#polyethylene sheeting

Explore tagged Tumblr posts

Text

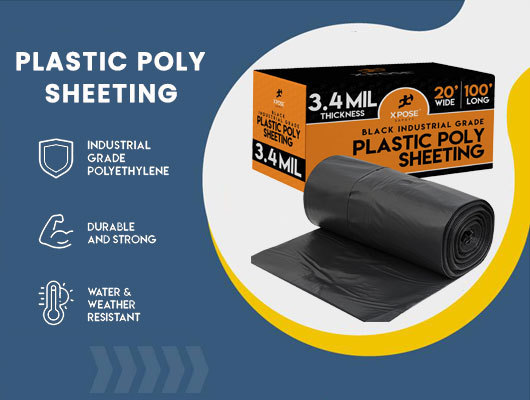

Plastic Poly Sheeting: A Multi-Purpose Protective Material for Your Works

It doesn’t matter if you are working on a renovation or a painting project or need storage solutions; plastic poly sheeting are handy in diverse projects. At The Tarps Wholesaler, you will find the latest in clear poly sheeting rolls and clear plastic poly sheeting rolls that are durable and effective.

#plastic poly sheeting#clear plastic poly sheeting#clear poly sheeting rolls#heavy duty plastic sheeting#poly sheeting#4 mil plastic poly sheeting#polyethylene sheeting#dropcloths#clear plastic sheeting

0 notes

Text

High-Density Polyethylene Sheet

High-Density Polyethylene (HDPE) Sheets are known for their remarkable strength and chemical resistance. They are made from a flexible, long-lasting plastic resin. These sheets are used in many different industries, such as packaging, construction, agriculture manufacturing, outdoor furniture, playground equipment and more. Discover the lightweight nature of HDPE sheets that doesn't compromise on durability, making them an ideal choice for various projects. With a smooth surface and excellent impact resistance, HDPE sheets offer a reliable solution for both indoor and outdoor applications.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#hdpesheet#hdpesheetmanufacturer#hdpesheetsupplier#pp#polypropylene#plasticsheet#plastic#polyethylene#sheets#sheetmanufacturer#ecommerce#marketing#artwork#ppbag#branding#sales#commercial

1 note

·

View note

Text

Best Silicone Rubber Sheets Supplier In Saudi Arabia By Diode Trading Est

Diode Trading Est. stands as a leading polypropylene manufacturer in Saudi Arabia, offering high-quality polypropylene products for various industrial and commercial needs. Our polypropylene materials are known for their durability, chemical resistance, and versatility.

Know More:- https://surl.li/wegyzn

#polyethylene suppliers in saudi arabia#polymer manufacturers in saudi arabia#polypropylene manufacturers in saudi arabia#silicone rubber sheet suppliers in saudi arabia#Saudi Arabia

0 notes

Text

Custom Foam Solutions & Polyethylene Foam Sheets in Aurora, CO

Colorado Industrial Packaging in Aurora, CO, specializes in custom foam solutions, including Polyethylene Foam Sheets in Aurora, CO. Protect your products with precision-cut, durable foam. Visit us for expert packaging solutions tailored to your needs!

https://cippack.com/custom-foam/

0 notes

Text

How HDPE Sheets Are Transforming the Infrastructure of Renewable Energy

Renewable energy sources such as solar, wind, and hydroelectric power have become essential in the transition toward a sustainable future. As demand for clean energy continues to rise, the infrastructure supporting these technologies must evolve to be more durable, cost-effective, and environmentally friendly. One material that has proven invaluable in this transformation is High-Density Polyethylene (HDPE). The use of High density polyethylene sheets in renewable energy infrastructure is revolutionizing the way we think about sustainable construction. In this article, we will explore how HDPE sheets are impacting renewable energy projects, their various applications, and why they are crucial for the future of energy.

HDPE Sheets and Their Unique Properties

At the heart of the renewable energy infrastructure transformation lies the exceptional properties of high density plastic sheets. HDPE sheets are known for their impressive strength-to-density ratio, meaning they are lightweight yet incredibly strong. This is a key advantage when it comes to constructing durable and long-lasting infrastructure in renewable energy projects.

The primary characteristics that make polyethylene high density sheets so valuable are their chemical resistance, UV stability, and moisture barrier capabilities. Renewable energy projects, especially those based outdoors like solar and wind farms, are exposed to harsh environmental conditions. From the scorching heat of the sun to constant exposure to rain, snow, and fluctuating temperatures, the materials used in these projects must be able to withstand these elements without degrading over time. HDPE sheets excel in these areas, maintaining their integrity under extreme conditions, which significantly extends the lifespan of the infrastructure.

Applications of HDPE Sheets in Solar Energy

Solar energy is one of the most popular and widely implemented forms of renewable energy. Solar farms require durable materials for various components such as mounting systems, protective covers, and cable management. High density plastic sheets are increasingly being used in solar farm projects due to their versatility and resilience.

For instance, high density polyethylene sheets are commonly used in the protective layers beneath solar panels. These sheets help to provide a strong foundation that resists erosion, prevents plant growth, and ensures that the panels remain securely mounted for optimal energy capture. The UV-resistant properties of HDPE sheets are crucial in this regard, as solar farms are typically exposed to intense sunlight for prolonged periods. Additionally, HDPE sheets are used in cable trays and conduits to protect the electrical wiring systems from environmental factors and mechanical damage.

In off-grid solar installations, particularly in remote or rural areas, polyethylene high density sheets are used to create durable and weatherproof enclosures for batteries and other electrical components. These enclosures need to be lightweight for easy transportation and installation, but strong enough to protect against environmental challenges. HDPE sheets fulfill these requirements perfectly, contributing to the overall efficiency and durability of solar energy systems.

HDPE Sheets in Wind Energy Projects

Wind energy infrastructure, like solar, requires materials that can withstand harsh environmental conditions while maintaining functionality for extended periods. The flexibility and durability of high density plastic sheets make them an ideal material for various applications within wind energy projects.

One of the critical components in wind energy systems is the foundation and base of wind turbines. High density polyethylene sheets are used as liners to prevent soil erosion and to protect the foundation from water and chemical penetration. Wind turbines are often placed in remote and rugged terrains where the environmental conditions can be unpredictable. HDPE sheets ensure that the structural integrity of the turbine’s foundation is maintained, thereby extending the life of the wind energy system.

Another important application of polyethylene high density sheets in wind energy is in the protection of underground cables. Wind turbines are connected to energy grids through extensive networks of underground cables. HDPE sheets are often used as a protective layer for these cables, shielding them from moisture, corrosive elements in the soil, and physical damage. This not only ensures the safe and efficient transmission of electricity but also reduces maintenance costs and downtime.

Enhancing Hydroelectric Power Systems with HDPE Sheets

Hydroelectric power systems rely heavily on the management and control of water. This is where High density plastic sheet play a crucial role. In hydroelectric dams, HDPE sheets are used as liners for water reservoirs, channels, and containment areas. These sheets act as a barrier to prevent water seepage, ensuring that water flow is efficiently directed toward the turbines for energy generation.

The chemical resistance of high density polyethylene sheets is particularly beneficial in hydroelectric systems, as water can carry various minerals and contaminants that could degrade traditional materials over time. HDPE sheets resist the corrosive effects of such elements, maintaining their integrity and preventing leaks. This not only improves the overall efficiency of the hydroelectric system but also reduces maintenance costs and prolongs the life of the infrastructure.

In addition, HDPE sheets are used to line the pipelines that transport water in hydroelectric facilities. These pipelines are subject to constant pressure and the wear and tear of flowing water. Polyethylene high density sheets provide a smooth, durable surface that minimizes friction and erosion, optimizing water flow and energy production.

Sustainability and Environmental Benefits of HDPE Sheets

The use of high density plastic sheets in renewable energy infrastructure aligns perfectly with the goals of sustainability and environmental protection. HDPE sheets are not only durable and efficient but also recyclable. At the end of their lifespan, these sheets can be reprocessed and used in new projects, reducing the need for virgin materials and minimizing waste.

Moreover, the production of high density polyethylene sheets has a relatively low carbon footprint compared to other construction materials such as concrete or metal. This makes HDPE an attractive option for renewable energy companies looking to reduce their environmental impact. Additionally, HDPE sheets contribute to the overall longevity of renewable energy systems, which means fewer resources are required for repairs or replacements over time.

Conclusion

As the renewable energy sector continues to grow, the demand for materials that are both durable and environmentally friendly will only increase. High density plastic sheets are playing a transformative role in the infrastructure of renewable energy projects, offering a range of benefits from enhanced durability to environmental sustainability. Whether in solar, wind, or hydroelectric power systems, high density polyethylene sheets are proving to be indispensable in creating resilient and efficient energy systems.

By leveraging the unique properties of Polyethylene high density sheet, renewable energy projects can reduce maintenance costs, increase the longevity of their infrastructure, and contribute to a more sustainable future. As technology continues to advance, the role of HDPE sheets in renewable energy will likely expand, further cementing their place as a critical material in the green energy revolution.

FAQs on HDPE Sheets in Renewable Energy Infrastructure

1. What are HDPE sheets?

HDPE (High-Density Polyethylene) sheets are made from a thermoplastic polymer known for its high strength-to-density ratio. These high density plastic sheets are used in various applications due to their durability, chemical resistance, and ability to withstand harsh environmental conditions.

2. How are HDPE sheets used in solar energy systems?

In solar energy projects, high density polyethylene sheets are used as protective layers beneath solar panels to prevent erosion, control plant growth, and ensure secure mounting. They are also used to encase and protect electrical cables, and in off-grid installations, they provide weatherproof enclosures for batteries and components.

3. What are the benefits of using HDPE sheets in wind energy projects?

Polyethylene high density sheets are commonly used as liners to prevent soil erosion and water penetration at wind turbine foundations. They also protect underground cables from moisture and physical damage, reducing maintenance needs and increasing the reliability of wind energy systems.

0 notes

Text

HDPE Plastic Sheet: A Comprehensive Overview

High Density Polyethylene (HDPE) Plastic Sheet has become an essential material in various industries due to its remarkable properties and versatility. This article aims to provide insight into HDPE plastic sheets, their applications, and the factors that influence HDPE Sheet Price in the market.

0 notes

Text

The Importance of PVC Rods and Components in Modern Manufacturing: A Detailed Look at PVC Rod Manufacturers

Polyvinyl Chloride (PVC) is one of the most versatile and widely used plastics in various industries today. Known for its durability, cost-effectiveness, and resistance to environmental factors, PVC plays a crucial role in the manufacturing sector. From the production of pipes and fittings to sheets and rods, the contribution of a reliable PVC rod manufacturer is vital in meeting industrial demands.

In this blog, we’ll delve into the various applications of PVC rods, the advantages they bring, and the role of PVC component suppliers in supporting manufacturing processes. Whether you are involved in construction, agriculture, or industrial equipment, the need for high-quality PVC sheets suppliers is paramount in ensuring a smooth and efficient operation.

The Role of a PVC Rod Manufacturer

PVC rods are an essential component in many industries due to their strength, flexibility, and resistance to chemicals. PVC rod manufacturers specialize in providing high-quality PVC rods that are widely used for machining, welding, and fabricating into various parts and components.

Key Features of PVC Rods

Durability and Strength: PVC rods are known for their ability to withstand harsh environmental conditions and maintain structural integrity over time.

Corrosion Resistance: One of the standout properties of PVC is its resistance to corrosion, making it ideal for environments where exposure to chemicals or moisture is common.

Easy to Fabricate: PVC rod manufacturers produce rods that can be easily fabricated into custom parts, making them ideal for industries requiring precision and customization.

Applications of PVC Rods in Various Industries

Construction and Building Materials: One of the most significant applications of PVC rods is in construction. They are commonly used for producing fittings, flanges, and other structural components that need to be both strong and lightweight.

Agriculture: In the agricultural sector, PVC components like rods and sheets are used in irrigation systems, greenhouses, and water storage tanks due to their chemical and UV resistance.

Machinery and Equipment: Industrial manufacturers rely on PVC rod manufacturers for high-quality rods used in the production of machine parts. These rods are ideal for making pulleys, rollers, and spacers, thanks to their flexibility and machinability.

Why Choose a Reliable PVC Sheets Supplier?

In addition to rods, PVC sheets are widely used in industries such as signage, automotive, and healthcare. Choosing a reliable PVC sheets supplier ensures that you receive a product that meets the specific requirements of your project, whether it's for roofing, cladding, or creating enclosures.

Key Benefits of Using PVC Sheets

Weather Resistance: PVC sheets suppliers provide materials that can endure extreme weather conditions without degrading, making them ideal for outdoor use.

Cost-Effective Solution: PVC sheets offer an affordable alternative to other materials like metal and wood while still delivering exceptional durability.

Versatile Applications: From cladding to the creation of custom components, PVC sheets can be easily fabricated, cut, and molded to suit various industrial needs.

PVC Components: A Vital Part of Modern Manufacturing

The flexibility and durability of PVC components make them indispensable in modern manufacturing. PVC rod manufacturers and PVC sheets suppliers play a pivotal role in providing components that can be customized to meet the demands of different industries.

Advantages of Using PVC Components

Chemical Resistance: PVC components are resistant to a wide range of chemicals, making them ideal for applications in chemical processing plants and laboratories.

Electrical Insulation: Many industries use PVC components for electrical insulation due to their non-conductive properties.

Fire Retardant Properties: PVC is naturally fire-resistant, which adds an extra layer of safety in applications like electrical wiring and industrial equipment.

How to Select the Right PVC Rod Manufacturer and Supplier

When choosing a PVC rod manufacturer or PVC sheets supplier, it’s crucial to consider several factors:

Quality of Materials: Ensure that the manufacturer offers high-quality PVC rods and components that meet your specific requirements.

Customization Capabilities: If you need custom components, select a supplier that offers fabrication and machining services.

Industry Expertise: Partner with a PVC component supplier who understands your industry's specific needs and can provide tailored solutions.

Conclusion

The role of PVC rod manufacturers, PVC sheets suppliers, and PVC component providers is essential in supporting industries ranging from construction and agriculture to industrial machinery and beyond. By providing high-quality, durable, and versatile materials, these manufacturers enable businesses to meet their operational demands efficiently.

Whether you're in need of custom PVC rods for machining parts or PVC sheets for construction, partnering with a reliable supplier is key to achieving the best results. Make sure to choose a PVC rod manufacturer that offers superior products, customization options, and a deep understanding of your industry’s needs.

0 notes

Text

The Foam Company: Your One-Stop Shop for All Things Foam in Australia

The Foam Company has carved a niche for itself as Australia's leading supplier of high-quality foam and polystyrene products. Since 2013, this proudly Australian-owned and operated company has been delivering innovative solutions for a wide range of industries across the country. Whether you're in construction, packaging, events, or anything in between, The Foam Company has the perfect foam product for your needs.

Beyond Polystyrene: A Diverse Foam Product Portfolio

While polystyrene is a core offering, The Foam Company goes far beyond that. Their extensive product catalog boasts a variety of foams to suit any application:

Expanded Polystyrene (EPS) & Extruded Polystyrene (XPS): These versatile foams offer excellent insulation properties, making them ideal for construction projects and packaging applications.

Foilboard Insulation: The Foam Company is a national distributor of Foilboard, a high-performance insulation product that provides superior thermal resistance.

Open Cell PU Foam: This lightweight foam is perfect for applications requiring buoyancy or impact absorption, such as flotation devices and padding.

Closed Cell PE & EVA Foams: These closed-cell foams offer excellent water resistance and are ideal for applications like thermal insulation, gaskets, and packaging.

3D Foam Signage: The Foam Company's specialty is creating custom 3D foam cut-outs for events, theater productions, weddings, and exhibitions, adding a unique and eye-catching touch to any space.

This diverse range of foams ensures that The Foam Company can cater to a wide variety of customer needs.

From Sheets to Custom Shapes: Tailored Foam Solutions

The Foam Company understands that a one-size-fits-all approach doesn't work when it comes to foam. They offer their products in various formats to meet your specific requirements:

Sheets: Available in various thicknesses and sizes, these pre-cut sheets are ideal for DIY projects, insulation applications, and packaging needs.

Blocks: Larger blocks of foam provide the perfect starting point for custom projects. You can cut and shape them to your exact specifications.

Profiles: The Foam Company can create custom foam profiles for specific applications in construction, theming, and other industries.

Custom Shapes: Their expertise in cutting and shaping foam allows them to bring your vision to life. From intricate 3D signage to packaging inserts, they can create anything you need.

This flexibility ensures you get the perfect foam solution for your project, eliminating the need for unnecessary material waste.

Benefits of Choosing The Foam Company

There are several compelling reasons to choose The Foam Company for your foam needs:

Australian-Made Quality: They source and manufacture their products locally, ensuring the highest quality standards and supporting the Australian economy.

Nationwide Distribution: With warehouses in Sydney, Melbourne, Brisbane, Perth, Adelaide, and Hobart, The Foam Company offers fast and efficient delivery across Australia.

Expert Advice: Their team of knowledgeable staff is always happy to answer your questions and recommend the right foam product for your specific application.

Custom Fabrication: The Foam Company's expertise in cutting, shaping, and fabricating foam allows them to create unique solutions that meet your exact needs.

Competitive Prices: They offer competitive prices on their entire range of products, ensuring you get the best value for your money.

By choosing The Foam Company, you're not just getting a product; you're getting a reliable partner who understands your needs and is committed to providing exceptional service.

The Foam Company: Beyond Products

The Foam Company is committed to environmental responsibility and recognizes the importance of sustainable practices. They offer advice on selecting eco-friendly foam options and responsible disposal methods to minimize environmental impact.

Additionally, they actively support the communities they operate in. Whether it's sponsoring local events or partnering with charities, The Foam Company demonstrates a dedication to giving back.

Get in Touch with The Foam Company Today

Whether you're a large corporation, a small business, or a DIY enthusiast, The Foam Company has the foam solution for you. Browse their extensive product catalog online or get in touch with their friendly team to discuss your specific needs. With their commitment to quality, innovation, and exceptional service, The Foam Company is the leading foam supplier you can trust in Australia.

1 note

·

View note

Text

Finding Geotextile Fabric Manufacturers in India?

Shankar Pack is one of the largest PP Geotextiles manufacturers in India. We provide high-strength polypropylene is widely used to filter, stabilize, reinforce, separate, drain, and isolate soils in geotextile manufacturers categories of civil construction applications, our products are quality tested on various parameters to ensure compliance with international industrial standards.

#pp woven geotextiles#pp non woven geotextile#plastic polyethylene sheeting#geotextile manufacturers#non woven geotextile suppliers#non woven geotextile fabric manufacturers#geotextile fabric suppliers#woven geotextile manufacturers in india#geotextile fabric manufacturers in india#geotextile fabric manufacturers in gujarat

0 notes

Text

HDPE T-Rib Liner Sheets

As prominent manufacturers of HDPE T-Rib Liners, we excel in providing superior-quality liners designed to meet stringent industry demands. Crafted from high-density polyethylene (HDPE), our T-Rib Liners offer exceptional durability, tear resistance, and puncture protection. Engineered with T-shaped ribs for added strength and stability, these liners ensure reliable containment and support in various applications, including pond lining, landfill covers, and construction projects. Our commitment to excellence drives us to deliver top-tier liners that guarantee enhanced performance, longevity, and protection for your valuable assets and environmental projects. Trust our expertise for unparalleled quality in HDPE T-Rib Liners that exceed industry standards.

#HDPE#T-Rib Liner#Liner Sheets#High-Density Polyethylene#Geomembrane#Environmental Protection#Waterproofing#Construction Materials#Civil Engineering#Infrastructure

0 notes

Text

youtube

EPE Sheet Production line machine Laxmi Enterprises [email protected]

Polyethylene foam sheet(film),also named as pearl cotton, is a kind of new-type packing material with the features of dampproof, shockproof, sound insulation, heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electronic product, commodity, glass, pottery, electrical household appliances, spraying, furniture, hardware product, toy, etc.

#Polyethylene foam sheet(film)#also named as pearl cotton#is a kind of new-type packing material with the features of dampproof#shockproof#sound insulation#heat preservation and good plasticity . It is an ideal substitute of traditional packing materials and used widely in the packing of electr#commodity#glass#pottery#electrical household appliances#spraying#furniture#hardware product#toy#etc.#Youtube

0 notes

Text

more zombie au :] (1.2k words)

The odor of rot has joined the damp growth of life from pots. Even if some things die off without human aid, there are always stronger elements that thrive in their absence.

The aisles are overgrown. Ritsu brushes past the vines as gently as he can, wooden floor groaning under his worn soles. There’s a gap of empty space in the middle of each aisle that he slots through, eyes roaming the shelves of largely useless things. Stronger stems snag onto his backpack and he tugs distractedly while perusing the labeled pots along the tables.

The barn is quaint, and Ritsu thinks he would love to stay. Moss eats at the boards under his feet and bugs swarm around him in the hot air incessantly, but it’s peaceful and there’s a constant sprinkle of sound to his ears that have grown so used to silence. Whoever owned this place beforehand put up a few wind chimes indoors—they must’ve always had the front entrance open for customers.

It’s a quiet little homemade garden center, or something similar, on the side of the highway. It’s an overgrown property with something dead in the backyard that Ritsu refuses to acknowledge or let Shigeo near. The shingles and boards in the roof have been replaced with polyethylene sheets—a barn-turned-greenhouse, uprooted from the hay and cattle it likely used to house and settled back into the Earth to be a paradise for plants.

There’s a large branch hanging through a hole poked into the plastic overhead. It sways with the wind and the chimes that follow, and Ritsu whistles with the leadless melody and gives it a direction while he studies old seed packets.

They didn’t stop here for any particular reason—a garden center doesn’t have much for apocalypse survivors, but Shigeo has always liked overgrown things. He’d always enjoyed taking care of their mother’s plants back home, and then Reigen’s at the office. His brother likes the humidity of greenhouses and the smell of soil and dirt and must.

He sees the top of Shigeo’s head over the aisles, across the barn. He walks past a shovel hanging on the wall and yelps out a grunt when it clangs to the floor behind him. Ritsu shakes his head and smiles, running his fingers along faded price tags.

The feeling of greenhouses has always had this… wet fullness, to Ritsu.

When he breathes in it’s like he can taste the life that breathes out and it feels like a conversation, a question and an answer, both of which he’s not sure how to articulate. The leaves wave to him and he waves back, the once-active sprinklers pepper his skin with dots, with compliments, with proclamations they are eager to share. The vines weave between fencing just to reach him, just to talk.

He understands why Shigeo likes it, and why he’d always asked to accompany their mother on trips to get new seeds. Ritsu hadn’t really understood, then, how pretty it could be, how full it could feel.

Shigeo had always been right about loving the little things. Ritsu wishes he’d seen that sooner.

His brother ambles down the aisle ahead of him and he listens to the quiet patter of his sloppy footwork, moving around a table of seed trays. His whistles carry across the barn, sort of aimless in their own right instead of leading the wind and the chimes somewhere worthwhile, but the sounds soak into the overhead plastic nicely, so he keeps going.

He pulls back a layering of vines and leaves to scan the contents of another shelf, and then he notices Shigeo stop in his peripherals. His dirty shoes stay planted in the corner of his vision, leaves burying the toes, and Ritsu looks away from the products.

He means to say something, to ask him what’s up even if saying things to Shigeo very rarely results in productivity, but he stops when he realizes his brother’s head is… tilted.

He’s looking at him with as much inquisitiveness as his dulled down awareness can muster, pale eyes flickering across Ritsu’s face like he’s working out some puzzle. He instinctively stops whistling, brain lagging behind on this new info of this new behavior, and the sound fizzles out into a little huff of air that leaves the greenhouse feeling oddly empty.

Shigeo studies him for a moment longer, blinking slowly, and then he straightens his head out as Ritsu stares back. His brother’s gaze lingers there on his mouth, like he’s still confused, like he still expects something to happen.

Ritsu blinks once, twice. The wind chimes call as wind pokes at his greasy spikes, as it prods at the ends of his jacket and fills the silence with a different flavor of itself. The interest in the zombie’s eyes fades a little, gaze straying to the vines around them.

Very tentatively, Ritsu wets his lips and blows. The whistle grabs his brother’s attention immediately, and he’s suddenly tilting his head like a curious dog.

He can’t help the laugh that spills out and makes the whistle a mess of exhales. His shoulders shake a little and he hurries to keep the tune steady and consistent; a few seconds pass and Shigeo tilts his head the other way, exhausted eyes big and more alert than they’ve been in days.

Ritsu experiments, and ventures around with the sound—goes lower and higher and watches his brother twist his head back and forth like he’s trying to understand calculus. There’s something very innocent about it, about the look in his eyes that reminds him of when they were kids and their father would show them magic tricks.

It’s muted by the ever-present fog there in his pupils, but Ritsu thinks he sees a spark of that life in them, of that curiosity born from a mind that knows little. He gives him a simple sensation, a simple experience, and his brother is eating it all up like he’s four again, like he’s new and everything is colorful and unknown and big.

Ritsu watches Shigeo tilt his head back and forth, watches the rusty gears behind his window panes move. He changes tactics, because some sad part of him tells him to, and whistles Shigeo’s favorite song instead.

He remembers the name, but he doesn’t need the name because when he thinks of the tune he thinks of his brother, and that’s all that matters. It’s happy, because Shigeo likes happy music. It’s chipper and yet it meanders, like it’s willingly getting lost, like it’s wandering where it wants to and it’ll eventually find its roots again. It’s happy the whole time. The whole adventure.

Shigeo stops tilting his head, and the gears behind his eyes churn a little bit faster. His gaze clings to Ritsu’s and his brother makes actual eye contact, sinks his own being into Ritsu’s head when he’s least prepared for it. The recognition in his gaze has his soul souring.

He keeps whistling. He doesn’t want to stop, because Shigeo feels like Shigeo right now, and he doesn’t want that to stop.

His brother stares. Ritsu’s grief tints the music.

#qkwrites#zombie au#mp100 ritsu#ritsu kageyama#shigeo kageyama#mp100 shigeo#mp100 mob#every time i think about this au too long i am filled with despair#last line of this . damn i was cookin#ritsu's grief tints Everything he does in this world#he's fucking haunted by it and it's awful bc it's not like he can just.not think abt it#bc the source of his grief is Shigeo. and shigeo still breathes and walks and reacts to things ritsu does like he's alive#and he Is alive. he's very much alive#but there is a lot missing. and ritsu Feels the absence every fucking second#it's like walking into a house that used to have another person in it. and all the familiar sounds ur used to will never be made again#it's very empty and stagnant and the things that Do stay are Different#and it changes a lot. one minute ritsu will be having an okay day—best mood u could possibly have in an apocalypse anyway#and then he looks over and shigeo is doing smth that he used to do Before but it's wrong and a little bit to the left#and without the life in it#pure muscle memory on shigeo's part#and suddenly ritsu's mood drops So fast and he's so Exhausted from these mood swings he keeps having#u know that thing that goes like .uhhhh grief doesn't fade life just gets bigger around it. or smth#yeah ritsu's life isn't rly getting bigger. he is not moving away from the grief bc the source of it keeps staring him in the face

55 notes

·

View notes

Text

Low-density polyethylene (LDPE) sheets have gained prominence in various industries due to their versatility, flexibility, and cost-effectiveness. Businesses across construction, packaging, and manufacturing sectors increasingly rely on these materials for a range of applications. Understanding how to maximize the benefits of LDPE sheets can significantly enhance operational efficiency and product quality. This article explores effective strategies to utilize LDPE sheets in your business, emphasizing their use in construction and other applications.

0 notes

Text

Diaper Materials: A Comprehensive Guide to What Makes the Best Diapers

When it comes to choosing the best diapers for your baby, understanding the materials used in their construction is crucial. Diaper materials not only determine the comfort and fit but also play a significant role in absorbency, skin health, and environmental impact. In this guide, we’ll dive deep into the world of diaper materials, exploring what makes them effective, safe, and eco-friendly. Whether you’re a new parent or simply looking to make more informed choices, this article will help you understand the science behind diaper materials and how they contribute to your baby’s well-being.

Why Diaper Materials Matter

Diapers are one of the most essential baby products, and their materials directly impact performance and safety. High-quality diaper materials ensure:

Superior Absorbency: Keeps your baby dry and comfortable.

Softness and Comfort: Prevents irritation and chafing.

Breathability: Reduces the risk of diaper rash.

Eco-Friendliness: Minimizes environmental impact.

Understanding the materials used in diapers can help you choose products that align with your priorities, whether it’s performance, sustainability, or affordability.

Key Diaper Materials and Their Functions

1. Absorbent Core: SAP and Fluff Pulp

The absorbent core is the heart of any diaper, responsible for locking in moisture and keeping your baby dry. Most modern diapers use a combination of Super Absorbent Polymers (SAP) and fluff pulp.

SAP: These tiny granules can absorb up to 30 times their weight in liquid, turning it into a gel to prevent leaks.

Fluff Pulp: A natural material derived from wood fibers, it provides bulk and helps distribute liquid evenly.

Together, these materials ensure maximum absorbency while keeping the diaper thin and lightweight.

2. Top Sheet: Soft and Breathable Fabrics

The top sheet is the layer that comes into direct contact with your baby’s skin. It’s typically made from non-woven fabrics like polypropylene or polyester, which are:

Soft: Gentle on delicate skin.

Breathable: Allows air circulation to reduce moisture buildup.

Quick-Drying: Wicks moisture away from the skin to prevent rashes.

Some premium diapers also use plant-based materials like bamboo or cotton for a more natural feel.

3. Back Sheet: Waterproof and Flexible

The back sheet is the outer layer of the diaper, designed to prevent leaks while allowing flexibility for movement. It’s usually made from polyethylene or biodegradable materials like PLA (polylactic acid).

Polyethylene: Durable and waterproof, but not eco-friendly.

PLA: Derived from renewable resources like cornstarch, making it a sustainable alternative.

4. Elastic Components: Fit and Comfort

Elastic materials are used in the leg cuffs and waistbands to ensure a snug fit. These are often made from synthetic rubber or spandex, which provide flexibility and prevent leaks.

5. Adhesives and Tapes: Secure Fit

Adhesives are used to bond the layers of the diaper together, while tapes allow for adjustable fastening. These materials are typically latex-free to avoid allergic reactions.

Eco-Friendly Diaper Materials: A Growing Trend

With increasing awareness of environmental issues, many parents are turning to eco-friendly diaper options. Here are some sustainable materials gaining popularity:

1. Bamboo Fiber

Bamboo is a renewable resource that grows quickly without pesticides. Diapers made with bamboo fibers are:

Biodegradable: Breaks down faster than synthetic materials.

Antibacterial: Naturally resists odors and bacteria.

Soft: Ideal for sensitive skin.

2. Plant-Based SAP

Traditional SAP is derived from petroleum, but plant-based alternatives made from corn or sugarcane are now available. These are:

Renewable: Sourced from sustainable crops.

Biodegradable: Reduces landfill waste.

3. Compostable Back Sheets

Some brands use compostable materials like PLA for the back sheet, which can break down in industrial composting facilities.

How to Choose the Right Diaper Materials for Your Baby

When selecting diapers, consider the following factors:

1. Skin Sensitivity

If your baby has sensitive skin, opt for diapers with natural, hypoallergenic materials like bamboo or cotton.

2. Absorbency Needs

For overnight use or heavy wetters, choose diapers with a high-quality absorbent core containing SAP.

3. Environmental Impact

If sustainability is a priority, look for diapers made with eco-friendly materials and minimal plastic content.

4. Fit and Comfort

Ensure the diaper has stretchable elastic components and a snug fit to prevent leaks and discomfort.

The Future of Diaper Materials

Innovation in diaper materials is ongoing, with researchers exploring new ways to improve performance and sustainability. Some exciting developments include:

Smart Diapers: Embedded with sensors to monitor hydration levels and health indicators.

Fully Biodegradable Diapers: Made entirely from plant-based materials that break down naturally.

Reusable Diapers: Modern cloth diapers with advanced absorbent layers for convenience and eco-friendliness.

Conclusion

Diaper materials play a critical role in ensuring your baby’s comfort, health, and well-being. From absorbent cores to eco-friendly alternatives, understanding these materials can help you make informed choices that align with your values and needs. Whether you prioritize performance, sustainability, or affordability, there’s a diaper out there that’s perfect for your little one.

By staying informed about the latest advancements in diaper materials, you can provide the best care for your baby while minimizing your environmental footprint. So, the next time you shop for diapers, take a closer look at the materials—they make all the difference!

5 notes

·

View notes

Text

The Ultimate Guide to Nylon Sheet and Rod Suppliers: Spotlight on Polestar Polymers

When it comes to sourcing high-quality nylon sheets and rods, choosing the right supplier is crucial. Polestar Polymers stands out as a leading manufacturer and supplier in this domain, offering a range of premium nylon products that cater to various industrial needs.

Why Choose Polestar Polymers?

1. Comprehensive Product Range: Polestar Polymers offers an extensive selection of nylon products, including both extruded and cast nylon rods, sheets, and custom components. This versatility ensures that you can find the right material for any application, from automotive to industrial machinery.

2. Superior Quality: Quality is a cornerstone at Polestar Polymers. Their nylon products are manufactured using top-tier raw materials and state-of-the-art processing techniques. Being ISO 9001:2015 certified, they guarantee materials and components that meet the highest industry standards.

3. Advanced Manufacturing Capabilities: With advanced in-house facilities for CNC milling, turning, and welding, Polestar Polymers can deliver precision-cut and shaped nylon products tailored to your specific requirements. Their capabilities include cutting sheets up to 3000mm in length and machining rods up to 600mm in diameter.

4. Global Reach: Polestar Polymers has a significant presence in both domestic and international markets. Their global collaborations and comprehensive logistics ensure timely delivery and support across various regions.

5. Industry Applications: Nylon products from Polestar Polymers find applications in numerous industries, including mechanical engineering, food processing, oil and gas, medical, and chemical industries. Their products are designed to withstand challenging environments, offering durability and performance.

6. Commitment to Innovation: With over 20 years of experience, Polestar Polymers continually evolves to meet the dynamic needs of the market. They provide end-to-end services, from material selection to final component machining, ensuring optimal solutions for their clients.

Featured Nylon Products

Extruded Nylon Rods and Sheets: Ideal for mechanical components like gears, bushings, and pulleys.

Cast Nylon Components: Suitable for heavy-duty applications requiring high strength and wear resistance.

Additional Services

Polestar Polymers also offers a range of machining, fabrication, and engineering services, ensuring that customers receive fully customized solutions. Their expertise includes sawing, planing, CNC milling, and turning, providing precision and efficiency in production.

For more information on their products and services, visit Polestar Polymers.

Conclusion

Polestar Polymers is a trusted name in the nylon manufacturing industry, known for its quality, innovation, and customer-centric approach. Whether you need standard nylon sheets and rods or custom-engineered components, Polestar Polymers delivers solutions that meet the highest standards of performance and reliability.

#polestar polymers#hdpe sheets manufacturers#pom plastic sheets#plastic materials manufacturer#polyethylene uhmwpe rods#plastic component manufacturers#plastic manufacturers#plastic components#plastic component manufacturer

0 notes