#plant-based textile yarn market scope

Explore tagged Tumblr posts

Text

Get deep insights of Plant-Based Textile Yarn Market

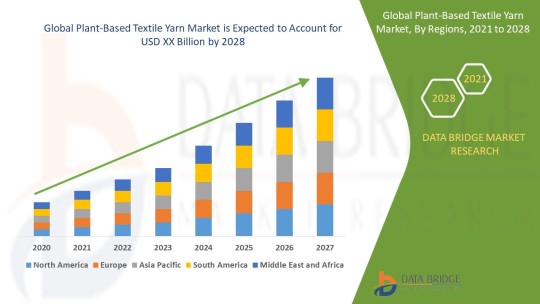

In the forecast period from 2021 to 2028, the plant-based textile yarn market is projected to expand at a rate of 4.40%. The rising demand for textile yarn for home textiles, apparel and other industrial purposes, which in the forecast period of 2021-2028 will act as a driver for the plant-based textile yarn market.

Global Plant-Based Textile Yarn Market Scope and Market Size

Plant-based textile yarn market is segmented on the basis of type, and application. The growth among segments helps you analyse niche pockets of growth and strategies to approach the market and determine your core application areas and the difference in your target markets.

On the basis of type, the plant-based textile yarn market is segmented into natural yarn, artificial yarn, and others. Natural yarn has been further segmented as plant yarn, and animal yarn. Animal yarn has been further sub segmented into silk yarn, and wool yarn. Plant yarn has been further sub segmented into cotton yarn, flax yarn, hemp yarn, jute yarn, and ramie yarn. Artificial yarn has been further segmented into polyester, nylon, acrylic, and viscose. Artificial yarn products will account for the largest share in the market due to the rising usages of the products in blended varieties.

Based on application, the plant-based textile yarn market is segmented into apparel, home textile, industrial, and other applications. Other applications have been further segmented into medical and sports applications.

Get the sample copy of the report here:

Market Analysis and Insights: Global Plant-Based Textile Yarn Market

A textile yarn is a strand of fibres or filaments that are natural or synthetic. In the textile industry, textile yarns are primarily used for the manufacture of clothing, home textiles, medical, and sports goods.

Increasing number of innovations in the production process of the product along with growth of the various end-use industries across the globe, rapid urbanization as well as industrialization, changing consumer preferences towards affordable and comfortable clothing such as silk, viscose, hemp, and others are some of the major as well as insightful factors which will likely to augment the growth of the plant-based textile yarn market in the projected timeframe of 2021-2028. On the other hand, growing demand for organic based yarns along with development of new varieties and blends which will further contribute by generating immense opportunities that will led to the growth of the plant-based textile yarn market in the above mentioned projected timeframe.

Stringent rules and regulations along with volatility in the prices of raw material which will likely to act as market restraints factor for the growth of the plant-based textile yarn in the above mentioned projected timeframe. High inventory holding cost, trans-pacific partnership, maintaining quality through scattered channels along with direct government assistance to raw material producers which will become the biggest and foremost challenge for the growth of the market.

Plant-Based Textile Yarn Market Country Level Analysis

Plant-based textile yarn market is analysed and market size, volume information is provided by country, type and application as referenced above.

The countries covered in the plant-based textile yarn market report are U.S., Canada, Mexico in North America, Germany, Poland, Ireland, Italy, U.K., France, Spain, Netherland, Belgium, Switzerland, Turkey, Russia, Rest of Europe in Europe, Japan, China, India, South Korea, New Zealand, Vietnam, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in Asia-Pacific (APAC), Brazil, Argentina, Chile, Rest of South America as a part of South America, U.A.E, Saudi Arabia, Egypt, Kuwait, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA).

Plant-Based Textile Yarn Market Share Analysis

Plant-based textile yarn market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to plant-based textile yarn market.

Leading Brands in Plant-Based Textile Yarn Market

The major players covered in the plant-based textile yarn report are Parkdale Mills, Inc.; VARDHMAN GROUP; Huvis; Grasim Industries Limited.; Raymond Limited; Weiqiao Textile Company Limited.; TORAY INDUSTRIES, INC.; Bonar Yarns & Fabrics Ltd; Thai Rayon Public Company Limited; Aksa; Asahi Kasei Corporation.; Barnhardt Natural Fibers.; Celanese Corporation; Far Eastern New Century Corporation; FORMOSA TAFFETA CO., LTD.; Indorama Ventures Public Company Limited.; FiberVisions, L.P.; KURARAY CO., LTD.; PT Polychem Indonesia Tbk; Reliance Industries Limited.; among other domestic and global players. Market share data is available for Global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: Plant-based textile yarn market

Get TOC Details

rowse Related Reports@

Global Methylene Chloride Market – Industry Trends and Forecast to 2029

Asia-Pacific Oil Refining Catalyst Market is expected to grow at 9.1% in the Forecast Period of 2020 to 2027

The Global Auto Catalyst Market is projected to Grow at A CAGR of 4.20% During the Forecast Period

Global Oil Refining Catalyst Market is expected to grow at 5.1% in the Forecast Period of 2021 to 2028

The Global Polyolefin Catalyst Market is projected to Grow at a CAGR of 5.00% During the Forecast Period

The Global Syngas Catalyst Market is projected to Grow at a CAGR of 8.00% During the Forecast Period

Global Refinery Catalyst Market – Industry Trends and Forecast to 2028.

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#Plant-Based Textile Yarn Market#Plant-Based Textile Yarn Market scope#Plant-Based Textile Yarn Market size#Plant-Based Textile Yarn Market share#Plant-Based Textile Yarn Market trend#Plant-Based Textile Yarn Market demand#Plant-Based Textile Yarn Market future

0 notes

Text

Global Sizing Agents Market

Global Sizing Agents Market was valued at US$ 3 Bn in 2019 and is expected to reach US$ 4.6 Bn by 2027, at a CAGR of 5.5 % during a forecast period.

Global Sizing Agents Market , by Region

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated market data and projections with a suitable set of assumptions and methodology. The report also helps in understanding Sizing Agents market dynamics, structure by identifying and analyzing the market segments and project the global market size. Further, report also focus on competitive analysis of key players by product, price, financial position, product portfolio, growth strategies and regional presence. The report also provide PEST analysis, PORTER’s analysis, SWOT analysis to address question of shareholders to prioritizing the efforts and investment in near future to emerging segment in Sizing Agents market.

The report study has analyzed revenue impact of covid-19 pandemic on the sales revenue of market leaders, market followers and disrupters in the report and same is reflected in our analysis.

Sizing agents are usually used to provide water resistance and printability to paper by surface application. These agents are applied to extensive range of papers such as fine paper, newspaper, ink-jet printing paper, and linerboard. Sizing agents are materials that are applied to fibers to impart desired qualities. These agents are mostly used to reduce porosity of fibers in order to make them suitable for printing. Sizing agents increase the resistance properties of fiber to the penetration of water or other liquid.

Increasing demand for sizing agents due to wide industrial application is the major drivers for the sizing agents market. Constant expansion and growing of packaging, automotive, medical, and apparel industries is anticipated to drive the demand for sizing agents during the forecast timeframe.

Sizing agents also enhanced the internal bond and surface strength values. Synthetic sizing agents are applied through the dry stage of paper manufacturing to fill surface voids, therefore optimizing the penetration of printing ink. Oxidized starches, linear film-forming polymers such as carboxymethyl cellulose, polyvinyl alcohol, and styrene acrylic acid are some types of the synthetic sizing agents. Increase in demand for sizing agents in various industrial applications is expected to drive the demand for these chemicals. Nevertheless, environmental concerns regarding the disposal of these chemicals into water is a major restraining factor of the sizing agents market.

Based on type, synthetic segment is expected to be the largest contributor to the sizing agents market during the tenure. Synthetic agents are increasingly consumed in various applications such as textile & fiber and paper& paperboard applications. The synthetic sizing agents segment is likely to expand during forecast period primarily attributed to the demand for synthetic sizing agents such as styrene and polyvinyl alcohol. The growing customer need for durability and aesthetics of paper and technical textiles is expected to create demand for sizing agents during the forecast timeframe.

In terms of application, textile & fiber segment is expected to hold a largest shares of the sizing agents market during the forecast period. Moreover, the several physical properties possessed by sizing agents help in strengthening of the yarn and impart abrasion resistance. The demand for sizing agents has increased due to the huge textile production capacity and strong demand for textile and clothing. Furthermore, expansion of automotive, aerospace, and medical industries and shift from the traditional low-value textile to high-value textile products also support the growth of the sizing agents market.

Geographically, Asia Pacific is a develop market, followed by North America. The demand in the area is high owing to the presence and development of end-use application for the product. The shifting of manufacturing plants from North America and Europe to APAC drives the growth of sizing agents market during the forecast period. Globally, Asia Pacific is one of the largest exporters of textiles and clothing products. Scope of Global Sizing Agents Market:

Global Sizing Agents Market, by Type:

• Natural • Synthetic Global Sizing Agents Market, by Application:

• Textile & Fiber • Paper & Paperboard • Cosmetics • Textile & Fiber • Others Global Sizing Agents Market, by Region:

• North America • Europe • Middle East & Africa • Asia Pacific • South America Key Players Operating In Global Sizing Agents Market:

• BASF • Aries Chemical • Pulcra Chemicals • Kemira OY • Solenis • OBnova Solutions • Buckman Laboratories • Seiko PMC Corporation • Evonik • Bodo Moller Chemie

For more information @ https://www.maximizemarketresearch.com/market-report/global-sizing-agents-market/24958/

This report submitted by Maximize market Research Company

Customization of the report:

Maximize Market Research provides free personalized of reports as per your demand. This report can be personalized to meet your requirements. Get in touch with us and our sales team will guarantee provide you to get a report that suits your necessities.

About Maximize Market Research:

Maximize Market Research provides B2B and B2C research on 20,000 high growth emerging opportunities & technologies as well as threats to the companies across the Healthcare, Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages, Aerospace and Defense and other manufacturing sectors.

Contact info:

Name: Lumawant Godage

Organization Address: MAXIMIZE MARKET RESEARCH PVT. LTD.

Email: [email protected]

: Omkar Heights, Sinhagad Road, Manik Baug, Vadgaon Bk,Pune, Maharashtra 411051, India.

Contact: +919607195908

1 note

·

View note

Text

Antimicrobial Textiles Market Growth, Trends, Size, Share, Players, Product Scope, Regional Demand, COVID-19 Impacts and Forecast 2028

This antimicrobial textiles market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localised market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on the antimicrobial textiles market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

The antimicrobial textiles market is expected to be growing at a growth rate of 9.1% in the forecast period of 2021 to 2028. The antimicrobial textiles market report analyses the growth, which is currently being growing due to the rising prevalence of chronic diseases.

Get Sample Copy of Report@ https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-antimicrobial-textiles-market

The utilization of antimicrobial textiles is a new practice from the traditional use of antimicrobial products mostly in the healthcare environments. The manufacturing of antimicrobial textiles includes the treatment with the additives during the intermediate or finishing stage of manufacture of the fabric. The method utilized is dependent on a multitude of factors, which involves the final usage of the fabric, manufacturer’s capability, and budget considerations.

Important factors that are expected to boost the growth of the antimicrobial textiles market in the forecast period are the increasing of the incidences of chronic diseases like the chickenpox, diphtheria, tuberculosis, and others, the growing of the prevalence of cross-infection and the growing adoption of the improved healthcare services have augmented the demand for antimicrobial textiles in the healthcare industry. On the other hand, the variations in the prices of raw materials for antimicrobial textiles and the increase in the cost of production are few of the factors estimated to further cushion the growth of the antimicrobial textiles market in the timeline period.

In addition, the growing popularity amongst the researchers and manufacturers due to their ability to provide safety and quality life to the users will further provide the potential opportunities for the growth of the antimicrobial textiles market in the coming years. However, the environmental and the health worries related with the release of the antimicrobial content in the surrounding might further challenge the growth of the antimicrobial textiles market in the near future.

Inquire About Report@ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-antimicrobial-textiles-market

Antimicrobial Textiles Market Scope and Market Size

The antimicrobial textiles market is segmented on the basis of active agents, fabric, finishing techniques and application. The growth amongst the different segments helps you in attaining the knowledge related to the different growth factors expected to be prevalent throughout the market and formulate different strategies to help identify core application areas and the difference in your target markets.

Based on the active agents, the antimicrobial textiles market is segmented into synthetic organic compounds, metal and metallic salts, bio-based agents, others. Synthetic organic compounds is further sub segmented into quaternary ammonium compounds (QACS), triclosan, polyhexamethylene biguanides (PHMB), zinc pyrithione, others. Metal and metallic salts is further sub segmented into silver, copper, zinc, others. Bio-based agents is further sub segmented into chitosan and others.

Based on the fabric, the antimicrobial textiles market is segmented into cotton, polyester, polyamide and others.

Based on the finishing techniques, the antimicrobial textiles market is segmented into pad-dry cure, exhaust, spraying, foam finishing method and others.

Based on the application, the antimicrobial textiles market is segmented into medical textiles, commercial textile, apparels, home textiles, industrial textile, others. Medical textiles is further sub segmented into attire, sheets and blankets, surgical supplies and wipes others. Commercial textiles is further sub segmented into protective wear and others. Apparels is further sub segmented into sportswear, intimates, outdoor clothing. Home textiles is further sub segmented into carpets, bedding, curtains and drapes and others. Industrial textile is further sub segmented into HVAC system, filters and others.

Antimicrobial Textiles Market Country Level Analysis

The antimicrobial textiles market is analysed and market size, volume information is provided by country, active agents, fabric, finishing techniques and application as referenced above.

Browse Complete Report@ https://www.databridgemarketresearch.com/reports/global-antimicrobial-textiles-market

The countries covered in the antimicrobial textiles market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the antimicrobial textiles market because of the growing utilization of implantable goods because of the limitations in the present drug therapies, treatment, and management of orthopedic, cardiovascular, ophthalmic, neurological, and several other chronic disorders. Moreover, the continuing advancements in the biotechnology which in turn will lead to the commercialization of the new and improved products will further boost the growth of the antimicrobial textiles market in the region during the forecast period. Asia-Pacific is projected to observe significant amount of growth in the antimicrobial textiles market because of the augmented governmental intervention in refining the healthcare facilities. Moreover, the growing wound care market is likely to rouse demand for the products and the occurrence of the major yarn and fiber manufacturers in Taiwan is further anticipated to propel the growth of the antimicrobial textiles market in the region in the coming years.

The country section of the report also provides individual market impacting factors and changes in regulation in the market domestically that impacts the current and future trends of the market. Data points such as consumption volumes, production sites and volumes, import export analysis, price trend analysis, cost of raw materials, down-stream and upstream value chain analysis are some of the major pointers used to forecast the market scenario for individual countries. Also, presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Antimicrobial Textiles Market Share Analysis

The antimicrobial textiles market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to antimicrobial textiles market.

The major players covered in the antimicrobial textiles market report are Microban International, Sciessent LLC, UNITIKA LTD., BASF SE, Dow, Lonza, BioCote Limited, Trevira GmbH, Herculite, Milliken & Company., Vestagen Protective Technologies, Inc., Resil Chemicals Pvt. Ltd., Smith & Nephew plc, Archroma, LifeThreads, Sinterama S.p.A., HeiQ Materials AG, smartfiber AG, PurThread Technologies Inc., Birlacril, among other domestic and global players. Market share data is available for global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

Global Antimicrobial Textile Market, By Active Agents (Synthetic Organic Compounds, Metal and Metallic Salts, Bio-based Agents, Others), Fabric (Cotton, Polyester, Polyamide and Others), Finishing Techniques (Pad-Dry Cure, Exhaust, Spraying, Others), Application (Medical Textiles, Commercial Textile, Apparels, Home Textiles Industrial Textile, Others), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Browse Related Reports From Chemical Industry:

Air separation Plant Market

1,6-Hexanediol Market

Acrylic Ester Market

Alpha-Methylstyrene Market

Antistatic Agents Market

Aerospace Interior Adhesive Market

0 notes

Text

Warp Knitting Machines Market- Industry Analysis and forecast 2027:

Warp Knitting Machines Market was valued US$ XX Bn in 2019 and the total revenue is expected to grow at a CAGR of 7.7% from 2019 to 2027, reaching US$ XX Bn.

Warp Knitting Machines Market To know about the Research Methodology :- Request Free Sample Report This is a comprehensive international report targeted on present and future prospects of the Warp Knitting Machines Market. This report presents a consolidation of primary and secondary analysis that provides market size, share, dynamics and forecast for numerous segments and sub-segments considering the macro and small environment factors. The report also covers an in-depth analysis of COVID 19 pandemic impact on the sales revenue of Warp Knitting Machines Market by year-wise and region and on the key players revenue affected and expected short term and long-term impact on the market.Warp Knitting Machines Market Overview: Warp Knitting represents the quickest technique for creating texture from yarn. Knitting is mainly of two kinds: weft knitting and warp sewing. In weft knitting, yarn (for example the string utilized in knitting) loops are connected over the width of the fabric. In wrap knitting, yarn loops are connected a vertical way. Weft sewing is done by utilizing a single yarn, while wrap knitting utilizes different yarns for the knitting cycle. Wrap knitting is a modern cycle. Warp Knitting differs from weft sewing wherein each needle circles its own string. The needles produce equal lines of circles all the while that are interlocked in a crisscross pattern. Fabric is delivered in sheet or level form utilizing at least one sets of wrap yarn. The yarns are fed from wrap bars to a line of needles reaching out over the width of the machine.Warp Knitting Machines market – Dynamics Rising demand for manufactured weaved items across the globe is driving the demand for warp knitting machines. Expanding demand for weaved sportswear over the globe is likewise powering the demand for warp knitting machines. Rising demand for sports footwear across the globe is enlarging the interest in sports materials, which is the crude material used to produce sports footwear. This is moving the interest in warp knitting machines utilized in the creation of sports materials. For instance, Dong-Jin Textile, a South Korea-based producer of sports materials, supplies sports shoe textures to driving sports brands over the world, for example, Nike, Adidas, Reebok, New Balance, and Asics. The organization utilizes Karl Mayer's warp knitting machines for creation of sports materials. Presently, Dong-Jin Textile has bought in excess of 250 warp knitting machines, solely from Karl Mayer. A significant open door for warp knitting machine makers lies in the choice of Dong-Jin Textile to set up its first assembling plant in Indonesia in the second half of 2019. Industry sources said Surat is emerging city as a warp knitting sector with installed capacity of over 1,000 warp knitting machines. The annual turnover of warp knitting sector in 2019 was nailed at Rs1,000 crore. As per Synthetic and Rayon Textiles Export Promotion Council (SRTEPC), the scheme for knitting and knitwear sector would mostly benefit MSME which comes under decentralized sector and it would give a major boost to employment generation in the knitting sector of the country. 27% knitted fabrics contribute of the total fabrication in the country and 15% of them are exported.Warp Knitting Machines market: Regional Analysis North America is expected to the leading market for Warp Knitting machine market during the forecast period. Asia-Pacific is expected to dominate the Warp Knitting Machines Market all through the forecasting period, China is expected to be leading country in the warp knitting machines market. Presence of the significant wrap knitting manufacturers in Japan, South Korea and India are major market to put resources into Asia-Pacific and development in number of joint ventures with worldwide brands driving the market growth. The objective of the report is to present a comprehensive analysis of the Warp Knitting Machines Market including all the stakeholders of the industry. The past and current status of the industry with forecasted market size and trends are presented in the report with the analysis of complicated data in simple language. The report covers all the aspects of the industry with a dedicated study of key players that includes market leaders, followers and new entrants. PORTER, SVOR, PESTEL analysis with the potential impact of micro-economic factors of the market have been presented in the report. External as well as internal factors that are supposed to affect the business positively or negatively have been analyzed, which will give a clear futuristic view of the industry to the decision-makers. The report also helps in understanding Warp Knitting Machines Market dynamics, structure by analyzing the market segments and project of the Warp Knitting Machines Market size. Clear representation of competitive analysis of key players By Type, Price, Financial position, Product portfolio, Growth strategies, and Regional Presence in the Warp Knitting Machines Market make the report investor’s guide. for more info:https://www.maximizemarketresearch.com/market-report/warp-knitting-machines-market/76955/ Scope of Warp Knitting Machines Market: Inquire before buying Warp Knitting Machines Market, By Type • Tricot Knit• Raschel Knit• Crochet Knit• Milanese KnitWarp Knitting Machines Market, By End-User • Inner Wears• Apparel• Household• Automotive• Industrial• ShoesWarp Knitting Machines Market, By Region • North America• Europe• Asia-Pacific• MEA & Africa• Latin AmericaWarp Knitting Machines Market Key Players • Karl Mayer• Jakob Müller AG• Santoni SpA• Taiwan Giu Chun Ind. Co., Ltd• Duksu Machinery Industry Co.• Changzhou Runyuan Warp Knitting Machinery Co., Ltd• Wuyang Textile Machinery (China) Co. Ltd.• Changzhou DIBA Textile Machinery Factory• Changzhou Longlongsheng Warp Knitting Machinery Co., Ltd.• COMEZ• Jingwei textile machinery• Ruanyuan• Xingang textile machinery• Diba Textile machinery• Longlongsheng• Voltas• A&L Simonyan German Engineering• Shima Seiki Mfg Ltd.• Pai Lung Machinery Mill Co. Inc.• Terrot GmbH For More Information Visit @:This Report Is Submitted By : Maximize Market Research CompanyCustomization of the report:Maximize Market Research provides free personalized of reports as per your demand. Thisreport can be personalized to meet your requirements. Get in touch with us and our sales teamwill guarantee provide you to get a report that suits your necessities. About Maximize Market Research:Maximize Market Research provides B2B and B2C research on 20,000 high growth emergingopportunities & technologies as well as threats to the companies across the Healthcare,Pharmaceuticals, Electronics & Communications, Internet of Things, Food and Beverages,Aerospace and Defense and other manufacturing sectors.

0 notes

Text

India Specialty Fibers Demand to Cross USD 50 billion by FY24

According to ChemAnalyst report, “India Specialty Fibers Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, Application, Type, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, the India Specialty Fibers market has grown tremendously in the past and is projected to grow at a CAGR of 6% during the forecast period on account of increasing thrust of the Indian government to support the domestic manufacturing of Specialty Fibers by devising favorable policies like the National Technical Textiles Mission (NTTM). The market growth will be further bolstered by skyrocketing demand for ballistic fabrics to meet the country’s rising Defense Requirements. Moreover, rising demand for meta-aramid or para-aramid protective clothing for firefighter suits would further drive the market in the forecast period.

With rapid industrialization and buoyant consumer demand, there is a consistent push by the Indian government to invest into domestic manufacturing of Specialty Fibers as the nation aggressively promotes its ‘Atmanirbhar Bharat Mission’ after heightening rifts between India and China. Because India lacks technical expertise required to manufacture Specialty Fibers, the Union Ministry of Textiles is initiating talks with leading producer countries like Japan and U.S. to adopt latest technologies and promote research and development in the field. Moreover, looking at the vast market potential that the industry holds, the Union government cleared a Rs 1,480 crore scheme in February this year to boost the production and usage of Specialty Fibres till the next four years in the Indian market. The governments of Tamil Nadu, Andhra Pradesh, Telangana and Karnataka are providing special incentives for investments made in Specialty Fibres sector. The Tamil Nadu government in its Integrated Textile Policy has announced 6% interest subsidy for Specialty Fibers products. These factors are likely to propel the Specialty Fibers market in the forecast period.

On the basis of type, the India Specialty Fibers market is dominated by the Spandex fibers whose demand is continuously increasing due to rising demand for lightweight, wrinkle resistant, stretchable and highly comfortable athleisure such as swimsuits, aerobic or exercise wear, ski pants, golf jackets etc. Growing demand for high performance para-aramid and meta-aramid fibers for specialized applications in diverse areas such as production of fire-resistant vests, ballistic applications for the defense, high altitude combat gear, as well as aerospace sector will further boost the Specialty Fibers demand in the foreseeable future. Increased investments by the Indian government on indigenous development of ballistic goods and automotive components would support the Specialty Fibers market growth in the forecast period.

Indian Specialty Fibers sector witnessed demand shock due to a dramatic shift in the market dynamics as several downstream sectors remained indefinitely shut during Q1FY19 and Q1FY20 quarter to contain the spread of COVID-19. As India’s Specialty Fibers demand is primarily met through imports, lockdown in China, shot up the prices of almost all Man-Made Fibre (MMF) in the domestic market. Moreover, Spandex prices rose in tandem with tightness in the key raw materials PET and MEG which is majorly imported from China. However, the industry remained relatively less impacted as the loss could be compensated with better sales across other industrial applications such as electronics and medical. Moreover, as the nation is speedily driving towards ‘new normal’, the Specialty Fibers demand has started rebounding. With a gradual lift in lockdown restrictions and government’s alignment towards its ‘Make in India’ strategy, the market outlook seems positive in longer terms and is likely to regain momentum by the second half of the year.

According to ChemAnalyst report, “India Specialty Fibers Market: Plant Capacity, Production, Operating Efficiency, Demand & Supply, Application, Type, End Use, Distribution Channel, Region, Competition, Trade, Customer & Price Intelligence Market Analysis, 2015-2030”, India’s fiber manufacturers do not produce certain specialty fibers and filaments such as nylon 66, high tenacity polyester yarns, etc. However, there are certain companies manufacturing particular categories of Specialty Fibers. India’s Indorama Industries Limited is a leading spandex manufacturer while Bombay Dyeing is into the production of high tenacity polyester fibers. Toray Group and Reliance Industries Ltd. are into Carbon Fiber production. Other global players operating in the Indian Specialty Fibers market are Dupont, Teijin, Yantai Tayho Advanced materials, Hyosung, Sinopec Yizheng Chemical Fibers and others.

“The Specialty Fibers sector has low penetration in the Indian market contrary to other developed countries which are registering remarkable expansion in the sector. The Indian government’s National Technical Textiles mission which is aimed at achieving the average growth rate of the technical textiles to 15-20% per annum will enable the Specialty Fibers to emerge as a sunrise sector in the coming years. The current Indian Specialty Fibers segment is estimated to cross $50 billion in the next four years, the figure however, is only 6% of the global market due to lack of technical expertise required to locally manufacture them. The production of Specialty Fibres requires huge investment in developing specialized high technology and advanced production facilities. Increased investments by the government of India towards expanding the scope of the market, global technical tie ups, and focus to step up local production would augment the growth of the market. Looking at the recent growth and development in the Specialty Fibers industry, market players are anticipating robust demand growth and hence eyeing on macroeconomic drivers for the market over the next few years.” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm promoting ChemAnalyst.

About Us

ChemAnalyst is a ‘one stop’ digital platform that offers comprehensive market intelligence data and in-depth analysis of the Indian chemical and petrochemical industry. ChemAnalyst’s team of 100+ analysts are engaged in tracking chemical prices daily, production capacity, demand and supply outlook, manufacturing plant locations, foreign trade data and news/deals for more than 400 major chemicals produced in India. ChemAnalyst is promoted by TechSci Research which is an award winning research based management consulting firm providing market research and advisory solutions to the customers worldwide, spanning a range of industries including Chemicals & Material, Automotive, Consumer & Retail, ICT, Energy & Power, Aerospace & Defense, Water and Waste Management, BFSI and more.

For more information, please visit us at- www.chemanalyst.com

Contact Us:

Nilesh Vishwakarma

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523948

Mob: +91-8882336899

0 notes

Text

Fundamentals of Natural Dyeing of Textiles: Pros and Cons-Juniper Publishers

Introduction

India is rich in natural wealth and there are ample scopes to explore and revive application of natural dyes on textiles for growing consciousness of eco friendliness. Hence around the world, there are more and more information are now made available [1,2] to understand the chemistry of natural dyes and interaction between metallic mordant , natural dyes and natural fibres, to get maximum depth of shade of natural colour ants with reproducible shades by optimizing extraction, mordanting method and dyeing conditions and also to improve colour fastness for such natural dyed textiles of natural fibres like cotton, silk, wool and jute etc.

In spite of the better performance of synthetic dyes, recently the use of natural dyes on textile materials has been attracting people more and more due to the following reasons [3]

o Wide availability of natural dyes in India and its subcontinent and their huge potential of producing wide range of shades with skin and eco-friendliness.

o Growing consciousness about allergic and toxic effects of some synthetic dyes, while understanding the non-toxic and non-allergic nature of natural dyes.

o To protect the ancient and traditional dyeing technology generating livelihood of poor artisan/dyers, with potential employment generation facility.

o To generate sustainable employment and income for the weaker section of population in rural and sub-urban areas both for dyeing as well as for non-food crop farming to produce plants for such natural dyes.

o Availability of some archaeological study for conservation and restoration of heritage of old textiles of India for natural dyed textiles.

o Availability more and more scientific study report on application methods for natural dyeing of specific textiles.

Production of synthetic dyes is dependent on petrochemical source, and some of the synthetic dyes contain toxic/ carcinogenic amines which are not eco-friendly The present global consumption of textiles is estimated at around 30 million tonnes, and such a huge amount of required textiles materials cannot be dyed with natural dye alone [2]. Hence, the use of eco-safe synthetic dyes is also essential. But a certain portion of coloured textiles can always be supplemented and managed by eco-safe natural dyes that too on natural fibres, assuring/ creating environment friendly measure of dyeing textiles, at least to a certain percentages.

Natural dyes consume 75% of 48,000 tonnes of dye stuff produced in the country [2]. The market for the natural dyestuffs is though very small but has a growing trend. Many textile manufacturers are not using these dyes regularly because these dyes are not easily available in ready form and finally the process of natural dyeing become more expensive than synthetic dyes. Researchers are however working to find out a cost effective way of dyeing with natural dyes, but at the same time efforts are on for obtaining reproducible shades with appreciable colour fastness properties.

U.S.A is one ofthe major importers of natural dyed textiles from India [4]. There is also very good demand in European countries. The primary importers in Europe are Germany, France, Italy and U.K. with demand for natural dyes is growing continuously due to awareness towards ecological and environmental problems related to the use of synthetic dyes. Use of synthetic dyes has cut down significantly due to toxic effluent resulting from the dyeing process of these dyes. Therefore, natural dyed products represent the good opportunity for value added manufacturing as the process is eco-friendly. These products are comfortable for the wearer as it has soothing colour and non-allergic properties [3]. The use of natural dyes will also generate more employment for rural people because natural dyes are originated in villages were the waste lands are used to grow the dye yielding plants [2].

The alchemy of colour has its origin deeply rooted thousands of years ago. From the epic age this colour has played a very important role in human life. This inspired us to explore the vast storehouse of the nature's palette to initially paint ourselves then to dye the apparels we wore. Natural colorants are dyes and pigments that are obtained from plant, animal or mineral sources with or without any chemical treatments.

Today, when the world is facing threats of destruction from the synthetic toxic chemicals, eco-friendly awareness should be the major focus, else, it would be difficult to save this planet from compete extinction. Here lies the relevance of revival of this art of dyeing with 'Natural Colorants' or 'Natural Dyes' [4,5].

It is told earlier that in general introduction that the production of synthetic chemicals involves many chemical reactions requiring high energy. Moreover, there are many undesirable by-products generated during the reactions [4,5]. These toxic or environment un-friendly by-products have to be discharged in the rivers, ponds or into the atmosphere. These drawbacks of the synthetic dyes have prompted researcher to look for alternatives of producing eco-friendly products and technologies using natural dyes for dyeing. Moreover, recently the consumers have become very much conscious about the environment, renaissance of eco-friendly products and process like dyeing of textiles with natural dyes.

Natural dyes many times lack in uniformity and reproducibility of colour. Also, the major problem encountered is their availability of natural dyes in bulk quantity. There is limited availability of scientific information on standardization of the methods application [5] of natural dyes. Sometimes natural dyes do not produce acceptable level of colour fastness. The question of cost is also a factor to reckon with. Antimicrobial and UV protection properties of natural dyes need to be explored after their application on textile fabrics. Hence, in the absence of any precise information of scientific analysis and technical knowledge on dyeing different natural fibre based textiles with natural dyes, there is a need to study the performance of various natural colorants on natural textiles including protein fibres and cellulosic/lignocellulosic fibres (having compositional differences) separately under different pre-treated/post treated conditions [5] varying different mordants and other additives.

Natural dyes have been used as a means to colour textiles for centuries. All the dyes until the later half of nineteenth century were made of different parts of plants and animals. For thousands of years people all over the world followed the same basic techniques using roots, stems, barks, leaves, hard wood, berries fruits, flowers of various dye plants and tree, as well as from certain insects and shell-fishes. Most natural dyes are nonsubstantive which means that they have little colouring power within themselves, and require the aid of mordant to penetrate the yarn/fibre.

In recent years, there has been an interest manifested towards natural dyes by both the consumers and producers of textile; the reasons being bio-degradability and eco-compatibility of natural dyes. Some other associated advantages include expected non-toxicity/lower toxicity [6,7] and anti-allergen [1] and some medicinal value as well as antimicrobial and UV protective character of some of the natural dyes.

Definition of natural dyes

The Society of Dyers & Colourist's Colour Index (3rd edition) defines natural colouring matters as 'the natural dyes and pigments comprise of all colours obtained from animal and vegetable matter with no or very little chemical treatments [1]. They are mainly mordant dyes [1,2], but they also include some vat, few disperse/solvent dyes, some pigment colour, a few direct, basic and acid dyes' [1].

The term natural dye covers all the dyes derived from the natural sources like plants, animal and minerals i.e., derived from natural resources [8]. Natural dyes with very few exceptions are non-substantive, but must be used in consumption with mordants. A mordant usually a metallic salt has an affinity for both the colouring matter and the fibre and combining with the dye in the fibre it forms an insoluble precipitate or lake. Application wise, natural dyes include some vat dyes, a few solvent dyes, some pigments, and some direct and acid dyes. Only one natural basic dye is known but natural sulphur, disperse, azoic or ingrain dyes are still not available so far.

Classification of natural dyes as per application method

Natural dyes can be classified [1,5] in a number of ways. The earliest classification was according to alphabetical order or according to the botanical names. Later, it was classified in various ways, e.g. on the basis of hue, chemical constitution, application method. Most widely used classification is based on application method.

Classification of natural dyes on the basis of the method of application [1,5,9] as given below :

a. Mordant dyes: These are dyestuffs which require a mordant in their application as they have no affinity for the fiber being dyed. A mordant dye should have electron donating groups capable of forming a complex with the transition metal salt, e.g., madder, fustic, Persian, berries, kermes, cochineal etc.

b. Vat dyes: These are water insoluble dyes which are first converted to their water soluble form (reducing with Na- hydrosulphite and then solubilising it with alkali) and then applied to the fibres. The true colour is produced only on treatment with a hot soap solution. The soaping treatment completes the oxidation process, e.g., Indigo.

c. Direct dyes: Direct dyes are those dyes that have tremendous affinity for the cellulosic fibres. They are dyed from a boiling dye bath. Turmeric, Harda, pomegranate rind etc. are a few of the direct natural dyes.

d.Acid dyes: These dyes are applied from an acidic medium. The dye molecules have either sulphonic or carboxylic group (s) which can form an electrovalent bond with amino groups of wool and silk. An after treatment with tannic acid and tartaremitic, known as back tanning improves the fastness of these types of dyes, e.g., Saffron.

e. Disperse dyes: Disperse dyes has a relatively low molecular mass, low solubility and no strong solubilizing groups. These dyes have hydroxyl and/or amino groups which impart same solubility to the dye molecule. Disperse dyes can be applied on to hydrophobic synthetic fibre from neutral to mildly acidic pH. They can also be applied to silk and wool. These dyes can be post-mordanted with chromium, copper and tin salts, e.g., lawsone and many other flavone and anthraquinone dyes.

f. Basic dyes: Basic or cationic dyes on ionization give coloured cations and form an electrovalent bond with the -COOH group of wool and silk. These dyes are applied from neutral to mildly acidic pH. These dyes have poor light fastness, e.g. berberine.

Methods of extraction of natural dyes

The vegetable dyes can be taken from various sources like flowers, roots, bark, animal sources, mineral sources etc. The colour component present in these sources needs to be extracted so that it can be applied on the textile. Most vegetable dyes are extracted by pulverizing, grinding or soaking and boiling the herbs in water. The natural dyes can be extracted from dried solid raw material source of plant parts etc using aqueous method [5] i.e., by using boiling/hot water for the extraction with or without addition of acid/alkali/alcohol in extraction bath [10] at specific pH, MLR, Temperature and time followed by distillation ,evaporation and vaccum drying etc or by waterless supercritical carbondioxide fluid extraction [11], or solvent extraction by using soxhlet apparatus extraction [12] by use of alcohol and benzene mixture and by using rotatory vacuum pump/or doing the extraction under reduced pressure etc. Some water insoluble plant material like indigo leaves (i.e Natural indigo being vat dye type) needs to be fermented and reduced to release the glucosides of the dye and this fermentation and reduction and solubilisation can be done with use of natural reducing agent and alkali combination (instead of Dithionite or disulphide and Caustic soda used for redcing synthetic vat dyes) like combination of liquid jiggery and citric acid, use of paste of citrous fruits like tomato, lemons, ripened banana paste and Ash soaked water etc., in combination with use of lime in all cases and heating. Various studies have also been reported, where ultrasonic assisted extraction and enzyme assisted extraction have been also now being used to improve the yield of colour. The colour developed in natural dyeing on different textiles is sometimes pH dependant besides it is mainly dependant on type of mordant used besides dye concentration and mordant concentration as well. However combination of similar types of natural dyes in different proportion of compatible natural dyes are also another way for producing different shades for colour matching for combined shades.

Methods and Steps for dyeing with natural dyes

Prior to dyeing with natural dyes, the fabric is to be prepared by proper desizing, scouring and bleaching followed by usual pre-mordanting with single or double mordants applied in sequence. The colour much depend on the type of single or double mordants used by selecting a suitable mordant and natural dye-mixture combinations depending upon the colour needed and colour fastness level desired. Dyeing with natural dyes on textiles comprises of five to six steps:

i. Mordanting.

ii. Preparation of Dye liquor from natural source or extraction and solubilisation of dye.

iii. Exhaustion,

iv. Diffusion and migration,

v. Fixation and

vi. After-treatments (optional) for improving fastness or topping for tonal variation and final colour matching etc.

To facilitate completion of dyeing in the shortest possible time, most dyeing systems make use of different additives and auxiliaries such as pH controller, retarders or exhausting agents, levelling agents etc. For dyeing with natural dyes, depending on the type and nature of natural dyes taken, the dyeing procedure and conditions will vary. Natural dyes often show non-reproducible shades due to variation in conditions of dyeing or following non-optimised conditions of dyeing. Hence, standardisation/optimisation of dyeing methods for specific dye-fibre-mordant combinations is essential. Most of the natural dyes being mordantable; dyeing with such natural dyes is carried out using aqueous extracts of natural dyes in aqueous medium in normal/not aqueous dye-bath. Dyeing with natural dyes may be carried by pre-mordanting, post-mordanting, simultaneous mordanting, following standardised dyeing process at low temperature water bath or in boiling water bath [5], HTHP technique [13], with additives controlling the pH of aqueous medium i.e. (acidity or alkalinity) [14,15], or using ultrasonic dyeing technique [2,16-19], using single natural colours or mixture of natural colours [12,20] extracted appropriately and found compatible scientifically

The major steps used in dyeing with natural dyes include the following:

a) The application of the suitable metallic mordant (mordanting) or bio mordant

b) The application of the tannin substance e.g. tannic acid, myrobolan fruit (harda) having chebulinic acid , gallnut etc. which is mainly done to increase the receptivity of the textile fabric for the dye to combine with the mordant and may be called as Mordanting Assistant (MA) increasing more and more dye- (mordant + MA )-fibre complexing in greater way

c) Dyeing of the fabric by the exhaust method.

The 2nd step can either precede or follow or be a part of the 3rd step (pre, post or simultaneous dyeing and mordanting).

Dye-bath assistants used for dyeing textiles with natural dyes

a) Tartaric acid: Dye bath solutions are acidified with it and it is used to neutralize calcareous luster

b) Cream of tartar: This white crystalline substance is used in conjunction with mordants. It brightens colors.

c) Glauber's salt/Common Salt: It is used extensively by silk dyers to obtain level dyeing.

d) Boiled-off liquor: The degumming solution, when used in the dye-bath, causes the colouring matter to be attracted more equally and evenly by the silk and helps preserve luster. Suggested quantities are 50-100ml boiled-off liquor to 1 litre of dye-bath solution.

e) Enzymes: Use of suitable enzymes as pre-treatment or in combination in dye bath for natural dyeing also enhance colour yield.

Advantages & disadvantages of natural dyes

In the recent years there has been an upsurge in the field of natural dyes. This is mainly because of the fact that although the synthetic colours are fast, durable and comparatively easy to apply, the natural dyestuffs have certain advantages over them. Some of these advantages are listed below:

a) Fairly non-polluting and have lower toxicity.

b) The naturally dyed shades are soft, lustrous and soothing to the human eye [1,5,21].

c) They produce a wide range of colours. A small variation in the dyeing technique or the use of different mordants with the same dye can create totally new colours, which are not possible with synthetic dyestuffs [1,5,22].

d) Natural dyestuffs produce rare colour ideas [1,5,23,24] and are automatically harmonizing.

e) Unlike the non-renewable which forms the basic raw materials for synthetic dyes, the vegetable based natural dyes are replaceable and at the same time biodegradable [1,2,5] . They save energy because the raw-materials are not from petroleum.

f) In some cases like hard a, indigo etc., the waste in the process becomes an ideal fertilizer for use in agricultural fields [1,5].

g) Many plants thrive on wastelands. Thus, wasteland utilization is an added merit of the natural dyes [1-2]. Dyes like madder grow as host in tea gardens. So there is no additional cost or effort required to grow it.

h) This is a labour intensive industry [1,5,21,23,24], thereby providing job opportunities for all those engaged in cultivation, extraction and application of these dyes.

i) It can increase the textile exports and thus help India in earning foreign exchange.

j) Some of its constituents are anti-allergens, hence prove safe for skin contact and are mostly non-hazardous to health [1,5,25].

k) Some of the natural dyes are enhanced with age, while synthetic dyes fade with time [9].

l) Natural dyes bleed but do not stain other fabrics [1,5,21,26], turmeric being an exception.

m) Naturally dyed materials have good resistance to moth and are anti-allergens; hence prove safe for body contact and are mostly non-toxic therefore non-hazardous to health [5].

n) Fabrics dyed with natural dyes can provide good protection against ultra violet rays without altering wear properties.

o) They are used in the conservation and repairs of historic textiles.

p) They can replace synthetic dyes in food-stuffs for safety [2,5].

Despite these advantages, they carry some inherent disadvantages [1,5], which were responsible for the decline of this art. Disadvantages of natural dyes:

a) There are lacks in sufficient scientific database and information on standardizing recipe and shade cards for the use of natural dyes [5,27] on different textiles. Hence, natural dyers are in complete uncertainty about dyeing shades and fastness results to obtained which vary from plant source to source, crop to crop and season to season (time to time and place to place and also from one crop to another) and even for mordant to mordant and their purity and extraction method. All these variations, if thus scientifically standardised, may be partially or completely avoided.

b) The extraction, preparation of textile materials requires and mordanting and natural dyeing need skilled craftsmanship and is thus expensive [5,28]. The use of expensive mordants, extraction of colouring component from raw material, low colour yield necessitating the use of more dyestuffs and long dyeing time sharply increase the cost of dyeing with natural dyeing considerably higher than synthetic dyes. However, if the natural dyeing of natural fibres is properly done maintaining eco-friendly processes, it has aspecilitynich market for eco friendly natural dyed products of textiles particularly for expensive textiles and garments of cotton, silk and wool etc.

c) Poor scientific back up of a large part of this branch of science is still being explored [5,29] and to be explored for its commercial exploitation in industrial scale for both small, medium and large scale sector. Natural dyeing using Jigger machine or Continuous dyeing range etc are the present days' need.

d) Lack of availability of precise scientific/technical knowledge on extraction and dyeing techniques [5,30] by optimizing dye wise and textile fibre wise process development for each natural dye type are essential to avoid the above said uncertainty for colour/shades and their colour fastness characters .

e) The natural dyed textile fabric may change colour when exposed to the sun (UV light), sweat (human perspiration) and air (oxygen) and moisture (water). This cannot be controlled if not scientific research are done in depth to understand the exact reasons of these effects and exact chemical interaction present in such cases for exposure to any particular agency at any particular time, which are not yet known [5,27].

f) Nearly all-natural dyes with a few exceptions require the use of metallic mordants to fix them on to the fabric substrate. While dyeing, a substantial portion of the metallic mordant remains unexhausted in the residual dye bath and these metals may pose some effluent disposal problem [5,23,24]. So, useof hazardaous metallic mordants like Copper/chromium etc are to be avoided.

g) With a few exceptions, most of the natural dyes are fugitive [1,5] even when applied in conjunction with a mordant. Therefore, their colour fastness performances are generally not always adequate for modern textile usage. Use of acidic pH in dye bath or post treatment with natural or eco safe dye fixer is needed to improve colour fastness to wash, light, rubbing and perspiration etc.

h) The widespread use of natural dyes will result in a major shift in the land use pattern throughout the world[30] . In reality the area needed to satisfy the demand for the production of natural dyes is unavailable, because higher priorities are placed on the growing of food crops for the world's burgeoning population. However, this may be noted that objective of promoting more and more natural dyeing is not to replace synthetic dyeing in totality or as majority, but objective of promoting natural dyeing is to promote eco- friendly dyed products of natural textiles forniche market for specific customers.

i) All natural products are not fully toxicity free. Very little work has been carried out to assess the toxicity of different natural dyes [23,24]. Although most of the natural dyes in use are known to have medicinal values and either antibacterial/ antimicrobial properties or UV protective properties and are eco safe , but there are reports on one or two natural dyes/ colour source materials that have been identified as posing potential ecological or toxicity problems, e.g. quercetin is considered to be mutagenic. On the other hand, new synthetic dyes are fully tested for their levels of toxicity, and when introduced in the market, they have a full set of data on their toxicity test and eco-toxicity profiles. Such studies and database for each natural dyes are needed essentially

j) There is severe shortage of trained dyers for application of natural dyes. Most of the so-called textile chemists in the country are trained to use synthetic dyes. If this technology is to be used for producing eco-friendly textiles, generating revenue, employment as well as for creating a strong base for renewable resources for the dye industry, a comprehensive training and interaction programme has to be launched.

k) Dearth of books and scientific literature on the technology of natural dyeing providing required the scientific basis for their application on different textiles.

l) Non-availability of the natural dyes in pure or standardised form, which may be powder, paste or in the solution form for easy and direct application in known shade percentage. Using source raw natural material directly for dyeing has many limitations, besides its being of unknown composition and colour yield, it generates considerable amount of biomass that is cumbersome to handle in the dye- house.

Inspite of the aforementioned limitations associated with natural dyes, it is expected to have a separate good export market potential for fabrics from natural fibers dyed and printed with natural dyes, because of the rigid standards imposed by the advanced countries in combating toxicity, eco- hazards and pollution control problems.

Constrains for the uses of natural dyes on textiles

The major hurdles for using natural dyes are serious gap and lack/non-availability of scientific data base and knowledge base required for their successful application on textiles. Most of the researchers worked in this area generated very general information on types of shades/colour fastness properties and their dyeing related information reported in literature that does not have complete profile of its chemical nature, materials data specification sheet, standardized extraction and dyeing procedure and scientific reasoning for its nature of problems and solution and basis for nature of bonding between dye-mordant and fibre system, methods of improvement of colour fastness to wash, light, rubbing and perspirations and compatibility of different natural dyes to apply together as mixture of different proportions for obtaining compound shades and required matching etc. There are very limited information available on use of binary and ternary mixture of natural dyes and their interaction/compatibility etc, for which use of mixture of natural dyes are still limited in traditional natural dyeing sector and have not advanced satisfactorily.

Unnecessary adverse talk and biased opinion are opinion of synthetic dye manufacturer/users against the use of natural dyes, where some of their logics are being over emphasised deliberately. One must keep in mind that natural dyes are NOT a substitute of synthetic dyes. They have their own market and any expansion in the market of natural dyed products is not going to be at the cost of losing synthetic dyes.

Colour fastness of natural dyes

Color fastness is the resistance of a material to change in any of its colour characteristics, to the transfer of its colourants to adjacent materials or both. Fading means that the change of colour strength (lightening or darkening) on washing or rubbing or in contact with human perspiration or on exposure to light. Cook [31] has described the use of post treatment with natural tannin related natural materials as after-treatment for improving the wash fastness and use of natural UV absorbers for improving the light fastness of mordant able natural dyes on cotton. There are many pre-treatments and post treatments known for improving either of wash-fastness, rub-fastness and light fastness of textiles dyed with synthetic dyes, but such treatments on textiles dyed with natural dyes are still very few. So, exploring such fastness improver from natural materials is essential.

The light fastness is the resistance of dyestuffs to the influence of UV-light energy [32], especially the ultraviolet (UV-A) part of the electromagnetic spectrum. UV light is subdivided into three category e.g UV-A (320-400nm), UV-B (280-320nm) and UV-C (100-280nm). The shorter is the wavelength (X), the higher is the energy E and higher is the damage to dyestuff or human skin (as per Einstein's rule: E= hv = [h X c/X)]. Fortunately UV-C is fully absorbed by ozone layer in the higher atmosphere (stratosphere), the usual content of UV-B in the total radiation intensity is less than 1% and is not that harmful, while to earth most common part of UV light reaches easily from Sunlight is UV-A part (320-400nm), which is about 5.6%. So, identifying of some UV absorbers from natural materials capable of absorbing UV -A part i.e in the region of 320-400nm and their application to dyed textiles are to be established.

The light fastness of the applied dyestuffs is sometimes also connected to the fading or inherent yellowing tendency of the fibre itself. Yellowing by UV Light exposure and associated damage to the fibre itself by exposure to UV light also accelerates fading of colour with or without photo-initiated fading of dyestuff[31] . Fading by UV light is generally promoted by moisture, heat, oxygen in air and other factors. The interactions of these influencing factors, including UV-absorbers photo-sensitizers, radical scavengers, singlet oxygen quenchers and their possible chemical reactions and interactions are quite complex. Moreover light fastness of natural dyes depends on its UV-absorption character of that dye [21,24,33]. Some natural dyes have inherent UV protective nature like anar peel/pomegranate rind.

Poor wash fastness of many natural dyes is mainly attributed because of weak dye-fibre bond formation between the natural dye -mordant and the fibre, change in hue due to breaking of dye- metallic mordant-fibre complex during washing for ionisation of the natural dyes during washing [12]. Since most of the natural dyes have hydroxyl groups which get ionised under alkaline conditions/acidic conditions and hence many fabrics dyed with natural dyes under acidic conditions change colour on washing with alkaline detergents or soap. Wash fastness of the natural dyes much depends on their chemical nature and type of bonds dye-mordant-fibre as a coordinating complex formed with specific dye-metal salt mordant-fibre combination. But as per expectations, many times there is less or limited very little or no such complex are formed actually and only H-bonding are formed causing poor wash fastness, which may be due to many reasons like stereo specific non fitting of physical structure/orientation of dye structure and fibre structure or any other problems.

Rubbing fastness is assessed by measuring change in colour on the rubbed textile surface or assessing the staining to the abrader white cloth after abrading in both dry and wet conditions (for wet rubbing fastness , additionally the migration of colour to the abrading cloth by bleeding is also included). Depending on the kind of fibre, especially its tensile strength, small abraded coloured fibre particles may fuzz out showing loss of depth of colour on the rubbed textile surface. If the dyestuff involved is water soluble and not sufficiently fixed on the fibre surface, this can also be the reason for staining during rubbing. Rub-fastness ratings, according to the standard grey scales for both loss of depth (fading) and staining scale, range from 1 (poor rating) to 5 (best rating). Parameters that influence rubbing fastness of natural dyes include:

a. Molecular size and structure, chemical nature and fixation mode of Natural dyes used.

b. Type of mordants and Concentrations of mordants.

c. Concentration of natural dyestuff, shade%, and extent of diffusion of dyes.

d. Dyeing procedure, degree of fixation and extent of surface dyeing and ring dyeing.

e. After treatment with dye fixing agents, softeners, silicones and cross linking agents.

f. Types of fibre and its tensile strength and dry and wet abrasion resistance.

g. Type of textiles used as abrading cloth in contact: Its surface, kind of fibre and fabric.

h. Intensity of the contact: pressure, time, moisture and temperature.

The influence of the moisture is taken into account in the test methods (dry or wet crocking tests). Wet cellulosic fibres may be partly damaged by rubbing, leading to additional staining. The rubbing force for the wet testing procedure is about double the rubbing force for dry rubbing. Therefore the wet rubbing ratings of the same sample are always poorer than the dry ones (up to two rating difference). For natural dye, if there are more unfixed dyes on the surface and when dyes are only bond by H-bonds without mordanting, both the dry and wet rubbing fastness may be inferior.

To know more about Journal of Fashion Technology-https://juniperpublishers.com/ctftte/index.php

To know more about open access journals Publishers click on Juniper Publishers

#Juniper Publishers#Juniper Publilshers Group#Open access Publishers#Fashion Technology#Textile Engineering#juniper publishers contact info

0 notes

Text

Plant-Based Textile Yarn Market 2021 : Evolving Opportunities, Trends, Growth, Demand, Industry Shares of Top Players, And Forecast

Plant-Based Textile Yarn Market report performs comprehensive Analysis about Global Market and tells about the market status in the forecast period. The report recognizes and analyses the growing trends along with major drivers, restraints, challenges and opportunities in the Plant-Based Textile Yarn industry. The market research report gives clear idea about strategic analysis of mergers, expansions, acquisitions, partnerships, and investment.It helps the purchaser in understanding the various drivers and restraints with their effects on the market during the forecast period.

In the forecast period from 2021 to 2028, the plant-based textile yarn market is projected to expand at a rate of 4.40%. The rising demand for textile yarn for home textiles, apparel and other industrial purposes, which in the forecast period of 2021-2028 will act as a driver for the plant-based textile yarn market.

Get Free PDF Sample Report @https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-plant-based-textile-yarn-market

The Plant-Based Textile Yarn Market report comprehensively studies consumption or sales of the market, focuses on the top players with respect to sales, price, revenue and market share (volume and value) for each region. The report explains the moves of top market players and brands that range from developments, products launches, acquisitions, mergers, joint ventures, trending innovation and business policies. Key Players in Plant-Based Textile Yarn Market:

The major players covered in the plant-based textile yarn report are Parkdale Mills, Inc.; VARDHMAN GROUP; Huvis; Grasim Industries Limited.; Raymond Limited; Weiqiao Textile Company Limited.; TORAY INDUSTRIES, INC.; Bonar Yarns & Fabrics Ltd; Thai Rayon Public Company Limited; Aksa; Asahi Kasei Corporation.; Barnhardt Natural Fibers.; Celanese Corporation; Far Eastern New Century Corporation; FORMOSA TAFFETA CO., LTD.; Indorama Ventures Public Company Limited.; FiberVisions, L.P.; KURARAY CO., LTD.; PT Polychem Indonesia Tbk; Reliance Industries Limited.; among other domestic and global players. Market share data is available for Global, North America, Europe, Asia-Pacific (APAC), Middle East and Africa (MEA) and South America separately. DBMR analysts understand competitive strengths and provide competitive analysis for each competitor separately.

The Plant-Based Textile Yarn Market report consists of information about historic data, present market trends, environment, technological innovation, upcoming technologies and the technical progress in the related industry. Thus, for better decision making and thriving business growth, the data and information covered in the global Plant-Based Textile Yarn market report is very imperative.

Key Point from Table of Content:

Market Overview: This section includes research scope, market segments by type, Plant-Based Textile Yarn market segments by application, major manufacturers covered, study objectives, and years considered.

Market Landscape And Profiles of Manufacturers : In this section the competition in the Global Plant-Based Textile Yarn Market is analysed, by price, revenue, sales, and market share by company, market rate,and latest trends, merger, expansion, acquisition, and market shares of top companies. This section includes Analysis of leading players of the Plant-Based Textile Yarn market based on sales area, key products, gross margin, revenue, price, and production.

Market Status and Outlook by Region: In this section, the report discusses about gross margin, production, sales, revenue, market share, CAGR, and market size by region. Plant-Based Textile Yarn Market is deeply analysed on the basis of regions and countries such as North America, Europe, China, India, Japan, and the MEA.

Market Forecast: In this part of the report, the authors have focused on production and production value forecast by peoduct type, Also Market Growth in future, Expected Developments in industry are also covered in this section.

Get Full Table of Contents with Charts, Figures & Tables @ https://www.databridgemarketresearch.com/toc/?dbmr=global-plant-based-textile-yarn-market

A Plant-Based Textile Yarn market research report is a complete overview of the market that covers various aspects of product definition, market segmentation based on various parameters, and the existing vendor landscape which helps buyer in understanding sense of evolving industry movements before the competitors.

Key questions answered in Plant-Based Textile Yarn Market Report:

What is key factor driving this market?

What are the key market trends?

what are top performing regions of Plant-Based Textile Yarn industry?

What are the challenges to market growth?

Who are the major key vendors in this market space?

What are the market opportunities, market risk and market overview and threats faced by the key vendors?

What are the strengths and weaknesses of the key vendors?

Get More Insight Before Buying @ https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-plant-based-textile-yarn-market

About Us:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.We ponder into the heterogeneous markets in accord with our clients needs and scoop out the best possible solutions and detailed information about the market trends. Data Bridge delve into the markets across Asia, North America, South America, Africa to name few.Data Bridge adepts in creating satisfied clients who reckon upon our services and rely on our hard work with certitude. We are content with our glorious 99.9 % client satisfying rate.

Contact Us:

Data Bridge Market Research

Tel: +1–888–387–2818

0 notes

Text

Acrylic Fiber Market Growth Trends, Cost Structure, Driving Factors and Future Prospects 2023

Acrylic Fibres Market- Competitive Landscape

The Global Acrylic Fibre Market is consolidated in nature as it is dominated by few established industry participants including. The players dominated global market are Aksa Akrilik Kimya Sanayii A.Ş. (Aksa), Dralon, Aditya Birla Group, Exlan Japan Co. Ltd., Taekwang Industry Co, Ltd., Indian Acrylics Limited and Pasupati Acrylon Limited which holds substantial global share. This market is heading towards growth stabilization and offers moderate degree of competition served by industry players.

Acrylic Fibre Market – Segments

For the convenience of the report and enhanced understanding; The Acrylic Fibre Market is segmented in to 2 key segments.

Segmentation by Form: Comprises Stable Acrylic Fibre and Filament Acrylic Fibre.

Segmentation by End User: Comprises Apparel Household Furnishing, Industrial, and Others.

Segmentation by Regions: Comprises Geographical regions – North America, Europe, APAC and Rest of the World.

Acrylic Fibre Market – Market Overview

Acrylic Fibre is a manmade fibre and known as synthetic fibre which is produced by two different methods including wet & dry spinning method. Acrylic Fibre closely resembles wool in its characters, which contain minimum 85% acrylonitrile in their chemical structure are called Acrylic Fibres. The Global Acrylic Fibre Market represents steady growth over the past seven years, and it is likely to continue in same trend over the assessment period. In addition to this, the global market anticipated to progress in terms of CAGR due to its increasing popularity driven by lower denier properties.

Get a Free Sample @ https://www.marketresearchfuture.com/sample_request/2125