#pneumatic diaphragm pumps

Explore tagged Tumblr posts

Text

The Importance of Air-Operated Diaphragm Pumps in Industrial Applications

In various industries, efficient fluid transfer is crucial for maintaining productivity and ensuring smooth operations. Air-operated diaphragm pumps have emerged as one of the most reliable and versatile solutions for handling a wide range of liquids, including corrosive chemicals, viscous fluids, and slurries. These pumps offer durability, energy efficiency, and ease of maintenance, making them an ideal choice for multiple industrial applications.

What is an Air-Operated Diaphragm Pump?

An air-operated diaphragm pump (AODD pump) is a type of pneumatic diaphragm pump that operates using compressed air instead of electricity. It features two flexible diaphragms that move back and forth, creating a vacuum to draw fluid into the pump and discharge it efficiently. This unique working mechanism makes the air-operated double diaphragm pump (AODD pump) highly reliable for various industries, including chemical processing, pharmaceuticals, water treatment, and food processing.

Key Advantages of AODD Pumps

Self-Priming Capability – AODD pumps can handle suction lifts and run dry without damage, making them ideal for demanding environments.

Corrosion Resistance – Constructed with durable materials such as polypropylene, stainless steel, and PTFE, these pumps resist chemical degradation.

Explosion-Proof Operation – Since they are air-driven diaphragm pumps, they do not require electricity, making them suitable for hazardous environments.

Low Maintenance & Cost-Effective – With fewer moving parts, AODD pumps require minimal maintenance, reducing downtime and operational costs.

Versatility – These pumps can handle a wide variety of fluids, including abrasive, high-viscosity, and shear-sensitive liquids.

Applications of AODD Pumps

Chemical Processing – Safe and efficient transfer of corrosive chemicals and solvents.

Pharmaceuticals – Precise fluid handling in drug manufacturing.

Water Treatment – Pumping sludge, wastewater, and chemicals for purification.

Food & Beverage – Hygienic transfer of liquids such as syrups and juices.

Oil & Gas – Handling fuel, lubricants, and hazardous fluids.

Other Pumping Solutions

Apart from AODD pumps, industries also rely on barrel pumps and drum pumps for transferring fluids directly from storage containers. These pumps ensure efficient handling of high-volume liquids with minimal spillage and wastage. Additionally, pneumatic pumps are widely used for applications where electric-powered pumps are not feasible.

Why Choose Ambica Machine Tools?

Ambica Machine Tools is a leading manufacturer of air-operated diaphragm pumps, AODD pumps, pneumatic diaphragm pumps, barrel pumps, and drum pumps. With a commitment to quality and innovation, we provide reliable industrial pump solutions tailored to specific industry needs.

0 notes

Text

Understanding the Mechanics of AODD Pumps

Air-Operated Double-Diaphragm (AODD) pumps are used to displace fluids by using compressed air. These pumps move fluids of various viscosities, even those with suspended solids. Not just that, AODD pumps can also handle corrosive and aggressive fluids with ease. These pumps are used for applications in a range of industries, including chemical processing, wastewater management, mining, construction, cleaning supplies and pharmaceuticals. Visit: https://www.idexindia.in/understanding-the-mechanics-of-aodd-pumps/

#aodd pump manufacturers#aodd pump supplier#Diaphragm Pump#Pneumatic Air Pump#air operated double diaphragm pump#IDEX_India

0 notes

Text

PTFE/Rubber Diaphragm Seals Please contact me for a quote if required. Henan Sixfluorine Chemical Co.,Ltd WhatsApp/Telegram:+(86)15038852660 Mail:[email protected]

1 note

·

View note

Text

0 notes

Text

Bellows, Boots, Rubber Bellows, Manufacturer, Mumbai, India

Bellows, Boots, Rubber Bellows, Rubber Bellows Manufacturer, Anti Vibration Mounts, Rubber Anti Vibration Mounts, Anti Vibration Mounts Manufacturer, Anti Vibration Mount Supplier, Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess

2 notes

·

View notes

Text

Discover the top-quality Chem-Feed Noir Diaphragm Metering Pump from Marine Shop 7, designed for high precision and consistent chemical dosing. Engineered for industrial and commercial applications, this pump delivers high output with low maintenance, making it ideal for water treatment, chemical processing, and more. Its robust diaphragm design ensures durability, accuracy, and resistance to corrosive fluids. Easy to install and operate, it’s a reliable choice for professionals seeking efficient and long-lasting performance.

Choose the trusted solution – the Chem-Feed Noir Diaphragm Metering Pump from Marine Shop 7 – where performance meets reliability in every drop.

Know More : https://www.marineshopseven.com/product-category/pneumatic-tools-equipment/

0 notes

Text

Pressure reducing valve working principle

What is a Pressure Reducing Valve (PRV)?

A Pressure Reducing Valve (PRV) is a mechanical device designed to lower and regulate high inlet pressure to a consistent, safe outlet pressure. It ensures stable fluid flow across various Udhhyog (industry) applications like manufacturing, chemical processing, and water treatment.

🔍 Step-by-Step Working

Fluid enters at high pressure from the inlet side.

Spring force and diaphragm/piston sense downstream pressure.

When outlet pressure is low, the valve opens to increase flow.

When outlet pressure rises, the valve closes partially.

A balanced, reduced pressure is maintained for downstream Udhhyog equipment.

🧾 Key Components of a PRV

ComponentFunctionValve BodyEncases the entire PRV mechanismDiaphragm/PistonSenses pressure changes and controls valve movementSpringProvides counter-force to maintain set pressureAdjusting ScrewSets desired downstream pressureValve DiscOpens/closes to control fluid flow

🏭 Industrial Udyog Applications of PRVs

Pressure reducing valves are crucial in maintaining safety and efficiency in various Udyog sectors, including:

Water Supply & Wastewater Treatment Udyogs

Boiler Systems in Textile & Paper Udyogs

HVAC Systems in Commercial Udyogs

Chemical & Petrochemical Plants

Food & Beverage Manufacturing Units

Steam Systems in Energy Udyogs

Hydraulic & Pneumatic Machinery

🔄 Types of Pressure Reducing Valves

1. Direct Acting PRV

Compact, ideal for small-scale Udyog setups

Basic pressure control for water and air lines

2. Pilot-Operated PRV

Advanced pressure accuracy

Widely used in large Udyogs (steam, hydraulic plants)

3. Spring-Loaded PRV

Standard type used in many Indian Udyogs

Adjustable with simple maintenance

✅ Benefits for Udyogs

🛠️ Protects Equipment – Prevents wear in downstream machinery

💸 Cost-Effective – Reduces damage, downtime, and repair costs

🔄 Energy Efficient – Optimizes pump and system performance

📏 Consistent Output – Maintains product/process quality

🔧 Low Maintenance – Easy replacement and adjustment

🚫 Common Issues in Udyog Usage & Solutions

ProblemPossible CauseUdyog-Focused SolutionPressure not steadyWorn diaphragm/springReplace parts during shutdownValve chatteringOversized PRVUse correctly sized valveLeakageSeat or disc damageInspect and reseat or replaceNoisy operationHigh inlet flow velocityInstall flow dampers or orifice

🧰 How to Install PRVs in Industrial Udyogs

Installation Tips:

Use isolation valves before and after PRV

Install pressure gauges at inlet and outlet

Mount PRV in horizontal pipelines where applicable

Ensure easy access for maintenance

Flush line before installation to remove debris

FAQ

What is a pressure reducing valve and how does it work?

It’s a valve that lowers incoming pressure using a spring and diaphragm. It balances outlet pressure to match a preset level in industrial systems.

What are pressure reducing valves used for in Udyogs?

They’re used in Udyogs for boiler control, steam regulation, hydraulic machinery, and to prevent damage to downstream equipment.

How do I select the right PRV for my Udyog?

Consider flow rate, fluid type, inlet/outlet pressure, and application (e.g., steam, water, chemical). Choose based on industrial specifications.

What’s the difference between PRV and pressure relief valve?

PRVs regulate ongoing pressure, while relief valves open momentarily to release excess pressure in emergencies.

0 notes

Text

"Environmental Advantages of Pneumatic Pumps: Energy Savings in Manufacturing"

Pneumatic pumps are multi-purpose equipment that employs compressed air or gas for the aim of displacing media of any form. They are used in common applications in industries as they are convenient, efficient, and can be used to achieve a range of applications. Of many types of pneumatic pumps, pneumatic grease pumps are especially well known in industrial lubrication.

What is Pneumatic Pump?

The Pneumatic pump works on the fundamental principle of working under compressed air pressure or compressed gas to supply the fluid flow. The fundamental idea is constructed on components such as pistons, diaphragms, or impellers to provide pressure pulses to enable the fluid movement. The Pneumatic pumps operate very efficiently with abrasive chemicals and viscous fluids and are hence applied universally in manufacturing, automobiles, and minerals industries.

The Key Features:

Positive Displacement Mechanism: Offers accurate fluid transfer without backflow.

Self-Priming Facility: For operation even under conditions when the pump chamber remains unfilled.

Cost-Effectiveness: Compressed air driven, thus lesser running costs over traditional pumps.

Pneumatic Grease Pumps: A Powerful Lubrication Tool

The Pneumatic grease pumps are sophisticated pneumatic equipment that have their applications in greasing to a precise and exact level. Compressed air operates them to push grease via pressure systems to provide constant lubrication to machine parts. They are used with applications of paramount importance in those industries where accuracy and certainty of lubrication are truly necessary.

Working Principle:

Compressed air powers the air motor of the pump, resulting in reciprocating motion of the piston.

This motion triggers the pump mechanism, generating pressure to propel grease out of the reservoir.

High-pressure hoses are used to facilitate accurate delivery of grease to the point of application.

Benefits:

Precise Lubrication: Imposes the optimal amount of grease to prevent over-lubrication or under-lubrication.

High Viscosity Operation: Operates in heavy greases in harsh operating conditions.

Long Life: Operating continuously for a long time even under harsh operating conditions such as very high temperature or dirty operating conditions.

Efficiency: Conserves physical effort compared to manual process and accelerates maintenance activities.

Applications in all Industries

All these Pneumatic grease pumps have universal application in every industry:

Manufacturing: Lubricates assembly lines, robots, and manufacturing equipment.

Automotive: Ensures smooth operation of chassis parts and assembly lines.

Mining and Construction: Lubricates severe-duty gear like crushers and drilling rigs in extreme conditions.

Conclusion

Both pneumatic grease pumps and pneumatic pumps are important agents in industrial process through improved efficiency, accuracy, and dependability. Pneumatic pumps suit fluid transfer from one viscosity to another, and pneumatic grease pumps suit lubrication delivery of the optimal type to equipment components. Both are very versatile and cost-effective and, as such, very useful tools in industries that wish to maximize the output of equipment and reduce maintenance.

By harnessing the power of compressed air, these technologies keep moving higher-quality manufacturing standards in the manufacturing, automotive, mining, and construction sectors.

0 notes

Text

Understanding Diaphragm Pumps and Their Applications

One of the key advantages of diaphragm pumps is their ability to operate in harsh environments. Because of their unique design, they can handle a variety of fluids, including those that are abrasive or have particulates. Additionally, diaphragm pumps minimize the risk of leaks, contributing to safer workplace conditions. They are commonly used in industries such as chemical manufacturing, wastewater treatment, food processing, and pharmaceuticals.

Moreover, diaphragm pumps are easy to maintain, with fewer moving parts compared to traditional centrifugal pumps. This simplicity translates to reduced downtime and lower maintenance costs, making them a preferred choice for many operations. Their ability to provide consistent flow rates across a range of pressures enhances their efficiency, allowing for precise control during fluid transfer processes.

The Role of IBC Mixers in Fluid Processing

In many industries, especially where large quantities of materials need to be mixed, IBC (Intermediate Bulk Container) mixers play a vital role. An IBC mixer is specifically designed to blend materials stored in large containers effectively. These mixers ensure that the components within the IBC are evenly distributed, which is crucial for achieving the desired product consistency.

IBC mixers often incorporate pneumatic mixer, which use compressed air to drive the mixing process. This feature enables the promotion of homogeneous mixtures and helps in the dispersion of particles or liquids with varying densities. Pneumatic mixers are advantageous in situations where electric mixers might pose an explosion risk or where an operator needs better control over mixing speed.

The efficiency of IBC mixers is significantly enhanced by the careful selection of mixing shaft designs. The mixing shaft must be robust enough to withstand the rigors of consistent use while also being versatile to accommodate various types of mixing heads. A well-designed mixing shaft for drill applications can optimize the mixing process, reduce energy consumption, and ensure that the flow dynamics within the IBC are favorable for effective mixing.

The Importance of Proper Mixing Equipment

In any industrial mixing application, using proper equipment is essential for achieving the desired results. Among the equipment choices, diaphragm pumps, IBC mixers, pneumatic mixers, and mixing shafts play a crucial role in ensuring product quality and operational efficiency. Each component contributes to the overall process of fluid handling and mixing, which can affect a company’s productivity and safety standards.

Efficiency in mixing operations not only leads to cost savings but also enhances product quality. By ensuring consistent product quality, businesses can better meet customer expectations and comply with regulatory standards. Investing in advanced mixing technologies, including those that utilize and IBC mixer, is essential for optimizing production lines.

0 notes

Text

The Ultimate Guide to Air Operated Diaphragm Pumps (AODD Pumps)

Air operated diaphragm pumps, also known as AODD pumps, are indispensable in industries requiring efficient, versatile, and reliable fluid transfer solutions. These pumps are particularly valued for their ability to handle a variety of liquids, from highly viscous materials to abrasive chemicals. In this comprehensive guide, we will explore everything you need to know about air operated diaphragm pumps, air operated double diaphragm pumps, pneumatic pumps, and more.

What is an Air Operated Diaphragm Pump?

An air operated diaphragm pump is a type of positive displacement pump that uses compressed air as its power source. These pumps feature two flexible diaphragms that move back and forth, creating a pumping action. The reciprocating motion of the diaphragms helps in sucking and discharging fluids effectively.

Key Features of Air Operated Diaphragm Pumps

Versatility: Ideal for handling a wide range of liquids, including acids, slurries, and solvents.

Self-Priming: Capable of dry running and self-priming from significant depths.

Portability: Lightweight and easy to transport, making them suitable for various applications.

Durability: Built with corrosion-resistant materials for longevity in harsh environments.

Ease of Maintenance: Simple design facilitates easy maintenance and repair.

Types of Air Operated Diaphragm Pumps

1. Air Operated Double Diaphragm Pump (AODD Pump)

The air operated double diaphragm pump (AODD pump) is a specific type of diaphragm pump featuring two diaphragms. These diaphragms work in tandem, ensuring continuous and smooth fluid transfer. The double diaphragm design enhances efficiency, allowing the pump to handle challenging applications like transferring slurries or viscous fluids.

Benefits of AODD Pumps:

Excellent chemical resistance

Capable of handling solids-laden fluids

Explosion-proof for hazardous areas

Minimal downtime due to easy maintenance

2. Pneumatic Diaphragm Pump

A pneumatic diaphragm pump operates using compressed air, making it ideal for areas where electricity is not feasible or safe. These pumps offer flexibility and safety, especially in chemical industries and hazardous environments.

Advantages of Pneumatic Diaphragm Pumps:

Safe for explosive environments

Low maintenance and easy to install

Adjustable flow rate and discharge pressure

3. Air Driven Diaphragm Pump

The air driven diaphragm pump is another variant, designed for high-performance operations where reliability and efficiency are critical. These pumps excel in industries like oil and gas, mining, and chemical processing.

Common Applications of Air Operated Diaphragm Pumps

Chemical Processing: Safely transferring acids, solvents, and chemicals.

Food and Beverage: Pumping food-grade materials like syrups, sauces, and oils.

Pharmaceuticals: Handling sensitive and sterile liquids.

Water Treatment: Moving sludges and other wastewater materials.

Mining: Pumping abrasive slurries and dewatering operations.

Understanding Barrel and Drum Pumps

Barrel Pump

A barrel pump is designed to transfer liquids from barrels and drums. They are compact and highly efficient, ideal for handling oils, chemicals, and other fluids stored in large containers.

Key Features:

Easy to install and operate

Prevents spillage and reduces waste

Suitable for various liquid types

Drum Pump

Similar to barrel pumps, drum pumps are used to empty liquids from large drums. They ensure efficient fluid transfer without the need for manual lifting or tilting of heavy containers.

Benefits of Drum Pumps:

Safe and efficient liquid transfer

Reduces risk of contamination

Versatile for different industries

How to Choose the Right Air Operated Diaphragm Pump

Selecting the right pump depends on various factors:

Type of Fluid: Determine the viscosity, abrasiveness, and chemical properties.

Flow Rate Requirements: Understand the volume of liquid that needs to be transferred per hour.

Material Compatibility: Ensure the pump material is resistant to the fluid being handled.

Port Size and Connection: Choose the right port size to match your system’s specifications.

Pressure Requirements: Evaluate the pressure requirements to ensure efficient operation.

Maintenance Tips for AODD Pumps

Regular Inspection: Check diaphragms, seals, and valves for wear and tear.

Lubrication: Ensure that all moving parts are adequately lubricated.

Clean After Use: Especially when pumping chemicals or viscous fluids.

Replace Parts Timely: Replace worn-out diaphragms or seals promptly to avoid downtime.

Check Air Supply: Ensure consistent and clean air supply for optimal performance.

Advantages of Using Pneumatic Pumps

Energy Efficiency: Consumes air only when required, reducing operational costs.

Versatile: Can handle a broad range of fluids, including hazardous and flammable ones.

Low Maintenance: Simple design results in fewer maintenance requirements.

Safety: Ideal for explosive or hazardous environments due to non-electric operation.

Why Choose Air Operated Pumps for Industrial Applications?

Durability: Built to withstand harsh conditions and aggressive fluids.

Flexibility: Suitable for a wide range of industrial applications.

Cost-Effective: Low initial and maintenance costs compared to electric pumps.

Eco-Friendly: Reduced risk of spillage and environmental contamination.

Conclusion

Air operated diaphragm pumps, including AODD pumps, pneumatic pumps, barrel pumps, and drum pumps, play a crucial role in various industries. Their versatility, durability, and efficiency make them a preferred choice for fluid transfer operations. Whether you need to transfer chemicals, food products, or wastewater, these pumps offer reliable and safe solutions.

Investing in high-quality air operated pumps ensures long-term operational efficiency, reduced downtime, and better cost management. Choose the right pump based on your specific requirements and experience the benefits of seamless fluid transfer in your industrial operations.

0 notes

Text

Buy Premium and Durable Marine Equipment from our Reliable Online Store

If you are looking for a reputable, reliable store to shop for wire cup brush, then choose our store. We are a leading supplier of premium and durable marine equipment. Whether you are looking for basic marine products or technical products, we are right here to deliver everything.

Our primary focus is to provide the best marine equipment to all our clients. Choose our store whenever you look for the best quality and durable marine product. We provide the best products.

Our store steals the limelight when dealing with quality marine essentials. Hence, you can entrust our company to you whenever you seek the best quality and most durable marine equipment. We deal with a huge range of marine products from basic to advance.

So, our store is the perfect option for all your marine needs. There is no need to look for here and there when our store is one click away. Make your shopping experience for marine equipment easy and quick with us. If you want a pneumatic diaphragm pump, choose our store now.

Our online store is the right place to access all kinds of marine products, including cotton working gloves, overalls, wringer mop buckets, and so on. The best thing about our company is that we only deal with premium and durable products. Choose our store whenever you look for the best quality and durable marine product.

How to find the right quality Wire cup Brush & Pneumatic diaphragm pump

Several critical aspects should be considered whenever you search for a premium and durable Wire cup Brush.

Visual inspection is the first thing you should do to ensure the device is in the best condition. Then, you should check the product's quality, durability, and safety features.

After this, you should look up the manufacturer’s guidelines for learning functionality. All these factors will help you select the right marine equipment. If you want a premium marine product, then make sure to select a reliable partner.

The other reason for choosing our company for the marine product is that we are a reputed and leading supplier of marine equipment. There is no need to look for here and there when our online store is one call away.

Indeed, finding a reliable online store is not easy for marine equipment. But do not take stress when we have created our online shop. In our shop, we deliver all kinds of marine equipment. We provide premium marine products.

Our store always offers the best quality products so that you can rely on us for the best shopping experience. Choose our online store now. Buy high-quality and durable Wire cup Brushes from our shop.

0 notes

Text

AODD Pump Operation: A Comprehensive Guide

An Air-Operated Double-Diaphragm (AODD) pump is a type of positive displacement pump driven by compressed air.

Working Principle of AODD Pump

AODD pumps work by using two opposing diaphragms connected to a rod. Compressed air moves the diaphragms, which creates suction and discharge cycles. Check valves control the flow of liquid into and out of the chambers.

#air operated double diaphragm pump#AODD Pump#diaphragm pump#Pneumatic Air Pump#Portable Pump#Sandpiper Diaphragm#Pump and Valves#IDEX India

0 notes

Text

A Comprehensive Guide to Pressure Gauges: Types, Applications, and Benefits

Pressure gauges are essential measuring instruments embraced by most industries to measure fluid, gas, or vapor pressure precisely. Pressure gauges ensure optimal performance and safety in process industries, HVAC systems, and industrial processes. As one of the leading Pressure Gauge Manufacturers and Pressure Gauge Suppliers, Avlok provides a comprehensive range of pressure gauges that are of high quality and can fulfill many requirements. In this article, we are introducing different pressure gauges, applications, and benefits.

Types of Pressure Gauges

Diaphragm Sealed Pressure Gauge: A Diaphragm Sealed Pressure Gauge is employed where the process fluid should not be in direct contact. The diaphragm seal is used to safeguard the gauge against corrosive, viscous, or high-temperature fluids, and thus it is more favorable in chemical, pharmaceutical, and food industries.

Differential Pressure Gauges: Differential Pressure Gauges indicate the difference between two points in a system. Differential Pressure Gauges are used in filtration systems, flow measurement, and level detection among others. Differential Pressure Gauges ensure smooth operation by detecting pressure losses and ensuring system performance.

Glycerin Filled Pressure Gauge: A Glycerin Filled Pressure Gauge is optimum for application under pulsating and high-vibration conditions. The glycerin inside the gauge takes in motion as well as protects the internal parts from wear and tear. The gauges find their application in hydraulic circuits, compressors, and pumps.

Test Pressure Gauges:Test Pressure Gauges are precise instruments designed for calibration and testing. They deliver highly accurate readings and are commonly used in laboratories and quality control departments. These gauges help ensure that other pressure measuring devices operate correctly and maintain their accuracy.

Stainless Steel Pressure Gauges: For environments requiring high durability and corrosion resistance, Stainless Steel Pressure Gauges are the preferred choice. These gauges are used in industries such as oil & gas, marine, and petrochemical, where exposure to harsh conditions is common.

Pressure Gauge Accessories: To enhance the performance and longevity of pressure gauges, various Pressure Gauge Accessories are available. These include:

Snubbers: Reduce pressure fluctuations and extend gauge life.

Gauge Protectors: Shield the gauge from external damage.

Overpressure Protectors: Prevent damage from sudden pressure spikes.

Adapters and Fittings: Ensure compatibility with different systems.

Applications of Pressure Gauges

Pressure gauges find extensive application in various industries, such as:

Oil & Gas: Keeping track of pressure in pipelines and storage tanks.

Chemical & Pharmaceutical: Guaranteeing safe pressure levels during production processes.

HVAC Systems: Controlling airflow and refrigerant pressure.

Food & Beverage: Ensuring accurate pressure for hygiene and quality assurance.

Manufacturing: Overseeing hydraulic and pneumatic systems.

Conclusion

Selecting the appropriate pressure gauge is essential for ensuring safety and efficiency in industrial settings. Avlok, a reliable manufacturer and supplier of pressure gauges, provides a diverse selection, including diaphragm sealed pressure gauges, differential pressure gauges, glycerin filled pressure gauges, test pressure gauges, and stainless steel pressure gauges, as well as top-notch pressure gauge accessories. Reach out to us today to discover the ideal pressure gauge solutions tailored to your requirements.

#Pressure Gauge Manufacturers#Pressure Gauge Suppliers#diaphragm sealed pressure gauges#differential pressure gauges#glycerin filled pressure gauges#test pressure gauges#stainless steel pressure gauges

0 notes

Text

Nirmala Pumps and Equipments offer Diaphragm Pumps that play a vital role in smooth fluid transfer operations. Our Aodd Pumps efficiently transfer liquids with minimal maintenance requirements. These Diaphragm pumps feature low noise vibrations tailored to our client's specifications. For any details, visit here.

1 note

·

View note

Text

Metal To Rubber Bonded Parts, Manufacturer, Mumbai, India

Find here to get more details of Metal To Rubber Bonded Parts, We are manufacturer, supplier and best service provider of Metal Bonded To Rubber Bonded parts in Mumbai, India.

Rubber Products, Moulded Rubber Parts, Extruded Rubber Parts, Sponge Moulded Parts, Metal Bonded Parts, Manufacturers Of Rubber Components, Manufacturers Of Moulded Rubber Parts, Manufacturers Of Extruded Rubber Parts, Rubber Moulded Parts, 'O' Rings, Oilseal, U Seal, V Seal, Chevron Packing For Pumps, Hydraulics Seal, Mechanical Seal, Neoprenen Rubber, Nitrile Rubber, Epdm Rubber, Hypalon Rubber, FKM Rubber, Natural Rubber, Polymers, Flourinated Rubber, FKM Rubber, Silicone Rubber, Polyurethane Rubber, Ethylene Propylene Terpolymers, Natural Rubber, Synthetic Rubber, Chemical Resistance, O Rings, U Seals, V Seals, Lip Seals, Wiper Seals, Oil Seals, Diaphragms, Electrical Control Valves, Pneumatic Control Valves, Pressure Regulators, Valve Positioner, Ball & Butterfly Valve, Solenoid Valve With Brass, Stainless Steel Stud, Fabric, Nylon, Canvas, Rayoncord, Wiremess, Gasket, Flange Packing, Pipe Fittings, Filters, Electrical Instrument Panel Board, Electrical Transformer, Packing For Plastic Drums, Packing For Plastic Carbouys, Metal To Rubber Bonded Product, Foundation Pad, Buffers, Coupling Bush With Ms, Coupling Bush With Brass, Coupling Bush With Ss, Bearing Cover, Brake Pad, Extruded Product, Chords, Sleeves, Conveyor System, Dyeing & Oven Packing, Electrical Panel Boards, Conveyor System, Cement & Fertilizers Plant, Switchgear Fittings, Electrical Fittings, Pharmaceutical Rubber Part, Filtration Rubber Part, Triclover Gasket, Envelope Gasket, Body Gasket, Nutche Filter Gasket, Silicone Colour Tubes, Transparent Tubes, Chemical Process Plant, Filtration Plants, Bulk Drugs Manufacturers, Electrical Pushbutton Switches Rubber Parts, Belt Ring, Diffuser Washer, Key Selector U Seal, Lense O Ring, Rubber Boots, Transparent Rubber Boots, Silicone Rubber Boots, Station Cover Gaskets.

0 notes

Text

What is A Shut Off Valve: A Guide to Safeguarding Plumbing

A shut off valve is a critical component in piping systems designed to control the flow of liquids or gases. By opening, closing, or partially obstructing pathways, these valves ensure safety, regulate pressure, and prevent leaks. Whether in residential plumbing, industrial processes, or oil and gas pipelines, shut off valves are indispensable for system efficiency and emergency management.

Types of Shut Off Valves

Shut off valves come in various designs, each suited for specific applications. Here are the most common types:

Ball Valve

A ball valve uses a rotating ball with a bore to control flow. It offers quick shut-off, durability, and minimal pressure drop. Ideal for water, gas, and oil systems.

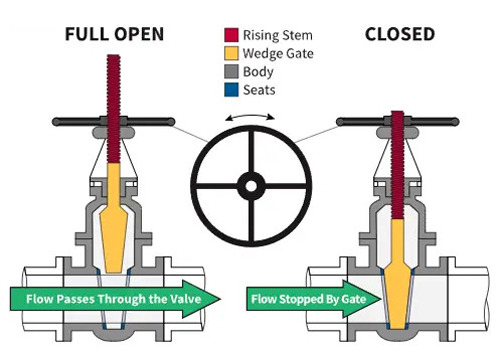

Gate Valve

Gate valves feature a wedge-shaped gate that lifts to allow flow. They’re best for on/off control in low-frequency applications, such as water supply lines.

Globe Valve

Known for precise flow regulation, globe valves use a disc and seat mechanism. Common in HVAC systems and fuel pipelines.

Butterfly Valve

A compact, lightweight valve with a rotating disc. Butterfly valves excel in large-scale water treatment and fire protection systems.

Check Valve

Allows flow in one direction only, preventing backflow. Used in sewage systems and pump discharge lines.

Diaphragm Valve

Utilizes a flexible diaphragm to isolate flow. Ideal for corrosive or slurry fluids in chemical processing.

Needle Valve

Designed for precise flow control with a tapered needle-like plunger. Common in instrumentation and hydraulic systems.

ESDV (Emergency Shutdown Valve)

A specialized valve for rapid closure during emergencies, often automated. Critical in oil refineries and gas pipelines.

Uses of Shut Off Valves

Shut off valves serve diverse roles across industries:

- Residential: Isolate water supply during repairs (e.g., ball valves under sinks). - Industrial: Regulate steam, chemicals, or fuels (globe valves, diaphragm valves). - Oil & Gas: Ensure safety with ESDVs during leaks or pressure surges. - Fire Protection: Butterfly valves enable rapid water flow control in sprinkler systems. - Pharmaceuticals: Needle valves maintain precision in fluid handling.

How Do Shut Off Valves Work

The operating mechanism varies by type but follows a general principle:

1. Actuation: Valves are operated manually (handwheel, lever) or automatically (electric/pneumatic actuators).

2. Flow Control:

– Ball/Butterfly Valves: Rotate 90° to open/close. – Gate/Globe Valves: Linear motion raises/lowers the gate or disc. – Check Valves: Rely on flow pressure to open/close.

3. Sealing: Tight seals (rubber, PTFE) prevent leaks when closed.

Choosing the Right Valve

Selecting a shut off valve depends on factors like:

- Fluid Type: Corrosive fluids demand diaphragm valves; gases suit ball valves. - Pressure/Temperature: High-pressure systems require robust ESDVs or gate valves. - Frequency of Use: Ball valves last longer in high-cycle applications.

Conclusion

From ESDVs in hazardous environments to simple ball valves in homes, shut off valves are the backbone of fluid control systems. Understanding their types, uses, and mechanics ensures optimal performance and safety. Regular maintenance and correct valve selection further enhance system longevity.

#ball valve manufacturers in india#ball valve suppliers#china ball valve#china valve manufacturer#valve manufacturer#valve factory#valve price#shut off valve#gate valve#butterfly valve#esdv

1 note

·

View note