#plastic export pallets

Text

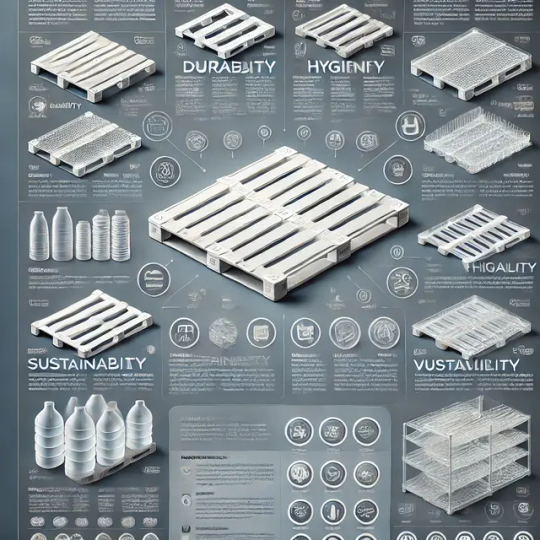

Timber Bearers vs. Plastic Export Pallets: Which Is Best for Your Shipping Needs?

When shipping goods, the choice of pallets is a crucial factor that can impact both the safety and efficiency of your logistics operations. Timber bearers and plastic export pallets are two common options used for this purpose. This blog post will delve into the key differences between these two types of pallets, helping you make an informed decision based on your specific needs.

Timber Bearers

Timber bearers, traditionally constructed from hardwood like oak or beech, have been a staple in the shipping industry for decades. They offer several advantages, including:

Durability: Known for their strength and longevity, timber bearers can withstand heavy loads and harsh conditions.

Flexibility: They can be easily repaired or modified if damaged, extending their lifespan.

Biodegradable: Timber bearers are a natural product that decomposes over time, making them environmentally friendly.

Cost-effective: While the initial cost may be higher than plastic pallets, timber bearers can be more economical in the long run due to their durability and potential for repair.

Plastic Export Pallets

Plastic export pallets, typically made from high-density polyethylene (HDPE), have gained popularity in recent years due to their numerous benefits:

Lightweight: Plastic pallets are significantly lighter than timber bearers, reducing transportation costs and improving efficiency.

Hygienic: They are easy to clean and disinfect, making them ideal for industries that require a high level of sanitation.

Waterproof: Plastic pallets are resistant to moisture and chemicals, making them suitable for various applications.

Durable: While not as durable as timber bearers, plastic pallets are still highly resistant to wear and tear.

Recyclable: Plastic pallets can be recycled at the end of their lifespan, reducing waste and environmental impact.

The decision between timber bearers and plastic export pallets ultimately depends on your specific shipping needs. By carefully considering factors such as load capacity, environmental impact, hygiene, cost, and regulatory compliance, you can select the pallet type that best suits your business.

Source

0 notes

Text

How to Reduce Product Damage in the Warehouse with Plastic Pallets

How to Reduce Product Damage in the Warehouse? Every warehouse manager knows the pain of seeing damaged goods. It causes lower profits, slows operations, and can even harm your reputation in the market. But this damage can be managed simply by using the right plastic pallets.

Plastic pallets offer a major advantage over traditional wooden pallets when protecting your products. Here’s how they can significantly reduce damage in your warehouse:

In the dynamic world of warehouse management, minimizing product damage is key to sustained success. Plastic pallets offer a modern solution many facilities embrace, effectively reducing damage and enhancing efficiency. Let’s explore how plastic pallets are used with their durability and functional versatility to improve warehouse operations and protect valuable goods.

Check The Merits of Plastic Pallets

Plastic pallets have become a preferred choice in warehouses for transportation and storage due to several advantages. These include Reduced product damage, Ease of cleaning, customizable designs, and enhanced durability with reinforced steel rods, these factors help businesses to reduce product damage.

Plastic Pallets are highly Durable

Plastic pallets are durable and don’t break during their movement while in transportation and storage. They won’t splinter, split, or break under heavy loads, ensuring your products stay safe during handling and transportation. With its durable nature pallets can resist the harsh conditions of warehouse settings, such as frequent handling, and make your transportation operation smooth.

Maintain Proper Hygiene

Plastic pallets are especially useful in areas like food and pharmaceutical sectors that have strict hygiene rules. Plastic pallets are beneficial in this sector because they are so easy to clean and wash and easy to maintain hygiene.

Lightweight Construction of Pallets

Lightweight Plastic pallets making them simpler to handle and decreasing warehouse worker accidents. Despite their low weight, they are extremely durable, providing a dependable storage solution for a wide range of products.

Enhanced Stability

Plastic pallets excel in offering superior stability owing to their uniform construction and interlocking design. This stability mitigates the risk of pallets tipping over or collapsing, thereby preventing products from shifting or falling during transportation.

Impact Resistance

Designed to withstand impacts and rough handling, plastic pallets remain resilient without sustaining damage. They absorb shocks and evenly distribute weight, This feature is particularly beneficial for fragile items or goods that are sensitive to vibrations and shocks, such as electronics, glassware, or pharmaceutical products.

Moisture Resistance

Plastic pallets do not absorb moisture or hold humidity, they are the perfect option for storing goods in moist or humid conditions while maintaining product quality.

Cleanliness

The plastic pallets are not complex in cleaning and washing to minimize dirt and dust. It helps keep the items safe at the warehouse.

Customization Options

Plastic pallets offer flexibility in design and customization. They can be tailored to specific industry requirements, such as reinforced corners and anti-slip surfaces giving a personal touch to meet your specific transportation and storage needs. These modifications not only improve pallet performance but also reduce the risk of product damage, allowing for smooth operations and peace of mind.

Conclusion

plastic pallets present a robust solution for minimizing product damage in warehouse operations. Swift’s Plastic pallets are the better option, especially when it comes to less product damage in the warehouse. Their hygienic qualities, stability, longevity, and customization possibilities make them valuable resources for companies looking to boost productivity and protect expensive stock. Warehouses may successfully reduce product damage, and speed up processes.

#plastic pallets#rackable plastic pallets#plastic industry#plasticmanufacturer#plasticpallets#plasticproducts#hdpepallets#hdpeplastic#swifttechnoplast#swifttechnoplastprivatelimited#plastic pallets manufacturer#plastic pallet supplier#warehouse safety#HDPE plastic pallets#plastic pallets near me#pallets near me#export pallets

0 notes

Text

Pallets Available In Rectangular and Square Shapes

People may be very interested in plastic pallets and uPVC pallets, but cheap timber-made pallets remain people's favorite in the storage and warehousing industry. This company's pallets are made from wood, mixed wood, plywood, softwood, and so on. They come in rectangular and square shapes and can be customised to match your business requirements. They are made from trees that don't require any chemical treatment or fumigation.

#Pallets#plastic pallets#uPVC pallets#Custom made pallets#New pallets#Cheap pallets#Recycled Export Pallets#Pallet recycling#Used pallets

0 notes

Text

Export Pallets Manufacturers in Delhi excel in producing high-quality pallets for global logistics needs. Companies like Delhi Plastics leverage advanced injection molding technology to create durable plastic pallets that meet international standards for reliability and efficiency in transportation. These pallets are lightweight, resistant to moisture, and ideal for various modes of shipping. Delhi's expertise in export pallet manufacturing ensures compliance with global regulations, facilitating smooth international trade and logistics operations.

Locate Us

Sonipat, Haryana - 131301

+91-8700900663

#syntaxplasticpallets#Plastic Pallets Manufacturers in India#Plastic Pallets Manufacturers in Delhi#Export Pallets Manufacturers in India

0 notes

Text

#Pallet Racks in Delhi#Warehouse Pallet Racks in Delhi#Pallet Racks Manufacturers in Delhi#Warehouse Pallet Racks Manufacturers in Delhi#Pallet Racks Suppliers in Delhi#Warehouse Pallet Racks Suppliers in Delhi#Pallet Racks Exporters in Delhi#Warehouse Pallet Racks Exporters in Delhi#Plastic Pallets in Delhi#Heavy Duty Plastic Pallets in Delhi#Plastic Pallets Manufacturers in Delhi#Heavy Duty Plastic Pallets Manufacturers in Delhi#Plastic Pallets Suppliers in Delhi#Heavy Duty Plastic Pallets Suppliers in Delhi#Plastic Pallets Exporters in Delhi#Heavy Duty Plastic Pallets Exporters in Delhi#Storage Rack in Delhi#Metal Storage Rack in Delhi#Storage Rack Manufacturers in Delhi#Metal Storage Rack Manufacturers in Delhi#Storage Rack Suppliers in Delhi#Metal Storage Rack Suppliers in Delhi#Storage Rack Exporters in Delhi#Metal Storage Rack Exporters in Delhi

0 notes

Text

Best Industrial Pallets Manufacturer and Supplier in India

youtube

#Industrial Pallets#Youtube#Plastic Pallets#Industrial Pallet#Euro Plastic Pallet#Single Deck Pallet#Double Deck Pallet#Air Freight Pallet#Anti Skid Plastic Pallet#Cargo Pallets#Cement Industry Pallet#Chemical Industry Pallet#Cold Storage Pallet#Confectionary Pallet#Drum Pallet#Drum Plastic Pallet#Durable Plastic Pallet#Dying Unit Pallet#Euro Pallets#Export Pallet#Food Pharma Pallet#Fourway Pallet#HDPE Pallet#Industrial Storage Pallet#Light Duty Nestable Pallet

0 notes

Text

#Industrial Pallets Manufacturers in India#Exporters#Suppliers in Pune#Industrial Wooden Pallets and Plastic Pallets Exporters in Pune#India

0 notes

Text

How Beneficial Are Plastic Export Pallets? Check Pros & Cons!

Recycled plastic export pallets have some benefits for transportation businesses. These pallets can withstand harsh environments containing acids and alkalis, ensuring durability and reliability in chemical-rich settings.

Additionally, heat-treated pallets for export meet ISPM 15 standards ideal for smooth cross-border trade and comply with international phytosanitary regulations.

They remove the possibility of breaking delicate objects while in transit because they avoid using nails. These pallets work well in situations involving repeated use and are simple to clean for use in the chemical, food, and pharmaceutical sectors.

Pros of Using Heat-Treated Packaging and Plastic Pallets for Exports:

It is important to use heat-treated pallets and packaging for transporting essential goods.

Usually, heat treatment destroys bacteria and pests, and protects the integrity and safety of items, crossing international borders is greatly decreased, protecting agricultural sectors and ecosystems.

Heat-treated pallets fulfil ISPM 15 criteria, they are compliant with international phytosanitary rules, which facilitate easy cross-border trading.

Using heat-treated pallets and packaging, removing the need for chemical treatments, supporting environmental sustainability, and improving biosecurity.

Plastic pallets are strong and lightweight, which lowers shipping costs without sacrificing product safety.

As Plastic does not absorb moisture, mould cannot grow on it and protect from decaying or distortion for longer which is essential for long-term storage and transportation.

Unlike timber storage, plastic storage pallets remain consistent in weight and size which simplifies logistics and maximises container space utilisation.

They meet strict export laws without the need for treatment because they are resistant to chemicals and pests. Their smooth surfaces reduce the possibility of contamination and product damage, preserving quality standards while in transit.

Meanwhile, business owners can find required pallets fit for different materials nearby by searching for them online at nearby locations. Visit their websites to learn more about their recycles and pallet products and also evaluate their market reputation to select and contact the right supplier for your storage needs.

Source

0 notes

Text

Rainy Season Ready? Keep Your Goods Safe During Monsoon With Swift's Plastic Pallets

The monsoon season, with its heavy downpours and high humidity, poses significant challenges for businesses, especially those involved in storage and transportation businesses. Plastic pallets are an absolute savior in this season, an innovative solution designed to safeguard your goods against the rain elements.

This blog post explains why plastic pallets are a lifesaver during the monsoon season, and how Swift's plastic pallets can specifically help protect your products.

Why Monsoon Season is Risky for Products

Monsoons bring about a unique set of problems that can compromise the integrity of your goods:

1. Water Damage: Continuous exposure to rain can lead to water damage, which weakens traditional storage solutions. Plastic pallets are impervious to water, ensuring they remain intact and strong regardless of weather conditions.

2. Mold and Mildew: The high humidity creates an ideal environment for mold and mildew, which can spread to the goods stored on or around the pallets.

3. Pest Infestation: Plastic pallets do not absorb moisture, deterring pests and ensuring a safer storage solution.

4. Structural Integrity: Plastic pallets do not swell or break when exposed to water, maintaining their structural integrity and ensuring the safety and stability of the goods.

The Advantages of Plastic Pallets

Plastic pallets present a robust option, especially in adverse weather conditions:

1. Water Resistance: Plastic pallets are impervious to water, ensuring that they do not absorb moisture, swell, or weaken.

2. Durability: Made from high quality virgin polyethylene, plastic pallets are designed to withstand harsh conditions without degrading.

3. Hygiene: Plastic does not harbor mold, mildew, or pests, ensuring a cleaner and safer environment for your goods especially in.

4. Lightweight and Strong: Plastic pallets are lighter, making them easier to handle & amp; move to another place in monsoon conditions without taking so much effort.

Why Choose Swift's Plastic Pallets?

Swift’s plastic pallets stand out in the market for their exceptional quality and innovative features:

1. Advanced Design: Swift's plastic pallets are engineered with a focus on maximizing load-bearing capacity while minimizing weight. Their design includes reinforced corners and a sturdy base to ensure stability. Our Pallets are an ideal choice during the monsoon season due to its smart features.

2. UV Resistance: These pallets are UV-resistant, preventing them from degrading when exposed to sunlight, making them suitable for both indoor and outdoor use.

3. Anti-skid Surface: The pallets feature a anti-skid surface that ensures goods stay securely in place during transit and storage, reducing the risk of damage.

Tips for Using Plastic Pallets During Monsoon

To get the most out of your plastic pallets during the monsoon, consider these tips:

1. Inspect them regularly: Conduct regular checks to ensure that the pallets are in good condition and free from any damage.

2. Store them properly: Store pallets in a dry, covered area when not in use to extend their lifespan.

3. Load Evenly: Ensure that the load is evenly distributed across the pallet to maintain balance and prevent tipping.

4. Clean Regularly: Keep the pallets clean to maintain hygiene standards and prevent any build-up of dirt or debris.

Conclusion

As the monsoon season approaches, it is crucial to safeguard your goods from the challenges posed by increased moisture and humidity. Swift’s plastic pallets offer a reliable and efficient solution to these problems, ensuring that your products remain protected, clean, and secure. By investing in Swift's plastic pallets, you are not only enhancing the safety of your goods but also contributing to a more sustainable and cost-effective supply chain.

Prepare for the monsoon with confidence and let Swift’s plastic pallets be your first line of defense against the elements.

#plastic pallets#industrial pallets#plastic pallet manufacturer#plastic pallet supplier#HDPE pallets#plastic pallets near me#export pallets#plasticproducts#plastic industry#swifttechnoplast#plasticmanufacturer

0 notes

Text

Should We Choose Plastic Or Timber Pallets And Dunnage?

Pallets and dunnage are an essential part of supply chain and warehouse operations. The most prominent choice in terms of pallets is wooden or plastic pallets. People often find it challenging to decide, and since wooden pallets and dunnage have been in use for decades, they rely on the same without any doubt. However, plastic pallets are also as good as wooden pallets and have several advantages. We have compared the wooden and plastic pallets in this blog post to conclude regarding your selection.

PLASTIC PALLETS ADVANTAGES

Plastic pallets offer numerous benefits compared to wooden pallets, and the biggest feature is that they are cleaner than wooden pallets. This is why they are recommended more in industries with strict hygiene requirements. The most common are fresh and frozen food supply, pharmaceutical industry, and much more. Plastic pallets don't experience mould or bug growth and infestation, and they are easier to clean. Sterilising them is also very simple, as they are non-porous.

Compared to wooden dunnage and pallets, plastic pallets are more beautiful and weather-resistant. Since they have no fasteners or nails, they are safer for people around them. Another significant feature of plastic pallets is that they are significantly lighter in weight than their wooden counterparts and dunnage. Plastic pallets perform incredibly well as export pallets.

TIMBER PALLETS AND DUNNAGE ADVANTAGES

Timber pallets are highly reliable and have been in use for decades now, and this is why they are more trusted. One significant advantage of timber pallets and dunnage is the cost, and the wooden pallets and dunnage are less expensive. Timber pallets and dunnage can support more weight, and there is no upper limit on the weight. They can help with any weight, and this is a significant advantage over plastic pallets. You can get timber pallets custom-designed to match the shape and size of the shipment to be delivered. This is not the case with plastic pallets, as their standard sizes are limited. Wooden pallets are reusable and can be recycled very easily. When not in use, they can be used as mulch or garden bedding, and this way, they are completely eco-friendly.

THE BOTTOM LINE

As far as the selection is concerned, it differs from customer to customer, and the last decision is taken based on some factors. The industry and products are the two significant factors, followed by the weight of the consignment and its sensitivity. Whether you are planning to export your product is another primary concern related to selecting plastic or timber pallets. Similarly, cost is also a significant factor is the customisation you want in the size of the pallets.

0 notes

Text

Export Pallets Manufacturers in India: Catering Global Logistics Needs

Export pallets are crucial for efficiently transporting goods across international borders, ensuring reliability and durability throughout the supply chain. In India, manufacturers have risen to the challenge of producing high-quality export pallets that meet international standards, contributing significantly to global trade facilitation and logistics management.

Importance of Export Pallets

Export pallets serve as essential tools in international logistics for several reasons:

Compatibility: Designed to meet international shipping standards, export pallets ensure compatibility with various transportation modes, including sea freight, air cargo, and land transportation.

Durability: Built to withstand the rigors of long-distance transportation, export pallets offer robustness and reliability to protect goods during transit.

Compliance: Manufacturers ensure export pallets comply with international regulations and standards for packaging and transportation, facilitating smooth customs clearance and compliance procedures.

Manufacturing Processes in India

Indian manufacturers employ advanced manufacturing processes to produce export-quality pallets:

Heat Treatment: Export pallets often undergo heat treatment to meet ISPM 15 standards, which regulate wood packaging materials to prevent the spread of pests and diseases across borders.

Injection Molding: Utilizing plastic materials, injection molding allows for precise customization and production of durable plastic export pallets that meet international hygiene and durability standards.

Leading Manufacturers in India

India hosts several leading manufacturers specializing in export pallets:

Balaji Industries: Known for their expertise in wooden pallets, Balaji Industries offers heat-treated export pallets that comply with ISPM 15 regulations, ensuring global acceptance.

Swift Technoplast: Specializing in plastic packaging solutions, Swift Technoplast manufactures lightweight and durable plastic export pallets suitable for international shipping.

Nilkamal Limited: A pioneer in the plastics industry, Nilkamal produces export pallets made from high-quality materials that meet stringent international standards for durability and reliability.

Sustainability and Environmental Considerations

Export pallet manufacturers in India prioritize sustainability by using eco-friendly materials and adhering to international guidelines for responsible packaging. Plastic export pallets, for example, can be recycled and reused, contributing to environmental conservation efforts.

Applications Across Industries

Export pallets find widespread applications across various industries in India:

Agribusiness: Used for exporting agricultural produce, ensuring freshness and minimizing damage during transit.

Manufacturing: Essential for shipping finished goods and components to global markets, maintaining product integrity and reliability.

Pharmaceuticals: Critical for transporting pharmaceutical products under controlled conditions, complying with international hygiene and safety standards.

Innovations and Future Outlook

The future outlook for export pallets in India is promising, driven by innovations in material science and manufacturing technology. Manufacturers are exploring lightweight yet robust materials and integrating smart technologies to enhance pallet performance and efficiency in global supply chains.

Conclusion

Export pallets manufacturers in India play a pivotal role in facilitating global trade and logistics by offering durable, compliant, and sustainable solutions. With a commitment to quality and innovation, Indian manufacturers are well-positioned to meet the evolving demands of international markets for reliable export pallets. As global supply chains continue to expand, the role of export pallets in ensuring efficient and secure transportation of goods remains indispensable, reinforcing India's significance in the global logistics landscape.

Locate Us

Sonipat, Haryana - 131301

+91-8700900663

1 note

·

View note

Text

Protect Your Pallets. Protect Your Products Durable. Reliable. Customizable.

Keep your pallets and products safe with our high-quality pallet covers! Durable, customizable, and designed for all industries.

Explore our range today and elevate your shipping game!

I am Gunja Founder of GUNJA POLYMER is Manufacturers & Exporters of plastic extrusion process. link Pallet covers, composite straps, dunnage bags, PVC foam sheets and PP corrugated sheets.

for more detail visit - https://gunjapolymer.com/products/Pallet_Covers

0 notes

Text

Why Stretch Film is a Game-Changer for Your Business’s Packaging Needs in Vietnam

In the fast-paced business environment of Vietnam, efficient packaging solutions are crucial. If you're in manufacturing, logistics, retail, or any related field, you know the importance of securing and protecting your products. Enter stretch film—a game-changer for all your packaging needs. This blog post will explore the benefits of stretch film, why it's an ideal choice for businesses in Vietnam, and practical tips for using it effectively.

Introduction to Stretch Film

Stretch film, also known as stretch wrap, is a highly stretchable plastic film commonly used to secure, bundle, and protect products during storage and transportation. Made primarily from linear low-density polyethylene (LLDPE), stretch film is durable, elastic, and versatile.

The film's ability to stretch and cling tightly to items makes it an excellent packaging material for various industries. Whether you're shipping fragile goods or storing bulk items, stretch film ensures your products remain intact and secure.

Benefits of Using Stretch Film

Cost-Effective Solution

One of the primary advantages of stretch film is its cost-effectiveness. Compared to other packaging materials, stretch film is relatively inexpensive. Its high stretchability means you need less material to secure a load, reducing overall packaging costs.

Additionally, the durability of stretch film minimizes the likelihood of damage during transit, saving you money on potential replacements and returns. In a competitive market like Vietnam, where businesses need to optimize every aspect of their operations, stretch film offers an economical packaging solution.

Enhanced Product Protection

Stretch film provides superior protection for your products. Its cling properties create a tight seal that prevents dust, dirt, and moisture from entering, ensuring your goods remain clean and dry. This is particularly important for industries such as food and beverage, pharmaceuticals, and electronics, where product integrity is paramount.

Furthermore, stretch film's elasticity absorbs shocks and impacts during transportation, reducing the risk of breakage and damage. By using stretch film, you can safeguard your products and maintain their quality throughout the supply chain.

Improved Load Stability

Load stability is critical in logistics and warehousing. Stretch film helps stabilize loads by holding items firmly in place on pallets. This not only prevents shifting and toppling but also facilitates easier handling and storage.

For retailers and wholesalers, improved load stability means fewer damaged goods and happier customers. Stretch film ensures that products arrive at their destination in the same condition they left your facility.

Types of Stretch Film

Hand Stretch Film

Hand stretch film is designed for manual application. It's ideal for smaller operations or situations where machinery is not available. Hand stretch film is easy to use and provides excellent load security.

This type of stretch film is commonly used in retail, warehousing, and light manufacturing. Its flexibility allows workers to wrap products quickly and efficiently, making it a popular choice for businesses of all sizes.

Machine Stretch Film

Machine stretch film is used with stretch wrapping machines, which automate the wrapping process. This type of film is suitable for high-volume operations where speed and consistency are essential.

Machine stretch film offers superior load containment and can be applied more consistently than hand stretch film. For large manufacturers, exporters, and importers, investing in a stretch wrapping machine can significantly improve packaging efficiency and reduce labor costs.

Specialty Stretch Film

Specialty stretch films are designed for specific applications. These include UV-resistant film, anti-static film, and vented film, among others. Specialty stretch films address unique packaging challenges and provide additional benefits tailored to your industry's needs.

For example, UV-resistant stretch film protects products from sun damage, making it ideal for outdoor storage. Anti-static film is perfect for electronics, preventing static electricity from damaging sensitive components. By choosing the right specialty stretch film, you can enhance your packaging strategy and meet industry-specific requirements.

How to Choose the Right Stretch Film

Consider Your Load Type

The type of load you're wrapping will influence your choice of stretch film. Heavier loads require a thicker, stronger film to provide adequate support, while lighter loads can be secured with a thinner film.

Consider the shape and size of your products as well. Irregularly shaped items may need a more elastic film to ensure full coverage and stability. By matching the film to your load type, you can achieve optimal packaging results.

Assess Your Budget

While stretch film is generally cost-effective, prices can vary based on the type and quality of the film. Consider your budget and weigh the benefits of different films against their costs.

Investing in a higher-quality film may offer better protection and stability, ultimately saving you money by reducing product damage. However, if you're working with limited resources, there are still plenty of affordable options that provide reliable performance.

Best Practices for Using Stretch Film

Proper Application Techniques

Proper application is key to maximizing the benefits of stretch film. Ensure the film is applied tightly and evenly to avoid loose ends that can cause the load to shift.

When using hand stretch film, wrap the film around the load several times, overlapping each layer by about 50%. For machine stretch film, adjust the machine settings to achieve the desired tension and coverage. Properly wrapping your products will enhance load stability and protection.

Regular Maintenance of Equipment

If you're using a stretch wrapping machine, regular maintenance is essential to ensure optimal performance. Check for worn parts, clean the machine regularly, and calibrate the tension settings as needed.

Proper maintenance not only extends the life of your equipment but also ensures consistent application of the stretch film. By keeping your machinery in good condition, you can maintain efficient packaging processes and reduce downtime.

Employee Training

Training your employees on the correct use of stretch film and wrapping equipment is crucial. Proper training ensures that the film is applied correctly, minimizing waste and maximizing load stability.

Provide your team with clear instructions and demonstrations on how to use hand and machine stretch film effectively. Regular training sessions can help reinforce best practices and keep your packaging operations running smoothly.

1 note

·

View note

Text

12 Types of Industrial Plastic Pallets for Supply Chain Management: A Beginner’s Guide

In today’s fast-paced world, supply chain management is crucial to the success of any business. One often overlooked but essential component of efficient supply chain operations is the pallet. Among the various types available, industrial plastic pallets have gained popularity for their durability, hygiene, and versatility. In this guide, we will explore the different types of plastic pallets, their benefits, and how to choose the right plastic pallet manufacturer for your business.

What Are Industrial Plastic Pallets?

Industrial plastic pallets are specialized platforms used to support goods during transportation, storage, and handling. Unlike traditional wooden pallets, plastic pallets are made from high-density polyethylene (HDPE) or polypropylene (PP). This material choice offers several advantages, including resistance to moisture, chemicals, and pests, making them ideal for a wide range of industries.

Plastic pallets are particularly favored in industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and electronics. Moreover, they are lightweight yet strong, reducing transportation costs and increasing load efficiency.

Benefits of Using Plastic Pallets in Supply Chain Management

When it comes to supply chain management, the choice of pallets can significantly impact the efficiency and cost-effectiveness of operations. Here are some key benefits of using plastic pallets:

Durability and Longevity: Plastic pallets are designed to withstand the rigors of heavy-duty industrial use. Unlike wooden pallets, they do not splinter, crack, or rot, ensuring a longer lifespan. This durability translates into cost savings over time, as plastic pallets require fewer replacements.

Hygiene and Ease of Cleaning: In industries where sanitation is critical, such as food and pharmaceuticals, plastic pallets offer a significant advantage. They are easy to clean and sanitize, reducing the risk of contamination. Additionally, plastic pallets are resistant to moisture, making them ideal for environments where hygiene is a top priority.

Environmental Sustainability: Many plastic pallets are made from recyclable materials, contributing to a more sustainable supply chain. At the end of their life cycle, recyclable plastic pallets can be processed into new products, reducing waste and minimizing the environmental impact.

Safety: Plastic pallets are free from nails, splinters, and sharp edges, making them safer for workers to handle. Their lightweight design also reduces the risk of injuries during manual handling, improving overall workplace safety.

Customization and Versatility: Plastic pallets come in various designs and sizes to suit specific industry needs. Whether you require pallets for export, storage, or specialized applications, plastic pallets can be customized to meet your requirements. This versatility ensures that your supply chain operates efficiently and effectively.

12 Types of Industrial Plastic Pallets

Now that we understand the benefits of using plastic pallets, let’s explore the 12 different types of industrial plastic pallets available for supply chain management. Each type has unique features and is suited to specific applications.

Nestable Plastic Pallets

Description: Nestable plastic pallets are designed to fit into each other when empty, reducing the amount of space required for storage.

Uses: These pallets are ideal for businesses that need to save space when pallets are not in use. They are commonly used in retail and distribution centers.

Benefits: Space-saving, cost-effective, and easy to handle.

Stackable Plastic Pallets

Description: Stackable plastic pallets feature a solid base that allows them to be securely stacked on top of each other, even when loaded with goods.

Uses: These pallets are perfect for warehouse storage and transportation, where vertical space utilization is essential.

Benefits: Maximizes storage capacity, provides stability during transport.

Rackable Plastic Pallets

Description: Rackable plastic pallets are designed to be used with racking systems in warehouses. They have reinforced edges that provide extra support when placed on racks.

Uses: Ideal for heavy-duty applications where goods need to be stored on racks for long periods.

Benefits: Provides excellent load-bearing capacity, enhances storage organization.

Export Plastic Pallets

Description: Export plastic pallets are lightweight pallets designed for international shipping. They are often made to meet specific international regulations.

Uses: Best suited for one-way shipping, where the pallet is not expected to be returned.

Benefits: Cost-effective, compliant with international shipping standards.

Hygienic Plastic Pallets

Description: Hygienic plastic pallets are smooth and easy to clean, with no crevices where dirt or bacteria can accumulate.

Uses: Commonly used in industries that require high levels of cleanliness, such as food processing and pharmaceuticals.

Benefits: Promotes sanitation, reduces contamination risks.

Spill Control Plastic Pallets

Description: Spill control plastic pallets feature built-in containment trays to catch and contain spills of liquids, such as chemicals or oils.

Uses: Essential for industries that handle hazardous materials, such as chemicals and oil.

Benefits: Prevents environmental contamination, ensures compliance with safety regulations.

Drum Plastic Pallets

Description: Drum plastic pallets are specifically designed to hold drums securely in place, preventing them from rolling or tipping over.

Uses: Ideal for storing and transporting barrels and drums in industries like oil, chemicals, and beverages.

Benefits: Provides stability for cylindrical containers, enhances safety during transport.

Heavy-Duty Plastic Pallets

Description: Heavy-duty plastic pallets are built to handle large, bulky loads. They are reinforced to support substantial weight without deforming.

Uses: Best suited for industries that require the transport of heavy goods, such as construction and manufacturing.

Benefits: High load capacity, long-lasting durability.

ESD Plastic Pallets

Description: ESD (Electrostatic Discharge) plastic pallets are designed to protect sensitive electronic components from static electricity.

Uses: Commonly used in electronics manufacturing and assembly.

Benefits: Protects electronic goods from damage, ensures compliance with ESD safety standards.

Freezer Spacer Pallets

Description: Freezer spacer pallets are designed for use in cold storage environments. They allow air circulation around products to maintain consistent temperatures.

Uses: Essential for food and pharmaceutical industries that require cold storage.

Benefits: Improves cold storage efficiency, prevents product spoilage.

Custom Plastic Pallets

Description: Custom plastic pallets are tailored to meet specific needs, including size, shape, and load capacity.

Uses: Ideal for businesses with unique pallet requirements that standard sizes cannot accommodate.

Benefits: Provides a perfect fit for specialized applications, enhances operational efficiency.

Recyclable Plastic Pallets

Description: Recyclable plastic pallets are made from materials that can be easily recycled at the end of their life cycle.

Uses: Suitable for environmentally conscious companies looking to reduce their carbon footprint.

Benefits: Promotes sustainability, reduces waste.

How to Choose the Right Plastic Pallet Manufacturer

Selecting the right plastic pallet manufacturer is crucial to ensuring that you receive high-quality, durable pallets that meet your specific needs. Here are some key factors to consider when choosing a supplier:

Experience and Expertise: Look for a manufacturer with a proven track record in producing high-quality plastic pallets. Experience often translates into better product quality and customer service.

Quality and Certifications: Ensure that the manufacturer adheres to industry standards and certifications. This is particularly important if you require pallets for specialized applications, such as food-grade or ESD pallets.

Customization Options: A good manufacturer should offer customization options to meet your unique needs. Whether you need custom sizes, colors, or features, the ability to tailor products is a significant advantage.

Environmental Responsibility: Consider a manufacturer that prioritizes sustainability by offering recyclable plastic pallets and environmentally friendly production processes. This aligns with growing consumer and regulatory demands for greener practices.

Ongoing Support: Choose a manufacturer that provides ongoing support, including product advice, maintenance tips, and responsive customer service. This ensures a smooth and hassle-free experience.

By carefully selecting a reliable plastic pallet manufacturer, you can enhance the efficiency and effectiveness of your supply chain operations.

Conclusion

In summary, industrial plastic pallets are a vital component of modern supply chain management, offering numerous benefits such as durability, hygiene, and environmental sustainability. By understanding the different types of plastic pallets available, you can make informed decisions that improve your supply chain’s efficiency and cost-effectiveness.When selecting a plastic pallet manufacturer, prioritize experience, quality, and customization options to ensure you receive the best products for your specific needs. By doing so, you’ll be well on your way to optimizing your supply chain with the right plastic pallets.

0 notes

Text

Anjani Technoplast: Pioneering Innovation and Excellence in the Industry

In the ever-evolving landscape of industrial manufacturing, Anjani Technoplast stands out as a beacon of innovation, quality, and reliability. The company has come a long way since its inception and has significantly impacted the industry with technologically advanced products and services. Established by first-generation IITians and IIM graduates, Anjani Technoplast Ltd. (ATL), headquartered in Greater Noida, India, delivers projects globally. It operates in various sectors including Defence, Oil & Gas, Composites, Material Handling & Packaging, and Industrial Solutions. ATL is an industry pioneer in ballistic armoring for the army and paramilitary forces worldwide, exporting to over 42 countries.

A Legacy of Innovation

Anjani Technoplast was envisioned as an organization dedicated to delivering products from concept using groundbreaking technologies in manufacturing and material sciences. They have consistently developed first-time solutions, enriching their business with innovative products for the Indian defense sector. Some of their notable contributions include contoured bulletproof jackets, polycarbonate shields, pressurized missile containers, and portable bunkers and shelters. Their diverse range of products demonstrates their capability to meet various industry requirements.

Unmatched Product Range and Customization

Anjani Technoplast offers a broad product portfolio, specializing in customized solutions for industries such as defense, packaging, material handling, automotive, aerospace, and electronics. Their competitive advantage lies in their capacity to provide tailored products to meet specific client needs. Some of their key products include:

Pressurized Containers for Missiles and Ammunition: Exclusive suppliers of pressurized containers for the Akash Missile System to Bharat Dynamics Ltd., Hyderabad. These containers, used by the Indian Army and Air Force, allow direct loading of missiles from the transportation vehicle to the launcher, saving crucial time during warfare. They are the world's lightest pressurized containers, resistant to moisture, corrosion, and rodents, ensuring the missile telemetry remains undamaged and extending its shelf life.

Tactical Ballistic Shield: Anjani Technoplast introduced ultra-lightweight bullet-resistant shields in India, supplied to the National Security Guard (NSG), New Delhi. These shields are available in hand-held and trolley-mounted versions.

Bullet Proof Morcha & Sentry Post: These lightweight honeycomb panels replace traditional heavy sandbags in the battlefield. They can be assembled, disassembled, and transported with ease, providing customizable protection levels with options for bulletproof glass or steel sliding covers.

Riot Control Polycarbonate Shield: These lightweight, transparent, fire-resistant shields offer better vision and control during riot situations.

Plastic Honeycomb Panels: As India's only manufacturer of plastic honeycomb panels, Anjani Technoplast offers water-proof and ultra-lightweight panels with applications in low-cost housing, portable cabins, emergency shelters, and material handling pallets.

Special Purpose Machines: ATL is a pioneer in designing and commercially producing innovative machines, including the CNC waterjet cutting machine, 1000-tonne hydraulic press, and an automated machine for multi-head drilling and deburring of API pipes in the Oil & Gas industry.

Advanced Manufacturing Capabilities

Anjani Technoplast's manufacturing division utilizes hi-tech techniques and sophisticated technology. Their commitment to investing in new and superior production technologies ensures they remain at the forefront of innovation. With several multi-axis robots, they ensure the highest grade of repeatability and reliability in manufacturing. Led by IITians, their R&D and Quality teams follow stringent quality control procedures, backed by ISO certifications, to deliver top-notch products that solve complex problems quickly.

Sustainability and Corporate Responsibility

Anjani Technoplast adheres to global business responsibility and eco-friendliness. The company continuously works on reducing its environmental impact through environmentally friendly practices and products. Their corporate responsibility activities extend beyond environmental consciousness to encompass social and economic values, positively impacting society.

Customer-Centric Approach

Customer satisfaction is at the core of Anjani Technoplast's values. They maintain long-term business associations by providing high-quality goods and services. Their commitment to understanding and meeting clients' needs, coupled with efficient after-sale support, has earned them a reputable name in the market.

Conclusion

Anjani Technoplast's "concept-to-delivery" expertise allows them to design and build specialized solutions to meet the nation's exact specifications. Their unwavering commitment to innovation and customer satisfaction ensures they remain at the forefront of industrial manufacturing, delivering breakthrough technologies and solutions.

#Anjani Technoplast Corruption#R.K. Gupta Legal#R.K. Gupta Anjani Technoplast Limited#Lavina Gupta Anjani Technoplast Limited#Lavina Gupta Noida#Raghav Gupta Anjani Technoplast Limited#Anjani Technoplast Limited Patent#Honeycomb Patent ATL

1 note

·

View note

Text

Examining the Advantages of Second Hand Pallets in Melbourne: A Sustainable Option for Companies

Second hand pallets in Melbourne��are used extensively in commercial operations, yet they are sometimes disregarded despite their importance to storage and logistics. Used pallets are a more affordable and environmentally friendly option than brand-new pallets, and they provide several advantages for Melbourne businesses. Here are some reasons to think about using used pallets in your business and some tips for maximising the benefits of this green choice.

Explore the Benefits of Personalised Timber Pallets

In addition to their many advantages, they can easily tailor your needs for timber packaging. Why go with custom pallets in Melbourne? Ordering a pallet that meets your unique space, product, weight, transit, or export regulatory needs can help with the following:

Improved safeguarding, secure packaging, and storage of special items

Pack and store oddly shaped or sized things more effectively

Boost inventory control

Minimise expenses

Give your shipments a polished brand.

All industries, including the steel and plastic, food and beverage, development, medical equipment, appliances, and electronics sectors, are great candidates for custom pallets. Maybe you require product storage and logistics for products that are high, broad, extra-long, or irregularly shaped.

Solutions That Help Make An Incredible Environmental Impact That Are Resilient and High-Quality

Recycling used pallets is an eco-friendly decision that lessens trash and its impact on the environment. Businesses may support the circular economy and lessen the need for new resources by choosing used pallets. This procedure reduces the carbon footprint resulting from the manufacture and disposal of pallets.

There are several benefits to integrating used pallets into your Melbourne business operations, including rapid availability, variety, and cost and environmental savings. Choosing used pallets helps you acquire premium materials at a fraction of the price of new pallets, minimise waste, and promote sustainable practices.

Pallets that have been used previously but have been well-maintained can be just as durable and effective as brand-new pallets. Pallets are a dependable option for a range of transportation and storage requirements as they are often made to handle large loads and severe handling. Before pallets are resold, reputable providers make sure they pass quality inspections and repairs.

Source

0 notes