#Polymer Material Testing Laboratory

Explore tagged Tumblr posts

Text

Polymer Material Testing .Our scientists have the industry expertise to provide you with the information you need to advance product development and launch a successful market launch for the application you're working on.

#Polymer Material Testing Laboratory#Polymer Material Testing in Chennai#maeon laboratories#rubber testing lab in chennai#plastic manufacturing

0 notes

Text

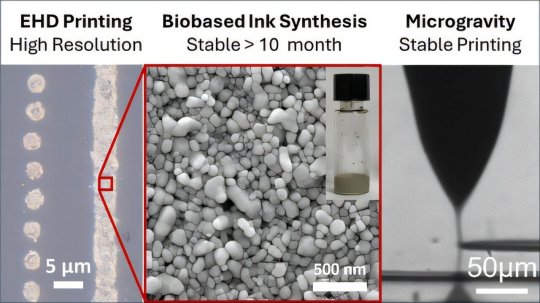

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Link

Casey Wolfe is developing and producing the next generation payload adapter for NASA’s SLS (Space Launch System) super-heavy lift rocket. The adapter is made with some of the world’s most advanced composite manufacturing techniques.NASA/Sam Lott While precision, perseverance, and engineering are necessary skills in building a Moon rocket, Casey Wolfe knows that one of the most important aspects for the job is teamwork. “Engineering is vital, but to get this type of work done, you need to take care of the human element,” said Wolfe, the assistant branch chief of the advanced manufacturing branch in the Materials and Processes Laboratory at NASA’s Marshall Space Flight Center in Huntsville, Alabama. Together with her team, Wolfe is developing and producing the next generation payload adapter for NASA’s SLS (Space Launch System) super-heavy lift rocket. The adapter is made with some of the world’s most advanced composite manufacturing techniques. Wolfe’s work integrates the technical day-to-day operations and personnel management of the composites manufacturing team and additive manufacturing team, balancing production of SLS hardware with the creation of new engines using the latest manufacturing technologies. “A lot of my day to day is in managing our two teams, making connections, building relationships, and making sure people feel supported,” Wolfe explains. “I conduct individual tag ups with each team member so we can be proactive about anticipating and addressing problems.” Wolfe grew up in Huntsville, a place known as the “Rocket City,” but it wasn’t until she visited a job fair while studying at Auburn University for a polymer and fiber engineering degree that she began to consider a career at NASA Marshall. Wolfe applied for and was selected to be a NASA intern through the Pathways Program, working in the non-metallic materials branch of the Materials and Processes Laboratory. Wolfe supported a coating system for electrostatic discharge on the first uncrewed test flight of the Orion spacecraft. Launching December 5, 2014, Orion traveled to an altitude of 3,600 miles, orbited Earth twice, and splashed down in the Pacific Ocean. It was during her internship that Wolfe realized how inspirational it felt to be treated like a vital part of a team: “The SLS program gave everyone permission to sign the hardware, even me – even though I was just an intern,” says Wolfe. “It was impactful to me, knowing that something I had worked on had my name on it and went to space.” Since being hired by NASA, Wolfe’s work has supported development of the Orion stage adapter diaphragms for Artemis II and Artemis III, and the payload adapters for Artemis IV and beyond. The first three Artemis flights use the SLS Block 1 rocket variant, which can send more than 27 metric tons (59,500 pounds) to the Moon in a single launch. Beginning with Artemis IV, the SLS Block 1B variant will use the new, more powerful exploration upper stage to enable more ambitious missions to deep space, with the cone-shaped payload adapter situated atop the rocket’s exploration upper stage. The new variant will be capable of launching more than 38 metric tons (84,000 pounds) to the Moon in a single launch. “While the engineering development unit of the payload adapter is undergoing large-scale testing, our team is working on the production of the qualification article, which will also be tested,” Wolfe says. “Flight components should be starting fabrication in the next six months.” When Wolfe isn’t working, she enjoys hiking, gardening, and hanging out with her dogs and large family. Recently, she signed another piece of SLS hardware headed to space: the Orion stage adapter for the second Artemis mission. With as many responsibilities as Wolfe juggles, it’s easy to lose sight of her work’s impact. “I work in the lab around the hardware all the time, and in many ways, it can become very rote,” she says. But Wolfe won’t forget what she saw one evening when she worked late: “Everybody was gone, and as I walked past the launch vehicle stage adapter, there were two security guards taking pictures of each other in front of it. It was one of those things that made me step back and reflect on what my team accomplishes every day: making history happen.” NASA is working to land the first woman, first person of color, and its first international partner astronaut on the Moon under Artemis. SLS is part of NASA’s backbone for deep space exploration, along with the Orion spacecraft, supporting ground systems, advanced spacesuits and rovers, the Gateway in orbit around the Moon, and commercial human landing systems. SLS is the only rocket that can send Orion, astronauts, and supplies to the Moon in a single launch.

3 notes

·

View notes

Text

Let's take a step back for a moment, please.

Yes, this isn't easy.

Lego did not completely obliterate that argument. Lego has not succeeded yet at meeting their own metrics at a pilot scale, let alone an industrial one. They are testing things to see if they will work well enough, and so far they have not gotten there. Because - yes - bioplastics and recycled plastics do not have the same material properties as standard plastics, and Lego has not finished solving that problem.

As of August 7, 2023, Lego has not provided any more information about their prototype recycled-plastic bricks.

The initial press release announcing their first prototype plastic bricks was from June 2021.

In that release, the team acknowledges that there is still a long path to getting recycled bricks into production. The formulation they have isn't a recycled version of what regular Lego bricks are made of (that's ABS, which isn't commonly recyclable in practice, particularly if colored). It's a modified version of PET, the plastic in single-use water bottles. That plastic is weaker than ABS and Lego is creating a bespoke formulation to get closer to the material properties they need, and they aren't there yet, because this is not easy.

(Even changing the color of a plastic can change its material properties. One standout example of this - there's a case study in which changing a defibrillator case from blue to red-cross red weakened the plastic enough that the case would fail.)

You can check out the WIRED mag article on the subject for more info. Don't take my word for it on the difficulty of this challenge -

Gregg Beckham from the US Department of Energy’s National Renewable Energy Laboratory, who, in 2018 along with Portsmouth University’s John McGeehan, engineered an enzyme that digests PET, is impressed with Lego’s progress.

“ABS is an amazing material. It is extremely versatile, because you can change the ratio of the A the B and the S. And depending on how you formulate it there are a very large number of versions of ABS plastic that you can make. We literally touch it every day,” Beckham says. “PET, on the other hand, is challenging to formulate in a manner that has the same material properties as ABS like you would find in Lego brick. That is an exceptional polymer science challenge, for sure. This is super exciting.”

As for why it has taken so many decades of plastic production to get to this point, Beckham says that while it would be nice if we could wave a magic wand and just make it happen, in many cases the task is deceptively difficult. “This is fundamental material science and engineering that needs to figure out how to meet the same types of material properties with feedstocks that are either from recycled plastic or become recyclable themselves,” he says. “In the case of ABS bricks, they are neither from recycled plastics nor are they recycled at end of life. This potentially could meet both of those challenges simultaneously.”

And those biobased plastics? They're currently not strong enough (as of this article from Sept 2022) to use for bricks. Only about half of all LEGO sets contain any biobased blocks, and bioplastics represent only about 2% of Lego products.

Side note - because they are colored, both the current ABS and future PET Legos pose major challenges for recycling. Even if they are made of recycled material, they will probably themselves not be recycled.

And lastly - Lego is not unique in its quality control or its standards. Plastic snapping together is extremely common (think of any of the bottles in your fridge whose lids snap closed, think of putting the cap back on a ballpoint pen, think of any number of containers which you can open or close, and then imagine a million more things whose assembly depends on snaps you'll never see). Discarding a mold when it reaches its end of life - everyone does that. Every mold has a limited number of pieces it can make before it wears out. Those things are normal.

No, Lego has it easy. Legos don't have to carry loads. They don't have to be exposed to heat, sunlight, rain, corrosion - any of the perils of the outdoors. They don't have to be safe for food contact, they don't have to hold liquid, they don't have to spin or wear or bend or flex, and they don't matter for human life safety. They aren't like any of the plastic in a car's airbag system which must maintain its performance from brutal cold to scorching heat only to fail perfectly when called upon. They aren't like the ketchup bottle in your fridge which must contain a mildly acidic liquid and keep it airtight. They aren't like the connectors of electrical wires; they're not like the gears in your fan that let it spin for days-hours-years; they aren't like the plastic stint in your great-uncle's heart; they aren't like the soles of your shoes, the chair you sat on in elementary school, the bulletproof windows of the bank, the rubber band around your groceries, or the seal that keeps the oil from spilling out of your bus's engine, the plastic case of the defibrillator in the hospital.

No, Legos get to snap together and sit pretty and still indoors.

There are many, many kinds of plastic. Those plastics do many jobs. Some of those jobs are unnecessary and some of those jobs are very difficult, and specific formulations are necessary to accomplish different tasks. Some things can be recycled mostly-easily, some can be recycled with difficulty, and some cannot be recycled at all because of chemical bonds that form in the plastic. Each has to be sorted and treated differently, and almost all plastics degrade with processing and over their service lives. There is no magic wand. There is only hard work and slightly less hard work.

Don't get me wrong - it is very, very cool that Lego is pursuing biobased and recycled plastics. But it is a pursuit and not a current victory. And it does not mean that the problem of plastics recycling is solved.

419K notes

·

View notes

Text

The Complete Guide to Epoxy Tile Grout and Polymer Grout Manufacturing in Andhra Pradesh

Introduction

Andhra Pradesh is rapidly becoming a leading force in construction materials and surface finish solutions, driven by rapid urbanization and modern infrastructure projects. In this evolving landscape, Epoxy Tile Grout and Polymer Grout Manufacturing and Supply in Andhra Pradesh has emerged as a game-changer, offering next-level durability, hygiene, and aesthetics.

As demand surges for high-performance grouts across residential and commercial projects, the region is witnessing a shift towards advanced, locally manufactured solutions. This article dives deep into the innovations, production, and market potential of epoxy and polymer grouts with exclusive insights into sourcing, supply chain, and installation excellence.

👉 Explore premium-grade grouts at Duroxz – Shop Now

Understanding Grout Technologies

What is Epoxy Tile Grout?

Epoxy tile grout is a high-performance two-part system made from epoxy resin and filler powder. Its resistance to water, stains, and harsh chemicals makes it the ideal choice for kitchens, bathrooms, hospitals, and laboratories.

What is Polymer Grout?

Polymer grout is cement-based grout enhanced with polymer additives to improve flexibility, adhesion, and stain resistance. It bridges the gap between traditional cement grouts and high-end epoxy solutions.

Cement Grout vs. Modern Grouts

Cement Grout: Porous and susceptible to cracking

Polymer Grout: Water-resistant and flexible

Epoxy Grout: Durable, non-porous, and long-lasting

Given Andhra Pradesh’s climate — from coastal humidity to interior heat — epoxy and polymer grouts outperform traditional options by maintaining surface integrity and resisting mold and mildew.

Manufacturing Excellence in Andhra Pradesh

Robust Regional Manufacturing

The surge in Epoxy Tile Grout and Polymer Grout Manufacturing and Supply in Andhra Pradesh is anchored by advanced facilities in Visakhapatnam, Vijayawada, Guntur, and Tirupati. Manufacturers benefit from access to raw materials, strong logistics, and skilled labor.

Material Sourcing

Epoxy Resins: High-purity resins sourced from both local and global providers

Polymers & Additives: Blended using proprietary formulations

Fillers & Pigments: Processed in-state, ensuring consistency and quality

Technology & Compliance

Manufacturers utilize automated mixers, quality testing labs, and robotic packaging units. All processes follow ISO 9001, IS, and ASTM standards for top-tier quality and reliability.

💡 Get certified epoxy and polymer grout delivered to your project – Order Now from Duroxz

Product Range and Applications

Epoxy Grout Options

General-purpose epoxy for home interiors

Chemical-resistant for factories and labs

Anti-microbial for hospitals and healthcare

Polymer Grout Formulations

Single-pack high-flex grouts

Water-repellent polymer-modified mixes

UV-resistant colored grouts

Customization and Use Cases

From luxury flooring to commercial tiling, grouts are available in over 40 shades, with custom color-matching on request.

Applications include:

Homes and Apartments

Malls and Airports

Hospitals and Clean Rooms

Hotels and Restaurants

Competitive Edge of Local Manufacturing

Key Advantages

Cost-effective: Low overhead due to local raw material access

Speed: Rapid turnaround on bulk orders

Customization: Products tailored for Andhra’s environment

Support: On-site demos and technical assistance

Choosing Epoxy Tile Grout and Polymer Grout Manufacturing and Supply in Andhra Pradesh means benefiting from local expertise, shorter lead times, and dependable service.

Distribution and Supply Chain Infrastructure

Widespread Access

With a network of over 1,500 dealers, local manufacturers ensure on-time delivery to cities, towns, and even remote job sites.

Bulk orders for builders

Retail presence in major construction hubs

B2B portals and e-commerce for easy access

🚚 Fast delivery and expert consultation – Shop Directly from Duroxz

Quality Testing & Compliance

Rigorous Testing

All batches go through:

Bond Strength Analysis

Thermal Cycling Tests

Water Penetration Resistance

Chemical Immersion Validation

Certifications

Products meet:

IS 15895 (India)

ASTM C881 (USA)

GreenPro and EcoLabel Standards

These certifications make Andhra Pradesh a top destination for quality-certified epoxy and polymer grout products.

Market Trends and Growth Scope

District-wise Growth

High demand is recorded in:

Visakhapatnam & Vizianagaram (residential boom)

Guntur & Nellore (commercial malls, hospitals)

Kadapa & Anantapur (smart city and infra projects)

Export Market

With ports at Kakinada, Krishnapatnam, and Gangavaram, local manufacturers export to:

Tamil Nadu

Telangana

Sri Lanka

The future is promising for Epoxy Tile Grout and Polymer Grout Manufacturing and Supply in Andhra Pradesh, with more companies expanding operations and exports.

Installation & Maintenance Best Practices

Installation Tips

Use mixing paddles for epoxy grout to ensure uniform consistency

For polymer grout, maintain water-to-powder ratio strictly

Avoid direct sunlight curing to prevent shrinkage

Maintenance

Clean regularly using neutral pH cleaners

Avoid bleach and harsh acids for longer life

Reapply sealing if specified after a few years

Case Studies and Success Stories

1. Tirupati Smart City Roads

UV-stable polymer grout used in pavements; 18-month performance review showed zero discoloration or cracking.

2. Guntur Government Hospital

Anti-microbial epoxy grout used in ICU, tested for resistance to sanitizers and high footfall.

3. Vizag Coastal Villas

Salt-resistant polymer grout retained shine and strength despite daily exposure to sea breeze and moisture.

Sustainable and Eco-Conscious Production

Green Initiatives

Low VOC and solvent-free grouts

Recycled packaging materials

Effluent management systems at manufacturing units

Sustainability is central to modern Epoxy Tile Grout and Polymer Grout Manufacturing and Supply in Andhra Pradesh, aligning with India’s push for green buildings and eco-rated materials.

Conclusion

The future of tiling is changing, and Andhra Pradesh is leading the transformation with high-quality, locally manufactured epoxy and polymer grouts. The combination of advanced technology, regional expertise, and sustainable manufacturing makes the state a powerhouse for the construction chemicals industry.

Looking to enhance your project with world-class grouts?

✅ Experience the best in epoxy and polymer grouts – Buy Now from Duroxz

0 notes

Text

Importance of Melt Flow Index Tester in Plastic Industry

Source of Info: https://www.perfectgroupindia.co.in/blog/importance-of-melt-flow-index-tester-in-plastic-industry

Introduction

With the goal to maintain quality control in the plastics industry the Melt Flow Index Tester offers accurate measurement of polymer melt flow. With the help of advanced testers from Perfect Group India , manufacturers can maintain stable material qualities, improve manufacturing environments and follow international standards by obtaining accurate results. Our trustworthy testers save on waste and reduce errors by quickly detecting batch differences and maintaining process stability. If you are searching for original Testing solutions that allow for high quality and effective plastic production pick Perfect Group India.

Use and Functions of Melt Flow Index Tester

A device used in laboratories to measure the flow rate of melted thermoplastic polymers under controlled pressure and temperature settings is called a Melt Flow Index Tester. The result of the test gives important data on the thickness of material and ability to process that is known as the Melt Flow Rate or Melt Flow Index. Manufacturers can use this simple yet efficient test to choose whether a polymer is suitable for a given process like blow molding or extrusion and injection molding. Plastic manufacturers in India as well as worldwide like testing equipment from Perfect Group India because they are designed with accuracy and stability with ease of use in mind.

Importance of Melt Flow Index Testing

1. Quality Control and Consistency

Maintaining stability in raw material quality is the main function of a Melt Flow Index Tester. The features of polymers that come from different batches or suppliers might change greatly. By verifying that these materials succeed properly through production, MFI testing reduces the possibility of errors and reduces downtime.

2. Material Selection and Compatibility

It is important to match the polymer's melt flow properties while creating new goods or changing suppliers. A high MFI polymer may fail to provide sufficient strength while a low MFI polymer might be too heavily thick for injection molding. You can now safely choose the best polymer for every specific use with the help of Perfect Group India.

3. Process Optimization

You can adjust processing factors like temperature and pressure by knowing your polymer's melt flow rate. This results in suitable process times, improved energy use, and less material waste. Therefore, a Melt Flow Index Tester is a tool for quality as well as a way to increase overall performance.

4. Compliance with International Standards

Many industries which include consumer goods, packaging and the automotive industry are required to use plastics that meet with international standards (such as ASTM D1238 or ISO 1133). Your products will be certified to meet these quality standards thanks to the testing equipment. Your items will always be ready for sale thanks to the equipment from Perfect Group India which are made to fulfill these international requirements.

Applications Across Plastic Industry

There are many different sectors that use the Melt Flow Index Tester, including:

Injection molding: Ensures the polymer flows easily into molds.

Film and packaging: Helps maintain thickness and tensile strength consistency.

Automotive plastics: Guarantees durability and material strength.

Recycling: Checks how recycled plastic material weakens.

Consumer electronics: Provides quality in molded parts.

Features of Melt Flow Index Tester from Perfect Group India

We at Perfect Group India provide testing equipment that mixes functionality and ease of use. Features of our tester include:

A digital display with accurate temperature control

Automatic sample cutting mechanism

For longer usage it has a resistant to rust barrel

Design that is simple to clean for fast maintenance

PC connectivity is optional for data collection.

Our MFI Testers are effective and easy to use because of these advanced capabilities, making them suitable for both big industrial installations and small labs.

Choosing the Right Equipment

Think about the following factors while choosing a Melt Flow Index Tester:

Material type (PP, PE, ABS, etc.)

Range of flow index values

Temperature stability

Ease of operation and maintenance

Perfect Group India provides a variety of types, ranging from simple manual units to fully automated systems, to suit different uses. In order to help you in selecting the best model for your use, our technical staff offers complete advice.

After-Sales Support and Calibration Services

Perfect Group India offers more than just delivery for your purchases. We offer complete post-purchase support, which includes installation, instructions and routine testing to make sure your Melt Flow Index Tester stays in top functioning order. What makes us unique is our dedication to client happiness. Our nationwide network of service engineers guarantees instant support anytime you require it.

Conclusion

Purchasing a trustworthy Melt Flow Index Tester is important for success in the plastics industry, where product quality, similarity and safety are all important factors. Along with providing accurate quality control, it improves customer happiness and increases productivity. Being a reputable brand in the polymer testing instrument industry makes us at Perfect Group India satisfied. Our dedication to creativity, accuracy and customer service can be seen by our testing equipment. You select excellence, reliability and peace of mind when you pick Perfect Group India.

With a trustworthy Melt Flow Index Tester from Perfect Group India you can speed up your plastic production process right now!

0 notes

Text

Melt Flow Index Tester

Source of Info: https://www.perfectgroupindia.co.in/melt-flow-index-tester.php

The flow rate of melted thermoplastic materials can be accurately measured with a Melt Flow Index Tester. For the purpose of analyzing the thickness of material and processing performance during molding or extrusion also calculates the melt flow index (MFI). The tester analyzes the speed at which a polymer melts and flows under special temperature and pressure settings and it can be found in quality control and research labs.

Manufacturers can choose suitable materials for specific needs that will improve manufacturing processes and maintain continuous material quality with the help of the results. A key instrument for polymer analysis is perfect for sectors like plastics, packaging and automobiles..

Perfect Group India created a high-performance Melt Flow Index Tester that meets international testing requirements. Here's a detailed look at its specifications:

Temperature Range: Ambient to 400 ºC (PID controlled)

Temperature Accuracy: ±1ºC

Least Count: 0.1 ºC

Diameter of Heater Tube Cavity: 9.55 mm

Dimensions of the Piston Head: 9.47 mm Diameter × 6.35 mm in Length

Dimensions of Jet Holes: 2.095 mm × 8.00 mm Long

Standard Weights Provided: 0.325 kg, 1.050 kg, 2.160 kg, 3.8 kg, and 5.0 kg

Everything to Know About Melt Flow Index Tester An equipment used in laboratories to test the flow rate of melted plastic material is called a Melt Flow Index Tester which is also known as an MFI Tester or Melt Flow Rate Tester. This flow rate is measured in grams per ten minutes and is referred to as the Melt Flow Index. For process control and product quality trust, the MFI gives information about a polymer's thickness and ability to process. A polymer sample is heated to a molten state and then allowed to flow through a standard die while being tested under a fixed load in order to perform the test. The MFI is found by measuring the resultant mass. The behavior of the polymer during processing methods like extrusion and injection molding has a direct connection with this value.

Importance of Melt Flow Index Testing The Melt Flow Index Testing is necessary for product development, quality assurance and material selection. Here's why:

Material Identification: Helps in comparing polymers or grades of the same polymer.

Quality Control: Maintains the same between batches in polymer synthetic methods.

Processing Conditions: Helps in optimizing injection molding and extrusion parameters.

Predicting Mechanical Properties: Provides direct knowledge of tensile strength, stretching and flexibility.

Advanced Temperature Control The PID-controlled temperature system is one of the Melt Flow Index Tester most notable characteristics. The device has a temperature range of ambient to 400 ºC and an accuracy of ±1 ºC, maintaining equal heating to the correct processing temperature for polymer samples. Using a 0.1 ºC minimum count improves test accuracy by providing fine resolution.

Precision Engineered Cavity and Piston The heater tube chamber (9.55 mm diameter) and piston head (9.47 mm diameter × 6.35 mm length) are made with exact measurements. These parts have an importance for maintaining steady pressure and molding during the test which has a direct impact on the MFI values reliability. Perfect Group India is committed to highly accurate manufacturing and makes a huge impact here.

Standard Jet Holes and Weights The jet hole size is 2.095 mm × 8.00 mm that meets international testing standards. With a wide weight range (0.325 kg to 5.0 kg), users can perform MFI testing under a variety of load settings that make this device suitable for both quality control and research uses.

Simple to Use Design Both new and experienced users can take advantage of Perfect Group India's Melt Flow Index Tester. Some of them are:

Digital display for temperature and test time.

Comfortable handle for piston loading.

Durable body construction to withstand high-temperature operations.

Easy maintenance and cleaning features to reduce downtime.

Applications Across Industries Because of its reliability and flexibility, Perfect Group India's Melt Flow Index Tester is commonly used in a variety of industries:

Plastic manufacturing: Check the differences between the quality of the resin.

Automobile business: Make sure thermoplastic materials are always of high quality.

Packaging industry: Verify the flow characteristics of the materials used in containers and sheets.

Research labs: Analyze polymer properties for producing new materials.

Quality assurance labs: Check for ISO and ASTM conformity on a regular basis.

Compliance and Standardization Every Melt Flow Index Tester created by Perfect Group India fits with international testing standards including ISO 1133 and ASTM D1238. This makes sure that the result is trusted and similar across laboratories and industries globally.

Why Choose Perfect Group India? Reliability and trust are important when purchasing specialized testing tools such as a Melt Flow Index Tester. Perfect Group India is unique for the following reasons:

Unmatched Expertise Having worked with material testing equipment for many years, Perfect Group India has knowledge of the requirements of both research organizations and industrial users.

Quality Assurance To make sure regular and trustworthy performance, each unit is put through a strict quality control and performance testing process before shipping.

After-Sales Support Perfect Group India provides complete support, which includes maintenance services to guarantee long-term functionality, installation advice and user instruction.

Competitive Pricing Perfect Group India shows fair prices to make quality accessible to all industries, even if it offers highly accurate production and advanced features.

Customization Options The Melt Flow Index Tester offers unmatched durability when it comes to customization of specific functions or settings based on client demands.

Real-World Impact of MFI Testing with Perfect Group India Customers in India and around the world are praising the Melt Flow Index Tester from Perfect Group India for its:

Durability in heavy-use situations

Similar test results

Easy measurement and functioning

Quick response times to get support and servicing.

Clients who choose Perfect Group India have increased their quality control, reduced material waste and made sure a higher level with client requirements and legal standards.

Conclusion Anyone who works with thermoplastic materials must have the Melt Flow Index Tester. Whether you work in a large quantities manufacturing facility or an R&D lab, accurate melt flow rate measurement is important for achieving success. Perfect Group India provides outstanding testing instruments that have been customized to your testing requirements, with improved features, excellent engineering and outstanding support. If you want to improve your quality control procedures or need trustworthy data for research and development, consult with Perfect Group India, a leading manufacturer of innovative material testing equipment.

0 notes

Text

Ensuring Quality with a Premier Plastic Testing Lab in Delhi NCR

Quality and safety, when it comes to the plastic and polymer products, are of paramount concern in the present competitive market environment. In terms of these products, manufacturers and importers and exporters must be certain that their goods adhere to very stringent national and international standards. This implies that one ought to be in touch with a recognized and resourceful plastic testing lab in Delhi NCR that could offer a comprehensive range of analysis services so as to ascertain product integrity and compliance.

Being a NABL-certified laboratory, the principal polymer testing service provider in and around this area is Atharva Laboratories. Atharva Laboratories has been offering testing services to businesses in various industries for over 17 years whereby it helped in enhancing product excellence along with adherence to laws and regulations.

Significance of Plastic and Polymer Testing

Rooted in interwoven processes for the auto, electronics, packaging, construction, and consumer goods industries, plastics and polymers function as a strong and stable structure. However, performance and safety often differ due to the properties of materials and their modes of processing. Insufficient testing can lead to product failure, safety compromise, and non-compliance with regulatory standards.

With engaged professional testing facilities in polymer testing existing in Delhi NCR, enterprises can strive to:

Ensure Product Safety: All materials meet safety standards for the protection of the end-use consumer.

Improve Product Performance: How well will the material perform under different variables of chemical and mechanical environments--for durability, flexibility, and resistance to weather-induced decay?

Be In Compliance: This directive encompasses recommended requirements imposed by BIS, ISO, ASTM, and IEC.

Build Customer Trust: Deliver high-quality products that fulfill, if not exceed, the expectation of the customer.

Various Testing Operations at Atharva Laboratories

Backgrounded in providing a suite of testing services tailored to diverse industries, Atharva Laboratories operates a robust laboratory with cutting-edge capability (sophisticated machinery) and highly skilled manpower passionate to deliver adversarial results timely.

Mechanical Tests Tensile Strength: Measurement of the resistance to breaking of the material under tension.

Flexural Strength: Ability of the material to resist deformation under load.

Impact Resistance: Assessment of the ability of the material to withstand sudden forces.

Hardness Tests: Determinations of the material resistant to surface indentation.

Thermal Tests Heat Deflection Temperature (HDT): Indicates the temperature at which the material starts to deform under load.

Vicat Softening Point: Point at which the material begins to soften.

Melting Point Analysis: Looks at the temperature at which the substance transitions from solid to liquid.

Chemical Tests Ash Content: Describes the inorganic residue that remains after combustion.

Moisture Content: Analyzed for the amount of water remaining in the material.

Chemical Resistance: Ability of the material to withstand exposure to various chemicals.

Environmental Tests UV Resistance: Evaluates the behavior of material from UV radiation.

Weathering Tests: Simulate long-term exposure to weather conditions.

Thermal Aging: Action of long-term effects of elevated temperatures on performance of material.

Why Atharva Laboratories

Selecting a suited testing partner becomes paramount importance when it comes to product quality and compliance. Atharva Laboratories, in effect, offers some key advantages:

NABL Accreditation: Accredited under ISO/IEC 17025:2017-internationally recognized benchmarks for testing.

Skilled Workforce: It has 17 years of experience in testing plastics and polymers across different sectors.

Sophisticated Infrastructure: Provision of the most sophisticated and advanced instrument for precision test.

On-Time Reporting: Prompt delivery of results as the company ensured accuracy during the stipulated time periods.

Made-to-Order Solution: Customizes a testing service to meet the needs of a specific client.

Industries Served

Atharva Laboratories caters to a diverse clientele inclusive of:

Automotive Manufacturers: Ensuring Components meet safety and performance standards.

Electronics Producers: Validating materials used in electronic devices for reliability.

Packaging Companies: Testing materials for durability and compliance with food safety regulations.

Construction Firms: Assessing materials for structural integrity and environmental resistance.

Consumer Goods Manufacturers: Ensuring products are safe and meet consumer expectations.

Contact Information

Any business seeking reliable plastic and polymer testing lab in delhi ncr may contact Atharva Laboratories.

Delhi NCR (Noida) Locations:

Unit 1: D-115A, Hosiery Complex, Phase-II, Noida - 201305

Unit 2: B-140, Phase-II, Noida - 201305

Hubli, Karnataka:

Unit 3: Plot No. 91, Rayapur Industrial Area, Hubli - 580026

Phone Numbers:

+91–7827983858

+91–8588840612

+91–7065088001

+91–9810281818

Email: [email protected]

Website: www.atharvalab.com

Forming an alliance with a prestigious plastic testing lab in Delhi NCR that is commensurate in quality and safety, like Atharva Laboratories, will make sure that the most rigorous market criteria have been met for the product's safety as well as for the confidence of consumers.

1 note

·

View note

Text

Upholstery Cleaning in Greeley, CO: Premier Methods for Leather Furniture Maintenance

Maintaining the luxurious allure and structural integrity of leather furniture demands a nuanced approach that transcends generic cleaning regimens. In locales such as Greeley, where seasonal fluctuations can affect indoor humidity and dust levels, discerning homeowners and businesses entrust their prized leather pieces to specialists in Upholstery Cleaning in Greeley, CO. Firms like Dougs Carpet Cleaning bring laboratory‑grade expertise and bespoke protocols to every assignment, ensuring that every hide—be it aniline, pigmented, or semi‑aniline—receives the precise care it merits. This article delineates best practices for cleaning and conditioning leather upholstery, empowering readers to preserve sophistication, comfort, and durability across the lifecycle of their furnishings.

Understanding Leather Varieties and Their Specific Requirements

Leather upholstery encompasses a spectrum of finishes, each defined by its tanning process and surface treatment. Aniline leather, prized for its natural patina and supple hand, is dyed exclusively with soluble aniline dyes and lacks a protective topcoat, rendering it vulnerable to stains and abrasions. Semi‑aniline hides incorporate a light protective coating, offering a balance between authenticity and resistance, whereas pigmented leathers bear a more robust polymer finish that shields against spills but may conceal some of the hide’s organic character. Prior to any cleansing operation, Dougs Carpet Cleaning technicians perform a meticulous fabric identification test—often employing pH‑neutral swabs and microscopic inspection—to ascertain the optimal cleaning agent and moisture threshold for each leather type. Such precision underpins effective Upholstery Cleaning in Greeley, CO, safeguarding against discoloration, cracking, or undue surface gloss loss.

Gentle Surface Cleaning: Removing Dust and Light Soiling

Routine removal of surface particulates is the cornerstone of leather care. Secondary contaminants, including household dust, pet dander, and airborne pollen, can abrade leather’s surface finish when left unattended. One common method involves the use of a soft‑bristle brush attachment on a low‑suction vacuum, which lifts detritus without abrading the hide. Alternatively, a lightly dampened microfiber cloth—mist‑sprayed with distilled water—can glide across panels to capture residual soils. For an elevated service, Dougs Carpet Cleaning applies a proprietary foaming cleaner formulated at a neutral pH, which encapsulates oils and light soils within fragile microbubbles. After gentle agitation with a non‑abrasive pad, the foam is vacuum‑extracted, leaving the leather visibly brighter yet entirely free of moisture‑induced distortion. This protocol exemplifies state‑of‑the‑art Upholstery Cleaning in Greeley, CO, wherein balance between cleanliness and hydration is rigorously maintained.

Deep Conditioning and Nutrient Restoration

Leather, being a collagen‑based material, benefits profoundly from periodic replenishment of natural oils that diminish over time through environmental exposure. Failure to compensate for this depletion can precipitate brittleness, fine cracks, and eventual structural failure. A robust conditioning regimen involves the application of lanolin‑infused emulsions or specialized balms containing mink oil, beeswax, and UVA‑filtering agents. Post‑cleaning, conditioners are massaged into the grain using circular motions to promote uniform absorption. Experienced technicians from Dougs Carpet Cleaning monitor ambient temperature and humidity to optimize cure time, ensuring that excess emollient is neither trapped within fibers nor left on the surface to attract dust. Through such calibrated restoration, leather upholstery regains its original suppleness, resists surface fissures, and maintains a rich, inviting patina—hallmarks of exemplary Upholstery Cleaning in Greeley, CO.

Specialty Products and Tools for Stubborn Residues

Certain contaminants—such as ink, adhesive residues, and dye transfer from clothing—necessitate targeted interventions beyond basic cleansers. Proprietary solvent‑based leather spotters, containing isopropyl alcohol blended with emulsifiers, can dissolve ink pigments without leaching natural oils. Similarly, adhesive release sprays reduce tackiness before mechanical removal with soft spatulas. Throughout these procedures, Dougs Carpet Cleaning adheres to strict dwell‑time protocols, preventing overexposure that could degrade topcoats or alter sheen. Ultraviolet inspection lamps further assist in identifying latent organic residues, ensuring comprehensive extraction. By integrating these advanced modalities, practitioners elevate ordinary Upholstery Cleaning in Greeley, CO into a science‑driven discipline, capable of restoring even heavily soiled heirloom pieces to showroom condition.

Preventive Maintenance: Safeguarding Investment and Aesthetic

Beyond reactive cleaning, proactive measures form a critical defense against premature aging. Application of a professional‑grade leather protector—often a fluoropolymer‑based spray—creates an invisible barrier that repels water and oil‑based spills. Dougs Carpet Cleaning recommends reapplying such protectants biannually, tailoring frequency to local climate factors and usage intensity. Moreover, strategic furniture placement away from direct sunlight and heat sources prevents uneven fading and thermal stress. Routine dusting with an antistatic soft cloth curtails particulate buildup, while quarterly professional inspections can identify early-stage cracks or color loss. Collectively, these preventive strategies integrate seamlessly into a comprehensive Upholstery Cleaning in Greeley, CO maintenance plan, preserving both functionality and visual allure.

When to Engage Professional Intervention

While homeowners can perform basic leather care confidently, certain scenarios necessitate expert involvement. Deep crevice soils, multi‑piece sectional assemblies, and intricate tufting present formidable challenges to DIY approaches. Likewise, extensive chemical damage or biological stains—such as those caused by perspiration or spilled dairy—may require enzyme‑based treatments and precision drying systems to prevent mold proliferation. Residents seeking the pinnacle of upholstery revitalization turn to Dougs Carpet Cleaning, whose technicians leverage heated low‑moisture extraction equipment, controlled‑environment drying chambers, and bespoke leather formulas developed for Colorado’s specific environmental conditions. Enlisting such professional services ensures not only stain eradication but also the reinforcement of hide resilience against future wear.

Leather furniture, with its inherent elegance and tactile luxury, commands meticulous care to endure through generations. Through a judicious blend of surface cleaning, deep conditioning, specialized spot treatments, and preventive maintenance, discerning custodians can extend the lifespan of their upholstery while retaining its original luster. Whether addressing minor spills or undertaking full‑scale restoration, the expert methodologies employed by Dougs Carpet Cleaning exemplify the highest standards of Upholstery Cleaning in Greeley, CO. By embracing these best practices, property owners affirm a commitment to both aesthetic refinement and long‑term value retention, ensuring that their leather furnishings remain emblematic of comfort and sophistication.

1 note

·

View note

Text

Polymer Material Testing

Polymer Material Testing and plastic testing lab are among the most versatile materials on the planet, and they are employed in virtually every area of our life. They've changed the way consumer goods and industrial applications like aerospace, automotive, electronics, and packaging are made. Our scientists have the industry expertise to provide you with the information you need to advance product development, assure compliance, and launch a successful market launch for the application you're working on.

#Polymer Material Testing Laboratory#Polymer Material Testing in Chennai#Polymer Material Testing in India#plastic testing laboratory#chennai#india#industry

0 notes

Text

NSF-funded research heads to the international space station on NASA's SpaceX CRS-32 mission

ISS national lab-sponsored investigations aim to enhance drug manufacturing and develop new materials for aerospace, defense, energy, and robotics

Three investigations funded by the U.S. National Science Foundation (NSF) and sponsored by the International Space Station (ISSInternational Space Station) National Laboratory are launching on SpaceX’s 32nd Commercial Resupply Services (CRS) mission, contracted by NASANational Aeronautics and Space Administration. These experiments leverage the microgravityThe condition of perceived weightlessness created when an object is in free fall, for example when an object is in orbital motion. Microgravity alters many observable phenomena within the physical and life sciences, allowing scientists to study things in ways not possible on Earth. The International Space Station provides access to a persistent microgravity environment. environment to advance fundamental science that could lead to improved pharmaceutical manufacturing, new materials with valuable industrial applications, and the next generation of soft active materials with lifelike properties.

These projects build on a strong, multi-year collaboration between the ISS National Lab and NSF, which allocates millions of dollars to space-based projects within the fields of tissue engineering and transport phenomena, including fluid dynamics. To date, more than 30 projects funded by NSF and sponsored by the ISS National Lab have launched to the orbiting laboratory, with nearly 70 additional projects preparing for flight. Below are details about the three NSF-funded investigations launching on NASA’s SpaceX CRS-32.

Improving Medicine Manufacturing

An investigation by Rensselaer Polytechnic Institute (RPI), supported by Tec-Masters, builds on previous research to examine protein fluid flow and clumping—a problem that occurs during manufacturing of protein-based pharmaceuticals that affects the quality of the drug.

“Proteins are used to make various therapies and must be concentrated in medicines to avoid needing to administer large amounts of fluid,” says Amir Hirsa, professor of mechanical, aerospace, and nuclear engineering at RPI. “But above a certain concentration, the proteins tend to form aggregates or clump.”

On Earth, studying protein behavior is complicated by interactions between the solution and the container used to hold it. But on the ISS, researchers can use the Ring-Sheared Drop module to form liquid into a self-contained sphere held between two rings.

Hirsa and his team can use this device to study protein motion and create more accurate models of the factors that lead to clumping, especially during drug manufacturing and dispensation to patients. The team also can test computer models that predict the behavior of proteins of vastly different concentrations and types, such as hormones and antibodies. Findings from this research could help uncover ways to avoid or reverse protein clumping, which would have a significant impact on the pharmaceutical industry.

“Another very important aspect of this work is making this data, which is so difficult to get, available to other scientists through open data repositories,” says Joe Adam, a research scientist at RPI. “Other scientists may see something even more interesting than we do.”

Developing New Materials

An investigation from the University of Alabama at Birmingham, supported by Leidos, will examine the formation of ceramic composites, which have valuable applications in several industries, including aerospace, defense, and energy. The study focuses on polymer-derived titanium carbide and silicon carbide composites that have electrical conductivity, are stable at high temperature, can be made into almost any shape and size, and are lightweight yet strong.

“These materials can be used in different extreme conditions, such as high temperatures and highly acidic or oxidative environments, where other materials become unstable or cannot survive,” says Kathy Lu, a professor in the Department of Mechanical and Materials Engineering.

Studying these composites in microgravity could reveal unique behaviors that cannot be replicated on Earth. Findings from this research could inform new techniques for ground- and space-based manufacturing of materials with specific properties for applications such as heat exchangers, electric systems, energy storage, electrodes, and microsystems.

“Nobody has studied microgravity’s effects on these ceramics, and the results could be helpful for the broader family of ceramics and other possible additives, such as fibers and nanoscale materials,” Lu says.

Studying Active Matter

A research team at the University of California, Santa Barbara (UCSB) will leverage microgravity to study active matter—microscopic particles that use energy to produce motion—and its effects on the separation of non-mixable liquids. These liquids, such as oil and water, separate into concentrated droplets of one substance dispersed in the other, a phenomenon known as active liquid-liquid phase separation (LLPS). This investigation, supported by Redwire Space Technologies, seeks a better understanding of active LLPS, which plays a key role in physics, materials science, engineering, and biology.

“Active fluids are made of billions of small molecular motors that push and pull on each other and generate a turbulent flow, like a windy day stirs the water on a beach,” says UCSB professor Zvonimir Dogic. “A long-term goal is using active matter in microfluidic devices to stir and control the separation of two substances. We’re trying to create simplified systems that start to mimic biology.”

Active LLPS could be used to create materials with lifelike properties, such as the ability to move, change shape, and self-repair, that could be used to develop more lifelike robotics.

SpaceX CRS-32 is scheduled to launch no earlier than April 21, 2025, at 4:15 a.m., from Launch Complex 39A at NASA’s Kennedy Space Center in Florida.

IMAGE: Left: A drop of protein solution less than two and a half centimeters in diameter formed in the RSD onboard the International Space Station. Right: An image showing a computed Newtonian flow diagram for the drop. Credit J. Adam

2 notes

·

View notes

Text

PCR Bottles Market Trends: Rising Usage in Molecular Diagnostics Propelling Future Market Opportunities

The PCR bottles market is witnessing a notable surge in demand, largely driven by the rapid expansion of molecular diagnostics across healthcare, biotechnology, and pharmaceutical sectors. The increasing prevalence of infectious diseases, heightened research activities in genomics, and growing global investment in diagnostic laboratories are fueling the use of polymerase chain reaction (PCR) technologies—and, by extension, the supporting consumables such as PCR bottles. As these trends continue to gain momentum, the PCR bottles market is poised for substantial growth, presenting numerous opportunities for manufacturers, suppliers, and investors.

Rising Demand in Molecular Diagnostics: A Key Growth Catalyst

Molecular diagnostics has emerged as a transformative tool in modern medicine. From early disease detection to personalized treatment strategies, PCR-based testing enables precise and rapid analysis of genetic material. This growing reliance on molecular diagnostics has intensified the need for high-quality, contamination-free lab consumables—including PCR bottles, which play a critical role in the accurate storage and handling of reagents, samples, and other sensitive biological materials.

One of the primary applications driving this demand is infectious disease testing, especially in the wake of global health crises like the COVID-19 pandemic. PCR has become the gold standard for detecting viral RNA, and laboratories worldwide have had to scale up operations. This expansion has directly translated into increased consumption of PCR-compatible containers and bottles, creating a robust growth trajectory for the market.

Material Advancements and Product Innovations

To meet evolving user requirements, manufacturers in the PCR bottles market are increasingly focused on innovation in terms of materials and bottle design. The trend is moving toward high-performance polymers that offer enhanced thermal resistance, chemical stability, and reduced leachability. Polypropylene (PP) and polyethylene (PE) continue to be the most commonly used materials, but newer variants and hybrid materials are being explored to further improve the efficacy of PCR workflows.

Another noteworthy innovation is the integration of ergonomic and automation-friendly features. As laboratory automation becomes more prevalent, PCR bottles are being engineered for compatibility with robotic arms, automated pipetting systems, and high-throughput processing. These improvements not only enhance efficiency but also reduce the risk of cross-contamination—a critical concern in molecular diagnostics.

Stringent Quality Standards Driving Premium Product Segments

PCR testing requires an ultra-clean environment with minimal chances of contamination. As a result, end-users are placing increasing importance on product certifications such as DNase/RNase-free, pyrogen-free, and non-cytotoxic labels. This trend is driving manufacturers to enhance quality assurance protocols and invest in cleanroom production facilities. Premium PCR bottles that meet these stringent criteria are finding growing demand in both research and clinical diagnostics settings.

Furthermore, regulatory compliance is a vital aspect of this market. Bottles that conform to international quality standards such as ISO 13485 and FDA regulations are more likely to be adopted by diagnostic labs and healthcare providers, thereby pushing manufacturers toward more rigorous documentation and quality control practices.

Regional Market Trends: Growth Hotspots

While North America continues to lead the global PCR bottles market—thanks to its well-established healthcare infrastructure and biotech ecosystem—emerging economies in the Asia-Pacific region are becoming significant growth drivers. Countries such as China, India, and South Korea are heavily investing in healthcare modernization and research capabilities, leading to a surge in diagnostic testing and lab setups.

Europe, too, is witnessing strong demand due to the presence of major life science companies and increasing government initiatives in disease surveillance. Meanwhile, Latin America and the Middle East are showing potential for future expansion, particularly as access to healthcare technologies improves.

Competitive Landscape and Strategic Moves

The PCR bottles market is moderately consolidated, with a mix of global giants and niche players competing for market share. Key participants such as Thermo Fisher Scientific, Corning Inc., Eppendorf AG, DWK Life Sciences, and Greiner Bio-One are leveraging their existing networks and product development capabilities to introduce advanced and reliable bottle solutions tailored for PCR applications.

Mergers, acquisitions, and strategic partnerships are common strategies used to strengthen market presence. For instance, companies are collaborating with diagnostic kit manufacturers and laboratory equipment suppliers to offer bundled solutions that include PCR instruments, reagents, and consumables. This integrated approach enhances customer loyalty and simplifies procurement for end-users.

Sustainability and Eco-Friendly Packaging

As sustainability becomes a core consideration in laboratory operations, manufacturers are exploring eco-friendly alternatives for PCR bottle production. This includes using recyclable materials, reducing packaging waste, and implementing closed-loop recycling programs. While these initiatives are still at an early stage, they are expected to gain traction as laboratories worldwide adopt greener practices.

Future Outlook

Looking ahead, the PCR bottles market is expected to maintain its upward trajectory, bolstered by sustained investments in molecular diagnostics, increased focus on public health infrastructure, and continued technological advancements. The rise of point-of-care testing, growing applications in cancer genomics, and the integration of AI and IoT in laboratory workflows will further open new frontiers for growth.

Manufacturers that can offer precision, quality, and compliance—while also innovating on materials and design—will be best positioned to capture value in this evolving market. As molecular diagnostics cements its role in modern healthcare, the humble PCR bottle is proving to be an indispensable enabler of scientific progress.

0 notes

Text

In most industries carbon fibre reinforced polymers is replacing aluminium and steel. Some of the vehicle manufacturers are making use of Carbon fibre reinforced polymers in their some modals. However, some other vehicle manufacturers like Ferrari, have tested carbon fibre reinforced polymers and other composites and evaluated that aluminium is better due some properties. Carbon fibre reinforced polymers are several advantages over conventional materials. It is strongest composite material and the material formation can be altered to suit various types of applications. Several layers of carbon fibres are applied to make the carbon fibre reinforced polymers strong enough to support ant type of application. Carbon fibres can be used in combination with aluminium, Kevlar, glass fibres and other metals to make the materials durable and attain more density to mass ratio. Unlike metals Carbon fibre reinforced polymers show low thermal expansion behaviour. It has less impact of hot or cold weather. Moreover, carbon fibre reinforced polymers has better thermal insulation properties as compared to metals (Sauder et al. 2002: 503). Aluminium, copper and steel are known bets for thermal conductivity. It is has very less density. When it comes to tension bearing capability, carbon fibres can bear an immense tension. None of the materials has the capability to bear such tension as that of carbon fibres according to the density of the fibres. Carbon fibre reinforced polymers are non corrosive materials. Theses materials can sustain the harshest corrosive atmosphere. In this way, the materials are good for the chemical industries. These materials can replace metals which are highly corrosive and weakens the strength of the material. Theses polymers are good conductor of electricity (Selzer and Friedrich 1997: 595). Carbon fibre reinforced polymer is very light material yet strong enough for any purpose. It is 10 times stronger than OR It is of utmost desire since the early years that I impart contribution in thefield of medicine inclined at improving general health and quality of life in the society I live in where I have frequently encountered people with poor sanitation and health practice. As a primary driving force, it encourages me to plan on proceeding to higher learning of professional approach in efficiently promoting public health measures to address health issues from case examination to prevention and treatment of either physical or mental ailments in which administration of remedy can be made by endorsing the right attitude or lifestyle to be fit and sound. Knowing that the competency-based curriculum of postgraduate academic community for public health possesses an educational method that enables each student to gain mastery of the preferred area of specialization as such, through a sequential and well-designed integration of subjects, I hope to seek optimum progress with my foundation of science and relevant courses including application in pursuit of a Master’s degree in Public Health. During my undergraduate years, I had essentially completed general chemistry courses 1 and 2 along with organic chemistry from which I acquired sufficient understanding of dimensional analysis and theoretical concepts of chemical reactions and syntheses. Through rigorous experimentations in biology and microbiology courses taken, I had been able to gain further insights on developing scientific attitudes the habitual manner, finding that a methodological nature of handling work in biological sciences is earned via constant exposure to laboratory operations with the right instruments. It had been quite tedious back then but our cautious and studious efforts paid off on getting accustomed to different procedures requiring certain analyses that are normally capable of determining or verifying how consistent theories are with the implementation of their counterparts in reality. Similar undertakings with anatomy and physiology which were responsible for my full comprehension of structures and functions of living systems have shaped my potential to analyze problems in biotechnology majors. By the time I reached biotechnological studies proper, I realized having to deal with critical thinking at depth for most subjects pertain to combined disciplines of biological science, medicine, and technology. The curricular settings of obtaining a bachelor’s degree in this course at Nnamdi Azikiwe University in Awka, Nigeria, had allowed me greater access to a variety of academic resources in biotechnology and certain fields that occur useful in relation to this particular area of study. Besides a wide range of textbook references, science journals, medical articles, and a complete electronic database detailing scholastic online references had altogether assisted my endeavor in doing research and creative reports. Utilizing the school’s well-sustained facilities for the course, I was able to yield to an extended capacity for laboratory functions where I found it significantly conducive to perform experiments, interpret outcomes hereafter, and become progressively independent at formulating results which satisfy curiosity and clarify doubts made through educated guesses. My personal laboratory experience of Health and Medical Sciences at Houston Community College in 2011 was fulfilling as well to the extent that it increased my appreciation of medicine with applied science and the analytical skills cultivated herein, apparently, can be of huge advantage in my aim to establish a serious career in public health. My previous institution taught us how to properly carry out independent research both as an individual and as a team and in this process, I have realized how delicate medical tasks could get based on the way we managed with assorted projects or assignments. I have discovered the real value in cooperation among group members. At first, it seemed difficult to adjust to the mindset of the rest of the team members considering the diversity of backgrounds they came from but eventually, as everyone could sense some degree of complications which necessitate collaboration of varied competencies, each member learned how to listen and be more open to accept views of others. Read the full article

0 notes

Text

Choosing the Right NABL Certified Lab in India for Accurate and Reliable Testing Services

A NABL-certified laboratory has essential roles in product testing for quality, compliance, and safety to get the products to end users in a competitive marketplace. Be it testing for electronics, textiles, construction, chemicals, or food products, laboratory testing has always been the primary step in ensuring the quality of these products. Testing laboratories, however, may not be equal in terms of their accuracy and recognition.

They are NABL-accredited. They speak about customer satisfaction and avoiding customer risk, giving confidence to the relevant authorities that the test results are reliable- end technically .

Importance of Using a NABL Certified Lab

When dealing with an NABL-certified lab in India, you are not really just opting for a service; instead, you are engaging the services of a recognized profession. Thus, the importance.

Accuracy: Testing procedures are strictly defined in the NABL-accredited laboratory and leave no room for uncertainty in the result.

Compliance: The accredited laboratories follow regulations so that you do not have to be concerned about possible penalties or delays in product approval.

Credibility: The certification lends credibility to your product in both national and international markets.

Efficiency: Saves time and money; the need for re-testing/audits is minimized.

Global Acceptance: The test reports of the NABL-certified laboratories enjoy easy acceptance across borders, making international trade all the more convenient.

What is NABL Certification?

NABL is an acronym for National Accreditation Board for Testing and Calibration Laboratories. NABL is a self-sufficient organization under which testing and calibration laboratories located within India are accredited to international bodies such as ILAC and APLAC: this is one of the functions provided by Quality Council of India (QCI).

From electronics to electrical appliances and textiles to plastics or mechanical components, proximity to reliable local labs helps cushion any fast-track actions toward the go-to-market strategy and certification of their products.

Atharva Laboratories-A Brand To Trust As NABL Certified Lab in Delhi NCR

At Atharva Laboratories, leading Nabl-certified lab in delhi ncr, founded in the year 2007. Accredited by NABL and recognized by all regulatory authorities like BIS, RDSO, and DSIR, thus giving the facility a higher degree of reliability for testing and certification. With over 17 years in the industry, Atharva Labs stands not only for testing but providing insights, compliance confirmations, and results ready for business.

Key Services Offered by Atharva Laboratories

Atharva is a multi-disciplinary lab that provides testing solutions in:

Electrical and Electronics Testing Including safety, performance, and EMC tests for consumer electronics and industrial equipment.

Textile and Garment Testing Quality testing for fabrics and garments to ensure colorfastness, durability, and compliance with OEKO-TEX and other standards.

Mechanical Testing Testing on furniture, industrial materials, packaging, and load-bearing equipment.

Plastic and Polymer Testing Testing for properties and performance of materials under stress, heat, and exposure in a particular environment.

Environmental Testing Testing for compliance with regulatory norms related to air, water, and noise pollution.

Customized Solutions Customized testing as per client's needs or as per the standards of a particular exporting country.

What Sets Atharva Apart?

NABL, BIS, RDSO, and DSIR Accreditations

Over 600 advanced testing instruments

Experienced team of analysts and scientists

Fast report turnaround and real-time client support

Pan-India client base across manufacturing and exports

Test reports accepted by government authorities and international buyers

Atharva Laboratories is not just another NABL certified lab in India; it is a partner walking alongside you in the journey of product development and quality assurance.

Industries Served

Atharva serves all kinds of clients from sectors including:

Consumer Electronics

Electrical Equipment

Textiles and Apparels

Plastic and Rubber

Furniture and Fixtures

Automotive Components

Industrial Machinery

Export Houses and Buying Agencies

Whether you are a startup, MSME, or multinational brand, Atharva Laboratories provides reliable testing solutions to help you scale with confidence.

Contact Information

For all your testing and certification requirements, contact:

Atharva Laboratories Pvt. Ltd. Plot No. 124, Udyog Vihar, Greater Noida, Uttar Pradesh – 201306 Delhi NCR, India

Phone: +91-7827983858 Email: [email protected] Website: www.atharvalab.com

While others name quality, compliance, and trust as pathways leading to success, choosing a right testing partner is worthy of consideration. With NABL assessment such as that of Atharva Laboratories, your products are tested with precision, on speed, and on trust. Working with a NABL accredited lab in Delhi NCR becomes extremely convenient and reliable and, thus, a peace of mind, especially if you are located in or around the capital region. This makes Atharva the apt partner for all your quality assurance needs.

#NABLCertifiedLab#TestingLabIndia#NABLLabDelhiNCR#ProductCertification#ComplianceTesting#BISApprovedLab#AtharvaLaboratories#QualityAssurance#ElectricalTesting#TextileTesting#IndustrialTesting#NABLAccredited#DelhiNCRLab#TrustedTestingPartner#LabTestingServices

0 notes

Text

Testing, To Baijian - Chemical Analysis and Chemical Testing (1) 🔬

Need reliable, efficient, and cost-effective chemical testing services? BaiJian is your one-stop solution for all industrial and specialty chemical analysis!

Why Choose BaiJian?

✅ COMPREHENIVE ("Full")

Wide testing coverage: Raw materials, additives, coatings, polymers, and more!

Multi-standard compliance: ISO, ASTM, REACH, RoHS, and global certifications.

⚡ FAST (Fast)

Express testing options: Get critical results in as little as 24-48 hours.

Streamlined process: Online submission + real-time tracking for maximum efficiency.

🏆 HIGH-QUALITY

CNAS/CMA-accredited labs with cutting-edge equipment.

Expert chemists ensuring precise, reproducible data.

💰 COST-SAVING ("Province")

Competitive pricing: No hidden fees, just transparent rates.

Bulk discounts: Save more on large-volume orders!

Our Key Services:

✔ Purity & Composition Analysis

✔ Physical/Chemical Property Testing

✔ Safety & Regulatory Compliance

Detection features:

1. Full coverage of the testing industry to meet different testing needs;

2. The laboratory is fully covered and locally distributed for testing;

3. Engineers provide one-on-one service to make testing more accurate

4. Free initial inspection, no testing fee charged for initial inspection

5. Free on-site sampling for self-service ordering and express delivery;

6. Short cycle, low cost, and attentive service;

7. Having authoritative qualifications such as CMA, CNAS, CAL, etc;

8. The testing report is authoritative, effective, and widely used in China;

📞 Contact us today! Call: 400-101-7153 (Global hotline,24 hour) 🌐 Visit our website : www.baijiantest.com for an instant quote!

BaiJian = Trusted Data, Faster Results, Smarter Costs! 🚀

0 notes

Text

Why ISO 17025 Accreditation Matters for Plastic Testing Labs?

In today’s competitive global market, ensuring product quality and regulatory compliance is more critical than ever—especially when it comes to plastic products. Whether it’s packaging, automotive components, construction materials, or medical devices, plastics must meet strict standards for performance, durability, and safety. This is where a Plastic Testing Lab plays a crucial role.

But not all testing labs are created equal. One of the most important indicators of a lab’s competence is ISO 17025 accreditation. In this article, we explore what ISO 17025 means, why it matters for plastic testing labs, and how it benefits manufacturers, exporters, and consumers alike.

What Is ISO 17025 Accreditation?

ISO/IEC 17025 is an internationally recognized standard that specifies the general requirements for the competence of testing and calibration laboratories. Developed by the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC), it is the gold standard for laboratory quality systems worldwide.