#polyester yarn for EPDM

Explore tagged Tumblr posts

Text

What is fish suction house? and every aspect of suction hose basics

In the fishing industry, a fish suction hose is essential because it makes it easier to move fish from nets to processing facilities quickly and carefully. These hoses, which are usually made of sturdy, fish-friendly materials like PVC or rubber, guarantee the secure handling of the catch. The hose's elasticity makes it simple to manoeuvre, which reduces the stress the fish experience during the transfer procedure. Suction pressure resistance is provided by the reinforcement layers, and size changes allow for varied fishing boats and processing configurations. Respecting industry guidelines and norms guarantees that the catch is treated humanely. Fish suction hoses are vital equipment that support ethical and sustainable fishing and seafood processing methods.

A strong and adaptable conduit for a range of industrial uses is the fiber-reinforced suction hose. This hose works well for suction and discharge applications. Typically, it is composed of a combination of sturdy materials, such PVC, and is strengthened with synthetic fibres. Because of its fibre reinforcement, which ensures flexibility and boosts strength, it is simple to manoeuvre and adjust to different operational requirements.

The hose is a common tool in mining, construction, and agriculture. It is effective at moving water, slurries, and even light chemicals. It is a solid solution for severe situations because of its longevity and resistance to kinking. With an emphasis on durability, adaptability, and functionality in a range of situations, the fiber-reinforced suction hose complies with industry standards and provides a safe and efficient method of conveying fluids.

When suction or hoover is used to move liquids or gases, a reinforced suction hose is a sort of specialist tubing that performs effectively. By including additional layers of reinforcement, this type of hose is made to withstand the negative pressure generated during suction operations.

Highlights of a reinforced suction hose consist of:

Strength and Durability: The hose is now stronger, more resilient, and less likely to collapse in a hoover thanks to the additional reinforcement.

Flexibility: These hoses are made to be flexible in spite of the reinforcement, making handling and installation simple.

Suction operations using reinforced hoses are less prone to cause kinking, ensuring a constant and efficient flow.

Versatility: A wide range of applications in numerous industries, such as manufacturing, construction, and agriculture, are catered to by the reinforced suction hoses' diverse diameters and configurations.

The materials used to make these hoses are suitable with the specific liquids or gases being transported in order to prevent any unfavourable reactions.

The 4 polyester yarn reinforced suction hose is a robust and versatile tube for dependable suction applications. Its four layers of sturdy polyester yarn provide improved resistance to collapse and tensile strength, guaranteeing reliable performance in a range of industrial environments. The hose is flexible enough to be easily handled and manoeuvred even with its reinforced design. It works well at efficiently moving liquids or gases, making it appropriate for industrial, agricultural, and construction applications.

Because of its chemical compatibility and resilience to temperature changes, the hose is a dependable option for a variety of environmental circumstances. This reinforced suction hose is a sturdy and dependable option for sectors needing strong suction capabilities. It is equipped with secure couplings and is made to meet industrial standards.

Flexibility is ensured by the EPDM material, making handling and manoeuvrability during suction procedures simple. It efficiently distributes water, liquids, and mild chemicals, making it perfect for use in industry, construction, and agriculture. The EPDM suction hose is appropriate for a wide range of temperatures and climatic situations due to its excellent suction capabilities and durability.

0 notes

Text

Textile production is India's second major economic industries

About the quota before the end of the market share of polyester yarn for EPDM Indian textiles set too high, but industry leaders and analysts say India is not competitive for the future and prepare for surge in demand. From January 1, 2005 onwards, all WTO member countries will be lifted all restrictions on textiles and clothing, it will produce low-cost countries, paving the way for large.Widely expected that China will occupy 50% of U.S. apparel import market, China in 2002 in the U.S. apparel import market share is 15%. The world textile market, 400 billion U.S. dollars, experts said that India will soon increase its market share doubled to 6%. Analysts estimate that, in order to keep up with demand in the next 5-6 years, the Indian textile industry needs 1.4 trillion rupees (310 million) investment.Big manufacturers Arvind Mills and Raymond India Company, and the benign operating companies such as Welspun India, has expanded production capacity, improve the export plan last year, rapid growth of their market share. India's largest denim factory Arvind's market share increased by more than 75%, while India's largest fabric market share in factory Raymond grew by over 80%.

Textile manufacturer Welspun's sales doubled.Khandwala's Sunil Agarwal said, "Our textile and apparel exports to nearly 70% of the quota countries, so we can expect after the abolition of quotas on exports of Indian goods. But in the last 10 years, India's market share of almost no growth Therefore, we can not blindly optimistic. "EU in 2001 and 2003, imports of Chinese textiles and clothing almost doubled, partly due to the quota since 1994, gradually be removed.U.S. textile manufacturers have been lobbying the Government to set up a new China textile and apparel import tariffs, while the EU is imported from China to develop a special monitoring system. India has rich raw materials, low cost and skilled labor advantages, these advantages lead to foreign buyers can not rely entirely on China.New Delhi hoped that by 2010 the scale of annual exports of textiles increased to 50 billion U.S. dollars, is now more than four times. But analysts said that to achieve this goal, large enterprises must enhance the value chain, healthy businesses should work to high-end market, small business should be to consolidate market share.

Textile production is India's second major economic industries, second only to agriculture, nearly 35 million workers. India has one billion population.Textile industry in a few large integrated companies, as well as hundreds of small companies, large companies with multinational clients, small companies rely heavily on quotas and trade protection policies was able to survive. Analysts said that many smaller companies will be shuffling out. Some companies may scale up, but they will face tremendous price pressure, the profit will be reduced.Ranmond company will invest 1 billion rupees in the suit, trousers, formal suits and denim clothing production, will invest 1.27 billion rupees in denim production, plans to raise annual output to 30 million meters, to become India's second largest denim fabric manufacturer. World's fifth largest towel manufacturer Welspun's production capacity more than doubled. It produces towels, bathrobes and bed linens, nearly 90% of exports to the U.S., major retailers, including Wal-Mart, JC Penney, and Shopko stores.

1 note

·

View note

Text

To become a physical therapist,

Find Physical Therapy Courses in polyester yarn for EPDM the United States and Canada. If you are interested in healthcare and have a genuine desire to help people, you can elect to enroll in a variety of physical therapy courses; with the prospects of earning a diploma, certificate or degree.

The uniqueness of physical therapy courses is that students will learn how to manually help patients through a variety of movement therapies, electrotherapeutic conveyances, functional training and other physical appliances. In addition, physical therapy courses teach candidates how to treat and manage common conditions like chronic pain (arthritis, back and neck pain, etc.), musculoskeletal conditions (cerebral palsy, fibromyalgia, etc.), sports injuries, and headaches, among several others.

In physical therapy courses, students are taught about anatomy and physiology, biomechanics, chemistry, biology, exercise and functional training, pathology, kinesiology, human growth and development, neuroanatomy, and associated subject matter.

To become a physical therapist, students must successfully complete all required physical therapy courses, and must pass the National Physical Therapy Examination in order to become a practicing physical therapist. Additionally, many states require that practicing physical therapists maintain licensure by taking continuing education physical therapy courses.

Once graduates have completed all physical therapy courses, and have become licensed in their respective state, they can work in several healthcare-related environments including physical therapy centers, rehabilitation clinics, hospitals, nursing homes, and other medical facilities. On average, physical therapists have the potential to earn between $47,000 and $64,000 annually.* (Pay commensurate with education and experience.)

If you (or someone you know) are interested in finding physical therapy courses, let professional training within fast-growing industries like massage therapy, cosmetology, acupuncture, oriental medicine, Reiki, and others get you started! Explore career school programs near you.

0 notes

Text

Reinforced Rubber Air Hose – Utility for Air Conveying

Rubber air hoses usually adopt SBR, NR or EPDM as tube material. The reinforcement layers are available in polyester fiber spiral line, high strength synthetic yarn and high strength synthetic cord. Finished products with bright appearance can remain flexible at temperatures ranging from -40 °C to +180 °C.

https://www.air-hose.org/material/rubber-air-hose.html

This type of high-pressure air hose is ideally for compressed air and inert gas delivering. Major application areas include mining, shipbuilding, civil engineering construction and casting.

STYLE Three rubber air hoses are reinforced by polyester fiber spiral line. QLR-01P: EPDM + polyester fiber + EPDM

Two rubber air hoses are reinforced by synthetic yarn. QLR-02SY: SBR/NR + synthetic yarn + SBR/NR

Five rubber air hoses are reinforced by synthetic cord. QLR-03SC: SBR/NR + synthetic cord + SBR/NR

We Keep Increasing the Product Properties

High pressure resistance & dimension stability. Superior torsion and kink resistance. Excellent wear resistance. Good aging & flame resistance. Resistance to cold weather and kink. Reusable fittings are available. A black rubber air hose is reinforced with synthetic yarn. There is a roll of rubber air hose with black color There is a double reinforcement rubber air hose. A black rubber air hose is reinforced with synthetic yarn. There is a roll of rubber air hose with black color There is a double reinforcement rubber air hose. A black rubber air hose is reinforced with synthetic yarn. Product Info

QLR-01P Parameter

QLR-02SY Parameter

QLR-03SC Parameter

Construction Tube: EPDM/SBR/NR. Reinforcement: high strength polyester yarn/synthetic yarn/synthetic cord. Cover: EPDM/SBR/NR. Temperature Range: -40 °C to +100 °C (-40 °F to 212 °F). Warranty: 1 year limited warranty. Fitting: 1/4" NPT. Color: yellow, red, blue, black, etc. Package: wrapped with plastic film, then packed with woven bag. Or packed as customers' requirement. APPLICATION The multipurpose utility hoses are widely used for compressed air and inert gas conveying in marine, mining, tunneling, drilling rigs, oil & gas exploration, shipbuilding, offshore & tank cleaning, etc.

Civil engineering equipment components. Machine service. Engine components. Pneumatic washing apparatus. Conveying air in pneumatic tool. Vehicle air brake system. Unprotected air circuit. Cleaning agents. Other applications: convey water, oil, gasoline, fuel, etc. Not suitable for transfer of petroleum products.

A worker is operating the breaker hammer on the road.Rubber air hose for breaker hammer A staff is working with compressed air gun.Rubber air hose for Mamachining engineering A free air station installed with red rubber station.Rubber air hose for free air station

1 note

·

View note

Text

USES OF POLYETHYLENE FILMS

Polyethylene (PE) films come to the rescue when shielding objects from specks of dust, spoilage, scratches, surfactants, humidity or any other undesirable adulteration. Along with a wide range of thickness and functionality, there are various monikers associated with PE films, namely Visqueen, poly-sheeting, polyethylene sheet and plastic film. The application of these films varies drastically; for instance in construction projects they act as vapour retarders, window films, flooring and countertop projections etc, while also being the primary material in the retail industry for packaging and manufacturing of products. Derived from petroleum and composed of hydrocarbons, let's take a look at the multiple types of Polyethylene films Megaplast offers, based on their specificity of need:

Stretch Films

Commonly designed to tightly bind around a product and keep it intact, the Megaplast stretch films with widths up to 5 metres protect packages from scratches, stains, and unwarranted contamination, especially when transiting from various locations. These films are made from linear low-density polyethylene (LLDPE) thus giving them their highly stretchable property. With 5 layers of high-quality polyethylene for more strength, these stretch films can stretch up to three times more than their original structure. The benefits of the stretch films include holding boxes together on a pallet for transportation to discourage load tampering and reduce worker injury.

Cling Films

Also known as plastic wrap or food wrap, the Megaplast cling films are befitting for storing and wrapping food items. With a thickness of approximately 0.0005 inches or less, this fine film “clings” to many smooth surfaces retaining its firmness without needing an adhesive to keep it attached to the opening of a container or a food item. The cling films are usually made of low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) that can add tensile strength for additional durability. As an essential member of one’s kitchen, the cling film gives an air-tight covering around cooked/uncooked dishes to protect their original form and nourishment by averting contamination and spoilage.

Agriculture Films

The increased demand for effective crop productivity and protection of quality calls for the usage of Megaplast Agriculture films whose plasticulture range includes Mulch Films, Pond Liners and Silage Films. Mulch Films help prevent moisture loss and pests, improve crop yield and precocity as well as maintain the soil temperature. Pond Liners immensely contribute to the conservation of water and marine habitat by restricting risks like UV rays exposure due to their puncture-resistant and impermeable membrane. As for Silage Films, with widths up to 24 metres, they are designed for the optimal preservation and fermentation of silage, hay and maize in areas with a short growth period of herding grass. Other than PE, the Silage films are also composed of Ethylene-vinyl acetate (EVA) and Ethylene Butyl Acrylate (EBA).

Industrial Films

Goods during transit need to be protected with the utmost care, which Megaplast ensures is accomplished when secured with Industrial films. Industrial films come in various forms such as Polyester yarn packing which is a thermoplastic made from polymeric melt and can be found in multiple dyes. Similarly, Rubber packing/ rubber gaskets is also an excellent material for forming seals and closures. Industrial rubber films usually comprise Ethylene Propylene Diene Monomer (EPDM), Silicon and other materials depending on the specifics required for packing.

In conclusion, Polyethylene Films come in a gamut of forms for a diverse range of applications. We can help you get the appropriate PE films with respect to your needs.

Send us your requirements at [email protected] or contact us at +91 022 - 6106 6000.

Also to know more: https://www.megaplast.in/blog-single.php?slug=uses-of-polyethylene-films

0 notes

Text

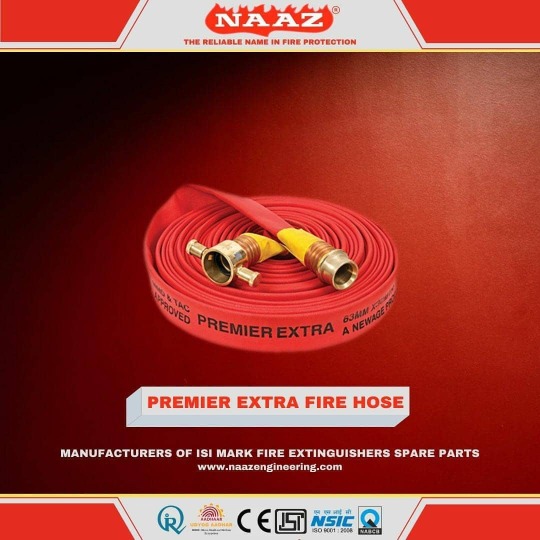

fire hoses

At Hydrofit Group, we are known for our premium quality fire hoses that feature rubber-lined jackets. The woven jacket covering the hose is made of premium polyester yarn, however, the lining is made of superior quality synthetic EPDM rubber. The flexible range of fire hoses also shows resistance to ozone, ageing, wear and tear, weather and seawater. The certified and top-graded range of fire hoses are known to combat fire and include an external coating of exclusively formulated synthetic elastomer. The hoses provide high resistance to abrasion and ease of handling. They have an amazingly long-service life and includes ease of repair.

0 notes

Link

Sep 02, 2021

We are providing daily prices of fibres of different grades for major cities in India. Prices are given for DTY, FDY, POY, Polyester chips, PET, polyester industrial yarn, PA-6, nylon yarn (POY, DTY, FDY), nylon tyre cord, spandex, pure polyester yarn, spun rayon, reactive dyes, disperse dyes, viscose filament, polypropylene. 8We cover a total of 40 different grades of fibres and we are expanding our coverage to around at least 80 different grades going ahead 8In rubber we have begun giving prices for NBR, butyl rubber, BIIR, CIIR, EPDM, isoprene rubber, chloroprene rubber, fluorine rubber, SBR, PBR, SBS, SEBS, precipitated silica, silane coupling agent, fumed silica, standard rubber, RSS ribbed smoked sheet rubber, compound rubber, carbon black, rubber accelerator, and antioxidant. We cover around 100 grades and this coverage too will expand

0 notes

Photo

Designed for Aggressive Fire Fighting Applications Circular woven Jacket made up of 100% Polyester yarn High Quality Synthetic EPDM Rubber Lining External Coating of specially formulated Synthetic Elastomer Heat and Abrasion Resistant #Manufacturers #fire #firesafety #safetytools #fireprevention #firealarm #extinguisher #fireextinguisher #firefighter #smokevents #safety #drychemicalpowder #fireworks #NaazEngineeringWorks #firefighterlife #firedepartment #firesigns #firetruck #fireservice #safetyfirst #naazengineering #ABCfireextinguisher #modulartype #twintrolley #Carbondioxide #Mothersday #careless #NewEx #cleanagent #Maharashtra https://www.naazengineering.com/ (at Mumbai, Maharashtra) https://www.instagram.com/p/CPptZrNh8cQ/?utm_medium=tumblr

#manufacturers#fire#firesafety#safetytools#fireprevention#firealarm#extinguisher#fireextinguisher#firefighter#smokevents#safety#drychemicalpowder#fireworks#naazengineeringworks#firefighterlife#firedepartment#firesigns#firetruck#fireservice#safetyfirst#naazengineering#abcfireextinguisher#modulartype#twintrolley#carbondioxide#mothersday#careless#newex#cleanagent#maharashtra

0 notes

Text

Adhesive tapes: an overview

What are adhesive tapes?

Adhesive tapes are a combination of a material and an adhesive film and are used to join or bond objects together rather than using fasteners, screws or welding.

The use of adhesive tapes instead of mechanical fasteners makes it possible to simplify manufacturing processes.

In addition, adhesive tapes can protect surfaces so that the surface is not damaged when fasteners or screws are used. Adhesive tapes are also used to provide electrical insulation, dissipate heat or seal against media.

Adhesive tapes are good solutions for automated product manufacturing, while liquid adhesives are messy and time-consuming because they must be sprayed or rolled onto the surface before bonding.

What are adhesive tapes made of?

Adhesive tapes consist of a material called a carrier material (e.g. paper, plastic film, fabric, foam), coated with an adhesive and covered with a release liner if required.

The adhesive-coated carrier is then wound into a jumbo roll. The jumbo roll is then cut into narrow strips to produce several small rolls or short rolls. Each roll and its composition is unique and can be tailored to specific applications for a variety of adhesive solutions.

How are adhesive tapes applied?

Adhesive tapes can be pressure sensitive, thermally activated or even require moisture to function. In many cases the tape is used in roll form, but often die-cuts are also made from tape.

Most popular types of adhesive tapes:

Pressure sensitive adhesives

Pressure-sensitive adhesives (PSAs) are tacky in dry form at room temperature. They adhere firmly to a variety of surfaces and require only the use of a finger or hand or a pressure tool. PSAs do not require water, solvent or heat activation to adhere to materials such as paper, plastic, glass, wood, cement and metal. The recommended adhesion pressure is 14.5 – 29 psi =^ 10 – 20 N/cm². The temperature during application should be moderate, somewhere between 15º C and 35º C. Lower temperatures could result in insufficient “wetting” or “coverage” of the adhesive on the substrate. Very high temperatures can cause the tape to stretch during application, which could create additional stress in the final application.

Heat activated adhesive

Heat-activated adhesive tape is normally tack-free until activated by a heat source. Heat-activated tape requires time to bond at elevated temperatures of 80˚C or higher. Heat-activated adhesive allows aggressive bonding to difficult surfaces such as rubber, EPDM, PU and PVC-based plastics. It can be produced with different carriers suitable for a variety of applications.

Water activated adhesive

Water-activated adhesive tape, gummed paper tape or rubberized tape is a starch or bone glue based adhesive that is applied to a kraft paper backing. When moistened, this coating becomes sticky. Water-activated adhesive tape is inexpensive and is used to close and seal cartons. Dr. Dietrich Müller GmbH does not offer this adhesive tape, but uses it to close cartons.

What types of adhesives are used for adhesive tapes?

Choosing the right adhesive for a project requires a good understanding of the application and the substrate or carrier used. The following adhesives are primarily used in the applications Dr. Dietrich Müller GmbH serves:

Acrylic adhesives offer excellent resistance to environmental influences and cure faster than other adhesives.

Epoxy resins exhibit high strength and low shrinkage during curing and are known for their toughness and resistance to chemical and environmental damage.

Rubber-based adhesives offer highly flexible bonds and are usually based on butadiene-styrene, butyl, polyisobutylene or nitrile compounds.

Silicone adhesives (polysiloxane) and sealants have high flexibility and are resistant to very high temperatures.

Polyurethane and isocyanate adhesives offer greater flexibility, impact strength, resistance and durability.

What materials are used for the carrier of the adhesive tapes?

Adhesive tapes and films differ in terms of the carrier or backing material. The most common carrier/support materials used by Dr. Dietrich Mueller GmbH are listed here:

Paper: Paper adhesive tape products have a paper carrier. This can also be creped. The tapes are also called crepe adhesive tapes.

Fabric: A fabric carrier often contains a woven fabric or fabric layer for reinforcement, for additional strength and heat resistance. Synthetic and glass fabrics are used here.

Felt and fleece: Felt or fleece tapes are often applied to substrates to avoid scratches.

Foam: Adhesive-coated foam backing tape contains an adhesive that is protected by a liner. Foam is often used for sealing, weather stripping and assembly.

Rubber: a rubber liner can be used to make a conformable rubber electrical insulation and sealing tape. There are also self-welding variants.

Metal foil: aluminum, aluminum-reinforced and leaded carrier materials resist flames, extreme temperatures and high humidity. Metal tapes are generally intended to seal joints and seams against moisture or steam. Aluminum foil is laminated to paper or plastic films to achieve greater strength. Copper foil is used in the manufacture of multilayer printed circuit boards (PCB).

Plastic foils: In general, there are two categories of plastics: Thermoplastics and thermosets. Plastic foil products contain one or more plastic layers. They consist of a plastic film, which can be clear, colored, printed or unprinted. They can be single or multilayer and can be combined with materials such as paper and/or aluminum. Dr. Dietrich Müller GmbH processes in particular polyester films, polyimide films and PVC films.

PET/Polyester: Polyethylene teraphthalate (PET)/Polyester products use a PET or polyester carrier in the form of a film or laminate. Mylar or hostaphane is often used as the carrier material.

Polyimide: Polyimide tape consists of a polyimide film and a heat-resistant silicone adhesive or an acrylic adhesive. Polyimide films are useful substrates for the manufacture of flexible circuit materials. Polyimide film retains its excellent physical, mechanical, chemical and electrical properties over a wide range.

PVC/Vinyl: Polyvinyl chloride (PVC)/vinyl products use a vinyl or PVC carrier to resist wear, weather and abrasion.

Silicone: Silicone is an excellent product for gaskets, insulators, press pads and stamped parts. Many types of silicone carriers can be used to meet different requirements. These include fabric reinforcements in particular.

Acrylic Films: Acrylic films are plastic or thermoplastic resin films manufactured using polymethyl methacrylate (PMMA) or polymethyl-2-methylpropanoate. Acrylic films have excellent clarity and are UV stable.

Glass/Fiberglass: Fiberglass composite material or a layer of glass provides exceptional stability in harsh environments by resisting shrinkage, decay or burning.

Filament: Filament tape, usually referred to as strapping tape, consists of thousands of filaments (usually glass fiber) woven into yarns and embedded in the adhesive. It is a strong and versatile material that allows the user to bundle similar or odd shaped items for shipping or storage. There are also filament tapes that are reinforced with a polyester film.

Fluoropolymer/PTFE/PVDF: Polytetrafluoroethylene (PTFE) is an insoluble compound with a high degree of chemical resistance and a low coefficient of friction. Fluoropolymer films, layers or coatings consist of plastics such as polytetrafluoroethylene (PTFE) or polyvinylidene fluoride (PVDF). Fluoropolymer is often used in applications that require superior chemical resistance, good dielectric properties, and water and dirt repellency. It is also used in applications where the conveyed material must not adhere to the belt, fabric or laminate.

Transfer adhesive tape: Transfer adhesive tape consists of a thin adhesive film without backing and can be transferred to most dry surfaces as a peelable adhesive layer. Transfer tapes often use a peelable protective film to improve handling and application of the tape.

Double sided tapes: Double sided tapes consist of carrier materials coated on both sides. Each side can have a different adhesive strength. The masking films are made of either paper, film or silicone.

Punched parts from adhesive tape

Dr. Dietrich Müller GmbH uses all adhesive tapes to produce die-cut or shaped die-cut parts or adhesive parts that are used in a variety of applications. Die-cut parts made of adhesive tape can be supplied on a roll, as a die-cut part on a roll, die-cut parts as individual parts or as a magazine-loaded die-cut part. There are also many options for quantities. Punched parts can be produced in small series or in large series as mass punched parts.

The post Adhesive tapes: an overview appeared first on Dr. Dietrich Müller GmbH.

from Dr. Dietrich Müller GmbH https://www.mueller-ahlhorn.com/adhesive-tapes-an-overview/

0 notes

Text

How To Choose Irrigation Hoses Supplier

Mantech range

Our company’s mantech range is light yet rough and sturdy. The hose is produced using a mix of PVC and nitrile rubber with an extra UV layer to protect from UV ray deterioration.

Where To Buy High Pressure Layflat Hose

The rubber mix is taken through a rounded woven coat created from high firmness filament polyester yarn. Because the coat is rounded woven and not just whirled, the hose doesn’t expand when pressed and has a high pressure score against wall density.

Its lightweight characteristic paired with a high pressure score makes the hose favorable and easy to handle.

The hose can be utilized without any safety concerns in temperatures between -30°C to +75°C.

Typical lengths are 30 and 60m but longer lengths up to 200m are also available on demand.

Mantech XP

Our mantech XP range is produced from two coats of rounded woven high toughness fiber polyester yarn. The hose is supported by an internal and external layer of oil tolerant thermoplastic polyurethane which offers a high degree of protection from corrosion and pressure paired with a very amped up burst pressure.

The hose is available with various types of couplings and screw links set up at our company.

Typical lengths for this range are 20 and 40 meters.

Working temperature scale: -50°C to +100°C.

Lay Flat Hose Manufacturer

Martech

Our company’s martecη is an exposed totally synthetic material fire hose produced with rounded woven polyester with an internal layer produced by EPDM rubber. The rounded woven polyester is powerful and doesn’t rot when exposed to liquid for longer periods of time. The hose has a very light weight and is indicated for use where hoses need to be transported by men and on lengthy distances.

Martech range is great when exposed to various environmental elements can be safely utilized within a temperature range between -40°C to +90°C.

The hose is supplied in various length upon demand.

Minemal

Our company’s minemal range is produced by thermoplastic polyether derived polyurethane (TPU) with great attrition attributes. The support is crafted from circular woven filament polyester yarn. The weave facilitated extrusion method of manufacturing allows a more powerful connection between cover and inlay as well as proper encasing of the supporting woven polyester.

The hose displays a high tolerance against frequently utilized chemicals and yields great protection from UV radiation, hydrolysis, and fungus deterioration. The corrosion protection of the TPU material is one of the greatest you’ll find out there, and this makes the hose ideal for usage in highly demanding and corrosive surroundings in open pit mines. Τhe external layer has been crafted with additional width in order to enhance it with a highly endurable jacket. This of course, increases the durability of the hose.

The rounded woven fibre polyester support yields a high flexibility power and enables effortless towing with tractors with minimized odds of impairment. The interlaced weave blocks the hose from lengthwise expansion when stretched or under pressure. This prevents stratification of the cover or lining from the woven support and controls “snaking” and bending effect.

lay flat water transfer hose

Minemal can function in a temperature range between -50°C to +75°C and can tolerate periodic usage of max. 80°C.

Typical lengths available up to 200m.

0 notes

Link

Chi tiết sản phẩm

Các dịch vụ của chúng tôi: + Cung cấp bình chữa cháy ( bình cứu hỏa ) + Thiết bị pccc ( Van, Lăng, Vòi, Tủ , Kệ ) + Bảo trì nạp sạc bình chữa cháy + Thiết kế thi công hệ thống báo cháy và chữa cháy Chính sách chế độ của chúng tôi: + Bảo hành 12 tháng cho từng loại sản phẩm ( 1 đổi 1 trong vòng 12 tháng ) + Kiểm tra định kỳ 6 tháng 1 lần + Cung cấp giấy chứng nhận Kiểm định CO - CQ khi khách hàng yêu cầu + Tùy vào số lượng và chủng loại của từng đơn hàng mà chúng tôi có giá cạnh tranh nhất cho khách hàng. 1/ Mô tả sản phẩmCuộn vòi chữa cháy Đức D65- Xuất xứ : Đức- Chiều dài (m) : 20- Chất liệu / Màu sắc : Polyester Yarn / Trắng- Áp xuất làm việc (Br) : 13- Đường kính : DN65- Đường kính vòi 76mm- Chất liệu : Nilon bên trong tráng cao su- Áp lực sử dung không quá 17MPA- Vòi A: D65 (2 1/2")- Vòi B: D50 (2 ")- Vòi Rulo: D27 (3/4")- Cuộn vòi chữa cháy nhập khẩu chính hãng Đức.- Cuộn vòi chữa cháy (hay còn gọi là vòi rồng) dùng để dẫn nước từ van chữa cháy đến đám cháy. trên thị trường có nhiều loại, tùy độ dày mỏng, chất liệu, quy cách khác nhau, có 3 loại chính TQ, Hàn quốc, Đức- Cuộn vòi bao gồm khớp nối nhôm, có thể nối trực tiếp vào van, máy bơm, hoặc nối tiếp các cuộn vòi với nhau. Sản phẩm cùng loại:

PCCC Phát Đạt chuyên cung cấp sỉ và lẻ bình chữa cháy, bình cứu hỏa, bình chữa cháy khí co2, bình bột MFZ, MT, thiết bị phòng cháy chữa cháy. Ngoài ra chúng tôi còn nhận bào trì nạp sạc bình chữa cháy...

Model

Đường kính(mm)

Chiều dài(m)

Chất liệu(Ngoài)

Chất liệu(trong)

Áp suất làm việc(bar)

Vòi TQ

D40-D50-D65

20-30

Polyeste

PVC-Cao su

8-10-13

Vòi Korea

D50-D65

20

Polyeste 2 lớp

Cao su

13

Vòi Đức (Jakob-Eschbach)

D50-D65

20

Polyeste

Cao su chống ăn mòn, chống ozon và lão hóa, chịu được nhiệt độ từ -40 - 100 độ C

17

Vòi Đức (Parsch)

D50-D65

20

Polyeste

Cao su chống ăn mòn, chống ozon và lão hóa, chịu được nhiệt độ từ -40 - 100 độ C

17

Vòi Đức (Gollmer Hummel)

D50-D65

20

Polyeste

Cao su cao cấp EPDM, Lớp cao su bên trong ống được làm rất mịn và làm giảm độ ma sát thấp nhất.

16

Vòi Rulo TQ

D27

30

Cao su

10

0 notes

Text

Air Hoses for Mining and Quarrying Applications

The air hose is responsible for transferring the power of compressed air to various pneumatic tools. In the compressed air distribution system, the air hose specifications required for different sizes of air compressors are also different.

https://www.air-hose.org/application/mining.html

A worker is drilling the wall with pneumatic rock drill. Brief Introduction Mining is a vast global industry focused on a wide variety of natural resources. Through mining, people can extract the most valuable, useful and beautiful natural resources on the earth for use in all areas of our lives. The modern mining process relies on a variety of mechanical equipment, most of which are powered by air compressors. Compressed air will be distributed to each machine through the proper air hoses. In order to achieve efficient operation, the discharge pressure must be high enough to deliver the compressed air to the machines at the a certain pressure. Special needs to be pointed out that the use of undersized hose in the compressed air distribution system is the primary cause of low air pressure. As a manufacturer, we will give professional advice according to our years of practical experience.

What is the Most Commonly Used Air Compressor in Mine? The appropriate compressors used at mines are of positive-displacement types. Reciprocating compressor, the air is compressed by a piston in a cylinder, is the most common choice of mine managers.

Main Machines Powered by Compressed Air A mine worker is operating with a stoper drill.Hand-held pneumatic rock drillPneumatic rock drill is ideally for development and stoping applications where high drilling speed is required. There are three primary variations include jackleg, stoper and sinker for practical work needs. A used mucking machine with black air hose.Mucking machinesMucking machines, powered by a small compressed air, are designed for loading the broken rock in underground mining. There are two pneumatic chain hoists with different styles.Pneumatic chain hoistsMining air hoists are powered by the safe and reliable compressed air. They are specifically designed for pulling and lifting operations in mining and tunneling industries. There is an air scraper winch on the ground.Air scraper winchAir scraper winch adopts compressed air as power to diver the air motor. It is used to move the ores at the underground mining or open air. A picture show the ventilation pipeline of the underground mine.BlowersBlowers have a wide range applications in underground minging industry. Such as dust control, cyclone solutions, ventilation and cooling. They act as different types of large vacuum cleaner to move dirt from the job site. Material Selection Where there is an air compressor, there will be one or more air hoses.

Rubber We adopt quality EPDM (Ethylene Propylene Diene Monomer), SBR (Styrene Butadiene Rubber) or NR (Natural Rubber) as tube material. Then reinforced by high strength polyester or synthetic yarn.

PVC PVC pneumatic hammer hose are available in polyester yarn reinforced type and high-pressure double polyester reinforced type.

Requirements Table 1: Air Requirements of Representative Drilling Machines Machine name Hammer diameter Weight of machine Free air required inch Lbs. CFM Sinker + 2-3/8 30 * 70 2-1/2 50 * 95 2-5/8 60 * 110 2-3/4 70 * 115 Stoper 2-9/16 100 140 2-3/4 120 160 Drifter 2-3/4 80 * 130 3 90 * 140 3-1/2 110 * 180 4-1/2 170 * 200 + The sinker drill can be equipped with an air-feed leg and used for drifting and stoping. * Mounting is not included in the weight. Table 2: Air Hose Size – 80 to 125 PSI Volume of free air to be carried(CFM) Length (feet) 50–200 200–500 500–1000 1000–2500 Diameter (inch) 60–100 1 1-1/4 1-1/2 2 100–200 1-1/4 1-1/2 2 2-1/2 200–500 2 2-1/2 3 3-1/2 500–1000 2-1/2 3 3-1/2 4 1000–2000 3 4 4-1/2 5 Why Choose Us? For use with high and low pressure compressors in mining industry. Manufactured from 100 % virgin material (not reground). Made with advanced production equipment and technology. Non-marring, abrasion-resistant. Various material and configurations for choice. Available in different sizes and pressures.

0 notes

Text

PVC and Rubber Air Hoses for Spray Finishing Operations

Air paint sprayer, a less waste type tool, is ideally for detail spraying since its HVLP (High Volume – Low Pressure) system. If you choose it as your helpful tool for painting the wall, ceiling, table, car, bicycle or any other projects. Equipped with a suitable air hose is essential for the whole painting system. The hose, can be manufactured from PVC, PU or rubber, is used to carry sufficient compressed air from the pressure tank to the spray gun. The proper hose diameter approved by the spraying industry is minimum 3/8" to 1/2". In addition, you should carefully consider choosing an appropriate hose length to improve hose effectiveness. So as to avoid tangles and clumsiness when trying to spraying.

https://www.air-hose.org/application/paint-spray.html

Material Selection Paint spraying system with attachment name annotation. There are various material options available for air paint sprayer.

Rubber We adopt quality EPDM (Ethylene Propylene Diene Monomer), SBR (Styrene Butadiene Rubber) or NR (Natural Rubber) as tube material. Then reinforced by high strength polyester or synthetic yarn.

PVC PVC pneumatic hammer hose are available in polyester yarn reinforced type and high-pressure double polyester reinforced type.

PU Paint spraying hose which are made of PU (polyurethane) has light weight, high strength and smooth surface. It offers a long service life.

Requirements The hose selection of the air paint sprayer must take into account the following factors:

Air compressor type. Piston-type or rotary screw? Air compressor size. Compressed air tank size. The hose length should match well with its inner diameter. Why Choose Us? For use with high pressure compressors and air paint sprayers. Manufactured from 100 % virgin material (not reground). Made with advanced production equipment and technology. Non-marring, abrasion-resistant. Various material and configurations for choice. Available in different sizes and pressures.

0 notes

Text

Double Reinforcement Air Hoses for Pneumatic Hammer

https://www.air-hose.org/application/pneumatic-hammer.html

Pneumatic hammer, also know as demolition hammer or breaker hammer, is an effective handheld pneumatic tool for drilling, splitting breaking, ramming and shoveling in road construction, quarrying and mining. Presumably, you can often see the scene of workers breaking the ground with a pneumatic hammer in your city. The pneumatic hammer is powered by a large air compressor. The important accessory connecting them is the a suitable air hose for compressed air delivery. In order to meet the high-pressure and high-speed power transmission needs, the hoses should be flexible, high strength, anti-aging and anti abrasive. As a manufacture, we are your one-stop supplier for pneumatic air hoses.

Material Selection A worker is breaking up the ground with pneumatic hammer. There are various material options available for pneumatic hammer.

Rubber We adopt quality EPDM (Ethylene Propylene Diene Monomer), SBR (Styrene Butadiene Rubber) or NR (Natural Rubber) as tube material. Then reinforced by high strength polyester or synthetic yarn.

PVC PVC pneumatic hammer hose are available in polyester yarn reinforced type and high-pressure double polyester reinforced type.

Requirements The selection of the pneumatic hammer hoses must take into account the following factors:

High temperature resistance A quality pneumatic hammer hose should be anti-explosion even in high temperature conditions.

Low temperature resistance The hoses should maintain good flexibility even in chilly winter.

Air compressor size Air compressor speed Why Choose Us? Manufactured from 100 % virgin material (not reground). Made with advanced production equipment and technology. 300 PSI working pressure and 900 PSI minimum burst pressure. Resistant to high temperature & aging, durable. Resistant to any weather, even extremely cold winter. Non-marring, abrasion-resistant. Non-toxic, tasteless and environmentally friendly. We Recommend There are four polyester reinforced PVC pneumatic hammer hoses.Polyester reinforced PVC pneumatic hammer hose There are three high-pressure PVC pneumatic hammer hoses with red, blue and black colors.High-pressure PVC pneumatic hammer hose There are four rubber air hoses reinforced by polyester fiber spiral line.

0 notes