your testing requirements. Identify the specific tests you need to perform on your rubber materials or products. These may include physical properties testing, chemical analysis, environmental testing, or specialized testing for particular industries such as automotive or healthcare.

Check Accreditation and Certification: One of the most important factors to consider is the accreditation and certification of the testing laboratory. Look for laboratories that are accredited by national or international bodies such as the National Accreditation Board for Testing and Calibration Laboratories (NABL) or the International Organization for Standardization (ISO). Accreditation ensures that the laboratory meets stringent quality standards and follows standardized testing procedures.

3. Evaluate Expertise and Experience: Assess the expertise and experience of the laboratory in rubber testing. Look for laboratories with a track record of conducting tests relevant to your industry or specific requirements. Experienced technicians and scientists familiar with the nuances of rubber testing are more likely to deliver accurate results and provide valuable insights.

4. Review Facilities and Equipment: Inspect the laboratory's facilities and equipment to ensure they are modern, well-maintained, and suitable for your testing needs. State-of-the-art equipment and advanced testing techniques can enhance the accuracy and reliability of test results. Additionally, verify that the laboratory follows proper calibration and maintenance procedures for all testing equipment.

5. Consider Turnaround Time and Cost: Evaluate the laboratory's turnaround time for testing and reporting results. Depending on your project timeline, you may require quick turnaround times without compromising on accuracy. Additionally, consider the cost of testing services and ensure they fit within your budget. However, prioritize quality and reliability over cost to avoid potential risks associated with inaccurate testing.

6. Assess Communication and Customer Support: Effective communication and customer support are essential for a smooth testing process. Choose a laboratory that maintains clear communication channels, provides updates on testing progress, and addresses any queries or concerns promptly. A responsive and customer-focused approach indicates a commitment to client satisfaction and quality service.

7. Seek References and Recommendations: Seek recommendations from industry peers or associations and inquire about their experiences with different testing laboratories. Additionally, ask potential laboratories for references or case studies showcasing their previous work. Hearing first hand accounts from satisfied clients can help validate the laboratory's capabilities and reliability.

Conclusion

Selecting the right rubber testing laboratory in India requires careful consideration of various factors, including accreditation, expertise, facilities, turnaround time, and cost. By following the guidelines outlined in this guide and conducting thorough research, you can choose a laboratory that meets your testing needs and ensures the quality and integrity of your rubber products. Remember, investing in quality testing is essential for maintaining product reliability, meeting regulatory requirements, and safeguarding your brand reputation.

For more information : https://maeonlabs.com/

1 note

·

View note

Text

The Importance of Quality Testing in Plastic Manufacturing

Quality testing in plastic manufacturing is a critical process that ensures the production of durable and safe products. In this article, we'll explore the various facets of quality testing and its profound impact on the industry.

Ensuring Product Quality

Quality control measures play a pivotal role in maintaining the integrity of plastic products. Raw material inspection, in-process monitoring, and final product testing are indispensable steps in guaranteeing the quality of the end product. Each stage is meticulously designed to catch defects and deviations from specifications.

For more quality testing check: Plastic Testing Laboratory

Impact on Durability

The relationship between quality testing and the longevity of plastic products cannot be overstated. Products that undergo rigorous quality testing are less prone to premature wear and tear, contributing to their overall durability. Unfortunately, instances of failed quality testing have led to catastrophic consequences in the industry, underlining the paramount importance of stringent testing protocols.

Compliance with Standards

Adhering to industry standards is non-negotiable for plastic manufacturers. We'll delve into an overview of these standards and explore the severe consequences that non-compliance can have on both the manufacturer and the end consumer. Meeting and surpassing these standards is a hallmark of a responsible and reliable manufacturer.

Cost Efficiency

Addressing defects early in the manufacturing process is not just about ensuring quality; it's also a strategic move for cost efficiency. By reducing wastage and minimizing the need for rework, manufacturers can optimize their processes and allocate resources more effectively, ultimately contributing to a healthier bottom line.

Customer Satisfaction

Quality testing goes hand in hand with meeting customer expectations. We'll explore how the implementation of robust quality control measures builds trust and reputation in the market. Satisfied customers are not just buyers; they have become loyal advocates for the brand.

Technological Advancements in Quality Testing of plastics

Modern technology has revolutionized the landscape of quality testing in plastic manufacturing. From sophisticated sensors to advanced imaging techniques, we'll discuss how these innovations benefit manufacturers by providing more accurate and efficient testing processes.

Challenges in Implementing Quality Testing

Despite its importance, implementing effective quality testing in plastic manufacturing comes with its own set of challenges. We'll highlight common obstacles faced by manufacturers and provide strategies to overcome them, emphasizing the need for a proactive approach.

Training and Skill Development

Ensuring the success of quality testing requires a skilled workforce. We'll discuss the importance of ongoing training programs to keep employees updated on the latest testing methodologies and technologies, fostering a culture of continuous improvement.

Environmental Impact

Quality testing isn't just about product integrity; it also has a significant impact on the environment. We'll explore how adopting quality measures can contribute to sustainable practices, reducing the environmental footprint of plastic manufacturing.

Industry Case Studies

Real-world examples provide valuable insights into the successes and failures of quality testing in the plastic manufacturing sector. By examining these case studies, manufacturers can learn from both positive implementations and unfortunate mistakes, further refining their own processes.

Future Trends

The landscape of quality testing is ever-evolving. We'll discuss predictions for the future of quality testing in plastic manufacturing, including emerging technologies and approaches that are set to redefine industry standards.

Conclusion

In conclusion, the importance of quality testing in plastic manufacturing cannot be overstated. From ensuring product quality to meeting customer expectations and contributing to cost efficiency, quality testing is a linchpin in the success of any plastic manufacturing operation. As the industry continues to evolve, embracing the challenges and opportunities presented by quality testing is key to sustained growth and success.

FAQs

What is the primary purpose of quality testing in plastic manufacturing?

Quality testing ensures that plastic products meet specified standards for durability, safety, and overall quality.

How does quality testing contribute to cost efficiency in manufacturing?

By identifying and addressing defects early in the process, manufacturers can minimize wastage and reduce the need for costly rework.

What role does technology play in modern quality testing for plastic products?

Advanced technologies, such as sensors and imaging techniques, have revolutionized the accuracy and efficiency of quality testing in the plastic manufacturing industry.

Why is compliance with industry standards crucial for plastic manufacturers?

Compliance with industry standards is essential for ensuring the safety and reliability of plastic products, as well as maintaining the reputation of the manufacturer.

How can manufacturers overcome challenges in implementing effective quality testing?

Manufacturers can overcome challenges through proactive approaches, employee training, and adopting modern technologies.

For more details

Maeon Laboratory

14, Lakshmikanthammal 1st Street, Rajiv Nagar,

Vanagaram, Chennai, Tamil Nadu,

Pincode - 600 077

9042055689

#plastic testing laboratory#plastic testing labs#polymer testing laboratory#maeon laboratories#maeon laboratory#plastic manufacturing#plastic testing lab#plastic product testing

0 notes

Text

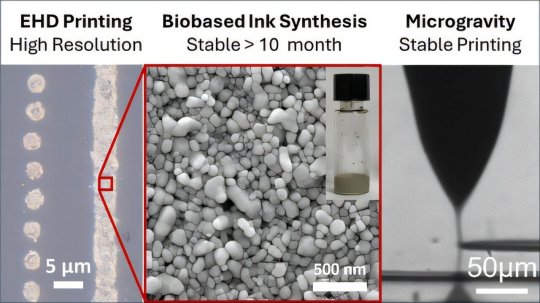

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Link

Casey Wolfe is developing and producing the next generation payload adapter for NASA’s SLS (Space Launch System) super-heavy lift rocket. The adapter is made with some of the world’s most advanced composite manufacturing techniques.NASA/Sam Lott While precision, perseverance, and engineering are necessary skills in building a Moon rocket, Casey Wolfe knows that one of the most important aspects for the job is teamwork. “Engineering is vital, but to get this type of work done, you need to take care of the human element,” said Wolfe, the assistant branch chief of the advanced manufacturing branch in the Materials and Processes Laboratory at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Together with her team, Wolfe is developing and producing the next generation payload adapter for NASA’s SLS (Space Launch System) super-heavy lift rocket. The adapter is made with some of the world’s most advanced composite manufacturing techniques. Wolfe’s work integrates the technical day-to-day operations and personnel management of the composites manufacturing team and additive manufacturing team, balancing production of SLS hardware with the creation of new engines using the latest manufacturing technologies. “A lot of my day to day is in managing our two teams, making connections, building relationships, and making sure people feel supported,” Wolfe explains. “I conduct individual tag ups with each team member so we can be proactive about anticipating and addressing problems.” Wolfe grew up in Huntsville, a place known as the “Rocket City,” but it wasn’t until she visited a job fair while studying at Auburn University for a polymer and fiber engineering degree that she began to consider a career at NASA Marshall. Wolfe applied for and was selected to be a NASA intern through the Pathways Program, working in the non-metallic materials branch of the Materials and Processes Laboratory. Wolfe supported a coating system for electrostatic discharge on the first uncrewed test flight of the Orion spacecraft. Launching December 5, 2014, Orion traveled to an altitude of 3,600 miles, orbited Earth twice, and splashed down in the Pacific Ocean. It was during her internship that Wolfe realized how inspirational it felt to be treated like a vital part of a team: “The SLS program gave everyone permission to sign the hardware, even me – even though I was just an intern,” says Wolfe. “It was impactful to me, knowing that something I had worked on had my name on it and went to space.” Since being hired by NASA, Wolfe’s work has supported development of the Orion stage adapter diaphragms for Artemis II and Artemis III, and the payload adapters for Artemis IV and beyond. The first three Artemis flights use the SLS Block 1 rocket variant, which can send more than 27 metric tons (59,500 pounds) to the Moon in a single launch. Beginning with Artemis IV, the SLS Block 1B variant will use the new, more powerful exploration upper stage to enable more ambitious missions to deep space, with the cone-shaped payload adapter situated atop the rocket’s exploration upper stage. The new variant will be capable of launching more than 38 metric tons (84,000 pounds) to the Moon in a single launch. “While the engineering development unit of the payload adapter is undergoing large-scale testing, our team is working on the production of the qualification article, which will also be tested,” Wolfe says. “Flight components should be starting fabrication in the next six months.” When Wolfe isn’t working, she enjoys hiking, gardening, and hanging out with her dogs and large family. Recently, she signed another piece of SLS hardware headed to space: the Orion stage adapter for the second Artemis mission. With as many responsibilities as Wolfe juggles, it’s easy to lose sight of her work’s impact. “I work in the lab around the hardware all the time, and in many ways, it can become very rote,” she says. But Wolfe won’t forget what she saw one evening when she worked late: “Everybody was gone, and as I walked past the launch vehicle stage adapter, there were two security guards taking pictures of each other in front of it. It was one of those things that made me step back and reflect on what my team accomplishes every day: making history happen.” NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

3 notes

·

View notes

Text

Dr. Henry Aaron Hill (May 30, 1915 – March 17, 1979) was a fluorocarbon chemist who became the first African American president of the American Chemical Society.

He graduated from Johnson C. Smith University with a BA before completing a Ph.D. from MIT. The title of his dissertation is “Test of Van’t Hoff’s Principle of Optical Superposition.”

After receiving his Ph.D., he joined Atlantic Research Associates, as a research chemist. He became the research director there and became VP. He was a civilian employee of the Office of Scientific Research and Development. He moved to Dewey & Almy Chemical Co., as a research group leader. He became the assistant manager and co-founder of National Polychemicals, Inc. He founded Riverside Laboratory for research, development, and consulting.

His research focused on chemical intermediates for the production of polymer products. #africanhistory365 #africanexcellence

4 notes

·

View notes

Text

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

New Post has been published on https://thedigitalinsider.com/scientists-3d-print-self-heating-microfluidic-devices-technology-org/

Scientists 3D Print Self-Heating Microfluidic Devices - Technology Org

The one-step fabrication process rapidly produces miniature chemical reactors that could be used to detect diseases or analyze substances.

MIT researchers have used 3D printing to produce self-heating microfluidic devices, demonstrating a technique which could someday be used to rapidly create cheap, yet accurate, tools to detect a host of diseases.

MIT researchers developed a fabrication process to produce self-heating microfluidic devices in one step using a multi-material 3D printer. Pictured is an example of one of the devices. Illustration by the researchers / MIT

Microfluidics, miniaturized machines that manipulate fluids and facilitate chemical reactions, can be used to detect disease in tiny samples of blood or fluids. At-home test kits for Covid-19, for example, incorporate a simple type of microfluidic.

But many microfluidic applications require chemical reactions that must be performed at specific temperatures.

These more complex microfluidic devices, which are typically manufactured in a clean room, are outfitted with heating elements made from gold or platinum using a complicated and expensive fabrication process that is difficult to scale up.

Instead, the MIT team used multimaterial 3D printing to create self-heating microfluidic devices with built-in heating elements, through a single, inexpensive manufacturing process. They generated devices that can heat fluid to a specific temperature as it flows through microscopic channels inside the tiny machine.

The self-heating microfluidic devices, such as the one shown, can be made rapidly and cheaply in large numbers, and could someday help clinicians in remote parts of the world detect diseases without the need for expensive lab equipment. Credits: Courtesy of the researchers / MIT

Their technique is customizable, so an engineer could create a microfluidic that heats fluid to a certain temperature or given heating profile within a specific area of the device. The low-cost fabrication process requires about $2 of materials to generate a ready-to-use microfluidic.

The process could be especially useful in creating self-heating microfluidics for remote regions of developing countries where clinicians may not have access to the expensive lab equipment required for many diagnostic procedures.

“Clean rooms in particular, where you would usually make these devices, are incredibly expensive to build and to run. But we can make very capable self-heating microfluidic devices using additive manufacturing, and they can be made a lot faster and cheaper than with these traditional methods. This is really a way to democratize this technology,” says Luis Fernando Velásquez-García, a principal scientist in MIT’s Microsystems Technology Laboratories (MTL) and senior author of a paper describing the fabrication technique.

He is joined on the paper by lead author Jorge Cañada Pérez-Sala, an electrical engineering and computer science graduate student. The research will be presented at the PowerMEMS Conference this month.

An insulator becomes conductive

This new fabrication process utilizes a technique called multimaterial extrusion 3D printing, in which several materials can be squirted through the printer’s many nozzles to build a device layer by layer. The process is monolithic, which means the entire device can be produced in one step on the 3D printer, without the need for any post-assembly.

To create self-heating microfluidics, the researchers used two materials — a biodegradable polymer known as polylactic acid (PLA) that is commonly used in 3D printing, and a modified version of PLA.

The modified PLA has mixed copper nanoparticles into the polymer, which converts this insulating material into an electrical conductor, Velásquez-García explains. When electrical current is fed into a resistor composed of this copper-doped PLA, energy is dissipated as heat.

“It is amazing when you think about it because the PLA material is a dielectric, but when you put in these nanoparticle impurities, it completely changes the physical properties. This is something we don’t fully understand yet, but it happens and it is repeatable,” he says.

Using a multimaterial 3D printer, the researchers fabricate a heating resistor from the copper-doped PLA and then print the microfluidic device, with microscopic channels through which fluid can flow, directly on top in one printing step. Because the components are made from the same base material, they have similar printing temperatures and are compatible.

Heat dissipated from the resistor will warm fluid flowing through the channels in the microfluidic.

In addition to the resistor and microfluidic, they use the printer to add a thin, continuous layer of PLA that is sandwiched between them. It is especially challenging to manufacture this layer because it must be thin enough so heat can transfer from the resistor to the microfluidic, but not so thin that fluid could leak into the resistor.

The resulting machine is about the size of a U.S. quarter and can be produced in a matter of minutes. Channels about 500 micrometers wide and 400 micrometers tall are threaded through the microfluidic to carry fluid and facilitate chemical reactions.

Importantly, the PLA material is translucent, so fluid in the device remains visible. Many processes rely on visualization or the use of light to infer what is happening during chemical reactions, Velásquez-García explains.

Customizable chemical reactors

The researchers used this one-step manufacturing process to generate a prototype that could heat fluid by 4 degrees Celsius as it flowed between the input and the output. This customizable technique could enable them to make devices which would heat fluids in certain patterns or along specific gradients.

“You can use these two materials to create chemical reactors that do exactly what you want. We can set up a particular heating profile while still having all the capabilities of the microfluidic,” he says.

However, one limitation comes from the fact that PLA can only be heated to about 50 degrees Celsius before it starts to degrade. Many chemical reactions, such as those used for polymerase chain reaction (PCR) tests, require temperatures of 90 degrees or higher. And to precisely control the temperature of the device, researchers would need to integrate a third material that enables temperature sensing.

In addition to tackling these limitations in future work, Velásquez-García wants to print magnets directly into the microfluidic device. These magnets could enable chemical reactions that require particles to be sorted or aligned.

At the same time, he and his colleagues are exploring the use of other materials that could reach higher temperatures. They are also studying PLA to better understand why it becomes conductive when certain impurities are added to the polymer.

“If we can understand the mechanism that is related to the electrical conductivity of PLA, that would greatly enhance the capability of these devices, but it is going to be a lot harder to solve than some other engineering problems,” he adds.

“In Japanese culture, it’s often said that beauty lies in simplicity. This sentiment is echoed by the work of Cañada and Velasquez-Garcia. Their proposed monolithically 3D-printed microfluidic systems embody simplicity and beauty, offering a wide array of potential derivations and applications that we foresee in the future,” says Norihisa Miki, a professor of mechanical engineering at Keio University in Tokyo, who was not involved with this work.

“Being able to directly print microfluidic chips with fluidic channels and electrical features at the same time opens up very exiting applications when processing biological samples, such as to amplify biomarkers or to actuate and mix liquids. Also, due to the fact that PLA degrades over time, one can even think of implantable applications where the chips dissolve and resorb over time,” adds Niclas Roxhed, an associate professor at Sweden’s KTH Royal Institute of Technology, who was not involved with this study.

Written by Adam Zewe

Source: Massachusetts Institute of Technology

You can offer your link to a page which is relevant to the topic of this post.

#3d#3D printing#additive manufacturing#amazing#applications#biodegradable#biomarkers#Biotechnology news#blood#chemical#chemical reactions#Chemistry & materials science news#chips#computer#Computer Science#conference#continuous#covid#Developing countries#Developments#devices#Disease#Diseases#energy#Engineer#engineering#equipment#Fabrication#Featured life sciences news#Featured technology news

2 notes

·

View notes

Text

Film industry and Production design

"Avatar The Way of Water" By James Cameron continues to be a show stopper, impressing people worldwide. Similar to the first Avatar movie James Cameron created immense use of cutting-edge performance capture technology. This technology allowed the actors to portray the roles of the alien species, the Na'vi which both films are based on. It shows the great detail of the technology considering the species are 10-feet-tall,blue-skinned, and have pointy ears.

When it came to making the watery scenes come to life, there would be none of the faking the water, actors dangling from wires, feigning weightlessness, making fake swimming motions in the air. According to members of Cameron’s crew, the director insisted on “wet-for-wet.” “Avatar: The Way of Water,” now released since December 2022, symbolizes a new milestone in the evolution of visual effects technology, and that milestone is underwater performance capture.

After some rough testing — the first experiments took place in the backyard pool of an “Avatar” producer names Jon Landau. A performance capture tank was assembled at Lightstorm Entertainment’s facility in Manhattan Beach, California. The tank was 32 feet deep and held around 90,000 gallons. Also created with viewing platforms on the deck and windows in the pool walls for camera operators to shoot through. This gives the tank the look and feel of a laboratory aquarium.

Another one of the main difficulties that the crew had faced was the prevention of overhead studio lights from interfering with performance-capture data. To solve this, James Cameron suggested that spreading a layer of small polymer balls across the water line would diffuse the light in the tank, allowing actors to surface safely from the water.

The artists at Weta who transformed the wetsuited actors into the famous Na’vi. They also created the highly detailed digital environments, taking the action from once a chlorinated tank to an enchanting underwater realm, with major fictional detail. According to the Artists at Weta, about 57 new species of sea creatures were created just for the film. Weta artists also conversed with researchers at Victoria University of Wellington about coral reef biology to get more perspective.

“Avatar: The Way of Water” by far the biggest visual effects project the company has ever taken on. Only two shots in the entire film contain no visual effects.As part of the teams research, the team shot hundreds of hours of reference footage such wind ripples on the surface of water, waves hitting rocks, the movement of seaweed.

James Cameron's "Avatar The Way of Water" continues to make a massive impact in the film industry even after hitting theaters. It was the first of Cameron's Pandora-centered sequels has now grossed $2.074 billion,

sources: https://collider.com/avatar-2-way-of-water-4th-highest-grossing-movie/ https://www.nytimes.com/2022/12/16/movies/avatar-2-fx-cgi.html

3 notes

·

View notes

Text

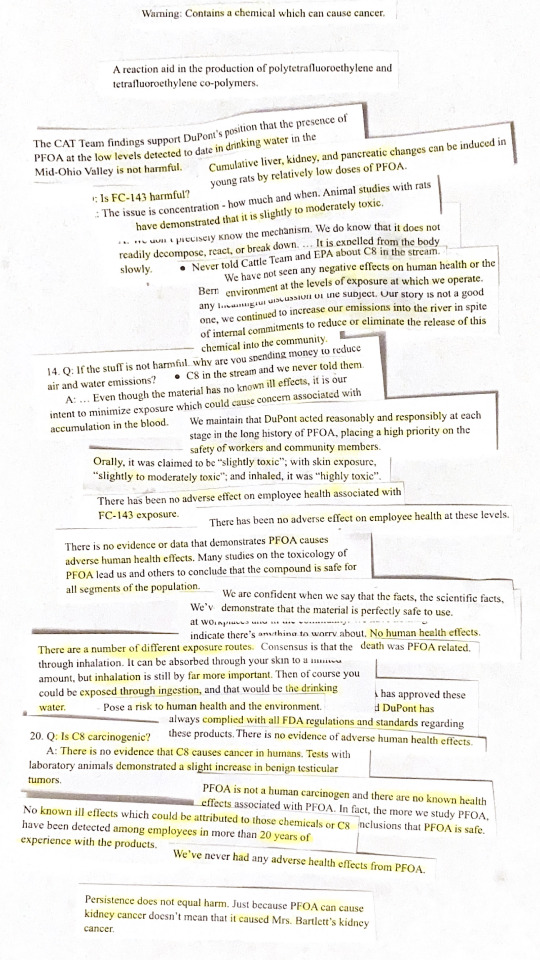

found poem i made after reading Exposure. it can be read two ways.

[Text ID continued: The unhighlighted words read: Warning: Contains a chemical which can cause cancer. / A reaction aid in the production of polytetrafluorothylene and tetrafluoroethylene co-polymers. / The CAT Team findings support DuPont's position that the presence of PFOA at the low levels defected to date in drinking water in the Mid-Ohio Valley is not harmful. / Cumulative liver, kidney, and pancreatic changes can be induced in young rats by relatively low doses of PFOA. / Q: Is FC-143 harmful? A: The issue is concentration - how much and when. Animal studies with rats have demonstrated that it is slightly to moderately toxic. / We do know that it does not readily decompose, react, or break down. … It is expelled from the body slowly. / [bullet point] Never told Cattle Team and EPA about C8 in the stream. / We have not seen any negative effects on human health or the environment at the levels of exposure at which we operate. / We continued to increase our emissions into the river in spite of internal commitments to reduce or eliminate the release of this chemical into the community. / 14. Q: If the stuff is not harmful, why are you spending money to reduce air and water emissions? / [bullet point] C8 in the stream and we never told them. / A: … Even though the material has no known ill effects, it is our intent to minimize exposure which could cause concern associated with accumulation in the blood. / We remain that DuPont acted reasonably and responsibly at each stage in the long history of PFOA, placing a high priority on the safety of workers and community members. / Orally, it was claimed to be "slightly toxic"; with skin exposure, "slightly to moderately toxic"; and inhaled, it was "highly toxic". / There has been no adverse effect on employee health associated with FC-143 exposure. / There has been no adverse effect on employee health at these levels. / There is no evidence or data that demonstrates PFOA causes adverse human health effects. Many studies on the toxicology of PFOA lead us and others to conclude that the compound is safe for all segments of the population. / We are confident when we say that the facts, the scientific facts, demonstrate that the material is perfectly safe to use. / …indicate there's nothing to worry about. No human health effects. / Consensus is that the death was PFOA related. / There are a number of different exposure routes. …through inhalation. It can be absorbed through your skin to a limited amount, but inhalation is still by far more important. Then of course you could be exposed through ingestion, and that would be the drinking water. / Pose a risk to human health and the environment. / DuPont had always complied with all FDA regulations and standards regarding these products. / There is no evidence of adverse human health effects. / 20. Q: Is C8 carcinogenic? A: There is no evidence that C8 causes cancer in humans. Tests with laboratory animals demonstrated a slight increase in benign testicular tumors. / PFOA is not a human carcinogen and there are no known health effects associated with PFOA. In fact, the more we PFOA, … conclusions that PFOA is safe. / No known ill effects which could be attributed to those chemicals or C8 have been detected among employees in more than 20 years of experience with the products. / We've never had any adverse health effects from PFOA. / Persistence does not equal harm. Just because PFOA can cause kidney cancer doesn't mean that it caused Mrs. Barlett's kidney cancer.

The highlighted words read: Contains a chemical which can cause cancer. / low levels detected in the drinking water is not harmful / Cumulative liver, kidney, and pancreatic changes can be induced by relatively low doses of PFOA. / Is FC-143 harmful? studies have demonstrated that it is slightly to moderately toxic. / it does not readily decompose, react, or break down / negative effects on human health or environment at the levels at we operate. / continued to increase our emissions into the river / internal commitments to reduce or eliminate the release of this chemical in the community / never told them / known ill effects could cause concerns associated with accumulation in the blood / DuPont acted reasonably and responsibly, placing a high priority on the safety of workers and community members / Orally, "slightly toxic" / Skin exposure, "slightly to moderately toxic" / Inhaled, "highly toxic" / adverse effect on employee health associated with FC-143 exposure / no adverse health effect on employee health / no evidence or data PFOA causes adverse human health effects. PFOA is safe for all segments of the population. / No human health effects / Death was PFOA related / There are a number of different exposure routes. inhalation far more important. exposed through ingestion, the drinking water / Risk to human health and the environment / DuPont has complied with all FDA regulations and standards / No evidence adverse human health effects / Is C8 carcinogenic? / There is evidence that C8 causes cancer in humans. Tests demonstrated a slight increase in benign testicular tumors. / PFOA is not a human carcinogen, there are no known health effects. PFOA is safe. / known ill effects could be attributed to those chemicals or C8 among employees in 20 years of experience with the products. / We've had adverse health effects from PFOA. / Persistence does not equal harm. PFOA can cause kidney cancer. It caused Mrs. Barlett's kidney cancer. End Text ID.

6 notes

·

View notes

Text

Let's take a step back for a moment, please.

Yes, this isn't easy.

Lego did not completely obliterate that argument. Lego has not succeeded yet at meeting their own metrics at a pilot scale, let alone an industrial one. They are testing things to see if they will work well enough, and so far they have not gotten there. Because - yes - bioplastics and recycled plastics do not have the same material properties as standard plastics, and Lego has not finished solving that problem.

As of August 7, 2023, Lego has not provided any more information about their prototype recycled-plastic bricks.

The initial press release announcing their first prototype plastic bricks was from June 2021.

In that release, the team acknowledges that there is still a long path to getting recycled bricks into production. The formulation they have isn't a recycled version of what regular Lego bricks are made of (that's ABS, which isn't commonly recyclable in practice, particularly if colored). It's a modified version of PET, the plastic in single-use water bottles. That plastic is weaker than ABS and Lego is creating a bespoke formulation to get closer to the material properties they need, and they aren't there yet, because this is not easy.

(Even changing the color of a plastic can change its material properties. One standout example of this - there's a case study in which changing a defibrillator case from blue to red-cross red weakened the plastic enough that the case would fail.)

You can check out the WIRED mag article on the subject for more info. Don't take my word for it on the difficulty of this challenge -

Gregg Beckham from the US Department of Energy’s National Renewable Energy Laboratory, who, in 2018 along with Portsmouth University’s John McGeehan, engineered an enzyme that digests PET, is impressed with Lego’s progress.

“ABS is an amazing material. It is extremely versatile, because you can change the ratio of the A the B and the S. And depending on how you formulate it there are a very large number of versions of ABS plastic that you can make. We literally touch it every day,” Beckham says. “PET, on the other hand, is challenging to formulate in a manner that has the same material properties as ABS like you would find in Lego brick. That is an exceptional polymer science challenge, for sure. This is super exciting.”

As for why it has taken so many decades of plastic production to get to this point, Beckham says that while it would be nice if we could wave a magic wand and just make it happen, in many cases the task is deceptively difficult. “This is fundamental material science and engineering that needs to figure out how to meet the same types of material properties with feedstocks that are either from recycled plastic or become recyclable themselves,” he says. “In the case of ABS bricks, they are neither from recycled plastics nor are they recycled at end of life. This potentially could meet both of those challenges simultaneously.”

And those biobased plastics? They're currently not strong enough (as of this article from Sept 2022) to use for bricks. Only about half of all LEGO sets contain any biobased blocks, and bioplastics represent only about 2% of Lego products.

Side note - because they are colored, both the current ABS and future PET Legos pose major challenges for recycling. Even if they are made of recycled material, they will probably themselves not be recycled.

And lastly - Lego is not unique in its quality control or its standards. Plastic snapping together is extremely common (think of any of the bottles in your fridge whose lids snap closed, think of putting the cap back on a ballpoint pen, think of any number of containers which you can open or close, and then imagine a million more things whose assembly depends on snaps you'll never see). Discarding a mold when it reaches its end of life - everyone does that. Every mold has a limited number of pieces it can make before it wears out. Those things are normal.

No, Lego has it easy. Legos don't have to carry loads. They don't have to be exposed to heat, sunlight, rain, corrosion - any of the perils of the outdoors. They don't have to be safe for food contact, they don't have to hold liquid, they don't have to spin or wear or bend or flex, and they don't matter for human life safety. They aren't like any of the plastic in a car's airbag system which must maintain its performance from brutal cold to scorching heat only to fail perfectly when called upon. They aren't like the ketchup bottle in your fridge which must contain a mildly acidic liquid and keep it airtight. They aren't like the connectors of electrical wires; they're not like the gears in your fan that let it spin for days-hours-years; they aren't like the plastic stint in your great-uncle's heart; they aren't like the soles of your shoes, the chair you sat on in elementary school, the bulletproof windows of the bank, the rubber band around your groceries, or the seal that keeps the oil from spilling out of your bus's engine, the plastic case of the defibrillator in the hospital.

No, Legos get to snap together and sit pretty and still indoors.

There are many, many kinds of plastic. Those plastics do many jobs. Some of those jobs are unnecessary and some of those jobs are very difficult, and specific formulations are necessary to accomplish different tasks. Some things can be recycled mostly-easily, some can be recycled with difficulty, and some cannot be recycled at all because of chemical bonds that form in the plastic. Each has to be sorted and treated differently, and almost all plastics degrade with processing and over their service lives. There is no magic wand. There is only hard work and slightly less hard work.

Don't get me wrong - it is very, very cool that Lego is pursuing biobased and recycled plastics. But it is a pursuit and not a current victory. And it does not mean that the problem of plastics recycling is solved.

418K notes

·

View notes

Text

Thermal Shock Testing Service Market Share, Trends by 2024 to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Thermal Shock Testing Service Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Thermal Shock Testing Service Market , size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Thermal Shock Testing Service Market?

The thermal shock testing service market is expected to grow at a CAGR of 6.1% during the forecast period of 2024 to 2032.

What are Thermal Shock Testing Service?

Thermal shock testing service is a specialized evaluation process designed to assess the resilience and performance of materials or products subjected to sudden and extreme temperature fluctuations. This testing involves rapidly alternating between high and low temperatures to simulate harsh environmental conditions and measure the material's ability to withstand thermal stress. The purpose is to identify vulnerabilities, such as cracking or warping, that could impact the product’s durability and functionality. Commonly used in industries such as electronics, aerospace, and automotive, thermal shock testing ensures that components can endure challenging conditions and maintain their performance over time.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1936

What are the growth prospects and trends in the Thermal Shock Testing Service industry?

The thermal shock testing service market growth is driven by various factors and trends. The market for thermal shock testing services is expanding as industries such as electronics, aerospace, automotive, and manufacturing increasingly require reliable and durable materials. The need for these testing services is growing as companies aim to ensure their products can endure extreme temperature fluctuations and maintain performance in challenging conditions. Factors driving market growth include advancements in testing technology, heightened focus on product quality and safety, and regulatory demands for thorough testing. Additionally, the rising complexity of products and materials necessitates detailed thermal shock assessments to verify their durability and functionality under thermal stress. Hence, all these factors contribute to thermal shock testing service market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By End-Use Industry:

Electronics

Automotive

Aerospace and Defense

Medical Devices

Telecommunications

Others

By Testing Type:

Mechanical Shock Testing

Thermal Cycling Testing

Combined Environmental Testing

By Service Provider:

In-house Testing Facilities

Third-Party Testing Labs

By Temperature Range:

High Temperature Range

Low Temperature Range

Wide Temperature Range

By Product Type:

Semiconductor Components

Electronic Circuit Boards

Mechanical Components

Plastics and Polymers

Glass and Ceramics

Others

Market Segmentation By Region:

North America:

United States

Canada

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Asia Pacific:

China

India

Japan

Australia & New Zealand

ASEAN

Rest of Asia Pacific

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Intertek Group PLC

Bureau Veritas SA

UL LLC (Underwriters Laboratories Inc.)

TÜV SÜD AG

SGS SA

Eurofins Scientific SE

MISTRAS Group Inc.

Element Materials Technology Ltd.

Exova Group Limited

ALS Limited

NTS (National Technical Systems, Inc.)

EAG Laboratories

Applus+ Laboratories

CEMEX Research Group AG

Soprema Group

Others

View Full Report: https://www.reportsandinsights.com/report/Thermal Shock Testing Service-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Thermal Shock Testing Service Market share#Thermal Shock Testing Service Market size#Thermal Shock Testing Service Market trends

0 notes

Text

Plastic Testing Labs in India

Plastic Testing Labs in India. Our Maeon plastic testing lab determines the temperature at which plastics deform when it is subjected to high temperature and load.

#Polymer Testing Services in India#Plastic Testing Services in India#Top Plastic Testing Laboratories in India

0 notes

Text

Polymer Material Testing .Our scientists have the industry expertise to provide you with the information you need to advance product development and launch a successful market launch for the application you're working on.

#Polymer Material Testing Laboratory#Polymer Material Testing in Chennai#maeon laboratories#rubber testing lab in chennai#plastic manufacturing

0 notes

Text

The Role of High Temperature Muffle Furnace in Modern Industries

A high temperature muffle furnace is an essential piece of equipment in various industries, including research laboratories, material testing, and manufacturing. These furnaces are designed to provide a controlled heating environment for applications that require extreme temperatures.

Understanding High Temperature Muffle Furnace

A high temperature muffle furnace is a type of laboratory furnace that can reach temperatures ranging from 900°C to 1800°C. It consists of a heating chamber, typically lined with ceramic insulation, which isolates the sample from direct exposure to heating elements. This feature ensures uniform heating and minimizes contamination, making it ideal for applications like ashing, sintering, and heat treatment of materials.

Key Features and Benefits

Temperature Precision: Advanced digital controllers in high temperature muffle furnaces allow for precise temperature regulation, ensuring consistent results.

Durability: The use of high-quality insulation and refractory materials enhances longevity and energy efficiency.

Versatility: These furnaces are used in industries such as ceramics, metallurgy, and pharmaceuticals for various thermal processing applications.

Safety Measures: Equipped with thermal cutoffs and insulation, these furnaces ensure safe operation even at extreme temperatures.

Common Applications

Material Testing: Many research laboratories utilize a high temperature muffle furnace for determining the properties of metals, ceramics, and polymers.

Heat Treatment: Industries rely on these furnaces for annealing, sintering, and hardening materials.

Ashing and Combustion Studies: They play a crucial role in analyzing organic and inorganic substances by burning off volatile components.

Glass and Ceramic Processing: The precise temperature control in these furnaces is critical for glazing, bonding, and crystallization processes.

Choosing the Right High Temperature Muffle Furnace

When selecting a high temperature muffle furnace, consider factors such as temperature range, chamber size, heating rate, and energy efficiency. Ensuring the furnace meets your specific application needs will maximize its performance and longevity.

Conclusion

A high temperature muffle furnace is a vital tool for laboratories and industries requiring high-precision thermal processing. Its advanced features and broad applications make it indispensable for research and manufacturing. If you are looking for a reliable and high-quality high temperature muffle furnace, Bionics Scientific offers state-of-the-art solutions tailored to meet your needs. Visit Bionics Scientific today for the best furnace solutions.

0 notes

Text

Fire & Flammability Testing Equipment Manufacturer in Delhi, India

In the modern era, safety and compliance have become paramount, particularly in industries that handle materials exposed to high temperatures or fire. Manufacturers, laboratories, and regulatory bodies rely on advanced fire and flammability testing equipment to ensure that materials meet stringent safety standards. Among the leading players in this domain is KDM Global, a Delhi-based manufacturer specializing in high-quality fire testing equipment.

Why Fire Testing Equipment Matters

Fire and flammability testing equipment are essential for assessing the behavior of materials under fire conditions. This testing ensures that products meet safety standards such as ISO, ASTM, BS, and UL, which are critical for industries like railways, construction, and aerospace. By simulating real-world fire scenarios, these machines help determine:

The flammability of materials

Heat release rates (HRR)

Smoke density and visibility

Toxicity of combustion gases

KDM Global: A Trusted Name in Fire Testing Equipment

KDM Global has established itself as a reliable manufacturer of fire and flammability testing equipment in Delhi, India. With a focus on innovation, compliance, and precision, the company serves industries ranging from railways to research laboratories. Here are some of the key reasons why KDM Global stands out:

Comprehensive Product Range: KDM Global offers a wide array of testing equipment tailored to various applications.

Standards Compliance: All products adhere to international standards like ISO, ASTM, and BS.

Customer-Centric Approach: The company prioritizes customer satisfaction by offering customization, training, and support.

Cutting-Edge Technology: From automation to advanced safety features, their machines incorporate the latest technological advancements.

KDM Global’s Fire Testing Equipment Portfolio

Below is an overview of KDM Global’s most popular fire testing equipment:

1. Cone Calorimeter

The Cone Calorimeter is one of the most advanced tools for fire testing, designed to measure the heat release rate (HRR) of materials. It complies with ISO 5660 standards and is widely used in research and development.

Key Features:

Fully automatic operation for ease of use

Accurate HRR and smoke density measurements

Built-in safety mechanisms

2. Smoke Density Chamber

The Smoke Density Chamber evaluates the amount of smoke generated by materials during combustion. It is essential for applications where visibility during fire incidents is critical.

Compliance: ISO 5659-2 Applications: Railways, aerospace, and construction industries

3. Flammability Chamber

This equipment tests the flammability of materials, determining their ability to resist ignition and flame spread. It complies with UL 94 standards and is a staple in material testing laboratories.

Key Features:

Multiple test modes

Compact and user-friendly design

4. Oxygen Index Tester

The Oxygen Index Tester determines the minimum concentration of oxygen required for a material to sustain combustion. It complies with ISO 4589-2 and ASTM D2863 standards.

Applications: Railway materials, textiles, and polymers

5. Toxicity Chamber

The Toxicity Chamber measures the toxic gases released during combustion, ensuring that materials meet safety requirements for human exposure.

Compliance: ASTM E1678 Key Features: High accuracy and reliability

6. Lateral Spread of Flame Tester

Designed to assess the flame spread characteristics of materials, this equipment complies with ISO 5658 standards and is commonly used for railway applications.

7. Fire Propagation Index Tester

This tester determines the fire propagation index of materials and is compliant with BS 476-6 standards. It is particularly useful for evaluating construction materials.

Applications of Fire Testing Equipment

KDM Global’s fire testing equipment serves a variety of industries, including:

Railways: Ensuring that materials used in railway coaches, seats, and interiors meet safety standards.

Construction: Evaluating the fire resistance of building materials like panels, insulation, and coatings.

Aerospace: Testing the flammability and toxicity of materials used in aircraft.

Automotive: Assessing the fire safety of materials used in vehicles.

Textiles: Ensuring fabrics meet flammability standards.

Benefits of Partnering with KDM Global

KDM Global’s commitment to quality and customer satisfaction makes it a trusted partner for fire and flammability testing needs. Here are some benefits of working with KDM Global:

Tailored Solutions: KDM Global provides customized equipment to meet specific testing requirements.

Comprehensive Support: From installation to training and maintenance, the company offers end-to-end support.

High Precision: Their machines deliver accurate results, ensuring compliance with international standards.

Cost-Effective Solutions: Competitive pricing without compromising on quality.

Why Choose a Local Manufacturer?

Partnering with a local manufacturer like KDM Global offers several advantages:

Quick Turnaround: Faster delivery times compared to international suppliers.

Cost Savings: Reduced shipping and import costs.

Personalized Service: Direct communication and better after-sales support.

Knowledge of Local Standards: Expertise in Indian safety regulations and testing needs.

Driving Innovation in Fire Safety

KDM Global’s commitment to innovation ensures that their products remain at the forefront of fire testing technology. By investing in research and development, the company continuously improves its equipment to meet evolving industry requirements.

Contact KDM Global

If you’re looking for reliable fire testing equipment in Delhi, India, KDM Global is your go-to manufacturer. With a wide range of products, exceptional service, and a commitment to safety, they have earned the trust of customers across industries.

Contact Information:

📞 Phone: +91-821847498, +91-7983475310

📧 Email: [email protected]

🌐 Website: https://sites.google.com/view/kdmglobal

Conclusion

Fire and flammability testing are crucial for ensuring material safety and compliance with global standards. As a leading manufacturer in Delhi, India, KDM Global provides cutting-edge solutions that meet the needs of various industries. Whether you’re in railways, construction, or any other sector, KDM Global’s fire testing equipment delivers precision, reliability, and peace of mind. Choose KDM Global for all your fire testing needs and experience the difference of working with a trusted industry leader.

#conecalorimeter#firetestingequipments#indianmanufacturer#railwayproducttesting#railwaymaterialtesting

0 notes

Text

Lactic Acid Manufacturer and Supplier in Delhi

In the bustling industrial landscape of Delhi, one company stands out as a leading lactic acid manufacturer and supplier in Delhi of high-quality lactic acid, playing a crucial role in multiple industries and sustainable chemical solutions. This Delhi-based manufacturer has established itself as a key player in the production of this versatile organic compound, serving diverse sectors with cutting-edge technology and commitment to quality.

Company Overview

Located in the industrial corridors of Delhi, the company has built a state-of-the-art manufacturing facility dedicated to producing pharmaceutical and food-grade lactic acid. With over two decades of experience in chemical manufacturing, the company has developed a reputation for excellence, innovation, and reliability in the production of this essential organic acid.

Manufacturing Capabilities

The manufacturer employs advanced fermentation techniques to produce lactic acid, utilizing carefully selected bacterial strains that ensure high purity and consistent quality. Their production process encompasses:

Precise fermentation of carbohydrate substrates

Advanced purification technologies

Stringent quality control measures

Sustainable manufacturing practices

Their facility can produce multiple grades of lactic acid, including:

Pharmaceutical grade

Food industry grade

Industrial grade

Cosmetic grade

Key Applications

Lactic acid produced by this Delhi-based manufacturer finds applications across various critical industries:

Food and Beverage Industry

Natural preservative

pH regulator

Flavor enhancer

Ingredient in dairy products

Pharmaceutical Sector

Active ingredient in medications

pH adjustment in drug formulations

Excipient in various pharmaceutical preparations

Cosmetic and Personal Care

Skin conditioning agent

pH balancer in skincare products

Chemical exfoliant

Natural preservative

Industrial Applications

Biodegradable polymer production

Cleaning and descaling agents

Chemical intermediate

Textile and leather processing

Commitment to Sustainability

The manufacturer has positioned itself as an environmentally conscious company, focusing on:

Reducing carbon footprint

Implementing green manufacturing processes

Using renewable raw materials

Minimizing waste generation

Developing bio-based chemical solutions

Quality Assurance

Maintaining exceptional quality is paramount for this lactic acid manufacturer. Their quality assurance process includes:

Regular laboratory testing

Compliance with international standards

ISO certifications

Advanced quality control equipment

Skilled technical team

Market Reach and Distribution

With a robust distribution network, the company supplies lactic acid across:

Delhi-NCR region

Other major Indian metropolitan areas

International markets

Various industrial clusters

Technological Innovation

Continuous investment in research and development allows the manufacturer to:

Improve production efficiency

Develop new product applications

Enhance existing manufacturing techniques

Explore sustainable production methods

Conclusion

This Delhi-based lactic acid manufacturer represents the intersection of industrial expertise, technological innovation, and sustainable chemical production. By providing high-quality lactic acid to multiple sectors, the company continues to play a pivotal role in supporting various industries and contributing to India's chemical manufacturing landscape.

With its commitment to quality, innovation, and sustainability, the manufacturer is not just a supplier but a strategic partner for businesses seeking reliable and advanced chemical solutions.

0 notes

Text

Benefits and Uses of Convection oven

In a laboratory setting, convection ovens serve essential functions in various scientific processes, providing controlled heat treatment for precise, consistent results. Here are the main benefits and uses of laboratory convection ovens:

Benefits of a Convection Oven in Labs

Uniform Heat Distribution:

The built-in fan circulates hot air evenly, ensuring consistent temperatures throughout the chamber, which is critical for applications requiring precise, uniform heating.

Reduced Drying Time:

Convection ovens allow for faster drying times by moving heated air across samples. This benefit makes them efficient for drying, curing, and dehydration processes in labs.

Temperature Stability and Control:

Laboratory convection ovens are designed with precise temperature controls, allowing for stable, consistent heating. This is essential for repeatable results and minimizes errors in sensitive applications.

Energy Efficiency:

By reaching and maintaining desired temperatures quickly and consistently, convection ovens in labs are more energy-efficient than conventional ovens, saving time and resources.

Enhanced Safety Features:

Many lab-grade convection ovens include safety features such as over-temperature alarms, automatic shut-off, and heat-resistant doors, which help reduce the risk of accidents in laboratory environments.

Uses of Convection Ovens in Labs

Drying and Dehydration:

Convection ovens are widely used to dry samples, glassware, or equipment by evaporating moisture quickly and evenly, essential in preparing samples for weighing or further analysis.

Curing and Polymerization:

In material science and chemistry labs, convection ovens are used to cure polymers, adhesives, and coatings, which requires precise, consistent heat to achieve optimal material properties.

Baking and Aging:

Convection ovens help simulate aging by exposing materials to specific temperatures over time, useful in testing the durability and longevity of products such as rubber, plastics, and coatings.

Sterilization:

Used to sterilize non-flammable equipment, tools, and glassware by heating to temperatures that destroy microorganisms. Convection ovens are an alternative to autoclaves for items sensitive to moisture.

Annealing and Heat Treatment:

Metals, ceramics, and alloys undergo annealing in convection ovens to relieve internal stress, enhance ductility, and alter mechanical properties, crucial for applications in metallurgy and materials research.

Evaporation of Solvents:

Labs use convection ovens to evaporate solvents safely from chemical mixtures. This is especially beneficial in preparing samples for qualitative and quantitative analysis.

Moisture Content Analysis:

Convection ovens are commonly used to measure moisture content in various materials. Samples are dried at controlled temperatures to constant weight, allowing accurate measurement of residual moisture.

Sample Pre-Treatment:

In analytical labs, convection ovens pre-treat samples by removing moisture, and stabilizing them for testing in procedures like chromatography, mass spectrometry, and elemental analysis.

When Not to Use Convection Ovens in Labs

Convection ovens may not be suitable for highly volatile materials or samples sensitive to oxidation due to the circulating air, which can encourage reactions. In such cases, vacuum ovens or inert gas purged systems are preferable.

In summary, laboratory convection ovens provide reliable, even heat for drying, curing, sterilizing, and other applications that require precise temperature control, making them indispensable for research, quality control, and analytical laboratories.

M-Kube Enterprise is an Indian company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.

#LaboratoryConvectionOvens#LabEquipment#ScientificProcesses#HeatTreatment#ThermalProcessing#MaterialScience#LabTechnology#ResearchTools#QualityControl#AnalyticalLabs#UniformHeatDistribution#DryingAndDehydration#CuringAndPolymerization#SterilizationOvens#SamplePreTreatment#MoistureContentAnalysis#HeatTreatmentEquipment#AnnealingOvens#ConvectionVsVacuumOvens#LabSafetyFeatures#MKubeEnterprise#CustomLabProducts#LabConsumables#GlobalLabSolutions#LaboratorySuppliesIndia#LaboratoryEquipmentAustralia#LabProductsUSA#ScientificSolutionsAsia#LabEquipmentSuppliers#CustomLabSolutions

1 note

·

View note