#plastic injection mold design services

Explore tagged Tumblr posts

Text

Why Design for Injection Molding (DfIM) Is Critical for High-Quality Plastic Parts

Imagine investing months into designing a groundbreaking plastic component—only to discover during production that it warps, cracks, or simply can’t be molded efficiently. This nightmare scenario is all too common when Design for Injection Molding (DfIM) is overlooked. In industries ranging from medical devices to automotive manufacturing, achieving high-quality plastic parts isn’t just about aesthetics or functionality—it’s about ensuring every step of the process, from design to production, aligns seamlessly.

Design for Injection Molding (DfIM) is the secret weapon that transforms good ideas into great products. By integrating principles like plastic part design optimization and leveraging expert injection mold design services, DfIM ensures your parts are manufacturable, cost-effective, and built to last. In this in-depth guide, we’ll explore why DfIM is indispensable, how it applies to specialized fields like DFM for medical devices, and why partnering with a design and manufacturing company—such as Aprios—can make all the difference. Let’s get started.

What Is Design for Injection Molding (DfIM)?

At its core, Design for Injection Molding (DfIM) is a strategic approach within the broader discipline of Design for Manufacturing (DFM). It focuses on tailoring plastic part designs specifically for the injection molding process—one of the most versatile and widely used methods for producing precise, repeatable components. DfIM isn’t just about making a part look good on paper; it’s about anticipating how that design will behave when molten plastic is injected into a mold under high pressure.

The process begins with understanding the unique demands of injection molding: material flow, cooling rates, and mold release. Whether you’re crafting a simple consumer product or a complex component requiring DFM for medical devices, DfIM ensures your design is optimized for production. This might mean adjusting wall thickness, adding draft angles, or rethinking feature placement—all part of plastic part design optimization.

Industries like healthcare, automotive, and electronics rely on DfIM to bridge the gap between creativity and practicality. By working with plastic injection mold design services, companies can avoid costly redesigns and bring their products to market faster. In short, DfIM is the foundation of efficient, high-quality plastic manufacturing.

Why DfIM Is Critical for High-Quality Plastic Parts

Injection molding is a high-stakes game. With pressures reaching thousands of PSI and cycle times measured in seconds, there’s little room for error. A poorly designed part can lead to defects like sink marks, warping, or incomplete fills—issues that compromise both quality and profitability. Here’s why Design for Injection Molding (DfIM) is essential for delivering high-quality plastic parts:

Defect Prevention: Uniform wall thickness is a cornerstone of DfIM. Uneven walls can cause uneven cooling, leading to stresses that distort the final part. Proper draft angles—slight tapers on vertical surfaces—make ejection easier and reduce surface imperfections. These details, often refined through injection mold design services, are what separate a flawless part from a flawed one.

Material Efficiency: Choosing the right resin is only half the battle; DfIM ensures the design maximizes that material’s potential. For instance, a part with excessive thickness wastes material and increases cooling time, while a thin, optimized design—crafted with design for manufacturing solutions—balances strength and efficiency.

Cost Savings: Every iteration of a mold or design tweak costs time and money. By incorporating DFM services early, DfIM minimizes trial-and-error, reduces scrap rates, and shortens production timelines. The result? Lower costs without sacrificing quality.

Consider a real-world example: a manufacturer designing a plastic housing for an electronic device. Without DfIM, they might overlook shrinkage rates, leading to parts that don’t fit their assemblies. With DfIM, they’d account for this upfront, ensuring a perfect fit every time. Across industries, high-quality plastic parts owe their success to this meticulous approach.

DfIM in Action – Key Principles and Best Practices

To truly harness the power of Design for Injection Molding (DfIM), designers must adhere to a set of proven principles. These aren’t just guidelines—they’re the building blocks of manufacturability. Here’s a closer look at the essentials, along with practical applications:

Avoid Sharp Corners and Undercuts: Sharp edges disrupt resin flow and create stress concentrations that can crack under load. Rounding corners improves mold filling and strengthens the part. Similarly, undercuts—features that trap the part in the mold—complicate ejection. Injection mold design services can suggest alternatives, like side actions or redesigns, to keep things simple.

Optimize Ribs and Bosses: Ribs add strength without excessive material, but they must be thin (typically 50-60% of wall thickness) to avoid sink marks. Bosses, used for screws or inserts, need proper spacing and support. These tweaks, part of plastic part design optimization, ensure durability without overcomplicating the mold.

Incorporate Proper Tolerances: Injection molding requires tighter tolerances than, say, 3D printing. DfIM aligns tolerances with the process’s capabilities—typically ±0.005 inches for precision parts. Collaborating with plastic injection mold design services ensures these specs are realistic and achievable.

Take a plastic gear as an example. A DfIM-optimized design might feature rounded tooth profiles, consistent thickness, and a slight draft for easy release—making it both functional and mold-friendly. These best practices, refined through design for manufacturing solutions, turn concepts into production-ready realities.

DfIM for Specialized Applications (e.g., Medical Devices)

When precision and reliability are non-negotiable, DFM for medical devices elevates DfIM to a whole new level. Medical components—like syringe barrels, catheter housings, or implant casings—must meet stringent regulatory standards (e.g., FDA or ISO 13485) while performing flawlessly in life-or-death scenarios.

Here, DfIM goes beyond basic manufacturability. It considers biocompatibility (ensuring materials won’t harm patients), sterilization compatibility, and microscopic tolerances. For instance, a poorly designed mold draft could leave burrs on a surgical tool, posing a contamination risk. DFM development services address these challenges by integrating regulatory insights into the design phase.

A practical case: designing a plastic inhaler component. DfIM ensures airtight seals and smooth surfaces for patient safety, while design for manufacturing services validate the design against medical standards. This specialized focus makes DfIM indispensable for industries where failure isn’t an option.

How Design and Manufacturing Companies Support DfIM

Bringing a plastic part from sketch to shelf is no small feat, and that’s where a design and manufacturing company shines. Companies like Aprios offer a suite of DFM services that amplify DfIM’s impact:

Plastic Injection Mold Design Services: Crafting molds tailored to your part’s geometry, material, and production volume. A well-designed mold can handle millions of cycles without wear.

Prototyping and Testing: Before committing to full production, prototyping—often via 3D printing or soft tooling—lets you validate DfIM principles. Adjustments here save headaches later.

DFM Analysis: Using simulations and expertise, injection mold design services identify potential issues—like resin flow bottlenecks or cooling inefficiencies—early in the process.

For example, a company developing a plastic automotive bracket might turn to design for manufacturing solutions to refine rib placement and test mold durability. The result is a part that’s lighter, stronger, and cheaper to produce. With expert support, DfIM becomes a competitive edge.

Common DfIM Mistakes to Avoid

Even seasoned engineers can trip over DfIM pitfalls without proper guidance. Here are the most common mistakes—and how DFM services can help you steer clear:

Ignoring Shrinkage Rates: Different plastics shrink at different rates (e.g., ABS at 0.5-0.8%, nylon at 1-2%). Failing to adjust for this distorts dimensions. Plastic injection mold design services calculate shrinkage upfront.

Overcomplicating Designs: Adding unnecessary features—like intricate textures or redundant supports—increases mold complexity and cost. Simplify with plastic part design optimization.

Skipping DFM Reviews: Rushing to production without a design for manufacturing services review risks missing flaws—like inadequate venting—that cause defects.

Picture a phone case with an overly elaborate logo. Without DfIM, it might stick in the mold or show burn marks from trapped air. A quick DFM check could streamline the design, saving thousands in rework. Prevention, powered by expertise, is always cheaper than correction.

Conclusion

Design for Injection Molding (DfIM) isn’t just a step in the process—it’s the backbone of producing high-quality plastic parts that meet performance goals and budget constraints. From DFM for medical devices to everyday consumer goods, DfIM ensures your designs are manufacturable, efficient, and built to impress. By embracing plastic part design optimization, avoiding common pitfalls, and tapping into design for manufacturing solutions, you’re setting your project up for success.

At Aprios, we specialize in turning your ideas into reality with expert plastic injection mold design services and comprehensive DFM development services. Don’t leave quality to chance—contact us today to discuss your next project. Let’s collaborate to create something extraordinary, from concept to completion.

#Design for Injection Molding (DfIM)#DFM for Medical Devices#Plastic Part Design Optimization#design and manufacturing company#plastic injection mold design services#injection mold design services#dfm services#design for manufacturing solutions#dfm development services#design for manufacturing services

0 notes

Text

Why Plastic Injection Mold Is The Go To For Durable Custom Products

Discover plastic injection molding is the top choice for creating durable, customizable products that are ideal for various industries and manufacturing needs. Read More:- https://www.plastic-injectionmolds.com/knowledge-base/why-plastic-injection-mold-is-the-go-to-for-durable-custom-products

0 notes

Text

Did you know about #AluminiumExtrusion Die Steel? Are you looking the best quality Aluminium Extrusion #DieSteelH13 in India?

Aluminium extrusion dies are essential tools used in the process of shaping aluminium profiles and components through extrusion. These dies are typically made from high-strength tool steel and are designed to withstand high pressures and temperatures during the extrusion process.

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance: Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory: With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more! https://www.viratsteels.com/h13.html

Any further queries feel free to contact us : ���+91 98140-21775 🌐https://www.viratsteels.com/ 📬 [email protected]

#india#ludhiana#gurgaon#viratspecialsteels#viratsteels#toolsteelsupplier#gurugram#pune#ExtrusionDies#AluminumProfiles#AluminumIndustry#PrecisionSteel#DIN2344Steel#H13DieSteel#IndustrialMaterials

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

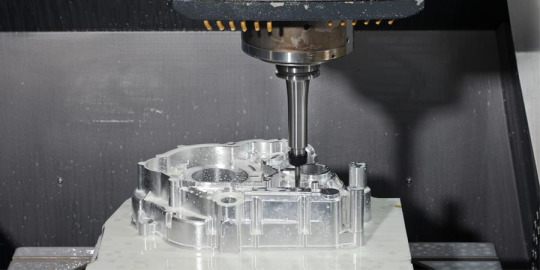

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

extruder screw barrel

There are plenty of enterprises these days creating plastic derivatives. Yet, every firm or manufacturing corporation requires a plastic type of tool. one essential part of plastic processing tools is a screw barrel, which has a threaded design for melting, mixing, and shaping plastic materials. This unique barrel, which is used in conjunction with a screw to efficiently melt, compress, and inject molten plastic into molds, is essential to the manufacturing processes that produce plastic goods. Without an Extruder Screw Barrel technique, any plastic derivative department can't achieve the final stage. Also, with the service of these Screw Barrels, the derivative unit can effortlessly achieve the crucial quantity of creation.

For more information, contact us : +91- 9081802800, e-mail : [email protected]

#ScrewBarrel#PlasticProcessing#IndustrialTools#ManufacturingComponents#MachineryParts#commercial#marketing#ecommerce#branding#sales

1 note

·

View note

Text

Expert mechanical design engineering company offering services such as 3D moulding products design, plastic mould design, 2D drafting DFM for mould manufacturing CNC programming for machines

Thiram is capable of providing product development and design. Our three decades of experience in the engineering field have helped us develop unmatched expertise in the market. Our strong material technology has helped us serve time and distance for the customers.

2 notes

·

View notes

Text

FOSHAN SHIKAI PLASTIC TECHNOLOGY CO., LTD.

Foshan Shikai Plastic Technology Co., Ltd.Factory located at the Nanhai District Foshan City.A manufacturer of PET plastic bottles of middle and High Grade Cosmetic packaging materials and cosmetic series.

It's a set of product design, mold customization, injection molding, blow molding, screen printing, bronzing, electroplating, spray paint in one of the cosmetics packaging manufacturers.

Since its establishment in 2020, it covers an area of 15000 square meters, has more than 20 production equipment, monthly production can reach 10 million, from production to design, processing, packaging, etc. to provide one-stop service.

2 notes

·

View notes

Text

Plastics Manufacturing Houston

Plastics Manufacturing Houston specializes in plastic injection molding, we make quality custom components for medical, energy, automation consumer industries, etc. We can offer complex injection molding services to our customers; we offer high-quality plastic products and services. Our state-of-the-art facility offers a wide range of plastics manufacturing capabilities, including design, engineering, prototyping, production, and assembly. Our team offers high-quality parts, on-time delivery, and precision injection molding. We have a team of design engineers who help customers through the design process by creating 3D/2D models and bringing their ideas to life.

0 notes

Text

From Design to Delivery: How an Injection Molding Turnkey Solution Works

1. What is a Turnkey Solution?

Defining Turnkey Solutions Across Industries

A turnkey solution is a complete service where one company handles everything in a project. From the early design to the final product delivery, the same provider takes care of all the steps. This makes things easier and faster for clients. It also means there is one contact point and no need to deal with many suppliers.

Turnkey project solutions are used in many industries. For example, turnkey manufacturing solutions for medical devices include cleanroom production and strict safety checks. Turnkey plastic injection molding is common in the automotive industry for parts like dashboards and connectors. Turnkey custom packaging solutions are great for companies that need strong and eco-friendly boxes or wraps for their products.

The main benefits of turnkey solutions are simple but powerful. They reduce confusion, save time, and cut down on costs. This is especially helpful for small businesses. Turnkey solution for small business options allow startups to go from concept to product quickly without huge teams or extra costs.

Turnkey vs. Traditional Manufacturing

Traditional manufacturing uses separate vendors for each part of the process—design, tooling, production, testing, and shipping. This takes more time, and mistakes can happen during hand-offs.

Turnkey injection molding solutions, however, use a smooth, integrated process. Everything happens under one roof, including design, CNC machining, molding, PCB production, and packaging. This is especially useful for fast-moving industries like electronics and automotive.

CNC turnkey solutions are a great example. Precision cutting is done using computer-guided machines, and then the same company molds, tests, and ships the product. In environmental industries, environmental turnkey solutions ensure everything from eco-materials to low-energy production is handled efficiently. PCB turnkey solutions are also key in electronics, helping companies build full systems—from the board to the case—without switching vendors.

2. The Anatomy of an Injection Molding Turnkey Solution

Stage 1: Collaborative Design & Engineering

Everything starts with a clear conversation between the provider and the client. What does the customer need? What are the challenges? Whether it’s a medical device, a car part, or an electronic case, the goals must be clear.

Then comes material selection. Medical devices might need silicone that meets safety standards. For eco-friendly packaging, bio-based plastics are used to meet environmental goals. These choices are part of smart environmental turnkey solutions.

Next is tooling design. This step uses advanced machines like CNC cutters and EDM (Electrical Discharge Machines). The goal is to make molds with tight accuracy—sometimes up to 0.01 mm. CNC turnkey solutions ensure this part is both fast and precise.

Stage 2: Prototyping & Validation

Before full production starts, the team builds samples or prototypes. 3D printing helps with fast tests for plastic designs. CNC machines shape metals into the right form.

Electronic products often need PCBs, so functional PCB turnkey solutions are tested at this stage. All products are checked under quality standards, like ISO 9001. For medical items, FDA regulations may also apply.

Stage 3: High-Volume Production

Once everything looks good, it’s time for mass production. Innovative turnkey automation solution systems use robotic arms and AI tools to do repetitive work faster and more accurately.

Scalability is key here. Whether it’s an OEM turnkey solution for large volume injection or a limited run of a custom part, the system should be flexible. This is important for both big clients and smaller companies using injection molding turnkey production.

Stage 4: Post-Processing & Assembly

After molding, many parts need extra work. Over-molding may combine materials, and surface finishing improves the look or touch. In electronic items, this step includes putting together wires, PCBs, and cases into one working device.

Medical items may need a cleanroom. These rooms have special filters to stop dust and germs. Turnkey manufacturing solutions for medical devices often include this type of setup.

Stage 5: Logistics & Global Delivery

A good turnkey solution doesn’t end when the product is finished. Full-service providers handle delivery too. They use DDP (Delivered Duty Paid) shipping, which means customs and fees are taken care of for the customer.

Packaging is another key point. Turnkey custom packaging solutions protect fragile PCBs or shiny car parts. Whether shipping by air, sea, or rail, the product stays safe.

3. Why Choose a Turnkey Partner Like Silkbridge?

Industry-Specific Expertise

Silkbridge understands different industries. In the automotive world, they make molds for parts like sensors and clips. Their injection molding turnkey production system meets the exact needs of car makers.

In healthcare, their cleanrooms help make safe, high-quality tools and components. Their turnkey electrical solutions and turnkey electronic solutions also support the growing medical tech field.

In electronics, they support wearables, smart home devices, and more. Their pcb turnkey solutions ensure each board works perfectly and fits into its molded case.

Advanced Technologies Driving Efficiency

Silkbridge uses smart systems to make things faster and better. Machines and sensors monitor each step, which means problems are spotted early. This is called smart manufacturing.

Their sustainability promise is also strong. They use recycled materials and green energy. Environmental turnkey solutions at Silkbridge help lower the impact on the planet.

Cost & Risk Mitigation Strategies

Turnkey project solutions should be clear and easy to understand. Silkbridge offers predictable pricing so companies know what they’ll pay.

Quality is another area they take seriously. They use machines like CMMs, AOI systems, and even X-rays to find tiny errors. All these tools are part of their turnkey injection molding solutions and help avoid costly mistakes.

4. Real-World Applications of Turnkey Solutions

Case Study 1: Medical Device Manufacturing

A client needed to make millions of syringe parts that passed FDA rules. Silkbridge designed the mold, chose safe materials, and used a cleanroom for production. The client received finished products quickly and safely thanks to this complete oem turnkey solution for large volume injection.

Case Study 2: Automotive Electronics Integration

Another customer needed flexible PCBs placed inside a heat-resistant case. Silkbridge used over-molding and thermal testing to solve the problem. Their cnc turnkey solutions and electronic assembly know-how made it possible.

Case Study 3: Eco-Friendly Packaging

A company wanted biodegradable boxes. Silkbridge picked green materials and used energy-saving molding methods. Their environmental turnkey solutions helped the client meet its climate goals while keeping costs low.

5. How to Evaluate a Turnkey Provider

5 Critical Questions to Ask

1.Do they support everything from design to delivery?

2.Can they help with certifications in strict industries?

3.What automation tools do they use for large-scale jobs?

4.Can they keep the supply chain stable during delays or shortages?

5.Do they offer services like packaging, repairs, or warehousing?

Silkbridge’s Differentiators

Silkbridge is a British-Chinese company. They combine smart Western ideas with the power of China’s supply chain. This mix makes their turnkey injection molding solutions fast, smart, and cost-effective.

They also offer everything under one roof. That includes design, mold-making, pcb turnkey solutions, shipping, and more. This “one-stop-shop” method means fewer delays and better teamwork.

7. FAQs About Turnkey Injection Molding

Q: What industries benefit most from turnkey solutions?

A: The top ones are automotive, medical, electronics, and industrial equipment.

Q: How do turnkey solutions reduce time-to-market?

A: They let many steps happen at the same time, like mold making and material buying.

Q: Can small businesses afford turnkey services?

A: Yes. Turnkey solution for small business packages are priced fairly and scaled to match your needs.

Ready to streamline your production? Explore how Silkbridge’s turnkey injection molding solutions can transform your ideas into market-ready products—from medical-grade components to smart IoT devices. Request a free quote now at [email protected]. Or use our WhatsApp link https://wa.me/8618122838771 . Let’s build your vision, one precision-molded part at a time.

0 notes

Text

Achieve Precision in Mold Design with Plastic Flow Simulation

In today’s competitive manufacturing landscape, optimizing plastic part design and mold tooling is critical to ensuring product quality, reducing time-to-market, and minimizing costly rework. Plastic Flow Simulation empowers mold designers and manufacturers to visualize the behavior of molten plastic during the injection molding process — before a single mold is cut. DDSPLM brings cutting-edge plastic flow simulation capabilities powered by Siemens NX and Moldex3D, enabling manufacturers to validate, optimize, and refine mold designs digitally.

What is Plastic Flow Simulation?

Plastic flow simulation is a virtual injection molding analysis process that predicts how molten plastic will fill a mold cavity. It provides insights into potential problems such as air traps, weld lines, sink marks, short shots, warpage, and cycle time inefficiencies. This simulation allows for early detection and correction of design flaws, reducing the number of mold trials and rework costs.

Features of Plastic Flow Simulation

Supports simulation of filling, packing, cooling, and warpage phases

Built-in material database for accurate behavior prediction

Gate optimization tools for ideal injection locations

Cooling channel analysis with 3D visualization

Shrinkage and warpage prediction using real-world parameters

Integration with NX CAD and Moldex3D for seamless workflow

Capability to simulate multi-cavity molds and hot runner systems

Benefits of Plastic Flow Simulation

Minimize mold trial costs and reduce development cycle

Improve part quality and reduce defects like warpage or sink marks

Optimize gate locations and runner design

Prevent costly mold modifications

Increase confidence in mold performance before manufacturing

Improve customer satisfaction by delivering consistent results

Ensure better part strength and dimensional accuracy

Why Choose DDSPLM?

DDSPLM is your trusted partner in delivering end-to-end digital manufacturing solutions. Here’s why leading mold makers and manufacturers choose DDSPLM for plastic flow simulation:

Expertise in Siemens NX & Moldex3D

Tailored Simulation Services

Proven Track Record

Training and Support

Seamless Integration

Conclusion

Plastic Flow Simulation is no longer optional — it’s essential for competitive mold and tooling design. By visualizing how molten plastic flows, cools, and warps, manufacturers can design better parts, reduce trial runs, and save on time and costs. DDSPLM enables this transformation with powerful tools and deep domain expertise. Whether you’re designing complex automotive parts or high-precision consumer goods, DDSPLM’s plastic flow simulation solutions help you bring reliable, defect-free products to market — faster.

0 notes

Text

Material Handling Systems Heat Master International engineers effective material handling systems to automate the movement, storage, and control of products during manufacturing processes. These systems are engineered for reliability and integration, improving productivity in automotive, metal processing, and heavy equipment manufacturing industries.

Turnkey Projects Providing whole end-to-end solutions, Heat Master International takes charge of turnkey projects incorporating design, engineering, fabrication, installation, and commissioning. Such projects are tailored to customers' needs for various industries such as energy, manufacturing, and process industries in terms of delivering efficiently and punctually.

Process Equipment Heat Master's process equipment accommodates diverse industrial uses, ranging from reaction and mixing systems to thermal processing units. Durable and engineered to precise standards, these systems are designed to provide consistent process quality as well as industry-standard conformity.

Industrial Immersion Heaters Heat Master's industrial immersion heaters are built to warm liquids directly in tanks or vessels. They are utilized in water, oil, and chemical heating systems and provide fast thermal transfer, corrosion resistance, and reliable performance in harsh environments.

Nozzle Heaters Heat Master nozzle heaters offer direct, intense heat for injection molding and extrusion applications. Designed with exacting temperature control and consistent heat distribution, they provide product consistency and lower cycle times in rubber and plastic processing.

Gas-Fired Pit Furnaces These heavy-duty furnaces are best suited for heat treating big metal parts, including gears and shafts. Heat Master gas-fired pit furnaces provide profound heat penetration, accurate atmosphere control, and energy efficiency for processes such as carburizing, annealing, and tempering.

Rotary Kiln Direct Firing Systems Heat Master direct-fired rotary kiln systems are intended for high-temperature processing of bulk materials like minerals, clays, and waste products. Stable flame control, even heat distribution, and maximum combustion efficiency are provided by the systems.

Roller Hearth Furnaces Roller hearth furnaces are continuous heat-treatment processes employed in high-volume production. Heat Master builds them with uniform temperature control, rapid throughput, and limited distortion in mind, perfect for processes such as brazing, annealing, and sintering.

Casting Heaters Casting heaters distribute consistent heat across casting surfaces and molds to ensure die casting and foundry operation consistency. Heat Master's designs aim at thermal stability and accurate control to minimize defects and enhance surface finish.

Ceramic Band Heaters Designed for high-temperature use, ceramic band heaters provide effective heat transfer and insulation. Used in plastic processing equipment, Heat Master's ceramic band heaters provide consistent heating with lower energy usage and extended service life.

Duct Heaters Heat Master's duct heaters are employed for air heating in HVAC applications and industrial drying. With provision for custom designs and intelligent safety features, they ensure consistent, reliable airflow heating in both commercial and industrial settings.

0 notes

Text

Chhaperia: Leading the Way as a Premier Mica Heater Manufacturer

One name that consistently meets and exceeds these expectations is Chhaperia, a renowned mica heater manufacturer with decades of expertise. Recognized for delivering world-class heating solutions, Chhaperia has earned its reputation through innovation, quality, and a deep commitment to customer satisfaction.

What Makes Mica Heaters Special?

Mica heaters are widely used in industries for their excellent thermal conductivity, durability, and ability to operate at high temperatures. These heaters are ideal for applications that demand uniform heat distribution and quick response times. Mica heaters are typically used in the plastics, packaging, medical, and food processing industries due to their compact design and efficiency.

Chhaperia specializes in the design and production of mica band heaters, strip heaters, and custom mica-based heating solutions that meet specific industry needs.

Chhaperia’s Expertise in Mica Heater Manufacturing

As a seasoned mica heater manufacturer, Chhaperia combines years of engineering experience with state-of-the-art manufacturing facilities. Their heaters are crafted using high-quality mica insulation, stainless steel sheathing, and precision-wound resistance coils, resulting in a product that delivers consistent heat with maximum energy efficiency.

What sets Chhaperia apart is not just their technical know-how, but their ability to provide customized solutions. Whether clients require heaters for standard applications or specialized machinery, Chhaperia tailors each product to match exact specifications, ensuring optimal performance and longevity.

Commitment to Quality and Innovation

Chhaperia’s commitment to quality is evident in every stage of the manufacturing process. From sourcing premium-grade materials to conducting rigorous in-house testing, each mica heater is built to meet international safety and performance standards. The company adheres to ISO-certified protocols and ensures that each unit undergoes electrical and thermal testing before leaving the facility.

This emphasis on quality control makes Chhaperia a trusted partner across industries that demand precision heating—where even minor performance issues can lead to costly downtime.

Serving Diverse Industrial Needs

Chhaperia’s mica heaters are designed to serve a wide range of applications:

Plastic processing equipment (injection molding, extrusion machines)

Packaging machinery

Medical devices

Food processing equipment

Die and platen heating

By understanding the unique needs of each industry, Chhaperia ensures that their mica heaters are not only fit-for-purpose but also exceed expectations in terms of durability and efficiency.

Why Choose Chhaperia?

Choosing Chhaperia as your mica heater manufacturer means you’re partnering with a company that prioritizes your operational success. Clients benefit from:

Custom-engineered mica heating solutions

Competitive pricing with no compromise on quality

Rapid response times and dependable delivery schedules

Experienced technical support and after-sales service

Whether you’re an OEM, systems integrator, or maintenance specialist, Chhaperia provides the heating expertise you need to keep your operations running smoothly.

Chhaperia continues to lead the field as a reliable and forward-thinking mica heater manufacturer, blending innovation with tradition to meet the ever-evolving needs of modern industry.

0 notes

Text

The Precision Powerhouse Behind Injection Molds in Dallas: Why Local Expertise Matters

In the heart of Texas, the manufacturing industry thrives with innovation, resilience, and precision. At the core of this industrial ecosystem lies a crucial element—injection molds. These meticulously crafted tools are vital for producing consistent, high-quality plastic parts used in countless applications, from automotive components to medical devices. For companies seeking top-tier injection molds Dallas, the region offers an impressive array of expertise, resources, and advanced machining capabilities.

Why Injection Molds Are Essential

Injection molds are the foundation of efficient and scalable plastic manufacturing. Precision is key: even a minor imperfection can compromise the integrity of a final product. That’s why businesses across Texas prioritize experienced partners that specialize in precision tooling, especially in fast-paced sectors like aerospace, electronics, and consumer products. Local manufacturers who understand the specific needs of Texas industries are better equipped to deliver consistent, high-performance results.

The Role of Machining Services in Dallas

Behind every durable injection mold is a robust support system of machining services in Dallas. These services include CNC machining, turning, milling, and surface finishing—all critical steps in crafting high-tolerance molds. The region is home to advanced shops like Lowrance Machine, a trusted name known for its commitment to quality and fast turnaround times.

Lowrance Machine combines decades of hands-on experience with state-of-the-art equipment to produce some of the most reliable tooling and mold solutions in the industry. Their capabilities span far beyond just molds—they are a full-spectrum CNC machine shop in Dallas offering custom fasteners, cast inserts, and specialized parts tailored for unique production needs.

CNC Milling Dallas: Precision at Its Finest

A key technology used in mold making is CNC milling. In Dallas, the level of innovation in CNC milling has grown significantly, with shops offering 3-, 4-, and even 5-axis milling solutions. This allows for intricate mold designs, tight tolerances, and optimized production cycles. Whether you're producing thousands of parts or limited prototypes, precision milling ensures the mold performs perfectly, batch after batch.

The Importance of Versatility in Industrial Solutions

Beyond mold-making, facilities like Lowrance Machine play a broader role in the manufacturing landscape. Their expertise in industrial equipment repair in Dallas makes them a go-to resource for companies needing fast, reliable service to keep operations running smoothly. Downtime in manufacturing is costly, and having a partner who can swiftly diagnose and repair critical equipment is invaluable.

Moreover, services like producing custom fasteners in Dallas and cast inserts allow local manufacturers to streamline their supply chains and ensure compatibility and performance across their products.

Conclusion: Partner with the Best

Choosing the right partner for injection molds in Dallas means looking for precision, speed, and reliability. Lowrance Machine has earned a reputation as one of the best in the region for all-encompassing machining services in Dallas. From high-precision CNC milling to reliable industrial equipment repair, they offer a one-stop solution for manufacturers who demand excellence.

For companies that refuse to compromise on quality, partnering with a local expert like Lowrance Machine isn’t just a choice—it’s a competitive advantage.

1 note

·

View note

Text

Supplier of PET Bottle Scrap Washing Line

R Mech Machine LLP is a leading and prominent Manufacturer, Exporter and Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha. Our manufacturing unit is based in Ahmedabad, Gujarat, India. R Mech Machine LLP provides PET Bottle Scrap Washing Line, HDPE/PP/PVC/PPCP Scrap washing line, LDPE/PP Film Scrap Washing Line. We design our machines for high performance, durability, and versatility to meet the ever-growing demands of the global recycling industry. We engineer this line to process post-consumer PET bottles into clean PET flakes, ideal for reuse in textiles, packaging, and more. This washing line efficiently processes rigid plastics like detergent bottles, milk jugs, and industrial plastic waste into clean, recyclable granules. We specifically designed it for handling soft plastics such as agricultural films, shopping bags, and packaging films. Features: Automated Control System: Smart PLC-based control panels for efficient and user-friendly operation. High-Efficiency Friction Washers & Float-Sink Tanks: Advanced washing technology ensures optimal separation and cleaning. Stainless Steel Contact Parts: Rust-resistant and food-grade compliant components. Energy-Efficient Design: Optimized motors and low-energy consumption systems reduce operating costs. Robust Construction: Built with premium-grade materials to ensure durability in demanding environments. Benefits: Superior Cleaning Efficiency: Delivers high-purity output with minimum residual contamination. Reduced Labor Costs: High degree of automation minimizes manual intervention. Flexible Input Material Handling: Capable of processing mixed, colored, and printed plastic waste. Minimal Water Usage: Closed-loop water systems ensure reduced water consumption and better environmental performance. Long Service Life: Heavy-duty design and minimal maintenance ensure consistent long-term operation. Return on Investment: Increases profitability through efficient plastic recovery and resale. Applications & Uses: Textile Industry Packaging Sector Film Extrusion Injection Molding Waste Management Firms FAQs Q1: What materials can be processed in a single washing line? A1: We offer both mono and multi-material configurations, depending on the customer’s input material and end use. Q2: Can your lines be customized to fit space constraints? A2: Yes, our engineers design modular systems tailored to specific space and capacity requirements. Q3: What is the typical installation time? A3: Depending on complexity, installations take 20 to 60 days from the date of site readiness. Q4: Do you offer operator training? A4: Yes, we provide comprehensive on-site or remote training with detailed operational manuals. R Mech Machine LLP is a Supplier of PET Bottle Scrap Washing Line in Jharkhand and Odisha including locations Ranchi, Jamshedpur, Dhanbad, Hazaribagh, Bokaro, Deoghar, Koderma, Giridih, Garhwa, Gumla, Bhubaneshwar, Cuttack, Rourkela, Angul, Mayurbhanj, Puri, Sambalpur, Brahmapur. Contact us today for a free consultation or a quote. View Product: Click here Read the full article

0 notes

Text

Choosing the Right Plastic Manufacturing Company in India: A Complete Guide

India’s plastic manufacturing industry has seen rapid growth in recent years, becoming a global hub for high-quality and cost-effective plastic products. Whether you're a startup looking for packaging solutions or a multinational sourcing plastic components, selecting the right plastic manufacturing company in India can make or break your supply chain efficiency.

Why India for Plastic Manufacturing?

India is one of the largest producers and consumers of plastics globally. Here’s why businesses around the world are turning to Indian manufacturers:

1. Cost-Effective Production

Labor and raw material costs are significantly lower compared to Western countries. This translates into competitive pricing without compromising quality.

2. Skilled Workforce

With decades of experience, Indian companies have developed deep expertise in plastic injection molding, extrusion, blow molding, thermoforming, and more.

3. Robust Infrastructure

India’s expanding industrial zones and port connectivity make logistics smoother for global clients.

4. Sustainability Focus

Many Indian manufacturers are adopting eco-friendly materials and green manufacturing processes to align with global ESG goals.

Services Offered by Plastic Manufacturing Companies in India

A plastic manufacturing company in India typically provides a wide range of services:

● Custom Plastic Injection Molding

Precision molding for automotive, electronics, consumer goods, and medical devices.

● Extrusion & Blow Molding

Used for creating pipes, bottles, and containers at high volumes.

● Thermoforming & Vacuum Forming

Commonly used in packaging and tray manufacturing.

● Tool and Die Manufacturing

In-house mold design and fabrication for high-efficiency production.

● Assembly & Packaging

Value-added services like assembly, labeling, and bulk packaging.

● OEM and White Labeling

Ideal for companies looking to brand and sell under their own name.

Key Industries Served

Plastic manufacturers in India cater to a wide array of industries:

Automotive – dashboards, housings, panels

Electronics – enclosures, connectors, casings

Healthcare – syringes, diagnostic kits, medical devices

Consumer Goods – kitchenware, toys, storage solutions

Packaging – bottles, containers, food-grade packaging

Agriculture – irrigation pipes, greenhouse components

Top Plastic Manufacturing Hubs in India

Certain regions in India specialize in plastic manufacturing, including:

Ahmedabad, Gujarat – Known for large-scale plastic and polymer industries.

Pune, Maharashtra – A hub for automotive and precision plastic parts.

Chennai, Tamil Nadu – Major center for blow molding and extrusion.

Delhi NCR – Home to many contract manufacturers and exporters.

Bangalore, Karnataka – Popular for electronics-related plastic molding.

How to Choose the Right Plastic Manufacturing Partner

Selecting the best plastic manufacturing company in India involves a strategic approach. Here are key factors to consider:

✅ Experience & Expertise

Look for companies with proven experience in your target industry and manufacturing process.

✅ Certifications

Check for ISO 9001, ISO 14001, or industry-specific certifications like IATF for automotive or ISO 13485 for medical devices.

✅ Scalability

Ensure the partner can scale production up or down depending on your business needs.

✅ Material Capabilities

From PP, PE, and PVC to advanced polymers like ABS, PC, and Nylon—material versatility matters.

✅ Quality Control

Look for stringent QA processes, in-house testing labs, and consistent inspection procedures.

✅ Communication & Support

Reliable customer service and transparent communication are critical for successful collaboration, especially for international clients.

Leading Plastic Manufacturing Companies in India (2025)

Here are a few reputed names (for illustrative purposes):

Supreme Industries Ltd – One of India’s largest plastic processors.

Nilkamal Ltd – Known for furniture and material handling solutions.

VIP Industries – Leader in molded luggage and consumer products.

Prima Plastics – Export-oriented manufacturer serving over 30 countries.

Time Technoplast Ltd – Specializes in industrial packaging and infrastructure components.

Need help sourcing the right plastic manufacturer in India? Our team can connect you with verified, quality-driven companies tailored to your project.

Why Work with a Trusted Plastic Manufacturing Connector?

Partnering with a sourcing specialist or manufacturing consultant can save you time, money, and risk. Here’s how we help:

Pre-vetted Suppliers: Only verified and audited manufacturers.

End-to-End Support: From RFQ to delivery and after-sales support.

Cost Optimization: We help you find the best price-performance ratio.

Transparency: Full visibility across every stage of the supply chain.

Final Thoughts

India’s plastic manufacturing industry offers immense opportunities for global and local businesses alike. With the right partner, you can achieve high quality, reliable supply, and excellent value.

If you're looking to collaborate with a plastic manufacturing company in India, make sure to prioritize experience, certifications, communication, and scalability. Or, better yet—reach out to a trusted industry connector who can guide you to the best-fit supplier for your exact needs.

📞 Ready to Find Your Ideal Plastic Manufacturing Partner in India?

Contact us today to get matched with top-tier, pre-screened plastic manufacturers in India. Let us simplify your sourcing journey.

0 notes

Text

Understanding the Production and Application of CIM

In today’s rapidly growing industry the demand of high performance parts is constantly rising. For industries looking for superior quality and intricate designs – ceramic injection molding emerged as a groundbreaking solution.

This blog aims to highlight Ceramic Injection Molding Process and why is it advantageous to choose CIM supplier for your specific needs.

A Brief Overview

Ceramic injection molding is a versatile manufacturing process to enable production of complex ceramic parts with exceptional precision. By combining plastic injection molding and ceramic powder technology – it allows efficient mass production for intricate ceramic component. The process includes the injection of ceramic powder-filled binder into mold cavity.

The production process is a breakthrough manufacturing process to revolutionize the production of different ceramic parts. CIM indeed orders unparalleled advantages to fabricate high-precision ceramic components with intricate geometries.

Importance of CIM for Ceramic Part Design

The production process has streamlined the fabrication of intricate geometric, thin walls and complex shapes. In addition, it also eliminates the limitation of traditional ceramic manufacturing method. Overall, it enables the production of high-quality parts with enhanced functionality and performance.

What are Ceramic Materials?

It refers to the inorganic, non-metallic compounds with wide variety of properties including high strength, temperature resistance and chemical inertness. The materials comprised of metallic and non-metallic elements that are bonded together through ionic and covalent bonds.

Varied application

CIM Ceramic Injection Molding makes it commercially feasible to manufacture intricate geometries, with features like undercuts, perpendicular holes, screws that were ideally difficult and expensive to fabricate with traditional production process.

By shaping the components in one process combined with the beneficial features of the product – make it a perfect technology to use for various market. CIM components can be used in different medical devices including orthodontics, automotive, vacuum application, consumer products and more.

Benefits of ceramic injection molding

The applications of CIM span a wide range of industries and huge areas of research:

Forming net or net shape parts

Improving productivity and efficiency

Lower manufacturing cost

Improving product performance and high degree reproducibility

Precise surface finish

Tight tolerance

Different Materials Used for Ceramic Injection Molding

Any production powder is suited for the precise manufacturing process; however, nano dimension specializes in:

Alumina

Zirconia

ATZ

ESD (Electrostatic discharge material)

Ceramic Materials Properties

Ceramic materials possess a wide range of properties making them highly desirable for multiple applications. By understanding these properties – it is crucial to select the appropriate ceramic material for the specific requirement.

Mechanic Properties

Ceramic material exhibits exceptional mechanic properties including high strength, hardness and stiffness. The production finish is known for unparallel wear resistance and its ability to withstand high compressive force.

Thermal Performance

Ceramic materials have outstanding thermal properties that includes high thermal conductivity and resistance to thermal shock. It can withstand extreme high and low temperature. with these characteristics ceramic becomes more suitable for applications requiring thermal insulation.

Wrapping Up

If you are in the search of top-notch ceramic injection molding solution, look no further. MIM Suppliers offers cutting-edge ceramic injection molding services tailored to your specific needs.

0 notes